DYNA-PRO®

SELF-PRIMING POOL/SPA PUMP

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

INSTALLATION AND

USER’S GUIDE

i

CUSTOMER SERVICE / TECHNICAL SUPPORT

If you have questions about ordering Pentair Aquatic Systems replacement parts, and pool products, please contact:

Customer Service and Technical Support, USA

(8 A.M. to 4:30 P.M. — Eastern/Pacific Times)

Phone: (800) 831-7133

Fax: (800) 284-4151

Web site

Visit www.pentairpool.com or www.staritepool.com for

information about Pentair products.

TABLE OF CONTENTS

Important Pump Warning and

Safety Instructions ................................................

Installation ..............................................................

Location

Piping

Taping Instructions

Fittings

Pump Suction Requirements

Suction Outlet Covers

Testing and Certification

Water Velocity

Electrical Installation

Wiring

Grounding

Bonding

Sanford, North Carolina (8 A.M. to 4:30 P.M. ET)

Phone: (919) 566-8000

Fax: (919) 566-8920

Moorpark, California (8 A.M. to 4:30 P.M. PT)

Phone: (805) 553-5000 (Ext. 5591)

Fax: (805) 553-5515

Operation ...............................................................

ii

1

1

1

1

1

2

2

2

2

3

3

3

3

Pressure Test

Priming the Pump

Draining the Pump

Winterizing

Start-up for Winterized Equipment

Maintenance ..........................................................

Cleaning the Strainer Basket

Pump Disassembly / Removing Old Seal

Pump Reassembly / Installing New Seal

Troubleshooting ....................................................

Replacement Parts ...............................................

