Pentair VLR 4-120, VLR 4-20A, VLR 8-20 A, VLR 8-40, VLR 16-30/2 User Manual

...

Index

1. GENERAL INFORMATION

1.1 Supplied documents

1.1.1 Manual

1.2 Information ownership

1.3 Machine identification data

1.4 EC declaration of conformity

1.5 General information on safety

1.5.1 Personnel qualification

1.5.2 Special compliance

1.6 Conventions

1.6.1 Word conventions

1.6.2 Typographical conventions

1.7 Expected uses

1.7.1 Expected uses

1.7.2 Expected modes of installation

1.8 Non expected uses

1.8.1 Liabilities resulting from non expected uses

1.9 Warranty

1.10 Service

1.11 How to use the supplied documents

2. DESCRIPTION

2.1 Description

2.1.1 Architecture and operating principles

2.1.2 Machine structure

2.2 Technical features

2.2.1 Noise

2.2.2 Liability

page 14

page 16

3. INSTALLATION

3.1 Hoisting

3.1.1 Machine free from any type of packaging

3.1.2 Machine packed in cardboard box

3.1.3 Machine packed in a wooden crate

3.1.4 Machines secured on a supporting surface

3.2 Transport

3.3 Storage

3.3.1 Characteristics of the storage area

3.3.2 Environmental characteristics of the storage area

3.4 Preliminary checks

3.4.1 Check for damages

3.4.2 Damage signalling

3.5 Preparation of the installation area

3.5.1 Characteristics of the installation area

3.6 Installation

3.6.1 Connection to piping

3.6.2 Terminal box position

3.6.3 Connection to the electric system

3.7 Adjustment

3.7.1 Machine motor coupling adjustment

4. USE

4.1 Priming

4.1.1 Machines installed under head

4.1.2 Machines installed above head (suction mode)

4.2 Starting

4.3 Start and stop frequency control

page 17

page 21

5. MAINTENANCE

5.1 Lubrication

5.2 Temporarily quiescing

5.3 Periodical inspection

5.4 Extraordinary maintenance

6. OPERATION TROUBLES

7. DISMANTLING

7.1 Disconnecting the machine

7.2 Residual risks after disconnection

page 22

page 23

page 24

13

1. GENERAL INFORMATION

1.1 Supplied documents

1.1.1 Manual

Data

Instruction manual

Issue 1

Version 1105

Code 253P7530

Recipients

This manual is dedicated to the operators charged of the

machine management during all the phases of its technical life

Contents

This manual includes the following information:

- Manufacturer declaration

- Information on safety

- Sales information

- Information on documents

- Machine description

- Transport information

- Storage information

- Installation information

- Adjustment information

- Use information

- Maintenance information

- Dismantling information

These pieces of information are subdivided into the following

chapters and appendixes of this manual:

Chapter 1 : General information

Chapter 2 : Description

Chapter 3 : Installation

Chapter 4 : Use

Chapter 5 : Maintenance

Chapter 6 : Operating troubles

Chapter 7 : Dismantling

Appendix : Product specification

1.2 Information ownership

The information contained in this manual is owned by PENTAIR

WATER ITALY Srl

The reproduction, also partial, of this manual is forbidden without

the express authorisation of PENTAIR WATER ITALY Srl

The information contained in this manual only concerns the

machine specified in the “Product specification” section.

PENTAIR WATER ITALY reserves the right to make to the

machines the changes not specified in “Machine identification

data” whenever deemed right.

1.3 Machine identification data

Machine acronym

Centrifugal electric pump

Vertical multistage

with “in line” mouth

cast iron base

VLR

VLRI steel base AISI 304

VLRX steel base AISI 316

Nominal delivery in m3/h

Number of stages (= nr. of impellers x 10)

Number of impellers (used when lower

than the number of stages only)

Version with oval flanges

Version with round flanges.

VLR VLRI VLRX 4 - 80 / 7 (A) (F)

1.4 EC declaration of conformity

See page 2

1.5 General information on safety

We recommend to carefully following the instructions contained in

this manual, paying special attention to notes, attention and

danger warnings.

