®

WHISPERFLOXF

®

MAX-E-PROXF

COMMERCIAL VARIABLE SPEED PUMP

VS AND

VS

INSTALLATION AND

USER’S GUIDE

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

i

F

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT NOTICE

This guide provides installation and operation instructions for this pump.

Consult Pentair with any questions regarding this equipment.

Attention Installer: This guide contains important information about the

installation, operation and safe use of this product. This information should

be given to the owner and/or operator of this equipment after installation

or left on or near the pump.

Attention User: This manual contains important information that will help

you in operating and maintaining this product. Please retain it for future

reference.

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This is the safety alert symbol. When you see this

symbol on your system or in this manual, look for

one of the following signal words and be alert to

the potential for personal injury.

Warns about hazards that can cause death,

serious personal injury, or major property damage

if ignored.

Warns about hazards that may cause death,

serious personal injury, or major property damage

if ignored.

Warns about hazards that may or can cause minor

personal injury or property damage

if ignored.

NOTE Indicates special instructions not related to

hazards.

Carefully read and follow all safety instructions in this manual and on

equipment. Keep safety labels in good condition; replace if missing

or damaged.

When installing and using this electrical equipment, basic safety

precautions should always be followed, include the following:

Do not permit children to use this product.

RISK OF ELECTRICAL SHOCK. Connect only to

a branch circuit protected by a ground-fault circuitinterrupter (GFCI). Contact a qualified electrician if you cannot verify that

the circuit is protected by a GFCI.

This unit must be connected only to a supply circuit

that is protected by a ground-fault circuit-interrupter

(GFCI). Such a GFCI should be provided by the installer and should

be tested on a routine basis. To test the GFCI, push the test button.

The GFCI should interrupt power. Push the reset button. Power should

be restored. If the GFCI fails to operate in this manner, the GFCI is

defective. If the GFCI interrupts power to the pump without the test button

being pushed, a ground current is flowing, indicating the possibility of an

electric shock. Do not use this pump. Disconnect the pump and have the

problem corrected by a qualified service representative before using.

This pump is for use with permanent swimming

pools and may also be used with hot tubs and spas

if so marked. Do not use with storable pools. A permanently-installed pool

is constructed in or on the ground or in a building such that it cannot be

readily disassembled for storage. A storable pool is constructed so that

it is capable of being readily disassembled for storage and reassembled

to its original integrity.

General Warnings

• Never open the inside of the drive motor enclosure. There is a

capacitor bank that holds a 230 VAC charge even when there is no

power to the unit.

• The pump is not submersible.

• The pump is capable of high flow rates; use caution when installing

and programming to limit pumps performance potential with old or

questionable equipment.

• Code requirements for electrical connection differ from country to

country, state to state, as well as local municipalities. Install equipment

in accordance with the National Electrical Code and all applicable

local codes and ordinances.

• Before servicing the pump; switch OFF power to the pump by

disconnecting the main circuit to the pump.

• This appliance is not intended for use by persons (including children) of

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning the use of the appliance by a person responsible for their

safety.

FAILURE TO FOLLOW ALL INSTRUCTIONS AND

WARNINGS CAN RESULT IN SERIOUS BODILY

INJURY OR DEATH. THIS PUMP SHOULD BE INSTALLED AND

SERVICED ONLY BY A QUALIFIED POOL SERVICE PROFESSIONAL.

INSTALLERS, POOL OPERATORS AND OWNERS MUST READ

THESE WARNINGS AND ALL INSTRUCTIONS IN THE OWNER’S

MANUAL BEFORE USING THIS PUMP. THESE WARNINGS AND

THE OWNER’S MANUAL MUST BE LEFT WITH THE POOL OWNER.

SUCTION ENTRAPMENT HAZARD: STAY OFF

THE MAIN DRAIN AND AWAY FROM ALL SUCTION

OUTLETS!

THIS PUMP PRODUCES HIGH LEVELS OF SUCTION AND CREATES

A STRONG VACUUM AT THE MAIN DRAIN AT THE BOTTOM OF THE

BODY OF WATER. THIS SUCTION IS SO STRONG THAT IT CAN TRAP

ADULTS OR CHILDREN UNDER WATER IF THEY COME IN CLOSE

PROXIMITY TO A DRAIN OR A LOOSE OR BROKEN DRAIN COVER

OR GRATE.

THE USE OF UNAPPROVED COVERS OR ALLOWING USE OF

THE POOL OR SPA WHEN COVERS ARE MISSING, CRACKED OR

BROKEN CAN RESULT IN BODY OR LIMB ENTRAPMENT, HAIR

ENTANGLEMENT, BODY ENTRAPMENT, EVISCERATION AND/OR

DEATH.

The suction at a drain or outlet can cause:

Limb Entrapment: When a limb is sucked or inserted into an opening

resulting in a mechanical bind or swelling. This hazard is present when

a drain cover is missing, broken, loose, cracked or not properly secured.

Hair Entanglement: When the hair tangles or knots in the drain cover,

trapping the swimmer underwater. This hazard is present when the flow

rating of the cover is too small for the pump or pumps.

Body Entrapment: When a portion of the body is held against the drain

cover trapping the swimmer underwater. This hazard is present when the

drain cover is missing, broken or the cover flow rating is not high enough

for the pump or pumps.

Evisceration/Disembowelment: When a person sits on an open pool

(particularly a child wading pool) or spa outlet and suction is applied directly

to the intestines, causing severe intestinal damage. This hazard is present

when the drain cover is missing, loose, cracked, or not properly secured.

WHISPERFLOXF® VS and MAX-E-PROXF® VS Commercial Variable Speed Pump Installation and User’s Guide

IMPORTANT SAFETY INSTRUCTIONS

ii

Mechanical Entrapment: When jewelry, swimsuit, hair decorations, finger,

toe or knuckle is caught in an opening of an outlet or drain cover. This

hazard is present when the drain cover is missing, broken, loose, cracked,

or not properly secured.

NOTE: ALL SUCTION PLUMBING MUST BE INSTALLED IN

ACCORDANCE WITH THE LATEST NATIONAL AND LOCAL CODES,

STANDARDS AND GUIDELINES.

TO MINIMIZE THE RISK OF INJURY DUE TO

SUCTION ENTRAPMENT HAZARD:

• A properly installed and secured ANSI/ASME A112.19.8 approved

anti-entrapment suction cover must be used for each drain.

• Each suction cover must be installed at least three (3’) feet apart, as

measured from the nearest point to nearest point.

