Pentair WATERFALL AFP-75, WATERFALL AFP-150, WATERFALL AF-120, WATERFALL AF-75, WATERFALL AFP-120 Installation And User Manual

Page 1

ENGLISH

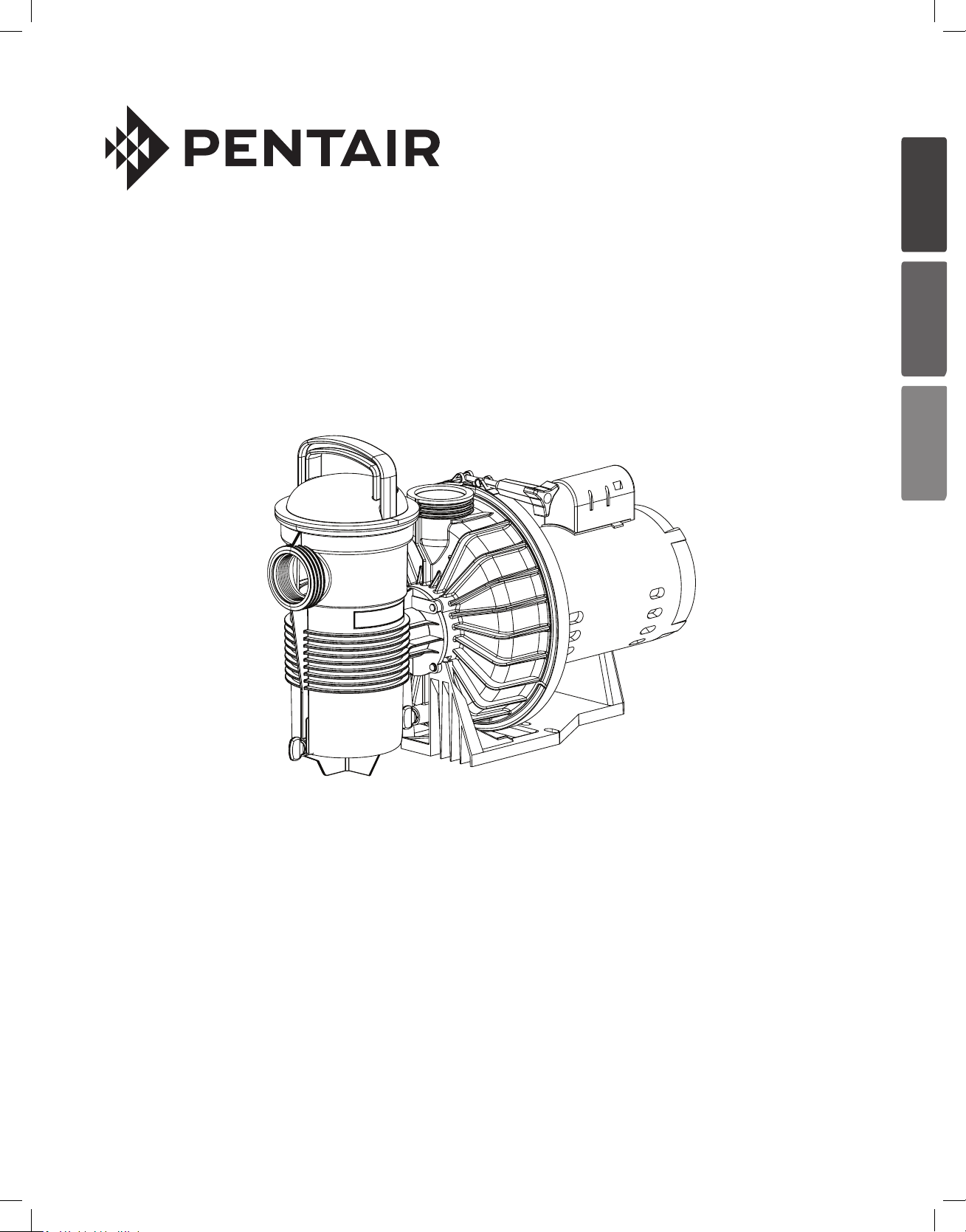

WATERFALL™

SPECIALTY PUMP

ESPAÑOL

FRANÇAIS

INSTALLATION AND

USER’S GUIDE

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Page 2

WATERFALL™ Specialty Pump Installation and User’s Guide

i

CUSTOMER SERVICE / TECHNICAL SUPPORT

If you have questions about ordering Pentair replacement parts, and pool products, please contact:

Customer Service and Technical Support, USA

(8 A.M. to 7:30 P.M. — Eastern Time)

Phone: (800) 831-7133

Fax: (800) 284-4151

Web site

Visit www.pentair.com for more information about

Pentair pool products.

TABLE OF CONTENTS

Important Pump Warning and

Safety Instructions ...............................................

Introduction ..........................................................

Pump Overview

Pump Strainer Basket

Installation ............................................................

Location

Selection of Pump and Piping

Piping, Fitting and Valve Installation

Electrical Installation

Wiring

Grounding

Bonding

Operating the Pump .............................................

Initial Start-Up

Maintenance .........................................................

Cleaning the Strainer Basket

Winterizing

Motor Care

Sanford, North Carolina (8 A.M. to 4:30 P.M. ET)

Phone: (919) 566-8000

Fax: (919) 566-8920

Moorpark, California (8 A.M. to 4:30 P.M. PT)

Phone: (805) 553-5000 (Ext. 5591)

Fax: (805) 553-5515

Servicing .............................................................

ii

1

1

1

2

2

2

3

4

4

4

4

5

5

6

6

7

7

Pump Disassembly

Shaft Seal Replacement

Pump Reassembly

Restart Instructions ...........................................

Priming the Pump

Troubleshooting .................................................

Replacement Parts .............................................

8

8

9

10

11

11

12

13

P/N 355143 Rev. D 5/17/19

Page 3

WATERFALL™ Specialty Pump Installation and User’s Guide

ENGLISH

IMPORTANT PUMP WARNING AND SAFETY INSTRUCTIONS

F

IMPORTANT NOTICE

This guide provides installation and operation instructions for this pump.

Consult Pentair with any questions regarding this equipment.

Attention Installer: This guide contains important information about the

installation, operation and safe use of this product. This information should

be given to the owner and/or operator of this equipment after installation

or left on or near the pump.

Attention User: This manual contains important information that will help

you in operating and maintaining this product. Please retain it for future

reference.

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This is the safety alert symbol. When you see this

symbol on your system or in this manual, look for

one of the following signal words and be alert to

the potential for personal injury.

Warns about hazards that can cause death,

serious personal injury, or major property damage

if ignored.

Warns about hazards that may cause death,

serious personal injury, or major property damage

if ignored.

Warns about hazards that may or can cause minor

personal injury or property damage

if ignored.

NOTE Indicates special instructions not related to

hazards.

Carefully read and follow all safety instructions in this manual and on

equipment. Keep safety labels in good condition; replace if missing

or damaged.

When installing and using this electrical equipment, basic safety

precautions should always be followed, include the following:

Do not permit children to use this product.

RISK OF ELECTRICAL SHOCK. Connect only to

a branch circuit protected by a ground-fault circuitinterrupter (GFCI). Contact a qualified electrician if you cannot verify that

the circuit is protected by a GFCI.

This unit must be connected only to a supply circuit

that is protected by a ground-fault circuit-interrupter

(GFCI). Such a GFCI should be provided by the installer and should

be tested on a routine basis. To test the GFCI, push the test button.

The GFCI should interrupt power. Push the reset button. Power should

be restored. If the GFCI fails to operate in this manner, the GFCI is

defective. If the GFCI interrupts power to the pump without the test button

being pushed, a ground current is flowing, indicating the possibility of an

electric shock. Do not use this pump. Disconnect the pump and have the

problem corrected by a qualified service representative before using.

This pump is for use with permanent swimming

pools and may also be used with hot tubs and spas

if so marked. Do not use with storable pools. A permanently-installed pool

is constructed in or on the ground or in a building such that it cannot be

readily disassembled for storage. A storable pool is constructed so that

it is capable of being readily disassembled for storage and reassembled

to its original integrity.

ii

General Warnings

• Never open the inside of the drive motor enclosure. There is a

capacitor bank that holds a 230 VAC charge even when there is no

power to the unit.

• The pump is not submersible.

• The pump is capable of high flow rates; use caution when installing

and programming to limit pumps performance potential with old or

questionable equipment.

• Code requirements for electrical connection differ from country to

country, state to state, as well as local municipalities. Install equipment

in accordance with the National Electrical Code and all applicable

local codes and ordinances.

• Before servicing the pump; switch OFF power to the pump by

disconnecting the main circuit to the pump.

• This appliance is not intended for use by persons (including children) of

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning the use of the appliance by a person responsible for their

safety.

FAILURE TO FOLLOW ALL INSTRUCTIONS AND

WARNINGS CAN RESULT IN SERIOUS BODILY

INJURY OR DEATH. THIS PUMP SHOULD BE INSTALLED AND

SERVICED ONLY BY A QUALIFIED POOL SERVICE PROFESSIONAL.

INSTALLERS, POOL OPERATORS AND OWNERS MUST READ

THESE WARNINGS AND ALL INSTRUCTIONS IN THE OWNER’S

MANUAL BEFORE USING THIS PUMP. THESE WARNINGS AND

THE OWNER’S MANUAL MUST BE LEFT WITH THE POOL OWNER.

SUCTION ENTRAPMENT HAZARD: STAY OFF

THE MAIN DRAIN AND AWAY FROM ALL SUCTION

OUTLETS!

THIS PUMP PRODUCES HIGH LEVELS OF SUCTION AND CREATES

A STRONG VACUUM AT THE MAIN DRAIN AT THE BOTTOM OF THE

BODY OF WATER. THIS SUCTION IS SO STRONG THAT IT CAN TRAP

ADULTS OR CHILDREN UNDER WATER IF THEY COME IN CLOSE

PROXIMITY TO A DRAIN OR A LOOSE OR BROKEN DRAIN COVER

OR GRATE.

THE USE OF UNAPPROVED COVERS OR ALLOWING USE OF

THE POOL OR SPA WHEN COVERS ARE MISSING, CRACKED OR

BROKEN CAN RESULT IN BODY OR LIMB ENTRAPMENT, HAIR

ENTANGLEMENT, BODY ENTRAPMENT, EVISCERATION AND/OR

DEATH.

The suction at a drain or outlet can cause:

Limb Entrapment: When a limb is sucked or inserted into an opening

resulting in a mechanical bind or swelling. This hazard is present when

a drain cover is missing, broken, loose, cracked or not properly secured.

Hair Entanglement: When the hair tangles or knots in the drain cover,

trapping the swimmer underwater. This hazard is present when the flow

rating of the cover is too small for the pump or pumps.

Body Entrapment: When a portion of the body is held against the drain

cover trapping the swimmer underwater. This hazard is present when the

drain cover is missing, broken or the cover flow rating is not high enough

for the pump or pumps.

Evisceration/Disembowelment: When a person sits on an open pool

(particularly a child wading pool) or spa outlet and suction is applied directly

to the intestines, causing severe intestinal damage. This hazard is present

when the drain cover is missing, loose, cracked, or not properly secured.

Page 4

WATERFALL™ Specialty Pump Installation and User’s Guide

iii

IMPORTANT PUMP WARNING AND SAFETY INSTRUCTIONS

Mechanical Entrapment: When jewelry, swimsuit, hair decorations, finger,

toe or knuckle is caught in an opening of an outlet or drain cover. This

hazard is present when the drain cover is missing, broken, loose, cracked,

or not properly secured.

NOTE: ALL SUCTION PLUMBING MUST BE INSTALLED IN

ACCORDANCE WITH THE LATEST NATIONAL AND LOCAL CODES,

STANDARDS AND GUIDELINES.

TO MINIMIZE THE RISK OF INJURY DUE TO

SUCTION ENTRAPMENT HAZARD:

• A properly installed and secured ANSI/ASME A112.19.8 approved

anti-entrapment suction cover must be used for each drain.

• Each suction cover must be installed at least three (3’) feet apart, as

measured from the nearest point to nearest point.

• Regularly inspect all covers for cracks, damage and advanced

weathering.

• If a cover becomes loose, cracked, damaged, broken or is missing,

replace with an appropriate certified cover.

• Replace drain covers as necessary. Drain covers deteriorate over

time due to exposure to sunlight and weather.

• Avoid getting hair, limbs or body in close proximity to any suction

cover, pool drain or outlet.

• Disable suction outlets or reconfigure into return inlets.

A clearly labeled emergency shut-off switch for the

pump must be in an easily accessible, obvious place.

Make sure users know where it is and how to use it in case of emergency.

The Virginia Graeme Baker (VGB) Pool and Spa Safety Act creates

new requirements for owners and operators of commercial swimming

pools and spas.

