Page 1

7100 Series Fire Alarm Control

Installation/Operating Manual

Document: 9000-0447

Print Date: 6/6/07 Rev. I

P/N 9000-0447 Rev. I ECN: 06-528

Copyright © 1998

Honeywell International Inc.

All Rights Reserved

Published in U.S.A.

12 Clintonville Road, Northford, CT 06472-1610 USA • TEL: (203) 484-7161 • FAX: (203) 484-7118

www.gamewell-fci.com

Page 2

Fire Alarm System Limitations

While a fire alarm system may lower insurance rates, it is not a substitute for fire insurance!

This manual is designed for use by factorytrained installers and operators of the GamewellFCI, 7100 Series, Fire Alarm Control. All

illustrations, functional descriptions, operating

and installation procedures, and other relevant

information are contained in this manual.

The contents of this manual are important, and

the manual must be kept with the fire alarm

control panel at all times. If building ownership is

changed, this manual, including any testing and

maintenance information, must be passed along

to the new owner(s).

The fire alarm control panel is part of a system.

Manuals and instructions for other devices

forming part of the system should be kept

together. Purchasers who install this system for

use by others must leave the instructions with the

user. A copy of these instructions is included with

each product and is available from the

manufacturer.

This equipment is Listed by various listing

agencies for use in fire alarm systems. Use only

components which are compatible with the

Gamewell-FCI System. The installation MUST be

in accordance with the instructions in this

manual. THEREFORE:

• DO NOT deviate from the procedures

described in this manual.

• DO NOT assume any details not shown in the

instructions.

• DO NOT modify any electrical or mechanical

features.

• DO comply with all codes and standards set

forth by the Authority Having Jurisdiction.

The term “Authority Having Jurisdiction” has

become a standard term in the fire alarm

industry. An acceptable definition of “Authority

Having Jurisdiction” is:

Fire alarm systems installed in the USA fall under

the jurisdiction of some authority. In some areas

this may be a local fire department; in other areas

it may be a building inspector, insurance firm, etc.

Different authorities may have their own local

requirements for the way the fire alarm system is

installed and used. Most local authorities base

their requirements on the National Fire Protection

Agency (NFPA) codes, but there may be

important differences. You must install this

system in the way in which the Authority Having

Jurisdiction requires. If you do not know which

authority has jurisdiction in your area, contact

your local fire department or building inspector for

guidance. It is important that you tell users to be

aware of any requirements defined by the

Authority Having Jurisdiction.

E3 Series™ is a trademark of Honeywell International Inc.

The installation MUST be in accordance with the

following standards:

• National Fire Alarm Code (NFPA 72)

• National Electrical Code (NFPA 70)

• Life Safety Code (NFPA 101)

• NFPA 92A – Recommended Practice for

Smoke Control Systems

WARNING: Touching components which are

improperly installed, applied or operated could be

hazardous and possibly fatal. Short circuits could

cause arcing that could result in molten metal

injuries. Therefore, only qualified technicians familiar

with electrical hazards should perform checkout

procedures.

Safety glasses should be worn, and test equipment

used for voltage measurements should be designed

for this purpose and be in good working order.

ENVIRONMENTAL CONSIDERATIONS:

It is important that this equipment be operated

within its specifications:

• Recommended operating

temperature range:

• Absolute maximum

operating temperature

range:

• Operating humidity:

Operating this equipment within the

recommended temperature range will extend the

useful life of the system standby batteries.

INSTALLATION CONSIDERATIONS:

Check that you have all of the equipment you

need to make the installation. Follow the field

wiring diagrams and installation notes in this

manual.

Install the equipment in a clean, dry environment

(minimal dust). Avoid installing equipment where

vibrations will occur.

Remove all electronic assemblies prior to drilling,

filing, reaming, or punching the enclosure. When

possible, make all cable entries from the sides;

being careful to separate the power-limited

conductors from the non power-limited

conductors. Before making modifications, verify

that they will not interfere with battery,

transformer and printed circuit board location.

Do not over-tighten screw terminals. Overtightening may damage threads, resulting in

9000-0447 Rev. I

i

60° to 80° F

(15° to 27° C)

32° to 120° F

(0° to 49° C)

Not to exceed 93%

Non-condensing at

90° F (32° C)

Page 3

reduced terminal contact pressure and difficulty

with screw terminal removal. Disconnect all

sources of power before servicing, removing, or

inserting any circuit boards. Control unit and

associated equipment may be damaged by

removing and/or inserting cards, sub-assemblies,

or interconnecting cables while the unit is

energized

WIRING CONSIDERATIONS:

This fire alarm control panel contains powerlimited circuits. You cannot connect external

sources of power to these circuits without

invalidating their approval.

Verify that wire sizes are adequate for all

initiating device and notification appliance

circuits. Most devices cannot tolerate more than

a 10% drop from the specified device voltage.

The installer must make sure that the wiring and

devices installed in the system meet the current

National Electrical Code, NFPA 70, and all

applicable state and local building code

requirements.

Use the conductor size and type required by local

codes. (See NFPA 70, Article 760). Wiring

resistance must not be more than that shown on

the field wiring diagrams.

To reduce errors and help in servicing the

system, all conductors should be tagged or

otherwise coded and logged at installation to

identify circuit assignment and polarity. If the

conductors are logged with a code, keep the log

that explains the code with the manual, so that it

is available to other people working on the panel.

Like all solid state electronic devices, this system

may operate erratically or be damaged when

subjected to lightening induced transients.

Although no system is completely immune to

lightening transients and interference, proper

grounding will reduce susceptibility. We do not

recommend the use of overhead or outside aerial

wiring due to the increased susceptibility to

nearby lightening strikes. Consult with the

Gamewell-FCI Technical Support Department if

any problems are anticipated or encountered.

To prevent the spread of fire, use proper patching

materials to areas where system wiring passes

through the fire-rated walls or floors.

SURVIVABILITY:

Per the National Fire Alarm Code, NFPA 72, all

circuits necessary for the operation of the

notification appliances shall be protected until

they enter the evacuation signaling zone that

they serve. Any of the following methods shall be

considered acceptable as meeting these

requirements:

1) A 2-hour rated cable or cable system

2) A 2-hour rated enclosure

3) Performance alternatives approved by

.

Authority Having Jurisdiction

MAINTENANCE:

To keep your fire alarm system in excellent

working order, ongoing maintenance is required

per the manufacturer’s recommendations and UL

and NFPA Standards, and applicable state and

local codes. At a minimum, the requirements of

Chapter 7 of NFPA, the National Fire Alarm

Code, shall be followed. A preventative

maintenance agreement should be arranged

through the manufacturer’s local representative.

Though smoke detectors are designed for long

life, they may fail at any time. Any smoke

detector, fire alarm system, or any component of

that system shall be repaired or replaced

immediately.

OTHER CONSIDERATIONS:

The equipment was tested according to EC

directive 89/336/EEC for Class A equipment and

was verified to the limits and methods of EN

55022.

An automatic fire alarm system—typically

made up of smoke detectors, heat detectors,

manual pull stations, audible warning devices,

and a fire alarm control panel with remote

notification capability can provide early warning

of a developing fire. Such a system, however,

does not assure protection against property

damage or loss of life resulting from a fire.

The Manufacturer recommends that smoke

and/or heat detectors be located throughout a

protected premise following the

recommendations of the current edition of the

National Fire Protection Association NFPA

Standard 72, manufacturer’s recommendations,

State and local codes. A study by the Federal

Emergency Management Agency (an agency of

the United States government) indicated that

smoke detectors may not into alarm in as many

as 35% of all fires. While fire alarm systems are

designed to provide early warning against fire,

they do not guarantee warning or protection

against fire. A fire alarm system may not provide

timely or adequate warning, or simply may not

function, for a variety of reasons:

Smoke detectors may not sense fire where

smoke cannot reach the detectors such as in

chimneys, in or behind walls, on roofs, or on the

other side of closed doors. Smoke detectors also

may not sense a fire on another level or floor of a

building. A second-floor detector, for example,

may not sense a first-floor or basement fire.

Particles of combustion or “smoke” from a

developing fire may not reach the sensing

chambers of smoke detectors because:

• Barriers such as closed or partially closed

doors, walls, or chimneys may inhibit particle or

smoke flow.

• Smoke particles may become “cold,” stratify,

and not reach the ceiling or upper walls where

detectors are located.

9000-0447 Rev. I

ii

Page 4

• Smoke particles may be blown away from

detectors by air outlets.

• Smoke particles may be drawn into air returns

before reaching the detector.

The amount of “smoke” present may be

insufficient to alarm smoke detectors. Smoke

detectors are designed to alarm at various levels

of smoke density. If such density levels are not

created by a developing fire at the location of

detectors, the detectors will not go into alarm.

Smoke detectors, even when working properly,

have sensing limitations. Detectors that have

photo-electronic sensing chambers tend to detect

smoldering fires better than flaming fires, which

have little visible smoke. Detectors that have

ionizing-type sensing chambers tend to detect

fast-flaming fires better than smoldering fires.

