Page 1

VLR

VLRI

VLRX

IT - ISTRUZIONI ORIGINALI IN LINGUA ITALIANA

133PAG.RUS1PAG. 45PAG. 67PAG. 89PA G.EDF23PA G.EN 111PA G.NLIT

Page 2

DICHIARAZIONE CE DI CONFORMITÀ

La Ditta PENTAIR INTERNATIONAL SARL dichiara sotto la propria responsabilità che i

prodotti sotto indicati sono conformi ai Requisiti Essenziali di Sicurezza e di Tutela della

Salute di cui alle Direttive sottoelencate e loro successive modifiche.

DECLARATION CE DE CONFORMITE

F D

La Société PENTAIR INTERNATIONAL SARL déclare sous sa propre responsabilité que

les produits sous-mentionnées sont conformes aux Conditions Essentielles de Sécurité

et de Tutelle de la Santé selon les directives indiquées et leurs modifications suivantes.

DECLARACIÓN CE DE CONFORMIDAD

E

La empresa PENTAIR INTERNATIONAL SARL declara bajo la propia responsabilidad

que los productos a continuación indicados cumplen con los requisitos esenciales

de seguridad y de protección de la salud establecidos en las directivas indicadas a

continuación y posteriores modificaciones.

CONFORMITEITSVERKLARING CE

NL

PENTAIR INTERNATIONAL SARL verklaart op eigen verantwoordelijkheid dat de

hieronder genoemde producten voldoen aan de essentiële eisen met betrekking tot

veiligheid en gezondheid van de onderstaande richtlijnen en latere wijzigingen.

TILLKÄNNAGIVANDE OM EU-ÖVERENSSTÄMMELSE

S

Företaget PENTAIR INTERNATIONAL SARL intygar under sitt eget ansvar att de nedan

indikerade produkterna överensstämmer med de hälso- och skyddsnormer som

specificeras i de nedanstående direktiven med senare tillägg.

EU-VAATIMUSTENMUKAISUUSVAKUUTUS

FIN GR

Yhtiö PENTAIR INTERNATIONAL SARL ilmoittaa omalla vastuullaan, että alla osoitetut

tuotteet ovat oleellisten turvallisuus- ja terveydensuojeluvaatimusten mukaisia, joista

alla luetelluissa direktiiveissä sekä niiden myöhemmissä muutoksissa.

DEKLARACJA ZGODNOŚCI Z UE

PL

Firma PENTAIR INTERNATIONAL SARL deklaruje pod własną odpowiedzialnością, że

wskazane poniżej produkty odpowiadają podstawowym Wymogom Bezpieczeństwa

i Ochrony Zdrowia stawianym przez wymienione poniżej Dyrektywy i ich kolejne

modyfikacje.

EURÓPAI UNIÓS MEGFELELÉSI NYILATKOZAT

H

A PENTAIR INTERNATIONAL SARL cég saját felelősségére kijelenti, hogy az alább

megjelölt termékek megfelelnek az alapvető biztonsági és egészségvédelmi

követelményeknek, melyekre az alábbi többször módosított irányelvek vonatkoznak.

AT UYGUNLUK BILDIRISI

TR

PENTAIR INTERNATIONAL SARL firmasi kendi sorumluluğu altlnda asagidaki

elektropompalnn Güvenlik ve Saglik Koruma Şartlarına, sayili direktiflere ve sonraki

değişmelere göre, uygun olduğunu bildirir.

ЕО ДЕЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ

BG

Фирмата PENTAIR INTERNATIONAL SARL декларира на своя собствена отговорност,

че споменатите по-долу продукти са в съответствие със съответните стандарти за

безопасност и здраве, посочени в изброените директиви и последващи изменения.

DEARBHÚ COMHRÉIREACHTA UM CE

GA

Dearbhaíonn an chuideachta PENTAIR INTERNATIONAL SARL, faoi bhun a fhreagrachta

féin, go bhfuil na táirgí thíosluaite i gcomhréir leis na caighdeáin Sláinte agus

Sábháilteachta arna sonrú sna treoracha sa liosta agus sna leasuithe ina dhiaidh sin.

EB ATITIKTIES DEKLARACIJA

LT

Įmonė PENTAIR INTERNATIONAL SARL išskirtinai savo atsakomybe pareiškia, kad

žemiau minimi gaminiai atitinka atitinkamus Sveikatos ir Saugos standartus, nurodytus

išvardytose direktyvose bei tolesnėse pataisose.

VYHLÁSENIE EHS O ZHODE

SK

Firma PENTAIR INTERNATIONAL SARL prehlasuje na vlastnú zodpovednosť, že

nasledovné výrobky spĺňajú predpisy Bezpečnosti o ochrane zdravia pri práci podľa

nižšie uvedených smerníc v znení neskorších úprav.

GBI

DK

RO

CZ

RUS

EE

LV

MT

SLO

EC DECLARATION OF CONFORMITY

The company PENTAIR INTERNATIONAL SARL declares, under its own responsibility,

that the below mentioned products are compliant with the relevant Health and Safety

standards specified in the listed directives and subsequent amendments.

EG KONFORMITÄTSERKLÄRUNG

Die unterzeichnende Firma PENTAIR INTERNATIONAL SARL erklärt unter eigener

Verantwortung, dass die unten aufgeführten Produkte den wesentlichen Sicherheits- und

Gesundheitsanforderungen der unten angegebenen Richtlinien in der jeweils geltenden

Fassung entsprechen.

DECLARAÇÃO DE CONFORMIDADE CE

P

A empresa PENTAIR INTERNATIONAL SARL declara sob a própria responsabilidade que

os produtos abaixo indicados estão em conformidade com os Requisitos Essenciais

de Segurança e Tutela de Saúde contidos nas Directivas abaixo descritas e sucessivas

modificações.

EF-OVERENSSTEMMELSESERKLÆRING

Undertegnede firma PENTAIR INTERNATIONAL SARL erklærer hermed under ansvar, at

nedennævnte produkter er fremstillet i overensstemmelse med de Væsentlige Sundheds- og

Sikkerhedskrav, der er anført i de nedenundernævnte direktiver og deres efterfølgende ændringer.

SAMSVARSERKLÆRING

N

Firmaet PENTAIR INTERNATIONAL SARL erklærer, under eget ansvar, at de elektriske

pumpene nevnt nedenfor, samsvarer med helse- og sikkerhetsstandardene i direktivene

gjengitt nedenfor.

ΗΛΣΗ ΠPOΣAPΜΟΓΗΣ ΕOΚ

H εταιρεία PENTAIR INTERNATIONAL SARL δηλώνει υπεύθυνα ότι τα παρακάτω

προϊόντα έχουν κατασκευαστεί σύφωνα ε τις Βασικές Απαιτήσεις Ασφαλείας και

Προστασίας της Υγείας των παρακάτω Οδηγιών και επακόλουθων τροποποιήσεών τους.

DECLARAŢIE CE DE CONFORMITATE

Firma PENTAIR INTERNATIONAL SARL declară pe propria ei răspundere că produsele

indicate mai jos sunt în conformitate cu Normele de Siguranţă şi de Tutela Sănătăţii, în

baza directivelor menţionate mai jos şi a succesivelor lor modificări.

PROHLÁŠENÍ ES O SHODĚ

Firma PENTAIR INTERNATIONAL SARL zodpovědně prohlašuje, že níže uvedené výrobky

jsou ve shodě spředpisy o Bezpečnosti práce a ochraně zdraví podle níže uvedených

směrnic směrnic a následujících změn.

ДЕКЛАРАЦИЯ O СООТВЕТСТВИИ EC

Фирма PENTAIR INTERNATIONAL SARL заявляет под свою ответственность, что

нижеуказанные изделия соответствуют основным требованиям по охране здоровья

и безопасности труда, в частности, требованиям перечисленных ниже директив и

их последующих поправок.

VASTAVUSE TUNNISTUS

Ettevõte PENTAIR INTERNATIONAL SARL kuulutab, oma vastutusel, et allpool mainitud

tooted vastavad Tervishoiu ja Ohutuse standarditele, mis on täpsustatud loendatud

direktiivides ja järgnevates parandustes.

EK ATBILSTОBAS SERTIFIKВTS

Uzņēmums PENTAIR INTERNATIONAL SARL paziņo uzņemoties atbildību, ka zemāk

minētie produkti ir atbilst attiecīgajiem Veselības un drošības standartiem, kas noteikti

uzskaitītajās direktīvās un sekojošos labojumos.

EB ATITIKTIES DEKLARACIJA

Il-kumpanija PENTAIR INTERNATIONAL SARL tidikjara, fuq responsabilità tag’ha stess, li

l-prodotti msemmija hawn isfel huma konformi mal-istandards rilevanti dwar is-Sa’’a u

s-Sigurtà kif speifikat fid-direttivi elenkati u sussegwenti emendi.

