Page 1

EN Instruction Manual

B 46256-17-1701 www.jung-pumpen.de

JUNG PUMPEN WCFIX PLUS

Page 2

9

ENGLISH

You have purchased a product made by JUNG

PUMPEN and with it, therefore, also excellent

quality and service. Secure this service by

carrying out the installation works in accordance with the instructions, so that our product can perform its task to your complete

satisfaction. Please remember that damage

caused by incorrect installation or handling

will adversely affect the guarantee.

Therefore please adhere to the instructions in

this manual!

As with all electrical devices, this product

can also fail to operate due to an interruption

in the electricity supply or due to a technical defect. If this could result in damage, a

mains-independent alarm system must be

installed. Depending on the application, you

may also wish to install an emergency power

generator, or a second system as a back-up.

SAFETY

INSTRUCTIONS

This instruction manual contains essential

information that must be observed during

installation, operation and servicing. It is

therefore important that the installer and

the responsible technician/operator read this

instruction manual before the equipment is

installed and put into operation. The manual must always be available at the location

where the pump or the plant is installed.

Failure to observe the safety instructions can

lead to the loss of all indemnity.

In this instruction manual, safety information

is distinctly labelled with particular symbols.

Disregarding this information can be dangerous.

General danger to people

Warning of electrical voltage

ATTENTION!

Danger to equipment and operation

Qualification and training of

personnel

All personnel involved with the operation,

servicing, inspection and installation of the

equipment must be suitably qualified for this

work and must have studied the instruction

manual in depth to ensure that they are sufficiently conversant with its contents. The supervision, competence and areas of responsibility of the personnel must be precisely

regulated by the operator. If the personnel do

not have the necessary skills, they must be

instructed and trained accordingly.

Safety-conscious working

The safety instructions in this instruction

manual, the existing national regulations

regarding accident prevention, and any internal working, operating and safety regulations

must be adhered to.

Safety instructions for the

operator/user

All legal regulations, local directives and

safety regulations must be adhered to.

The possibility of danger due to electrical energy must be prevented.

Leakages of dangerous (e.g. explosive, toxic,

hot) substances must be discharged such

that no danger to people or the environment

occurs. Legal regulations must be observed.

Safety instructions for installation, inspection and maintenance works

As a basic principle, works may only be carried out to the equipment when it is shut

down. Pumps or plant that convey harmful

substances must be decontaminated.

All safety and protection components must

be re-fitted and/or made operational immediately after the works have been completed.

Their effectiveness must be checked before

restarting, taking into account the current

regulations and stipulations.

Unauthorised modifications,

manufacture of spare parts

The equipment may only be modified or altered in agreement with the manufacturer.

The use of original spare parts and acces-

sories approved by the manufacturer is important for safety reasons. The use of other

parts can result in liability for consequential

damage being rescinded.

Unauthorised operating

methods

The operational safety of the supplied equipment is only guaranteed if the equipment is

used for its intended purpose. The limiting

values given in the "Technical Data" section

may not be exceeded under any circumstances.

Instructions regarding accident prevention

Before commencing servicing or maintenance

works, cordon off the working area and check

that the lifting gear is in perfect condition.

Never work alone. Always wear a hard hat,

safety glasses and safety shoes and, if necessary, a suitable safety belt.

Before carrying out welding works or using

electrical devices, check to ensure there is

no danger of explosion.

People working in wastewater systems must

be vaccinated against the pathogens that

may be found there. For the sake of your

health, be sure to pay meticulous attention to

cleanliness wherever you are working.

Make sure that there are no toxic gases in the

working area.

Observe the health and safety at work regulations and make sure that a first-aid kit is

to hand.

In some cases, the pump and the pumping

medium may be hot and could cause burns.

For installations in areas subject to explosion

hazards, special regulations apply!

This appliance can be used by children aged

8 years or over and by persons with limited

physical, sensory or intellectual capabilities,

or with limited experience and knowledge,

provided that they are supervised or have

been instructed in the safe use of the appliance and are aware of the dangers involved.

Children must not be allowed to play with the

appliance. Cleaning and user maintenance

must not be carried out by children unless

they are supervised.