Commercial pools or spas constructed on or after December 19, 2008,

shall utilize:

(A) A multiple main drain system without isolation capability with suction

outlet covers that meet ASME/ANSI A112.19.8a Suction Fittings for

Use in Swimming Pools, Wading Pools, Spas, and Hot Tubs and either:

(i) A safety vacuum release system (SVRS) meeting ASME/ANSI

A112.19.17 Manufactured Safety Vacuum Release systems (SVRS)

for Residential and Commercial Swimming Pool, Spa, Hot Tub,

and Wading Pool Suction Systems and/or ASTM F2387 Standard

Specification for Manufactured Safety Vacuum Release Systems

(SVRS) for Swimming pools, Spas and Hot Tubs or

(ii) A properly designed and tested suction-limiting vent system or

(iii) An automatic pump shut-off system.

Commercial pools and spas constructed prior to December 19, 2008,

with a single submerged suction outlet shall use a suction outlet cover

that meets ASME/ANSI A112.19.8a and either:

(A) A SVRS meeting ASME/ANSI A112.19.17 and/or ASTM F2387, or

(B) A properly designed and tested suction-limiting vent system, or

(C) An automatic pump shut-off system, or

(D) Disabled submerged outlets, or

(E) Suction outlets shall be reconfigured into return inlets.

For Installation of Electrical Controls at Equipment Pad (ON/OFF

Switches, Timers and Automation Load Center)

Install all electrical controls at equipment pad, such as

on/off switches, timers, and control systems, etc. to

allow the operation (startup, shut-down, or servicing)

of any pump or filter so the user does not place any

portion of his/her body over or near the pump strainer

lid, filter lid or valve closures. This installation should

allow the user enough space to stand clear of the filter

and pump during system start-up, shut down or servicing of the system filter.

HAZARDOUS PRESSURE: STAND CLEAR OF

PUMP AND FILTER DURING START UP

Circulation systems operate under high pressure.

When any part of the circulating system (i.e.

locking ring, pump, filter, valves, etc.) is serviced,

air can enter the system and become pressurized.

Pressurized air can cause the pump housing cover, filter lid, and valves

to violently separate which can result in severe personal injury or death.

Filter tank lid and strainer cover must be properly secured to prevent

violent separation. Stand clear of all circulation system equipment when

turning on or starting up pump.

Before servicing equipment, make note of the filter pressure. Be sure

that all controls are set to ensure the system cannot inadvertently start

during service. Turn off all power to the pump. IMPORTANT: Place filter

manual air relief valve in the open position and wait for all pressure

in the system to be relieved.

Before starting the system, fully open the manual air relief valve and place

all system valves in the “open” position to allow water to flow freely from the

tank and back to the tank. Stand clear of all equipment and start the pump.

IMPORTANT: Do not close filter manual air relief valve until all

pressure has been discharged from the valve and a steady stream

of water appears. Observe filter pressure gauge and be sure it is not

higher than the pre-service condition.

General Installation Information

• All work must be performed by a qualified service professional, and

must conform to all national, state, and local codes.

• Install to provide drainage of compartment for electrical components.

• These instructions contain information for a variety of pump models

and therefore some instructions may not apply to a specific model. All

models are intended for use in swimming pool applications. The pump

will function correctly only if it is properly sized to the specific application

and properly installed.

Pumps improperly sized or installed or used in

applications other than for which the pump was

intended can result in severe personal injury or death. These risks

may include but not be limited to electric shock, fire, flooding, suction

entrapment or severe injury or property damage caused by a structural

failure of the pump or other system component.

The pump can produce high levels of suction within

the suction side of the plumbing system. These

high levels of suction can pose a risk if a person comes within the close

proximity of the suction openings. A person can be seriously injured

by this high level of vacuum or may become trapped and drown. It is

absolutely critical that the suction plumbing be installed in accordance

with the latest national and local codes for swimming pools.

Pumps and replacement motors that are single speed and

one (1) Total HP or greater cannot be sold, offered for sale, or

installed in a residential pool for filtration use in California, Title

20 CCR sections 1601-1609.

Warnings and safety instructions for Pentair Aquatic Systems pumps

and other related products are available at:

http://www.pentairpool.com/pool-owner/safety-warnings/ or call

(800) 831-7133 for additional free copies of these instructions.

Please refer to http://www.pentairpool.com/pool-owner/safety-

warnings/ for warning and safety instructions related to the this

product.

Warning Page P/N 352557 Rev. C 7/18

Page 5

WATERFALL™ Specialty Pump Installation and User’s Guide

ENGLISH

INTRODUCTION

1

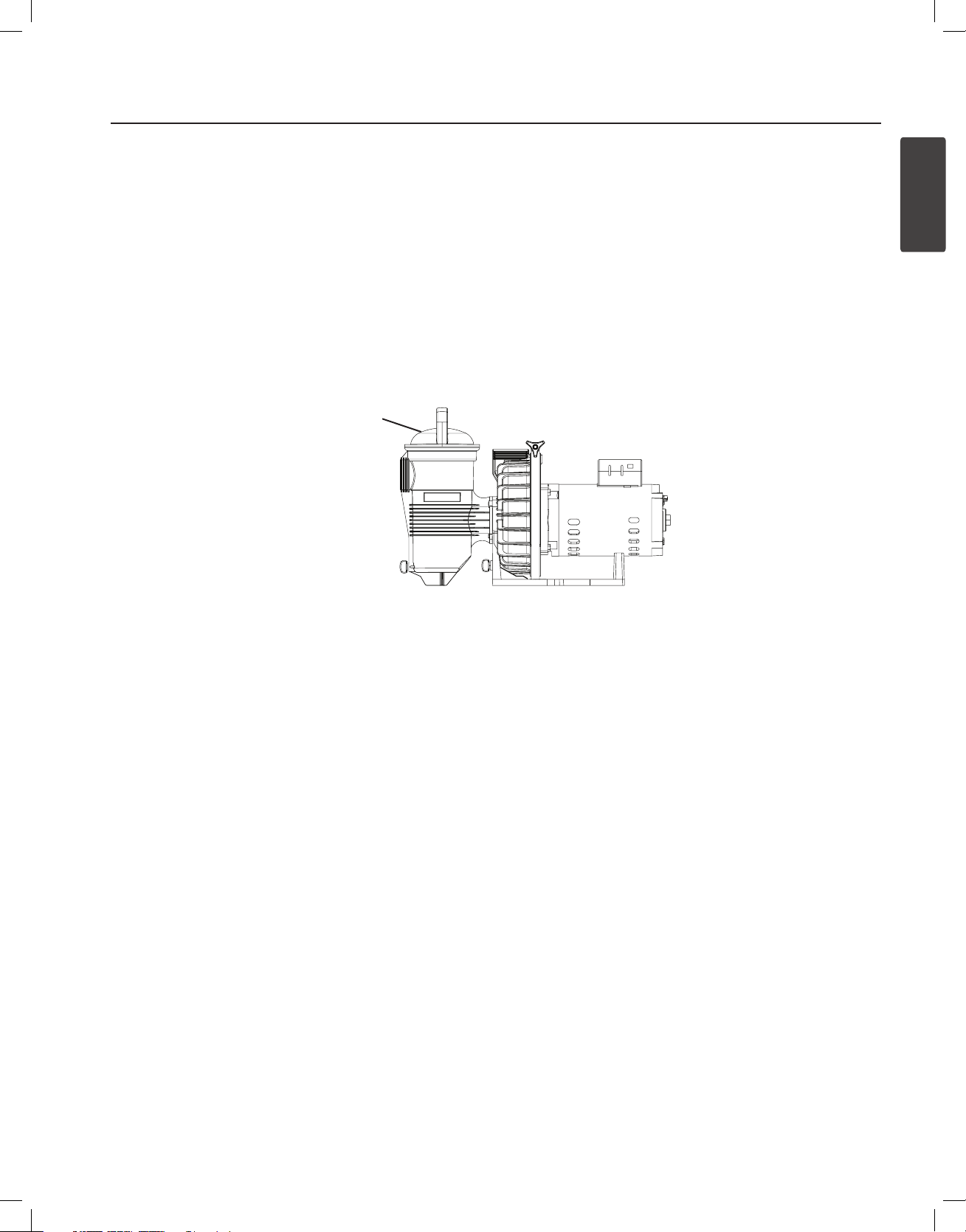

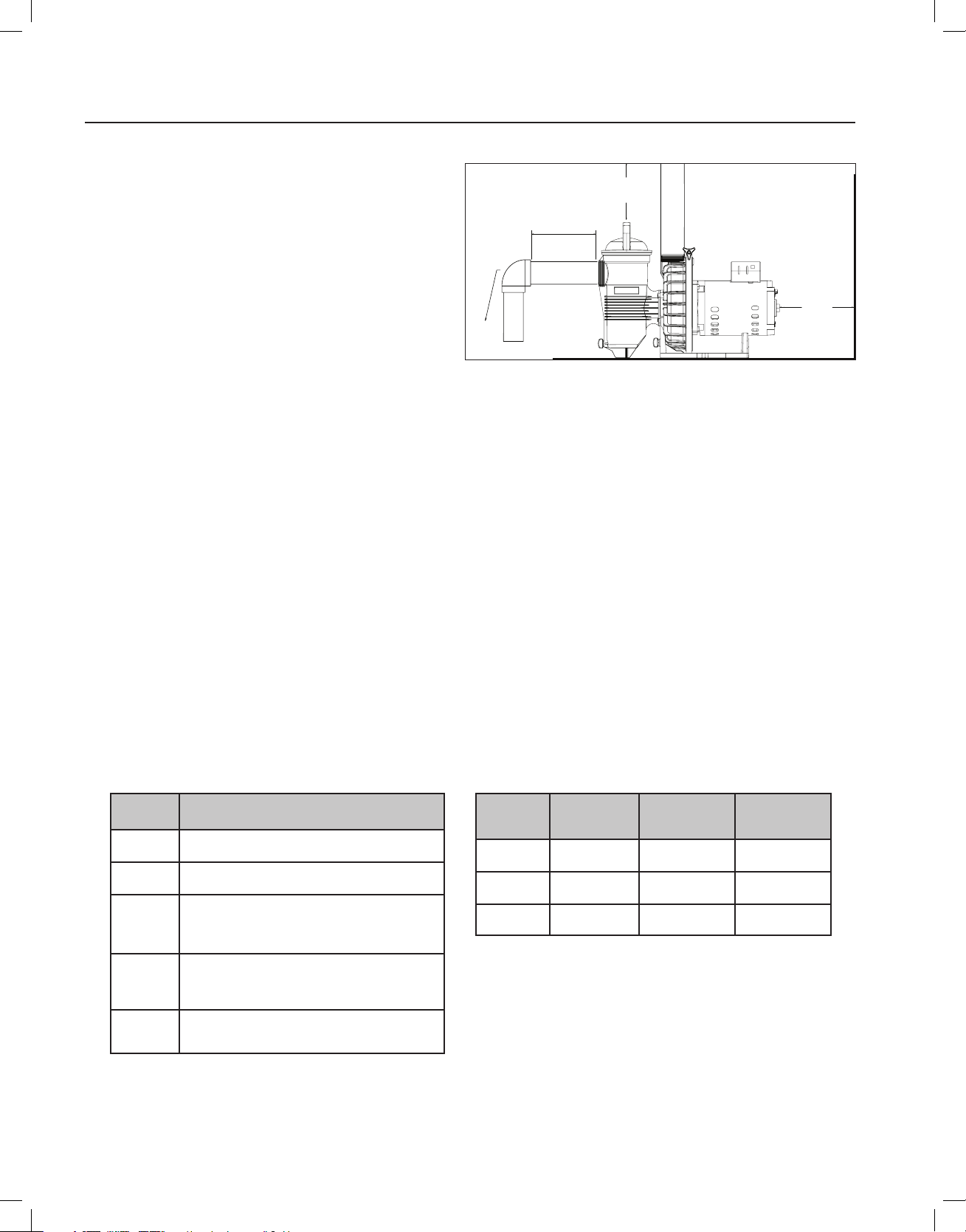

Pump Overview

Typical pool pumps are designed to circulate water through relatively high loss plumbing systems that include many

plumbing restrictions (i.e. pool filter, valves, heater, small plumbing fittings, etc.) and therefore must produce a

significant amount of pressure to push the water through all the components. If installed on plumbing systems that

do not have these types of plumbing restrictions, pool pumps will often operate very noisily and sometimes cause

damage to the system via cavitation.

The Waterfall™ Specialty Pump is specifically intended for these kind of applications, where quiet and efficient delivery

of water through low-restriction plumbing systems is required. These applications often require a pump to create some

visual effect such as a waterfall, cascade or spillway, or when water must be moved a relatively short distance.

This pump is not intended to be used in typical pool filtration pump or spa applications where pressure is required. It is

also not intended for use in systems that require water to be elevated more than 5 ft. (1.5 m) above the pool reservoir.

Strainer

Basket

Waterfall Specialty Pump

Pump Strainer Basket

The strainer basket, sometimes referred to as the ‘Hair and Lint Pot’, is located in front of the pump housing. Inside the

chamber is the basket which must be kept clean of leaves and debris at all times.

