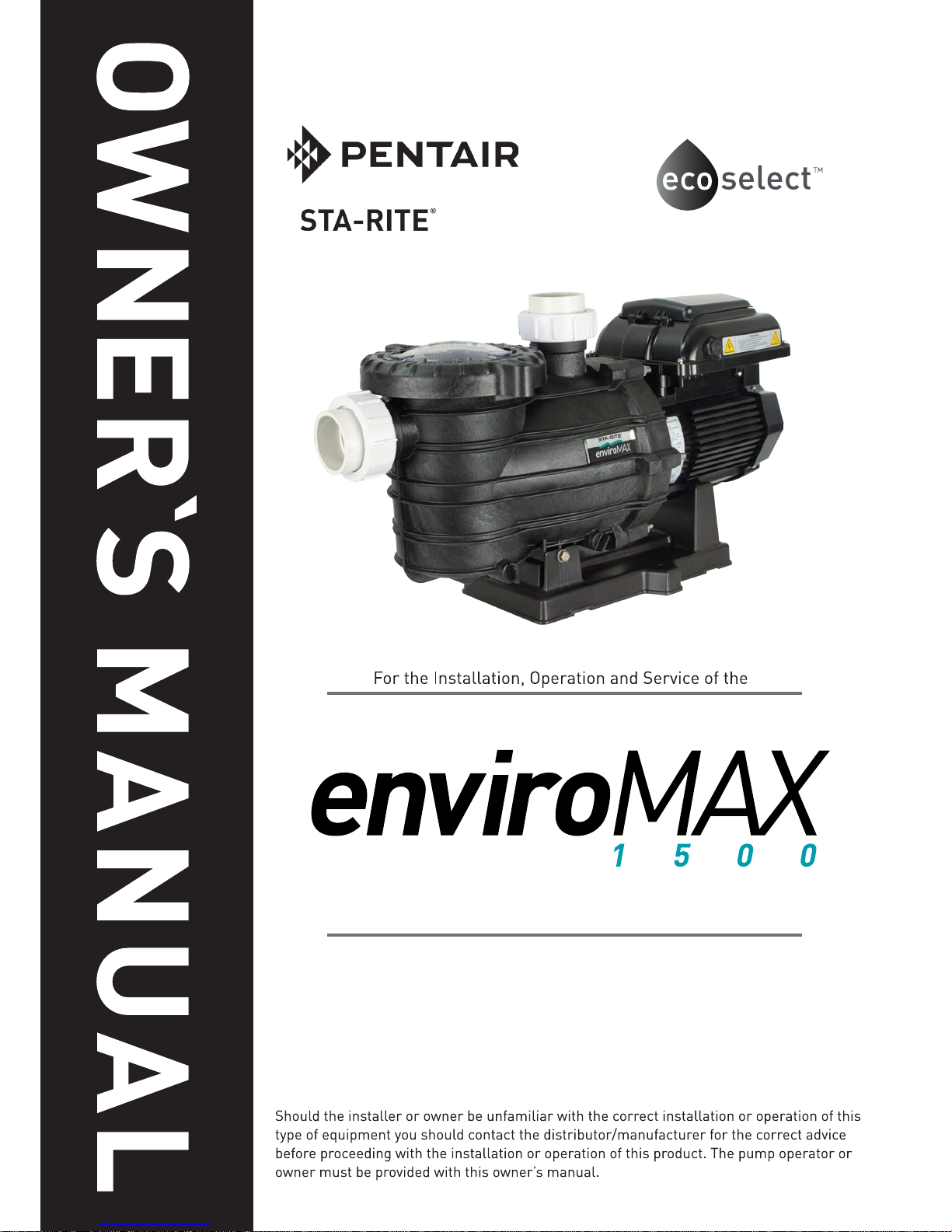

Pentair Sta-rite EnviroMAX 1500 Installation, Operation And Service Manual

Variable Speed Pool Pump

Eco Select

®

The Eco Select® brand identifies our most eco-friendly products

As the global leader in pool and spa equipment, we’ve made a strong commitment to develop and offer the

most environmentally responsible products available.