ES IZJAVA O SKLADNOSTI

Podjetje PENTAIR INTERNATIONAL SARL z vso odgovornostjo izjavlja, da so spodaj

navedeni proizvodi skladni z bistvenimi zahtevami varnosti in varovanja zdravja,

navedenimi v spodaj navedenih direktivah in njihovih kasnejših spremembah.

MOD.

VLR 2B

VLR 4

VLR 8

VLR 16

VLR 32

VLR 66

VLRI 2B

VLRI 4

VLRI 8

VLRI 16

VLRX 2B

VLRX 4

VLRX 8

VLRX 16

DIRECTIVES:

2006/42/EC 2006/95/EC

2004/108/EC

HARMONIZED STANDARDS:

EN 809 EN 60335-1

EN 60335-2-41 EN 61000-6-3

EN 61000-6-1 EN 55014

EN 60555

09

Pentair International S.a.r.l.

Avenue de Sevelin, 18

1004 Lausanne, Switzerland

Vittorio Brundu

PLANT MANAGER

Lugnano (Pisa)

20/12/2012

Page 3

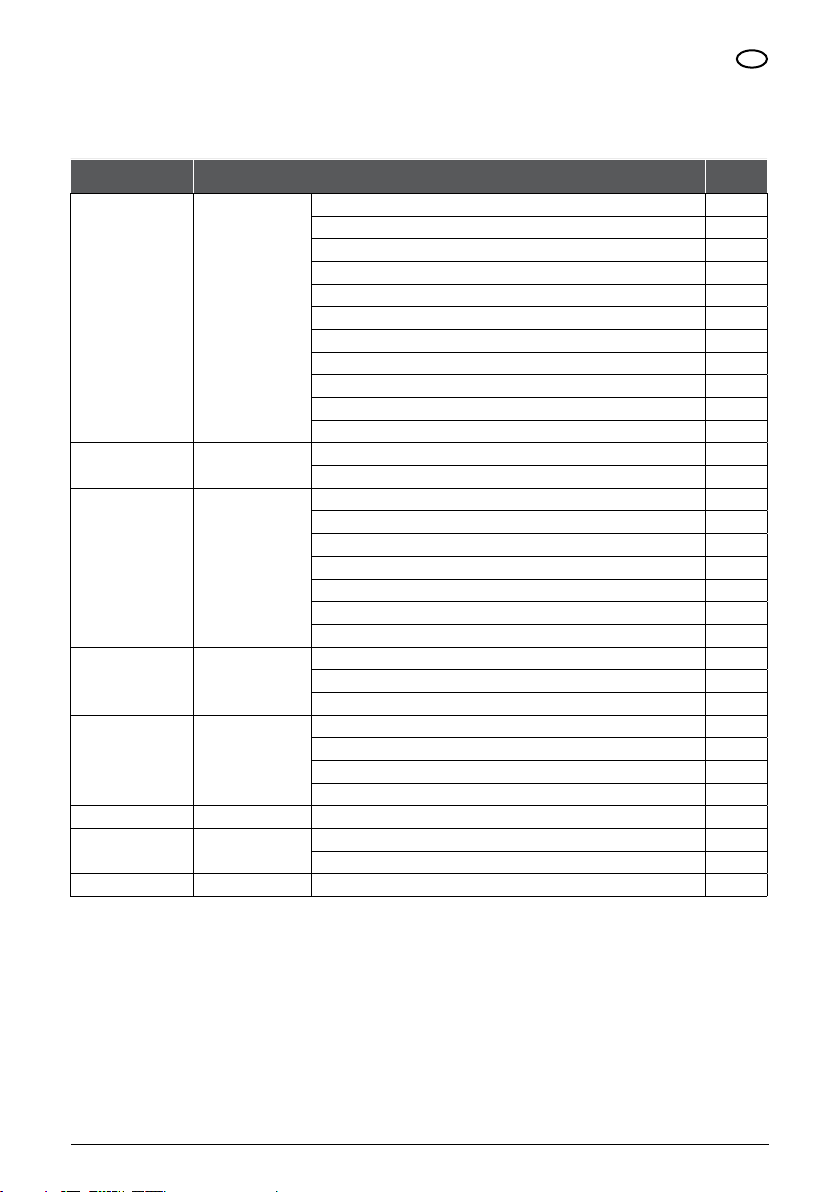

SUMMARY

CHAPTER DESCRIPTION PAGE

1.1 Supplied documents 24

1.2 Information ownership 24

1.3 Machine identification data 24

1.4 EC declaration of conformity 25

1.5 General information on safety 25

1 GENERAL INFORMATION

2 DESCRIPTION

3 INSTALLATION

4 USE

5 MAINTENANCE

6 OPERATION TROUBLES Table 43

7 DISMANTLING

- WARRANTY - 157

1.6 Conventions 27

1.7 Expected uses 27

1.8 Non expected uses 28

1.9 Warranty 28

1.10 Service 29

1.11 How to use the supplied documents 29

2.1 Description 29

2.2 Technical features 30

3.1 Hoisting 31

3.2 Transport 32

3.3 Storage 33

3.4 Preliminary checks 33

3.5 Preparation of the installation area 33

3.6 Installation 35

3.7 Adjustment 37

4.1 Priming 39

4.2 Starting 41

4.3 Start and stop frequency control 41

5.1 Lubrication 42

5.2 Temporarily quiescing 42

5.3 Periodical inspection 42

5.4 Extraordinary maintenance 43

7.1 Disconnecting the machine 44

7.2 Residual risks after disconnection 44

GB

23

Page 4

GB

CHAPTER 1

GENERAL INFORMATION

1.1 SUPPLIED DOCUMENTS

1.1.1 MANUAL

DATA

Instruction manual

Issue 2

Version 082014

Code 253P9070

RECIPIENTS

This manual is dedicated to the operators charged of the machine management during all the phases of its technical life.

CONTENTS

This manual includes the following information:

• Manufacturer declaration

• Information on safety

• Sales information

• Information on documents

These pieces of information are subdivided into the following chapters and appendixes of this manual:

• Chapter 1: General information

• Chapter 2: Description

• Chapter 3: Installation

1.2 INFORMATION OWNERSHIP

The information contained in this manual is owned by PENTAIR INTERNATIONAL S.a.r.l.

The reproduction, also partial, of this manual is forbidden without the express authorisation of PENTAIR INTERNATIONAL S.a.r.l.

The information contained in this manual only concerns the machine specified in the “Product specification” section.

PENTAIR INTERNATIONAL S.a.r.l. reserves the right to make to the machines the changes not specified in “Machine identification

data” whenever deemed right.

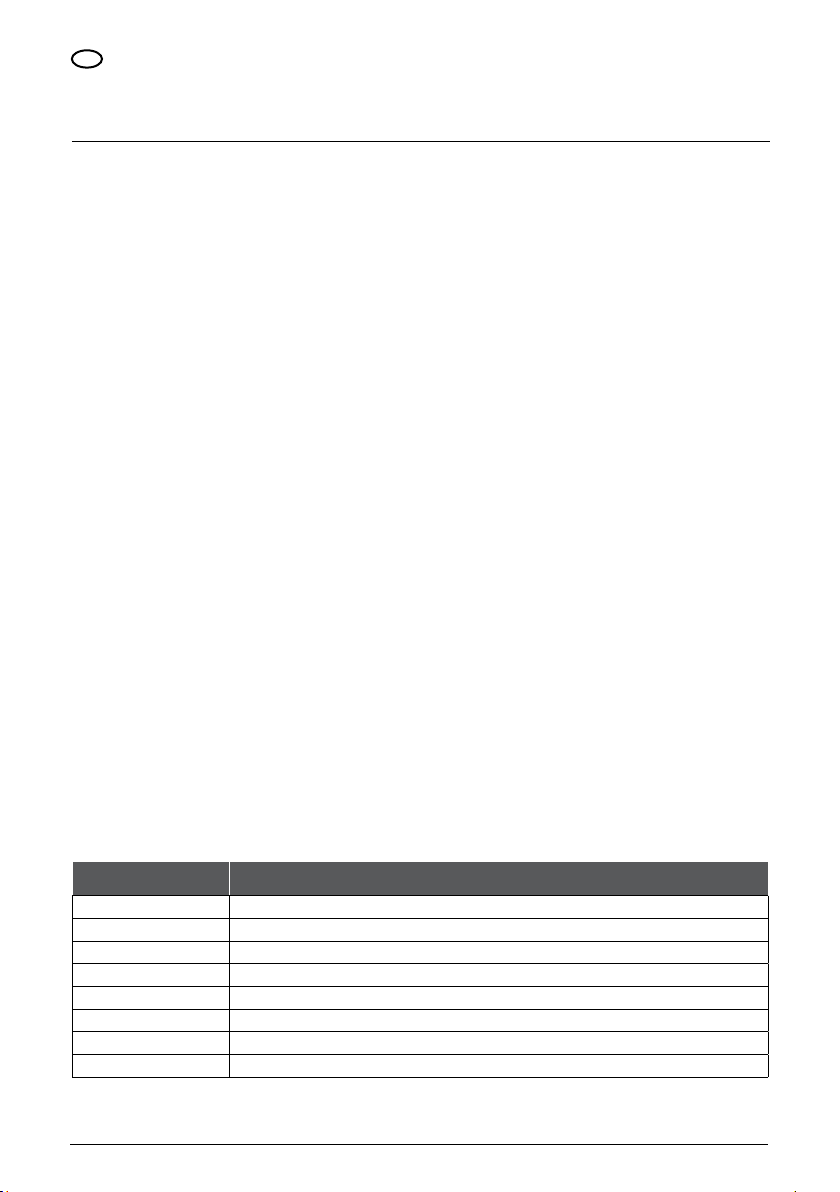

1.3 MACHINE IDENTIFICATION DATA

MACHINE ACRONYM DESCRIPTION

VLR VLR cast iron base (centrifugal electric pump vertical multistage with “in line” mouth).