Page 3

10

ENGLISH

APPLICATION

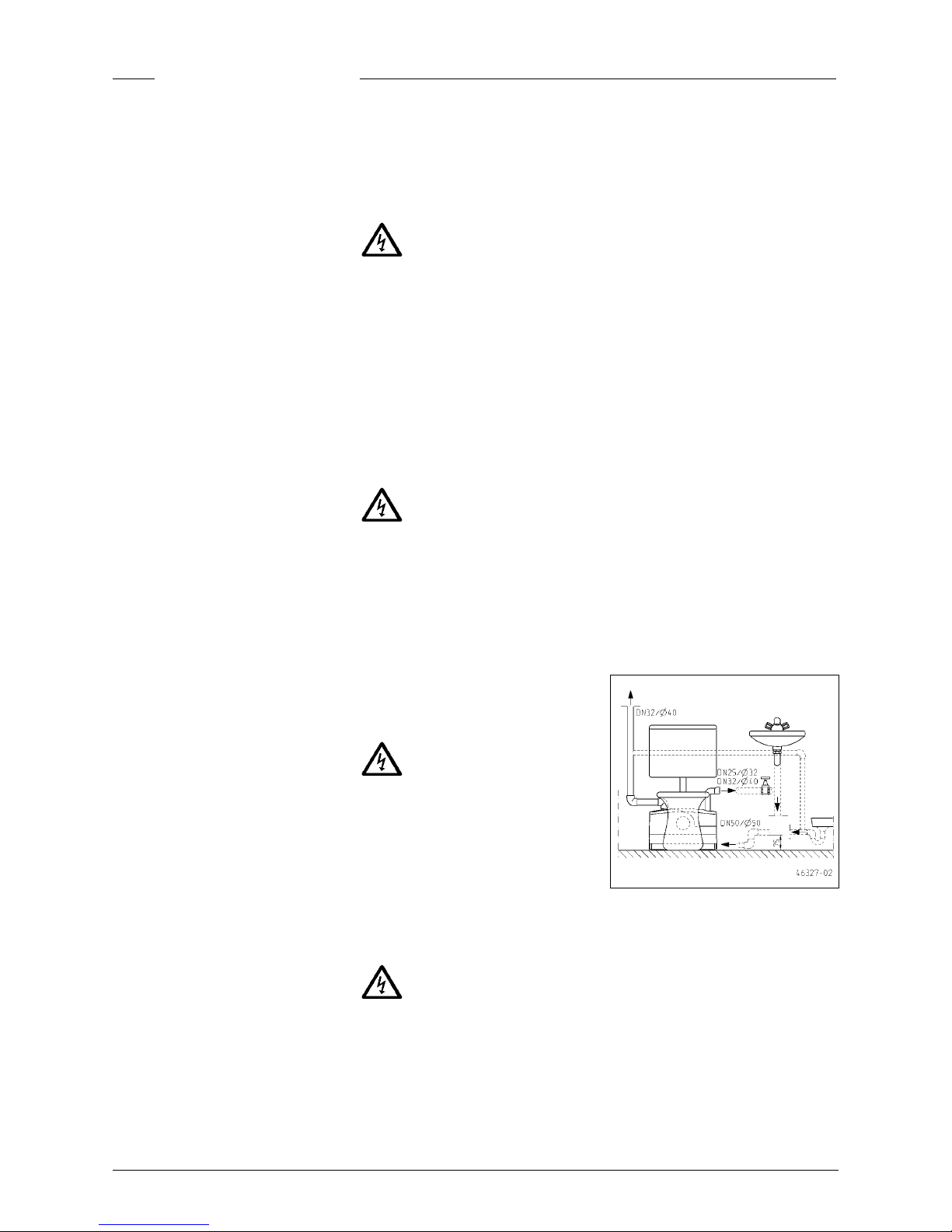

The WCFIX PLUS is used to dispose of

sewage from a directly connected toilet,

even if this lies below the local backflow

level.

∙ The number of people using the toilet

should be small, and an additional

toilet, installed above the backflow

level, must be available for them to

use.

∙ Only domestic wastewater, without

any harmful substances as defined

in EN 12056, may be disposed of.

∙ The unit operates in combination

with a with cistern that supplies a

flush volume of at least six litres.

Proper operation cannot be guaranteed if the flush volume is less than

six litres. This may be the case if an

economy flush button is used, for example.

∙ A maximum of one wash basin, one

shower and one bidet can be connected in addition to the toilet. All of

the fixtures must be installed in the

same room as the WCFIX PLUS. If

no additional units are to be served,

a flush volume of 9 litres is recommended for the toilet.

∙ In accordance with EN 12050-3, the

connection of other appliances, such

as washing machines, kitchen sinks,

dishwashers or bathtubs, is not permitted.

When installed correctly and used for

its intended purpose, the unit meets

all the protection requirements of EMC

Directive 2014/30/EU and is suitable for

domestic use and for connection to the

public power supply network.

It is ideal for use in renovation or conversion works in domestic situations

where the installation of a toilet would

be desirable. The unit pumps the sewage and toilet paper from the toilet into

an existing foul water drainage pipe.

When installed below the backflow level, the unit also provides backflow protection. This requires the installation of

a vertical backflow prevention loop in

the pressure pipe.

ATTENTION!

∙ The unit must never be used for the

disposal of hygiene articles, paper

towels, moist toilet tissues, left-over

food, solvents, chemicals, grease

etc.

∙ The flow velocity in the pressure pipe

must be at least 0.7 m/s.

∙ The operating limit with regard to

manometric head is 0.6 bar (6.0 m

head).

Permissible temperature of the pumped

fluid: 35°C, operating mode: intermittent operation S3, 30% (3 minutes operation – 7 minutes rest)

When installing the system in

bathrooms or shower rooms,

German VDE regulation 0100

Part 701 must be observed.

The WCFIX PLUS is frost resistant

down to a temperature of –20 °C when

stored in dry conditions. Once the unit

is installed, however, the residual water in the system must not be allowed

to freeze.

ELECTRICAL

CONNECTION

Only qualified electricians may

carry out electrical works to

the pump, connector plugs or

controls.

ATTENTION! Never put the mains plug

into water! If water gets into the plug,

this can cause malfunctions or damage.

The relevant standards (such as EN

standards), country-specific regulations

(such as VDE in Germany), and the regulations of the local power supply companies must be observed.

Observe the operating voltage (see the

type plate)!

Only connect the pump to

sockets that have been in-

stalled properly in accordance

with the regulations and are fitted with

at least a 10 A (delay) fuse and a residual-current circuit breaker (≤ 30 mA).

No additional motor protection is required, since the system has an integrated coil thermostat.

Unacceptably high temperatures and

long periods of continuous operation

cause the thermostat to shut down the

motor.

After the thermostat has

switched off the system, you

must pull out the mains plug

before remedying the fault, because the

device switches itself on again automatically.

System controls

The WCFIX PLUS has a level controller

that switches the pump on and off depending on the level of the water.

The start-up delay and shut-off delay

are set via DIP switches on the control

circuit board.

The mains-dependent alarm sounds to

indicate a malfunction if the pumping

operation continues for longer than 43

seconds. A potential-free fault indicator

contact (5 A/250 V) on the circuit board

can be used to relay the alarm.