When you see the Eco Select® brand on one of our products, you’ll know it is our “greenest” and most

efficient product in that equipment category.

These products do the best job of saving energy, conserving water, reducing noise, or otherwise

contributing to a more environmentally responsible equipment system. In every case, a product that earns

the Eco Select brand is clearly our “greenest” and most efficient choice.

Table of Contents

Page

Features and Benefits 3

Technical Information

Model Data 4

Hydraulic Performance 5

Dimensions 5

Installation

Pump positioning 6

Piping 6

Pool Outlets 6

Electrical 7

Equipotential Bonding 7

Operation

Priming the Pump 9

Control Panel Overview 10

Setting Clock 11

Using Default Schedule 11

Custom Schedules 12

Operating the Pump While Running 14

Quick Clean 15

Keypad Lockout 16

Factory Reset 17

External Controls 18

Troubleshooting

Troubleshooting Guide 21

Motor Flash Codes 23

Spare Parts 24

Features & Benefits

The Sta-rite EnviroMAX is the ideal pump for new or existing pools. Utilising advanced hydraulic design and

the latest technology in permanent magnet, variable speed motors, the Sta-rite EnviroMAX has the perfect

combination of efficiency and performance. The Sta-rite EnviroMAX delivers energy savings and the power

when you need it. You will also have the peace of mind that you are doing your bit for the environment and

reducing your carbon foot print

► Variable speed pump, with 4 programmable speeds, allows you to effortlessly select the most efficient

setting to meet you filtration, cleaning and water feature needs.

► Radial flux, brushless permanent magnet motor delivers high efficiency and low noise levels.

► Fault protected motor prevents damage by automatically shutting down the motor in the event of a

locked rotor, under voltage, over voltage or over current condition and will automatically reduce the

speed during an over temperature condition.

► Precision-fit internal components and superior hydraulic design deliver effortless performance,

energy savings and extended pump life.

► A specially designed sound-dampening pump casing and base make pump operation incredibly quiet.

► Constructed of our durable, thermoplastic, composite resin, so you can be sure it will stand up to the

harshest conditions.

► A heavy-duty construction and a motor rated for continuous operation make the enviroMAX a tough,

long-lasting performer.

► The high-capacity trap holds a large amount of debris, so you clean less often.

► The Cam and Ramp™ lid is easy to remove and locks in place with a quarter turn, making inspection

and cleaning a breeze.

► Quick-disconnect plumbing unions.

3

Technical Information

Model Data

RPM: Low 1200RPM

Med 2200RPM

High 3000RPM

Override: 3150RPM

Electrical Rating: 230-240V 50Hz single phase

Rated Current: Low: 1.0A (max)

Med: 3.4A (max)

High: 8A (max)

Override: 9.6A

Motor Input Power (P

1

): Low: 188W (max)

Med: 750W (max)

High: 1840W (max)

Override: 2100W

Motor Output Power (P

2

): Low: 150W (max)

Med: 600W (max)

High: 1470W (max)

Override: 1700W

IP Rating: IPX6

Inlet (Suction): ABS Barrel Union to suit 50mm PVC pressure pipe

to AS/NZS 1477

Outlet (Discharge): ABS Barrel Union to suit 50mm PVC pressure pipe

to AS/NZS 1477

Max Total Head: 21m

Max Working Pressure: 260 kPa

Water Temperature Range: 5°C – 40°C

Maximum Ambient temperature: 55°C

Recommended pH Range: 7.2 - 7.8 (Guide Only)

Sound Power Level (Lwa): Low: 69dB

Med: 63dB

High: 57dB

Motor: Axial flux, permanent magnet, DC

Protection: Mains over voltage, mains under voltage, over

temperature, under temperature, locked rotor, over

current, phase disconnect.

Supply cord: 10A, H07RNF, 2m.