Regardless of the length of time between filter cleaning, it is important to visually inspect the hair and lint pot basket at

least once a week. A dirty basket will reduce the efficiency of the filter and heater and also put an abnormal stress on

the pump motor.

Page 6

2

WATERFALL™ Specialty Pump Installation and User’s Guide

3 IN.

(7.6 CM)

MINIMUM

REAR CLEARANCE

5x SUCTION

PIPE DIAMETER

ELBOW

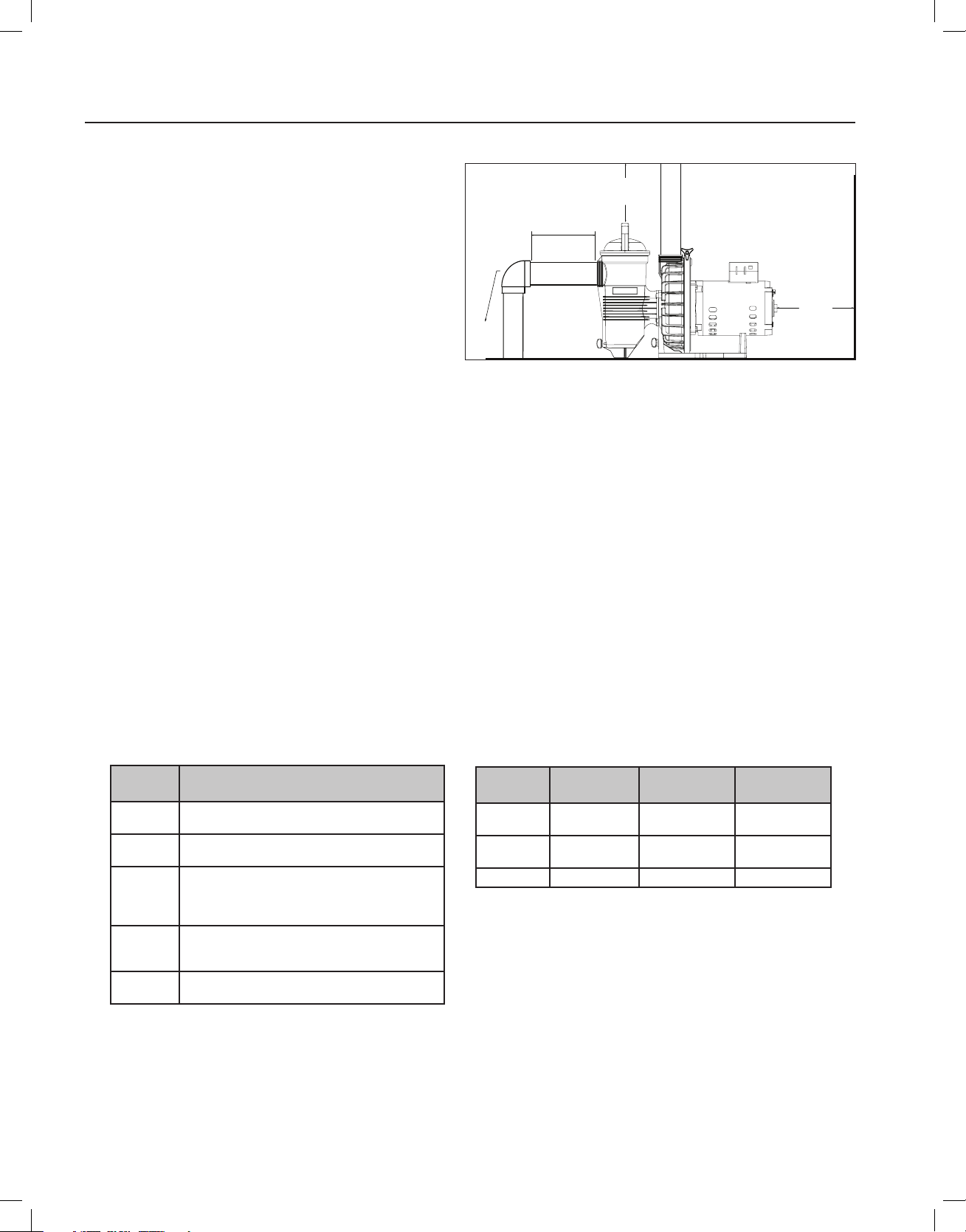

12 IN. (30.5 CM)

MIN. VERTICAL

CLEARANCE

INSTALLATION

Location

Be sure the Waterfall™ Specialty Pump location meets

the following requirements:

Note: Do not install this pump within an outer

enclosure or beneath the skirt of a hot tub or spa

unless marked accordingly.

1. Install the pump as close to the pool or spa as

possible. To reduce friction loss and improve

efficiency use short, direct suction piping returns.

2. Install a minimum of 5 feet (1.5 meters) from

the inside wall of the pool or spa. Canadian

installations require a minimum of 9.8 feet (3

meters) from pool water.

3. Install the pump a minimum of 3 feet (0.9 meters) from the heater outlet.

4. Do not install the pump more than 5 feet (1.5 m) above the water level.

5. Install the pump in a well ventilated location protected from excessive moisture (i.e., rain gutter downspouts,

sprinklers, etc.).

6. Install the pump with a rear clearance of at least 3 inches (7.6 cm) so that the motor can be removed easily for

maintenance and repair. A vertical clearance of 12 inches (30.5 cm) is required for strainer basket removal. See

Figure 1.

Figure 1

Selection of Pump and Piping

Many installations require that the pump elevate the water several feet to supply a waterfall or similar water feature.

This lifting requires energy and therefore reduces the amount of flow the pump can deliver. See Table 1 for estimates

on flow loss.

It is always recommended that the total system head loss be calculated and compared to the pump performance

curve before the pump and plumbing sizes are selected. However, Table 2 can be used as a quick guide to pump

selection and pipe sizing on simple installations.

Table 1: Effect of Elevation Change on Flow

Elevation

Change

Under 2’

2’ - 4’

4’ - 10’

10’ - 15’

Above 15’

Effect on Flow

Negligible reduction in flow if plumbed according to

guidelines.

Slight reduction in flow if plumbed according to

guidelines.

Flow reduced to 50-90% of maximum rating,

depending on exact elevation and system

installation. Must determine plumbing system head

loss to estimate flow.

Not usually recommended. Flow may be reduced

to 50% or less of maximum rating. This loss may be

acceptable in certain low-flow applications.

Not recommended. No flow possible above 27’ of

elevation change.

Table 2: Plumbing Size Recommendations

Pump

Model

AF-75

AFP-75

AF-120

AFP-120

AFP-150 150 GPM 2-1/2” 3”

* Maximum Rated Flow is the approximate flow the pump can discharge through a

short system of “high flow plumbing size” pipe. The pump will produce lower flow

rates if it has to raise water to a higher elevation and/or circulate water through a

long piping system.

** Minimum Plumbing Size may be used on installations where the plumbing

system is very short and direct, with few fittings or elbows. In applications, where

it is important to achieve the maximum possible flow, always use the larger “High

Flow Plumbing Size”.

Maximum*

Rated Flow

75 GPM 1-1/2” 2”

120 GPM 2” 2-1/2”

Minimum**

Plumbing Size

High Flow

Plumbing Size

Page 7

WATERFALL™ Specialty Pump Installation and User’s Guide

ENGLISH

Piping, Fitting and Valve Installation

1. Use thread seal tape or pipe sealants on all male connections of pipes and fittings. Use only pipe sealant

compounds suited for plastic pipe. DO NOT USE PETROLEUM BASED PRODUCTS.

2. Support pipe to prevent strains on the systems filter, pump and valves.

3. When connecting fitting to the pump, apply a pipe sealant to the threads and then hand tighten plus 1½ turns. DO

NOT OVERTIGHTEN.

4. Long piping runs and elbows restrict flow. For best efficiency, use the fewest possible fittings, large diameter pipe

(at least 1.5 inches) and locate equipment as close to the pool as possible. The pump suctions line should not be

smaller than the pipe size on the inlet of the pump.

5. Suction fittings must conform to ASME/ANSI A 112.19.8 M Standards. Use double suction fittings.

6. For most installations Pentair recommends installing a valve on both the pump suction and return lines so that

the pump can be isolated during routine maintenance. We also recommend a valve, elbow or tee installed in the

suction line should be no closer to the front of the pump than five (5) times the suction line pipe diameter. See

Figure 1 on previous page.

Example: A 1.5 inch pipe requires a 7.5 inch (19 cm) straight run in front of the suction inlet of the pump. This will

help the pump prime faster and last longer.

Note: DO NOT install 90° elbows directly into the pump inlet and outlet.

7. Maximum operating pressure of this pump is 50 PSI. NEVER OPERATE THIS PUMP ABOVE THIS PRESSURE.

8. This pump is NOT intended to be operated in series with other pumps.

3

Page 8

4

WATERFALL™ Specialty Pump Installation and User’s Guide

Electrical Installation

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION. This pump must be installed by a licensed or certified electrician or a

qualified service professional in accordance with the National Electrical Code (NEC) and all other applicable national or local codes

and ordinances. Improper installation will create an electrical hazard which could result in death or serious injury to users, installers, or

others due to electrical shock, and may also cause damage to property.

Always disconnect power to the pump at the circuit breaker before servicing the pump. Failure to do so could result in death

or serious injury to service people, users or others due to electric shock.

Read all servicing instructions before working on the pump.

Wiring

1. Be sure all electrical breakers, switches and automatic

controls are turned off before wiring motor.

STORED CHARGE - Wait at least sixty

(60) seconds before servicing.

2. Become familiar with the wiring diagram, volts, hertz,

amps and phase of your particular pump motor. All of

this information is provided on the motor nameplate

label found on the side of the motor.

3. Be sure that the supply voltage meets the requirements

listed on the motor nameplate. If these requirements

are not met, permanent motor damage may occur.

4. For wiring sizes and general guidelines for proper

electrical installation, please follow the specifications

defined in the National Electrical Code and all other

applicable national or local codes.

5. 3-Phase motors require external overload protection.

An initial inspection is needed to ensure proper

rotation of the pump.

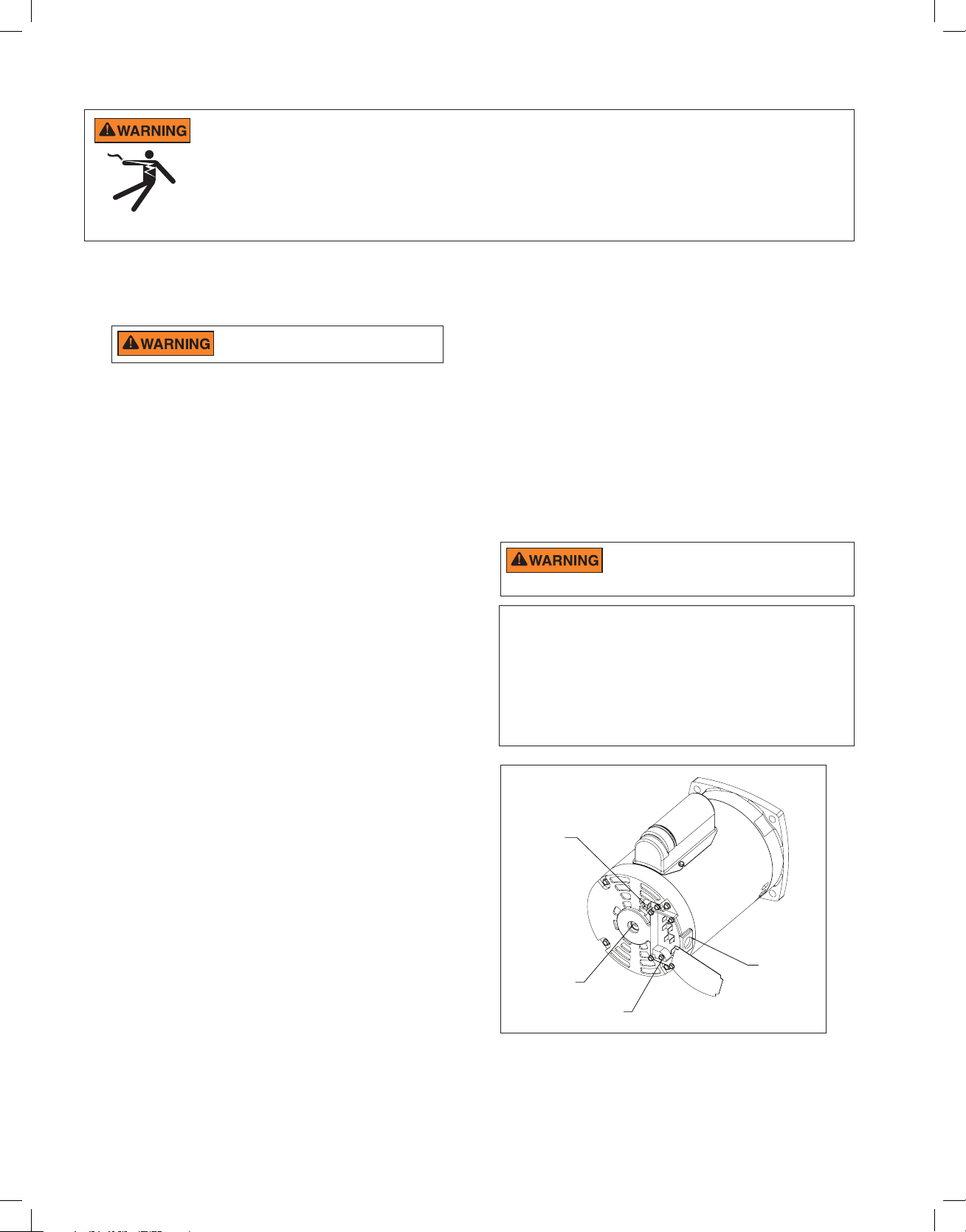

Once installed, momentarily cycle the power on and

then off. Note the rotation of the motor fan or shaft as

it comes to a stop. If wired correctly the motor shaft

and/or fan will match the rotation arrow noted on the

pump.

