Page 1

Technicians See Separate Installation Manual

OWNERS OPERATION MANUAL

Models:

MiniMax Plus HP 400 (XLS400)

MiniMax Plus HP 600 (XLS600)

MiniMax Plus HP 800 (XLS800)

MiniMax Plus HP 1000 (XLS1000)

MiniMax Plus HP 230 (CP12)

WARNING

FOR YOUR SAFETY - READ BEFORE OPERATING

Warning: If you do not follow these instructions exactly, a fire or explosion may result, causing

property damage, personal injury or loss of life.

WARNING

Improper installation, adjustment, alteration, service or maintenance may cause property damage, personal injury or

death. Installation and service must be performed by a qualified technician or service agency.

Part #471949 Revision #A

© 2001 HydroTemp Manufacturing Co., Inc.

Note: Specifications may change without notice.

Owners Operational Information Only

Page 2

OWNERS SECTION - TABLE OF CONTENTS

1. OPERATIONAL INSTRUCTIONS ..............................................................................................

a. Introduction & Design Features

b. Heater Control Panels & L.E.D. Status Lights

2. START UP PROCEDURES ...........................................................................................................

a. Compressor Warm Up Time

b. Filter System Cleaning

c. Operational Description

c. Circulation Pump Timer

d. Thermostat Setting

e. Heat Loss & Pool Covers

3. OWNERS CARE .............................................................................................................................

a. Placement Area

b. Sprinkler Placement & Plants & Condensation Run Off

c. Clearance and Air Flow.

d. Cleaning The Unit

e. Pool Circulation System Maintenance

f. Auto Vacuum's & Vacuuming

4. PLUMBING & WATER FLOW ....................................................................................................

a. Plumbing Connections & Auto Bypass

b. Large Water Pump Plumbing Bypass

c. Mandatory Chlorinator Loop & Check Valve

5. CHEMICAL & CHLORINATOR APPLICATION & USE ......................................................

a. Water Quality and Testing Values

a. Heat Exchanger Protection & Sacrificial Water Fittings

b. Chemical Feeder Placement & Use & Hand Feeding Chemicals

c. Commercial Feeders

d. Spa Chemical Application.

6. SHUT DOWN AND FREEZE PROTECTION PROCEDURES ................................................

a. Seasonal Shut Down

b. Short Term and Long Term Freezing Protection

7. OWNERS TROUBLE SHOOTING GUIDE................................................................................

8. ELECTRICAL WIRING SPECIFICATIONS BY MODEL NUMBER ....................................

8. HOW TO GET SERVICE .............................................................................................................

10. GLOSSARY OF TERMS .............................................................................................................

ADDITIONAL MANUALS AVAILABLE:

INSTALLATION MANUAL - TECHNICIAN ONLY

OPTIONS/ACCESSORY MANUAL - TECHNICIANS ONLY

OWNERS MANUALS

3 - 7

8 - 13

14 - 17

18 - 19

20 -24

25

26 - 27

28

29

30 - 33

Manufactured for Pentair Pool Products by HydroTemp Mfg. Co., Inc.

Page 3

WARNING

THE MISUSE OF THIS PRODUCT CAN RESULT IN SEVERE INJURY, DEATH,

OR PROPERTY DAMAGE. BE ADVISED OF THE FOLLOWING CONDITIONS THAT MAY EXIST:

1. ELECTROCUTION AND/OR FIRE DUE TO IMPROPER WIRING.

2. HAND AND HAIR ENTRAPMENT MAY OCCUR NEAR THE FAN LO CATED ON THE TOP OF THIS UNIT.

3. LOSS OF POOL WATER AND/OR FLOODING AND/OR PROPERTY DAM AGE.

4. DAMAGE AND/OR MISUSE TO THE PRODUCT RESULTING IN FAILURE

OR EXCESSIVE WEAR.

5. ALL ELECTRICAL WORK BY LICENSED PROFESSIONAL ONLY.

Owners/users should contact the factory service department for advice at:

HYDROTEMP MANUFACTURING CO., INC.

12155 Metro Pkwy, Ste. 5

Ft Myers, FL 33912

(941) 768-1555

(941) 768-2856 (fax)

www.warmpool.com

HEAT PUMP EFFICIENCY

Your new highly efficient heat pump pool/spa heater

will deliver warm pool water for your comfort for pennies a day. For every dollar you spend to run your heat

pump, you will receive between $4.00 and $5.00 worth

of heat in return. The heat pump transfers the heat from

the outside air to your pool or spa. Your heat pump

costs about 60 to 75 percent less than L.P. Gas heaters

to operate with less maintenance and gas storage tank

is not needed. Your heat pump produces no pollution

and no pilot lights to deal with.

$2.34

Cost Per 100,000 Btu's of Heat

$1.65

Approximate

RETURN ON INVESTMENT

The costs of installing a heat pump are somewhat higher

than a gas heater but you will save enough in operational costs to offset the difference, probably in the first

year or two. After a few heating seasons you will have

saved enough, compared to LP gas heat, to pay for the

entire heat pump and installation

.

LONGER SWIMMING SEASON

A heat pump is the least expensive way to heat your

pool. It will out perform solar by delivering heat on

demand, no matter how much sunshine is available. A

solar system with a gas back L.P. Gas back up will cost

more to operate than the heat pump alone.

In Florida, a heat pump offers a full 12 months of swimming season compared to a solar systems 10 month

swimming season. A heat pump will provide higher

temperatures than a solar system. Solar will not heat a

spa on demand after sundown & during inclement

weather.

Electric

$1.10

Oil

LP Gas

$ 0.96

Natural

Gas

$ 0.32

Heat

Pump

LOW MAINTENANCE

Maintenance cost can be more for a gas heater, considering the fact that a gas heater starts to lose efficiency

as it gets older. The heat pump's sealed system needs

far less attention.

Page 4

4

Super Quiet & Highly Efficient Compressor Design

Sturdy Elevated

Fiberglass

Rust Proof

Bottom Provides

Proper Drainage

Large Aluminum & Copper

Lanced Fin

Evaporator Air Coil and

Coil Guard

Easy Connect

2 Inch Plumbing With

"Internal Automatic Bypass"

Up To 90 GPM

Sturdy Rust Proof

Fiberglass Top

Non Fading

Quiet

High Volume

Fan With

Vinyl Coated

Guard

Product

Name Plate

Chemical

Warning Label

Automatic Diagnostics With

L.E.D. Display & Electronic

Thermostat

Optional Pool/Spa Wiring

Access Holes

Separate Air Handling / Electric Compartment

An internal electrical compartment substantially reduces

future service from moisture and salt laden air flow.

SPECIAL FEATURES

TRANE®

COMPRESSOR

with 410-A, the safe

and clean refrigerant.

And

SCROLL

COMPRESSOR

Page 5

DESIGN ADVANTAGES

Internal Automatic Bypass

Free Flow 2" Plumbing

Automatically adjusts the water flow.

Lowest water flow restriction available.

Internal

Automatic

Bypass

WARNING

The heater must be electrically grounded and bonded in accordance with local codes, or in the

absence of local codes, with the latest national electrical codes ANSI/NFPA No. 70. All wiring

must comply with all local codes, or in the absence of local codes, with the latest national electrical codes ANSI/NFPA No. 70. For proper wire and/or breaker size, please refer to specification

sheet and your local licensed electrician. Always bond heat pump cabinet to pool steel and

4250

The electrical panel has

an isolated compartment,

located within the mechanical compartment to

prevent corrosion there.

The heat from the compressor located just below

the electrical compartment helps eliminate moisture as well. This exclusive design will substantially extend the life cycle

of the heater. The fiberglass cabinet is corrosion

proof and is much stronger than plastic cabinets.