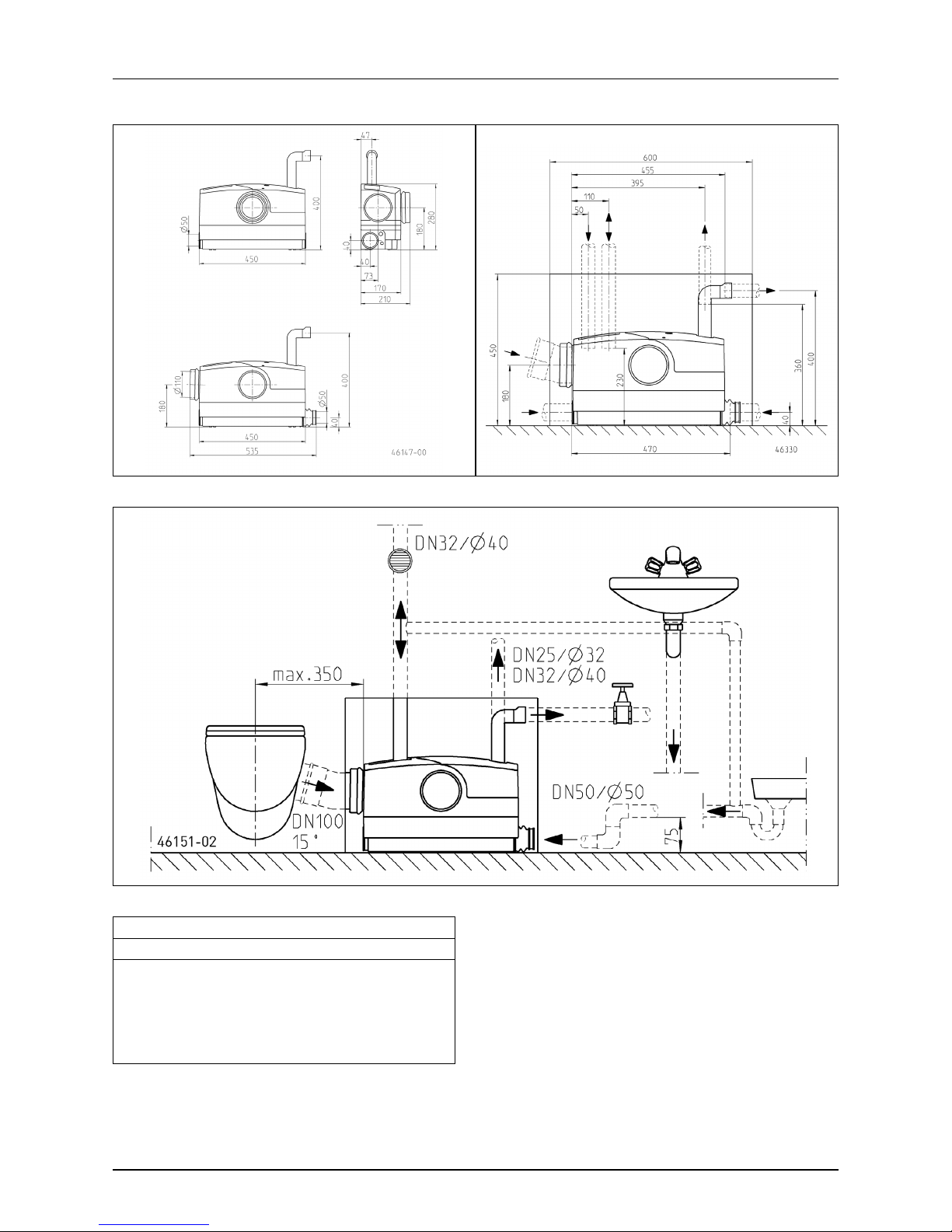

INSTALLATION

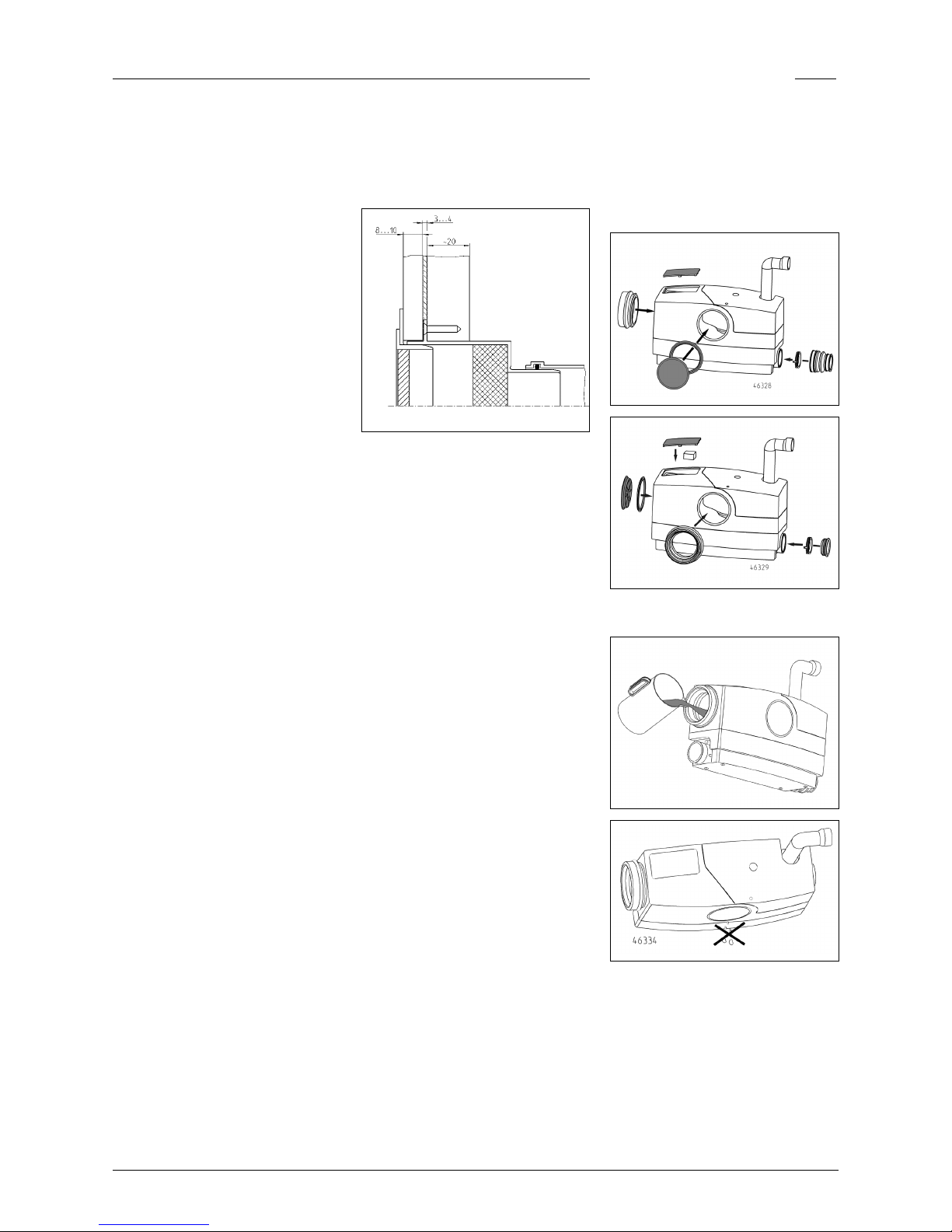

For front-wall installations

If the toilet is wall-mounted, the WCFIX

PLUS is installed immediately adjacent

to the toilet module. The unit is connected to the outlet bend of the frontwall installation via a 15º bend with a

nominal diameter (DN) of 100 mm and

high temperature resistance (HT). The

WCFIX PLUS can be installed to the left

or right of the toilet.

For free-standing toilets

The WCFIX PLUS is fitted directly to

standard toilets (complying with DIN

1387 or 1388) with a horizontal outlet. The vertical distance between the

mounting surface and the centre of the

outlet branch must be at least 180 mm.

ATTENTION! If a connecting pipe is fitted between the WCFIX and the toilet,

this will result in malfunctions. This

method of installation does not comply

with the approval of the Deutsches Institut für Bautechnik (the German approval body for construction products

and types of construction).

The distance between the wall and the

end of the connection branch of the

toilet must be at least 220 mm if the

WCFIX PLUS is to be installed without

moving the toilet.

ATTENTION! The connection pipes from

the shower and washbasin must be fitted with a so-called back-up bend, in-

Page 4

11

ENGLISH

stalled as close to the unit as possible.

The pipe invert of this bend must be at

a height of at least 75 mm above the

mounting surface on which the unit is

fixed. Air pockets in the connecting pipe

can cause run-off problems and the water could back up. To prevent back-ups,

the inlet pipe from the shower must be

vented at its highest point. The ventilation pipe can be connected into the tank

ventilation.

When installing a shower, the priority

valve supplied with the unit must be inserted into the corresponding connection port.

Note. We recommend installing a shutoff valve after the check valve in the

pressure pipe. This allows the check

valve to be serviced easily.

In the case of front-wall installations,

the WCFIX PLUS should be installed before the panelling is fixed to the frame.

This makes it easier to install the unit

and to check the connections.

Instructions regarding ventilation of

the tank

ATTENTION!The tank ventilation is es-

sential for proper operation of the system and must be fed out through the

front-wall panel. A pipe with a nominal diameter of 40 mm and high temperature resistance (not supplied) can

be used to connect the system to the

ventilation insert (supplied) or to a roof

vent. This connection pipe ensures that

no damp air can escape from the tank

into the room in which the WCFIX PLUS

is installed, where it could otherwise

cause hidden moisture-related damage

or mould growth. An activated carbon

filter is supplied with the unit to minimise unpleasant odours. The protective film must be removed before use.