VLRI VLRI steel base AISI 304.

VLRX VLRX steel base AISI 316.

4 - Nominal delivery in m

80 Number of stages (= nr. of impellers x 10).

/ 7 Number of impellers (used when lower than the number of stages only).

(A) Version with oval flanges.

(F) Version with round flanges.

• Machine description

• Transport information

• Storage information

• Installation information

• Chapter 4: Use

• Chapter 5: Maintenance

• Chapter 6: Operating troubles

3

/h.

• Adjustment information

• Use information

• Maintenance information

• Dismantling information

• Chapter 7: Dismantling

• Appendix: Product specification

24

Page 5

1.4 EC DECLARATION OF CONFORMITY

See related page.

1.5 GENERAL INFORMATION ON SAFETY

We recommend to carefully following the instructions contained in this manual, paying special attention to notes, attention and

danger warnings.

DANGER

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use

of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

WARNNG

Users should always follow the accident prevention laws in force in the country

where the product is installed.

DANGER

Before repairing or servicing the electropump, disconnect it from the socket and/or turn the main switch to Off (when

present) to interrupt the power supplied to the electropump. This prevents the electropump from accidentally restarting

and from causing accidents to people and/or damages to the people.

DANGER

Do not service, install or move the electropump while it is powered, because these operations can cause serious

accidents or even death.

WARNNG

During operation, do not remove or move the electropump.

DANGER

Before using the electropump, always check that the cable and all electric devices are efficient, shielded and protected.

DANGER

When starting the electropump (by inserting the plug into the socket and/or turning the main switch to on), always wear

shoes and make sure that the hands are dry.

NOTE

Failure to follow the safety procedures and precautions contained in the documentation supplied shall relieve PENTAIR

INTERNATIONAL S.a.r.l. from all liability thereof.

GB

25

Page 6

GB

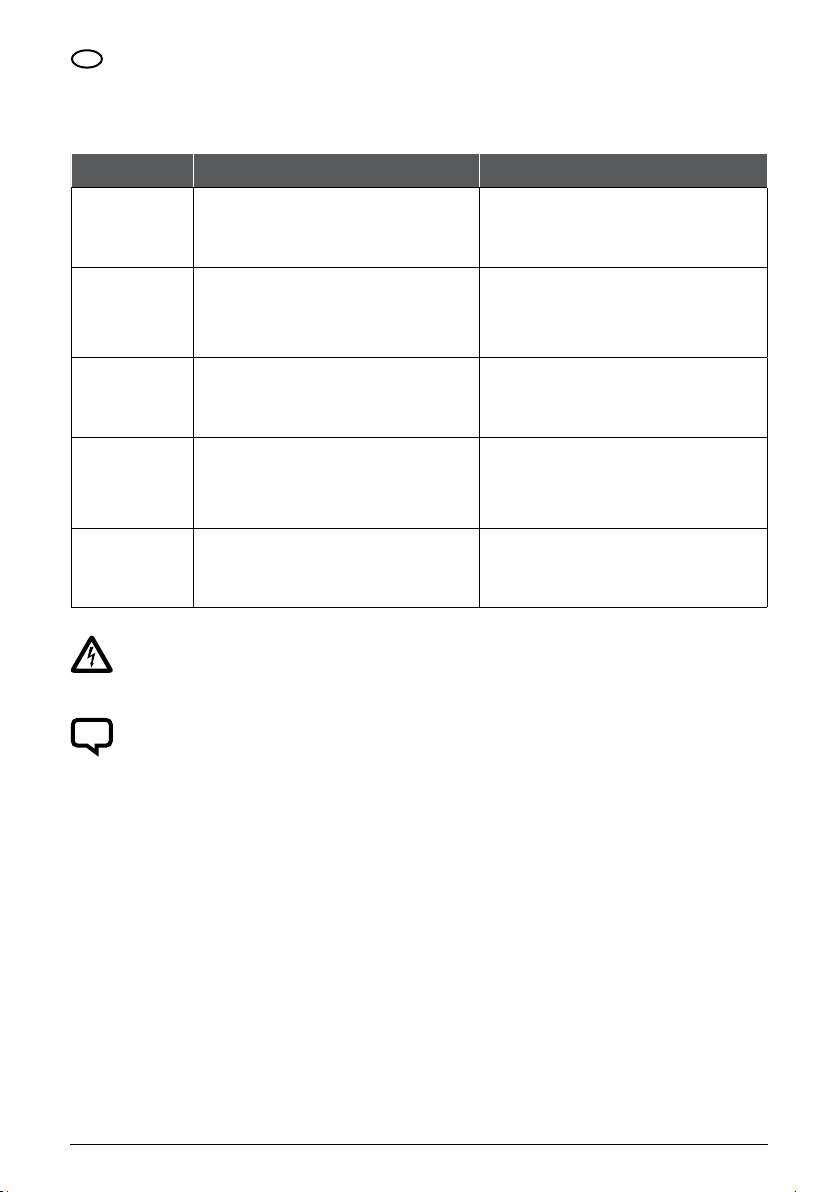

1.5.1 PERSONNEL QUALIFICATION

Qualification and protection restrictions foreseen for the operators.

OPERATOR QUALIFICATION RECCOMENDED INDIVIDUAL PROTECTION MEAN

Knowledge and command of the chapters:

CARRIER

INSTALLER

USER

MAINTENANCE MAN

DEMOLISHER

• General information

• Description

• Installation

Qualification complying with the provisions of the Country of installation,

knowledge and command of the chapters:

• General information

• Description

• Installation

Knowledge and command of the chapters:

• General information

• Description

• Use

Fitness acknowledged by PENTAIR INTERNATIONAL Sarl, knowledge and

command of the chapters:

• General information

• Description

• Maintenance

Knowledge and command of the chapters:

• General information

• Description

• Dismantling

Protective shoes and gloves.

Protective shoes and gloves.

Protective shoes and gloves, high temperature protecting overall and gloves.

Protective shoes and gloves.

Protective shoes and gloves.

DANGER

The machine operates in safety conditions if it is used by qualified personnel in accordance with the instructions and

information contained in this manual and present on board.

All the operations referred to in this manual should be performed by qualified personnel equipped with the protection

means described in this manual.

NOTE

PENTAIR INTERNATIONAL S.a.r.l. shall not be liable for accidents if the machine is used from non qualified or

unauthorised personnel and originating from the failure to follow the instructions contained in this manual and present

on the machine board.

26

Page 7

1.5.2 SPECIAL COMPLIANCE

The use of personnel having a qualification different from the specified one may involve risks for people and/or the machine.

1.6 CONVENTIONS

1.6.1 WORD CONVENTIONS

The following conventions have been adopted throughout the manual

GB

• Machine: elettropompe specificate in

"Scheda prodotto"

1.6.2 TYPESETTING CONVENTIONS

DANGER

Danger indications show the procedure whose non or partial compliance may cause physical damages to the operator.

WARNNG

Attention indications show the procedures whose non or partial compliance may cause damages to the machine or to

the equipment connected to it.

NOTE

Note indications contain important information highlighted outside the text to which they refer.

1.7 EXPECTED USES

1.7.1 EXPECTED USES

The machine has been designed, manufactured and protected to allow the conveying, circulation and the increase in pressure of the

following types of fluids:

• Water having a -15 °C to 120 °C

temperature (for temperature lower

than 0°C the addition of a fit quantity

of ice-preventing agent is expected)

• Authorised technician:

person authorised by PENTAIR

INTERNATIONAL S.a.r.l. to perform

even the operations not specifically

indicated in this manual

• Water glycol mixtures

(or ice-preventing products having

chemical physical characteristics

similar to glycol) with a glycol

percentage up to 50%

• Specialized technician: person

authorised to perform even the

operations not specifically indicated

in this manual after being authorised

by PENTAIR INTERNATIONAL S.a.r.l.

