OWNER’S MANUAL

High Head Centrifugal Pump

SSCX, SSCXS Series

HP Model Number

1/2 SS1XN-1⁄2 B78635 B78636 B78647 B78648

3/4 SS1XN-3⁄4 B78637 B78638 B78649 B78650

3/4 SS1XS-3⁄4 B82411 B82412 B82413 B82414

1 SS1XN-1 B78639 B78640 B78651 B78652

1 SS1XS-1 B82415 B82416 B82417* B82418

1-1/2 SS1XN-11⁄2 B78641 B78642 B78653* B78654

1-1/2 SS1XS-11⁄2 B82419 B82420 B82421 B82422

2 SS11⁄4XN-2 B78643* B78644 B78655* B78656

2 SS1XS-2 B82423* B82424 B82425* B82426

2-1/2 SS11⁄4XN-21⁄2 B78645* B78646 B78657* B78658

2-1/2 SS1XS-21⁄2 B82427* B82428 B82429* B82430

* 230 Volt only.

115/230/60/1 208-230/460/60/3 115/230/60/1 208-230/460/60/3

ODP MOTORS TEFC MOTORS

Important

For best possible performance and continuous, satisfactory

operation, read these instructions before installing your new pump.

Should service be required, this manual can be a valuable guide. It

should be kept near the installation for ready reference.

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.BERKELEYPUMPS.COM

PH: 888-782-7483

© 2013 Pentair, Ltd. All Rights Reserved. BE495 (Rev. 03/21/13)

Safety 2

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product.

Save this manual for future reference.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury!

indicates a hazard which, if not avoided, will

result in death or serious injury.

indicates a hazard which, if not avoided,

could result in death or serious injury.

indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE addresses practices not related to

personalinjury.

The manufacturer cannot anticipate every possible

circumstance that might involve a hazard. The warnings

in this manual, and the tags and decals affixed to the unit

are, therefore, not all-inclusive. If you use a procedure

or operating technique that the manufacturer does not

specifically recommend, you must satisfy yourself that it

is safe for you and others. You must also make sure that

the procedure or operating technique that you choose

does not render the system unsafe.

To avoid risk of serious bodily injury and property

damage, read and follow all safety instructions in this

manual and on equipment carefully before installing this

pump. Keep safety labels in good condition; replace if

missing or damaged.

Risk of explosion. The pump body

may explode if used to boost pressure above 100 psi

(689kPa). Do not use this pump with inlet pressure

greater than 70 psi (483 kPa). If not already in the

piping system, install a pressure relief valve in the pump

discharge line capable of passing the full pump flow at

100 psi (689 kPa). If local code requires installation of a

pressure relief valve capable of handling the full pump

flow at a pressure less than 100 psi (689 kPa), follow the

code requirements.

Risk of fire or explosion. To avoid risk of

fire and explosion, Pump Water Only with this pump. Do

not pump salt water, flammable liquids or chemicals. Do

not use the pump near gas pilot lights or where chemical

or gas fumes are present. Use of an electric pump with

liquids other than water or in an atmosphere containing

chemical or gas fumes may ignite those liquids or

gases and cause injury or death due to an explosion

and/orfire.

Burn hazard. If water is trapped in the

pump during operation it may turn to steam. Trapped

steam can lead to an explosion and burns. Never run the

pump with the outlet closed or obstructed.