• Regularly inspect all covers for cracks, damage and advanced

weathering.

• If a cover becomes loose, cracked, damaged, broken or is missing,

replace with an appropriate certified cover.

• Replace drain covers as necessary. Drain covers deteriorate over

time due to exposure to sunlight and weather.

• Avoid getting hair, limbs or body in close proximity to any suction

cover, pool drain or outlet.

• Disable suction outlets or reconfigure into return inlets.

A clearly labeled emergency shut-off switch for the

pump must be in an easily accessible, obvious place.

Make sure users know where it is and how to use it in case of emergency.

The Virginia Graeme Baker (VGB) Pool and Spa Safety Act creates

new requirements for owners and operators of commercial swimming

pools and spas.

Commercial pools or spas constructed on or after December 19, 2008,

shall utilize:

(A) A multiple main drain system without isolation capability with suction

outlet covers that meet ASME/ANSI A112.19.8a Suction Fittings for

Use in Swimming Pools, Wading Pools, Spas, and Hot Tubs and either:

(i) A safety vacuum release system (SVRS) meeting ASME/ANSI

A112.19.17 Manufactured Safety Vacuum Release systems (SVRS)

for Residential and Commercial Swimming Pool, Spa, Hot Tub,

and Wading Pool Suction Systems and/or ASTM F2387 Standard

Specification for Manufactured Safety Vacuum Release Systems

(SVRS) for Swimming pools, Spas and Hot Tubs or

(ii) A properly designed and tested suction-limiting vent system or

(iii) An automatic pump shut-off system.

Commercial pools and spas constructed prior to December 19, 2008,

with a single submerged suction outlet shall use a suction outlet cover

that meets ASME/ANSI A112.19.8a and either:

(A) A SVRS meeting ASME/ANSI A112.19.17 and/or ASTM F2387, or

(B) A properly designed and tested suction-limiting vent system, or

(C) An automatic pump shut-off system, or

(D) Disabled submerged outlets, or

(E) Suction outlets shall be reconfigured into return inlets.

For Installation of Electrical Controls at Equipment Pad (ON/OFF

Switches, Timers and Automation Load Center)

Install all electrical controls at equipment pad, such as

on/off switches, timers, and control systems, etc. to

allow the operation (startup, shut-down, or servicing)

of any pump or filter so the user does not place any

portion of his/her body over or near the pump strainer

lid, filter lid or valve closures. This installation should

allow the user enough space to stand clear of the filter

and pump during system start-up, shut down or servicing of the system filter.

WHISPERFLOXF® VS and MAX-E-PROXF® VS Commercial Variable Speed Pump Installation and User’s Guide

HAZARDOUS PRESSURE: STAND CLEAR OF

PUMP AND FILTER DURING START UP

Circulation systems operate under high pressure.

When any part of the circulating system (i.e.

locking ring, pump, filter, valves, etc.) is serviced,

air can enter the system and become pressurized.

Pressurized air can cause the pump housing cover, filter lid, and valves

to violently separate which can result in severe personal injury or death.

Filter tank lid and strainer cover must be properly secured to prevent

violent separation. Stand clear of all circulation system equipment when

turning on or starting up pump.

Before servicing equipment, make note of the filter pressure. Be sure

that all controls are set to ensure the system cannot inadvertently start

during service. Turn off all power to the pump. IMPORTANT: Place filter

manual air relief valve in the open position and wait for all pressure

in the system to be relieved.

Before starting the system, fully open the manual air relief valve and place

all system valves in the “open” position to allow water to flow freely from the

tank and back to the tank. Stand clear of all equipment and start the pump.

IMPORTANT: Do not close filter manual air relief valve until all

pressure has been discharged from the valve and a steady stream

of water appears. Observe filter pressure gauge and be sure it is not

higher than the pre-service condition.

General Installation Information

• All work must be performed by a qualified service professional, and

must conform to all national, state, and local codes.

• Install to provide drainage of compartment for electrical components.

• These instructions contain information for a variety of pump models

and therefore some instructions may not apply to a specific model. All

models are intended for use in swimming pool applications. The pump

will function correctly only if it is properly sized to the specific application

and properly installed.

Pumps improperly sized or installed or used in

applications other than for which the pump was

intended can result in severe personal injury or death. These risks

may include but not be limited to electric shock, fire, flooding, suction

entrapment or severe injury or property damage caused by a structural

failure of the pump or other system component.

The pump can produce high levels of suction within

the suction side of the plumbing system. These

high levels of suction can pose a risk if a person comes within the close

proximity of the suction openings. A person can be seriously injured

by this high level of vacuum or may become trapped and drown. It is

absolutely critical that the suction plumbing be installed in accordance

with the latest national and local codes for swimming pools.

Pumps and replacement motors that are single speed and

one (1) Total HP or greater cannot be sold, offered for sale, or

installed in a residential pool for filtration use in California, Title

20 CCR sections 1601-1609.

Warning Page P/N 352557 Rev. C 7/18

iii

CUSTOMER SERVICE / TECHNICAL SUPPORT

If you have questions about ordering Pentair replacement parts, and pool products, please contact:

Customer Service and Technical Support, USA

(8 A.M. to 4:30 P.M. — Eastern/Pacific Times)

Phone: (800) 831-7133

Fax: (800) 284-4151

Web site

Visit www.pentair.com for information about

our products.*

TABLE OF CONTENTS

Important Safety Instructions ..............................

Introduction ...........................................................

Motor Features

Drive Assembly and Keypad

Drive Features

External Control

Using the Drive Keypad .......................................

Installation .............................................................

Location

Piping

Fittings and Valves

Electrical Requirements

Electrical Installation

Wiring, Grounding and Bonding

External Control via RS-485

External Control via Digital Inputs

Using the Pump's Output Signal

Using an External Input Signal

External Control Only Mode

Operation ...............................................................

Setting the Clock and Pump Address

Using the Default Schedule

Programming Custom Schedules

Program Priorities (Non-External Control)

Priming the Pump

Priming Adjustment

Operating the Pump While Running

Programming Quick Clean

Keypad Lockout

Factory Reset

Operating the Pump in Flow Mode

Flow Mode Setup and Configuration

Adjusting Flow Setting

i

1

1

1

1

1

2

3

3

3

3

3

4

4

5

6

6

7

7

8

8

8

8

9

10

11

12

12

13

13

14

14

15

Sanford, North Carolina (8 A.M. to 4:30 P.M. ET)

Phone: (919) 566-8000

Fax: (919) 566-8920

Moorpark, California (8 A.M. to 4:30 P.M. PT)

Phone: (805) 553-5000 (Ext. 5591)

Fax: (805) 553-5515

Maintenance ...........................................................