Heat Exchanger

Special Cupronickel Alloy

Encased In A Block of Foam

to Prevent Heat Loss & Corrosion

L.E.D. Status Lights

Self

Diagnostic Indicators

(On selected models)

Page 6

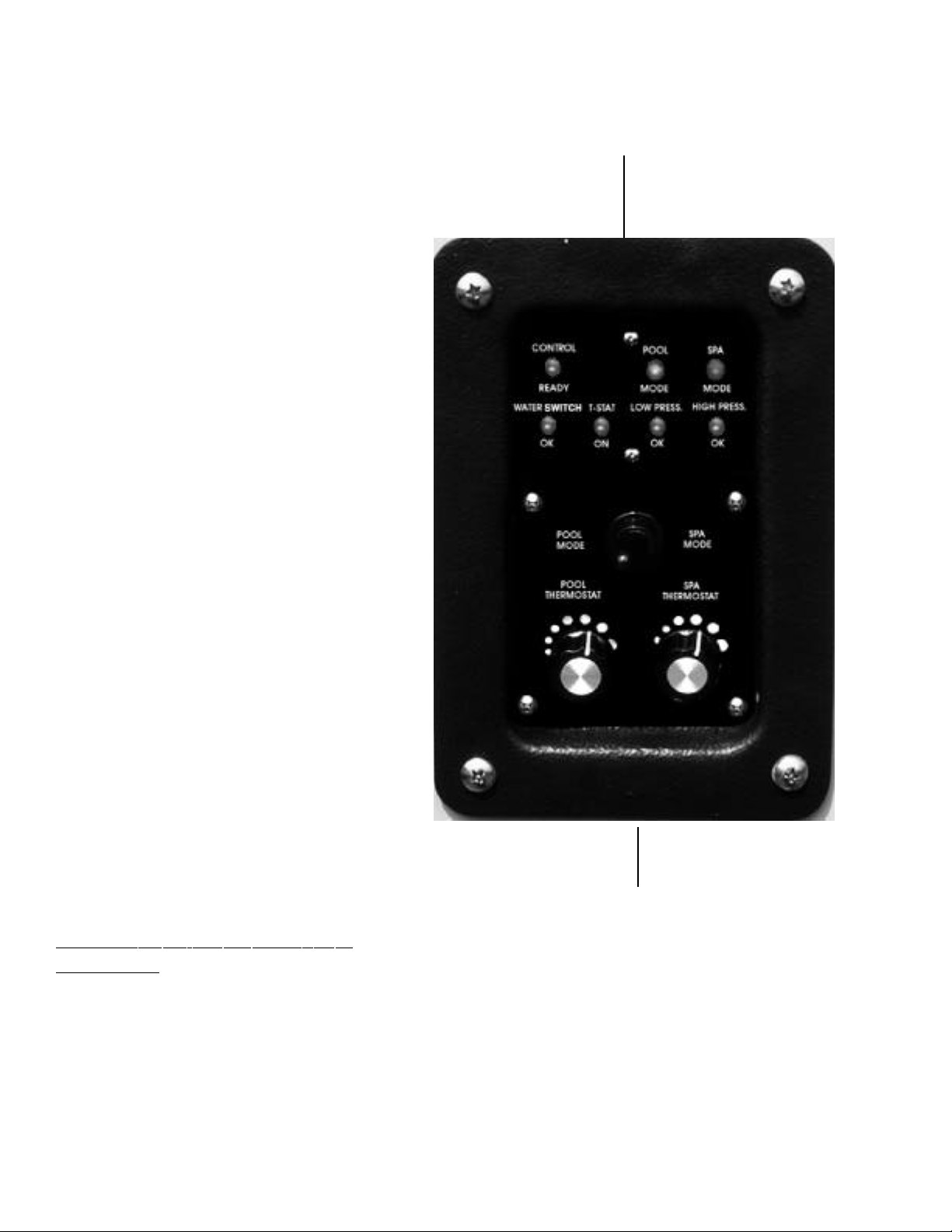

DUAL THERMOSTAT CONTROL PANEL

THERMOSTAT

The thermostat dial is just like any other,

when you set it at a certain setting the

heater will heat up to that temperature

and then shut off. When the pool/spa water temperature drops below this setting

the heater will come on and start heating

the water back up to the setting on the

thermostat.

You will notice there are no number settings printed on the dial face. There is a

certain procedure to follow to determine

the exact temperature you have the thermostat set at. This is described further

on next pages.

The maximum setting for a thermostat is

104 degrees F. You will only be able to

reach this high temperature in a spa application. Pool temperatures are normally between 78 and 82 degrees F. Actual pool temperatures are determined by

your installer, when the unit is sized to

your specifications. The lowest setting

on the thermostat is around 60 degrees F.

To disable the heater, turn the thermostat dial all the way to the left. If you

live in a climate where the water temperature may drop below 60 degrees F

you must shut the circuit breaker off.

Otherwise do not use the breaker as an

on/off switch.

See "Start up Procedures" regarding

compressor preheating if the main power

breaker is shut off. The compressor must

be preheated for 8 hours after the power

supply has been disconnected.

L.E.D. STATUS LIGHT PANEL

The indicator lights will help you determine that the unit is running

normally or if there is a condition that may keep the heater from

running. Note that the spa light is inactive on single thermostat

units. See next page for details on reading the status lights.

L.E.D. Status Lights

( See page 7 for details.)

DUAL Thermostat

Page 7

regarding water flow. When this light is off the heater will not run.

Control Ready "Green": The green control ready indicator light lets you know that the heater has power and it

is ready to heat. This light must be on before the heater can run. If this light is off, check you power supply and

circuit breakers. If this light is off, none of the others will light either.

L.E.D. STATUS LIGHT PANEL

The unit may still have "live voltage" when the control light is off.

NOTE: The bottom four indicator lights work in sequence from left to right.

SPA MODE "Orange": The orange spa mode indicator light tells you that you have selected the spa mode

with the pool spa select switch, (dual thermostat control only). This light will be inactive when used with the

standard single thermostat control (pool only).WATER PRESS. OK "Green": The green water pressure OK

indicator light tells you that the internal water pressure switch is OK. The internal water pressure switch is used

to shut the heater on and off with the circulation pump. The heater should not run when the water pump is not

pumping water through the heater. Dirty filters and lint traps will cause low water flow to the heater and may

cause the water pressure switch to deactivate the heater. If this light stays off, clean all filters and check all

filter system valving to insure proper water flow. See pages 12, 13 and 20, for more information regarding

water flow requirements. When this water flow indicator light is off the t-stat light and the low and high press.

lights will not come on either and the heater will stay off.

T-STAT ON "Green": The green thermostat on indicator light is used to let you know that the thermostat is set

higher than the pool or spa water temperature. If the light is not on, turn the thermostat to a higher position and the

fan should then start, (compressor starts after a 5 minute delay). If the thermostat is already all the way up and the

light is still off, means that the pool or spa water temperature has reached the maximum of 104˚F + or - allowed.

When this light goes off, the heater has heated the pool or spa to the preset temperature. When this light is off the

heater and the low and high pressure lights will stay off.

LOW PRESS. OK "Green": The green low pressure indicator light is designed to let you know that the low side

refrigerant pressure is OK. If the refrigerant pressure was too low for the unit to operate this light the heater will

shut off. The heater is charged with Freon™ (refrigerant). If the outside air temperature drops below 40 degrees

the refrigerant pressure will drop below the required operational range. The internal low refrigerant pressure

switch will act as a defrost control to keep the unit from forming ice on the outer evaporator coil when this light is

off. It may also indicate that the unit may have a refrigerant leak as well. When this light is off the high pressure

light and the heater will be off as well.

HIGH PRESS. OK "Green": The green high pressure OK indicator light is used to tell you that the heater is

operating at the correct high side refrigerant pressure range. If the refrigerant pressure exceeds the maximum

needed for proper operation, this light and the heater will shut off. Excessive high refrigerant pressure is usually

caused by low water flow through the heater. If this light goes out, clean the filtering system and check all

plumbing valves to insure proper water flow then try to restart the heater. See pages 8,18 and 19 for information

CAUTION

(To use indicator lights see

troubleshooting guide pages 26 & 27)

POOL MODE "Yellow": The yellow pool mode in-

dicator light lets you know that you have selected the

pool mode with the pool /spa select switch, (dual thermostat control only). This light will be off when the

control is in spa mode.

Page 8

START UP PROCEDURES

COMPRESSOR TIME DELAY

BE AWARE THERE IS A 5 TO 7 MINUTE TIME DELAY BEFORE THE COMPRESSOR WILL START

ONCE THE UNIT IS TURNED ON OR WHENEVER

IT RESTARTS. All models.

TURN T-STAT ALL THE WAY DOWN

Make sure the thermostat dial is turned all the way to

the “LEFT” so the unit will not start until you are ready.

Then turn the circuit breaker on.

CLEAN FILTERING SYSTEM

Next, make sure that the pool filter is as clean as possible. A dirty filter will hamper the efficiency of the

unit and cause the unit to cycle on and off resulting in

damaging effects. Filters may look clean but can be

clogged with oils or minerals. Replacement is suggested

every year and a half for cartridge type filters. See manufacturers directions for proper filter cleaning methods.