Because fires develop in different ways and are

often unpredictable in their growth, neither type of

detector is necessarily best and a given type of

detector may not provide adequate warning of a

fire.

Smoke detectors cannot be expected to provide

adequate warning of fires caused by arson,

children playing with matches (especially in

bedrooms), smoking in bed, and violent

explosions (caused by escaping gas, improper

storage of flammable materials, etc.).

Heat detectors do not sense particles of

combustion and alarm only when heat on their

sensors increases at a predetermined rate or

reaches a predetermined level. Rate-of-rise heat

detectors may be subject to reduced sensitivity

over time. For this reason, the rate-of-rise feature

of each detector should be tested at least once

per year by a qualified fire protection specialist.

Heat detectors are designed to protect property,

not life.

IMPORTANT! Smoke detectors must be

installed in the same room as the control panel

and in rooms used by the system for the

connection of alarm transmission wiring,

communications, signaling, and/or power. If

detectors are not so located, a developing fire

may damage the alarm system, crippling its

ability to report a fire.

Audible warning devices such as bells may not

alert people if these devices are located on the

other side of closed or partly open doors or are

located on another floor of a building. Any

warning device may fail to alert people with a

disability or those who have recently consumed

drugs, alcohol or medication. Please note that:

Strobes can, under certain circumstances, cause

seizures in people with conditions such as

epilepsy.

Studies have shown that certain people, even

when they hear a fire alarm signal, do not

respond or comprehend the meaning of the

9000-0447 Rev. I

iii

signal. It is the property owner's responsibility to

conduct fire drills and other training exercise to

make people aware of fire alarm signals and

instruct them on the proper reaction to alarm

signals. In rare instances, the sounding of a

warning device can cause temporary or

permanent hearing loss.

A fire alarm system will not operate without any

electrical power. If AC power fails, the system will

operate from standby batteries only for a

specified time and only if the batteries have been

properly maintained and replaced regularly.

Equipment used in the system may not be

technically compatible with the control panel. It is

essential to use only equipment listed for service

with your control panel.

Telephone lines needed to transmit alarm

signals from a premise to a central monitoring

station may be out of service or temporarily

disabled. For added protection against telephone

line failure, backup radio transmission systems

are recommended.

The most common cause of fire alarm

malfunction is inadequate maintenance. To keep

the entire fire alarm system in excellent working

order, ongoing maintenance is required per the

manufacturer's recommendations, and UL and

NFPA standards. At a minimum, the

requirements of NFPA 72 -2002-1999 shall be

followed. Environments with large amounts of

dust, dirt or high air velocity require more

frequent maintenance. A maintenance agreement

should be arranged through the local

manufacturer's representative. Maintenance

should be scheduled monthly or as required by

National and/or local fire codes and should be

performed by authorized professional fire alarm

installers only. Adequate written records of all

inspections should be kept.

While installing a fire alarm system may make the

owner eligible for a lower insurance rate, a fire

alarm system is not a substitute for insurance.

Property owners should continue to act prudently

in protecting the premises and the people in the

premises and should properly insure life and

property and buy sufficient amounts of liability

insurance to meet their needs.

Limit-C-9-2005

Page 5

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of

power can be connected to the fire alarm

control panel. Disconnect all sources of power

before servicing. Control unit and associated

equipment may be damaged by removing and/or

inserting cards, modules, or interconnecting

cables while the unit is energized. Do not attempt

to install, service, or operate this unit until

manuals are read and understood.

CAUTION - System Re-acceptance Test after

Software Changes: To ensure proper system

operation, this product must be tested in

accordance with NFPA 72 after any programming

operation or change in site-specific software. Reacceptance testing is required after any change,

addition or deletion of system components, or

after any modification, repair or adjustment to

system hardware or wiring. All components,

circuits, system operations, or software functions

known to be affected by a change must be 100%

tested. In addition, to ensure that other

operations are not inadvertently affected, at least

10% of initiating devices that are not directly

affected by the change, up to a maximum of 50

devices, must also be tested and proper system

operation verified. Equipment used in the system

may not be technically compatible with the

control panel. It is essential to use only

equipment Listed for service with this control

panel.

This system meets Underwriter’s Laboratories

requirements for operation at 0-49º C/32-120º F

and at a relative humidity (non condensing) of

85% at 30°C (86°F) per NFPA, and 93% ± 2% at

32°C ± 2°C (89.6°F ± 1.1°F) per UL 93% ± 2%

RH (non-condensing) at 32°C ± 2°C (90°F ± 3°F).

However, the useful life of the system's standby

batteries and the electronic components may be

adversely affected by extreme temperature

ranges and humidity. Therefore, it is

recommended that this system and its

peripherals be installed in an environment with a

normal room temperature of 15-27º C/60-80º F.

Verify that wire sizes are adequate for all

initiating and indicating device loops. Most

devices cannot tolerate more than a 10% I.R.

drop from the specified device voltage.

Like all solid state electronic devices, this

system may operate erratically or can be

damaged when subjected to lightening induced

transients. Although no system is completely

immune from lightening transients and

interference, proper grounding will reduce

susceptibility. Overhead or outside aerial wiring is

not recommended, due to an increased

susceptibility to nearby lightening strikes. Consult

with the Technical Services Department if any

problems are anticipated or encountered.

Disconnect AC power and batteries prior to

removing or inserting circuit boards. Failure to do

so can damage circuits.

Remove all electronic assemblies prior to any

drilling, filing, reaming, or punching of the

enclosure. When possible, make all cable entries

from the sides or rear. Before making

modifications, verify that they will not interfere

with battery, transformer, or printed circuit board

location.

Do not tighten screw terminals more than 9 inlbs. Over-tightening may damage threads,

resulting in reduced terminal contact pressure

and difficulty with screw terminal removal.

This system contains static-sensitive

components. Always ground yourself with a

proper wrist strap before handling any circuits so

that static charges are removed from the body.

Use static suppressive packaging to protect

electronic assemblies removed from the unit.

Follow the instructions in the installation,

operating, and programming manuals. These

instructions must be followed to avoid damage to

the control panel and associated equipment.

FACP operation and reliability depend upon

proper installation.

Precau -D1-9 -2005

FCC Warning: This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause interference to radio communications. It has been tested and found

to comply with the limits for Class A computing device pursuant to Subpart B of Part 15 of FCC Rules, which is designed

to provide reasonable protection against such interference when operated in a commercial environment. Operation of

this equipment in a residential area is likely to cause interference, in which case the user will be required to correct the

interference at the user’s expense.

If these instructions are not clear, or if additional information or clarification is needed, please consult your local

authorized Gamewell-FCI distributor.

Because of design changes and product improvements, the information in this manual is subject to change without

notice. Gamewell-FCI reserves the right to change hardware and/or software design, which may subsequently affect the

contents of this manual. Gamewell-FCI assumes no responsibility for any errors that may appear in this manual. Neither

this manual nor any part of it may be reproduced without the advance written permission of Gamewell-FCI.

9000-0447 Rev. I

iv

Page 6

Documentation Feedback

Your feedback helps us keep our documentation up-to-date and accurate. If you have any

comments or suggestions about our online Help or printed manuals, you can email us.

• Please include the following information:

• Product name and version number (if applicable)

• Printed manual or online Help

• Topic Title (for online Help)

• Page number (for printed manual)

• Brief description of content you think should be improved or corrected

• Your suggestion for how to correct/improve documentation

Send email messages to:

FireSystems.TechPubs@honeywell.com

Please note this email address is for documentation feedback only. If you have any technical

issues, please contact Technical Services.

9000-0447 Rev. I

v

Page 7

TABLE OF CONTENTS

1.0

System Overview................................................................................................................ 4

1.1 Description ........................................................................................................................ 4

1.2 Features ............................................................................................................................ 4

1.2.1 Standard Features ..................................................................................................... 4

1.2.2 Optional Features ...................................................................................................... 5

1.3 Control and Indicators ....................................................................................................... 5

1.3.1 Switch Controls .......................................................................................................... 5

1.3.2 LED Indicators ........................................................................................................... 5

1.3.3 Audible Sounder ........................................................................................................ 5

1.4 Optional Modules .............................................................................................................. 5

1.4.1 Digital Alarm Communicator (DACT)......................................................................... 5

1.4.2 Class A Option Module (CAOM)................................................................................ 5

1.4.3 Municipal Circuit Option Module (MCOM) ................................................................. 6

1.4.4 Printer Transient Module (PTRM).............................................................................. 6

1.4.5 LCD-7100 Remote Serial Annunciator Module ......................................................... 6

1.4.6 LDM-7100 Remote LED Driver Module ..................................................................... 6

1.4.7 INI-7100-UTP, Intelligent Network Interface, Unshielded, Twisted-Pair.................... 6

1.4.8 INI-7100-FO, Intelligent Network Interface, Fiber-Optic ............................................ 6

1.5 Specifications .................................................................................................................... 6

2.0 Installation........................................................................................................................... 9

2.1 General.............................................................................................................................. 9

3.0 Basic System Module (BSM)............................................................................................ 11