• Liquids and waters chemically

compatible with the materials that

are part of the machine

• Neutral, non explosive fluids

having a viscosity similar to water

The machine has been designed,

manufactured and protected to

allow a fluid delivery depending on

the required head (see “Product

specification”)

27

Page 8

GB

1.7.2 EXPECTED MODES OF INSTALLATION

The machine has been designed, manufactured and protected to be installed both:

• Indoor

The machine has been designed, manufactured and protected to be used under the following atmospheric conditions:

• Temperature range: -15 °C to +40 °C

The machine has been designed, manufactured and protected to be installed in a vertical position with the motor in the upper part.

The machine has been designed, manufactured and protected to be:

• Fixed on foundations having the

characteristics shown in the appendix

“Product specification” paragraph

“Foundations”

The machine has been designed, manufactured and protected to be fed by electric power having one of the following

characteristics:

• 230 V, 50 Hz, single phase

Different voltages and frequencies are available on request.

1.8 NON EXPECTED USES

The machine has not been designed, manufactured, nor protected for all the uses not expressly specified in “Expected uses”.

In particular, the machine has not been designed, manufactured, nor protected for the conveying, circulation and increase in

pressure of the following fluids:

• Explosive

• Corrosive

For special uses, please contact out technical office.

• Outdoor with a protection from

atmospheric agents

• Allowed relative humidity range:

30 to 90%

• Connected to pipes able to bear the

machine weight

• 230 V, 50 Hz, three-phase

• Oil-derivatives and mixtures

containing oil-derivatives

• 400 V, 50 Hz, three-phase

• Mixtures containing material or fibres

in suspension

• Sea water

1.8.1 LIABILITIES RESULTING FROM NON EXPECTED USES

NOTE

PENTAIR INTERNATIONAL S.a.r.l. is not liable for possible damages to people, animals or things resulting from a

non-expected use of the machine.

1.9 GARANZIA

NOTE

Non authorised installation, adjustment and maintenance operations and/or operations carried out by non qualified

personnel imply the termination of the warranty

28

Page 9

1.10 SERVICE

WARNNG

If the pump has been used with noxious or toxic fluids, the pump will be classified as polluted and PENTAIR

INTERNATIONAL S.a.r.l. will have the right to refuse offering its assistance for the pump.

For all assistance requests, contact:

PENTAIR INTERNATIONAL S.a.r.l. – Servizio Assistenza

Via Masaccio, 13

56010 Lugnano - PISA - ITALY

Tel. 050/71.61.11 - Fax 050/70.31.37

1.11 HOW TO USE THE SUPPLIED DOCUMENTS

We recommend the operators to carefully read the supplied documents before carrying out any operation on the machine

The supplied documents must be kept for the whole life of the machine so that it can be easily found when necessary.

If the machine is sold as second-hand, it must be sold together with the supplied documents.

CHAPTER 2

DESCRIPTION

2.1 DESCRIPTION

2.1.1 ARCHITECTURE AND OPERATING PRINCIPLES

• VLR motor-pumps are centrifugal,

vertical multistage motor-pumps with

“in-line” suction inlets and delivery

• VLR motor-pumps are directly

coupled to an asynchronous single or

three-phase motor with closed casing

and external ventilation

• VLR motor-pumps are not

self-priming and need a priming

procedure

• VLR motor-pumps can be equipped

with oval or round flanges

GB

2.1.2 MACHINE STRUCTURE

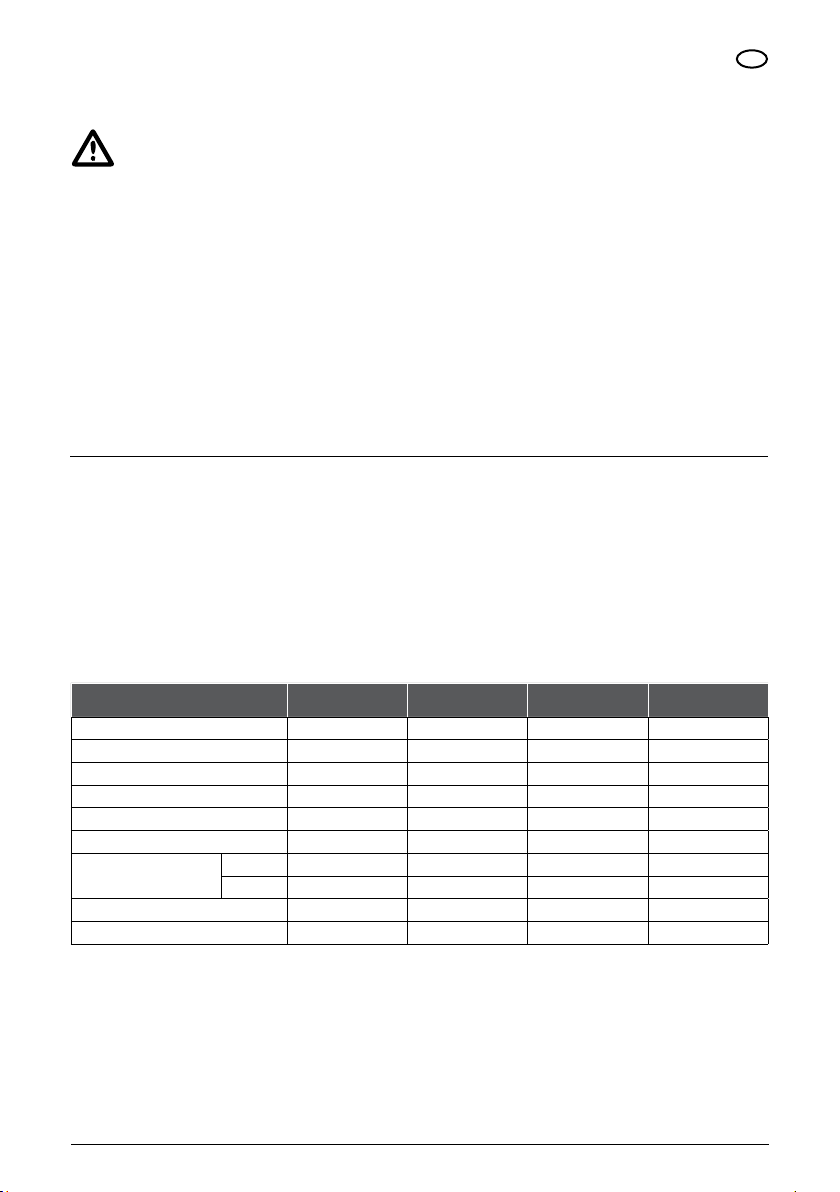

COMPONENTS VLR VLR32 VLRI VLRX

BASE

HEADATOCK

SHAFT

IMPELLERS AND CHOKE

EXTERNAL CYLINDER

TIE RODS

MECHANICAL SEAL

O-RING

SEALS

NOTE: EN GJL 200 (ex G220) cast iron with internal steel drivehead.

ROTATING Tungsten Tungsten Tungsten Tungsten

FIXER Tungsten Grafite Tungsten Tungsten

Ghisa EN GJL 200 Cast iron Ghisa EN GJS 500 Cast iron AISI 316 AISI 316

Ghisa EN GJL 200 Cast iron Ghisa EN GJL 200 Cast iron See note 1 See note 1

AISI 316 AISI 431 AISI 316 AISI 316

AISI 304 AISI 304 AISI 304 AISI 316

AISI 304 AISI 304 AISI 304 AISI 316

Steel zincate AISI 316 AISI 316 AISI 316

EPDM EPDM EPDM EPDM

Paper - Paper Paper

29

Page 10

GB

2.2 TECHNICAL FEATURES

• Machine size and weights:

See "Product specification"

• Electrical data:

See "Product specification " and

identification plate

• Pressure:

maximum operating pressure

NUM

1

2

3

4 32 - 1 ÷ 32 - 14

30

MACHINE

VLR VLRI VLRX

2B - 30 / 2 A ÷ 2B - 150 A

4 - 20 A ÷ 4 - 160 A

8 - 20 A ÷ 8 - 120 A

2B - 180F ÷ 2 B - 160 F

4 - 190 F ÷ 4 - 260 F

8 - 140 F ÷ 8 - 200 F

16 - 30 / 2 F-100 F ÷ 16 - 160 F

MACHINE

VLR VLRI VLRX

2B - 30 / 2A

2B - 30 ÷ 2B - 110 A

2B - 130 ÷ 2B - 260 F

4 - 20A ÷

4 - 30 ÷ 4 - 100 A

4 - 120 ÷ 4 - 260 F

8 - 20 A ÷ 8 - 30 A

8 - 40 ÷ 8 - 200 F

16 - 30 / 2 ÷ 16 - 30 F

16 - 40 ÷ 16 - 160 F

32 - 1 ÷

32 - 2 ÷ 32 - 4

32 - 5 ÷ 32 - 10

32 - 11 ÷ 32 - 14

PRESSIONE - BAR

3 4 6 10 15

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Page 11

2.2.1 NOISE

Sound pressure weighed equivalent continuous maximum level A issued by the machine: 82 dB (A)

2.2.2 LIABILITY

PENTAIR INTERNATIONAL S.a.r.l. is not liable if the values shown in this paragraph are not complied with.