Cleaning the Pump Strainer Basket

Winterizing

Motor and Drive Care

Pump Disassembly

Shaft Seal Replacement

Pump Reassembly

Replacing the Drive Assembly

Troubleshooting ....................................................

Faults and Alarms

Replacement Parts ................................................

Technical Data .......................................................

Performance Curves

Pump Dimensions

Electrical Specifications

Mechanical Specifications

16

16

16

17

17

18

18

19

20

22

23

24

24

24

24

24

* Translated versions of this manual are available online at / La versión en español de este manual del producto, se puede encontrar en

línea a /

https://www.pentair.com/content/pentair/en/products/pool-spa-equipment/pool-pumps/whisperfloxf-variable-speed-pump.html

https://www.pentair.com/content/pentair/en/products/pool-spa-equipment/pool-pumps/max-e-proxf-variable-speed-pump.html

WHISPERFLOXF® VS and MAX-E-PROXF® VS Commercial Variable Speed Pump Installation and User’s Guide

La version française de ce manuel est disponible à

:

INTRODUCTION

1

The WhisperFloXF® VS or Max-E-ProXF® VS

Commercial Variable Speed Pump can be programmed

to run at specic speeds and time intervals for maximum

operating eciency and energy conservation for a

variety of inground pools.

• The pump can operate at any speed between 300

RPM to 3450 RPM for dierent applications, with four

preset speeds of 1720, 2500, 3000 and 3450 (Quick

Clean).

• Alarm LED and error messages warn the user against

under and over voltage, high temperature and over

current, etc.

• Communicates with most Pentair automation systems

via the Digital Input Wiring Kit (P/N 353129Z- Almond)

or RS-485 Automation Wiring Kit (P/N 356324Z Black).

• Adjustable priming speed for easy start-up

• Compatible with most cleaning systems, lters, and

jet action spas

• WEF 5.0 THP 5.0

Motor Features

• Superior speed control for commercial applications

• Operates at lower temperatures due to high

eciency

• Designed to withstand outdoor environment

• 56 Square Flange Totally Enclosed Fan Cooled

(TEFC) Motor

• Low noise

Drive Assembly and Keypad

The pump features a variable frequency drive capable

of controlling the motor speed according to programmed

settings. This provides exibility in meeting your ltration

system’s specic needs.

The pump is intended to run at the lowest speeds

needed to maintain a sanitary environment and, at the

same time, minimize energy consumption. Factors

such as pool size, the presence of additional water

features, type of chemicals used to maintain sanitary

conditions, and local environmental factors will impact

optimal programming to maximize energy conservation.

Determining the optimal settings and programming for

your pool may require some trial-and-error.

Drive Features

• Active Power Factor Correction

• High Drive Operational Eciency

• Flow Control Capable when Paired with a 4-20mA

Flowmeter (Pentair P/N 97014-4203KIT).

• Versatile Power Input:

– Single-Phase, 208-230/277-460V, 20-21/17-11A

– 3-Phase, 208-460V, 13-6A

External Control

The pump can be externally controlled via digital inputs

using the Digital Input Wiring Kit (P/N 353129Z - Almond)

the RS-485 Automation Wiring Kit (P/N 356324Z Black). See External Control via Digital Inputs, page

6 or External Control via RS-485, page 5.

When connected to external controls, the pump will

prioritize commands as follows:

RS-485 > Digital Inputs > Drive Programmed Schedules

Refer to your control system manual for further details

on how to connect and program your pump with your

control system.