Attention

Danger When carrying out repair or maintenance

Danger

Attention

Danger Before using the motor-pump, check every

Danger When starting the motor-pump (by connect-

The user must always comply with the

accident prevention local prescriptions in

force in the Country where the product is

installed.

operations on the motor-pump, remove the

plug from the outlet and/or turn off the

switch (if existing) disconnecting in this

way the power supply to the motor-pump.

This will prevent the accidental starting

which may cause damages to people and/or

things.

Never carry out maintenance, installation or

handling operations on the motor-pump

with the electric system live: this may

cause serious accidents to people, even

their death.

During operation, do not remove or handle

the motor-pump.

time that the cable and all the electric

devices are efficient, repaired and protected.

ing the plug to the outlet and/or turning off

the switch) make sure not to be barefoot

and that your hand are not wet.

The non-compliance to the procedures and

safety precautions contained in the supplied documents causes the exclusion of

PENTAIR WATER ITALY from any liability.

14

1.5.1 Personnel qualification

Qualification and protection restrictions foreseen for the operators

RECCOMENDED

OPERATOR QUALIFICATION

Carrier Knowledge and

command of the

chapters:

- "General information"

- "Description"

- "Installation"

Installer Qualification

complying with the

provisions of the

Country of installation, knowledge and

command of the

chapters:

- "General information"

- "Description"

- "Installation"

User Knowledge and

command of the

chapters:

- "General information"

- "Description"

- "Use"

Maintenance

man

Demolisher Knowledge and

Danger The machine safely operates when used by

Fitness acknowledged by PENTAIR

WATER ITALY,

knowledge and

command of the

chapters:

- "General information "

- "Description"

- "Maintenance"

command of the

chapters:

- "General information"

- "Description"

- "Dismantling"

personnel qualified according to the

instructions contained in this manual and

on board the machine.

All the operations shown by this manual

must only be carried out by qualified

personnel equipped with the protecting

means provided for by this manual

PENTAIR WATER ITALY is not liable in

case of accidents deriving from the use of

non qualified and non authorised personnel

and by the non compliance to the instructions present in this manual an on board

the machine.

INDIVIDUAL

PROTECTION

MEANS

Protective shoes

and gloves

Protective shoes

and gloves

Protective shoes

and gloves, high

temperature

protecting overall

and gloves

Protective shoes

and gloves

Protective shoes

and gloves

1.5.2 Special compliance

The use of personnel having a qualification different from the

specified one may involve risks for people and/or the machine.

1.6 Conventions

1.6.1 Word conventions

The manual adopts the following conventions

-

Machine

-

Authorised technician

-

Skilled technician

: motor-pumps specified in the

“Product specification” "

: person authorised by PENTAIR

WATER ITALY to carry out on the

machine operations not documented

by this manual

: person authorised to carry out on the

machine operations not documented

by this manual after contacting

PENTAIR WATER ITALY

1.6.2 Typographical conventions

Danger Danger indications show the procedure

whose non or partial compliance may

cause physical damages to the operator

Attention

Attention indications show the procedures

whose non or partial compliance may

cause damages to the machine or to the

equipment connected to it

Note indications contain important information highlighted outside the text to which

they refer

1.7 Expected uses

1.7.1 Expected uses

The machine has been designed, manufactured and protected to

allow the conveying, circulation and the increase in pressure of

the following types of fluids:

- Water having a -15 °C to 120 °C temperature (for temperature

lower than 0°C the addition of a fit quantity of ice-preventing

agent is expected)

- Water glycol mixtures (or ice-preventing products having

chemical physical characteristics similar to glycol) with a glycol

percentage up to 50%

- Liquids and waters chemically compatible with the materials that

are part of the machine

- Neutral, non explosive fluids having a viscosity similar to water

The machine has been designed, manufactured and protected to

allow a fluid delivery depending on the required head (see

“Product specification”)

1.7.2 Expected modes of installation

The machine has been designed, manufactured and protected to

be installed both:

- Indoor

- Outdoor with a protection from atmospheric agents

The machine has been designed, manufactured and protected to

be used under the following atmospheric conditions:

- Temperature range: -15 °C to +40 °C

- Allowed relative humidity range: 30 to 90%

15

The machine has been designed, manufactured and protected to

be installed in a vertical position with the motor in the upper part.