Motor Table

Parts List

4

4

4

4

4

5

6

6

6

7

8

9

9

10

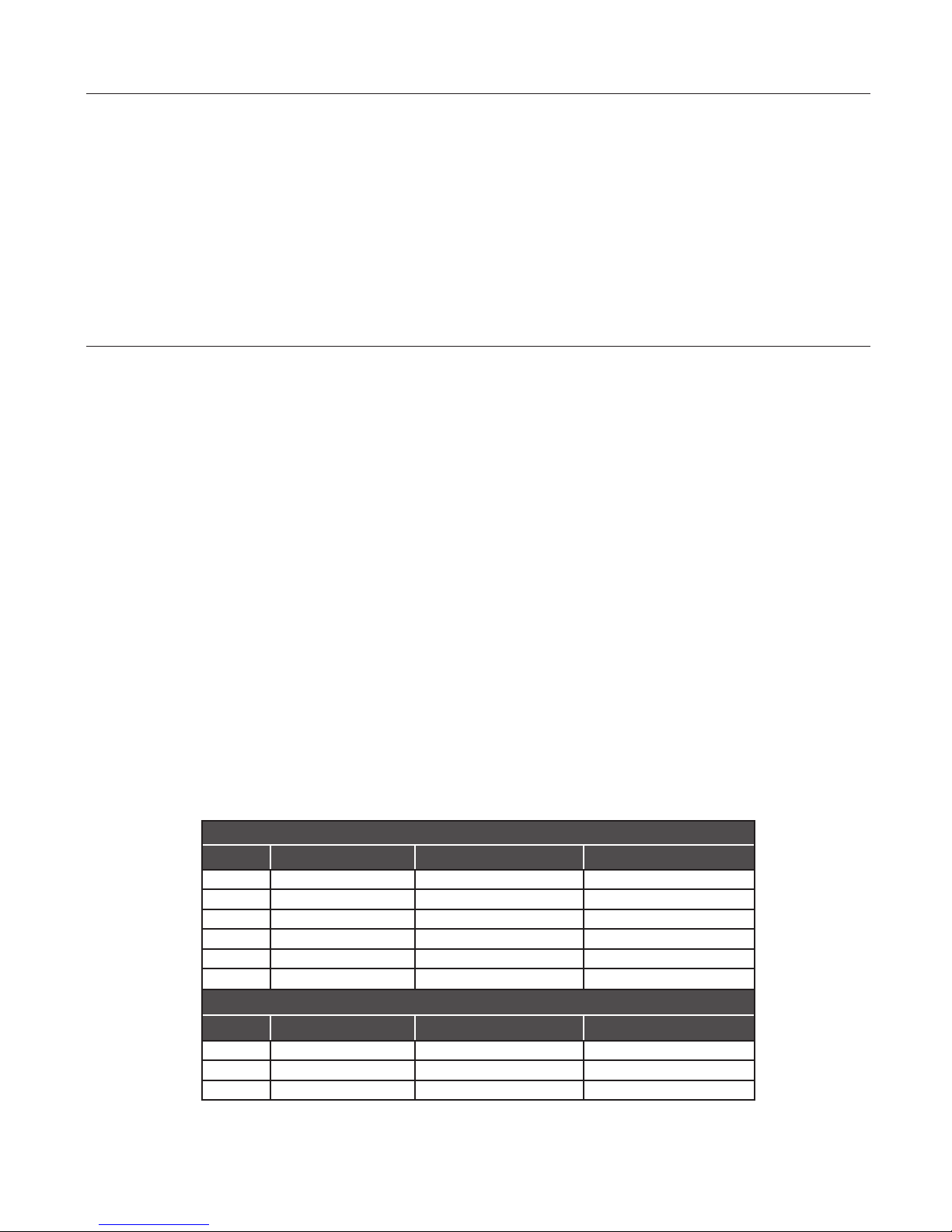

HP MPRA Series MPE Series MPEA Series

1/2 MPE6C-204L

3/4 MPRA6D-204L MPE6D-205L MPEA6D-204L

1 MPRA6E-205L MPE6E-206L MPEA6E-205L

1-1/2 MPEA6F-206L

2 MPE6G-208L MPEA6G-207L

2-1/2 MPEAA6G-208L

HP MPRA Series MPE Series MPEA Series

1-1/2 MPRA6YF-206L

2 MPE6YG-208L

2-1/2 MPEAA6YG-208L

P/N S771 Rev. E 7/19/18

DYNAPRO® Self-Priming Pool/Spa Pump Installation and User’s Guide

Pump Models

SINGLE SPEED MODELS

TWO SPEED MODELS

IMPORTANT PUMP WARNING AND SAFETY INSTRUCTIONS

F

IMPORTANT NOTICE

This guide provides installation and operation instructions for this pump.

Consult Pentair with any questions regarding this equipment.

Attention Installer: This guide contains important information about the

installation, operation and safe use of this product. This information should

be given to the owner and/or operator of this equipment after installation

or left on or near the pump.

Attention User: This manual contains important information that will help

you in operating and maintaining this product. Please retain it for future

reference.

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This is the safety alert symbol. When you see this

symbol on your system or in this manual, look for

one of the following signal words and be alert to

the potential for personal injury.

Warns about hazards that can cause death,

serious personal injury, or major property damage

if ignored.

Warns about hazards that may cause death,

serious personal injury, or major property damage

if ignored.

Warns about hazards that may or can cause minor

personal injury or property damage

if ignored.

NOTE Indicates special instructions not related to

hazards.

Carefully read and follow all safety instructions in this manual and on

equipment. Keep safety labels in good condition; replace if missing

or damaged.

When installing and using this electrical equipment, basic safety

precautions should always be followed, include the following:

Do not permit children to use this product.

RISK OF ELECTRICAL SHOCK. Connect only to

a branch circuit protected by a ground-fault circuitinterrupter (GFCI). Contact a qualified electrician if you cannot verify that

the circuit is protected by a GFCI.

This unit must be connected only to a supply circuit

that is protected by a ground-fault circuit-interrupter

(GFCI). Such a GFCI should be provided by the installer and should

be tested on a routine basis. To test the GFCI, push the test button.

The GFCI should interrupt power. Push the reset button. Power should

be restored. If the GFCI fails to operate in this manner, the GFCI is

defective. If the GFCI interrupts power to the pump without the test button

being pushed, a ground current is flowing, indicating the possibility of an

electric shock. Do not use this pump. Disconnect the pump and have the

problem corrected by a qualified service representative before using.

This pump is for use with permanent swimming

pools and may also be used with hot tubs and spas

if so marked. Do not use with storable pools. A permanently-installed pool

is constructed in or on the ground or in a building such that it cannot be

readily disassembled for storage. A storable pool is constructed so that

it is capable of being readily disassembled for storage and reassembled

to its original integrity.

ii

General Warnings

• Never open the inside of the drive motor enclosure. There is a

capacitor bank that holds a 230 VAC charge even when there is no

power to the unit.