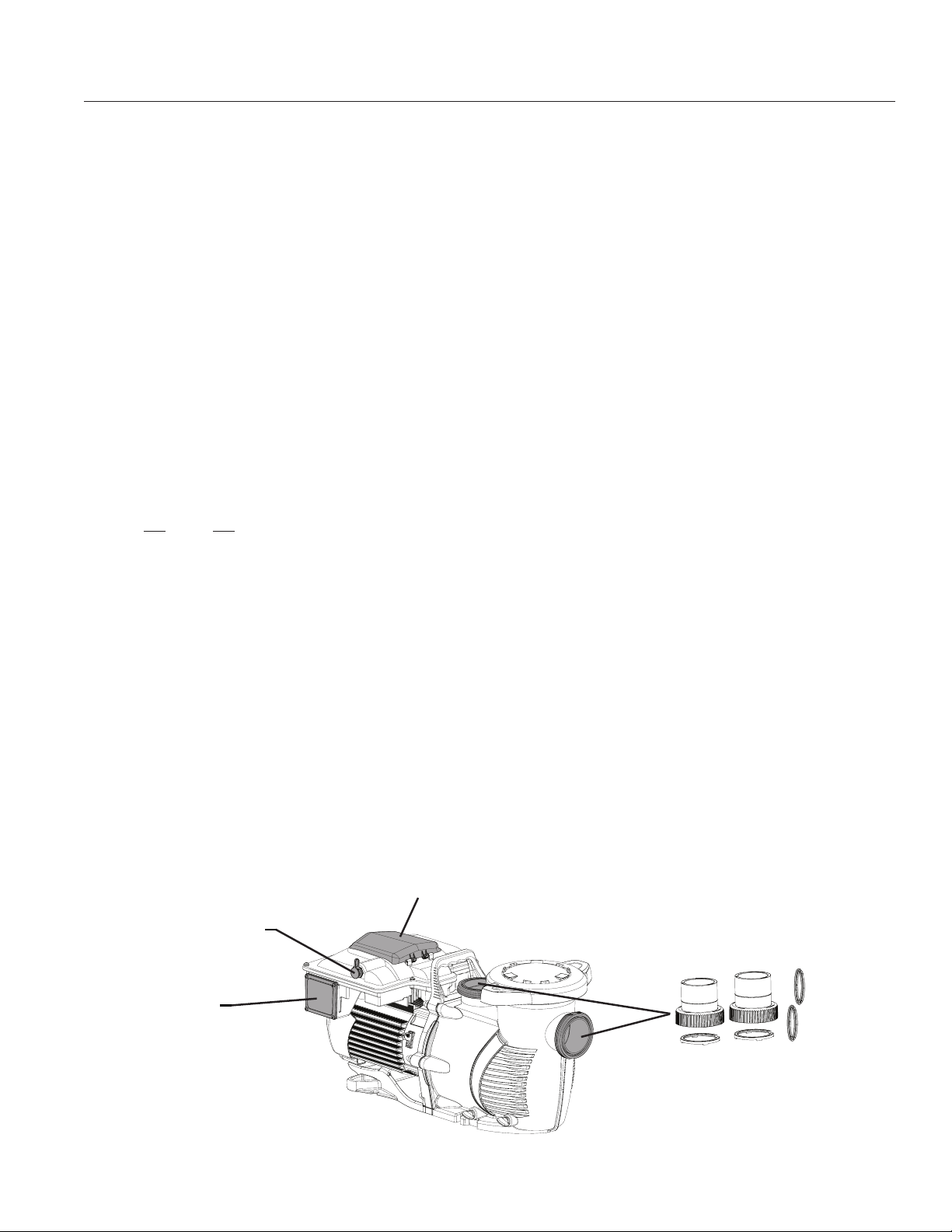

COM port for connection

to control system or

4-20mA owmeter

Wiring Compartment

for Incoming Power

Keypad Cover

(Buttons and LEDs Beneath)

Union Kit

(Suction and Discharge Fittings)

Pump Overview

WHISPERFLOXF® VS and MAX-E-PROXF® VS Commercial Variable Speed Pump Installation and User’s Guide

2

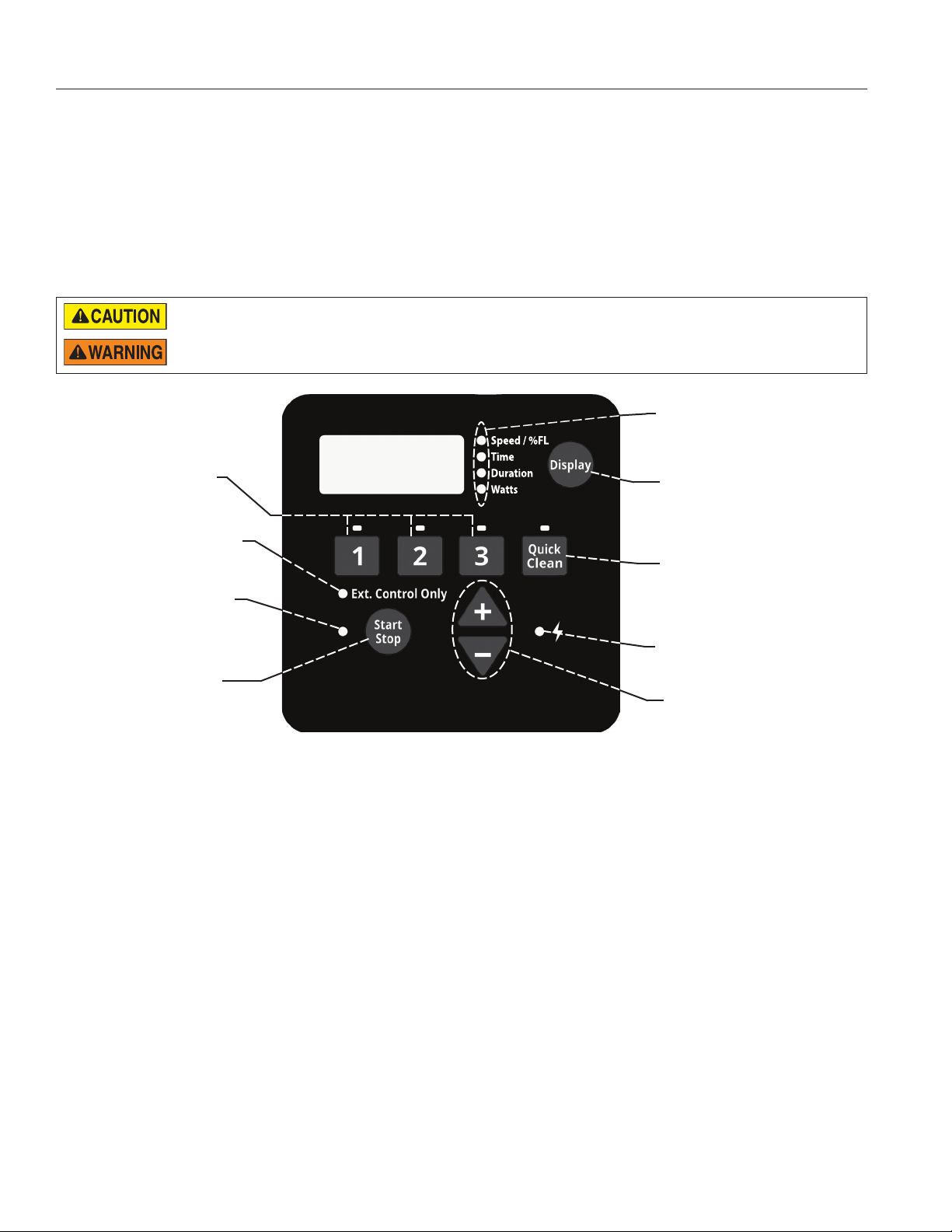

USING THE DRIVE KEYPAD

Before operating the pump for the rst time, the pump’s internal clock and operational schedules must be programmed.

Please refer to Setting the Clock and Pump Address and Programming Custom Schedules, page 8, for instructions

regarding the programming of this pump for scheduled operation.

This pump is capable of maintaining either constant speeds or constant ows. The default setting is Speed Control. For

information on conguring the pump for Flow Control via 4-20mA owmeter, refer to Operating the Pump in Flow Mode,

page 14.

The pump can be programmed and controlled from the drive keypad. Pump features and settings are also accessed

using this keypad.

Note: Always close the keypad cover after use. This will prevent damage to the keypad and other drive components.

Only press keypad buttons with your ngers. Using screwdrivers, pens or other tools to program the pump will damage the keypad.

If power is connected to the pump motor, pressing any of the following buttons referred to in this section could result in the motor

starting. Failure to recognize this could result in personal injury or damage to equipment.

(5) Display Parameter

LEDs

(1) Program

(6) Display Button

Buttons

(2) External Control

Only LED

(7) Quick Clean Button

(3) Start/Stop LED

(8) Power LED

(4) Start/Stop Button

(9) “+” and “-” Arrows

1. Program Buttons - Used to select a desired program. When the LED above a Program Button is illuminated that

program has been selected or is currently running. A blinking LED indicates that an External Control has activated

that program.

2. External Control Only LED - Indicates whether the pump is in External Control mode. When LED is illuminated

the drive-programmed schedules are disabled and only commands from digital inputs will be acted upon.