Next clean the lint trap basket inside the circulation

pump. Then clean the skimmer leaf trap basket of all

debris. A clogged lint trap or skimmer basket will

restrict the water flow to the unit. Make sure there is

adequate water in the pool so that the skimmer does not

draw air. Never place any chemicals of any type, especially chlorine, in the skimmer.

ADVISE YOUR POOL SERVICE CO.

If you have a regular pool service on a weekly basis

make sure your owners manual available for them to

inspect. You may request that one be sent to them, by

calling the factory service department at (941) 768-1555.

Be sure that they are aware of the chemical balance and

chemical introduction rules, in this manual. The conditions in this manual must be followed in accordance with

the warranty, if for any reason, the heater is improperly

installed and or operated, the manufacturers warranty

may be void.

If you are unfamiliar with your pool filtering system,

you should consult your local pool company. The diagram shown above are not of any specific brand but are

common in nature. The following diagram is of a typi-

WATER FLOW & EXISTING WATER PUMP

To filter the pool water each day, the water pump will

come on & off according to the existing timer device.

The heater will only heat if there is water running through

it.

Filter & Trap Locations

WATER PRESSURE SWITCH

If there is proper water flow through the unit

the water pressure switch will close allowing

the unit to run. When the circulation pump

timer stops the water flow, the water pressure

switch will shut the unit down. When the pump

restarts for the next day, the pressure switch

will close and allow the heater to run.

Water

Pressure

Switch

Location

Page 9

THERMOSTAT CONTROL & SETTINGS

COMPRESSOR

Once the fan is running, the compressor will start 5 to

7 minutes later, it's controlled by a time delay device.

The compressor pumps and compresses refrigerant gas. When refrigerant gas is compressed it intensifies the heat before it is

release to the pool water. This compressed

hot gas is pumped through the heat exchanger where it delivers heat to the pool

water passing through the same heat exchanger.

EVAPORATOR AIR COIL

The fan circulates the warmer outside air through the evaporator air

coil to collect any available heat. The

cooler Freon™ absorbs this heat

causing it to evaporate into a gas.

Therefore the compressor can compress the gas to maximize the gain

heat from the air. The fan discharges

cooler air when the compressor is running. Process is

reversed in Heat & Cool models while in cooling mode.

Warm WaterInCool Water

Out

Warm

Air

In

Cool Air Out

Compressor

Heat

Plumbing Bypass

Manifold

Freon™

Hot Gas

SYSTEM OVERVIEW

The heat pump system

uses 410-A refrigerant to

transfer the heat from the

outside air to the pool

water.

OPERATIONAL SEQUENCE

THERMOSTAT CONTROL & SETTINGS FOR

HEAT & COOL MODELS

For heating modes on these models,

make sure toggle is selected to heat and

follow the previous instructions above.

For cooling mode make sure toggle is

selected to cool. Turning down the thermostat counter clockwise will start the

unit running. When the pool water has

been cooled to the thermostat setting,

the unit will shut off. When the pool

water temperature rises one to two degrees, the thermostat will activate the unit. There are no temperature graduate numbers printed on the thermostat face. To obtain an

exact temperature, turn the t-stat all the way down and

then place a pool type thermometer in the pool water itself. Once the water has reached your target temperature

on the thermometer, turn the thermostat knob forwards

until the heater just shuts off. Therefore your thermostat

will be set at the thermometer reading.

Heat Cool

Turning up the thermostat will start the

unit running. When the pool water has

been heated to the thermostat setting, the

unit will shut off. When the pool water

temperature loses one to two degrees,

the thermostat will activate the unit.

There are no temperature graduate num-

bers printed on the thermostat face. To

obtain an exact temperature, turn the t-stat

all the way up and then place a pool type

thermometer in the pool water itself. Once

the water has reached your target temperature on the thermometer, turn the thermostat knob backwards until the heater just

shuts off. Make a mental note of knob indicator. Therefore your thermostat will be

set at the thermometer reading.

FAN-AIR CIRCULATION

Once the t-stat is activated the

fan will begin to turn. To absorb heat energy, the fan circulates warmer air through the

evaporator coil at about 4000

cubic feet per minute. The fan

runs independently from the

compressor. The compressor

will start within 5 to 7 minutes

HEAT EXCHANGER

The compressed hot refrigerant releases it's heat to the

pool water inside the heat exchanger. The exchanger is

a tube within a tube construction, water passing through

the inner tube, hot gas passing

through the outer tube. The refrigerant is transformed into a liquid state

as it exits the heat exchanger. There-

fore it is also referred to

as a condenser coil. (Heat & Cool Models,

process is reverse). The exchanger is encased inside a block of closed cell foam to

prevent heat loss and corrosion.

See the cross section.

Page 10

TIME CLOCK SETTING

Now that all the filters are clean and the pump is running with a full prime, you will need to set the pool

circulation pump timer. Set the filter pump time clock

for a long enough period of time to heat the pool or spa.

The heater will not operate unless there is water running through the heat exchanger supplied by the circulation pump. Therefore, your pool will only heat during the period set on the timer. When setting the timer,

be sure that you shut off the pool circulation pump circuit breaker. Then follow the timer manufacturers instructions to prevent electrical shock. Consult your

dealer first.

INITIAL HEAT UP TIME (HEATERS)

You should start by letting the circulation pump run 24

hours a day until the pool reaches the desired temperature. Once the pool is up to your desired temperature

you should reset the timer for a cycle of 6 to 18 hours

per day during the hottest part of the day. Heat up time

and operational time will vary with pool size, exposure

and weather conditions. Spas will require considerably

less time to reach temperature, usually in a matter of

hours if a cover is used.

INITIAL COOL DOWN TIME

(HEAT & COOL MODELS)

You should start by letting the circulation pump run 24

hours a day until the pool reaches the desired temperature. Once the pool is down to your desired temperature you should reset the timer for a cycle of 6 to 18

hours per day during the coldest part of the day. Cool

down time and operational time will vary with pool size,

exposure and weather conditions.

ADJUSTING THE TIMER

Timer styles vary, read the manufacturers instructions

before attempting to reset timer. Make sure the plastic

guard is in place. On this type of timer, note the On

and OFF trippers located on the clock face. If you

loosen the lock screw on the tripper you can move it to

a new time. Make sure the time of day is correct.

To run the 24 hours needed for the initial heat up, just

remove the "OFF" tripper. When the pool reaches temperature, replace the tripper and set timer to run the water

pump during the hottest part of the day.

OFF Tripper Peg

ON Tripper Peg

24 Hour Clock Face

Time of Day

Indicator

ON/OFF

Switch

COMMON MECHANICAL TIMER

Read your particular timer manufacturers instructions

to identify the one you have. Do not attempt to adjust

the timer unless you have read these instructions.

NORMAL RUNNING TIME

The heat pump system extracts the heat from the outside air and delivers it to your pool. Therefore it produces more BTU's (heat) the warmer it is outside. So

take advantage of the higher air temperatures during

the day by setting the timer for the warmest hours. Winter operation (during cold fronts) may require longer

run times up to 16 hours daily.

SET THERMOSTAT TO MAXIMUM

Turn the thermostat dial all the way to the right. You

will turn the thermostat back to a lower position later,

as described on the next page. The fan should now be

turning.

There is a compressor start time delay and generally it

will not start for about 5 to 7 minutes. Cooler air will

come from the fan when the compressor is running.

Become familiar with the compressor sound and remember the compressor time delay.

Scroll compressors may not start on the first try. Allow

Scroll type compressors several starts and time delay

cycles before the compressor starts. This condition is

most common to new compressors or when starting

Page 11

THERMOSTAT SETTING

If the pool temperature on the thermometer reads 80 degrees F, and

you turn the thermostat to the "left" until the heater shuts off, the

thermostat will now be set at 80 degrees F.

Thermometer

104˚F

Max.

There are no temperature reading numbers printed on the thermostat dial due to calibration changes from unit to

unit. The demand for exact temperatures should be regulated by using a high quality thermometer right in the pool

water. Normal temperatures for pools are 78 to 82 degrees F. Spa temperatures are 98 to a maximum of 104

degrees F.

You should place a high quality "tie on type" or a "floating type" thermometer directly in the pool or spa water, so you can determine what temperature that is suitable to you. Check the pool temperature occasionally during

the heat up time until it has reached the temperature you desire.

Then go to the heater and turn thermostat counter clockwise, to the left,

away from warmer, SLOWLY until the unit just shuts off. Therefore, the

thermostat will be set exactly at the current temperature shown on your

floating thermometer. Make a mark on the thermostat dial so you know the

approximate setting that you desire.

50˚F

Min.