The machine has been designed, manufactured and protected to

be:

- Fixed on foundations having the characteristics shown in the

appendix “Product specification” paragraph “Foundations”.

- Connected to pipes able to bear the machine weight.

The machine has been designed, manufactured and protected to

be fed by electric power having one of the following characteristics:

- 230 V, 50 Hz, single phase

- 230 V, 50 Hz, three-phase

- 400 V, 50 Hz, three-phase

Different voltages and frequencies are available on request.

1.8 Non expected uses

The machine has not been designed, manufactured, nor protected for all the uses not expressly specified in “Expected uses”.

In particular, the machine has not been designed, manufactured,

nor protected for the conveying, circulation and increase in

pressure of the following fluids:

- Explosive

- Corrosive

- Oil-derivatives and mixtures containing oil-derivatives.

- Mixtures containing material or fibres in suspension

- Sea water

For special uses, please contact out technical office

1.8.1 Liabilities resulting from non expected uses

PENTAIR WATER ITALY is not liable for

possible damages to people, animals or

things resulting from a non-expected use of

the machine.

1.9 Warranty

Non authorised installation, adjustment and

maintenance operations and/or operations

carried out by non qualified personnel

imply the termination of the warranty

1.10 Service

1.11 How to use the supplied documents

We recommend the operators to carefully read the supplied

documents before carrying out any operation on the machine

The supplied documents must be kept for the whole life of the

machine so that it can be easily found when necessary.

If the machine is sold as second-hand, it must be sold together

with the supplied documents.

2. DESCRIPTION

2.1 Description

2.1.1 Architecture and operating principles

VLR motor-pumps are centrifugal, vertical multistage motorpumps with “in-line” suction inlets and delivery.

VLR motor-pumps are directly coupled to an asynchronous single

or three-phase motor with closed casing and external ventilation.

VLR motor-pumps are not self-priming and need a priming

procedure. VLR motor-pumps can be equipped with oval or round

flanges.

2.1.2 Machine structure

Components VLR VLR32

Base EN GJL 200 Cast iron EN GJS 500 Cast iron

Headatock EN GJL 200 Cast iron EN GJL 200 Cast iron

Shaft AISI 316 AISI 431

Impellers and choke AISI 304 AISI 304

External cylinder AISI 304 AISI 304

Tie rods Steel zincate AISI 316

Mechanical

seal

O-ring EPDM EPDM

Seals Paper ---

Componenti VLRI VLRX

Base AISI 316 AISI 316

Headatock See note 1 See note 1

Shaft AISI 316 AISI 316

Impellers and choke AISI 304 AISI 316

External cylinder AISI 304 AISI 316

Tie rods AISI 316 AISI 316

Mechanical

seal

O-ring EPDM EPDM

Seals Paper Paper

rotating Tungsten Tungsten

fixer Tungsten Grafite

rotating Tungsten Tungsten

fixer Tungsten Tungsten

NOTA: EN GJL 200 (ex G220) cast iron with internal steel

drivehead

2.2 Technical features

Machine size and weights

See "Product specification"

Electrical data

See "Product specification " and identification plate.