Table 3-1 Field Wiring Connections...................................................................................... 11

Table 3-2 LEDs Jumpers ...................................................................................................... 12

3.1 Power .............................................................................................................................. 12

3.1.1 AC Input ................................................................................................................... 12

3.1.2 Battery Connections................................................................................................. 12

3.1.3 Auxiliary Power Output, Resettable/Non-resettable (Special Application) .............. 12

3.1.4 Earth Ground Connection ........................................................................................ 12

3.2 Relay Connections .......................................................................................................... 13

Table 3-3 Battery Standby Chart .......................................................................................... 14

3.3 Notification Appliance Circuits......................................................................................... 15

3.4 Signaling Line Circuits..................................................................................................... 15

3.4.1 Style 7 Signaling Line Circuit Installation................................................................. 16

3.5 Analog Sensors ............................................................................................................... 17

3.5.1 Address Switches .................................................................................................... 17

3.5.2 Drift Compensation .................................................................................................. 17

3.6 Addressable Modules...................................................................................................... 17

3.6.1 Address Switches .................................................................................................... 17

3.7 Deleted. ........................................................................................................................... 17

3.8 Deleted. ........................................................................................................................... 17

3.9 Optional Modules ............................................................................................................ 18

3.9.1 Class A Option Module (CAOM).............................................................................. 18

3.9.2 Municipal Circuit Option Module (MCOM) ............................................................... 18

3.9.3 Printer Transient Module (PTRM)............................................................................ 18

Table 3-4 Optional Module Wiring Connections ................................................................... 18

3.10 Digital Communicator Operation (7100-D Model) ................................................... 19

3.11 Central Station Reporting ........................................................................................ 19

Table 3-5 UL Listed Receivers Compatible with the 7100.................................................... 19

3.12 7100-D DACT Event Reporting Codes .................................................................... 20

Table 3-6 DACT-E3 Event Reporting Codes ........................................................................ 20

3.13 Telephone Requirements ........................................................................................ 21

3.14 Digital Communicator............................................................................................... 21

3.15 Telephone Company Rights and Warnings ............................................................. 21

9000-0447 Rev. I

Page 1 of 42

Page 8

3.16 FCC Required Information ....................................................................................... 21

3.17 Repairs..................................................................................................................... 21

3.18 Optional Accessories ............................................................................................... 22

3.18.1 LCD-7100 Serial Remote Annunciator ................................................................ 22

Table 3-7 Resistance Limitations.......................................................................................... 22

3.18.2 LDM-7100 LED Driver Module ............................................................................ 22

Table 3-8 Resistance Limitations.......................................................................................... 22

4.0 Programming/Operation Instructions................................................................................ 23

4.1 LED Indicators................................................................................................................. 23

Table 4-1 LED Indicators ...................................................................................................... 23

4.2 Panel Switches................................................................................................................ 24

Table 4-2 Switches ............................................................................................................... 24

5.0 System Programming ....................................................................................................... 25

5.1 MAIN Menu Selections.................................................................................................... 25

5.1.1 Addresses/Default settings after Autoconfiguration................................................. 25

5.2 CONFIG. Menu Selections.............................................................................................. 27

Table 5-1 7100 Series Menu System ................................................................................... 28

Table 5-2 Sensor Sensitivity Settings ................................................................................... 29

5.3 WALK / DRILL Menu Selections ..................................................................................... 34

5.4 I/O Menu Selections ........................................................................................................ 34

5.5 CLOCK Menu Selections ................................................................................................ 36

5.6 LOG Menu Selections ..................................................................................................... 38

5.7 INFO Menu Selection ...................................................................................................... 38

6.0 Power Up Procedure ........................................................................................................ 40

6.1 General............................................................................................................................ 40

6.2 To set the system time (Keyswitch must be engaged). .................................................. 40

6.3 Automatic Configuration.................................................................................................. 40

Table 6-1 7100 Series Device Types and Functions............................................................ 41

Figure 11 Power-Limited/Non Power-Limited Wiring............................................................ 42

9000-0447 Rev. I

Page 2 of 42

Page 9

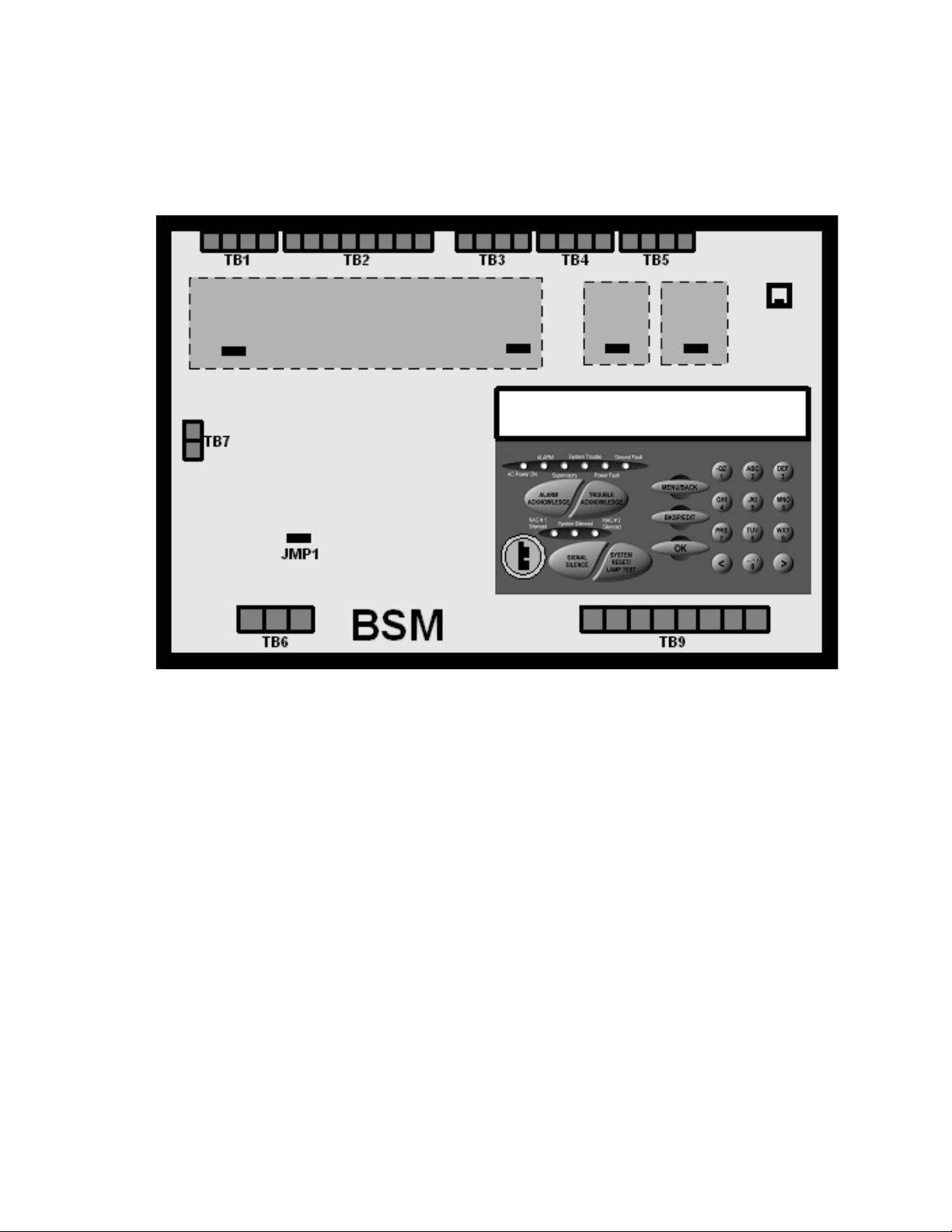

Figure 1 Basic System Module (BSM)

9000-0447 Rev. I

Page 3 of 42

Page 10

1.0 System Overview

1.1 Description

The Gamewell-FCI 7100 is a multiprocessor-based analog/addressable system, designed for commercial, industrial and institutional fire alarm applications. It is available

with either one or two signaling line circuits.

The 7100 Series is Listed by Underwriter’s Laboratories, Standard UL 864, 9th Edition. It

is suitable for the following signaling services:

• Automatic Fire Detector Alarm

• Manual Fire Alarm

• Waterflow Alarm

• Supervisory

• Automatic Smoke Alarm, non-coded and master coded operation

• Releasing Device Service

The 7100 Series complies with the requirements of the following National Fire Protection

Association (NFPA) Standards:

• NFPA 13 - Installation of Sprinkler Systems

• NFPA 16 - Deluge Foam-Water Sprinkler Systems

• NFPA 72 - National Fire Alarm Code:

- Central Station Fire Alarm Systems

- Local Fire Alarm Systems

- Auxiliary Fire Alarm Systems

- Remote Station Fire Alarm Systems

- Proprietary Fire Alarm Systems

1.2 Features

1.2.1 Standard Features

• Two (2) Class B, Style 4 Signaling Line Circuits

• Two (2) Class B, Style Y Notification Appliance Circuits

• Alarm and Trouble dry contacts

• Accommodates 99 Gamewell-FCI Approved, UL Listed compatible analog

sensors per SLC

• Accommodates 98 Gamewell-FCI Approved, UL Listed compatible

addressable monitor/control devices per SLC

• 80-character alphanumeric LCD display

• 280 event history buffer (non-volatile)

• Power-limited

• Resettable/Non-resettable 1.0 amp. @ 24 VDC power output, FWR

• Alarm verification

• Walk test

• Multi-level alarm processing

• Positive alarm Sequence (PAS) operation

• NAC coding

• Trouble reminder

• Integral RS-232 port

• Key Switch - keyed alike with the door lock and renders the key pad

inoperative until activated.