The filter can be replaced and serviced

from outside via the ventilation grille.

The ventilation insert can be fixed into

the front wall at the top, the side or the

front of the wall, if required. However, it

must be installed above the height of all

of the fixtures that are connected to the

WCFIX PLUS.

If the WCFIX PLUS is not installed behind a front wall, an activated carbon

filter can be fitted at the tank.

ATTENTION! Activated carbon filters

reduce unpleasant odours, whereas a

roof vent prevents them.

A hole 76 mm in diameter must be

drilled for the installation of the ventilation system.

Cross-section through the finished wall

where the ventilation insert is installed.

If the system is ventilated via a roof vent,

then the ventilation insert and activated

carbon filter are not required.

Instructions regarding the modules

for front-wall installation

The WCFIX PLUS is compatible with all

commercially available front-wall installation systems that have a footprint

depth of at least 18 cm.

ATTENTION! A maintenance hatch

opening measuring at least 60 x 45 cm

must be created. An installation kit for

integrating a frameless, tiled maintenance hatch cover can be ordered separately, as an accessory (JP41075).

Mounting

Before commencing work, check the

contents of the package and the conditions that need to be taken into account

at the installation site. The inlet pipes

and the pressure pipe must be installed

in advance in the room where the unit is

to be installed.

Fitting the connection pipes

Fit the toilet connector into the desired

inlet opening. Make sure that the sealing lip is fitted properly in the tank.

For the other inlets, remove the stopper

and then use DN 50 plug-in seals or, in

the case of front-wall installations, use

the connection sleeves with hose clips.

ATTENTION! When installing a shower,

the priority valve supplied with the unit

must be inserted into the corresponding

connection port.

Before fitting the priority valve, lubricate

the seal area with petroleum jelly. Then

insert the valve into the open inlet port,

making sure that it locks properly into

place. Check that the valve flap works

properly.

Seal the unused toilet inlet port

Insert the sealing ring into the unused

toilet inlet port, making sure that that

the sealing lip is fitted properly in the

tank. Then grease the seal and close

the opening by fitting the cover.

Leakage test prior to installation

Installation

Push the WCFIX PLUS with the toilet

connector onto the toilet connection

branch or, in the case of front-wall installations, onto the outlet pipe. Make

sure that the connections are fitted

properly.

Page 5

12

ENGLISH

Connect the DN 50 inlet pipes using

plug-in seals or, in the case of front-wall

installations, with sleeves and clips.