CHAPTER 3

INSTALLATION

3.1 HOISTING

The machine hoisting can be made under one of the following conditions:

GB

• Machine free from any type of

packaging

• Machine packaged in a cardboard box

3.1.1 MACHINE FREE FROM ANY TYPE OF PACKAGING

It is possible to hoist one machine at a time only:

3.1.2 MACHINE PACKED IN CARDBOARD BOX

It is possible to hoist more than one machine packed in a cardboard box depending on the machine weight. The packed machines

are kept in position using filling inert material used to fill the box.

• Machine packaged in a wooden crate • Machine secured on a supporting

• For machines having a weight lower

than 25 kg: hand hoisting made by

one person

• For machines having a weight

between 25 and 50 kg: hand hoisting

made by two persons

• For machines having a weight

exceeding 50 kg: hoisting using

hoisting means and sling

• For machines having a weight lower

than 25 kg: hand hoisting made by

one person

• For machines having a weight

between 25 and 50 kg: hand hoisting

made by two persons

• For machines having a weight

exceeding 50 kg: hoisting using

hoisting means and sling

surface

31

Page 12

GB

3.1.3 MACHINE PACKED IN A WOODEN CRATE

It is possible to hoist more than one machine packed in a wooden crate depending on the machine weight. Packed machines are

kept in position using wooden spacers.

• For machines having a weight lower

than 25 kg: hand hoisting made by

one person

• For machines having a weight

between 25 and 50 kg: hand hoisting

made by two persons

• For machines having a weight

exceeding 50 kg: hoisting using

hoisting means and sling

3.1.4 MACHINES SECURED ON A SUPPORTING SURFACE

It is possible to hoist more than one machine secured by means of fixing nuts on a surface having bent sides. The packed machines

are kept in position using wooden spacers. Position on a suitably sized pallet and hoist using hoisting means.

DANGER

Risk of machine fall. Do not stand under the machine during hoisting.

ATTENTION

Make sure that during hoisting the machine is kept in vertical position with the motor in the upper part.

3.2 TRANSPORT

The machine transport must be made under the following conditions:

• Machine vertical position with the

motor in the upper part

DANGER

Make sure that the above listed conditions are complied with during transportation.

32

• Machine in fixed position without

possibility of movements

• Machine protected from atmospheric

agents

Page 13

3.3 STORAGE

3.3.1 CHARACTERISTICS OF THE STORAGE AREA

The storage area must have the following physical characteristics:

GB

• An extent fit for containing the

machine and the possible packaging

and allowing the hoisting by means of

the foreseen hoisting means

3.3.2 ENVIRONMENTAL CHARACTERISTICS OF THE STORAGE AREA

The storage area must have the following environmental characteristics:

• Allowed temperature range:

-15 °C ÷ +50 °C

DANGER

Possibility of machine fall. Secure the machine or store it in an inaccessible place.

Do not put the machines one on top of the other.

ATTENTION

Keep the machine in vertical position with the motor in the upper part.

3.4 PRELIMINARY CHECKS

3.4.1 CHECK FOR DAMAGES

• Check the integrity of the packaging

if present

Check that the machine is not damaged, in particular check the integrity of:

• Motor fan cover

• Terminal box cover

ATTENTION

Keep the original packaging, if present, for a possible future transport of the machine.

• Even and horizontal resting surface

• Resting surface having a carrying

capacity exceeding the weight of the

number of stored machines

• Relative humidity range: 30 ÷ 90% • Protection from atmospheric agents

• Open the packaging, if present, and

extract the machine

• External lining • Cast iron parts

• Protection form possible accidental

bumps

• Check that the received machine

matches the ordered one

3.4.2 DAMAGE SIGNALLING

In case of non-compliance or damages, signal to PENTAIR INTERNATIONAL S.a.r.l. or to the seller the problem within 8 (eight)

days from the purchase date.

3.5 PREPARATION OF THE INSTALLATION AREA

3.5.1 CHARACTERISTICS OF THE INSTALLATION AREA

The machine installation area must have the following characteristics:

• Facilitate the positioning and access

to the machine

• Allow a safe connection to the electric

system

• Allow safe connections to piping

• Presence of a fit natural

and/or artificial lighting allowing safe

operation

• A minimum distance of 150 mm

between any machine point and any

obstacle

• Ensure sufficient ventilation for the

motor fan

33

Page 14

GB

ATTENTION

Do not cover or obstructs the motor fan covering grid.

ENVIRONMENTAL CONDITIONS

• Allowed temperature range:

-15 °C ÷ +40 °C

CONNECTION

The piping to which the machine must be connected must have the following characteristics:

• Axiality among the delivery and

suction piping with minimum

diameters fit for the machine

• Distance between the two pipelines as

shown in the “Product specification”

paragraph “Foundations””

• Fastening to a fixed support, in order

not to discharge stresses and/or

vibrations on the machine

If the machine can work with a valve closed on the delivery piping, recycling piping for safeguarding the machine with the

following characteristics:

PIPING ASSEMBLY

incorrect correct

air locks

• Allowed relative humidity range:

30 ÷ 90%

• Absence of air locks, as shown in the

piping figure

• Suction piping length reduced as

much as possible

• Load losses in the suction piping

minimised (if the machine works

in suction mode. See “Machines

installed above head”)

• Protection from atmospheric agents

• Gates on delivery and suction pipe

lines

• If the machine is installed above head,

check valve on the suction piping

• If the machine feeds a boiler, check

valve on the delivery piping

• If the fluid circulating in the piping

has a temperature exceeding 65 °C,

protection against high temperatures

Connection between:

• Delivery and suction pipe lines

• Delivery and drain pipe lines

Control by mean of:

• Thermostatic valve

• Solenoid valve controlled by

pressure gauge or thermostat

POWER SUPPLY

The power supply mains must have the following characteristics:

• A differential protection

• Voltage and frequency values

matching the ones shown on the

machine motor rating plate

• A power output not lower than the

value shown on the machine motor

rating plate

ACCESS

Connect the machine in a place that can be easily accessed for maintenance operations.

34

• An electromagnetic switch having a fit

thermal protection

• A self-balanced thermal relay

adjusted on the basis of the actual

absorbed current

• A cut-off switch with protecting fuses

• Cables having a section fit for the

current absorbed by the motor.

Page 15

SUPPORT

The machine fastening system can match one of the following systems:

GB

• The machine can be connected to

fixed piping able to keep the machine

in its position.

3.6 INSTALLATION

3.6.1 CONNECTION TO PIPING

MACHINES WITH OVAL FLANGES

Carry out the following operations to connect the machine to piping:

MACHINE WITH ROUND FLANGES

Carry out the following operations to connect the machine to piping:

• The machine can be connected to a

pipeline and positioned on a surface

having the characteristics shown in

“Product specification” paragraph

“Foundations”

• The machine can be connected to a

pipe line secured by means of nuts to

a surface having the characteristics

shown in “Product specification”

paragraph “Foundations”

• Unscrew the screws fastening the

counterflanges to the machines

• Remove the two counterflanges

• Remove the two gaskets present

between counterflanges and machine

base

• Brake the protecting central disks

along the marked lines to get two

gaskets with central holes

• Screw the two counterflanges at the

threaded ends of the piping

• Position the machine so that the

arrows on the base match the fluid

flow direction

• Position the two circular gaskets

between couterflanges and machine

• Alternatively tighten the screws

fastening the counterflanges to the

machine

• Fit two counterflanges having a

size matching those of the machine

flanges to the pipe ends

• Remove the two protecting caps on

the machine flanges

• Position the machine so that the

arrows on its base match the fluid

flow direction

• Fit the two circular gaskets between

counterflanges and flanges

• Fit the screws in the flange and

counterflange holes

• Alternatively tighten the nuts on the

screws

35

Page 16

GB

3.6.2 TERMINAL BOX POSITION

Carry out the following operations to direct the terminal box in the required position:

• Remove the connection covering grids

• Unscrew the assembly bolts of motor

and machine body

• Rotate the motor of 90° or 180° or

270° (in relation to the initial position)

• Screw the bolts alternatively and in a

uniform way

• Refit the connection covering grids

3.6.3 CONNECTION TO THE ELECTRIC SYSTEM

MACHINES WITH THREEPHASE MOTORS

DANGER

The installer shall make sure that the power supply system is fitted with an efficient ground system according to the

provisions in force.