9000-0447 Rev. I

Page 4 of 42

Page 11

1.2.2 Optional Features

g

• Class A Module (CAOM) with Disconnect Switches for NACs and SLCs

• Digital Alarm Communicator (DACT) (Model 7100-D)

• RS-232 Printer Transient Module (PTRM), Supervised

• Municipal Circuit Option Module (MCOM)

1.3 Control and Indicators

1.3.1 Switch Controls

• Alarm Acknowledge

• Trouble Acknowledge

• Signal Silence

• System Reset/Lamp test

• Programming buttons

- Menu/Back

- Back Space/Edit

- OK

1.3.2 LED Indicators

• 12 button keypad

• AC Power On

• Alarm

• Supervisory

• System Trouble

• Power Fault

Fi

(green)

(red)

(yellow)

(yellow)

• Ground Fault

• NAC 1 Silenced

• NAC 2 Silenced

• System Silenced

(yellow)

(yellow)

(yellow)

(yellow)

(yellow)

ure 2

1.3.3 Audible Sounder

An Alarm/Trouble sounder is located on the Basic System Module (BSM).

1.4 Optional Modules

The following optional modules and features are available:

1.4.1 Digital Alarm Communicator (DACT)

The Model 7100-D provides an integral digital communicator (DACT), fully

programmable from the keypad, which is compatible with Digital Alarm Receivers

(DACRs) that can receive the following formats:

• SIA DC8

• SIA DCS20

• Ademco Contact ID

• 3+1 1400 Hz

• 3+1 2300 Hz

• 4+2 1400 Hz

• 4+2 2300 Hz

1.4.2 Class A Option Module (CAOM)

All 7100 Models are supplied with Class B Notification Appliance Circuits and

Class B Signaling Line Circuits. For Class A operation, the addition of a CAOM

Module is required. This module operates with all 7100 Models and enables the

signaling line circuits to operate as Class A, Style 6 or 7 and notification

appliance circuits to operate as Class A, Style Z. It supplies the additional

terminals for these circuits.

9000-0447 Rev. I

Page 5 of 42

Page 12

1.4.3 Municipal Circuit Option Module (MCOM)

The MCOM Module can trip a Local Energy City Master Box, or operate in

reverse polarity mode for leased line connection. It can also energize a solenoid

for releasing.

1.4.4 Printer Transient Module (PTRM)

The serial output on the BSM is connected via an existing RS-232 RJ-11

connector, J3. This can be used to communicate to the control with a laptop

computer while at the panel. The PTRM module is intended for systems where a

permanent connection is required. This type of connection requires that the RS232 port have sufficient transient protection to comply with the applicable codes

for wiring leaving the confines of the control box, as well as the proper isolation of

the signal to prevent damage or interference caused by the connection to certain

EDP devices. Connections are limited to the same room. The PTRM supplies

supervision and transient protection as well as the necessary isolation.

1.4.5 LCD-7100 Remote Serial Annunciator Module

The LCD-7100 Serial Remote Annunciator provides an 80-character display and

function keys for “Alarm Acknowledge”, “Trouble Acknowledge”, “Signal Silence”,

“System Reset/Lamp Test” and “System Drill Test”.

The 80-character display shows all pertinent information except for menus.

1.4.6 LDM-7100 Remote LED Driver Module

Each LDM-7100 LED Driver Module provides 7100 Control Panel output for

thirty-three (33) remote LEDs. Three (3), LDM-7100 modules may be mounted in

a single annunciator for a maximum total of 99 points per annunciator.

The annunciator may be located up to 4,000 feet from the panel and up to four

(4), additional annunciators can be connected, configured identically with the

first.

1.4.7 INI-7100-UTP, Intelligent Network Interface, Unshielded, Twisted-Pair

E3 Broadband

terminations only. It occupies one node on the E3 Series

1.4.8 INI-7100-FO, Intelligent Network Interface, Fiber-Optic

E3 Broadband Network interface connection to the 7100 FACP using either fiberoptic cable or copper wire network terminations. It occupies one node on the E3

Broadband Network.

Note: The Network Graphic Annunciator Module (NGA) is required when more

than seven (7), 7100 Series panels are networked. See the E3 Broadband

Installation/Operating Manual Part Number: 9000-0575 for details.

1.5 Specifications

Power Supply Output

Supervisory current 1.0 amp. (max.) (24 VDC nominal)

Alarm current 3.335 amp. (max.) (24 VDC nominal)

9000-0447 Rev. I

Network interface to the 7100 FACP using copper wire network

™

Broadband Network.

OR

Page 6 of 42

Page 13

Notification Appliance Circuits (TB1)

• Two (2) regulated power outputs

• Power-limited

• Supervised

• Non-coded

• Max. alarm load 1.5 amp. /circuit

Special application: See Compatibility Addendum/ P/N 9000-0427 for a list of

Gamewell-FCI Approved, UL Listed notification appliances.

Use U.L. Listed End of Line Resistor EOL-N (47K), P/N 4700-0512

Alarm Dry Contacts (TB2)

• Form “C”

• Rated 2 amp. @ 30 VDC Resistive

Alarm signals latch in. Supervisory and System Trouble signals do not latch in.

Trouble Dry Contacts (TB2)

• Form “C”

• Rated 2 amp. @ 30 VDC Resistive

Transfer Relay Control (TB2) (Special Application)

Transmit loss of AC power or brown out to Gamewell-FCI Model DRBC-1 battery

charger.

• Power-limited

• Unsupervised

Signaling Line Circuits (TB3)

• One (1) or two (2) Class “B”, Style 4 circuits

• 24 VDC nominal

• Power-limited

• Supervised

• 40 Ohm max. line resistance

• 0.5 µf max. capacitance

Capacity of 99 analog sensors and 98 addressable devices per circuit

Earth Ground Connection (TB4)

AC Input (TB6)

• 120/240 VAC, 50/60 Hz, 2 amp. @ 120 VAC, 1 amp. @ 240 VAC

• Non-power-limited

9000-0447 Rev. I

NOTICE: Terminal TB4 must be connected to an earth ground connection per Article 760 of

the National Electrical Code. Failure to make a proper earth ground connection to a metallic

cold water pipe or driven ground rod to this terminal will result in loss of lightening protection,

reduce the tolerance of the system to transients, and will adversely affect the operation of the

system. Panel neutral or conduit ground is not acceptable; minimum wire size is 14 AWG.

24 VDC external power, system (TB4) (Special Application)

• Unregulated, FWR

• Resettable and non-resettable

• 1.0 amp. max. each circuit, 1.0 amp. max. combined

• Unsupervised

Page 7 of 42

Page 14

Battery Connection (TB7)

• Supervised

• 24 VDC nominal

• Maximum battery size 31 AH

• Non-power-limited

• 0.6 A max. battery charge current

The RS-232 port, consists of an RJ11 connector which provides a standard serial port for

the connection to a Listed output device for supplementary type service. Typical

examples of such devices include any UL Listed EDP device (remote printer or video

terminal), any UL Listed Signaling Device (such as the Keltron VS4095/5 printer), or any

UL Listed Signal System Unit.

Ratings: 15 VDC (max.)

.05 amp. (max.) current

9600 baud

8 bits, 1 stop bit, no parity.