Connect the pressure pipe with the

pressure port discharge elbow and hose

clips.

Buoyancy prevention

Sewage lifting units must be protected

against buoyancy. The installation site

should never be flooded.

A hole must be drilled for the wall plug,

using a long drill with a diameter of 10

mm. The anti-buoyancy hanger bolt

should later lie on the tank or have just

a small amount of play. Insert the wall

plug and screw the M8, 200-mm-long

hanger bolt tightly into place.

Emergency disposal

To drain the tank in an emergency, a

section of garden hosepipe be connected to the tank at the bottom on the

right-hand side. First, you will have to

open up the 13-mm-diameter port by

drilling through it with a spiral drill

(maximum diameter: 9 mm). Push the

hosepipe onto the port and secure it

with a hose clip (tightening torque: 1.5

Nm). Make sure that the outlet opening

of the hosepipe is securely sealed.

Before installing the unit, fasten the

DN 50 and DN 100 connecting sleeves

to the discharge pipes using the clips

(supplied). Make sure that they are

properly fitted and do not leak.

ATTENTION! All of the pipe connections

must be properly sealed and free of

leaks.

The sticker that is supplied with the unit

and shows symbols giving instructions

for use must be attached where it can

be clearly seen by people using the toilet: for example above the toilet lid or on

the inside of the lid.

ATTENTION! Putting prohibited materials into the toilet can cause malfunctions, damage the unit and invalidate

the warranty.

Practical tips

After using commercially available

cleaning agents, flush the toilet several times to ensure that no aggressive

cleaning agent residues are left in the

WCFIX PLUS.

Toilet rim blocks must be fastened particularly securely to the toilet bowl rim

so that they cannot be flushed into the

unit.

SERVICING

Only qualified electricians may

carry out electrical works to the

WCFIX PLUS.

Before carrying out any work,

always disconnect the WCFIX

PLUS from the power supply

and ensure that it cannot be switched

on again by other persons.

When used properly, the WCFIX PLUS

requires little maintenance. The unit

should be checked at least once a year,

however, to ensure that all of the connections are still watertight.

The activated carbon filter should be

changed once a year.

Clearing blockages after an alarm

1. Open the maintenance hatch.

2. If the pump is sluggish or blocked,

it can be set in motion again using a

screwdriver, without any further disassembly. To do this, remove the stopper

from the hole in the cover. Insert a long

screwdriver (Torx 30 or grub-screw H5)

through the hole in the cover. Turn the

screwdriver gently until it engages with

the slot in the motor shaft and then turn

the shaft forcefully in both directions to

clear the blockage.

Then connect the mains plug to

the power supply temporarily,

to check that the pump now

works properly.

3. If the unit still does not pump normally after completing step 2, then the

motor/pump unit must be removed.

Before dismantling the unit, any water that is backed up in the toilet bowl

and in the unit must be drained off.

The emergency draining procedure can

be carried out using an electric drill

(n > 2000 RPM anticlockwise) and a

130-mm-long screwdriver bit.

Page 6

13

ENGLISH

If a hose was fixed to the tank during

installation, then the water in the system can be drained away quite simply

through the hose and into a shallow

container. The hose must then be resealed using a suitable stopper.

The tank remains installed during the

next steps. Only the motor/pump unit

needs to be removed.

1. To do this, first unfasten the screw

on the cover. Slide the cover gently

towards the pressure pipe until it

comes free. Then remove the cover.

The motor unit may be hot.

2. Now disconnect the condenser, connector plug and earth cable from the

motor and unfasten the screw of the

motor unit in the tank.

3. Loosen the motor/pump unit with

a screwdriver, then grip the handle

and turn the unit before lifting it out

of the tank.

4. Remove any foreign matter from the

tank and the pump through the suction

opening and clean the components if

necessary.

5. Carefully reassemble the parts in reverse order.

ATTENTION! Before reassembly, the

seal of the motor/pump unit must be

cleaned and greased with petroleum

jelly.

Press the motor/pump unit into the seal

seat and couple it with the pressure

pipe by turning anticlockwise. Then attach the connector plug and condenser

and connect the earth cable.

Activated carbon filter

The installation of the activated carbon

filter (in the accessory packet included

in the scope of delivery) is recommended if unpleasant odours are present. To

install or change the filter, remove the

ventilation grille/cover from the ventilation housing. Take out the old filter and

insert the new filter (after removing the

protective film) into the opening. When

servicing the unit or when the filter is

saturated, replace the filter with a new

one. Then replace the ventilation grille/

cover.

If unpleasant odours are an issue, the

filter should be replaced at least once

a year.