6. Use a strain relief and be sure all electrical connections

are clean and tight.

7. Cut the wires to the appropriate length so they do

not overlap or touch when connected.

Bonding

1. Bond the motor to the structure in accordance with the

National Electrical Code and all other applicable national

or local codes. Use a solid copper bonding conductor

not smaller than 8 AWG. For Canadian installations,

a 6 AWG or larger solid copper bonding conductor is

required. Run a wire from the external bonding screw

or lug to the bonding structure.

2. Connect the wire from the accessible bonding lug on the

motor to all metal parts of the swimming pool, spa, or

hot tub structure and to all electrical equipment, metal

conduit, and metal piping within 5 feet (1.52 meters) of

the inside walls of the swimming pool, spa, or hot tub.

Run a wire from the external bonding screw or lug to the

bonding structure.

Before establishing or restoring power to the

pump, be sure all electrical connections are tight

and all electrical and wiring compartment covers are properly installed.

Note: When the pump is started and stopped by removing

power with a relay or timer, a two-pole device should be

used to apply and remove power to both POWER LINE

TERMINALS.

Pentair offers GFCI breakers which offer appropriate

personal protection while meeting 2008 to current NEC

Standards for Pool Pumps. See Pentair product catalog

for details.

Figure 2

Grounding

1. Per manently ground the motor using the green ground

screw, as shown below. Use the correct wire size

and type specified by National Electrical Code. Be

sure the ground wire is connected to an electrical

service ground.

2. The pump should be permanently connected to either

a circuit breaker, 2-pole timer or 2-pole relay.

Note: If AC power is supplied by a GFCI circuit breaker,

the pump should be wired on its own independent

circuit unless the pump is operated in tandem

with a Pentair salt chlorine generator.

Section P/N 350486 Rev. D 4/9/19

Bonding

Lug

Motor Shaft

Slot for 3/8” or

1/2” Flathead

Screwdriver

Ground

Screw

1/2” NPT

Receptacle

for Liquid

Tight

Connector

Page 9

WATERFALL™ Specialty Pump Installation and User’s Guide

ENGLISH

OPERATING THE PUMP

Initial Start-Up

1. Relieve all system pressure and open all air bleeders on entire hydraulic system prior to starting the

Waterfall™ Specialty Pump. See filter owner’s manual.

2. Ensure that all fittings, clamps, closures and couplings are tight and in accordance with equipment

manufacturer’s recommendations.

3. Open suction and discharge valve to allow free flow of water. On flooded suction pumps with strainer pot, the

water source is higher than the pump. The water will flow into the pump strainer pot and the pot will fill with

water. On pumps without strainer pot, the water will fill the pump housing.

4. On non-flooded suction systems, the pump lid will have to be removed by rotating the lid counter-clockwise

and lifting.

5. The pump strainer pot should be filled with water up to suction/inlet port on the pump.

6. It is good practice to lubricate the lid o-ring with silicone lubricant each time the lid is removed. The o-ring

should be cleaned and inspected every time the strainer pot is opened.

7. The lid should be replaced by pressing the lid down and twisting the lid clockwise.

8. The pump is now ready to prime. Energize the motor and the pump will prime. The time to prime will depend

on the suction lift and the distance and size of suction piping. Turn off power if the pump does not prime

within thirty (30) minutes and refer to “Troubleshooting” on page 12.

5

DO NOT run the pump dry. If the pump is run dry, the mechanical seal will be damaged and the pump will start

leaking. If this occurs, the damaged seal must be replaced. ALWAYS maintain proper water level in your pool

(half way up skimmer opening). If the water level falls below the skimmer opening, the pump will draw air through the skimmer,

losing the prime and causing the pump to run dry, resulting in a damaged seal. Continued operation in this matter could cause a

loss of pressure, resulting in damage to the pump case, impeller, and seal and may cause property damage and personal injury.

Page 10

6

WATERFALL™ Specialty Pump Installation and User’s Guide

MAINTENANCE

This section describes how to maintain the Waterfall™ Specialty Pump.

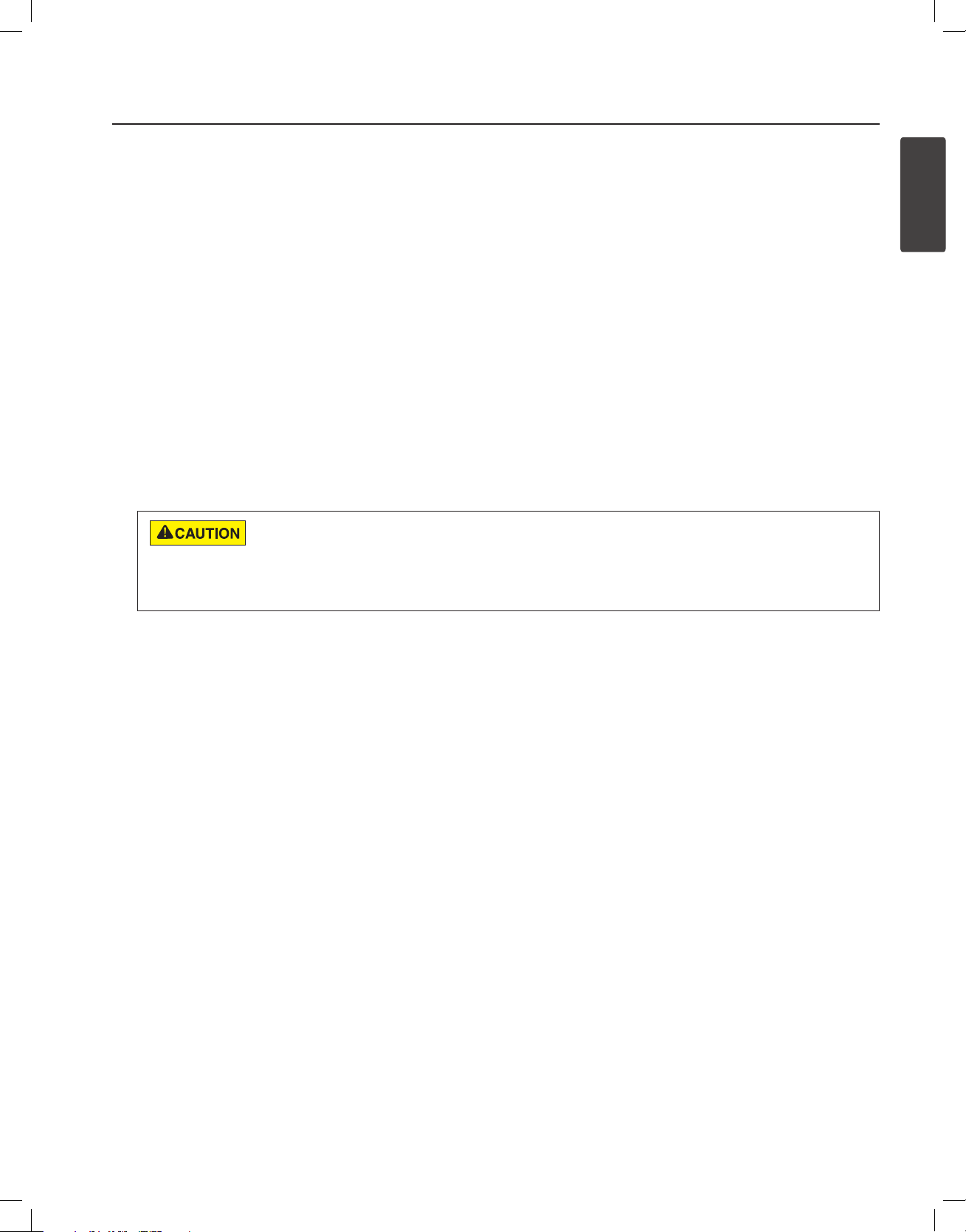

Cleaning the Pump Strainer Basket

The strainer basket in the pump should be visually inspected at least once a week. Remove the clear lid and the

basket and clean debris from basket. Inspect the lid o-ring; if damaged replace. The pump seal requires no lubrication.

DO NOT open the strainer pot if pump fails to prime or if pump has been operating without water in the strainer

pot. Pumps operated in these circumstances may experience a build up of vapor pressure and may contain

scalding hot water. Opening the pump may cause serious personal injury. In order to avoid the possibility of personal injury, make

sure the suction and discharge valves are open and strainer pot temperature is cool to touch, then open with extreme caution.

To prevent damage to the pump and filter and for proper operation of the system, clean pump strainer and

skimmer baskets regularly.

1. Turn off the pump at the breaker.

2. Close the inlet and discharge valves.

3. Relieve pressure in the system.

4. Turn the strainer lid in a counter-clockwise direction to remove the lid and

remove the basket from the pump.

5. Remove the debris from the strainer basket and rinse out the basket. Replace

the basket if it is cracked.

6. Replace the basket.

7. Fill the pump strainer pot and volute up to the suction/inlet port with water.

8. Clean the lid, O-ring, and sealing surface of the strainer pot.

Note: It is important that the O-Ring be kept clean and well lubricated.

9. Reinstall the lid by placing the lid back onto the strainer pot and turning the

lid clockwise.

Note: Be sure the lid O-ring is properly placed around the entire sealing

surface of the strainer pot.

10. Open the inlet and discharge valves.

11. Turn the power “ON” at the circuit breaker.

Figure 3

THIS SYSTEM OPERATES UNDER HIGH PRESSURE.

When any part of the circulating system (e.g., Lock Ring,

Pump, Filter, Valves, etc.) is serviced, air can enter the

system and become pressurized. Pressurized air can

cause the lid to separate which can result in serious

injury, death, or property damage. To avoid this potential

hazard, follow these instructions.

Strainer

Lid

O-Ring

Strainer

Basket

Strainer

Pot

Drain Plug

12. Open the manual air relief valve on top of the filter.

13. Stand clear of the filter. Start the pump.

14. Bleed air from the filter until a steady stream of water comes out. Close the manual air relief valve.

Page 11

7

WATERFALL™ Specialty Pump Installation and User’s Guide

ENGLISH

Winterizing

You are responsible for determining when freezing conditions may occur. If freezing conditions are expected, take the

following steps to reduce the risk of freeze damage. Freeze damage is not covered under warranty.

In mild climates, when temporary freezing conditions may occur, run your filtering equipment all night to prevent

freezing.

To prevent freeze damage, follow the procedures below:

1. Shut off electrical power for the pump at the circuit breaker.

2. Drain the water out of the pump housing by removing the two thumb-twist drain plugs from the housing. Store

the plugs in the pump basket.

3. Cover the motor to protect it from severe rain, snow and ice.

Note: DO NOT wrap the motor with plastic or other air tight materials during winter storage. The motor may be

covered during a storm, winter storage, etc., but never when operating or expecting operation.

Motor Care

Protect from heat

1. Shade the motor from the sun.

2. Any enclosure must be well ventilated to prevent overheating.

3. Provide ample cross ventilation.

Protect against dirt

1. Protect from any foreign matter.

2. Do not store (or spill) chemicals on or near the motor.

3. Avoid sweeping or stirring up dust near the motor while it is operating.

4. If a motor has been damaged by dirt it may void the motor warranty.

5. Clean the lid and clamp, O-ring, and sealing surface of the pump pot.

Protect against moisture

1. Protect from continuous splashing or continuous sprayed water.

2. Protect from extreme weather such as flooding.

3. If motor internals have become wet - let it dry before operating. Do not allow the pump to operate if it has been flooded.

4. If a motor has been damaged by water it may void the motor warranty.

Note:

• DO NOT wrap motor with plastic or other air tight materials. The motor may be covered during a storm, for

winter storage, etc., but never when operating, or expecting operation.

• When replacing the motor, be certain that the motor support is correctly positioned to support the size of motor

being installed.

Page 12

8

WATERFALL™ Specialty Pump Installation and User’s Guide

SERVICING

This section describes how to service the Waterfall™ Specialty Pump.