Connections to the RJ11 serial connector are as follows:

Terminal Description

2 RXD

3, 4 GND

5 TXD

6 Supervision

Available cables for RS-232 connection are:

Part No. Model Description

6100-0077 RJ11-DB9PC RJ11 to 9-pin DB9

6100-0074 RJ11-DB25 RJ11 to 25-pin (DB25) (connector only-printer)

6100-0075 RJ11C-6 RJ11 to RJ11 cable, 6-inches

6100-0076 RJ11C-20 RJ11 to RJ11 cable, 20 feet

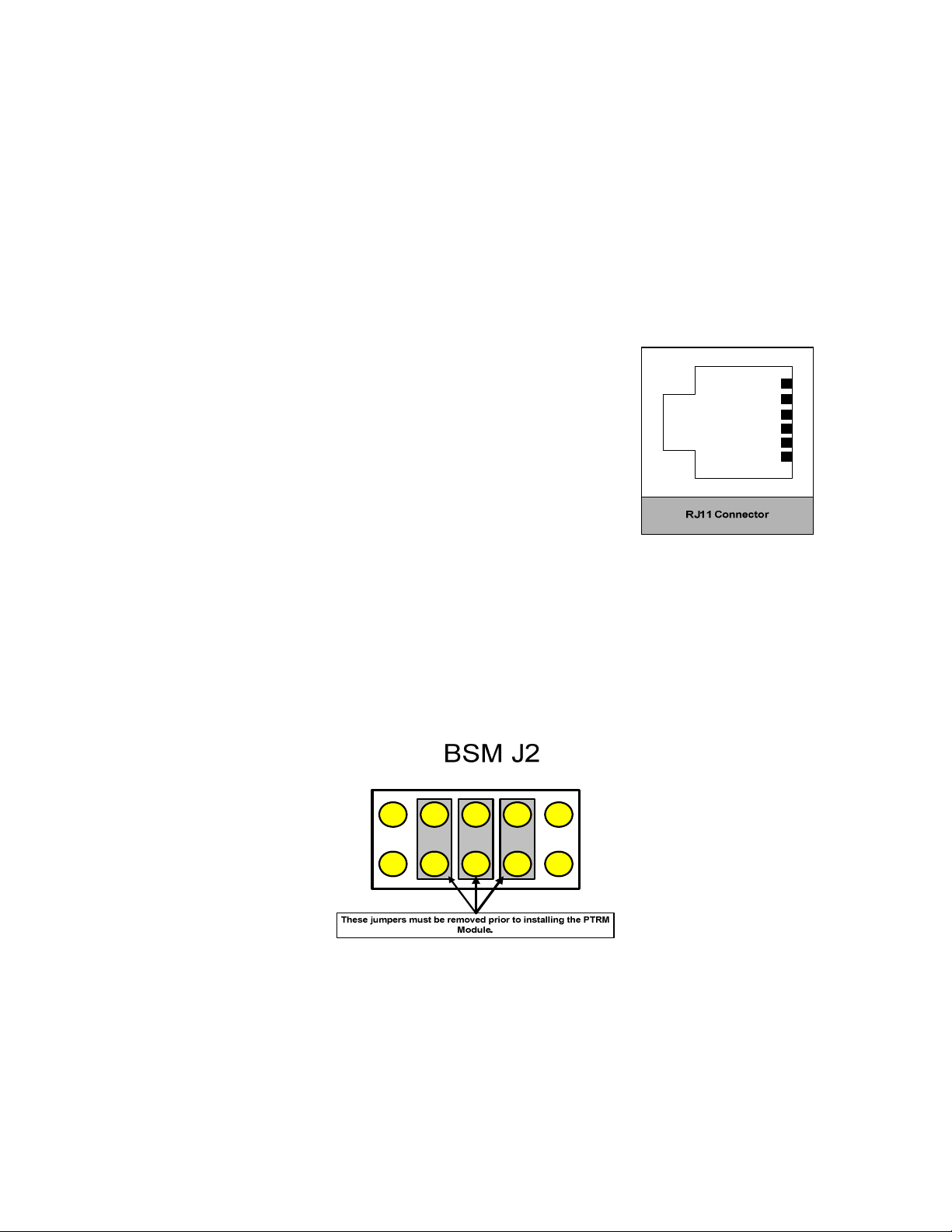

NOTE: The BSM is shipped with jumpers installed on the middle three pairs of pins on

J2. These jumpers must be removed when the PTRM is installed.

9000-0447 Rev. I

(Connector only - PC Laptop)

Figure 4

Page 8 of 42

1

2

3

4

5

6

Figure 3

Page 15

2.0 Installation

2.1 General

Components are ordered and shipped in separate packaging for the enclosure and Basic

System Module kit. The 7100 is intended for installation indoors, in a dry location. The

shipping carton contains an installation drawing, backbox, Basic System Module (BSM),

power transformer and door.

1) Refer to the System Assembly Drawing, P/N 9000-0457.

2) The BSM module consists of a main operating board with pluggable terminal strips, an

80-character LCD display and programming keypad. Install this module immediately

unless any optional modules are to be used in the system. The optional modules are

supplied separately, and should be installed on the BSM before it is mounted in the

backbox. Before installing the BSM into the system backbox, refer to the installation

instruction sheets shipped with each module for the proper installation procedures.

3) Install the transformer into the backbox. Connect the transformer to the BSM.

4) Install the door after the BSM is in place.

Note that the door can only be installed (or removed) when it is opened at least 90°

from the backbox.

9000-0447 Rev. I

Page 9 of 42

Page 16

9000-0447 Rev. I

Figure 5 7100 Wire Connections

Page 10 of 42

Page 17

3.0 Basic System Module (BSM)

Table 3-1 Field Wiring Connections

Designation Description Comments

TB1-1 NAC Circuit 1 (+) Class B, Style Y

TB1-2 NAC Circuit 1 (-) Class B, Style Y

TB1-3 NAC Circuit 1 (+) Class B, Style Y

TB1-4 NAC Circuit 2 (-) Class B, Style Y

TB2-1 TRBL Trouble contacts, N/O, 2 amp @ 30 VDC (resistive)

TB2-2 TRBL Trouble contacts, Common

TB2-3 TRBL Trouble contacts, N/C

TB2-4 ALM Alarm contacts, N/O, 2 amp. @ 30 VDC (resistive)

TB2-5 ALM Alarm contacts, Common

TB2-6 ALM Alarm contacts, N/C

TB2-7 Transfer control

TB2-8 Not used

TB3-1 Signaling Line Circuit 1 (+) Class B, Style 4

TB3-2 Signaling Line Circuit 1 (-) Class B, Style 4

TB3-3 Signaling Line Circuit 2 (+) Class B, Style 4 (7100-2, -2D only)

TB3-4 Signaling Line Circuit 2 (-) Class B, Style 4 (7100-2, -2D only)

TB4-1 Resettable Power, 24 VDC 1.0 amp.

TB4-2 Non-resettable Power, 24 VDC 1.0 amp.

TB4-3 System Common

TB4-4 Earth Ground

TB5-1 COM B To LCD-7100 TB1-2

TB5-2 COM A To LCD-7100 TB1-1

TB5-3, -4 Not used

TB6-1 AC “Hot” 120 VAC “Hot”, 50/60 Hz 2 amp., 240 VAC “Hot”, 50/60 Hz 1 amp.

TB6-2 Ground Ground

TB6-3 AC Neutral 120 VAC Neutral, 240 VAC “Hot”

TB7-1 Batt+ Battery terminal (+)

TB7-2 Batt- Battery terminal (-)

TB9-1 DACT Line 1 Tip In (non-power-limited) From street

TB9-2 DACT Line 1 Ring In (non-power-limited) From street

TB9-3 DACT Line 1 Tip Out (non-power-limited) To phone

TB9-4 DACT Line 1 Ring Out (non-power-limited) To phone

TB9-5 DACT Line 2 Tip In (non-power-limited) From street

TB9-6 DACT Line 2 Ring In (non-power-limited) From street

TB9-7 DACT Line 2 Ring Out (non-power-limited) To phone

TB9-8 DACT Line 2 Ring Out (non-power-limited) To phone

9000-0447 Rev. I

Page 11 of 42

Page 18

Designation Description Comments

LEDs

LED25

LED26 Yellow Line 2 Trouble

Jumpers

W1

W2 OUT to disable battery

W3 IN – No Local Phone Line 1

W4 IN – No Local Phone Line 2

J6 Connection to keypad

JMP1 Cut for 240 VAC input operation

3.1 Power

3.1.1 AC Input

Connection of the 120/240 VAC, 50/60 Hz power source must be made per the

requirements of the National Electrical Code, NFPA 70, Article 760, the

applicable NFPA requirements, and/or the Authority Having Jurisdiction.

Guidelines to follow are:

• Connections must be to a dedicated branch circuit.

• Connections must be mechanically protected.

• All means of disconnecting the circuit must be clearly marked: “FIRE ALARM

CIRCUIT CONTROL".

• Accessible only to authorized personnel.

• For 240 VAC operation, no conductor shall have a potential greater than 150 V

to ground.

See Table 3-1 for AC input and battery connections.

IMPORTANT: Always apply AC power first, then connect the batteries.

Yellow

Table 3-2 LEDs Jumpers

Line 1 Trouble

Not used

3.1.2 Battery Connections

3.1.3 Auxiliary Power Output, Resettable/Non-resettable (Special Application)

3.1.4 Earth Ground Connection

9000-0447 Rev. I

• TB7-1 is positive. See Table 3-1.

• TB7-2 is negative. See Table 3-1.

• Observe polarity

See Table 3-3 for Battery Calculations

• TB4-1 Resettable, 24 VDC, max. 1.0 amp., FWR. Suitable for use with

projected beam smoke detectors SPB-24, or DH Series duct detectors.

• TB4-2 Non-resettable, 24 VDC, max. 1.0 amp., FWR. Suitable for use with the

Firemark door holders.

NOTE: Total output is 1.0 amp max. combined.

• TB4-3 Common negative

• TB4-4 Not used

• TB4-4 Earth Ground

Page 12 of 42

Page 19

3.2 Relay Connections

System Trouble Contacts

• TB2-1 Normally Open

• TB2-2 Common

• TB2-3 Normally Closed

Transfers on any trouble condition and/or supervisory alarm.