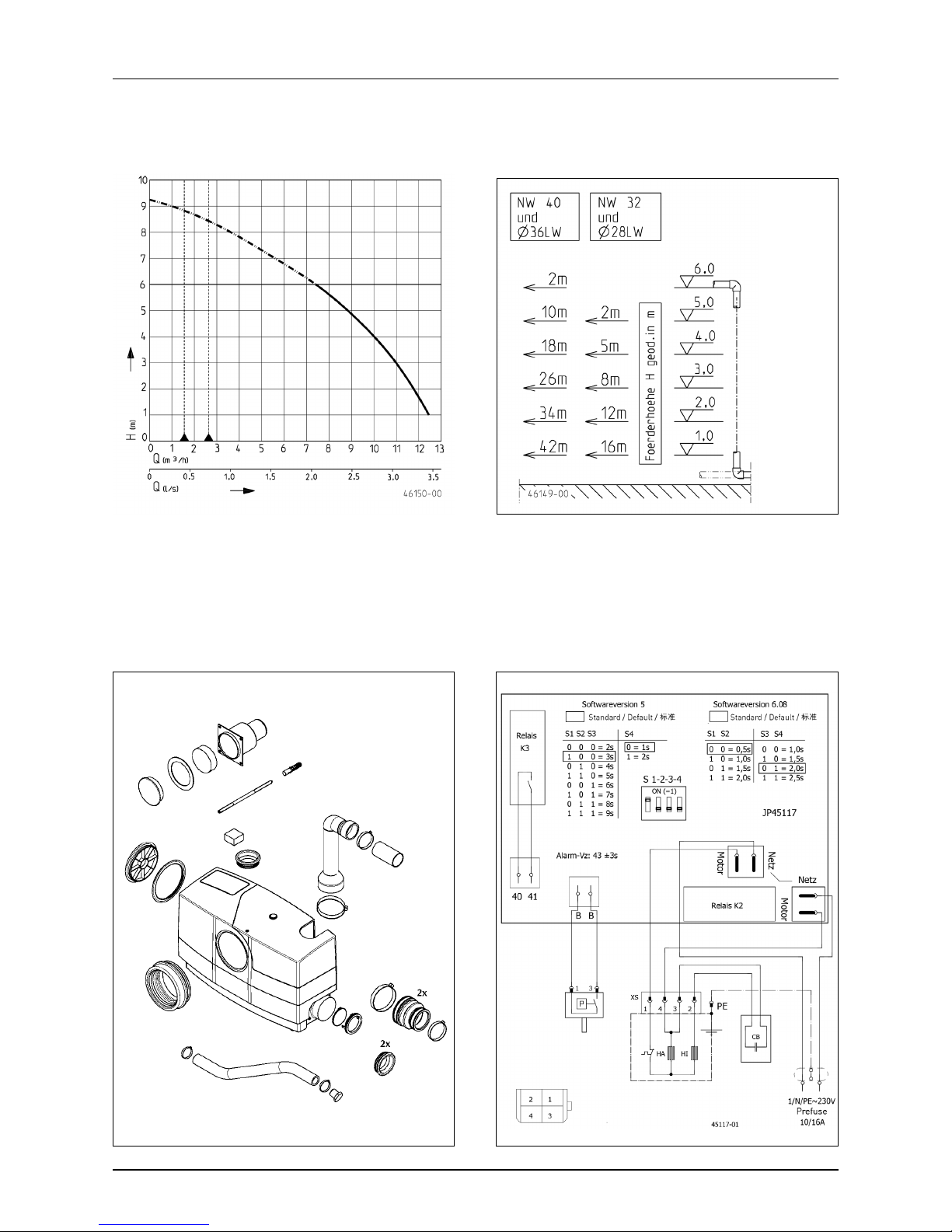

Shut-off delay and start-up delay

These delay times are adjusted via DIP

switches on the circuit board (s. Technical Data).

Software 5.0: Shut-off delay (S1-S3) and

start-up delay (S4)

Software 6.08: Shut-off delay (S1-S2)

and start-up delay (S3-S4)

Connecting the potential-free fault

alarm

A 2-lead sheathed cable with a rated

voltage of at least 300/500 V (e.g. H05...

or equivalent) must be used to connect

to the potential-free normally open

contact. To ensure that the strain-relief

clamp functions properly, the diameter

of the cable must lie between 6.5 and

8.0 mm.

- Strip only a short section of the

cable (freeing a length of no more

than 20 mm) and strip the leads. If

the leads are fine or stranded, then

use end sleeves.

- Keeping the sheathed cable above

and parallel to the mains cable,

feed the sheathed cable through

the strain-relief clamp in front of

the housing and then through the

entry sleeve and into the unit (see

image).

- Inside the unit, the cable is also

laid parallel to the mains cable and

through the plastic strain-relief

clamp that lies in front of the circuit

board.

- Feed the two leads through the cable tie on the circuit board to terminals 40/41. Once they have been

connected to the terminals, tighten

the cable tie (see image).

Page 7

14

ENGLISH

Quick tips for remedying faults

WCFIX will not start up and water remains in the toilet

bowl

∙ Check the mains voltage, fuse is defective

∙ mains cable is damaged. ATTENTION! The special cable

may be replaced only by our customer service or a qualified electrician.

∙ Impeller is blocked, see servicing instructions.

Water drains only very slowly from the toilet bowl

∙ Check the amount of flushing water available in the toilet

cistern and set it to nine litres or to the maximum quantity if necessary. If more water than usual remains in the

toilet bowl, flush again and repeat, if necessary, provided

that the water continues to be pumped out. If this does

not help, then please call customer service.

∙ Discharge head is too large.

WCFIX switches on repeatedly after normal pumping cycle

∙ Cistern valve is leaking and water flows constantly

through the toilet bowl and into the unit.

∙ After the pump stops, water runs back into the WCFIX

because the non-return valve is leaking or defective.

∙ Obstruction in the tank upstream of the pump, resulting

in water only being pumped away at short intervals.

Noisy operation

∙ Foreign matter in the unit. Follow servicing instructions.

∙ Note. Due to the fact that the switching points are au-

tomatically calibrated after operation, a louder noise is

heard after every 15th start-up.

Alarm signal sounds

∙ Running time too long (> 43 seconds), because the pres-

sure pipe or pump suction opening is blocked.

∙ Water level in the WCFIX is too high, because the pump is

obstructed or blocked.

Periodic blocking

∙ No homogenisation of the waste matter = extend the

shut-off delay time until sipping mode can be heard.

0197

JUNG PUMPEN GmbH - Industriestr. 4-6 33803 Steinhagen, Germany

13

451.12.1701

EN 12050-3:2001

Lifting plant for limited applications

WCFIX 260 (JP09268/1)

WCFIX PLUS (JP45367)

WCFIX PLUS UK (JP48517)

Automatic lifting of wastewater above the backflow level, for limited

applications.