4

Dimensions

5

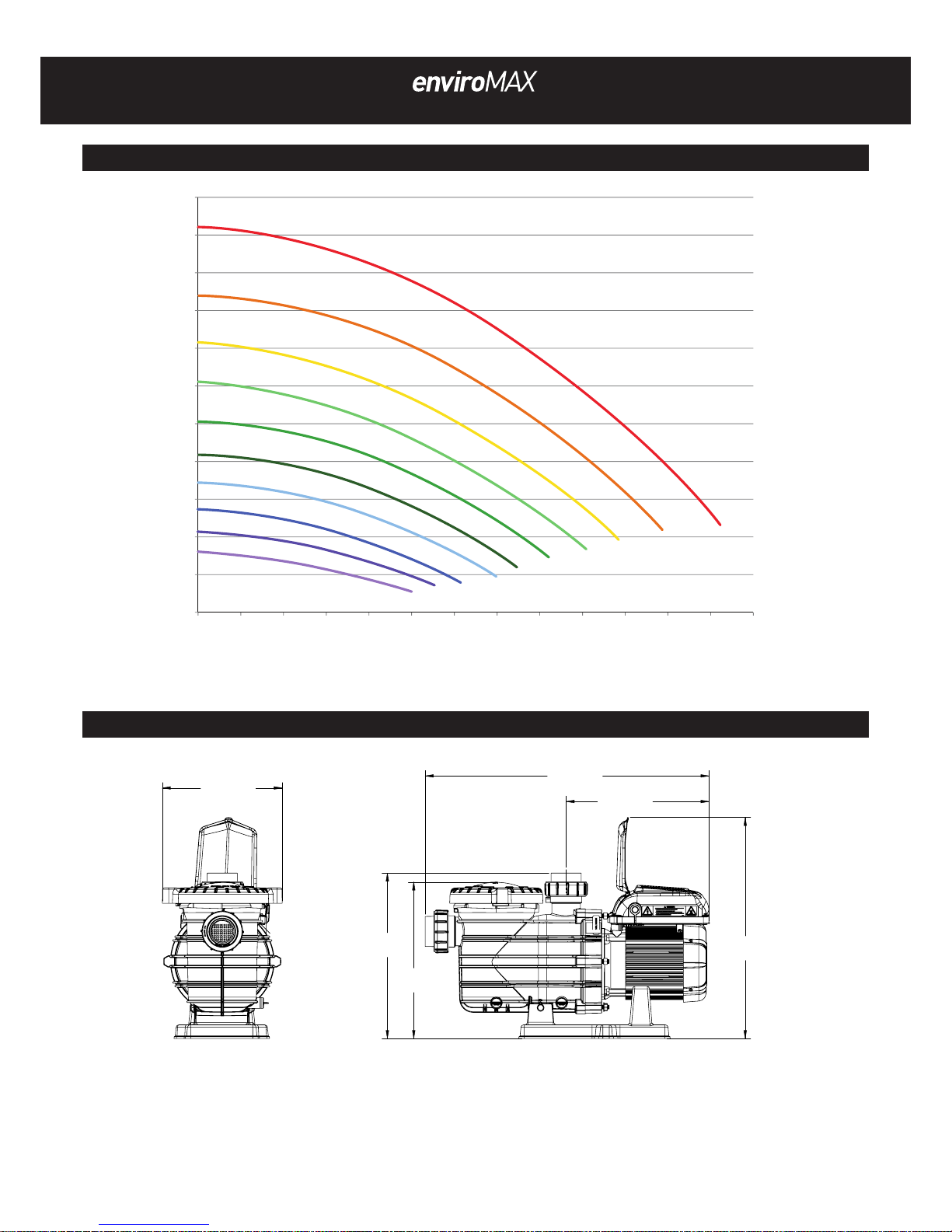

Hydraulic Performance

EnviroMAX 1500 Performance Chart

Technical Information

0

2

4

6

8

10

12

14

16

18

20

22

Head

(m)

3150RPM

2850RPM

2600RPM

2400RPM

2200RPM

2000RPM

1800RPM

1600RPM

1400RPM

1200RPM

0

50

100

150

200 250

300

350 400 450 500

550

600 650

279mm

515mm

364mm

385mm

333mm

661mm

ALLOW MINIMUM

CLEARANCE OF

515mm FOR

KEYPAD

COVER

1. Plan the position of the pump

2. Piping

The pump must be installed and serviced by a suitably qualified person in

order to avoid hazard. Incorrectly installed or tested equipment may fail,

causing severe injury or property damage.