+ or - 1.5˚F

Now the heater will come on each day when the circulation pump starts, then it will bring the pool up to that set

temperature. The pool will lose some heat overnight but will come back up to temperature with minimal delay. If

you have a pool and spa combination, you can set the spa thermostat the same way once you are in the spa heating

mode. When adjusting the thermostat, remember that it will take some time for the water temperature to reach a

higher setting. The cooler the outside air, the longer heat up time needed.

CAUTION

MAKE SURE YOU ADJUST THE THERMOSTAT BACK FROM THE HIGHEST POSITION SET DURING

THE START UP PROCEDURE OR THE POOL MAY GET TOO WARM. BE SURE TO RESET THE CIRCULATION PUMP TIMER FOR 6 TO 18 HOURS PER DAY OR AS NEEDED, ACCORDING TO THE SIZE OF

YOUR POOL AND WEATHER CONDITIONS. COLDER CLIMATES WILL REQUIRE MORE TIME.

LARGER POOLS WILL REQUIRE MORE TIME. EXPOSED POOLS WILL REQUIRE MORE TIME. WINTER TIME OPERATION WILL REQUIRE MORE OPERATIONAL TIME EACH DAY.

Page 12

Pool Shell

Pool Surface

Warm Pool

Water

UNDERSTANDING HEAT LOSS

It is important to understand how your pool loses heat. The greatest heat loss occurs at the water surface. You will

need to adjust the operational time to compensate for added heat loss during the colder months. See the diagram

on the next page. There are four types of heat loss to be concerned with:

Evaporation accounts for the greatest amount of heat loss. As the water changes from a liquid to a vapor it

requires heat taken from the pool. You are usually heating the pool when temperatures and humidity are low. The

temperature difference between the pool and outside air increase the evaporation rate. Windy conditions will

accelerate evaporation heat loss.

Convection is simply the loss of heat due to the cooler outside air moving across the waters surface. Heat moves

from hot to cold only, so the warmer pool heat transfers to the moving cooler air. Windy conditions will accelerates heat loss. Pools and spas located on or nearby open area such as the ocean, lakes, fields or golf courses will

experience increased wind speeds therefore heat loss will be greater for these conditions. Evaporation and Convection account for as much or more than 82% of the total heat loss.

Conduction is the transfer of heat from the warm pool through the pool or spa shell to the surrounding cooler

earth. Conduction only accounts for 5 % or less of the total heat loss. If you live in an area where the ground water

surrounds the pool shell and plumbing, this type of heat loss will be greater.

Reradiation is the transfer for heat from the warm pool to the cooler sky. Reradiation heat loss will be at it's

greatest on clear nights. Cloud cover will reduce this type of heat loss.

.

RERADIATION CONVECTION

WIND

EVAPORATION

Page 13

CONTROLLING HEAT LOSS

A good way to control heat loss is to slow the wind

speed through your pool area by placing plants such as

shrubs or bushes around the pool's perimeter. Plants

will break up the air flow and diffuse the wind speed.

If the pool area is to be fenced in, choose a wood shadow

box type design.

A solid type fence or wall does not act as a good wind

break. They tend to create a wind spoil (vortex) across

the water surface increasing air turbulence and heat loss.

Pools located in windy areas such as water front, golf

courses or open fields will experience greater heat loss.

COVERS SAVE TIME & MONEY

As discussed on the previous page, the greatest heat loss

is at the water surface. The very best way to reduce

heat loss (and operational cost), is to cover the pool or

spa.

Covering the pool or spa during the initial heat up time

will help the pool get to the desired temperature much

faster. If properly used, a cover can lower your total

operating costs as much as 50%. Covers reduce evaporation, thus you will save on pool chemicals and fill

water usage as well.

13

SPAS HEATING TIPS

It is strongly suggested that you use a cover during the

initial heat up time. This will save time as well as electrical costs.

When heating a spa make sure that there are no air

bubbles coming from the air blower or hydrotherapy

air inlets. The air bubbles will dissipate the heat into

the air and prolong the heating time.

Electric air blowers inject cooler outside air into the

spa and will lower the temperature. You can shorten the

heating time of your spa by shutting off any air injection devices until the spa is up to the desired temperature.

If you have any health problems, high blood pressure

etc., consult a doctor before using a hot water spa. You

should get out of the spa and cool off every fifteen minutes. Do not consume alcoholic beverages while using

the spa. To prevent drowning, do not use the cover while

in the spa.

Using a pool cover can be somewhat cumbersome but

they are worth the trouble in regards to the great cost

savings. Covers are sometimes referred to as blankets

or solar blankets.

TYPICAL POOL BLANKET & ROLLER

WARNING

NEVER SWIM WITH POOL COVER ON. Swimmers can tangle easily in the pool cover and subsequently may result in drowning. See manufacturer's

Safety Precautions before using.

Page 14

OWNERS MAINTENANCE & CARE

There are some considerations that should be taken concerning the environment where your heater is installed.

The heater is usually placed near the pool filtering system. There are certain things in this area you will need to be

aware of to insure long life and prevent unnecessary damage.

SPRINKLERS

Make sure there are absolutely no sprinkler heads near the heater that will in any way spray on or into the heater.

Sprinkler damage is not covered under the warranty agreement.

Make sure that they are a sufficient distance away so that normal winds

will not carry the mist to the heater. If your filtering system area has

plants that need water, use a trickle type irrigation sprinkler instead of

the broadcast type.

The heater is designed to handle the wettest weather conditions that are

typical of rain and humidity, etc. Sprinkler heads force high pressure

water into the unit from the side at an odd angle. Most sprinkler systems are connected to a well system. Most well water is high in minerals, sulphur and other aggressive contaminates. These contaminates

will leave a build up on the evaporator coils and electronics causing

corrosion and hamper the efficiency. If you are located within 15 miles

of the coast, salt may be in the well water also.

PLANTS

Plants in the installation area should be kept trimmed away to the proper clearances shown

here. Plants too close to the heater will restrict the air flow into the unit from the side as

well as air flow through the top. Plants also bring extra moisture and insects that may get

inside the unit. There should be enough clearance to easily service and adjust the heater.

CONDENSATION DRAINS

The unit will produce a condensation of water that will drain from the unit at a steady rate. This condensation is

from the humidity in the outside air. The more humidity, the more condensation the unit will produce. There are

several drain ports in the bottom of the unit, make sure they do not become clogged with debris. This condensation

will attract weeds and insects, make sure that the water drains properly and plants are kept trimmed. (Heat and

Cool Models) In the cooling mode this unit will produce no condensation.

The air handling compartment below the fan should be cleaned and vacuumed to remove debris that may clog the

condensation drains at the bottom of the heater. Accumulated debris will clog the condensation drains causing the

water to pool in the bottom of the heater. Accumulated condensation water will cause corrosion to the heaters

components.

14

CAUTION

Chemicals should NOT be stored near the heater. The fan may draw corrosive chemical vapor

through the unit causing damage. Do NOT store anything on top, underneath or around the heater.

You will need access to the disconnect breakers in the event of an emergency.

Page 15

15

WATER PIPING LEAK ?

When the unit operates, it will produce condensation that will drain from the bottom of the unit. Do not mistake

condensation with a water piping leak. There is a certain procedure to follow to check the unit for leaks: Shut the

heat pump and filtering system off. Allow all the condensation to drain from the unit for at least an hour or so.

Then start the circulation pump only, leave the heater off. If the unit is still leaking water steadily, you may have

a water piping leak. The unit should not condensate when the heater is off. Consult your dealer.

AIR FLOW

Do not install the unit in an area where the cooler discharge air may accumulate and be drawn back into the unit.

Provide ventilation through containment walls or fencing for the air intake if needed. Do not install this unit

indoors or in filtering system equipment rooms. Do not restrict the air flow in any way.

ROOF RUN OFF

To prevent large amounts of rain water from running through the unit you may need to install a gutter and down

spout when the roof has a sharp pitch. IMPORTANT: Do not allow roof run off water to rush through the

unit. Do not install the unit under roof valleys, where two roof sections meet. The two roof sections channel water

to the valley and will allow massive amounts of water to run through the unit at high velocity.

CLEANING

To clean the heater, you should take a sponge and mild soapy water and wipe the surfaces clean. Do not use a

pressurized garden hose to clean the heater. Never force water into the unit from any direction. You may use a

garden hose at low pressure with no nozzle attachment. Clean the evaporator coils at least twice a year. If you live

near the sea coast you will need to clean at least four times a year to remove salt and sand. Use a very soft brush

with soap and gently remove any build up. Clogged evaporator coils will reduce the efficiency of the unit and

cause corrosion. Use a fin comb to straighten any minor indentations in the evaporator coils

Slab

Evaporator

Coils

Do not allow roof

run-off to flow into

the unit.