REACTION TO FIRE NPD

WATERTIGHTNESS, AIRTIGHTNESS

- Water tightness Pass

- Odour tightness Pass

EFFECTIVENESS (LIFTING EFFECTIVENESS)

- Pumping of solids Pass

- Pipe connections Pass

- Minimum dimensions of ventilating pipes system Pass

- Minimum flow velocity Pass

- Minimum free passage of the plant Pass

MECHANICAL RESISTANCE Pass

NOISE LEVEL ≤ 70 dB(A)

DURABILITY

- of structural stability Pass

- of lifting effectiveness Pass

- of mechanical resistance Pass

DANGEROUS SUBSTANCES NPD

Page 8

44

∙ DE Max. waagerechte Druckleitungslänge inkl. 2 Winkel und Rück-

schlagklappe 1 1/4 "

∙ EN Max horizontal lenght of pressure pipe incl. 2 elbows and a swing-

type check valve 1 1/4"

∙ FR Longueur maximale de la conduite de refoulement horizontale incl. 2

jarret et clapet de retenue 1¼“

∙ NL Max. horizontale persleidingslengte incl. 2 hoeken en terugslagklep

1¼“

∙ IT Lunghezza massima della condotta a pressione orizzontale con 2

angoli e valvola di non ritorno 1¼“

∙ PL Maksymalna długość rurociągu ciśnieniowego w poziomie

wraz z 2 kolanami i klapą zwrotną 1¼“

Technische Daten - Technical Data - Caractéristiques Techniques - Technische Gegevens

Dati tecnici - Dane Techniczne - 技术指标

Page 9

45

[kg] 6,2

DN 40

P1 [W] 730

P2 [W] 470

U [V] 1/N/PE ~230

I [A] 3,2

f [Hz] 50

Page 10

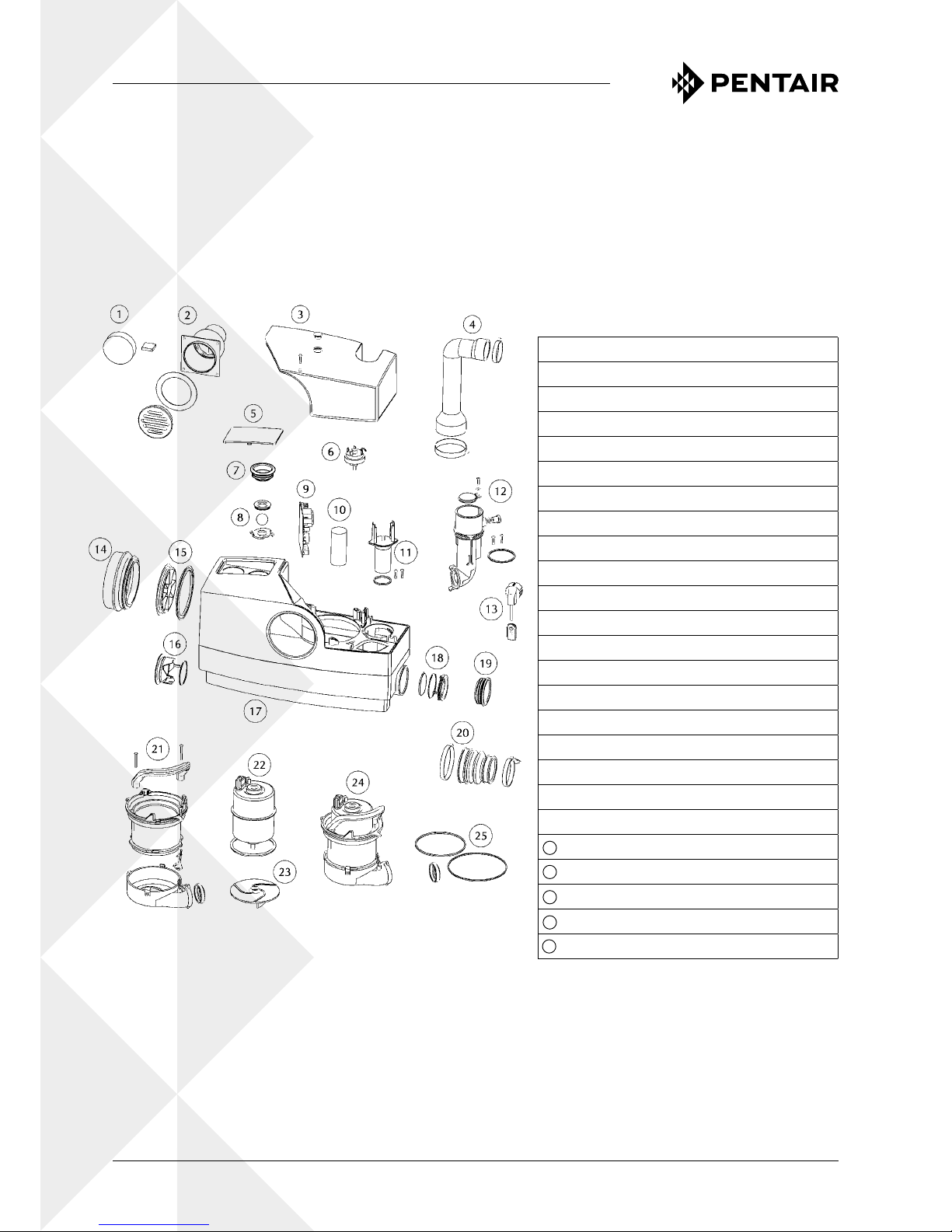

Ersatzteile - Spare parts - Pièces de rechange - Reserveonderdelen - Parti di ricambio - Reservedele - Reservdelar Varaosat - Części zamienne - Náhradní díly - Alkatrészek - Piese de schimb - Запасные части -

备件

JUNG PUMPEN WCFIX PLUS (JP45367)

