Pentair Everpure CB20-312E Installation Manual

Part Number EV9100-37

INSTALLATION AND OPERATING INSTRUCTIONS

CB20-312E WATER FILTRATION SYSTEM

GENERAL PRECAUTIONS

Maximum Pressure: 20-100 psi non-shock (1.4-6.9 bar)

Temperature: 35-100°F (2-38°C)

Install On Cold Water Lines Only

Installation By a Certified Installer Is Recommended

Housing Inlet & Outlet:1/2"

Rated service flow: 5 gpm (19 Lpm)

Capacity: 60,000 gal (227,100 L)

For cold water use only!

WARNING: This filter must be protected from freezing. Failure to do

so may result in cracking of the filter and water leakage.

Do not install where unit is exposed to direct sunlight.

Allow a minimum of 4" clearance under the filter to facilitate cartridge

change. Make certain that the installation complies with all state and

local laws and regulations.

WARNING: Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before or after the

system.

NOTE: The carbon taste/odor cartridge may contain small amounts

of carbon fines (very fine black powder) and a new cartridge, after

installation, should be flushed with sufficient water to remove the fines

before using the water.

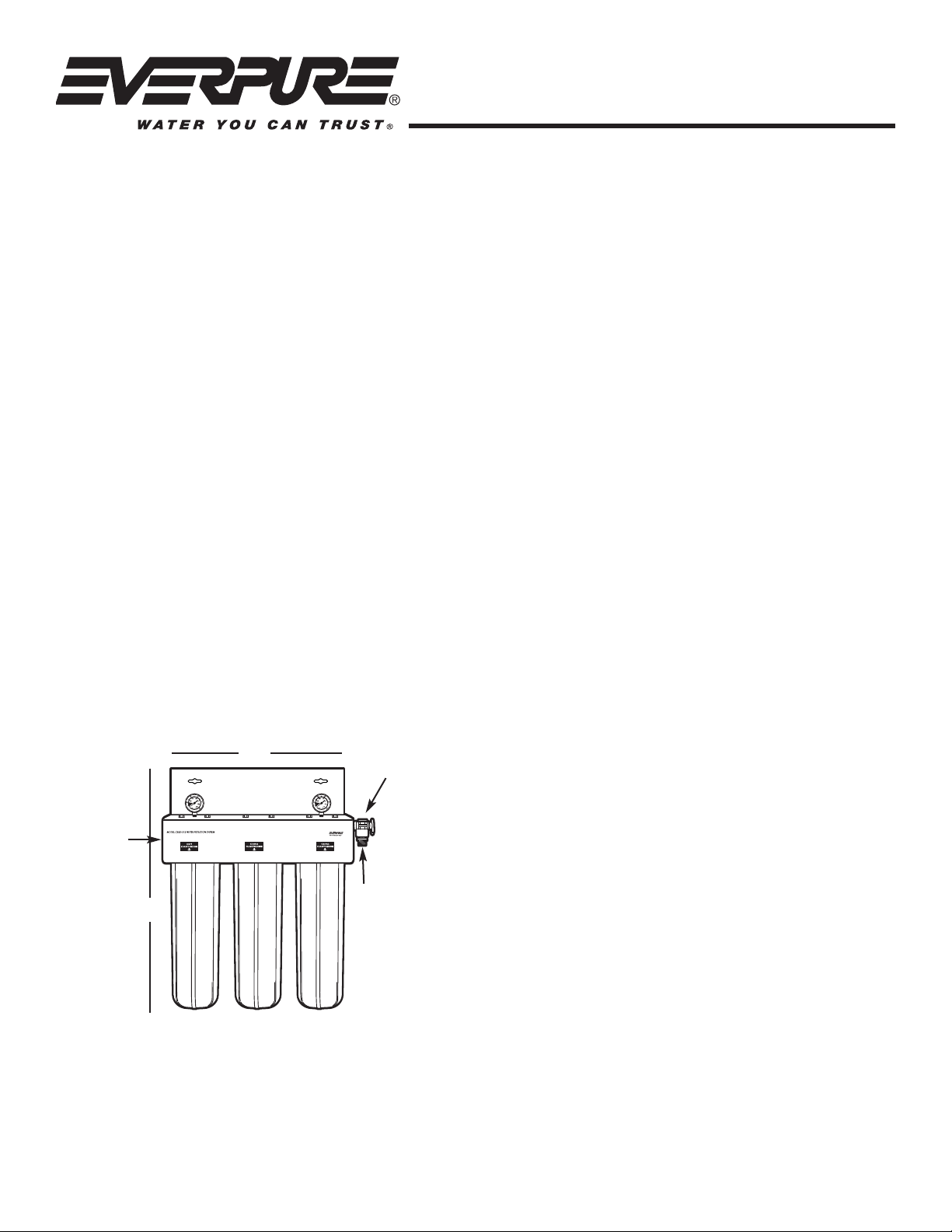

CB20-312E WATER FILTRATION SYSTEM

1

/2" Female

Inlet

Connection

fr

om Supply

25"

29 1/2"

Mounting Depth: 15 1/8"

Operating Weight: 90 lbs.