DANGER

Make sure that the power supply system is fitted with a high-sensitiveness differential switch

Δ= 30 mA (DIN VDE 0100T739).

DANGER

Before removing the terminal box cover and before making any operation on the motorpump, make sure that the power

supply line has been cut-off.

Carry out the following operations to connect the machine to the power supply system:

• Make sure that the motor is fit for the

mains voltage

• Cut-off the electric system by means

of the cut-off switch

• Unscrew the screws securing the

terminal box cover

• Fit the power supply cable in the

fairlead

A - If the rotation direction matches the one shown by the arrows on the machine head, the connections are correct.

B - If the rotation direction is the opposite to the one shown by the arrows on the machine head, carry out the following operations:

36

• Connect the phases and the ground to

the terminals

• Refit the terminal box cover with the

gasket

• Tighten the screws securing the

terminal box cover

• Cut-off the electric system by means

of the cut-off switch

• Unscrew the screws fastening the

terminal box cover

• Change the connection of two phases

• Refit the terminal box with the gasket

• Tighten the screws of the terminal

box cover

• Connect the power supply by means

of the cut-off switch

• Give a current pulse to the machine

• Check the motor rotation direction

Page 17

MACHINE WITH SINGLEPHASE MOTORS

Carry out the following operations to connect the machine to the power supply system:

GB

• Make sure that the motor is fit for the

voltage mains

• Cut-off the electric system by means

of the cut-off switch

• Unscrew the screws of the terminal

box

• Fit the power supply cable in the

fairlead

A - If the rotation direction matches the rotation direction shown by the arrows on the machine head, the connections are

correct

B - If the rotation direction is the opposite to the one shown by the arrows on the machine head, carry out the following

operations:

• Cut-off the electric system by means

of the cut-off switch

• Unscrew the screws fastening the

terminal box cover

3.7 ADJUSTMENT

3.7.1 MACHINE MOTOR COUPLING ADJUSTMENT

Carry out the following operations to adjust the machine-motor coupling:

• Cut-off the power supply system by

means of the cut-off switch

• Unscrew the screws fastening the

joint protection

A - If it freely rotates, carry out the following operations:

• Refit in place the joint protection • Tighten the screws securing the joint

• Connect the lines and the ground

• Refit the terminal box cover with the

gasket

• Tighten the screws of the terminal

box cover

• Connect the power supply by means

of the cut-off switch

• Using a jumper, temporarily shortcircuit the condenser terminals

• Change the jumper positions

• Remove the jumper

• Remove the joint protection

• Manually rotate the joint

protection

• Give a current pulse to the machine

• Check the rotation direction

• Refit the terminal box cover with the

gasket

• Tighten the screws of the terminal

box cover

• Check that the joint freely rotates

B - If the joint does not rotate easily, carry out the following operations:

• Loosen the socket-head screws

joining the two half-joints

• Adjust the distance between motor

and impeller centres using a

screwdriver as a lever

• Tighten the socket-head screws

joining the two half joints

• Refit the joint protection

• Tighten the screws fastening the joint

protection

37

Page 18

GB

A

B

VLR 32

38

Page 19

CHAPTER 4

USE

ATTENTION

Never start the machine before filling it with fluid as shown in “Use”, “Priming”.

4.1 PRIMING

NOTE

A machine is considered under head if, in closed circuit systems, the level of the fluid to be pumped is above the suction

inlet of the machine.

4.1.1 MACHINES INSTALLED UNDER HEAD

Carry out the following operations to fill a machine under head:

GB

• Close the gate on the delivery piping

• Unscrew the priming cap

When the fluid comes out in a continuous way from the priming cap, carry out the following operations:

• Screw the priming cap

• Tighten the air valve (if present)

DANGER

Make sure that the priming cap and the air valve are perfectly tightened.

DANGER

If the fluid flowing in the pipes and circulating in the machine has a temperature higher than 65 °C, Use overall

and gloves protecting against high temperatures.

• Loosen the air valve (if present) • Slowly open the gate on the suction

• Completely open the gate on the

suction piping

piping

• Open the gate on the delivery piping

39

Page 20

GB

4.1.2 MACHINES INSTALLED ABOVE HEAD (SUCTION MODE)

NOTE

A machine is considered above head if, in open circuit systems, the level of the fluid to be pumped is under the machine

suction inlet.

Carry out the following operation to fill the machine above head:

• Open the gate on the suction piping

• Close the gate on the delivery piping

• Open the priming cap

When it is no more possible to further fill the machine, carry out the following operations:

• Tighten the air cap

• Tighten the drain and discharge cap

(if present)

• Tighten the air valve (if present)

DANGER

If the fluid flowing in the pipes and circulating in the machine has a temperature higher than 65 °C, Use overall

and gloves protecting against high temperatures.

DANGER

Make sure that the priming cap and the air valve are perfectly tightened.

priming

primimg

cap

cap

drain cap

drain cap

• Loosen the air valve (if present)

• Rotate the drain and/or discharge cap

counterclockwise (if present)

• Start the machine

• Open the gate on the delivery piping

• Loosen the air valve

primimg

priming

cap

air

air

valve

valve

discharge

discharge

cap

cap

cap

drain

drain cap

cap

• Pour the liquid in the machine

through the priming cap until it

comes out from it

• When the fluid comes, tighten the

air valve (if present) or open the

priming cap

• Stop the machine

air

air

valve

valve

discharge

discharge

cap

cap

VLR 2B VLR 4

priming

primimg

cap

cap

drain cap

drain cap

air

valve

valve

primimg

cap

air

cap

drain cap

drain cap

air

valve

valve

air

priming

VLR 8 VLR 16

40

Page 21

priming

primimg

cap

cap

priming

primimg

cap

cap

GB

drain cap

drain cap

drain cap

drain cap

priming

cap

air valve

discharge

cap

discharge

cap

VLRI VLRX VLR 32

4.2 STARTING

We suggest carrying out the following operations for the first starting:

• Loosen the air valve (if present) or

open the priming cap

• If air comes out from the air valve,

carry out a new priming operation

• Tighten the air valve (if present) or

open the priming cap

4.3 START AND STOP FREQUENCY CONTROL

Carry out the following operations to control the frequency of starts and stops (control the machine operation for one hour):

A - For machines fitted with a motor having an absorbed power up to 4 kW, if the number of starts/hour is higher than 40,

adjust the machine control equipment so that the frequency is reduced.

B - For machines fitted with a motor having an absorbed power higher than 4 kW, if the number of starts/hour is higher than

30, adjust the machine control equipment so that the frequency is reduced.

DANGER

In case of high temperature fluids, wait for an adequate time for the fluid contained in the machine to cool before

unscrewing the screws securing the machine to piping.

DANGER

Always check the machine filling. Never start the machine before filling it up with fluid as shown in “Use”, “Priming”.

• Open the gate on the delivery piping

• Start the machine

• Slowly open the gate on the delivery

piping in order to prevent water

hammering on the delivery piping

• Adjust the thermal relay depending

on the current absorbed by the

machine

• Adjust the start and stop pressure of

the pressure gauge controlling the

machine operation, if present

41

Page 22

GB

CHAPTER 5

MAINTENANCE

5.1 LUBRICATION

• The seal on the shaft is self-adjusting

• The seal surfaces are wear-resistant

and are lubricated by the pumped

fluid

ATTENTION

If the machines are installed, used and maintained according to the instructions contained in this manual, they do not

need lubrication. Comply with the instructions of this manual.

5.2 TEMPORARILY QUIESCING

Carry out the following operations to set the machine to quiescing for a long period of time.

Cut-off the power supply system by means of the cut-off switch.

Carry out the following operations if it is possible that ambient temperature falls under the pumped fluid freezing temperature.

A - If the whole system must be set to quiescing, empty the system.

B - SIf the whole system must not be set to quiescing:

• The machine plain bearings are

lubricated by the pumped fluid

• The motor ball bearings are selflubricated by heat-resistant grease

• Electric motors with grease cup:

lubricate every 1500 functioning

hours with bearing grease

• Close the gates on the delivery and

suction piping

• Remove the priming cap and the drain

and discharge cap (if present)

DANGER

In case of high temperature fluids, wait for an adequate time for the fluid contained in the machine to cool before

unscrewing the screws securing the machine to piping.

ATTENTION

Before restarting the machine fill it as shown in “Use”, “Priming”.

5.3 PERIODICAL INSPECTION

Carry out the following checks at regular time intervals:

• Hydraulic performances

• No fluid leakage

• Motor overheating

A - If the checks do not find malfunctions, keep on using the machine up to another inspection.

