Pentair Warrior Instructions Manual

Warrior™ D.E. Filter Operating Procedures

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Table of Contents

SECTION I. FILTER INSTALLATION..................................................................................... 1

SECTION II. FILTER OPERATION........................................................................................... 4

SECTION III. TROUBLESHOOTING ...................................................................................... 10

SECTION IV. REPLACEMENT PARTS. ...................................................................................11

WARNING

Before installing this product, read and follow all warning notices and instructions accompanying

this filter. Failure to follow safety warnings and instructions can result in severe injury, death, or

property damage. Call (800) 831-7133 for additional free copies of these instructions.

SECTION I. FILTER INSTALLATION

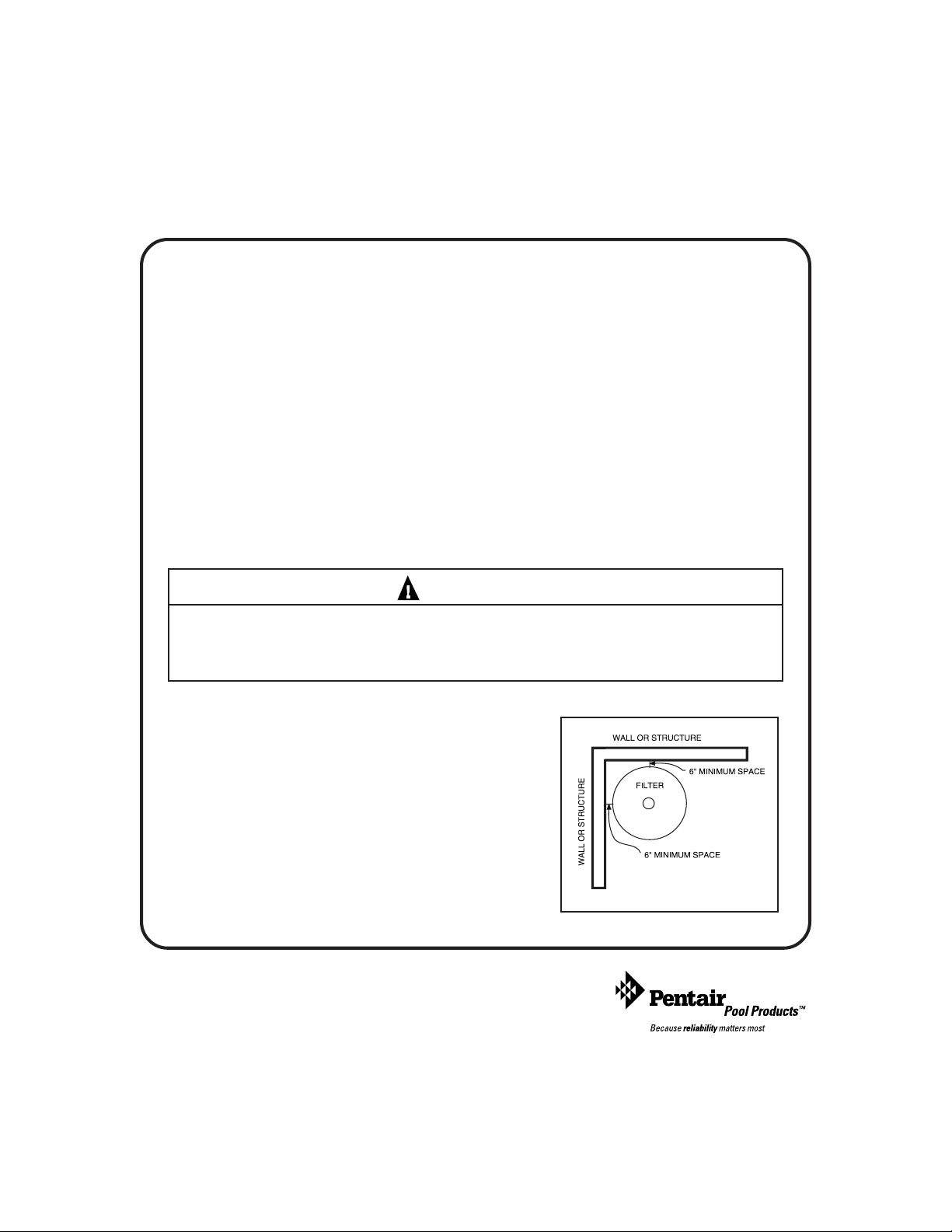

1. The filter should be mounted on a level concrete slab.

Position the filter so that the instructions, warnings

and pressure gauge are visible to the operator. Also,

position the filter so that the piping connections,

control valve and drain port are convenient and

accessible for servicing and winterizing.

Figure 1.

