Pentair Everpure 804-023 Installation Manual

WATER BOOST SYSTEM

PUMP SPECS (8025-934-399)

Motor Design 115 VAC 60 Hz permanent magnet; thermally protected and a non-replaceable integral fuse

Duty Cycle

Turn-On/Off Pressure 70 PSI [4.8 bar] / 90 PSI [6.2 bar]

Max. inlet pressure

Check Valve

Temp. Limits

Pump materials

Port / Fitting

TANK SPECS

Total Volume (air/liquid)

*Approx. Draw Down Vol. 123 Oz. [3.6 lt.]

Bladder Material:

Housing Material

Temp. Limits

Max. Working Pressure

Port

Intermittent (max. run time 20 min. within one hour)

30 psi [2 bar]

Internal (prevent reverse flow)

34 º - 120 º F [1.1 º - 49 º C]

EPDM valves, Santoprene diaphragm, Nylon housing

QD ports female / 3/8" barb fittings

2 gal [7.6 lt]

Butyl

Stainless Steel

34 º - 120 º F [1.1 º - 49 º C]

117 psi [8 bar]

1/2" NPT Female

* Draw down volume varies with tank pre-charge, pump operating pressure and city water pressure. Specs

reflect tests at 40 psi [2.7 bar] pre-charge w/20 psi [1.3 bar] city water pressure.

WATER BOOST SYSTEM LIMITED WARRANTY

SHURflo Water Boost Systems are warranted to be free of defects in material and workmanship under normal

use, for a period of one (1) year from the date of manufacture, or one (1) year of use, with proof of purchase.

This limited warranty will not exceed two (2) years, in any event.

The limited warranty will not apply to Water Boost Systems that were improperly installed, misapplied, or

incompatible with fluids or components not manufactured by SHURflo. Water Boost System failure due to

foreign debris is not covered under the terms of this limited warranty. SHURflo will not warrant any Water

Boost System which is damaged or modified outside the SHURflo factory.

Returns are to be shipped postage prepaid to either service center; SHURflo Garden Grove, CA or Elkhart, IN.

SHURflo shall not be liable for freight damage incurred during shipping, package returns carefully.

For complete warranty details consult S/B #1049.

« ISO Certified Facility

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo «

5900 Katella Ave.

Cypress, CA 90630

(800) 854-3218 (562) 795-5200

FAX (562) 795-7564

Shipping/UPS: 5900 Katella Ave., Ste.B

Cypress, CA 90630

SHURflo East

52748 Park Six Court,

Elkhart, IN 46514-5427

((800) 762-8094

(219) 262-0478

FAX (219) 264-2169

© 2002 Printed in USA

Unit 5 Sterling Park, Gatwick Road,

SHURflo Ltd.

Crawley, West Sussex, RH10 2QT

United Kingdom

+44 1293 424000

FAX +44 1293 421880

INSTALLATION AND OPERATION MANUAL

WARNING: “Risk of electrical shock.” The pump is supplied with a grounding connector and grounding-type

attachment plug. To reduce the risk of electrical shock, be certain that it is connected only to a

properly grounded, grounding-type receptacle. To prevent electrical shock, disconnect power

before initiating any work. In the case of pump failure, the motor housing and/or the pumped fluid

may carry high voltage to components normally considered safe.

WARNING: Never pressurize the accumulator tank higher than its maximum operating pressure of 117 psi [8

bar] limit. Never expose the tank to higher than 120ºF [49ºC] ambient temperature environment.

CAUTION: DO NOT adjust the pump pressure switch setting. Switch setting will not significantly alter flow

rate or pressure. Improper adjustment may cause severe overload or premature failure, not covered

under warranty.

CAUTION: DO NOT operate the pump at pressures, which cause the motor to exceed the amperes rating

indicated on the nameplate. The pump is equipped with thermal breakers to interrupt operation

due to excessive heat. Once the temperature of the motor is within proper limits it will

automatically reset, and the pump will start operation without warning. The motor is equipped

with an integral non-serviceable fuse. Pumps which have an “open” fuse are not covered under

the limited warranty.