3. Start/Stop LED - Indicates whether the pump is in a “Start State”. When illuminated the pump can be started at

any time by external controls, drive-programmed schedules or manual inputs. When the pump is stopped and the

LED is not illuminated, the pump is unable to run from any type of input.

Functionality may vary based on other active features such as external control only mode or keypad lockout.

4. Start/Stop Button - Used to start and stop the pump. When the pump is stopped and the Start/Stop LED is not

illuminated, the pump is unable to run from any input.

5. Display Parameter LEDs - When illuminated, LED indicates the information being displayed on screen. A blinking

LED indicates that the parameter is currently being edited.

6. Display Button - Used to toggle between the dierent available display modes. This button is also used to set the

clock, screen brightness and pump address.

7. Quick Clean Button - Used to run the speed and duration programmed for Quick Clean. When the LED above

the Quick Clean Button is illuminated a Quick Clean cycle is active.

8. Power LED - When illuminated, LED indicates that there is live power being supplied to the pump.

9. “+” and “-” Arrows - Used to make adjustments to the pump settings. The “+” arrow increases a value, while “-”

decreases a value. Pressing and holding either arrow button will increase or decrease incremental changes faster.

WHISPERFLOXF® VS and MAX-E-PROXF® VS Commercial Variable Speed Pump Installation and User’s Guide

INSTALLATION

Only a qualied plumbing professional should install the WhisperFloXF® VS and Max-E-ProXF® VS Commercial

Variable Speed Pumps. Refer to “Important Safety Instructions” on pages i - ii for additional installation and safety

information.

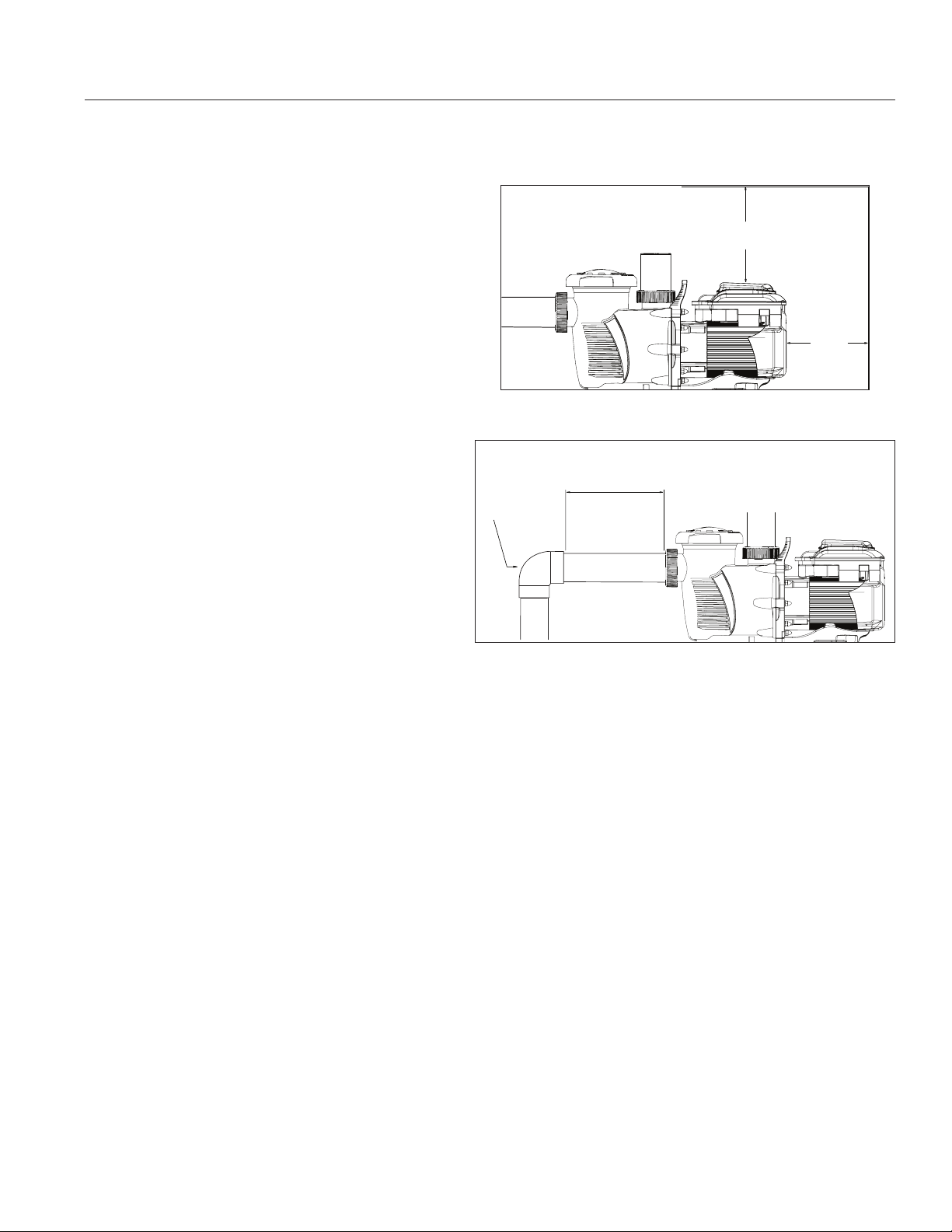

Location

Note: Do not install this pump within an outer enclosure

or beneath the skirt of a hot tub or spa unless marked

accordingly.

Note: Ensure the pump is secured to the equipment

pad.

6 IN. (15.2 CM)

MINIMUM

3

ENSURE THE INSTALL LOCATION MEETS THE

FOLLOWING REQUIREMENTS:

1. Install the pump as close to the pool or spa as

possible. To reduce friction loss and improve

eciency, use short, direct suction and return piping.

2. Install a minimum of 5 feet (1.5 meters) from the

inside wall of the pool and spa. Canadian

installations require a minimum of 9.8 feet

(3 meters) from the inside wall of the pool.

3. Install the pump a minimum of 3 feet

(0.9 meters) from a heater outlet.

4. Do not install the pump more than 10 feet

(3.1 meters) above the water level.

5. Install the pump in a well ventilated location

protected from excess moisture (i.e. rain gutter

downspouts, sprinklers, etc.).

6. Install the pump with a rear clearance of at

least 3 inches (7.6 cm) so that the motor can

be removed easily for maintenance and repair. See

Figure 1.

Piping

1. For improved pool plumbing, it is recommended to

use a larger pipe size.