Allow a minimum of 4" clearance under

the filter to facilitate cartridge change.

1

/2" Female

Outlet

Connection to

Equipment

Flush Valve

SYSTEM INSTALLATIONS

OTE:Always use a good grade of pipe sealant or teflon

N

connections.

1. Reduce product weight by removing bowls from header assembly

efore mounting unit.

b

2. Determine installation location using head assembly.

3. Assemble flush valve kit per illustration on its instruction sheet.

4. Screw stem adapter into flush valve.

5. Firmly press tube end of stem adapter into “T” fitting at filtration

unit’s outlet.

6. Install system bracket. Mount system. Mount system to wall studs

16" on center on other surface capable of supporting 90 pounds

when system is filled with water.

7. Turn off water and power supply to all beverage equipment and

icemaker.

8. Connect cartridge system to feed water supply, beverage sys-

tems, and icemaker.

9. Sanitize filter bowls using dilute (0.5%) household bleach solution,

Diversol™ or equivalent.

10. Handle cartridges by plastic wrap to minimize contact.

11. Lubricate “O-rings” with silicone lubricant and secure to system

head. Hand tighten.

12. Cartridge Flush Procedure:

-Install the CC1E cartridge, leaving the CC3E bowls empty

-Flush cartridges at full flow for 5 minutes

-Install CC3E cartridges and flush system for 10 minutes

13. Close flushing valve and inspect for leaks.

15. Turn power to beverage equipment and icemaker back on.

16. Clean up and give final inspection.

17. Obtain Manager sign-off on work confirmation form.

®

ape on

t

REPLACEMENT CARTRIDGES

CC1E Carbon Filter (gray end caps)

CC3E Cyst Filter (white end caps)

Replace CC1E, and both CC3E cartridges every 6 months or 60,000

gallons (whichever comes first).

1. Turn power off to beverage equipment.

2. Turn water off to CB20-312E system.

3. Unscrew bowl assembly from header, remove exhausted cartridge

and discard.

4. Unwrap new cartridge and place in bowl. Screw bowl into appro-

priate head on system.

5. Turn on water and flush cartridges. (Refer to cartridge flush proce-

e Step 12 under System Installation.)

dur

For assistance or to locate the near

or service call:

CAUTION: Bowl is heavy with water.

est dealer for r

Everpure Customer Service 1-800-323-7873

Everpur

echnical Service

e T

1-800-942-1153

eplacements parts

FEATURES

• Finely polishes treated water to premium quality for drinking and

cooking.

• Reduces disinfectant chlorine taste & odor and chloramine taste &

odor.

• Reduces dirt, rust, and other particulates such as oxidized iron,

manganese, and sulfides.

• Reduces parasitic protozoan cysts such as

Giardia, Entamoeba,

Cryptosporidium.

• Reduces common earthy, moldy, fishy tastes and odors.

OPERATING SPECIFICATIONS

Capacity: 60,000 gallons (227,100 L)

Pressure requirement: 20 - 100 psi (1.4 - 6.9 bar), non-shock

Temperature: 35 - 100°F (2-38°C)

Flow Rate: 5 gpm (19 Lpm)

Operating Weight: 90 lbs.

GENERAL INSTALLATION/OPERATION/

MAINTENANCE REQUIREMENTS

• Mount system to wall studs 16" on center (spacing of mounting

plate holes) on other surface capable of supporting 90 pounds

when system is filled with water.

• Connect water supply to inlet of CB20-312E system.

• Connect outlet water to beverage equipment.

• After installing the CC1E cartridge, flush cartridge at full flow for 5

minutes. Install CC3E cartridges and flush system for

10 minutes.

• Replace cartridges when capacity is reached, or when flow

becomes too slow, but at least every 6 months.

SPECIAL NOTICES

Installation instructions, parts and service availability, and

•

standard warranty are included with the product when shipped.

Installation by certified installer is recommended.

This drinking water system must be maintained according to man-

•

ufacturer’s instructions, including replacement of filter

cartridges.

• Do not use with water that is microbiologically unsafe, or of

unknown quality without adequate disinfection before or after the

system. Systems certified for cyst reduction may be used on disinfected waters that may contain filterable cysts.

• The contaminants or other substances removed or reduced by

this water treatment system are not necessarily in your water.

• Check for compliance with state and local laws and

regulations.

• Testing was performed under standard laboratory conditions;

actual performance may vary.

©2009 by Everpur

e, LLC

EVERPURE,

1040 Muir

Hanover Park, IL 60133

TEL 800-323-7873

Customer Service

FAX 800-942-0081

isit us online at: www

V

LLC

field Drive

.everpur

e.com

ope:

In Eur

EVERPURE EUR

Toekomstlaan 30

B-2200 Herentals

Belgium

el 32 14 28 35 00

T

FAX 32 14 28 35 05

OPE NV

In Japan:

EVERPURE JAPAN, INC.

Hashimoto MN Bldg. 7F

3-25-I Hashimoto Sagamihara-Shi

Kanagawa 229-1103

Japan

Tel: 81.(0)42.775.3011

Fax: 81.(0)42.775.3015

SH147957 Rev A MY09

Loading...

Loading...