• The pump is not submersible.

• The pump is capable of high flow rates; use caution when installing

and programming to limit pumps performance potential with old or

questionable equipment.

• Code requirements for electrical connection differ from country to

country, state to state, as well as local municipalities. Install equipment

in accordance with the National Electrical Code and all applicable

local codes and ordinances.

• Before servicing the pump; switch OFF power to the pump by

disconnecting the main circuit to the pump.

• This appliance is not intended for use by persons (including children) of

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning the use of the appliance by a person responsible for their

safety.

FAILURE TO FOLLOW ALL INSTRUCTIONS AND

WARNINGS CAN RESULT IN SERIOUS BODILY

INJURY OR DEATH. THIS PUMP SHOULD BE INSTALLED AND

SERVICED ONLY BY A QUALIFIED POOL SERVICE PROFESSIONAL.

INSTALLERS, POOL OPERATORS AND OWNERS MUST READ

THESE WARNINGS AND ALL INSTRUCTIONS IN THE OWNER’S

MANUAL BEFORE USING THIS PUMP. THESE WARNINGS AND

THE OWNER’S MANUAL MUST BE LEFT WITH THE POOL OWNER.

SUCTION ENTRAPMENT HAZARD: STAY OFF

THE MAIN DRAIN AND AWAY FROM ALL SUCTION

OUTLETS!

THIS PUMP PRODUCES HIGH LEVELS OF SUCTION AND CREATES

A STRONG VACUUM AT THE MAIN DRAIN AT THE BOTTOM OF THE

BODY OF WATER. THIS SUCTION IS SO STRONG THAT IT CAN TRAP

ADULTS OR CHILDREN UNDER WATER IF THEY COME IN CLOSE

PROXIMITY TO A DRAIN OR A LOOSE OR BROKEN DRAIN COVER

OR GRATE.

THE USE OF UNAPPROVED COVERS OR ALLOWING USE OF

THE POOL OR SPA WHEN COVERS ARE MISSING, CRACKED OR

BROKEN CAN RESULT IN BODY OR LIMB ENTRAPMENT, HAIR

ENTANGLEMENT, BODY ENTRAPMENT, EVISCERATION AND/OR

DEATH.

The suction at a drain or outlet can cause:

Limb Entrapment: When a limb is sucked or inserted into an opening

resulting in a mechanical bind or swelling. This hazard is present when

a drain cover is missing, broken, loose, cracked or not properly secured.

Hair Entanglement: When the hair tangles or knots in the drain cover,

trapping the swimmer underwater. This hazard is present when the flow

rating of the cover is too small for the pump or pumps.

Body Entrapment: When a portion of the body is held against the drain

cover trapping the swimmer underwater. This hazard is present when the

drain cover is missing, broken or the cover flow rating is not high enough

for the pump or pumps.

Evisceration/Disembowelment: When a person sits on an open pool

(particularly a child wading pool) or spa outlet and suction is applied directly

to the intestines, causing severe intestinal damage. This hazard is present

when the drain cover is missing, loose, cracked, or not properly secured.

DYNAPRO® Self-Priming Pool/Spa Pump Installation and User’s Guide

iii

IMPORTANT PUMP WARNING AND SAFETY INSTRUCTIONS

Mechanical Entrapment: When jewelry, swimsuit, hair decorations, finger,

toe or knuckle is caught in an opening of an outlet or drain cover. This

hazard is present when the drain cover is missing, broken, loose, cracked,

or not properly secured.

NOTE: ALL SUCTION PLUMBING MUST BE INSTALLED IN

ACCORDANCE WITH THE LATEST NATIONAL AND LOCAL CODES,

STANDARDS AND GUIDELINES.

TO MINIMIZE THE RISK OF INJURY DUE TO

SUCTION ENTRAPMENT HAZARD:

• A properly installed and secured ANSI/ASME A112.19.8 approved

anti-entrapment suction cover must be used for each drain.

• Each suction cover must be installed at least three (3’) feet apart, as

measured from the nearest point to nearest point.

• Regularly inspect all covers for cracks, damage and advanced

weathering.