2. Piping on the suction side of the pump should be the

same or larger than the return line diameter.

3. Plumbing on the suction side of the pump should be

as short as possible.

4. For most installations Pentair recommends installing

a valve on both the pump suction and return lines

so that the pump can be isolated during routine

maintenance. However, we also recommend that

a valve, elbow or tee installed in the suction line

should be no closer to the front of the pump than ve

(5) times the suction line diameter. See Figure 2.

Example: A 2.5 inch pipe requires a 12.5 inch

(31.8 cm) straight run in front of the suction port.

This will help the pump prime faster and last

longer.

Note: DO NOT install 90° elbows directly into the

suction or discharge ports.

3 IN.

(7.6 CM)

MINIMUM

Figure 1

5 x SUCTION

PIPE DIAMETER

ELBOW

Figure 2

Fittings and Valves

1. Do not install 90° elbows directly into suction port.

2. Flooded suction systems should have gate

valves installed on suction and discharge pipes

for maintenance, however, the suction gate valve

should be no closer than ve (5) times the suction

pipe diameter as described in this section.

3. Use a check valve in the discharge line when

using this pump for any application where there is

signicant height to the plumbing after the pump.

4. Be sure to install check valves when plumbing in

parallel with another pump. This helps prevent

reverse rotation of the impeller and motor.

Electrical Requirements

• Install all equipment in accordance with the National

Electrical code and all applicable local codes and

ordinances.

• A means for disconnection must be incorporated in

the xed wiring in accordance with the wiring rules.

WHISPERFLOXF® VS and MAX-E-PROXF® VS Commercial Variable Speed Pump Installation and User’s Guide

4

Electrical Installation

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION. This pump must be installed by a licensed or certied electrician or a

qualied service professional in accordance with the National Electrical Code and all applicable local codes and ordinances. Improper

installation will create an electrical hazard which could result in death or serious injury to users, installers, or others due to electrical

shock, and may also cause damage to property.

Always disconnect power to the pump at the circuit breaker before servicing the pump. Failure to do so could result in death

or serious injury to service people, users or others due to electric shock.

Read all servicing instructions before working on the pump.

Note: ALWAYS reinstall the cover onto the eld wiring compartment when leaving the pump unsupervised. This will

prevent foreign matter (rainwater, dust, etc.) from accumulating inside the compartment.

Note: When connecting the pump to an automation system, continuous power must be supplied to the pump

by connecting it directly to the circuit breaker. When using an automation system, be sure that no other lights or

appliances are on the same circuit.

Wiring

DO NOT install this pump in conjunction with a

motor starter. Using a motor starter with this pump

can cause low voltage alarms and may cause permanent drive damage.

1. Be sure all electrical breakers and switches are

turned o before wiring motor.

STORED CHARGE - Wait at least sixty

2. Be sure that the supply voltage meets the

requirements listed on the motor nameplate. If these

requirements are not met, permanent motor damage

may occur.

3. For wiring sizes and general guidelines for proper

electrical installation, please follow the specications

dened in the National Electric Code and any local

codes as required.

4. Use a strain relief and be sure all electrical

connections are clean and tight.

5. Cut the wires to the appropriate length so they do not

overlap or touch when connected.

6. Wire the pump according to instructions given on the

inside of the eld wiring cover, then secure the eld

wiring cover with the four (4) corner screws.

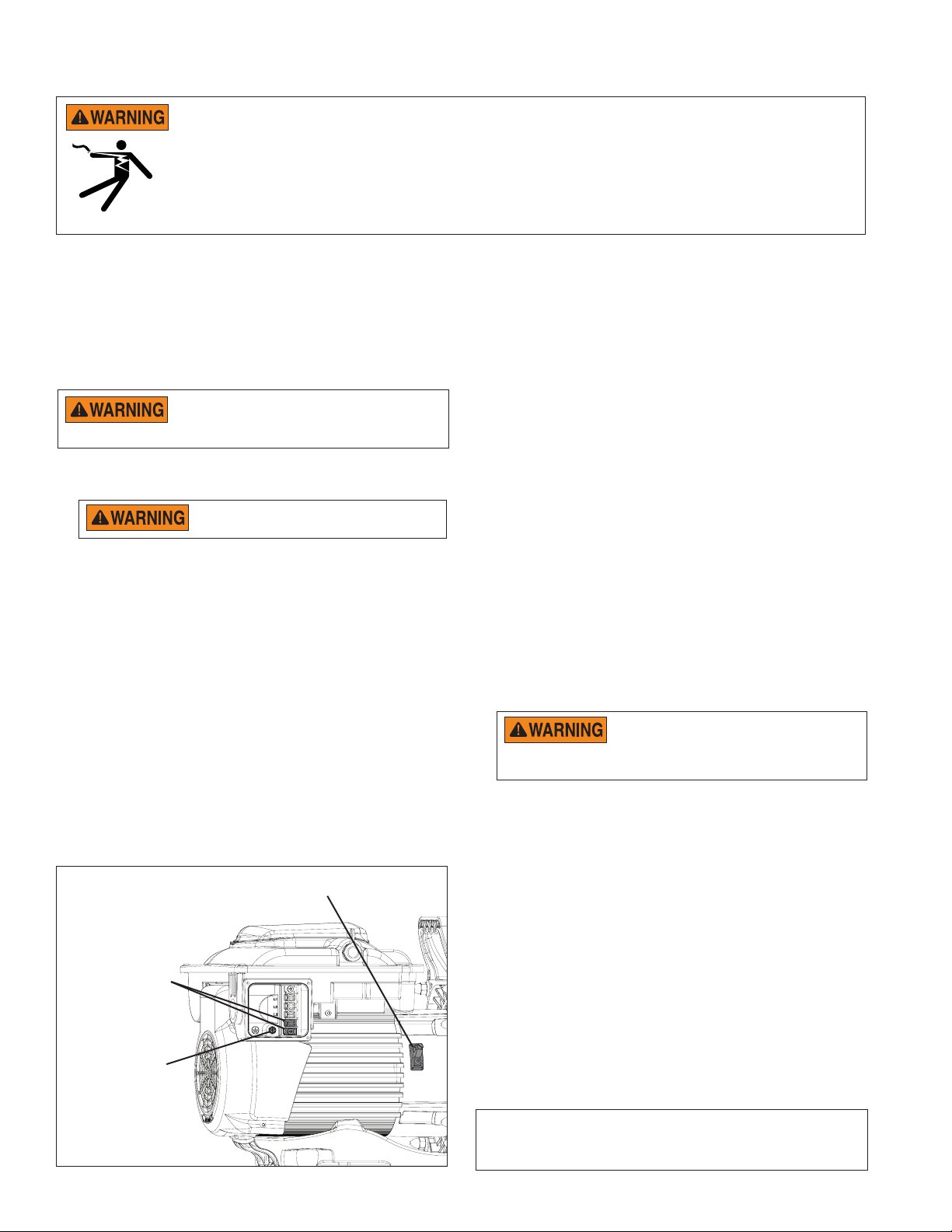

Factory-Installed

Surge Jumper

Ground Wire

Connection

(Green Screw)

(60) seconds before servicing.