California Proposition 65 Warning

This product and related accessories

contain chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

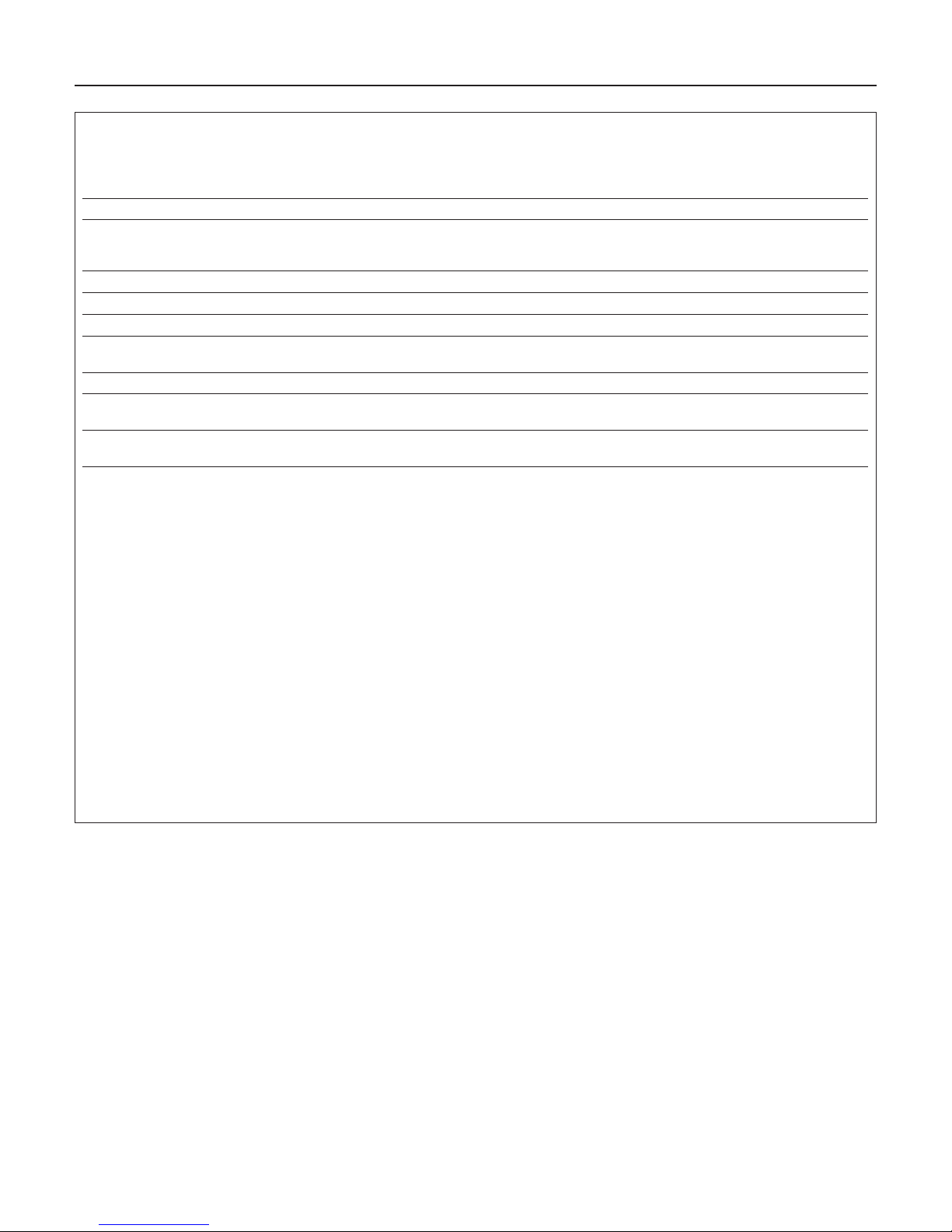

Warranty 3

Limited Warranty

BERKELEY warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free

from defects in material and workmanship for the Warranty Period shown below.

Product Warranty Period

Water Systems:

Water Systems Products — jet pumps, small centrifugal pumps, submersible pumps and

related accessories

Pro-Source™ Composite Tanks 5 years from date of original installation

Pro-Source™ Steel Pressure Tanks 5 years from date of original installation

Pro-Source™ Epoxy-Lined Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products

Agricultural/Commercial:

Centrifugals – close-coupled motor drive, frame mount, SAE mount, engine drive, VMS,

SSCX, SSHM, solids handling, submersible solids handling

Submersible Turbines, 6” diameter and larger

whichever occurs first:

12 months from date of original installation, or

18 months from date of manufacture

12 months from date of original installation, or

18 months from date of manufacture

12 months from date of original installation, or

24 months from date of manufacture

12 months from date of original installation, or

24 months from date of manufacture

Our limited warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication,

improper installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase

power through a phase converter will void the warranty. Note also that three phase motors must be protected by three-leg,

ambient compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and BERKELEY’s only duty, is that BERKELEY repair or replace defective products (at BERKELEY’s choice). You

must pay all labor and shipping charges associated with this warranty and must request warranty service through the installing

dealer as soon as a problem is discovered. No request for service will be accepted if received after the Warranty Period has

expired. This warranty is not transferable.