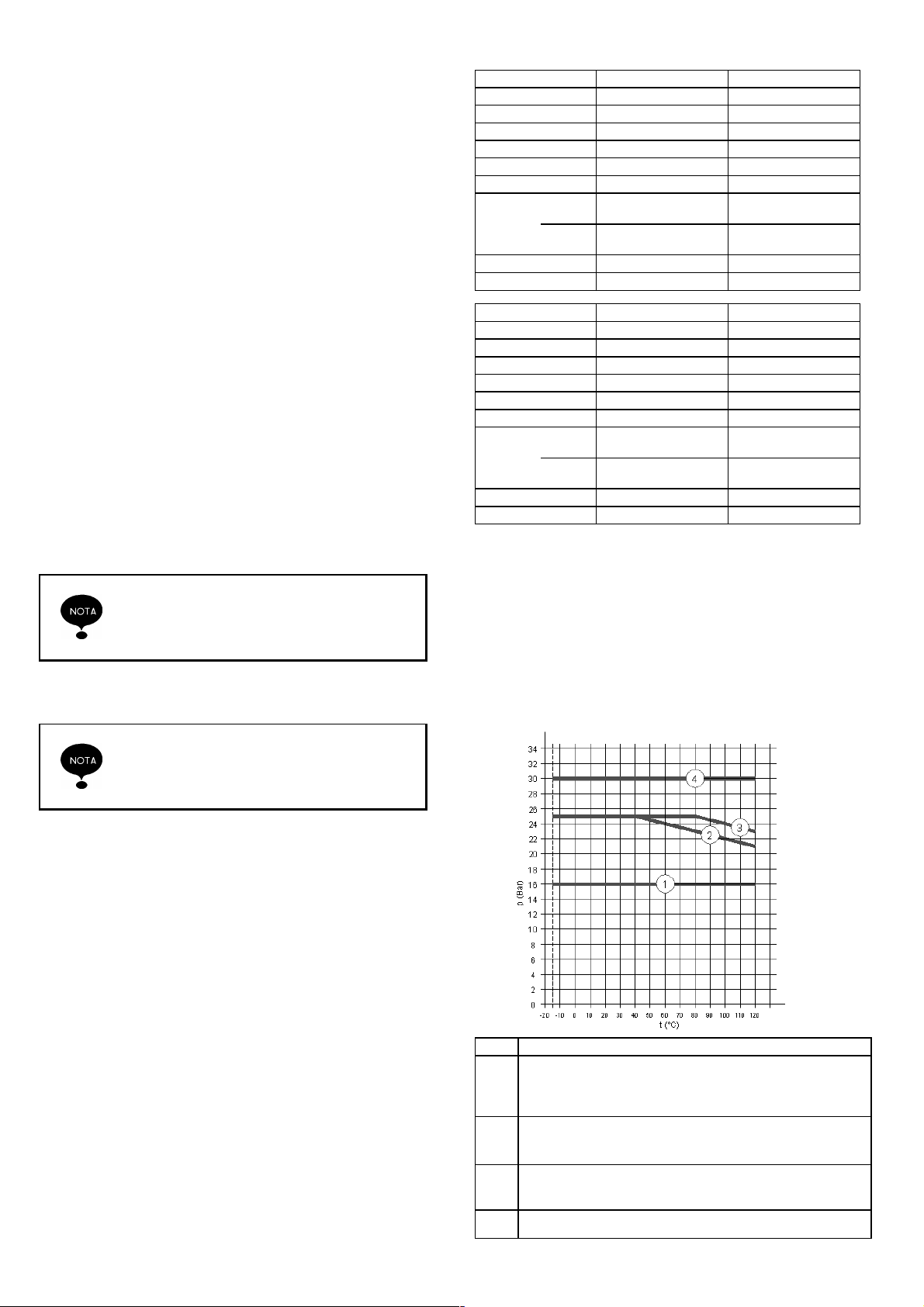

Pressure

- maximum operating pressure

Num.

n

o

p

q

2B - 30/2 A ÷ 2B - 150 A

4 - 20 A ÷ 4 - 160 A

8 - 20 A ÷ 8 - 120 A

2B - 180 F ÷ 2B - 160 F

4 - 190 F ÷ 4 - 260 F

8 - 140 F ÷ 8 - 200 F

16 - 30/2 F - 100 F ÷ 16 - 160 F

32 - 1 ÷ 32 - 14

Machine VLR – VLRI - VLRX

16

Loading...

Loading...