These instructions are a guide only. Should you the installer or owner of

the product be unfamiliar with the correct installation or operation of this

product you should contact a suitably qualified person for advice.

Do not connect system to high pressure or mains water system.

This pump is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the

pump.

The EnviroMAX is electrically connected. Ensure that it is isolated from

electrical supply during installation and any subsequent service work.

a. Have enough ventilation to keep ambient temperature below the motor’s rated ambient temperature

whenever the pump is running. If installed in an enclosure/pump house, the enclosure must have

adequate ventilation (200sq.cm min, inlet & outlet) and air circulation. Allow 200mm to keep rear of

motor clear.

b. Have adequate floor drainage to prevent flooding and be protected from excess moisture.

c. Be solid, level, rigid and vibration free.

d. To reduce vibration and pipe stress, bolt pump to mount. Fixing holes accept 12mm fasteners.

e. Be within 2m of a power outlet for electrical connection (refer to AS/NZS 3000 for rules regarding

connection of electrical equipment in pool zones).

f. Allow adequate access for servicing pump and piping.

a. Use only Australian Standard PVC pressure pipe. For best performance use at least 50mm diameter

pipe for all connections to the pump. Never use a suction pipe smaller than pump suction connections

(50mm) and use larger pipe for long suction distances.

b. To avoid stress on the pump, support both suction and discharge pipes independently. Place these

supports as close to the pump as possible.

c. To avoid a strain left by a gap at the last connection, start all piping at the pump and run pipe away

from the pump.

For best performance, allow pump

suction inlet height to be as far

below water level as possible and

allow the use of short, direct suction

pipe with minimum bends (to reduce

friction losses).

For best performance, allow pump

suction inlet height to be as far

below water level as possible and

allow the use of short, direct suction

pipe with minimum bends (to reduce

friction losses).

6

Installation

3. Pool Outlets

4. Electrical

a. The pump suction system must provide protection against hazard of suction entrapment or hair

entrapment/entanglement. The pool outlet piping must be in accordance with the latest AS1926.3

standard

b. Suction outlet covers and skimmers must have been tested and found to comply with the latest

AS1926.3 standard or ASME/ANSI specification for Suction Fittings.

a. Electrical installation shall be in accordance with the national wiring rules (AS/NZS 3000) taking into

account its ratings (Class I, IPX6). The pump is supplied with a standard Australian 10 amp plug and 2

metres of cord. Select the correct Pool Zone for installation.

b. An RCD with maximum rated residual current of 30mA is required for the power supply to the pump.

Additionally, if a suitable socket outlet is not available a weatherproof socket must be installed by an

electrician in a suitable location. RCD tripping indicates an electrical problem. If RCD trips and will not

reset have a qualified electrician inspect and repair electrical system.

c. Incorrect voltage can cause fire or seriously damage pump and voids warranty.

d. Voltage at pump must not be more than 6% above or 10% below motor nameplate rated voltage or

pump may overheat, causing overload tripping and reduced component life. If voltage is less than 90%

or more than 106% of rated voltage when pump is running at full load, consult the power company.

Do not use extension leads as they

are unsafe in and around the Pool Zone.

Hazardous voltage. Can shock, burn or

cause death.

To avoid dangerous or fatal electrical

shock, turn OFF power to pump and

remove plug from outlet before

working on electrical connections.

7

Installation

5. Equipotential bonding

If equipotential bonding is required, connect all metal parts of the swimming pool or spa structure and to

all electrical equipment, metal conduit, and metal piping in accordance with the wiring rules. Run a wire

from the equipotential bonding terminal on the pump (bottom, left motor bolt with serrated washer) to the

pool bonding structure.

Figure 1.

Bonding

Lug

The bonding lug should be used to bond the motor

frame to the equipment pad.

8

Installation

Loading...

Loading...