Page 16

WATER FLOW

FILTER SYSTEM MAINTENANCE REQUIREMENTS

Air Bleed

Valve

PSI

Gauge

Locking Nut &

O-Ring

O-Ring

Element

Filter Tank

Typical

Cartridge

Filter

Inlet

Outlet

Pump Lid

"Suction"

Inlet

Electric

Motor

Lint Trap

Discharge Outlet

"Pressure"

Impeller

Housing

Typical Circulation Pump

16

Proper water flow is critical to the heaters performance

and longevity. The maintenance of your filtering system is directly related to the proper operation of the

heat pump. See pages 8 for other information regarding

filter cleaning and the start up procedures.

FILTER CLEANING & CARE

Your filter system should be cleaned at least twice a

month. See manufacturer's directions for proper filter

cleaning methods. Size and conditions may require you

to clean the filter more often. A filter is considered

"dirty", whenever it restricts the flow rate by 10% or

more.

CIRCULATION PUMP

The circulation pump must be kept in good working

order to provide a steady rate of flow to the heater and

filtering system as a whole. The circulation pump must

be producing a flow rate in accordance with the manufacturers specifications within 10%. The pump should

run with a "full prime" without excessive restriction on

the vacuum and pressure side of the filtering system.

You can use the pressure gauge on the filter tank to determine a restriction in the filter due to clogging. After

the filter has been replaced or when it is new, you should

record the actual operating pressure with a "clean filter". When the pressure increases more than 5 p.s.i.,

the filter should be cleaned. If the pressure does not

return to normal you must replace it. Make sure your

pressure gauge is kept in good working condition.

VACUUM & PRESSURE LEAKS

All vacuum and pressure leaks in the filtering system

must be eliminated immediately after occurring. Air

allowed into the filter system from the vacuum side of

the circulation pump will cause premature wear and

physical erosion to the heat exchanger and water piping inside the heater. Air turbulence will cause the water pressure switch to malfunction.

Pressure leaks on the filtering system will allow the system to lose vacuum and cause the water in the filter and

piping to back siphon or reverse flow through the system when the circulation pump is off. Reverse flow

may cause the water pressure switch to malfunction.

CHLORINATORS

See chlorinator placement and chemical use guidelines.

There are some after market filter element cleaning solutions that will help remove oil and minerals that may

clog the filter. Oil and minerals can not be removed

with normal cleaning and back-washing. Spas are particularly susceptible to oil build up in the filter. Do not

acid wash a filter until you have removed all oil and

grease with a solution designed to remove such. Acid

washing a filter with oil in it will cause that oil to become permanently embedded in the fibers. Cartridge

filter element replacement is suggested every 1 to 2

years. Sand filters should have the sand replaced every

3 to 5 years. D.E. type filter elements should be removed and soaked in a solution at least every two years.

Page 17

AUTOMATIC POOL VACUUMS

Automatic pool cleaners will decrease the water flow

by restricting the suction of the circulation pump. Most

automatic type pool cleaners operate from the suction

provided by the circulation pump.

Some automatic pool vacuums are plugged into the

skimmer suction port. The main floor drain is then restricted some, so that the auto vac has enough vacuum

to operate. It can then move freely and not become

stuck to the main drain port.

Typical

Automatic

Pool Cleaner

17

When manually vacuuming the pool or performing service to the filtering system, "shut the heater off !"

When the vacuum hose is plugged in, it may cause the

pump to loose prime due to the air in the hose. You

may also need to restrict the main drain suction port to

gain more vacuum to the vacuum hose and head. This

will lower the overall flow through the unit and cause it

to cycle on & off, possibly causing damage. Shut the

heater off whenever there is a chance of restricted water flow or loss of prime.

PROFESSIONAL SERVICE

As part of routine maintenance you should schedule a

licensed air conditioning contractor or the factory service department to check the refrigeration circuit and

components of the heat pump against factory specifications. An improper adjustment or diagnosis by others

may limit your warranty. You can call the factory service department for a list of factory authorized service

centers in your area. Have all the refrigeration components checked against the factory specifications. You

can request this information from the factory service

department.

Verify correct installation according to the owners and

installation manuals. Verify water flow through the heat

exchanger and filtering system. Check all chlorinator

placement and pool water balance. Test the supply voltage, amperage draw, wire size against factory specifications and local codes. Test the operating refrigerant

pressures and corresponding components to factory

specifications. Adjust refrigerant according to the sub

cooling reading and factory specification.

Clean and flush the evaporator coils to remove debris,

salt and mineral build up at least twice a year. Clean

more often if you live in a costal and or sandy environment. Clean them with a mild soap and a very soft

brush. Do not use a pressurized garden hose. The air

handling compartment below the fan must be cleaned

of debris regularly. Contact an air conditioning contractor for proper methods of cleaning the evaporator

coils. Remember to make sure the irrigation sprinkler

system does not spray on the unit!

The fan motor should be oiled when the unit is serviced

otherwise once per year or more if needed. Coastal installation should oil the fan motor 4 times per year or

more depending on exposure.

CAUTION

Often times, when these auto vacuums begin to wear,

they require more suction from the pump to operate.

Diverting all vacuum through the auto vac may help it

run better but will restrict the overall water flow through

the entire system and the heater.

If you have a low water flow situation where the heater

is not getting enough water through the condenser coil,

remove the pool vac and open all skimmer and main

floor drain vacuum valves to provide maximum flow.

The auto vac manufacturer has a special valve that plugs

into the skimmer before the auto vac hose. These special valves will properly regulate the water flow through

the auto vac without creating too much vacuum restriction on the skimmer suction port.

The hose connecting the auto vac to the skimmer should

be checked for the presence of suction leaks that allow

air into the system. (See damage caused by vacuum

leaks previously). As the auto vac hose gets older and

sun damaged, it may develop an air vacuum leak or

known as a "suction leak".

In all cases, you should do what ever necessary to gain

the proper water flow through the heat exchanger. Once

the pool vac is working, make sure you have the proper

water flow through the heater at all times. If the low

flow created by an auto vac is causing a problem with

the unit, it is not considered a warranty condition.

Page 18

PLUMBING CONNECTIONS

PLUMBING & WATER FLOW

INTERNAL AUTOMATIC BYPASS

See mandatory chlorinator placement

and install of the loop & check valve.

Water

Pump

Filter

Chlorinator or

Chemical Feeder

Heater

Chlorinator Loop & 2 lb. Chem.

Resistant Check Valve

WATER IN

WATER

OUT

1. PUMP

2. FILTER

3. HEATER

4. LOOP & CHECK

5. CHLORINATOR

6. RETURN TO POOL

Warning

No Chemicals In

Skimmer !!

IN

Special

Compression Fitting

Sacrificial Chemical Protec-

tion Piping

Marine Grade

Cupronickel

Heat Exchanger

Encased in

Closed Cell Foam

Free Flow

Flexible

Water Inlets

WARNING

Filtered Water “IN” on the LEFT front.

Heated Water "OUT" on the RIGHT front.

The plumbing inlets are "slip" p.v.c. pipe that will accept

a 2 inch p.v.c. glue fitting. The pipe is left plain so you

can adapt to your needs. Use p.v.c. cleaner to prime the

fitting and pipe. Use a quality medium body p.v.c. glue.

FOR PUMPS UP TO 2 H.P. OR 90 G.P.M. MAX.

SEE PAGE 19 FOR LARGER WATER PUMPS.

The heat pump in equipped with

a internal "Automatic Bypass"

valve. A variable rate spring

valve is used to regulate the water flow through the heat exchanger. Steady flow will be delivered over a wide range of flow

rates. This automatic valve can

handle a maximum flow rate of

90 gallons per minute.

The automatic valve will compensate for flow loss due to normal filter debris accumulation or

changes if flow due to valving

and other conditions.

See chlorinator

placement guidelines.

Automatic Bypass Valve

Variable Rate Self Adjusting

Page 19

8"

2 LB

CHEMICAL

RESISTANT

CHECK VALVE

Part# 888-018

LOOP ABOVE

TO

CHLORI-

NATOR

FROM

HEATER

The chemical resistant check valve and loop must be installed with all types of chlorinators to prevent chlorine

migration to the heater. The loop should extend at least 8

inches above the chlorinator top. The chemical resistant check

valve should be placed on the pipe leading "up" to the chlorinator. Therefore, the weight of the water above the check

valve will hold it closed even if the spring is weak or damaged. Mount it as low as possible. Be sure to keep the chlorinator, pump and filter lid o-rings lubricated with silicone

grease to insure a good seal. If it looses its seal, it will allow

the chlorine to migrate to the heater when the system shuts

off. The loss of vacuum allows reverse flow.