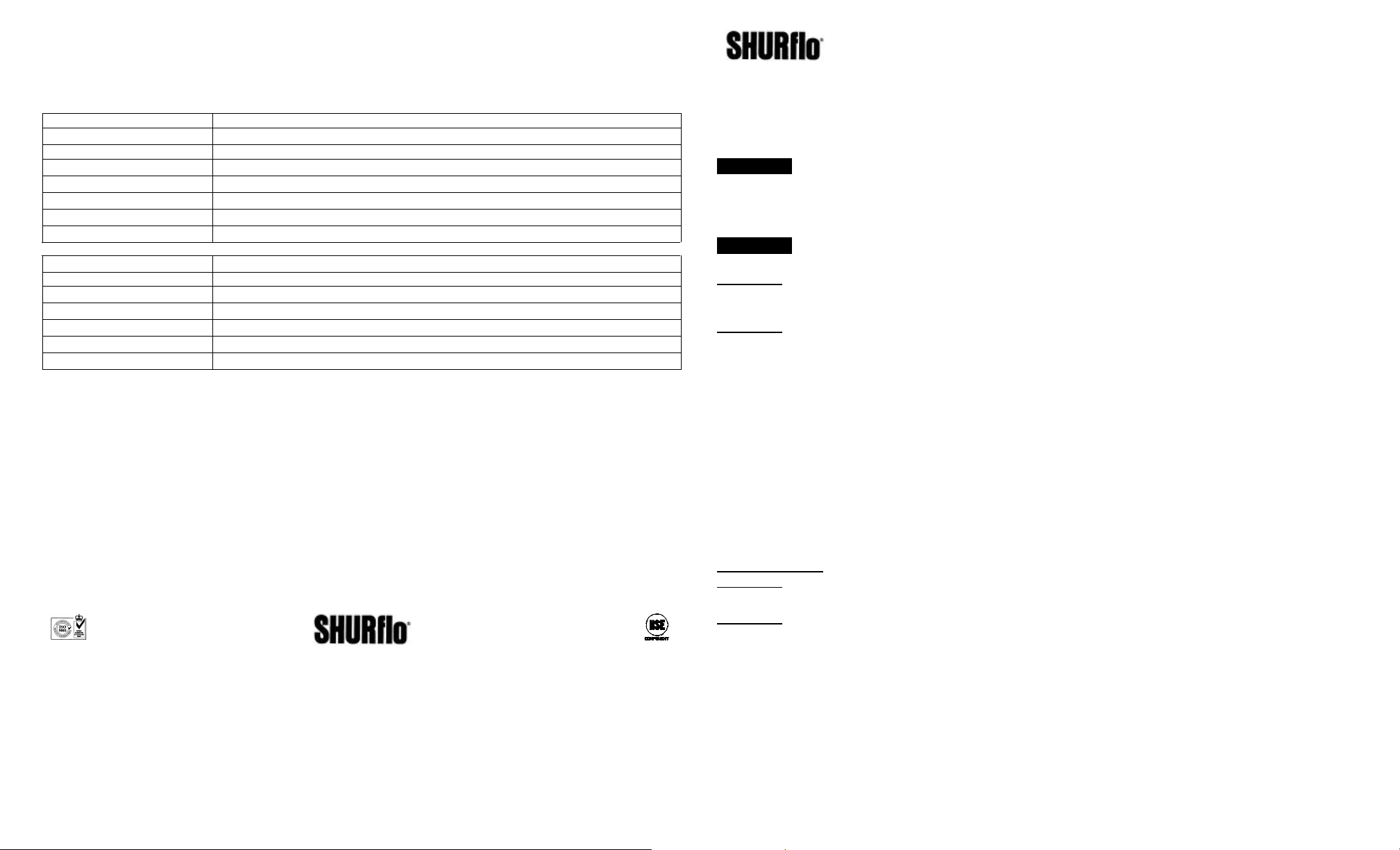

ACCUMULATOR STORAGE/FLOW-RATES

SHURflo Water Boost Systems are for applications when low, fluctuating, or no water pressure exists. The

pump and accumulator maintain consistent water pressure to a source (for a given duration) as long as incoming

water is sufficient. Depending upon the Water Boost System model, support of up to 4 non-carbonated valves in

moderate volume accounts is achievable. The Water Boost Systems may be used to supply water to a carbonator

for back-up, during short periods of insufficient water pressure. The pump pressurizes the accumulator to 90

psi. [6 bar]. Consult the flowchart for projected length of flow and/or back-up. The pump is NSF, UL and C-UL

listed.