BERKELEY SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE. THE FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION

PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an

implied warranty, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and

You may also have other rights which vary from state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

In the U.S.: BERKELEY, 293 Wright St., Delavan, WI 53115

In Canada: 269 Trillium Dr., Kitchener, Ontario N2G 4W5

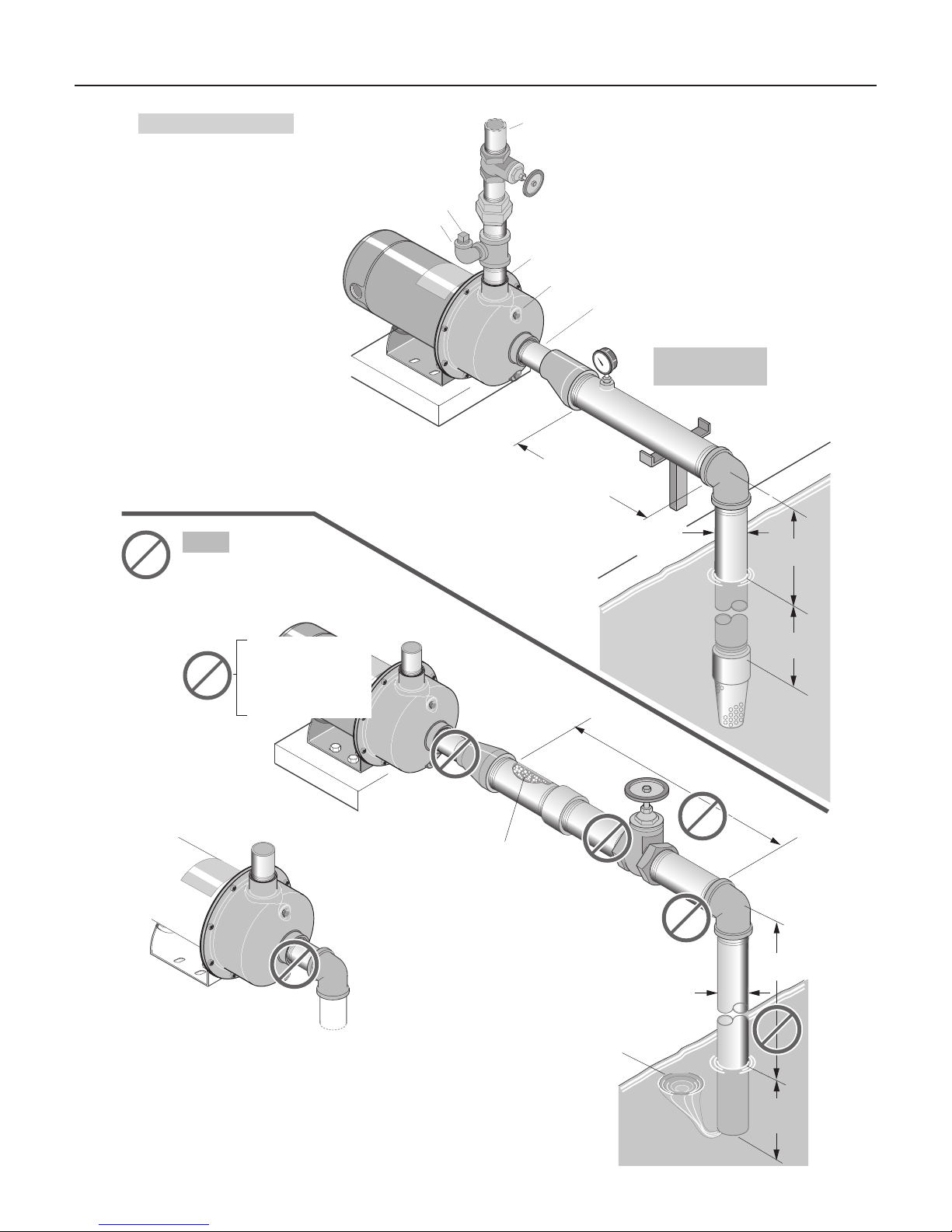

Installation 4

Recommended pump suction

Support discharge

and discharge connections

Priming

Street Elbow

Plug

Solid, level

base

Straight run, as short as possible

but at least 6 times pipe diameter ("D"),

sloping away from pump (pump inlet

is highest point).

pipe as required

Gate

Valve

Union

Discharge

to service

Vent

Plug

Eccentric

Reducer

Short length of

straight pipe

after reducer

Important:

All connections must

be air tight

Support suction pipe

as required

Not

recommended

pump suction and

discharge connections

On the discharge avoid:

Quick closing valves.

Small I.D. pipe.

Numerous fittings.

Misalignment.

Sharp turns in piping run.

Elbow immediately

in front of pump

suction.

Figure 1

Concentric

Reducer

Concentric Reducer causes

high spots along the suction

line resulting in

air pockets.

Use of excess fittings

means potential

Pipe diameter

Valve

air leaks

Pipe diameter "D"

too small

Pipe submerged

less than 4 x "D"

will suck air

"D"

Foot

Valve

Long suction

run

Unsupported

Pipe

As close

as possible

4 x "D"

minimum

High

lift

Do not rotate

discharge.

Figure 2

Installation 5

Piping - General

Support both suction and discharge piping independently

at a point near the pump to avoid putting a strain on the

pump housing. Start all piping AT THE PUMP.

Increase pipe diameter at both the suction and discharge

by one (1) standard pipe size (minimum) to obtain

desired performance and flow rate. Refer to Table I when

sizing pipe for your pumping system.

NOTICE Do not use pipe with smaller diameter on the

suction side of pump.

Table I