"Excessive Flow Valve Manifold"

Do not valve in a manner that will totally

isolate heater from water flow see page 25.

EXCESSIVE FLOW BYPASS MANIFOLD FOR LARGE

2 H.P. PUMPS OR OVER 90 G.P.M.

If the pool circulation pump is over 2 HP OR if the total

flow exceeds 90 GPM you will have to add the "excessive

flow valve" as shown here. Do not install a bypass valve

that will completely shut off flow to the heater, see shutdown procedures.

Some larger water pumps may be restricted if the pipe size is

not adequate therefore reducing its overall flow rate. When

determining if you need an excessive bypass valve, one has to

consider the hydraulic restriction of the filter, valving, amount

of 90˚ fittings and the distance of pipe to the pool in the existing filtering system. If you have a 2 HP water pump that does

not exceed 90 G.P.M. considering the above, you may not need

the excessive bypass. Excessive water flow can damage the

heat exchanger. SPECIAL NOTE: See chlorinator placement instructions at the bottom of this page.

HIGH RATE WATER PUMPS

Ball Valve

@ 45 Deg.

Bypass Pipe Size:

1.5" or 2" pipe @ 2 H.P.

2" pipe @ 3 +.H.P

2" p.v.c. "T"

2" p.v.c. "T"

All others must be set by flow meter.

See Commercial Plumbing Diagram

2 H.P Pumps

Close Bypass 50%

3 H.P. Pumps

Close Bypass 25%

BE SURE THE BYPASS VALVE IS

POSITIONED TO ALLOW REMOVAL

OF THE FRONT ACCESS PANEL!

Position the valve so that the access panel can be

easily removed, always check before final gluing. Angle the valve out 45˚ to provide adequate

clearance. You may use a 2-way valve or other

type if desired. "Do not" use a brass gate valve

or a 3-way valve for bypass !

Exercise care when installing chemical feeders so as not to allow

back siphoning of chemicals into the heater, filters or pump.

CAUTION

CAUTION

Place plumbing so

access panel can

be opened

Page 20

WATER BALANCE MAINTENANCE

The chemical balance of your pool/spa water and the methods used in adding pool chemicals will directly effect

the life of your heater. Like no other precaution you could take, it is very important that these guidelines are

followed in order to prevent damage to the heat exchanger/water coil and possibly the entire system.

Improperly maintained water balance and incorrect introduction of pool chemicals will cause extreme corrosion to

the heat exchanger. If this condition goes unnoticed, it will eventually damage the compressor and evaporator coil.

The heat exchanger in your unit is made of the highest quality cupronickel metal alloy. This makes the heat

exchanger as chemical resistant as possible. The heat exchanger will withstand what is considered normal pool

water balance. Unfortunately, chemical damage is usually diagnosed after the unit has failed because the corrosive

pool/spa water attacks the metal from the inside out.

The following are water balance specifications that are considered standard pool and spa water testing values and

quality. These water balance values are the industry standard in which professional pool contractors follow. Make

sure your pool water is tested and balanced on a weekly basis or more if required. Spas will need extra attention.

20

SACRIFICIAL WATER FITTINGS

The sacrificial fittings alert the user before "it's too late"

STANDARD POOL WATER

BALANCE REQUIREMENTS

Ph................................7.4 to 7.8

Chlorine/Bromine.......1 to 5 ppm

Total Alkalinity...........90 to 120 ppm

Calcium Hardness......250 to 400 ppm

ADVANCED HEAT EXCHANGER DESIGN

This diagram is a cross section of the heat exchanger. The seamless tube within another tube design transfers heat very efficiently.

The inner water tube is made of thicker resilient cupronickel metal

alloy to help resist corrosive pool water. The outer heavy gauge

Freon™ tube is dipped in a special weather proofing material.

Then to insulate from heat loss and help prevent exterior corro-

sion the heat exchanger is encased in a block of special closed cell

foam.

Water Passage

Cupronickel

Metal Alloy

Closed Cell Insulation Foam

Hot

Refrigerant

Passage

Heat Exchanger Cross Section

WARNING

See your local pool dealer for help in properly balancing the water chemistry.

Chemical damage to the unit and / or heat exchanger in any way is not covered under the warranty agreement.

Note: The internal 90˚ elbows show in this diagram are de-

signed as a sacrificial fittings to protect the very expensive cupronickel alloy heat exchanger.

These fittings may develop a leak if the pool water balance gets

very acetic or very over chlorinated. If there were no sacrificial

fittings, chemical damage could cause a "breach" from the water

passage to the refrigerant passage. If a" breach" occurs in the

heat exchanger, chlorinated water would be pumped into the refrigerant system thus making the heater non-repairable! The sacrificial fittings act as an early warning indicator to the user that

the pool water balance is not correct, chemicals are being fed improperly (through the skimmer) or the flow rate has been exceeded.

Alloy Heat

Exchanger

Sacrificial

Water Fittings

Page 21

21

These chemical outlines should not be considered as a

“how to” balance your pool/spa water, but just a reference on how chemical balance effects the heater and gives

suggested test values. You should always consult a pool

professional and follow all chemical manufacturers directions, unless they conflict with this manual.

CHLORINE

Chlorine levels should remain within a range from 1

p.p.m. to a maximum of 5 p.p.m. (p.p.m.=parts per million). Excessive chlorine saturation of the pool water will

cause corrosive damage to the heat exchanger.

Chlorines Effect on pH

Review the diagram on the previous page. Some tablets,

granular and gas forms of chlorine have an acetic nature

to start with and may lower the pH of the water when

introduced (see diagram on previous page). Be sure that

the pH remains between 7.4 and 7.8 after adding chlorine. If these types of chlorine are introduced into the

system in the wrong place, you can run full strength chlorine through the heat exchanger before it has a chance to

mix with the rest of the pool water. See the next section

on chemical usage and chlorinator placement.

Shock Treatments

A shock treatment is a large dose of chlorine added to the

pool water all at once to reduce the amount of combined

(contaminated) chlorine in the water or to kill algae. Make

sure you do not over shock treat, calculate the exact

amount of chlorine needed. When “shock treating” the

pool make sure that the pH levels remain at the prescribed

levels after the chlorine is introduced. Do not add any

more chlorine to the water until the chlorine levels have

dropped to normal. Prolonged high chlorine levels will

cause damage to the heat exchanger. The combination of

high chlorine and low pH (acetic) will deteriorate the heat

exchanger at an accelerated rate. Do not add shock treatment or chlorine tablets in the skimmer.

Read and follow the chemical manufacturers directions

when adding chemicals unless they conflict with this booklet. Contact your dealer or the factory service department

for advice.

The pH level in your pool should be maintained within

the range of 7.4 to 7.8. A pH test will tell you how

acetic or how alkaline the pool water is. For example,

acetic like orange juice or alkaline like milk. A 7.6 pH

is considered the middle of the road. Lower than 7.6

means that the water has an acetic tendency. Higher

than 7.6 indicates that the water has alkaline tendency.

pH Below 7.4 Will...

A lower (acetic) pH reading will cause corrosion to the

heat exchanger. Prolonged exposure to low pH and / or

high chlorine will damage the heat exchanger. The

lower the pH the more aggressive the chlorine is and

the quicker the damage takes place. The metal is oxidized and deteriorates.

Piping Leaks & Stains

An early indicator of low pH and / or high chlorine

would be if a leak were discovered in the piping leading to the heat exchanger. The copper in the piping will

dissolve into a solution and mix with the pool water.

This dissolved metal will show back up as a blue-green

colored stain on the masonry materials in your pool.

The commonly used, white plaster (Marcite) finishes

will stain from the metal in the water quite easily.

Although there will have already been some chemical

damage. You can make corrections immediately to protect the very expensive cupronickel heat exchanger.

Follow the chemical guidelines in order to prevent such

damage from occurring. Do not wait until you see the

metal stains or piping leaks.

pH Above 7.8 Will...

If your pool water is extremely high in pH (alkaline),

you may get a mineral build up in the heat exchanger

and piping. Restriction from build up will restrict the

water flow to the heater. This condition is very rare

except where mineral content is high in the tap water

used for the pool.