Bonding Lug

Grounding

1. Permanently ground the motor using the green

ground screw (Figure 3). Use the correct wire size

and type specied by National Electrical Code. Be

sure the ground wire is connected to an electrical

service ground.

2. The pump should be permanently connected to either

a circuit breaker, 2-pole timer or 2-pole relay.

Note: If AC power is supplied by a GFCI circuit

breaker, the pump should be wired on its

own independent circuit unless the pump is

operated in tandem with a Pentair salt chlorine

generator.

3. A surge jumper has been factory-installed between

the two (2) bottom screw terminals in the wiring

compartment. Ensure this surge jumper is in place

before wiring the pump. See Figure 3.

This surge jumper grounds all drive components

and will protect them from repeated voltage

surges. If surge jumper is not installed damage to the pump drive may

occur.

Bonding

1. Bond the motor to the structure in accordance with

the National Electrical Code. Use a solid copper

bonding conductor not smaller than 8 AWG. For

Canadian installations, a 6 AWG or larger solid

copper bonding conductor is required. Run a wire

from the external bonding screw or lug to the bonding

structure.

2. Connect the wire from the accessible bonding lug

on the motor to all metal parts of the swimming

pool, spa, or hot tub structure and to all electrical

equipment, metal conduit, and metal piping within 5

feet (1.5 meters) of the inside walls of the swimming

pool, spa, or hot tub. Run a wire from the external

bonding lug to the bonding structure. See Figure 3.

Note: When the pump is started and stopped by removing

Figure 3

WHISPERFLOXF® VS and MAX-E-PROXF® VS Commercial Variable Speed Pump Installation and User’s Guide

power with a relay or timer, a two-pole device should be used to

apply and remove power to both POWER LINE TERMINALS.

External Control via RS-485

YELLOW

GREEN

Automation System

COM Port

Note: Only the GREEN and

YELLOW wires will be used. All

other wires should be cut off at the

cable sheath.

From

Pump

4

3

2

1

The following instructions only apply to pumps

manufactured after December 2020. For all other

pumps, refer to External Control via Digital Inputs on

page 6.

When paired with the RS-485 Automation Wiring Kit

(P/N 356324Z - Black) the pump can be externally

controlled by a control system through an RS-485

communication cable.

Note: When externally controlled via RS-485, the

pump can only operate in Speed Mode. To operate in

Flow Mode digital inputs must be used.

Note: IntelliConnect® Control and Monitoring Systems

can NOT externally control this pump via RS-485.

The pump will need to be connected via digital inputs.

Refer to External Control via Digital Inputs, page

6.

Note: If the pump is manually stopped using the

Start/Stop button, the pump will not run until the

Start/Stop button is pressed. If the Start/Stop LED is

illuminated, the pump is active and can be controlled

externally.

Only the GREEN and YELLOW conductors will be used

to wire the pump for external control via RS-485. See

Figure 4.

Refer to the control system manual for specic details

on connecting and programming. Control systems using

older rmware may require the pump to be designated

as “IntelliFlo VS".

5

TO WIRE FOR EXTERNAL CONTROL USING RS-485:

1. Route the communication cable from the Pump

Com Port (Figure 5) to the control system wiring

compartment.

2. Ensure the cable reaches all necessary terminals

and cut to the necessary length.

3. Strip the cable 3/4" (19 mm).

4. Strip the 24 AWG GREEN and YELLOW conductors

1/2" (13 mm).

5. Cut back and terminate unused conductors

according to local and national electrical codes.

6. Connect YELLOW and GREEN conductors to the

control system as shown in Figure 4.

7. Program the pump's internal clock and pump

address. Refer to Setting the Clock and Pump

Address, page 8.

8. Set PROGRAM 1 to a speed of 0 RPM and

duration of 24 hours. Refer to Programming Custom

Schedules on page 8.

9. Disable priming at the pump. Priming duration and

speeds will be controlled by the control system.

Note: If priming is not disabled at the pump,

priming will continue to be controlled by

the pump’s programming. Refer to Priming

Adjustment, page 11.

10. Plug the communication cable into the pump’s Com

Port (Figure 5).

Figure 4

WHISPERFLOXF® VS and MAX-E-PROXF® VS Commercial Variable Speed Pump Installation and User’s Guide

COM Port

Figure 5

6

External Control via Digital Inputs

When paired with either the Digital Input Wiring Kit (P/N 353129Z - Almond) or RS-485 Automation Wiring Kit (P/N

356324Z - Black), the pump can be externally controlled by digital input signals.

Note: If the pump is manually stopped using the

Start/Stop button, the pump will not run until the

Start/Stop button is pressed. If the Start/Stop

LED is illuminated, the pump is active and can be

controlled externally.

The communication cable provided with these kits

features a watertight connection that plugs into

the Pump Com Port (Figure 5 on page 5). The

opposite end of the cable has either 6 or 8 conductors

dened in Table 1.

A trigger signal is required to externally control the

pump via digital inputs. This required output signal can

to be provided in one of the following ways:

• By the pump drive. Refer to Using the Pump’s

Output Signal.

• By an external low voltage signal. Refer to Using

an External Input Signal on page 7.