• If a cover becomes loose, cracked, damaged, broken or is missing,

replace with an appropriate certified cover.

• Replace drain covers as necessary. Drain covers deteriorate over

time due to exposure to sunlight and weather.

• Avoid getting hair, limbs or body in close proximity to any suction

cover, pool drain or outlet.

• Disable suction outlets or reconfigure into return inlets.

A clearly labeled emergency shut-off switch for the

pump must be in an easily accessible, obvious place.

Make sure users know where it is and how to use it in case of emergency.

The Virginia Graeme Baker (VGB) Pool and Spa Safety Act creates

new requirements for owners and operators of commercial swimming

pools and spas.

Commercial pools or spas constructed on or after December 19, 2008,

shall utilize:

(A) A multiple main drain system without isolation capability with suction

outlet covers that meet ASME/ANSI A112.19.8a Suction Fittings for

Use in Swimming Pools, Wading Pools, Spas, and Hot Tubs and either:

(i) A safety vacuum release system (SVRS) meeting ASME/ANSI

A112.19.17 Manufactured Safety Vacuum Release systems (SVRS)

for Residential and Commercial Swimming Pool, Spa, Hot Tub,

and Wading Pool Suction Systems and/or ASTM F2387 Standard

Specification for Manufactured Safety Vacuum Release Systems

(SVRS) for Swimming pools, Spas and Hot Tubs or

(ii) A properly designed and tested suction-limiting vent system or

(iii) An automatic pump shut-off system.

Commercial pools and spas constructed prior to December 19, 2008,

with a single submerged suction outlet shall use a suction outlet cover

that meets ASME/ANSI A112.19.8a and either:

(A) A SVRS meeting ASME/ANSI A112.19.17 and/or ASTM F2387, or

(B) A properly designed and tested suction-limiting vent system, or

(C) An automatic pump shut-off system, or

(D) Disabled submerged outlets, or

(E) Suction outlets shall be reconfigured into return inlets.

For Installation of Electrical Controls at Equipment Pad (ON/OFF

Switches, Timers and Automation Load Center)

Install all electrical controls at equipment pad, such as

on/off switches, timers, and control systems, etc. to

allow the operation (startup, shut-down, or servicing)

of any pump or filter so the user does not place any

portion of his/her body over or near the pump strainer

lid, filter lid or valve closures. This installation should

allow the user enough space to stand clear of the filter

and pump during system start-up, shut down or servicing of the system filter.

DYNAPRO® Self-Priming Pool/Spa Pump Installation and User’s Guide

HAZARDOUS PRESSURE: STAND CLEAR OF

PUMP AND FILTER DURING START UP

Circulation systems operate under high pressure.

When any part of the circulating system (i.e.

locking ring, pump, filter, valves, etc.) is serviced,

air can enter the system and become pressurized.

Pressurized air can cause the pump housing cover, filter lid, and valves

to violently separate which can result in severe personal injury or death.

Filter tank lid and strainer cover must be properly secured to prevent

violent separation. Stand clear of all circulation system equipment when

turning on or starting up pump.

Before servicing equipment, make note of the filter pressure. Be sure

that all controls are set to ensure the system cannot inadvertently start

during service. Turn off all power to the pump. IMPORTANT: Place filter

manual air relief valve in the open position and wait for all pressure

in the system to be relieved.

Before starting the system, fully open the manual air relief valve and place

all system valves in the “open” position to allow water to flow freely from the

tank and back to the tank. Stand clear of all equipment and start the pump.

IMPORTANT: Do not close filter manual air relief valve until all

pressure has been discharged from the valve and a steady stream

of water appears. Observe filter pressure gauge and be sure it is not

higher than the pre-service condition.

General Installation Information

• All work must be performed by a qualified service professional, and

must conform to all national, state, and local codes.

• Install to provide drainage of compartment for electrical components.

• These instructions contain information for a variety of pump models

and therefore some instructions may not apply to a specific model. All

models are intended for use in swimming pool applications. The pump

will function correctly only if it is properly sized to the specific application

and properly installed.

Pumps improperly sized or installed or used in

applications other than for which the pump was

intended can result in severe personal injury or death. These risks

may include but not be limited to electric shock, fire, flooding, suction

entrapment or severe injury or property damage caused by a structural

failure of the pump or other system component.