System Alarm Contacts

• TB2-4 Normally Open

• TB2-5 Common

• TB2-6 Normally Closed

Transfers upon any system alarm except supervisory.

9000-0447 Rev. I

Page 13 of 42

Page 20

Table 3-3 Battery Standby Chart

Qty

BSM-1 Basic System Module, 1 SLC 0.056 A 0.076 A

BSM-2 Basic System Module, 2 SLC 0.065 A 0.085 A

BSM-1D Basic System Module, 1 SLC w/DACT 0.075 A 0.095 A

BSM-2D Basic System Module, 2 SLC w/DACT 0.085 A 0.095 A

PTRM Printer Transient Module 0.020 A 0.020 A

CAOM Class A Option Module 0.001 A 0.001 A

MCOM Municipal Circuit Option Module 0.001 A 0.001 A

LCD-7100 Optional Remote Serial Annunciator 0.050 A 0.075 A

LDM-7100 LED Driver Module 0.035 A 0.200 A*

INI-7100 Intelligent Network Interface Module 0.040 A 0.040 A

Addressable Modules

Smoke and heat sensors

Notification Appliances

Aux. Power Devices

Misc. Devices

A Total Supv. Current

B Enter number of standby hours required**

C Multiply Line A times hours in Line B – enter

D Total alarm current from above

E Enter alarm sounding period in hours. (5 minutes = .084 hr.)

F Multiply Line D times Line # - enter

G Total of Lines C & F – enter

H Multiply Line G by 1.2 – enter (Total ampere/hours required***)

NOTE:

* With all LEDs and optional buzzer energized.

** 24 hrs for NFPA 72 protected premises or Central Station signaling, or Auxiliary, or Remote Supervising

Station Fire Alarm Systems.

*** Use the next size battery with a capacity greater than required. Maximum 31 A/H capacity.

Module

Description

TOTALS

Supv.

Current

Alarm

Current

Total

Supv.

Current

Total

Alarm

Current

9000-0447 Rev. I

Page 14 of 42

Page 21

3.3 Notification Appliance Circuits

The 7100 provides two (2), 24 VDC Class B, Style Y

notification appliance circuits. Class A, Style Z operation is

accomplished by adding the Class A Option (CAOM) Module.

Wiring Instructions

• NAC 1 - TB1-1 (+), TB1-2 ( - )

• NAC 2 - TB1-3 (+), TB1-4 ( - )

(Polarity markings indicate the polarity of the circuit in

alarm condition).

Use U.L. Listed End of Line Resistor EOL-N (47K),

P/N 4700-0512

Circuit Ratings

• 24 VDC regulated

• Max. alarm load 1.5 amp./circuit

• Ground fault test impedance: 20 kOhms

• 18 AWG minimum

• If synchronization of strobes is required

MDL-FC Synchronization Modules must be connected.

Class B, Style Y operation only

Special application: See Compatibility Addendum/

P/N 9000-0427 for a list of Gamewell-FCI Approved, UL Listed notification appliances.

• Supervised

• Power-limited

NOTE: The CAOM module is furnished with the End of Line resistor installed.

Figure 6 Notification

Appliance

Circuit Wiring

3.4 Signaling Line Circuits

The 7100 provides one (1), or two (2), 24 VDC Class B,

Style 4 signaling line circuits. Class A, Style 6 or 7

operation is accomplished by adding the Class A Option

(CAOM) Module. See Figure 7 for Style 4 or 6 wiring, and

Figure 8 for Style 7 wiring.

Wiring Instructions

SLC 1 - TB3-1 (+), TB3-2 ( - )

SLC 2 - TB3-3 (+), TB3-4 ( - ) (7100-2 only)

(Polarity markings indicate the polarity that should

be maintained throughout the circuit. Polarity must be

observed on all devices connected to the circuit).

Circuit Ratings

24 VDC (nominal)

Current: 0.090 amp max. (supervisory)

0.097 amp max. (alarm)

0.750 amp max. (short circuit)

• 40 Ohms max. line resistance

• 0.5 µf max. line capacitance

• Ground fault test impedance: 20 kOhms

• 18 AWG minimum, straight lay or twisted-pair

unshielded

• Power-Limited

• Supervised

See Compatibility Addendum/ P/N 9000-0427 for a list of Gamewell-FCI Approved, UL

Listed sensors and modules.

NOTE: A white wire lead of The NCM-1

module (if used) must be connected to earth

ground.

Figure 7 Signaling Line Circuit Wiring

9000-0447 Rev. I

Page 15 of 42

Page 22

3.4.1 Style 7 Signaling Line Circuit Installation

When using a Control Module as a Notification Appliance Circuit (NAC), the isolation

described in Section 3.4, Signaling Line Circuits, Style 7, Figure 7 is required, or riser

conductors must be installed in accordance with the survivability from attack by fire

requirements in National Fire Alarm Code, NFPA 72.

Figure 8

9000-0447 Rev. I

Page 16 of 42

Page 23

3.5 Analog Sensors

The 7100 accommodates only Gamewell-FCI approved, UL Listed, analog sensors and

bases. See the Gamewell-FCI Publication, P/N 9000-0427 for a list of approved sensors

and bases. Each signaling line circuit can accommodate 99 sensor address points, using

Address numbers 01 to 99.

3.5.1 Address Switches

Addresses are set via the rotary switches on each sensor or module. Setting the

address is accomplished by turning each of the two (2) rotary switches until they

point to the numbers indicating the proper address (e.g., SW1 @ #2 and SW2 @

#5 would indicate address #25).

3.5.2 Drift Compensation

The 7100 contains a program which performs continuous testing of analog

sensors, including sensitivity tests. This program will compensate all analog

sensors for age and environmental conditions. Should a problem occur in a

sensor, a “Failed Test”, “Dirty” or “Very Dirty” indication for the specific device will

appear on the system display and be recorded in the Event Log and the Serial

Port.

3.6 Addressable Modules

The 7100 accommodates only Gamewell-FCI approved, U.L. Listed, addressable monitor

and/or control modules. See the Gamewell-FCI Compatibility Addendum, P/N 9000-0427

for a list of approved modules. Each SLC can accommodate 98 addressable module

points, using Addresses 101 through 198.

In the event of common mode noise problems, a Noise Control Module (NCM-1) may be

installed. See Figure 7. The white wire lead must be connected to earth ground.

3.6.1 Address Switches

These addresses are set via the rotary switches on each module. Setting the

address is accomplished by turning each of the two (2) rotary switches until they

point to the numbers indicating the proper address (e.g., SW1 @ #5 and SW2 @

#7 would indicate address # 157). Note that the “100" digit is pre-set in all

addressable modules.

IMPORTANT: In systems incorporating the Positive Alarm Sequence (PAS)

in conjunction with addressable modules, (AMM-2F, -4F, -4SF), only one (1)

initiating device may be connected to each module (address).

EXAMPLE: Connect only one manual station per AMM-2F module.

3.7 Deleted.

3.8 Deleted.

9000-0447 Rev. I

Page 17 of 47

Page 24

3.9 Optional Modules

3.9.1 Class A Option Module (CAOM)

The Class A Option Module (CAOM) provides Class A signaling for the

notification appliance circuits and Class A, Style 6 or 7 signaling for the signaling

line circuits. Style 7 wiring requires the use of an M500X Isolator Module on both

sides of a device. It also provides a disconnect switch for each signaling line

circuit and a common disconnect switch for both notification appliance circuits.

See Table 3-4 for wiring connections.

3.9.2 Municipal Circuit Option Module (MCOM)

The Municipal Circuit Option Module (MCOM) provides output for a local energy

city master box, releasing solenoid programmed via the FCP or CAMWORKS, or

reversed polarity output for leased line connection intended for connection to a

polarity reversal circuit of a remote station receiving unit having compatible

ratings. See Table 3-4 for wiring connections. Refer to the Compatibility

Addendum P/N 9000-0427 for a list of compatible solenoids.

Ratings

Nominal voltage 24 VDC 24 VDC 24 VDC

Supervisory current .0018 amp. .012 amp. .0005 amp.

Alarm current .510 amp. (max.) .012 amp. .700 amp.

Line resistance 35 ohms (max.) 2 ohms (max)

Trip coil resistance 14.5 ohms (max.)

3.9.3 Printer Transient Module (PTRM)

The Printer Transient Module (PTRM) provides sufficient transient protection to

the RS-232 output to comply with the applicable codes for wiring leaving the

confines of the control box, as well as the proper isolation of the signal to prevent

damage or interference caused by a connection to certain EDP devices.