B - If the checks find malfunctions, carry out the following operations:

• Make reference to the table “Defect/

Cause” in “Operation troubles”

• Discharge all the fluid from the

machine

• Relay intervention time

• Start frequency

• Automatic control correct operation

• If the defect and the cause are

listed in the table "Defect/Cause"

in "Operation troubles", contact an

authorised technician or a skilled

technician and show them the cause

of the found defect

• Hold the priming cap and the drain

and discharge cap for a new machine

employment without refitting them.

• Vibrations

• Noise

• If the defect and the cause are not

listed in the table "Defect/Cause"

in "Operation troubles", contact an

authorised technician or a skilled

technician

42

Page 23

5.4 EXTRAORDINARY MAINTENANCE

For extraordinary maintenance operations, following malfunctions, faults, breaking or technical upgrading only contact an

authorised technician or a skilled technician.

NOTE

PENTAIR INTERNATIONAL S.a.r.l. is not liable and cancels every warranty contract in case of:

• Operations carried out on the machine and not documented by this manual.

• Extraordinary maintenance operations carried out by personnel different from authorised or skilled technicians.

CHAPTER 6

OPERATION TROUBLES

DEFECT CAUSES

1) Mains voltage is cut-off

2) Blown fuse

AT STARTING, THE MOTOR DOES NOT RUN

THE MOTOR STARTER THERMAL RELAY INTERVENES WHEN

VOLTAGE IS CONNECTED

THE THERMAL RELAY SOMETIMES INTERVENES WITHOUT ANY SPECIAL

THE THERMAL RELAY INTERVENTION HAS NOT OCCURRED BY THE

THE MACHINE DELIVERY IS NOT CONSTANT

THE MACHINE RUNS BUT DOES NOT DELIVER FLUID

AT STOP THE MACHINE RUNS IN THE OPPOSITE DIRECTION

REASON

MACHINE DOES NOT WORK

3) Intervention of the thermal relay

4) Either the motor starter contacts do not conduct or the coil is faulty

5) The auxiliary circuit fuses are blown

6) The machine motor is faulty

1) Blown fuse

2) The motor starter contacts are faulty

3) The electric connections are faulty

4) The motor windings are faulty

5) The machine is mechanically blocked

6) The thermal relay calibration is too low

1) The thermal relay calibration is too low

2) Mains voltage periodically lacks

3) During peak hours mains voltage is too low

1) Mains voltage is cut-of

2) Blow fuse

3) Either the motor starter contacts do not conduct or the coil is faulty

4) The auxiliary circuit fuses are blown

1) The suction pipe is undersized

2) The availability of sucked fluid is not enough

3) The fluid level is too low

4) The head pressure is not enough

5) The suction pipe is partially obstructed

1) The suction pipe or the pump are obstructed

2) The foot valve (or check valve) is blocked in closed position

3) Leakage is present in the suction pipe

4) Air is present in the suction pipe or in the pump

1) The suction pipe or the pump are obstructed

2) The foot valve (or check valve) is faulty

3) The foot valve (or check valve) is blocked in partial or total opening position

GB

43

Page 24

GB

CHAPTER 7

DISMANTLING

7.1 DISCONNECTING THE MACHINE

• Cut-off the power supply system by

means of the cut-off switch

• Close the gates on the suction and

delivery piping

• Unscrew the screws fastening the

terminal box cover

• Disconnect the wires from the

terminals

If the machine is reused, carry out the following operations:

• Screw the priming cap and the drain

and discharge cap on the machine

If the machine has oval flanges, carry out the following operations:

• Unscrew the counterflanges from

the pipes

• Assemble the couterflanges with the

gaskets on the machine

DANGER

If the fluid flowing in the piping and circulating in the machine has a temperature higher than 65 °C, arrange a

protection against high temperatures around the machine.

NOTE

PENTAIR INTERNATIONAL S.a.r.l. is not liable in case of recycling or reuse of machine parts.

7.2 RESIDUAL RISKS AFTER DISCONNECTION

ATTENTION

The machine is manufactured using nonbiodegradable materials.

Carry the machine in a deposit equipped for its disposal.

• Remove the power supply cable from

the fairlead

• Remove the priming cap and the drain

and discharge cap

• Discharge all the fluid from the

machine

• Unscrew the screws fastening the

machine to the pipes

• Refit the terminal box cover with the

gasket

• Close the delivery and suction holes

so that dirt cannot enter in the

machine

• Unscrew the screws possibly

fastening the machine to the resting

surface

• Hoist the machine as shown in

“Installation”, “Hoisting”

• Transport the machine as shown in

“Installation”, “Transport"

• Tighten the screws securing the

terminal box cover

• Store the machine as shown in

“Installation”, “Storage"

ONLY FOR EU COUNTRIES

Do not dispose of electric tools together with household waste material!

In observance of European Directive 2002/96/EC on waste electrical and electronic

equipment and its implementation in accordance with national law, electric tools that

have reached the end of their life must be collected separately and returned to an

environmentally compatible recycling facility.

44

Page 25

SOLO PER PAESI UE

Non gettare le apparecchiature elettriche tra i rifiuti domestici. Secondo la Direttiva Europea 2002/96/CE sui rifiuti di apparecchiature elettriche ed elettroniche e la sua attuazione in conformità alle norme nazionali, le apparecchiature elettriche esauste devono

essere raccolte separatamente, al fine di essere reimpiegate in modo eco-compatibile.

POUR LE PAYS EUROPÉENS UNIQUEMENT

F D

Ne pas jeter les appareils électriques dans les ordures ménagères ! Conformément à

la directive européenne 2002/ 96/EG relative aux déchets d’équipements électriques ou

électroniques (DEEE), et à sa transposition dans la législation nationale, les appareils

électriques doivent être collectés à part et être soumis à un recyclage respectueux de

l’environnement.

SÓLO PARA PAÍSES DE LA UNIÓN EUROPEA

E

No deseche los aparatos eléctricos junto noc los residuos domésticos! De conformidad

con la Directiva Europea 2002/96/ CE sobre residuos de aparatos eléctricos y

electrónicos y su aplicación de acuerdo con la legislación nacional, las herramientas

eléctricas cuya vida útil haya llegado a su fin se deberán recoger por separado y

trasladar a una planta de reciclaje que cumpla con las exigencias ecológicas.

ALLEEN VOOR EULANDEN

NL

Geef elektrisch gereedschap niet met het huisvuil mee! Volgens De europese richtlijn

2002/96/eg inzake oude elektrische en Elektronische apparaten en de toepassing

daarvan binnen de Nationale wetgeving, dient gebruikt elektrisch gereedschap

Gescheiden te worden ingezameld en te worden afgevoerd naar Een recycle bedrijf dat

voldoet aan de geldende milieu-eisen.

GÄLLER ENDAST EULÄNDER

S

Elektriska verktyg får inte kastas i hushållssoporna! Enligt direktivet 2002/96/EG som

avser äldre elektrisk och elektronisk utrustning och dess tillämpning enligt nationell

lagstiftning ska uttjänta elektriska verktyg sorteras separat och lämnas till miljövänlig

återvinning.

KOSKEE VAIN EUMAITA

FIN GR

Älä hävitä sähkötyökalua tavallisen kotitalousjätteen mukana! Vanhoja sähkö- ja

elektroniikkalaitteita koskevan EU-direktiivin 2002/96/ETY ja sen maakohtaisten sovellusten mukaisesti käytetyt sähkötyökalut on toimitettava ongelmajätteen keräyspisteeseen ja ohjattava ympäristöystävälliseen kierrätykseen.

Dotyczy tylko państw UE

PL

Nie wyrzucaj elektronarzędzi wraz z odpadami z gospodarstwa domowego! Zgodnie z

Europejską Dyrektywą 2002/96/WE w sprawie zużytego sprzętu elektrotechnicznego i

elektronicznego oraz dostosowaniem jej do prawa krajowego, zużyte elektronarzędzia

należy posegregować i zutylizować w sposób przyjazny dla środowiska.

Csak EU-országok számára

H

Az elektromos kéziszerszámokat ne dobja a háztartási szemétbe! A használt villamos

és elektronikai készülékekről szóló 2002/96/EK irányelv és annak a nemzeti jogba való

átültetése szerint az elhasznált elektromos kéziszerszámokat külön kell gyűjteni, és

környezetbarát módon újra kell hasznosítani.

Sadece AB ülkeleri için

TR

Elektrikli el aletlerini evdeki çöp kutusuna atmayınız!

Kullanılmış elektrikli aletleri, elektrik ve elektronikli eski cihazlar hakkındaki

2002/96/EG Avrupa yönergelerine göre ve bu yönergeler ulusal hukuk kurallarına

göre uyarlanarak, ayrı olarak toplanmalı ve çevre şartlarına uygun bir şekilde tekrar

değerlendirmeye gönderilmelidir.