The pump can produce high levels of suction within

the suction side of the plumbing system. These

high levels of suction can pose a risk if a person comes within the close

proximity of the suction openings. A person can be seriously injured

by this high level of vacuum or may become trapped and drown. It is

absolutely critical that the suction plumbing be installed in accordance

with the latest national and local codes for swimming pools.

Pumps and replacement motors that are single speed and

one (1) Total HP or greater cannot be sold, offered for sale, or

installed in a residential pool for filtration use in California, Title

20 CCR sections 1601-1609.

Warnings and safety instructions for Pentair Aquatic Systems pumps

and other related products are available at:

http://www.pentairpool.com/pool-owner/safety-warnings/ or call

(800) 831-7133 for additional free copies of these instructions.

Please refer to http://www.pentairpool.com/pool-owner/safety-

warnings/ for warning and safety instructions related to the this

product.

Warning Page P/N 352557 Rev. C 7/18

INSTALLATION

Trapped air in the system can cause permanent equipment damage. Ensure all air is relieved from the system

before operating, testing or servicing the equipment.

Do NOT connect system to a high pressure or city water system.

1

Location

Only qualified, licensed personnel should install the pump

and pump wiring.

Be sure the Dyna-Pro® Self-Priming Pool/Spa Pump

equipment pad or plumbing meets the following

requirements:

• Pump mount must be solid, level, rigid and

minimize vibration. To reduce vibration and stress

to piping, bolt the pump to the equipment pad.

• Allow for enough ventilation to maintain air

temperature at less than the maximum ambient

temperature rating listed on the motor nameplate.

• If installed in an enclosure/pump house, the

enclosure must have adequate ventilation and

air circulation to keep the temperature inside the

enclosure at or below the maximum rated ambient

temperature when the pump is running.

• Locate away from corrosive or flammable liquids.

• Suction port should be as close to water level as

possible. This pump will not lift water more than 10

ft. (3m).

• To reduce friction losses use short, straight suction

pipe.

• Allow for gate valves in both the suction and

discharge piping.

• Provide adequate floor drainage to prevent flooding

and protect the pump from excess moisture.

• Allow adequate access for servicing pump and

piping.

Port Threads:

Internal - 2” NPT for direct connection to pipe. External

- 3” Buttress. Fits Sta-Rite 38405-4094 Union Collar for

quick disconnect.

Order: Union Kit #77703-0105 (1.5” and 2” Union Halves).