Pipe Tapping Size On Pump Recommended Pipe Size

Suction Discharge Suction Discharge

1-1/4 1 1-1/2 1-1/4

1-1/2 1-1/4 2 1-1/2

Suction Pipe

Increase pipe size from pump tapping as shown in

TableI.

Figure 1 depicts a recommended run of pipe and fittings

for the suction side of a centrifugal pump. Please refer to

this illustration when choosing pipe and fittings for your

suction connection.

NOTICE All connections must be air tight!

Figure 2 depicts conditions that are NOT DESIRABLE

on the suction side of a centrifugal pump and may

cause problems in flow rate and priming. Please look

this illustration over carefully before choosing pipe and

fittings for your suction connection.

Discharge Piping

Increase pipe size from pump tapping as shown in

TableI. Figure 1 depicts a recommended run of pipe and

fittings for the discharge. Install tee with priming plug

as close to pump as possible. Figure 2 notes conditions

that should be avoided. Please read over carefully before

making discharge connection.

Priming The Pump

A pump is primed when all air in the suction line

and pump volute has been evacuated and replaced

withwater.

To Prime:

1. Close valve in discharge line.

2. Remove priming plug from tee and fill pump and

suction line with water until water is flowing back

out of tee.

3. Replace priming plug.

4. Start pump and slowly open valve until desired water

flow is achieved.

NOTICE If no water is pumped after 5 minutes, turn

off pump, close valve, and repeat steps 1 thru 4.

Risk of explosion and scalding. Never run

pump against closed discharge. To do so can boil water

inside pump, causing hazardous pressure buildup and

possible explosion.

Risk of flooding. Can cause personal injury

and/or property damage. Do not run the pump dry. This

will damage mechanical seal and void warranty. It may

cause burns to person handling pump.

Risk of burns. Motor normally operates

at high temperature and will be too hot to touch. It is

protected from heat damage during operation by an

automatic internal cutoff switch. Before handling pump

or motor, stop motor and allow it to cool for 20 minutes.

Loading...

Loading...