Denition Signal Range

+24V Output for Digital Inputs 0-20mA Red Red

RS-485 A -7V to +12V - Yellow

RS-485 B -7V to +12V - Green

PROGRAM 1 Digital Input 0, 5-30V AC/DC Green White

PROGRAM 2 Digital Input 0, 5-30V AC/DC Yellow Blue

PROGRAM 3 Digital Input 0, 5-30V AC/DC Orange Orange

QUICK CLEAN Digital Input 0, 5-30V AC/DC Brown Brown

Common Ground 0V Black Black

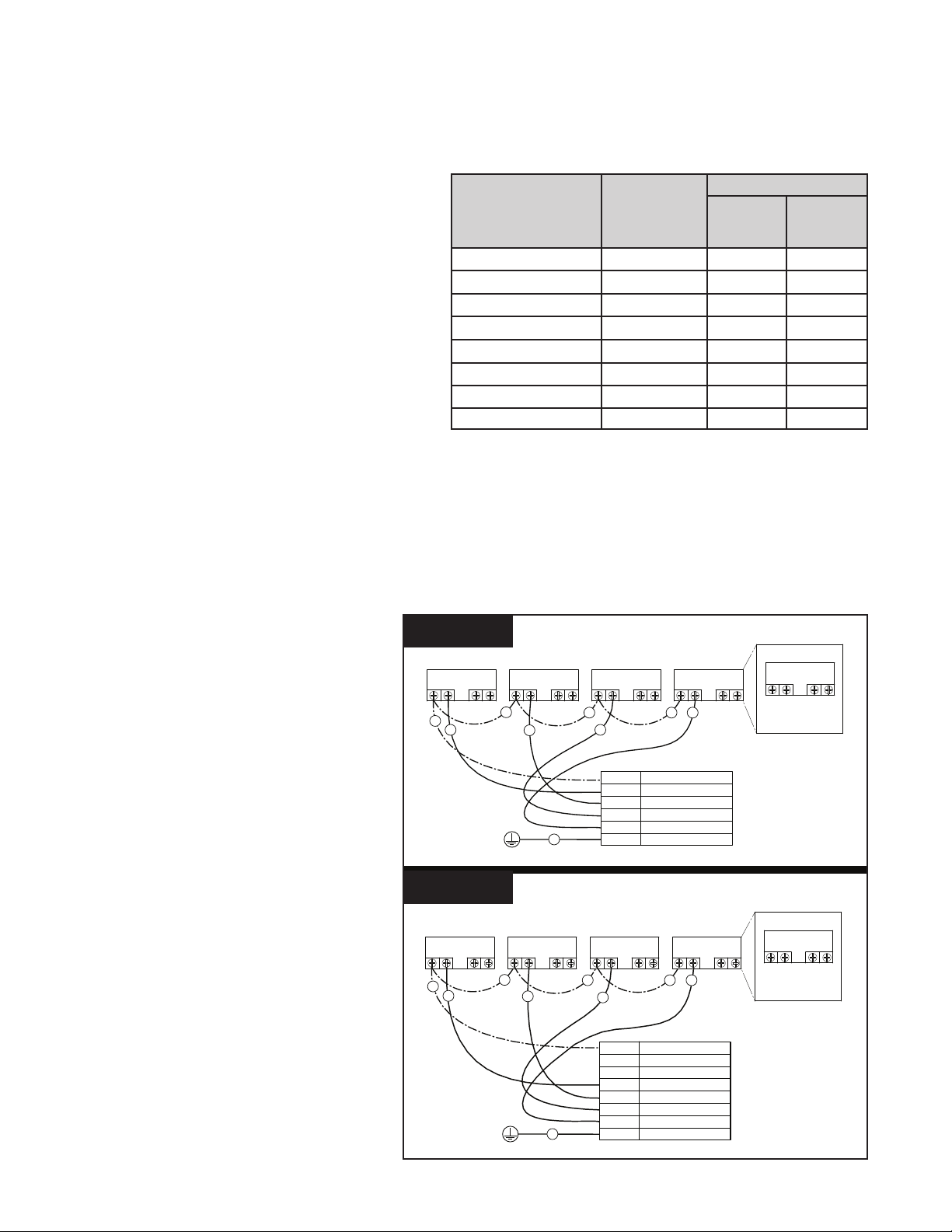

Table 1

Wire Color

Wiring Kit

353129Z

Almond

Wiring Kit

356324Z

Black

Using the Pump's Output Signal

1. Route the communication cable from the Pump Com Port (Figure 5 on page 5) to the control system wiring

compartment.

2. Ensure the cable reaches all necessary terminals and cut to the necessary length.

3. Strip the cable 3/4" (19 mm).

4. Strip all 24 AWG conductors 1/2" (13 mm).

5. If using Digital Input Wiring Kit (P/N

353129Z - Almond): Wire communication

cable to control system as shown in Figure

6A.

If using RS-485 Automation Wiring

Kit (P/N 356324Z - Black): Wire

communication cable to control system as

shown in Figure 6B.

Note: Unused conductors should be cut

o and terminated according to local

and national electrical codes.

6. Using the pump keypad, program the

pump's internal clock. Refer to Setting the

Clock and Pump Address on page 8.

7. Using the pump keypad, set PROGRAM 1

to 0 RPM and a duration of 24 hours. Refer

to Programming Custom Schedules on

page 8.

8. Using the pump keypad, disable priming.

Refer to Priming Adjustment on page 11.

9. When ready to start the pump, place the

pump into External Control Only mode.

Refer to External Control Only Mode on

page 7.

10. Plug the communication cable into the

Pump Com Port.

Figure 6A

RELAY 1 RELAY 2RELAY 3RELAY 4

R

G

Figure 6B

RELAY 1 RELAY 2RELAY 3RELAY 4

R

W

Digital Input Wiring Kit

(P/N 353129Z - Almond)

R

Y

R

O

RED (R)

GREEN (G) SPEED 1 DIGITAL INPUT

YELLOW (Y) SPEED 2 DIGITAL INPUT

ORANGE (O)

BROWN (B) SPEED 4 DIGITAL INPUT

K

BLACK (K)GROUND

RS-485 Automation Kit

(P/N 356324Z - Black)

R

Bl

R

O

RED (R)

GREEN (G)NOT USED

YELLOW (Y) NOT USED

WHITE (W) SPEED 1 DIGITAL INPUT

BLUE (Bl) SPEED 2 DIGITAL INPUT

ORANGE (O)

BROWN (B) SPEED 4 DIGITAL INPUT

K

BLACK (K)GROUND

R

B

OUTPUT FOR D.I. TRIGGER

SPEED 3 DIGITAL INPUT

R

B

OUTPUT FOR D.I. TRIGGER

SPEED 3 DIGITAL INPUT

POWER RELAY (DPST)

RELAY

LINE 1

LOAD 1

POWER RELAY (DPST)

RELAY

LINE 1

LOAD 1

LINE 2

LOAD 2

LINE 2

LOAD 2

WHISPERFLOXF® VS and MAX-E-PROXF® VS Commercial Variable Speed Pump Installation and User’s Guide

Loading...

Loading...