Page 22

22

TOTAL ALKALINITY

Total Alkalinity is a test given to determine the over-

all mineral content of the water. Total alkalinity levels should be within the range from 90 p.p.m. to 120

p.p.m. The total alkalinity is described as a buffer

against acetic conditions and acts as a stabilizer for the

pH. It keeps the pH from fluctuating up and down.

A low alkalinity will allow the pH to fluctuate, usually

to the acetic side. A high alkalinity may cloud the water. The pH of your water will change when it is used

after rain, from dirt and debris and many other natural

conditions. The proper total alkalinity will prevent

those changes from being drastic. Test for total alkalinity on a weekly basis.

CALCIUM HARDNESS

Calcium Hardness levels should remain within the

range from 250 p.p.m. to 400 p.p.m. Calcium hardness

is a test that determines the saturation levels of calcium

and magnesium salts in the water. This tells you in layman terms how “hard” the water is. Please refer to your

pool builders instructions concerning calcium hardness

and how it effects your particular pool surfacing material.

POOL CHEMICAL & CHLORINATOR USE

When you are adding pool chemicals as part of your regular maintenance there are several rules of thumb to

follow. Where you add the chemicals are just as important as how much you add. This section will discuss the

“do’s and don’ts" of where you add chemicals or where chlorinators are placed.

VACUUM LEAKS

Suction leaks that allow air into the system when the

pump is running will cause damage to the heat exchanger. Suction leaks are what cause the system to

back siphon or reverse flow. Make sure that all the oring seals in the pump lid, filter and chlorinator are in

good condition and are lubricated with silicone grease.

If your filter repeatedly has excessive air inside it when

you open, air the bleed valve, you may have a vacuum

leak. Vacuum leaks that allow an accumulation of air in

the filter and will cause the system to lose prime when

the pump is off and allow reverse flow. Reverse flow

may allow chlorine solution to migrate to the heat exchanger.

Vacuum leaks will cause premature wear to the heat exchanger. The air allowed into the system causes turbulence in the heat exchanger. The result is physical erosion to the metal alloy water channel.

Note: Chlorine solution is heavier than water and

will migrate through the plumbing even if there is

no vacuum leak.

PROTECT HEAT EXCHANGER

You want to prevent any chemicals from running

through the piping and heat exchanger of the unit. Chlorine solution will damage the heat exchanger. Some

chlorinating devices inject chlorine solution through the

suction side of the filtering system, thus the chlorine

passes through the heat exchanger at full strength before it has a chance to mix and dilute with the rest of the

pool water. Also note: The overall chemical balance of

the pool water will directly effect the life of the heat

exchanger.

CHLORINE MIGRATION

Some chlorinating devices will back siphon when the

system is shut off, therefore allowing the chlorine solution to migrate through the heat exchanger causing damage. You have to make sure your filtering system does

not have a vacuum leak that would allow the system to

lose prime. When this happens, water will move backwards through the chlorinator thus moving the chlorine

solution into the heat exchanger. Note: Chlorine solu-

tion is heavier than water and will migrate through the

plumbing even if there is no vacuum leak.

Page 23

CHLORINATOR PLACEMENT

1. All chlorinators should have a chemical resistant

check valve and a loop plumbed at least 8 inches above

the chlorinator, between it and the heater, as far down

line from the heater as possible.

2. Never plumb a chlorinator into the suction side of

the circulation pump. All automatic chemical feeders

should be as far down line of the heaters water flow as

possible.

3. Off line type chlorinators should be tapped into the

plumbing only as shown on the diagram. See pool/spa

combinations requiring special placement. See plumbing diagram.

4. Never install a chlorinator at a higher elevation than

the lowest heater piping even if a loop check valve is

used. Doing so may allow chlorine to migrate to the

heat exchanger, causing damage.

5. Do not allow floating chlorinators to be drawn up to

the skimmer inlet.

6. Keep the chlorinator lid o-ring lubricated with silicone grease. Replace when needed.

Do not place any chemicals in the skimmer throat.

Chlorine tablets placed in the skimmer will allow a

concentrated solution of chlorine to pass through the

heat exchanger causing damage.

7. Do not place any chemicals in the pump lint trap cavity or filter. Make sure the lint trap basket is placed

properly to prevent debris from clogging the heat exchanger.

8. Do not over load chlorinator feeder cavity. Excessive amounts of chlorine tablets will increase the chance

of migration of acetic, concentrated chlorine to migrate

to the heat exchanger causing damage. 25% of maximum is suggested.

9. When adding gas chlorine make sure that the pH does

not drop below 7.4. Make sure that the total alkalinity

does not drop below 90 p.p.m. Gas chlorine is very acetic.

10. Do not isolate the heater from the water flow unless

you have installed a drain plug to drain all the water

from the heat exchanger and then blow out with pressurized air. Stagnant water will corrode the heat exchanger and piping.

See plumbing & water flow and high rate water pumps for more information.

2lb Chemical Resistant

Check Valve

Chemical Loop

8" Above

Chlorinator

Off Line Type

Chlorinator

In Line Type

Chlorinator

No chemicals or chlorine

tablets in the skimmer !!!

Absolutely no chemicals in the skimmer !

CAUTION

ADDING CHEMICALS

Page 24

COMMERCIAL FEEDERS

We strongly suggest that all chemical feeders be placed "down line" of the heater. In a "closely monitored"

commercial pool situation where a vacuum type filter system is used in conjunction with a surge tank, there are

some exceptions to chemical injection. Some liquid chlorine (sodium hypochlorite) feeders and liquid muriatic

acid feeders will inject their solutions into the surge tank on the suction side of the unit. You may inject diluted

liquid chlorine and muriatic acid as long as each are diluted with 75 % water in the supply tank. The feeders must

be adjusted to a slow enough rate to prevent the water in the surge tank from dropping below 7.6 pH and or

chlorine levels above 5 p.p.m. You can test the surge tank water while the feeders and circulation pump is running

just as you would the pool water. Then adjust the solution or rate of feed accordingly. The circulation pump

usually moves the water through the surge tank rapidly enough to keep chemical concentrations down. Never

place chlorine tablets in the surge tank.

Also note: Electric type feeders must be electrically relayed to the circulation pump, so the feeders will shut

off when the pump does.

CHEMICAL APPLICATION FOR SPAS

Spas require some special attention due to their small water volume and high heat compared to a normal swimming pool. A spas water balance fluctuates more rapidly than a pool. The following are suggestions that we feel

will prolong the life of the heat exchanger used for a spa heater.

1. Test the water frequently to prevent drastic fluctuations in pH and sanitizer levels especially after usage. Keep

total alkalinity at 100 p.p.m. to 120 p.p.m.

2. Spas react quickly to chemicals when added. Use small amounts and retest the water until you reach the desired

chemical values.

3. Some chlorine tablets are very acetic and will lower the pH of the spa water as the solution is fed. Make sure the

spa water does not drop below 7.4 pH, see page 20 and 21 for more information.

4. Bromine has a more neutral pH value and works well in spa water if pH is maintained at 7.8-8.0. It is a form of

chlorine widely used for spas. Do not install a brominator on the suction side of the filtering system.

5. Using muriatic acid right from the bottle at the same strength as packaged may drastically lower the pH

uncontrollably. There are some dry powdered forms of acid that work better for spas and are somewhat milder and

are easier to handle.

6. All the same rules of chemical application and chlorinator placement that apply in the previous chemical section

also apply to spas. Always consult a professional pool builder or service and follow the chemical manufacturers

directions.

WARNING

Working with muriatic acid can be dangerous. When cleaning elements always

wear rubber gloves and eye protection. Add acid to water, do not add water to

acid. Splashing or spilling acid can cause severe personal injury and/or property

damage.

Never allow a tablet type chlorinator to inject solution into the surge tank, under any circumstances.

CAUTION

Page 25

SHUT DOWN & FREEZE PROTECTION PROCEDURES

When shutting the unit down for the end of the swimming season you must consider some items to protect the unit

from inclement weather. It is best in most situations to shut the unit off by turning the thermostat all the way

down, to the "left". Leave power ,(circuit breaker), to the unit “on” unless the pool or spa water temperature

drops below 50 degrees F. If you shut off the main power supply due to freezing conditions, be sure to preheat

the compressor for 8 hours before attempting to start the heater.

SHORT TERM FREEZE PROTECTION PROCEDURES

When the outside air temperature is forecast to drop below 32 degrees F for a short time:

You should set the circulation pump timer to run 24 hours per day in order to circulate water through the unit and

filtration system. Standing water inside the unit will freeze and damage the units heat exchanger and refrigerant

system.