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

REV. D 6-8-01 1 P/N 98725500

2. Install electrical controls (e.g., on/off switches, timers control systems, etc.) at least five (5) feet

from the filter. This will allow you enough room to stand clear of the filter during system start

up.

3. Provide sufficient clearance around the filter to permit visual verification that the clamp is

properly installed, see Figure 1.

4. Provide sufficient space above the filter to remove the filter lid or control valve for cleaning and

servicing. This distance will vary with the model of filter you are using. See Table 1 for the

required vertical clearance.

WARNING

Risk of electrical shock or electrocution. Position the filter and High Flow™ manual air

relief valve to safely direct water drainage and purged air or water. Water discharged

from an improperly positioned filter or valve can create an electrical hazard that can

cause severe personal injury as well as damage property.

TABLE 1

Model Size Vertical Clearance Req.

56408600 44 GPM 36 in.

56408700 66 GPM 46 in.

56408800 88 GPM 68 in.

5. When installing the High Flow™ manual air relief valve use the O-ring only, there is no need for

thread sealing compounds. Position the filter to safely direct water drainage. Rotate the High

Flow™ manual air relief valve to safely direct purged air or water. Water discharged from an

improperly positioned filter or valve can create an electrical hazard as well as damage property.

6. Make all plumbing connections in accordance with local plumbing and building codes. Filter

plumbing connections are provided with an O-ring seal. Use only a silicone base lubricant on the

O-rings. Do not use pipe joint compound, glue or solvent on the bulkhead connections.

7. The base of this filter is provided with two (2) mounting bosses for the purpose of anchoring the

filter to the concrete.

8. The maximum working pressure of this filter is 50 psi. Never subject this filter to pressure in

excess of this amount, even when conducting hydrostatic pressure tests. Pressures above 50 psi

can cause the lid to be blown off, which can result in severe injury, death or property damage.

P/N 98725500 2 REV. D 6-8-01

When performing hydrostatic pressure tests or when testing for external leaks of the

completed filtration and plumbing system, insure that the Maximum Pressure that the

filtration system will be subjected to DOES NOT EXCEED THE MAXIMUM WORKING

PRESSURE OF ANY OF THE COMPONENTS CONTAINED WITHIN THE SYSTEM. In

most cases, the maximum pressure will be stated on each component of the system.

If doubt exists as to the pressure to which the system will be subjected, install an ASME

approved automatic Pressure Relief or Pressure Regulator in the circulation system for the

lowest working pressure of any of the components in the system.

REV. D 6-8-01 3 P/N 98725500

SECTION II. FILTER OPERATION

THIS FILTER OPERATES UNDER HIGH PRESSURE. WHEN ANY PART OF THE

CIRCULATING SYSTEM (e.g., LOCK RING, PUMP, FILTER, VALVES, ETC.) IS

SERVICED, AIR CAN ENTER THE SYSTEM AND BECOME PRESSURIZED.

PRESSURIZED AIR CAN CAUSE THE LID TO BLOW OFF WHICH CAN RESULT IN

SEVERE INJURY, DEATH, OR PROPERTY DAMAGE. TO AVOID THIS POTENTIAL

HAZARD, FOLLOW THESE INSTRUCTIONS.

1. BEFORE REPOSITIONING VALVES AND BEFORE BEGINNING THE ASSEMBLY,

DISASSEMBLY, OR ADJUSTMENT OF THE LOCK RING OR ANY OTHER

SERVICE OF THE CIRCULATING SYSTEM: (A) TURN THE PUMP OFF AND SHUT

OFF ANY AUTOMATIC CONTROLS TO ASSURE THE SYSTEM IS NOT

INADVERTENTLY STARTED DURING THE SERVICING. (B) OPEN AIR RELIEF

VALVE, AND (C) WAIT UNTIL ALL PRESSURE IS RELIEVED -PRESSURE GAUGE

MUST READ ZERO (0).

2. WHENEVER INSTALLING THE FILTER LOCK RING, FOLLOW THE FILTER LOCK

RING INSTALLATION INSTRUCTIONS EXACTLY.

WARNING

3. ONCE SERVICE ON THE CIRCULATING SYSTEM IS COMPLETE, FOLLOW

SYSTEM RESTART INSTRUCTIONS EXACTLY.

4. MAINTAIN CIRCULATION SYSTEM PROPERLY. REPLACE WORN OR DAMAGED

PARTS IMMEDIATELY (e.g., lock ring, pressure gauge, relief valve, O-rings, etc.)

5. BE SURE THAT THE FILTER IS PROPERLY MOUNTED AND POSITIONED

ACCORDING TO INSTRUCTIONS PROVIDED.

P/N 98725500 4 REV. D 6-8-01

Loading...

Loading...