RISK OF ELECTRICAL AND ELECTROCUTION

This pool pump must be installed by a licensed or certified electrician or a qualified pool serviceman

in accordance with the National Electrical Code and all applicable local codes and ordinances.

Improper installation will create an electrical hazard which could result in death or serious injury to

pool users, installers, or others due to electrical shock, and may also cause damage to property.

Always disconnect power to the pool pump at the circuit breaker before servicing the pump.

Failure to do so could result in death or serious injury to serviceman, pool users or others

due to electric shock.

Read all servicing instructions before working on the pump.

DO NOT open the strainer pot if pump fails to prime or if pump has been operating without water in

the strainer pot. Pumps operated in these circumstances may experience a build up of vapor pressure

and may contain scalding hot water. Opening the pump may cause serious personal injury. In order

to avoid the possibility of personal injury, make sure the suction and discharge valves are open and

strainer pot temperature is cool to touch, then open with extreme caution.

Be sure not to scratch or mar the polished shaft seal faces; seal will leak if faces are damaged.

Pump Disassembly

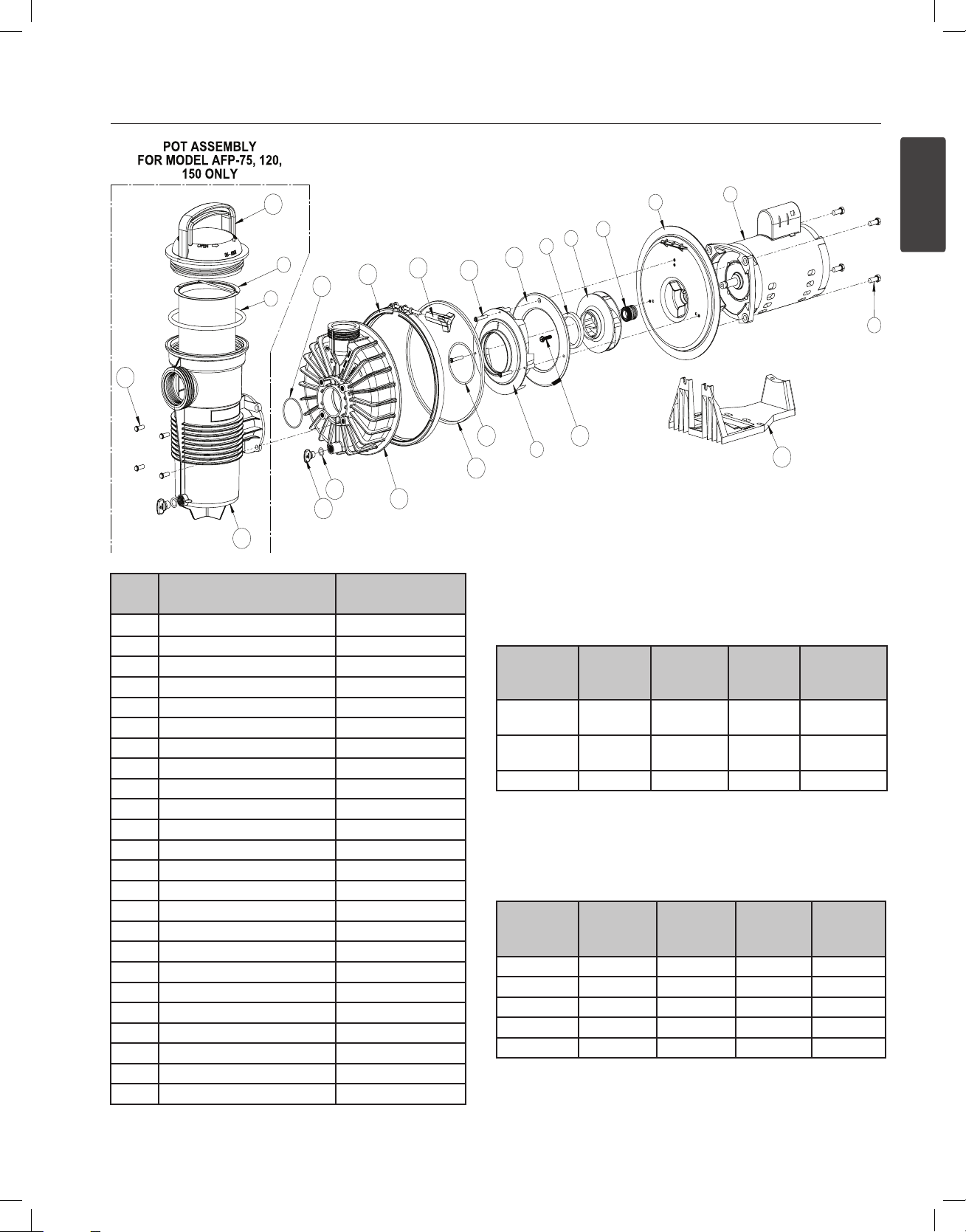

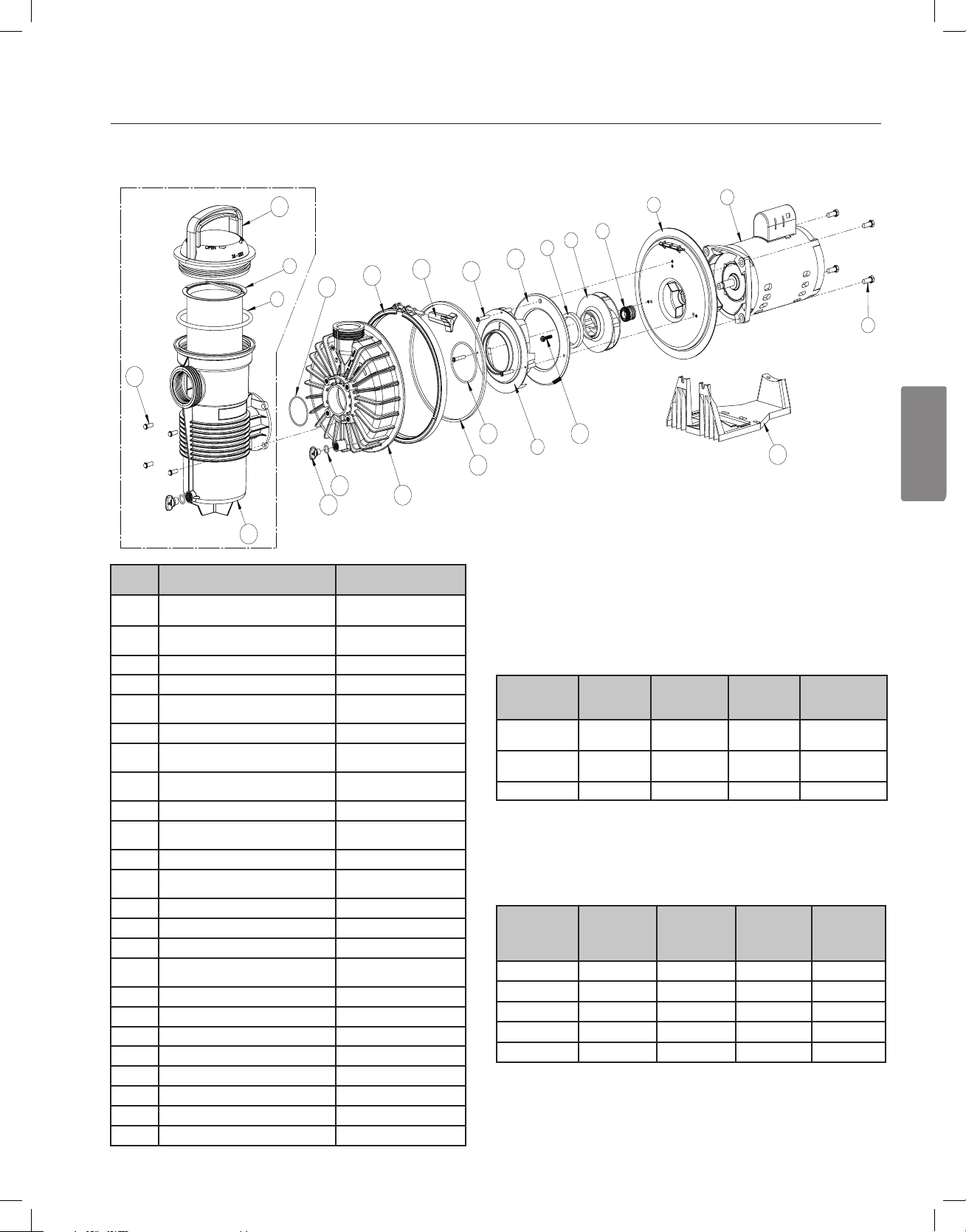

All moving parts are located in the rear sub-assembly of this pump. Refer to Figure 5 on page 10 for an illustrated

parts view.

Tools required:

• 1/4-inch Flat Blade Screwdriver

• 3/8-inch or 1/2-inch Flat Blade Screwdriver

• 9/16-inch Open End Wrench

• Rubber Mallet

• Adjustable Wrench or Locking Pliers

To remove and repair the motor sub-assembly perform the following procedures:

1. Turn off the pump circuit breaker at the main panel. Close suction and discharge valves to relieve system

pressure.

2. Drain the pump by removing the drain plugs. The drain plugs can be removed by hand. No tools are needed.

3. Loosen the band clamp by turning the band clamp knob counter-clockwise. The band clamp holds the rear subassembly to the housing (strainer pot/volute).

4. Remove the rear sub-assembly from the housing (strainer pot/volute) and place the band clamp to the side.

Note: If the band clamp does not separate from the pump housing and seal plate when loose, lightly tap the top of

the band clamp with a rubber mallet. This will free the clamp from the housing.

5. Place the rear sub-assembly upright and on a flat surface. Use a flat blade screwdriver to remove the three (3)

holding screws located on the diffuser.

6. Remove the diffuser and diffuser spacer from the rear sub-assembly.

7. Use a flat blade screwdriver to remove the impeller screw located in the center of the pump’s impeller.

Note: The impeller screw is a left-handed thread and loosens in a clockwise direction.

8. Use the 3/8-inch or 1/2-inch flat blade screwdriver to hold the motor shaft in place. The motor shaft is accessible

through the back of the motor.

Note: If the torque is too high to hold the screwdriver by hand then an adjustable wrench may be used to hold the

screwdriver shaft in place. Use locking pliers instead if your screwdriver has a round shaft.

Page 13

9

WATERFALL™ Specialty Pump Installation and User’s Guide

ENGLISH

Pump Disassembly (continued)

9. Unscrew the impeller from the motor shaft by twisting the impeller counter-clockwise.

10. Remove the rotating portion of the spring seal by hand.

Note: When placing the rotating seal to the side, ALWAYS place flat side down. The portion of the rotating spring

seal that contacts the white ceramic seal must be kept as free from contaminants (dust, dirt, debris, etc.) as possible.

11. Use the 9/16-inch wrench to remove the four (4) bolts that hold the motor to the seal plate.

Shaft Seal Replacement

The mechanical seal can be changed without disconnecting piping by removing the band clamp and pulling the motor

with pump bracket diffuser and impeller assembly away from front pump housing body.

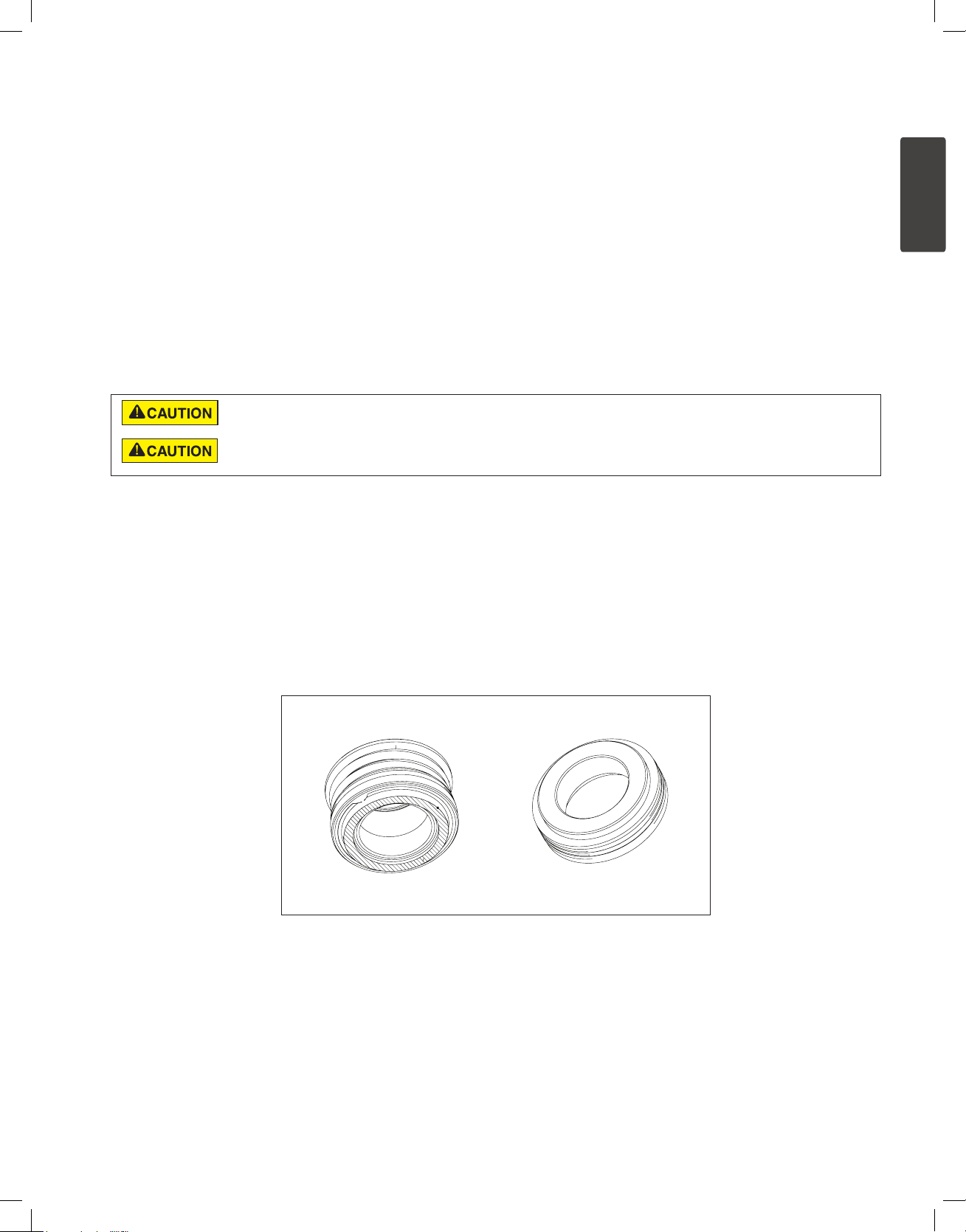

The Shaft Seal consists primarily of two parts, a rotating spring seal and a ceramic seal. See Figure 4.