Table 3-4 Optional Module Wiring Connections

CAOM Module

Designation Description Comments

TB1-1 NAC1 NAC Circuit 1, Class A return (+)

TB1-2 NAC1 NAC Circuit 1, Class A return (-)

TB1-3 NAC2 NAC Circuit 2, Class A return (+)

TB1-4 NAC2 NAC Circuit 2, Class A return (-)

TB2-1 SLC1 SLC Circuit 1, Class A return (+)

TB2-2 SLC1 SLC Circuit 1, Class A return (-)

TB2-3 SLC2 SLC Circuit 2, Class A return (+) (7100-2, -2D only)

TB2-4 SLC2 SLC Circuit 2, Class A return (-) (7100-2, 2D only)

MCOM Module

TB1-1 Output (+)

TB1-2 Output (-)

Jumpers

W1 MCOM UP for Polarity Reversal operation

W2 MCOM UP for Polarity Reversal operation

PTRM Module

Jumper

W1 PTRM OUT for supervision of PTRM Module

NOTE: The BSM is shipped with jumpers installed on the middle three pairs of pins on J2.

These jumpers must be removed when the PTRM is installed.

9000-0447 Rev. I

Master Box

(NPL)

DOWN for city master box or releasing operation.

DOWN for city master box or releasing operation.

IN for no supervision

Page 18 of 42

Polarity

Reversal (PL)

Releasing

Service

Page 25

3.10 Digital Communicator Operation (7100-D Model)

The 7100-D digital communicator model features numerous formats for communication to

a central station. The 7100-D provides the following functions:

• Line seizure - takes control of the phone lines, disconnecting any premises phones

using the same lines.

• Off/On-Hook - perform on and off-hook status to phone lines.

• Listen for dial tone - 440 Hz tone typical in most networks.

• Dialing the Central Station phone number – programmable.

• Discern proper Central Station “ACK” and “Kiss-off” tone.

• Transmit data to the Central Station.

• Verify that data has been accepted by the Central Station.

• Hang-up and release phone lines.

• Communicate in a variety of formats.

3.11 Central Station Reporting

UL Listed receivers compatible with the 7100 are listed in Table 3-5 below:

Table 3-5 UL Listed Receivers Compatible with the 7100

Manufacturer Receiver Model Formats

Silent Knight Model 9000† SIA-8

SIA-20

SK4/2

3/1 14

3/1 23

Silent Knight Model 9800/9500 SIA-8

SIA-20

SK4/2

3/1 14

3/1 23

Contact ID

Ademco Model 685 3/1 14

3/1 23

Sur-Gard

(Ver. 1.64 or higher)

Osborne Hoffman Quickalert SIA-8

† If you are using the Model 9000 and the message “HELP” appears on the printer after

attempting to download, the 9000 software must be upgraded.

The Model 9000 must have the Model 9307 software package, Revision 900501 or later,

to print the PROGRAMMING PASS and PROGRAMMING FAIL messages.

SG-MLR2-DG SIA-8

SIA-20

SK4/2

3/1 14

3/1 23

Contact ID

SIA-20

9000-0447 Rev. I

Page 19 of 42

Page 26

3.12 7100-D DACT Event Reporting Codes

The 7100-D DACT event reporting codes are shown in Table 3-6 below:

Table 3-6 DACT-E3 Event Reporting Codes

Event SIA Contact ID 4/2 3/1

Fire Alarm (Smoke or Manual Station) FA GGT 1 110 00 GGT 0T 0

Fire Alarm Restored FH GGT 3 110 00 GGT 2T 2

Waterflow Alarm SA GGT 1 113 00 GGT 0T 0

Waterflow Alarm Restored SH GGT 3 113 00 GGT 2T 2

Trouble (except Waterflow or Special AMM) FT GG0 1 373 00 GG0 8T 8

Trouble Restored FJ GG0 3 373 00 GG0 7T 7

Trouble (Waterflow AMM) ST GG0 1 370 00 GG0 8T 8

Trouble Restored (Waterflow AMM) SJ GG0 3 203 00 GG0 7T 7

Trouble (Special AMM) UT GG0 1 370 00 GG0 8T 8

Trouble Restored (Special AMM) UJ GG0 3 370 00 GG0 7T 7

Supervisory / Tamper (Module) SS GGT 1 203 00 GGT 6T 6

Supervisory Restored (Module) SR GGT 3 203 00 GGT 7T 7

PAS/Action/Supervisory (Sensor) FS GGT 1 200 00 GGT 6T 6

PAS/Action/Supervisory Restored (Sensor) FR GGT 3 110 00 GGT 7T 7

Disable (except Waterflow or Special AMM) FB GG0 1 571 00 GG0 8T 8

Disable Restored FU GG0 3 571 00 GG0 7T 7

Disable (Waterflow AMM) SB GG0 1 570 00 GG0 8T 8

Disable Restored (Waterflow AMM) SU GG0 3 570 00 GG0 7T 7

Disable (Special AMM) UB GG0 1 570 00 GG0 8T 8

Disable Restored (Special AMM) UU GG0 3 570 00 GG0 7T 7

AC Fail AT 0 1 301 00 000 8T 8

AC Fail Restored AR 0 3 301 00 000 7T 7

Phone Line 1 Fault LT 1 1 351 00 000 81 8

Phone Line 1 Fault Restored LR 1 3 351 00 0000 71 7

Phone Line 2 Fault LT 2 1 352 00 000 82 8

Phone Line 2 Fault Restored LR 2 3 352 00 000 72 7

Automatic Test (NORMAL) RP 0 1 602 00 000 90 9

Automatic Test (With Exception) RP991 1 602 00 991 91 9

For Contact ID and SIA Formats:

GG = group number assigned to the device, 00-99

(For networked systems, GG = Node number)

T = Type of device or event causing the event to be reported.

0= Non-loop event

1= Any event or device type not listed below

2= Manual Station

3= Supervisory Device (Non-latching)

4= Supervisory Device (Latching)

5= Waterflow (Non-silenceable)

6= Smoke Alarm

8= Multilevel Device

Note:Special AMMs include the following functions:

Reset Switch, Silence Switch, Drill Switch, Alarm Acknowledge Switch, Trouble Acknowledge

Switch.

9000-0447 Rev. I

Page 20 of 42

Page 27

3.13 Telephone Requirements

• DC Ringer Equivalence Number (REN) = 0.5B

• AC Ringer Equivalence Number = 1.3

• Complies with FCC Part 8

The REN is used to determine the quantity of devices that may be connected to the

telephone line. Excessive RENs on the telephone line may result in the devices not

ringing in response to an incoming call. In most, but not all areas, the sum of the RENs

should not exceed five (5). To be certain of the number of devices that may be connected

to the line, as determined by the total RENs, contact the telephone company to determine

the maximum REN for the calling area.

3.14 Digital Communicator

Before connecting the 7100-D to the public switched telephone network, the installation

of two (2) lines is necessary. The following information is provided if required by the local

telephone company:

Manufacturer:

Gamewell-FCI

12 Clintonville Road

Northford, CT 06472-1610 USA

Product Model Number: 7100-D

FCC Registration Number: 6KWUSA-34215-AL-T

Ringer Equivalence: 0.5B

3.15 Telephone Company Rights and Warnings

The telephone company, under certain circumstances, may temporarily discontinue

services and/or make changes in its facilities, services, equipment or procedures which

may affect the operation of this digital communicator. However, the telephone company is

required to give advance notice of such changes or interruptions. If the digital

communicator causes harm to the telephone network the telephone company reserves

the right to temporarily discontinue service. Advance notification will be provided except

in cases when advance notice is not practical. In such cases, notification will be provided

as soon as possible. The opportunity will be given to correct any problems and to file a

complaint.

DO NOT CONNECT THIS PRODUCT TO COIN TELEPHONE, GROUND START OR

PARTY LINE SERVICES.

• When the digital communicator activates, premise phones will be disconnected.

• Two separate phone lines are required. Do not connect both telephone interfaces to the

same telephone line.

• The digital communicator must be connected to the public switched telephone network

upstream of any private telephone system at the protected premises.

• This equipment is designed to be connected to the telephone network or premises

wiring via terminal blocks.

3.16 FCC Required Information

This equipment complies with Part 68 of the FCC Rules. The Ringer Equivalence

Number (REN) is listed in Section 3.13, while the FCC Registration Number is listed in

Section 3.14. These numbers must be provided to the telephone company, if requested.

3.17 Repairs

The 7100-D Digital Communicator does not contain any user-serviceable parts. The unit

must be returned to the factory for repair through an authorized Gamewell-FCI distributor.

9000-0447 Rev. I

Page 21 of 42

Page 28

3.18 Optional Accessories

3.18.1 LCD-7100 Serial Remote Annunciator

The LCD-7100 Serial Remote Annunciator provides an 80-character display and

function keys for the following:

- “Alarm Acknowledge” - “System Reset/Lamp Test”

- “Trouble Acknowledge” - “System Drill Test”

- “Signal Silence”

• The 80-character display shows all pertinent information except for menus.

• Keypad functions are enabled only when the keylock is turned to the

“Unlocked” position, with the exception of the “Trouble Acknowledge” switch

which silences the local audible trouble sounder.

• Operating LEDs provided are as follows:

- “Alarm” - “Power Fault” - “NAC #1 Silenced”

- “Supervisory” - “System Silenced” - “NAC #2 Silenced”

- “System Trouble”

• The LCD-7100 is flush or surface-mounted on a standard 4-gang electrical box.