①

Filter Filter JP45092

②

Filtergehäuse Filter housing JP47205

③

Haube Hood JP47187

④

Druckabgang Discharge connection JP47191

⑤

Abdeckung Cover JP47186

⑥

Druckschalter Pressure switch JP47193

⑦

Steckdichtung Plug in seal JP45098

⑧

Lüftungsventil Ventilation valve JP47188

⑨

Platine PCB JP47189

⑩

Kondensator Capacitor JP47190

⑪

Staurohr Pilot tube JP47196

⑫

Rückschlagklappe Reflux valve JP47192

⑬

Netzleitung Cable JP47202

⑭

WC-Anschluss Toilet connection JP47197

⑮

Deckel DN 100 Cover DN 100 JP47198

⑯

Deckel DN 50 Cover DN 50 JP47199

⑰

Behälter Tank JP47194

⑱

Vorrangklappe Priority valve JP47195

⑲

Steckdichtung Plug in seal JP45099

⑳

Manschette Collar JP45100

Gehäuse Housing JP47204

Motor Motor JP47200

Laufrad Impeller JP47201

Pumpeneinheit Pump unit JP47185

25

Motorabdichtung Motor sealing JP47203

22

21

23

24

Page 11

46

EU-Konformitätserklärung

EU-Prohlášeni o shodě

EU-Overensstemmelseserklæring

EU-Declaration of Conformity

EU-Vaatimustenmukaisuusvakuutus

EU-Déclaration de Conformité

EU-Megfelelöségi nyilatkozat

EU-Dichiarazione di conformità

EU-Conformiteitsverklaring

EU-Deklaracja zgodności

EU-Declaraţie de conformitate

EU-Vyhlásenie o zhode

EU-Försäkran om överensstämmelse

JUNG PUMPEN GmbH - Industriestr. 4-6 - 33803 Steinhagen - Germany -

www.jung-pumpen.de

DE · Wir erklären in alleiniger Verantwortung, dass das Produkt den aufgeführten Richtlinien entspricht.

CS · Prohlašujeme na svou výlučnou odpovědnost, že výrobek odpovídá jmenovaným směrnicím.

DA · Vi erklærer under ansvar at produktet i overensstemmelse med de retningslinjer

EN · We hereby declare, under our sole responsibility, that the product is in accordance with the specified Directives.

FI · Me vakuutamme omalla vastuullamme, että tuote täyttää ohjeita.

FR · Nous déclarons sous notre propre responsabilité que le produit répond aux directives.

HU · Kizárólagos felelősségünk tudatában kijelentjük, hogy ez a termék megfelel az Európai Unió fentnevezett irányelveinek.

IT · Noi dichiariamo sotto la nostra esclusiva responsabilità che il prodotto è conforme alle direttive citate

NL · Wij verklaren geheel onder eigen verantwoordelijkheid dat het product voldoet aan de gestelde richtlijnen.

PL · Z pełną odpowiedzialnością oświadczamy, że produkt odpowiada postanowieniom wymienionych dyrektyw.

RO · Declarăm pe proprie răspundere că produsul corespunde normelor prevăzute de directivele mai sus menţionate.

SK · Na výlučnú zodpovednosť vyhlasujeme, že výrobok spíňa požiadavky uvedených smerníc.

SV · Vi försäkrar att produkten på vårt ansvar är utförd enligt gällande riktlinjer.

CE 351-14-1701

Steinhagen, 10-01-2017

______________________ i.V. ____________________

Stefan Sirges, General Manager Rüdiger Rokohl, Sales Manager

DE · Weitere normative Dokumente CS · Jinými normativními dokumenty DA · Andre normative dokumenter EN · Other normative documents FI · Muiden normien FR · Autres documents normatifs HU

· Egyéb szabályozó dokumentumokban leírtaknak IT · Altri documenti normativi NL · Verdere normatieve

documenten PL · Innymi dokumentami normatywnymi RO · Alte acte normative SV · Vidare normerande

dokument SK · Iným záväzným dokumentom:

EN 60335-2-41:2003/A2:2010

• 2006/42/EG (MD) EN 809:1998/AC:2010, EN ISO 12100:2010, EN 60335-1:2012/AC:2014

• 2011/65/EU (RoHS)

• 2014/30/EU (EMC) EN 55014-1:2006/A2:2011, EN 55014-2:1997/A2:2008, EN 61000-3-2:2014, EN 61000-3-3:2013

DE · Richtlinien - Harmonisierte Normen

CS · Směrnice - Harmonizované normy

DA · Direktiv - Harmoniseret standard

EN · Directives - Harmonised standards

FI · Direktiivi - Yhdenmukaistettu standardi

FR · Directives -

Normes harmonisées

HU · Irányelve - Harmonizá szabványok

IT · Direttive - Norme armonizzate

NL · Richtlijnen - Geharmoniseerde normen

PL · Dyrektywy - Normy zharmonizowane

RO · Directivă - Norme coroborate

SK · Smernice - Harmonizované normy

SV · Direktiv - Harmoniserade normer

WCFIX 260 (JP09268/1)

WCFIX 260 V (JP09320/3)

WCFIX PLUS (JP45367)

WCFIX PLUS UK (JP48517)

DE · Bevollmächtigter für technische Dokumentation CS · Oprávněná osoba pro technickou dokumentaci

DA · Autoriseret person for teknisk dokumentation EN · Authorized person for technical documentation

FI · Valtuutettu henkilö tekninen dokumentaatio FR · Personne autorisée à la documentation technique

HU · Hivatalos személy műszaki dokumentáció IT · Persona abilitata per la documentazione tecnica

NL · Bevoegd persoon voor technische documentatie PL · Pełnomocnik ds. dokumentacji technicznej

RO · Persoană autorizată pentru documentatiei tehnice SV · Auktoriserad person för teknisk dokumenta-

tion SK · Oprávnená osoba pre technickú dokumentáciu:

JUNG PUMPEN - Stefan Sirges - Industriestr. 4-6 - 33803 Steinhagen

Page 12

47

Page 13

Pump Technical Services Limited - Pump House - Unit 12 - Bilton Road

Industrial Estate - Erith - Kent - DA8 2AN

Tel: 01322 357 080 - Fax: 01322 341 341 - Email: sales@pts-jung.co.uk

Loading...

Loading...