Shut the heat pump off and do not try to heat the pool during freezing temperatures. If the unit is left running it

may ice up and the compressor will stop running. The defrost control inside the unit will shut the compressor off

but allow the fan to run. The fan will circulate air through the unit to help defrost the evaporator air coil. If you

know that the temperatures are going to be below 36 degrees F, you should eliminate the possibility of icing and

just shut the unit off. Do not use the circuit breaker as the “on”/“off” switch, but keep the water pump running.

LONG TERM FREEZE PROTECTION / DRAIN VALVE INSTALLATION

If you live in a climate that has a seasonal swim season due to winter, you should follow these

long term freezing precautions.

If you live in an area that experiences freezing temperatures, the heat exchanger/water coil and bypass plumbing

must have all water removed to prevent damage to the heat

pump system. This procedure should be done prior to the

first freeze along with your other pool winterizing routine.

When you drain the filter system and piping you should include the heat pump as well.

There should be two spigot type drains plumbed into the

heaters water in and water out piping. Place these valves as

close to the heater and at the lowest point possible so as

much water will drain as possible. Install two shut off valves

on the water in and out lines as shown here. The rest of the

water should be blown out with pressurized air to insure all

water is removed. A antifreeze designed for pool equipment

may be used, see a local pool professional.

You may shut the circuit breaker off for the season as

long as you remember to preheat the compressor next

season before start up see start up procedures.

Spigot Type

Drain Valves

Shut the water pump off. Close both shut off

valves. Open both drains and allow water to

exit. Use pressurized air on the water in spigot

only, to force the rest of the water out the other

spigot.

Do not add isolation valves unless you

intend to clear the heat exchanger of water

with pressurized air. Stagnate water left in

the heat exchanger can cause corrosion.

IN

OUT

Shut Off

Valves

CAUTION

CAUTION

Page 26

POSSIBLE CAUSECONDITION

POSSIBLE REMEDY

All control lights off.

Unit will not start.

Control Ready light ON.

Water Press. OK light OFF.

T-Stat On light OFF.

Low & High Press. lights OFF.

Unit will not start.

Low water flow through heater. Dirty or worn

filters or clogged lint traps. Clogged filter pump

impeller. Improper plumbing valve settings.

Suction leak allowing air into the water flow.

Internal water pressure switch failure.

No power supply to heater. Tripped breaker or

blown fuse. Control failure.

Reset breaker. Replace fuse. Call dealer for

advise. Call factory for advise.

Clean entire filtering system and or replace

filter element. Inspect & clean pump impeller. Adjust plumbing valves. Repair suction air leaks, grease pump lid o-ring. Replace filter. Replace water pressure switch.

Control Ready light ON.

Water Press. OK light ON.

T-Stat On light OFF.

Low & High Press. lights OFF.

Unit will not start.

Thermostat is not set higher than the pool/spa

water temperature. The water temperature has

reached the maximum setting. The thermostat

is malfunctioning. (Dual thermostat), the pool

spa select switch is not in the correct mode.

Turn the thermostat up to the "right" more.

Use a high quality thermometer to test the

water temperature. Maximum water temperature is 104˚F + or - 3˚F. Call your dealer

for advise. Call the factory for advise.

Control Ready light ON.

Unit is cycling on & off.

Low or restricted water flow through heater.

Dirty or worn filters or clogged lint traps.

Clogged filter pump impeller. Improper plumbing valve settings. Suction leak allowing air

into the water flow. Low water flow when

switched to spa mode. Unit is plumbed backwards. Heat exchanger clogged with debris.

Internal bypass valve damaged or clogged with

debris.

Clean entire filtering system and or replace

filter element. Inspect & clean pump impeller. Adjust all plumbing valves. Repair

suction air leaks, grease pump lid o-ring.

Replace filter. Wrong filter pump pipe size.

Automatic pool vacuum causing restriction.

Call your dealer for advise. Call the factory for advise.

Control Ready light ON.

Water Press. OK light ON.

T-Stat On light ON.

Low Press. light OFF.

High Press. light OFF.

Unit will not start.

OR

Unit is forming ice or frost on the

outer air coil, usually at the bottom.

Outside air temperature below operating range

of 40˚F., unit is in "defrost" mode. Discharge

air flow is restricted. Discharge air is accumulating and being drawn back through the outer

air coil. The fan is obstructed, low air flow.

Large amounts of roof run off water restricting

fan blade rotation. Sprinklers spraying on the

outer air coil during cooler temperatures. Outer

air coil clogged with debris. Plants too close to

heater, blocking air flow. Low refrigerant pressure caused by a Freon™ leak. Possible malfunctioning of the internal low refrigerant pressure switch.

Do not try to operate the heater when the

outside air temperature drops below 36˚F

and 45˚F with very high humidity or high

wind speed. Make sure heater is installed

with the required placement clearances for

air flow and roof clearance. Do not install

indoors. Make sure that your sprinklers do

not spray on the heater in any way what so

ever. If ice forms on the outer coil, shut the

heater off and allow ice to thaw. You may

use water at low pressure to thaw ice build

up on the outer coil, shut the heater off when

doing so. Call the factory for advice.

Control Ready light ON.

Water Press. OK light ON.

T-Stat On light ON.

Low Press. light ON.

High Press. light OFF.

Unit will not start.

Low or restricted water flow through heater.

Dirty or worn filters or clogged lint traps.

Clogged filter pump impeller. Improper plumbing valve settings. Suction leak allowing air

into the water flow. Low water flow when

switched to spa mode. Unit is plumbed backwards. Heat exchanger clogged with debris.

Internal bypass valve damaged or clogged with

debris. Water temperature exceeding 104˚F

maximum. Refrigerant system malfunction.

Clean entire filtering system and or replace

filter element. Inspect & clean pump impeller. Adjust all plumbing valves. Repair

suction air leaks, grease pump lid o-ring.

Replace filter. Wrong filter pump pipe size.

Automatic pool vacuum causing restriction.

Thermostat not shutting unit off at 104˚F.

Call your dealer for advise. Call the factory for advise.

Risk of electrical shock or electrocution.

Improper installation will create an electrical hazard which could result in death or serious injury to pool users,

installers, or others due to electrical shock, and may also cause damage to property.

Do NOT attempt any internal adjustments inside the heater.

1. Keep your hands and hair clear of the fan blades to avoid injury.

2. If you are not familiar with your pool filtering system and heater:

a. Do not attempt to adjust or service without consulting your dealer, professional pool or air conditioning

contractor.

b. Read the entire Owner and Installation Manual before attempting to use, service

or adjust the heater or pool filtering system.

OWNER TROUBLE SHOOTING GUIDE

WARNING

Page 27

Control Ready light ON.

Water Press. OK light ON

T-Stat On light ON

Fan is not turning.

Unit will not start.

Low water flow through heater. Dirty or worn

filters or clogged lint traps. Clogged filter pump

impeller. Improper plumbing valve settings.

Wait for the 90 second compressor time delay.

Clean entire filtering system and or replace filter element. Inspect & clean pump impeller.

Adjust plumbing valves. Call factory or dealer.

Compressor has not started yet. Low water flow

through heater. Dirty or worn filters or clogged

lint traps. Clogged filter pump impeller. Improper plumbing valve settings.

All control lights ON

Fan is turning, no cool air discharging out the top of heater.

Unit is not heating.

Clean entire filtering system and or replace filter element. Inspect & clean pump impeller.

Adjust plumbing valves. Call the factory for

advice.

Spa will not heat to maximum

temperature of 104˚F + or - 3˚.

Thermostat is turned all the way

up.

OR

Spa is heating very slowly.

Low or restricted water flow through heater.

Dirty or worn filters or clogged lint traps.

Clogged filter pump impeller. Improper plumbing valve settings. Suction leak allowing air

into the water flow. Low water flow when

switched to spa mode or the control is not in

spa mode. Unit is plumbed backwards. Heat

exchanger clogged with debris. Internal bypass

valve damaged or clogged with debris. Your spa

thermometer is not reading the correct temperature. Air blower is running. Venturi air inlets

are open. It is very cold outside. Spa pump is

not running.

Clean entire filtering system and or replace filter element. Inspect & clean pump impeller.

Adjust all plumbing valves. Repair suction air

leaks, grease pump lid o-ring. Shut off air

blower and or Venturi inlets that allow air turbulence in the spa. Use a cover while heating

the spa. Outside air temp. too cold. Set spa

pump timer for longer time. Call your dealer

for advise. Call the factory for advice.

Pool is heating very slowly.