GBI

DK

RO

CZ

RUS

ONLY FOR EU COUNTRIES

Do not dispose of electric tools together with household waste material! In observance

of European Directive 2002/96/EC on waste electrical and electronic equipment and its

implementation in accordance with national law, electric tools that have reached the end

of their life must be collected separately and returned to an environmentally compatible

recycling facility.

NUR FÜR EULÄNDER

Werfen Sie Elektrowerkzeuge nicht in den Hausmüll! Gemäss Europäischer Richtlinie

2002/96/EG über Elektro- und Elektronik- Altgeräte und Umsetzung in nationales Recht

müssen verbrauchte Elektrowerkzeuge getrennt gesammelt und einer umweltgerechten

Wiederverwertung zugeführt w erden.

DECLARAÇÃO DE CONFORMIDADE CE

P

Não deite ferramentas eléctricas no lixo doméstico! De acordo com a directiva europeia

2002/96/CE sobre ferramnetas eléctricas e electrónicas usadas e a transposição para as

leis nacionais, as ferramentas eléctricas usadas devem ser recolhidas em separado e

encaminhadas a uma instalação de reciclagem dos materiais ecológica.

KUN FOR EULANDE

Elværktøj må ikke bortskaffes som almindeligt affald! I henhold til det europæiske direktiv

2002/96/EF om bortskaffelse af elektriske og elektroniske produkter og gældende national

lovgivning skal brugt elværktøj indsamles separat og bortskaffes på en måde, der skåner miljøet

mest muligt.

KUN FOR EULAND

N

Kast aldri elektroverktøy i husholdningsavfallet! I henhold til EU-direktiv 2002/96/EF om

kasserte elektriske og elekrtoniske produkter og direktivets iverkselting i nasjonal rett,

må elektroverktøy som ikke lenger skal brukes, samles separat og returneres til et

miljøvennlig gjenvinningsanlegg.

Μόνο για τις χώρες της EE

Μην πετάτε τα ηλεκτρικά εργαλεία στον κάδο οικιακών

απαρριμμάτων! Σύμφωνα με την ευρωπαϊκή οδηγία 2002/96/

EK περί ηλεκτρικών και ηλεκτρονικών συσκευών καιτην

ενσωμάτωσή της στο εθνικό δίκαιο, τα ηλεκτρικά εργαλεία

πρέπει να συλλέγονται ξεχωριστά και να επιστρέφονται για

ανακύκλωση με τρόπο φιλικό προς το περιβάλλον.

Numai pentru ţările UE

A nu se arunca echipamentele electrice împreună cu deşeurile domestice.

Conform Directivei Europene 2002/96/CE privind deşeurile din echipamente electrice

şi electronice, şi transpunerea sa conform legilor naţionale, aparaturile eletrice uzate

trebuie colectate separat, pentru a fi refolosite în mod ecologic.

Jen pro státy EU

Elektrické nářadí nevyhazujte do komunálního odpadu! Podle evropské směrnice 2002/96/

EG o nakládání spoužitými elektrickými a elektronickými zařízeními a odpovídajících

ustanovení právních předpisů jednotlivých zemí se použitá elektrická nářadí musí sbírat

odděleně od ostatního odpadu a podrobit se ekologicky šetrnému recyklování.

Только для стран ЕС

Не выкидывайте электроприборы вместе с обычным мусором! В соответствии

с европейской директивой 2002/96/EG об утилизации старых электрических и

электронных приборов и в соответствии с местными законами электроприборы,

бывшие в эксплуатации, должны утилизовываться отдельно безопасным для

окружающей среды способом.

156

Page 26

I

GARANZIA

Questo apparecchio è coperto da garanzia legale in base alle leggi e norme in vigore alla data e nel paese di acquisto, relativamente

ai vizi e difetti di fabbricazione e/o del materiale impiegato. La garanzia si limita alla riparazione o alla sostituzione, presso i Centri

Assistenza autorizzati da PENTAIR INTERNATIONAL S.a.r.l., della pompa o delle parti riconosciute mal funzionanti o difettose.

I componenti soggetti ad usura quali, ad esempio, tenuta meccanica e controfaccia, anelli e guarnizioni di tenuta, girante e parte

idraulica, membrane e cavi elettrici sono garantiti per un periodo non superiore alla loro vita utile. Per il corretto utilizzo e durata

del prodotto, nonché per usufruire del diritto alla garanzia, è necessario far revisionare ed eventualmente sostituire dai centri

assistenza autorizzati tali parti, in funzione del loro utilizzo. Per esercitare il diritto di garanzia, in caso di guasto, rivolgetevi

direttamente al Vostro rivenditore e/o al Centro Assistenza autorizzato.

L’eventuale denuncia del prodotto ritenuto difettoso deve essere avanzata non appena viene riscontrata l’anomalia e comunque

entro e non oltre i termini previsti dalla legge. Il diritto alla garanzia decorre dalla data di acquisto e deve essere dimostrato

dall’acquirente mediante presentazione contestuale del documento comprovante l’acquisto: scontrino fiscale, fattura o documento

di consegna.

La garanzia decade: se il guasto è provocato da trattamenti o operazioni improprie e messa in opera o magazzinaggio errati, errori

di collegamento elettrico o idraulico, mancata o inadeguata protezione. Se l’impianto o l’installazione dell’apparecchio non sono

stati eseguiti correttamente. Se il guasto è dovuto a cause di forza maggiore o altri fattori esterni ed incontrollabili. Se il prodotto

è utilizzato con liquidi abrasivi o corrosivi o diversi da quelli consentiti e comunque non compatibili con i materiali impiegati nella

costruzione delle pompe. Nel caso di utilizzo del prodotto oltre i limiti dichiarati in targa o in condizioni non consentite e di interventi

da parte dell’acquirente o di personale non autorizzato per smontaggio anche parziale del prodotto, modifiche o manomissioni.

Se i materiali sono avariati a seguito del naturale logoramento. Ogni uso diverso da quello indicato sul manuale d’uso e

manutenzione non è garantito se non espressamente indicato per iscritto dal produttore. Si raccomanda sempre di leggere

attentamente e preventivamente il libretto di istruzioni.

Avvertenze:

Qualora il Vostro apparecchio non funzionasse, controllate che il mancato funzionamento non sia provocato da altri motivi, ad

esempio interruzione dell’alimentazione di corrente apparecchi di controllo o di comando oppure manipolazione non appropriata.

ricordarsi di allegare all’apparecchio difettoso la seguente documentazione: Ricevuta di acquisto (fattura, scontrino fiscale)

descrizione dettagliata del difetto riscontrato.

GB

WARRANTY

This device is covered by legal warranty, based on the regulations and standards in force to date and in the country of purchase,

as regards manufacturing and/or material defects.The warranty only covers fixing or replacement of the pump or defective parts,

at the PENTAIR INTERNATIONAL S.a.r.l. authorized service centers.Components subject to wear, such as mechanical seal and

counter face, sealing rings and gaskets, impeller and hydraulic part, membranes and electric cables are guaranteed for a period

not exceeding their useful life. For a proper use and life of the product, and to make use of the warranty rights, have these parts

inspected and optionally replaced at the authorized service centers, based on their use.To exercise warranty rights, in the event

of fault please contact your retailer and/or the authorized service center. Any defects of the product should be reported as soon

as the fault is discovered and in any event, within the terms set forth by law. The warranty is valid as of the date of purchase, as

proved by the user submitting a purchase receipt, invoice or delivery note.The warranty becomes void: if the failure is caused by

improper treatments or operations, incorrect startup or storage, wrong electric or hydraulic connections, failed or inappropriate

protection; if the equipment installation or system were not performed correctly; if the failure is due to force majeure or external

non-controllable factors; if the product is used with abrasive or corrosive liquids or other than those allowed, or in any event not

compatible with the materials used in the pump construction; if the product is used besides the limits reported on the plate or in

conditions not allowed and in the event of unauthorized interventions by the user or other personnel for even partial disassembly

of the product, changes or tampering; if the materials are naturally worn.Any use differing from that indicated on the use and

maintenance manual is not guaranteed, unless otherwise indicated in writing by the manufacturer. Please read the instruction

manual carefully before using the product.

Warnings:

If the unit does not work, check whether the failure is due to other reasons, such as power supply failure, control or command

equipment or wrong handling. Please enclose the following documents with the faulty equipment:Purchase receipt (invoice slip)

Detailed description of the fault found

157

Page 27

credits

PENTAIR INTERNATIONAL S.a.r.l.

Avenue de Sevelin, 18 - 1004 LAUSANNE - SWITZERLAND

All Pentair trademarks and logos are owned by Pentair, inc. All other brand or product names are trademarks or registered marks of their respective owners.

Because we are continously improving our products and services, Pentair reserves the right to change specifications without prior notice.

Pentair is an equal opportunity employer.

253P9070 Rev.1 11/2014 © 2013 Pentair, Inc. All Rights Reserved.

Loading...

Loading...