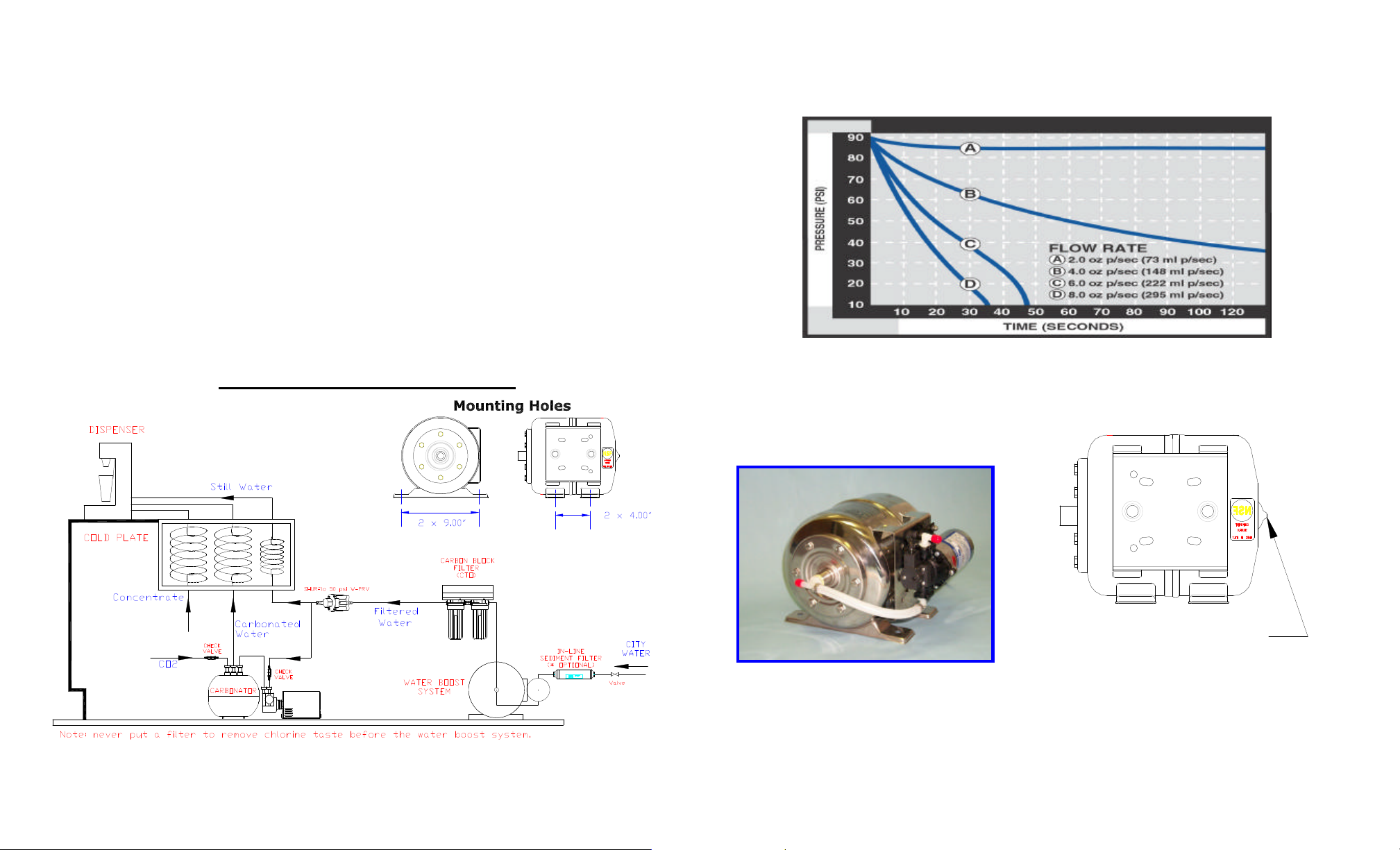

INSTALLATION

CAUTION: DO NOT pre-charge the accumulator with CO

2. In the event of failure

carbonated water will react

with brass components in system equipment. Use clean, dry air or nitrogen.

CAUTION: a qualified electrician, in accordance with all local electrical codes should perform all electrical

outlet (receptacle) wiring connections. Circuit protection is dependent on the individual application

requirements. Failure to provide proper circuit protection may result in a motor failure, which is not covered

under warranty.

1. The water booster system is to be installed between the water source and non-carbonated valve(s) or

carbonator (see Installation figure in the following page). Turn off city water supply before installation.

Note 1: Depending upon your application, it is recommended that a SHURflo 50 psi water pressure reducer

valve be installed after the filter system before the line is teed to the carbonator and the non-carb valves.

911-592 Rev. A 4-22-02 4 of 4 911-592 Rev. A 4-22-02 1 of 4

2. Use NSF listed high pressure braided 3/8" ID [9.5 mm] tubing to connect the inlet/outlet ports. Secured all

tubing connections with SS, step-less Oetiker clamps. Cable-tie all tubing securely to prevent kinks or sags

that can inhibit performance or cause damage to the pump.

3. Remove Accumulator air fitting cap and pre-charge with clean pressurized air, or nitrogen. Tank should be

pre-charged at the minimum required pressure of the application. Replace air fitting cap securely. Check

pressure bi-monthly.

4. In most cases 50 psi [3.4 bar] will provide the required pressure at a typical beverage dispense system. For

best pump performance, set accumulator pre-charge pressure at approximately 20 psi [1.3 bar] below max.

pump pressure (as stated on the pump label), and/or at approximately the pump turn-on pressure. For further

information consult the factory.

5. Turn ON incoming water supply.

6. Open the dispenser valves and purge air/water from tubing/accumulator. Close the dispenser valve(s) and let

the pump fill the accumulator. The pump may not obtain shut-off pressure if excessive air is trapped within

the system. Repeat this step 3-5 times as necessary, before taste testing.

NOTE 2: if subject to freezing temperature, the pump, tubing and accumulator tank MUST be drained of all

water.

Water Boost System Installation Diagram

.

WATER BOOST SYSTEM PERFORMANCE (Units tested with 40 psi pre-charge and 20 psi city water pressure)

Remove cap to precharge tank.

Recap after charging tank.

NOTE 3: the accumulator tank pre-charge should be

checked bimonthly or as necessary. All outlet water

pressure must be depleted prior to checking or recharging

2 of 4 3 of 4

Loading...

Loading...