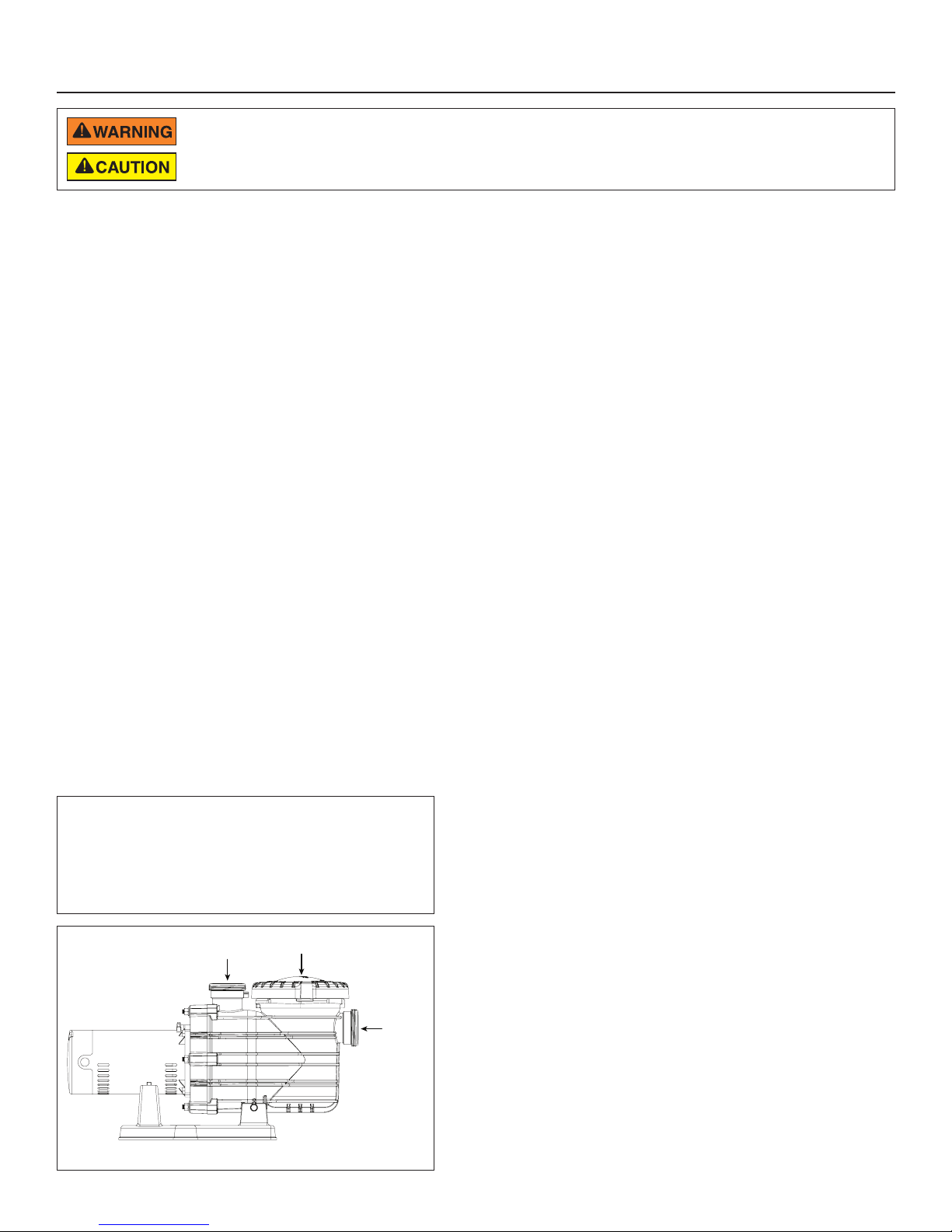

Figure 1

Discharge

Port

Strainer

Pot Lid

Piping

1. Use at least 2” (51mm) pipe. Increase size if a long run is needed.

2. Support both the suction and discharge piping independently,

placing these supports as close to the pump as possible. This will

prevent unnecessary strain on the pump.

3. During piping installation, start all piping and run the pipe away

from the pump. This will prevent strain caused by a gap at the last

connection.

4. Slope suction pipe slightly upward toward the pump to prevent

airlocking.

5. To prevent flooding when removing the pump for service, all

flooded suction systems must have a gate valve in both the

suction and discharge pipes.

6. For most installations Pentair recommends installing a valve

on both the pump suction and return lines so that the pump

can be isolated during routine maintenance. However, we also

recommend a valve, elbow or tee installed in the suction line

should be no closer to the front of the pump than five (5) times

the suction line diameter.

Example: A 2 inch pipe requires a 10 inch (25.4 cm) straight run

in front of the suction inlet of the pump. This will help the pump

prime faster and last longer.

Note: Do not install 90° elbows directly into the pump inlet or

outlet.

Taping Instructions

1. If connecting threaded pipe directly to the pump, apply one or

two layers of thread seal tape to the male pipe threads. Cover the

entire threaded portion of the pipe.

Note: Do NOT use pipe dope; pipe dope can lead to cracking in

some plastics and may damage components in the piping system.

2. If plumbing threaded pipe to the pump using unions, apply thread

seal tape between the pipe and union adapter. The union collar

should be installed hand-tight. Be sure the union’s O-ring is

seated correctly in its groove.

Note: DO NOT overtighten or tighten past the thread stops within

the pump ports.

If leaks occur, remove pipe, clean off old tape, rewrap with one or two

layers of new tape and reinstall the piping.

Pump may be bolted to level

foundation or mounting bracket

Suction

Port

Fittings

1. Fittings restrict flow. Use the fewest number of fittings possible to

maximize system efficiency.

2. Avoid fittings that could lead to air traps in suction piping.

3. Pool and spa drains must conform to International Association of

Plumbing and Mechanical Officials (IAPMO) standards.

4. Use only non-entrapping suction fittings and dual suction outlets.

DYNA-PRO® Self-Priming Pool/Spa Pump Installation and User’s Guide

Loading...

Loading...