The Waterfall™ Specialty Pump requires little or no service other than reasonable care, however, a Shaft Seal may

occasionally become damaged and must be replaced.

The polished and lapped faces of the seal could be easily damaged if not handled with care.

In mild climate area, when temporary freezing conditions may occur, run your filtering equipment all night to

prevent freezing.

To replace the pump seal:

12. Follow steps 1-11 in the “Pump Disassembly” section.

13. Place the seal plate face down on a flat surface and tap out the old ceramic seal.

14. Lubricate the seal seat with clean water.

15. Press the new ceramic seal into the seal plate with your thumbs and wipe off the white ceramic with a clean cloth.

16. Using a 9/16-inch wrench, remount the seal plate to the motor via the four (4) bolts that hold the motor to the seal plate.

17. Grease the motor shaft thread and continue with steps 2-10 from the “Pump Reassembly” section to reassemble

the pump.

Spring Seal Ceramic Seal

Figure 4

Page 14

10

WATERFALL™ Specialty Pump Installation and User’s Guide

Pump Reassembly

1. Use the 9/16-inch wrench to remount the seal plate to the motor via the four (4) bolts that hold the motor to the seal

plate.

2. Reseat the spring seal onto the white ceramic seal. Ensure that the carbon face of the spring seal contacts the

ceramic face of the stationary seat.

3. Grease the motor shaft thread and screw the impeller onto the motor shaft.

Note: Use the 3/8-inch or 1/2-inch flat blade screwdriver to hold the motor shaft in place when screwing down the

impeller. The motor shaft is accessible through the back of the motor.

4. Using a flat blade screwdriver, screw in the impeller lock screw.

Note: The impeller screw is a left-handed thread and tightens in a counter-clockwise direction.

5. Remount the diffuser spacer and diffuser using a flat blade screwdriver and the three (3) diffuser screws.

6. Reseat the pump housing (strainer pot/volute) onto the rear sub-assembly.

7. Place the band clamp around the pump housing an rear sub-assembly. Tighten with the band clamp knob.

Note: The band clamp knob should be parallel to the floor of the equipment pad when the clamp is installed properly.

8. Reinstall the drain plugs. Hand tighten only!

9. Fill the pump strainer pot with water.

10. Refer to page 5 “Initial Start-Up” procedures to restart the pump.

Figure 5

Page 15

11

WATERFALL™ Specialty Pump Installation and User’s Guide

ENGLISH

RESTART INSTRUCTIONS

If the Waterfall™ Specialty Pump is installed below the water level of the pool, close return and suction lines prior to

opening hair and lint pot on pump. Make sure to reopen valves prior to operating.

DO NOT run the pump dry. If the pump is run dry, the mechanical seal will be damaged and the pump will start

leaking. If this occurs, the damaged seal must be replaced. ALWAYS maintain proper water level in your pool

(half way up skimmer opening). If the water level falls below the skimmer opening, the pump will draw air through the skimmer,

losing the prime and causing the pump to run dry, resulting in a damaged seal. Continued operation in this matter could cause a

loss of pressure, resulting in damage to the pump case, impeller, and seal and may cause property damage and personal injury.

Priming the Pump

The pump strainer pot must be filled with water before the pump is initially started. Follow these steps to prime the pump:

1. Remove the pump lid.

2. Fill the pump strainer pot with water.

3. Reassemble the pump lid onto the strainer pot. The pump is now ready to prime.

4. Open the air release valve on the filter, and stand clear of the filter.

5. Turn on the switch or time clock.

6. When water comes out of the air release valve, close the valve. The system should now be free of air and recirculating

water to and from the pool.

7. This pump will prime within thirty (30) minutes. Do not allow your pump to run longer than this time without developing

full flow. If the pump does not prime, see “Troubleshooting” on page 12.

8. Two speed pumps should run on high speed for priming.

Page 16

12

WATERFALL™ Specialty Pump Installation and User’s Guide

TROUBLESHOOTING

Use the following troubleshooting information to resolve possible Waterfall™ Specialty Pump problems.

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION.

Improper installation will create an electrical hazard which could result in death or serious injury to

pool users, installers, or others due to electrical shock, and may also cause damage to property.

1. If you are not familiar with your pool filtering system and/or heater:

a. DO NOT attempt to adjust or service without consulting your dealer, or a qualified

pool professional.

b. Read the entire Installation & User’s Guide before attempting to use, service or adjust

the pool filtering system or heater.

2. SWITCH OFF power to the pump at the breaker before attempting service or repair.

Problems and Corrective Actions

Problem Cause Remedy

Pump will not prime 1. No water in strainer pot. Add water to pot.

2. Strainer pot lid is not tight. Tighten lid.

3. Damaged lid o-ring. Replace o-ring.

4. Water level is below skimmer. Adjust pool water level.

5. Strainer basket or skimmer basket is clogged. Clear basket.

6. Closed valve in piping system. Check all valves and open all

necessary valves.

7. Pump is on low speed (two speed units only). Adjust to high speed.

8. Air leak in suction line. Find & fix leak.

Low Flow 1. Restriction in return line. Open return line restriction.

2. Strainer basket or skimmer basket is clogged. Clean basket.

3. Clogged impeller. Clean obstruction.

4. Air leak in suction line. Find & fix leak.

5. Restriction in suction line. Find and open restriction.

Motor does not turn 1. Power switch is off. Check power switch & reset.

2. Circuit breaker has tripped. Check circuit breaker & reset, if

re-trips, contact electrician.

3. Pump is in “Off-mode” on a timer controlled circuit. Check timer mode.

4. Motor terminal connections are incorrect. Have terminal connections checked by

electrician.

5. Motor shaft is locked by bad bearing. Have motor bearings replaced or

replace pump.

6. Impeller is locked by debris. Clean impeller.

Motor Over-Heating 1. Electrical supply connections are incorrect. Have terminal connections checked by

electrician.

2. Wiring to pump is undersized. Consult electrician to rewire pump.

3. Power Company supply voltage is low. Notify Power Company.

4. Ventilation is inadequate for motor. Remove any restrictions to air flow.

Page 17

13

WATERFALL™ Specialty Pump Installation and User’s Guide

ENGLISH

1

2

4

5

6

12

11

13

7

15

18

14

17

19

20

21

16

3

23

8

10

24

9

22

REPLACEMENT PARTS

ITEM

#

1 Motor See Motor Table

2 Seal Plate See Strainer Table

3 Motor Bolt (4x) 070429

4 Seal 354545S

5 Impeller See Motor Table

6 Nose Bearing 355142

7 Diffuser See Motor Table

8 Strainer Basket See Strainer Table

9 Lid O-ring 350013

10 Lid See Strainer Table

11 Impeller Screw 355389

12 Diffuser Spacer See Motor Table

13 Diffuser Screw (3x) 355141

14 Diffuser O-ring 355227

15 Seal Plate O-ring 355329

16 Housing See Strainer Table

17 Band Clamp 354629

18 Band Clamp Knob 175025

19 Base 355305

20 Drain Plug O-ring (2x) 192115

21 Drain Plug (2x) 357161

22 Front Housing O-ring 355330

23 Strainer Pot 355300

24 Strainer Pot Bolt (4x) 354265

DESCRIPTION

PART

NUMBERS

Motor Table

Model

AFP-75,

AF-75

AFP-120,

AF-120

AFP-150 356075** 355220 355140 355495

Motor

(Item #1)

356076* 355544 355545 355317

356076* 355068 355069 355495

Impeller

(Item #5)

Diffuser

(Item #7)

(*) - Replaced P/N 355218 after May 2019

(**) - Replaced P/N 355222 after May 2019

Strainer Table

Model

AFP-75 355303 355387 355301 355468

AFP-120 355497 355387 355301 355468

AFP-150 355497 355441 355300 355468

AF-75 355303 - - 355302

AF-120 355497 - - 355302

Seal Plate

(Item #2)

Strainer

Basket

(Item #8)

Lid

(Item #10)

Diffuser

Spacer

(Item #12)

Housing

(Item #16)

Page 18

1620 HAWKINS AVE., SANFORD, NC 27330 • (919) 566-8000

*355143*

10951 WEST LOS ANGELES AVE., MOORPARK, CA 93021 • (805) 553-5000

WWW.PENTAIR.COM

All Pentair trademarks and logos are owned by Pentair or one of its global aliates. Waterfall™ is a trademark of Pentair Water Pool and Spa, Inc. and/or

its aliated companies in the United States and/ or other countries. Unless expressly noted, names and brands of third parties that may be used in this

document are not used to indicate an aliation or endorsement between the owners of these names and brands and Pentair Water Pool and Spa, Inc.

Those names and brands may be the trademarks or registered trademarks of those third parties. Because we are continuously improving our products

and services, Pentair reserves the right to change specications without prior notice. Pentair is an equal opportunity employer.

© 2019 Pentair Water Pool and Spa, Inc. All rights reserved. This document is subject to change without notice.

P/N 355143 REV. D 5/17/19

Page 19

ENGLISH

ESPAÑOL

WATERFALL™

BOMBA ESPECIAL

MANUAL DE INSTALACIÓN

GUÍA DEL USUARIO

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

LEA Y SIGA TODAS LAS INSTRUCCIONES

GUARDE ESTAS INSTRUCCIONES

Page 20

Manual de instalación y guía del usuario de la bomba especial WATERFALL™

i

SERVICIO AL CLIENTE / SOPORTE TÉCNICO

Si tiene dudas acerca de cómo pedir piezas de repuesto de Pentair y productos para piscina, comuníquese con:

Servicio al cliente y soporte técnico, EE. UU.

(8 a. m. a 7:30 p. m. hora del este/Pacífico)

Teléfono: (800) 831-7133

Fax: (800) 284-4151

Sitio web

Para obtener más información acerca de los

productos Pentair, visite www.pentair.com.

ÍNDICE

Advertencias e instrucciones de seguridad

importantes de la bomba .....................................

Introducción ..........................................................

Vista general de la bomba

Canasta del colador de la bomba

Instalación ............................................................

Ubicación

Selección de bomba y tubería

Instalación de tuberías, conexiones y válvulas

Instalación eléctrica

Cableado

Conexión a tierra

Empalmes

Funcionamiento de la bomba ..............................

Arranque inicial

Mantenimiento ......................................................

Limpieza de la canasta del colador

Preparación para el invierno

Cuidado del motor

Sanford, North Carolina (8 a. m. a 4:30 p. m. hora del este)

Teléfono: (919) 566-8000

Fax: (919) 566-8920

Moorpark, California (8 a. m. a 4:30 p. m. hora del Pacífico)

Teléfono: (805) 553-5000 (Ext. 5591)

Fax: (805) 553-5515

Servicio ...............................................................

ii

1

1

1

2

2

2

3

4

4

4

4

5

5

6

6

7

7

Desmontaje de la bomba

Reemplazo del sello del eje

Volver a montar la bomba

Instrucciones de reinicio ...................................

Cebado de la bomba

Solución de problemas ......................................

Piezas de reemplazo ..........................................