• The 7100 Series control can accommodate up to five (5), remote LCD-7100

annunciators which may be located up to 4,000 feet from the main control

panel. See Table 3-7 below for resistance limitations of the connecting circuit.

No. of LCD-7100 Units 1 2 3 4 5

Max resistance of 24 VDC power

circuit (ohms) to most distant LCD

Table 3-7 Resistance Limitations

70 38 24 17 4

3.18.2 LDM-7100 LED Driver Module

Each LDM-7100 LED Driver Module provides 7100 Control Panel output for

thirty-three (33), remote LEDs. Three (3), LDM-7100 modules may be mounted in

a single annunciator for a maximum total of 99 points per annunciator.

The annunciator may be located up to 4,000 feet from the panel and up to four

(4), additional annunciators can be connected, configured identically with the

first. See Table 3-8 for resistance limitations for the connecting circuit.

Note, that if more than four (4), LDM-7100 modules are installed, an external

regulated and power-limited power supply Listed for use with fire protective

signaling units is required.

The module is intended for mounting inside the enclosure of a UL Listed remote

annunciator. It may be mounted by means of mounting screws or stacked using a

metal hex standoff kit. Wire routing and installation methods are to be in

accordance with the annunciator installation instructions.

Table 3-8 Resistance Limitations

Qty. of LDM-7100 modules 1 2 3 4 5 to 15

Max resistance of 24 VDC power

Circuit (ohms) to most distant LDM

NOTE 1: Maximum attenuation for the entire fiber-optic line is 8 dB.

NOTE 2: The use of fiber-optic cable is not permitted in New York City.

40 20 14 10 See above.

9000-0447 Rev. I

Page 22 of 42

Page 29

4.0 Programming/Operation Instructions

4.1 LED Indicators

Designation Description Comments

AC Power On (green) Lights to indicate presence of 120/240 VAC input.

Alarm (red) Lights when system is in alarm, flashes until alarm is

Supervisory (yellow) Lights when supervisory condition exists, flashes until

System Trouble (yellow) Lights to indicate trouble condition, flashes until

Power Fault (yellow) Lights during a LOW or NO Battery condition.

Ground Fault (yellow) Lights to indicate a ground on a field conductor

NAC 1 Silenced (yellow) Lights to indicate that NAC Circuit has been silenced

NAC 2 Silenced (yellow) Lights to indicate that NAC Circuit has been silenced

System Silenced (yellow) Lights when a System Silence has been performed.

Figure 9 LED Indicators

Table 4-1 LED Indicators

acknowledged.

trouble acknowledge is performed.

trouble is acknowledged.

via the Signal Silence Switch (if programmed as

silenceable).

via the Signal Silence Switch (if programmed as

silenceable).

Flashes when disabled.

9000-0447 Rev. I

Page 23 of 42

Page 30

4.2 Panel Switches

Designation Comments

Alarm Acknowledge Silences the panel audible sounder. This switch must be pressed once for

Trouble Acknowledge Silences the panel audible sounder. This switch must be pressed once for

Signal Silence Press once and any outputs programmed as silenceable will be

Lamp Test/Reset Press momentarily and all LEDs (including all elements in the display) will

Menu/Back Used in programming. The display will prompt the operator as to which

BKSP/Edit Used in programming. The display will prompt the operator as to which

OK Accepts any changes made in the programming field.

Alphanumeric Keys These 12 keys allow the user to choose a specific point address by using

PK-625 Key Switch This key switch is keyed alike with the door lock, and must be operated in

Figure 10 Switches

Table 4-2 Switches

each Alarm condition present in the system.

each Trouble or Supervisory condition present in the system.

deactivated.

(All applicable silence LEDs will light). A second activation will re-activate

the previously silenced outputs. This switch only functions if an Alarm or

Supervisory condition exists in the system.

light momentarily. Press and hold to reset the system.

function applies. “Menu” is pressed to initially put the 7100 into

programming mode. The “Back” function will step the operator out of the

programming mode one element at a time.

function applies.

the numbers for point sensitivity reading, disabling an address, etc.

Press each key the number of times necessary to display the correct

character on the display.

Example: Pressing the “2” key,

Once will display the letter “A”

Twice will display the letter “B”

Three times will display the letter “C”

Four times will display the number “2”

order to activate the keypad.

9000-0447 Rev. I

Page 24 of 42

Page 31

5.0 System Programming

System programming can be performed either by front

panel programming as shown below or via portable

computer and the Gamewell-FCI Field Configuration

Program.

5.1 MAIN Menu Selections

CONFIG

WALK/DRILL

I/O

CLOCK

LOG

INFO

5.1.1 Addresses/Default settings after Autoconfiguration

Sensors occupy Addresses 01-99 on the signaling line

circuits. Sensors are ion, photoelectronic, or thermal. They

are latching and non-verified when autoconfigured.

Monitor/Control modules occupy Addresses 101-198. The

type of device assigned to a monitor module during

autoconfiguration depends on the address as shown below:

Address Device

100-149 Manual station

150-159 Supervisory switch

160-169 Waterflow switch

170 Silence switch

171 Reset switch

172 Fire Drill switch

173 Alarm/Acknowledge switch

174 Trouble/Supv. Acknowledge switch

175 Aux switch

176-179 Tamper switch

180-184 Control panel

185-189 Remote zone

190-198 Normally open contacts

AOM modules are silenceable and activate on general alarm (day or night). AOM modules modified

by breaking off tabs are non-silenceable and activate on general alarm (day or night).

9000-0447 Rev. I

Where automatic configuration of the

system is accomplished, as well as all of

the system global programming, input to

output group programming and NAC

coding.

Allows the user to select Audible or Silent

Walk Test as well as activating and deactivating the System Drill function.

Allows the user to activate (turn on) or deactivate (turn off) any output in the system.

Selection supplies the options for

programming the system time, date,

day/night weekend and holidays.

Options for manipulating the Event Log are

display, print, clear (buffer) and selecting

to print only the Sensitivity Report.

Gives the user basic system information

such as the current firmware version, the

last configuration date as well as the last

menu Designation used during the last

system configuration update.

Page 25 of 42

Page 32

Main

Any selection

(Only opens if adequate access has not

already been obtained)

Main

Config

Password

Main

Config

Inputs

Type

Edit

(If BKSP/EDIT is pressed, and editing is

possible).

Main

Config

Inputs

Type

Define Type

(After response category is accepted)

Main

Config

Inputs (or Outputs)

Select

Location

Edit

_____________or_________________

Main

Config

System ID

Edit

Various

(If OK is pressed when an illegal value

has been entered).

[GAIN ] Type password for level 3:

[ACCESS] 000000

keypad: enters password (shows as “XXX…” on display)

OK: if password is valid for desired level (or higher), opens

access, logs the event, and continues to next menu. If not,

returns to Main Menu.

[CHANGE ] Level 1, User 1 111111

[PASSWORD] select key in password

keypad: enters new password for specified level and user

<>: scrolls through levels and users.

If current access level is lower than selection, password is

shown as XXXXXX, otherwise as digits.

[DEFINE] AMM Type 43 (Alarm)

[TYPE ] 1: select response

<>: scrolls through available response categories:

• Alarm • Tamper

• Manual Station • Waterflow

• Supervisory

Note that Alarm, Manual Station and Waterflow all produce

alarm response, except Manual Station which may use PAS

(depending on the global PAS settings) and Waterflow

disables silencing.

OK: accepts the response selection and opens the Edit

Device Type Menu.

[EDIT ] Spark De (__ Alpha, repeat

[TYPE LBL] move, EDIT flip case, OK

Initially, label comes up all underscores.

Keypad: enters text via telephone codes. Scrolls through the

numeral’s associated lower case letters, plus the numeral

itself.

Example:

• Press “2” key once for ‘a’, again for ‘b’, again for ‘c’, and

again for ‘2’. Press again to scroll back to ‘a’.

• To change to/from upper case, press “BKSP/EDIT”, or

scrolls to the previous or next letter.

• “BACK” exits to the Add Type menu without making a

change.

• OK accepts new label and exits to the Select Input Type

Menu.

[EDIT 1ST] (____ Alpha key, repeat

[LOC WORD] move, EDIT flip case, OK

Keypad: enters text (See Edit Device Type Menu). OK:

accepts new text for selected address.

Error! Entry is not valid. Press BACK, then

change value or press BACK again.

9000-0447 Rev. I

Page 26 of 42

Page 33

5.2 CONFIG. Menu Selections

AUTO

GLOBAL

INPUTS

OUTPUTS

GROUPS

DIALER

NOTE:

The DACT account programming options for Alarm, Test, Trouble and Supervisory

events are defaulted to “MUST” in the Reporting Options section. In order to use this

panel for remote signaling purposes all events must be transmitted off-premises.

If one account is used, it is required that the Reporting Option for each event (Alarm,

Test, Trouble, Supervisory) be set to “MUST”. If two accounts are used, it is required that

the reporting option for each event be set to “MUST” between the two accounts.