8

8

9

10

11

11

12

13

P/N 355143 Rev. D 5/17/19

Page 21

Manual de instalación y guía del usuario de la bomba especial WATERFALL™

ENGLISH

ESPAÑOL

ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD IMPORTANTES DE LA BOMBA

PELIGRO

PELIGRO

F

PELIGRO

Advertencias generales

NOTA IMPORTANTE

Esta guía ofrece las instrucciones de instalación y operación para este producto.

Consulte a Pentair por cualquier pregunta relacionada con este equipo.

Atención, instalador: Esta guía contiene información importante sobre

la instalación, la operación y el uso seguro de este producto. Se le debe

proporcionar esta información al dueño y/u operador del equipo luego de la

instalación o se debe dejar esta información encima o cerca de la bomba.

Atención, usuario: Este manual contiene información importante que

le ayudará a operar y mantener este producto. Por favor, consérvelo para

futura referencia.

LEA Y SIGA

TODAS LAS INSTRUCCIONES

GUARDE ESTAS INSTRUCCIONES

Este es el símbolo de alerta de seguridad. Cuando vea

este símbolo en su sistema o en este manual, busque

una de las siguientes palabras de señal y esté alerta a

la posibilidad de que alguna persona resulte lesionada.

Advierte sobre peligros que pueden causar la muerte,

serias lesiones personales o daños importantes a la

propiedad si se ignoran.

Advierte sobre peligros que pueden causar la muerte,

serias lesiones personales o daños importantes a la

propiedad si se ignoran.

Advierte sobre peligros que pueden provocar lesiones

personales leves o daños a la propiedad si son

ignorados.

NOTA indica instrucciones especiales no relacionadas con peligros.

Lea y siga cuidadosamente todas las instrucciones de seguridad en este

manual y en relación a los equipos. Conserve las etiquetas de seguridad

en buenas condiciones; reemplácelas si faltan o están dañadas.

• Nunca se debe abrir el interior del recinto del motor del accionador.

Hay un bloque de condensadores con una carga de 230 VCA incluso

cuando la unidad no está conectada a la fuente de alimentación.

• La bomba no es sumergible.

• La bomba puede alcanzar caudales de salida elevados; tenga cuidado

al instalar y programar el límite potencial de rendimiento de las bombas

con equipos antiguos o dudosos.

• Los códigos requeridos para la conexión eléctrica varian dependiendo

del país, estado o municipalidad local. Instale el equipo de acuerdo al

código de electricidad nacional y todos los demás códigos y normas

aplicables.

• Antes de efectuar el mantenimiento de la bomba; apague la alimentación

de energía eléctrica a la bomba desconectando el circuito principal

que va hacia la bomba.

• Este artefacto no debe ser utilizado por personas (incluyendo niños)

con capacidades físicas, sensoriales o mentales reducidas, o que no

tengan la experiencia y los conocimientos, a menos que hayan sido

supervisados o instruidos en el uso del artefacto por una persona

responsable por su seguridad.

EL INCUMPLIMIENTO DE TODAS LAS

INSTRUCCIONES Y ADVERTENCIAS PUEDE DAR

COMO RESULTADO LESIONES CORPORALES SERIAS O LA MUERTE.

ESTA BOMBA DEBE SER INSTALADA Y MANTENIDA ÚNICAMENTE POR

UN PROFESIONAL DE MANTENIMIENTO DE PISCINAS CUALIFICADO.

LOS INSTALADORES, OPERADORES DE PISCINAS Y DUEÑOS DEBEN

LEER ESTAS ADVERTENCIAS Y TODAS LAS INSTRUCCIONES EN

EL MANUAL DEL USUARIO ANTES DE USAR ESTA BOMBA. ESTAS

ADVERTENCIAS Y EL MANUAL DEL USUARIO DEBEN QUEDARSE

CON EL DUEÑO DE LA PISCINA.

PELIGRO DE ATASCAMIENTO: ¡MANTÉNGASE

ALEJADO DEL DRENAJE PRINCIPAL Y DE TODAS

LAS SALIDAS DE SUCCIÓN!

ii

Cuando instale y use estos equipos eléctricos, siempre se deben seguir las

precauciones de seguridad básicas, entre las que se incluye las siguientes:

No permita que los niños usen este producto.

RIESGO DE DESCARGA ELÉCTRICA. (Para todas las

unidades instaladas de manera permanente, diseñadas

para usarse en circuitos derivados monofásicos de 15 o 20 amperes y 125 a 240

voltios). Conecte solamente a un circuito derivado protegido por un interruptor

de circuito por falla a tierra (GFCI). Contacte a un electricista cualificado si no

puede verificar que el circuito esté protegido por un GFCI. Esta unidad debe

conectarse solamente a un circuito de alimentación protegido por un interruptor

de circuito por falla a tierra (GFCI). Dicho GFCI debe proporcionarlo el instalador

y debe ser sometido a pruebas de rutina. Para probar el GFCI, oprima el botón

de prueba. El GFCI debe cortar la energía. Oprima el botón de reanudar.

La energía debería restaurarse. Si el interruptor de circuito por falla a tierra

(GFCI) no puede funcionar de esta manera, el GFCI es defectuoso. Si el GFCI

interrumpe la alimentación a la bomba sin haberse oprimido el botón de prueba,

estará fluyendo una corriente a tierra, indicando la posibilidad de un choque

eléctrico. No use esta bomba. Desconecte la bomba y pídale a un representante

de servicio cualificado que corrija el problema antes de usarla.

Esta bomba es para ser utilizada en piscinas

permanentes y también puede usarse con jacuzzis y

spas, si así se especifica. No la use con piscinas que se deban almacenar.

Una piscina instalada permanentemente se construye en el suelo o en un

edificio de manera tal que no se pueda desmontar para ser almacenada.

Una piscina que se debe almacenar está construida con el fin de poder

desmontarla fácilmente para su almacenamiento y montarla nuevamente

con posterioridad.

ESTA BOMBA PRODUCE ALTOS NIVELES DE SUCCIÓN Y CREA UN

FUERTE VACÍO EN EL DRENAJE PRINCIPAL, EN LA PARTE INFERIOR

DE LA MASA DE AGUA. LA SUCCIÓN ES TAN FUERTE QUE PUEDE

ATRAPAR A ADULTOS O NIÑOS BAJO EL AGUA SI SE ENCUENTRA

PRÓXIMOS A UN DRENAJE O A UNA CUBIERTA O REJILLA ROTA O

SUELTA DEL DRENAJE.

EL USO DE CUBIERTAS INADECUADAS O PERMITIR EL USO DE LA

PISCINA O EL SPA CUANDO HAY CUBIERTAS AUSENTES, FISURADAS

O ROTAS PUEDE DAR COMO RESULTADO EL ATASCO DE ALGUNA

PARTE DEL CUERPO O ARTICULACIÓN, ENREDO DE CABELLO,

ATASCO DEL CUERPO, EVISCERACIÓN Y/O LA MUERTE.

La succión en el drenaje o salida puede causar:

Atascamiento de un miembro: Cuando un miembro del cuerpo es

succionado o insertado en una abertura y produce una obstrucción o

atrapamiento mecánico. Este peligro se presenta cuando la cubierta de

un drenaje falta, está rota, suelta, fisurada o incorrectamente asegurada.

Enredo de cabellos: Cuando el cabello se enreda o anuda en la cubierta del

drenaje y atrapa al nadador debajo del agua. Este peligro se presenta cuando

la velocidad del flujo de la cubierta es demasiado baja para la(s) bomba(s).

Atascamiento del cuerpo: Cuando una parte del cuerpo queda atrapada

contra la cubierta del drenaje manteniendo al nadador debajo del agua.

Este peligro se presenta cuando la cubierta del drenaje falta, está rota o

cuando la velocidad de flujo de la cubierta no es lo suficientemente alta

para la(s) bomba(s).

Evisceración/desentrañamiento: Cuando una persona se sienta en una

piscina abierta (particularmente una piscina de chapoteo para niños) o en la

salida de un spa y se aplica la succión directamente a los intestinos, causando

un daño intestinal severo. Este peligro se presenta cuando la cubierta del drenaje

falta, está suelta, fisurada o incorrectamente asegurada.

Page 22

Manual de instalación y guía del usuario de la bomba especial WATERFALL™

iii

PELIGRO

ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD IMPORTANTES DE LA BOMBA

Atrapamiento mecánico: Cuando las joyas, el traje de baño, los accesorios

para el cabello, lo dedos de manos o pies, o un nudillo se atascan en la abertura

de una salida o de una cubierta de drenaje. Este peligro se presenta cuando la

cubierta del drenaje falta, está suelta, rota, fisurada o incorrectamente asegurada.

NOTA: TODA LA FONTANERÍA DE SUCCIÓN DEBE INSTALARSE

EN CONFORMIDAD CON LOS ÚLTIMOS CÓDIGOS, ESTÁNDARES Y GUÍAS

NACIONALES Y LOCALES.

PARA MINIMIZAR EL RIESGO DE LESIONES DEBIDO

AL PELIGRO DE ATASCO POR SUCCIÓN:

• Para cada drenaje, se debe usar una cubierta de succión anti-atascos

apropiadamente instalada y asegurada y aprobada por el ANSI/ASME A112.19.8.

• Cada cubierta de succión debe ser instalada al menos a tres pies (3’) de

distancia, medidos desde el punto más cercano hasta el punto más cercano.

• Inspeccione todas las cubiertas con regularidad en busca de fisuras, daños e

intemperización avanzada.

• Si una cubierta está suelta, fisurada, dañada, rota o ausente, reemplácela con

una cubierta certificada apropiada.

• Reemplace la cubierta del drenaje según sea necesario. Las cubiertas del drenaje

se deterioran con el tiempo debido a la exposición a la luz solar y el clima.

• Evite que el cabello, los miembros superiores e inferiores o el cuerpo estén en

proximidad cercana a las cubiertas de succión, el drenaje o la salida de la piscina.

• Deshabilite las salidas de la succión o vuelva a configurar las entradas de retorno.

La Ley de Seguridad para Piscinas y Spas Virginia Graeme Baker (VGB) crea

nuevos requerimientos para los dueños y operadores de piscinas y spas comerciales.

Las piscinas o spas comerciales construidos el 19 de diciembre de 2008 o después

de esa fecha, deberán utilizar:

(A) Un sistema de drenaje principal sin capacidad de aislamiento con cubiertas

de salida de succión que cumplan con el ASME/ANSI A112.19.8a en relación a

aditamentos de succión para uso en piscinas, piscinas de chapoteo, spas y jacuzzis,

y, ya sea:

(i) Un sistema de liberación de vacío de seguridad (SVRS) que cumpla con el estándar

ASME/ANSI A112.19.17 de sistemas de seguridad de liberación del vacío (SVRS)

fabricados para sistemas de piscina, spa, jacuzzi y piscina de niños residenciales

y comerciales, y/o la especificación del estándar ASTM F2387 para sistemas de

seguridad de liberación del vacío (SVRS) fabricados para piscinas, spas y jacuzzis o

(ii) Un sistema de ventilación limitado por succión debidamente diseñado y

comprobado o

(iii) Un sistema de apagado de bomba automático.

Las piscinas o spas comerciales construidos antes del 19 de diciembre de 2008, con

una sola salida de succión sumergida deberán usar una cubierta de la salida de la

succión que cumpla con el ASME/ANSI A112.19.8a y, ya sea:

(A) Un sistema de liberación de vacío de seguridad (SVRS) que cumpla con las

normas ASME/ANSI A112.19.17 y/o ASTM F2387, o

(B) Un sistema de ventilación limitado por succión debidamente diseñado y

comprobado, o

(C) Un sistema de apagado de bomba automático, o

(D) Bocas sumergidas desactivadas, o

(E) Las salidas de succión se deben configurar nuevamente como entradas de retorno.

Para la instalación de los controles eléctricos en la plataforma del equipo

(interruptores de encendido/apagado, temporizadores y centro de carga

automatizada)

Instale todos los controles eléctricos en la plataforma del

equipo, como los interruptores de encendido/apagado (ON/

OFF), los cronómetros y los sistemas de control, etc. para

permitir la operación (arranque, cierre o mantenimiento)

de cualquier bomba o filtro para que el usuario no coloque

ninguna porción de su cuerpo sobre o cerca de la tapa

coladora de la bomba, la tapa del filtro o los cierres de

la válvula. Esta instalación debe otorgar al usuario suficiente espacio para

mantenerse alejado del filtro y la bomba durante el arranque del sistema, el cierre

o el mantenimiento del filtro del sistema.

Debe haber un interruptor de cierre de emergencia

claramente etiquetado para la bomba en un lugar obvio

y de fácil acceso. Asegúrese que los usuarios sepan dónde está y cómo usarlo

en caso de emergencia.

PRESIÓN PELIGROSA: MANTENGA DISTANCIA DE

LA BOMBA Y EL FILTRO DURANTE EL ARRANQUE

Los sistemas de circulación funcionan bajo alta presión.

Cuando se hace mantenimiento a una parte del sistema

de circulación (es decir, el anillo de bloqueo, la bomba,

el filtro, las válvulas, etc.), el aire puede ingresar al

sistema y presurizarse. El aire presurizado puede hacer

que las válvulas y la tapa del filtro de la cubierta de la carcasa de la bomba se

separen violentamente, lo que puede ocasionar lesiones personales severas

o la muerte. La tapa del tanque del filtro y la cubierta del colador deben estar

correctamente aseguradas para evitar la separación violenta. Manténgase

alejado de los equipos del sistema de circulación de aire cuando encienda o

haga arrancar la bomba.

Antes de efectuar el mantenimiento a los equipos, tome nota de la presión del

filtro. Asegúrese de que todos los controles estén configurados para garantizar

que el sistema no arranque inadvertidamente durante el mantenimiento. Apague

toda alimentación a la bomba. IMPORTANTE: Coloque la válvula manual

de alivio de aire del filtro en posición abierta y espere que se alivie toda

la presión que se encuentra en el sistema.

Antes de hacer arrancar el sistema, abra completamente la válvula manual de

alivio de aire y coloque todas las válvulas del sistema en la posición abierta

para permitir que el agua fluya libremente desde el tanque y de regreso a él.

Manténgase alejado de todos los equipos y encienda la bomba.

IMPORTANTE: No cierre la válvula manual de alivio de aire del filtro hasta

que toda la presión haya sido descargada de la válvula y que aparezca

una corriente constante de agua. Observe el medidor de presión del filtro y

asegúrese de que no sea más alta que la condición previa al mantenimiento.

Información de instalación general

• Todo el trabajo debe realizarlo un profesional de servicio cualificado, y debe

cumplir con todos los códigos nacionales, estatales y locales.

• Instale de manera tal que haya drenaje del compartimiento para los

componentes eléctricos.

• Estas instrucciones contienen información para una variedad de modelos

de bombas y por tanto algunas instrucciones podrían no aplicarse a un

cierto modelo específico. Todos los modelos han de usarse en piscinas. La

bomba funcionará correctamente solamente si tiene el tamaño adecuado

en relación a la aplicación y si está apropiadamente instalada.

Las bombas de tamaño incorrecto o mal instaladas

o que se usen con aplicaciones diferentes a las que

fueron diseñadas para la bomba pueden provocar graves lesiones personales

o la muerte. Estos riesgos pueden incluir, entre otros, choques eléctricos,

incendios, inundaciones, atascamientos por succión o lesiones graves o

daños a la propiedad provocados por una falla estructural de la bomba u otro

componente del sistema.

La bomba puede producir altos niveles de succión del

lado de la succión del sistema de conexiones. Estos

niveles elevados de succión pueden representar un riesgo si una persona

se encuentra muy cerca de las aberturas de succión. La persona puede

lesionarse seriamente debido a este alto nivel de vacío, o puede atascarse y

ahogarse. Es absolutamente crítico que las conexiones de succión se instalen

de acuerdo con los códigos nacionales y locales para piscinas más recientes.

Las bombas y los motores de repuesto con velocidad única y un

(1) HP total o superior no se pueden vender, poner a la venta o

instalar en un grupo residencial para su uso en California, Título

20 del CCR, secciones 1601-1609.

Las advertencias y las instrucciones de seguridad para las bombas y otros

productos relacionados de Pentair Water Pool and Spa, Inc. se encuentran

disponibles en:

http://www.pentairpool.com/pool-owner/safety-warnings/ o llame al

(800) 831-7133 para obtener copias adicionales y gratuitas de las instrucciones.

Consulte en http://www.pentairpool.com/pool-owner/safety-warnings/ para

ver las instrucciones de advertencia y seguridad relacionadas con este producto.

Warning Page P/N 352557 Rev. C 7/18

Page 23

Manual de instalación y guía del usuario de la bomba especial WATERFALL™

ENGLISH

ESPAÑOL

INTRODUCCIÓN

Vista general de la bomba

Las bombas para piscinas comunes están diseñadas para que el agua circule a través de sistemas de tuberías con

pérdidas relativamente altas, lo que incluye muchas restricciones con respecto a las tuberías (por ejemplo, filtro para

piscinas, válvulas, calentador, conexiones para tuberías pequeñas, etc.) y, por lo tanto, deben generar una cantidad

significativa de presión para empujar el agua a través de todos los componentes. Si se instalan en sistemas de

tuberías que no tienen estos tipos de restricciones, las bombas para piscina tendrán un funcionamiento muy ruidoso

y a veces dañan el sistema mediante la cavitación.

La bomba especial Waterfall™ está específicamente diseñada para estos tipos de aplicaciones donde se necesita

suministrar el agua de manera silenciosa y eficiente a través de sistemas de tuberías con bajas restricciones. Estas

aplicaciones suelen requerir una bomba para crear efectos visuales como saltos, cascadas y aliviaderos, o cuando el

agua debe ser trasladada una distancia relativamente corta.

Esta bomba no está diseñada para usar como una bomba de filtración para piscinas común o en aplicaciones para

spa donde se requiere presión. Tampoco está diseñada para usar en sistemas donde se debe elevar el agua a más

de 10 pies (3 metros) sobre el depósito de la piscina.

Canasta del

colador

1

Bomba especial Waterfall

Canasta del colador de la bomba

La canasta del colador, conocida algunas veces como el ‘colector de cabello y pelusa’, se encuentra delante de

la carcasa de la bomba. La canasta, que debe estar siempre libre de hojas y residuos, se encuentra dentro de la

cámara.

Independientemente de cuánto tiempo pase entre limpiezas del filtro, es muy importante realizar una inspección

visual del colector de cabello y pelusa al menos una vez por semana. Una canasta sucia reducirá la eficiencia del

filtro y del calentador, además de que provocará un esfuerzo anormal en el motor de la bomba.

Page 24

2

Manual de instalación y guía del usuario de la bomba especial WATERFALL™

3 IN.

(7.6 CM)

MÍNIMO

5 x DIÁMETRO DE

TUBERÍA DE SUCCIÓN

CODO

12 IN

(30.5 CM)

MÍNIMO

INSTALACIÓN

Ubicación

Asegúrese de que la ubicación de la bomba especial

Waterfall™ cumpla con los siguientes requerimientos:

Nota: No instale esta bomba dentro de un

compartimiento externo o bajo el faldón de un

jacuzzi o spa, a menos que se marque de manera

correspondiente.

1. Instale la bomba tan cerca como pueda de la

piscina o spa. Para reducir la pérdida de fricción

y mejorar la eficiencia, use retornos de tubería de

succión corta y directa.

2. Instale como mínimo a 5 pies (1.5 metros) de la pared interna de la piscina o spa. Las instalaciones canadienses

requieren un mínimo de 9.8 pies (3 metros) desde el agua de la piscina.

3. Instale la bomba a un mínimo de 3 pies (0.9 metros) desde la salida del calentador.

4. No instale la bomba a más de 5 pies (1.5 metros) sobre el nivel del agua.

5. Instale la bomba en un lugar bien ventilado y protegido de la humedad excesiva (es decir, de desagües de

canaletas para la lluvia, rociadores de agua, etc.).

6. Instale la bomba con una holgura trasera de por lo menos 3 pulgadas (7.6 cm) para poder quitar el motor

fácilmente a fin de realizar su mantenimiento o reparación. Se requiere una holgura vertical de 12 pulgadas (30.5

cm) para quitar la canasta del colador. Véase la Figura 1.

Figura 1

Selección de bomba y tubería

Muchas instalaciones necesitan que la bomba eleve el agua varios pies para suministrar agua para una cascada o

decorativos acuáticos similares. Para esta elevación se necesita energía y, por lo tanto, se reduce la cantidad de flujo

que la bomba puede suministrar. Consultar la Tabla 1 para calcular la pérdida de flujo.

Siempre se recomienda que se calcule y se compare la pérdida de carga del sistema total con la curva de

rendimiento de la bomba antes de seleccionar los tamaños de la bomba y de la tubería. Sin embargo, la Tabla 2 se

puede usar como guía rápida para seleccionar la bomba y el tamaño de las tuberías en instalaciones simples.

Tabla 1: Efecto del cambio de elevación en el

Cambio de

elevación

Más de 15’

Menos

de 2’

2’ - 4’

4’ - 10’

10’ - 15’

flujo

Efecto en el flujo

Reducción insignificante del flujo si se instalan las

tuberías según las instrucciones.

Reducción leve del flujo si se instalan las tuberías

según las instrucciones.

El flujo se reduce entre 50 y 90% del índice

máximo, según la elevación exacta y la instalación

del sistema. Se debe determinar la pérdida de

carga del sistema de tubería para calcular el flujo.

Por lo general, no se recomienda.

El flujo se puede reducir hasta 50% o menos del

índice máximo.

Esta pérdida puede resultar aceptable en ciertas

aplicaciones de bajo flujo.

No se recomienda. No es posible el flujo con un

cambio de elevación mayor de 27’.

Tabla 2: Recomendaciones para el tamaño de

las tuberías

Modelo de

bomba

AF-75

AFP-75

AF-120

AFP-120

AFP-150 150 GPM 2-1/2” 3”

* El flujo máximo estimado es el flujo aproximado que la bomba puede descargar

a través de un sistema corto de tubería de “flujo alto”. La bomba generará flujos

de agua más bajos si tiene que elevar el agua a una mayor altura y/o hacer

circular el agua a través de un sistema de tuberías largo.

** Se pueden usar tuberías de tamaño mínimo en instalaciones donde el sistema

de tuberías es muy corto y directo, con pocas partes o codos. En aplicaciones

donde es importante lograr el máximo flujo de agua posible, siempre se deben

usar tuberías más grandes de “flujo alto”.

Flujo máximo*

estimado

75 GPM 1-1/2” 2”

120 GPM 2” 2-1/2”

Tamaño de

tuberías

mínimo**

Tamaño de

tuberías de flujo

alto

Page 25

Manual de instalación y guía del usuario de la bomba especial WATERFALL™

ENGLISH

ESPAÑOL

Instalación de tuberías, conexiones y válvulas

1. Use cinta de sello de rosca o selladores de tubo en todas las conexiones macho de los tubos y accesorios. Use

solo compuestos selladores de tubo adecuados para la tubería de plástico. NO USE LOS PRODUCTOS A BASE

DE PETRÓLEO.

2. Apoye el tubo para evitar tensiones en el filtro, la bomba y las válvulas del sistema.

3. Cuando conecte un conjunto de unión a la bomba, aplique un sellador de tubo a las roscas y luego apriete a

mano 1½ vuelta adicional. NO APRIETE EXCESIVAMENTE.

4. Los tendidos largos de tubería y los codos obstruyen el flujo. Para una mejor eficiencia, use la menor cantidad de

conexiones posibles, un tubo de diámetro grande (por lo menos 1.5 pulgadas) y coloque el equipo lo más cerca

posible de la piscina. La línea de succión de la bomba no debe ser más pequeña que el tamaño del tubo en la

entrada de la bomba.

5. Las conexiones de succión deben cumplir con los estándares ASME/ANSI A 112.19.8 M. Use conexiones de

succión doble.

6. Para la mayoría de las instalaciones que Pentair recomienda instalar una válvula en la aspiración de la bomba

y mangueras de retorno para que la bomba puede ser aislada durante el mantenimiento rutinario. Sin embargo,

recomendamos que una válvula, codo o tee instalado en la línea de succión debe ser no más cerca de la parte

delantera de la bomba de cinco 5 veces la línea de succión de diámetro. Ver Figura 1 en la página anterior.

Ejemplo: Un tubo de 1.5 pulgadas requiere una distancia de 7.5 pulgadas (19 cm) del frente de la entrada de

succión de la bomba. Esto ayudará a que la bomba cebe más rápido y dure más.

Nota: No instale codos de 90° directamente en la entrada o toma de corriente de la bomba.

7. La presión de funcionamiento máxima de esta bomba es de 50 PSI. NUNCA se debe hacer funcionar esta

bomba por encima de esta presión.

8. Esta bomba NO está diseñada para un funcionamiento en serie con otras bombas.

3

Page 26

4

Manual de instalación y guía del usuario de la bomba especial WATERFALL™

Tornillo

a tierra

Ranura del eje

del motor para

destornillador

de cabeza plana

de 1/2” o 3/8”

Lengüeta

de empalme

Receptáculo

con tubo de

1/2" NPT para

conector de

líquido

Instalación eléctrica

RIESGO DE DESCARGA ELÉCTRICA O ELECTROCUCIÓN. Esta bomba debe ser instalada por un electricista con licencia o certificado o

por un profesional de servicios calificado conforme al Código Nacional de Electricidad (NEC) y los códigos y las ordenanzas locales aplicables.

Una instalación inadecuada generará un riesgo eléctrico que podría causar la muerte o lesiones graves a usuarios, instaladores y otras

personas debido a una descarga eléctrica, y también podría provocar daños a la propiedad.

Desconecte siempre la bomba desde el interruptor de circuito antes de realizarle el servicio. No hacerlo podría causar la muerte o