InstallatIon and servIce Manual

SPD50H/100H

Submersible Effluent Pump

NOTE! TO THE INSTALLER: Please make sure

you provide this manual to the owner of the

pumping equipment or to the responsible party

who maintains the system.

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.HYDROMATIC.COM

PH: 888-957-8677

269 TRILLIUM DRIVE, KITCHENER, ONTARIO, CANADA N2G 4W5

PH: 519-896-2163

© 2013 Pentair, Ltd. All Rights Reserved. W-03-193 (Rev. 03/04/13)

General

Information

Thank you for purchasing your

HYDROMATIC

ensure years of trouble-free

op er a tion, please read the

fol low ing manual carefully.

Before Operation:

Read the following in struc tions

care ful ly. Reasonable care and

safe meth ods should be practiced.

Check local codes and requirements before installation.

Attention:

This manual contains important

information for the safe use of

this product. Read this manual

completely before using this

product and refer to it often for

con tin ued safe product use.

DO NOT THROW AWAY OR

LOSE THIS MAN U AL. Keep

it in a safe place so that you may

refer to it often.

WARNING: Before handling

these pumps and controls,

always disconnect the power

first. Do not smoke or use

sparkable electrical devices or

flames in a septic (gaseous) or

possible septic sump.

California Proposition 65

Warning

related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductive harm.

®

pump. To help

This product and

Pump

Warning

To reduce risk of electrical

shock:

1. Risk of Electrical Shock:

This pump has not been

in ves ti gat ed for use in

swimming pool areas.

2. Risk of Electrical Shock:

Connect only to a properly

ground ed receptacle.

Septic tank to be vented in

ac cor dance with local

plumbing codes.

Do not smoke or use sparkable

electrical devices or flame in

a septic (gaseous) or possible

septic sump.

If a septic sump condition

exists and if entry into sump

is necessary, then (1) provide

proper safety precautions

per OSHA re quire ments and

(2) do not enter sump until

these precautions are strictly

adhered to.

Do not install pump in location

clas si fied as hazardous per

N.E.C., ANSI/NFPA 70 -

2001.

Failure to heed above cautions

could result in injury or death.

Pump

Installation

These important instructions

mustbe followed for satisfactory

per for mance of your pump:

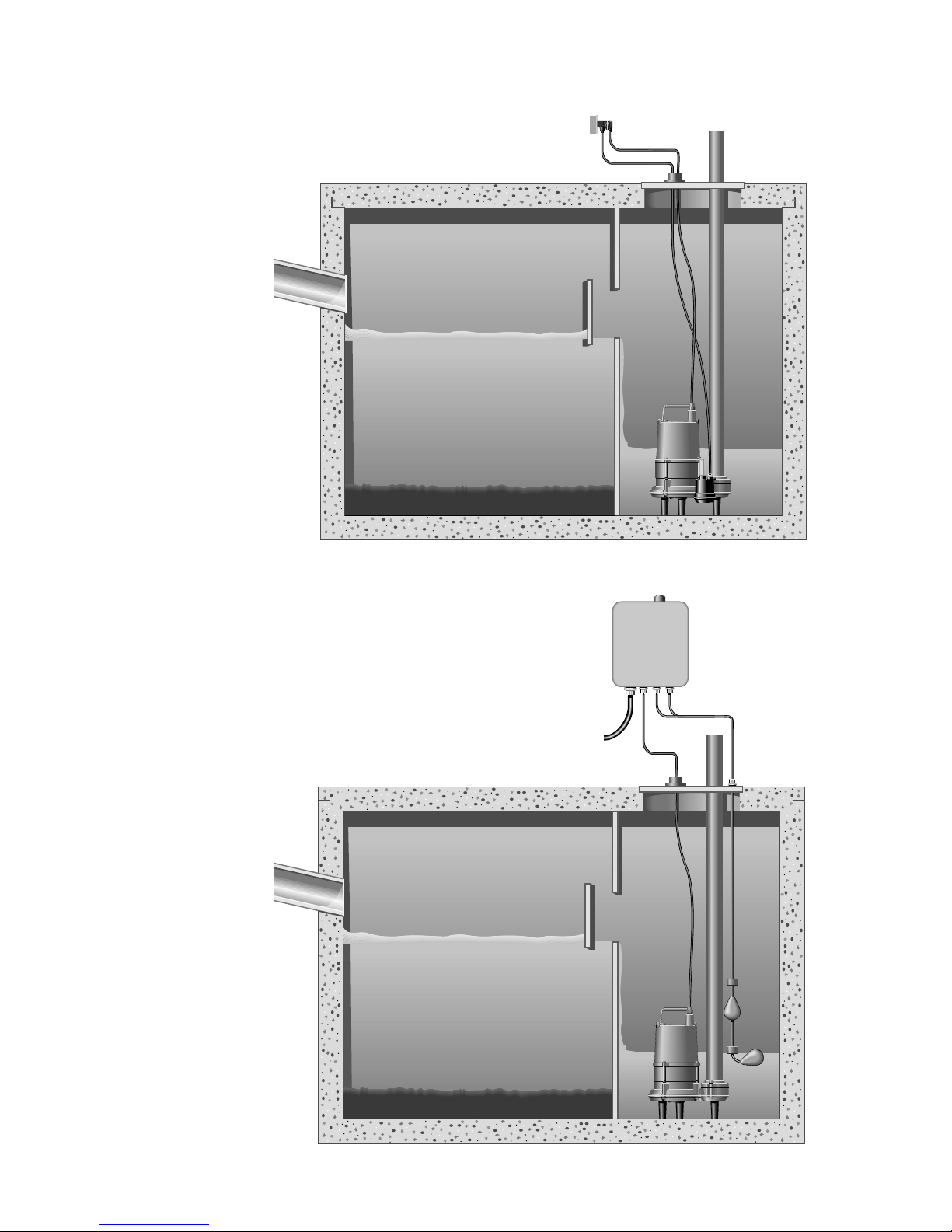

1. Provide proper sump

(rec om mend ed minimum

sump diameter is 30").

2. Do not set pump directly on

the bottom of sump if it is

not solid. Raise the pump by

using bricks or concrete

blocks un der neath it.

3. Make sure sump is free of

string, cloth, nails, gravel, etc.

before installing pump.

4. Risk of electrical shock —

connect only to a properly

grounded receptacle.

5. Do not remove ground pin

from electrical plug.

6. Do not use an extension cord.

7. For proper automatic operation,

make sure the pump power

cord is plugged into the

piggyback receptacle on the

diaphragm switch cord.

8. Connect to separate electrical

circuit taken directly from

main switch.

9. Use steel or plastic pipe for

all connecting lines between

pump and sewer outlet.

Note: Some city regulations

do not allow installing a

pump with plastic pipe.

Check local reg u la tions.

10. In applications in which the

pump may sit idle for months

at a time, it is rec om mend ed

that the pump(s) be cycled

every month to ensure the

pumping system is working

properly when needed.

11. HYDROMATIC check valve

should be installed in

discharge pipe.

12. An audible alarm system such

as the Q Alert (indoor use

only) for high water con di tions

should be installed in every

pump for greater protection.

Contact your HYDROMATIC

distributor for ad di tion al

panel applications.

Warning: When using the

automatic diaphragm switch,

the vent tube in the plug

must be clear of obstructions.

Do not bend cord. This will

cause a crimp in the vent

tube and switch failure

will occur. Pump should

be plugged into a single

outlet, where vent tube

can “breathe.” Blocking

tube or bending cord will

void the warranty.

2

Pump

Servicing

Read the following instructions

carefully before replacing any

parts. Reasonable care and safe

methods should be practiced.

Check local codes and

requirements before installation.

Only a com pe tent electrician

should make the installations.

Tools Required

General shop tools include socket

wrenches and a bearing puller.

An ohmmeter is required

to thoroughly check motor

and wiring.

For proper au to mat ic op er a tion,

make sure the pump power

cord is plugged into the piggy back re cep ta cle on the float

switch cord.

Before removing the pump from

its installation for repairs, check

first to see if the trouble is

caused by:

1. Miswiring of the pump into

the terminal block.

2. Miswiring of the float level

controls into the panel.

3. Miswiring inside the control

panel.

4. Trip circuit breaker. If the

breaker is manually reset and

then trips off again, the

problem could be:

a. short circuit in motor or

control panel

b. water in the motor housing

c. insufficient amp capacity of

wiring or breakers

d. improper panel wiring

5. Tripped overload. If overload

is manually reset and then

trips off again, the problem

could be:

a. pump or piping is clogged

b. pump motor or bearings

may be defective

c. start capacitor in motor may

have failed

d. pump may be miswired to

terminal block

e. head is lower than rating,

pumping too much liquid

6. Air locked pump. Disconnect

piping at union and run until

all air bubbles are expelled.

7. Wrong impeller rotation.

Ro ta tion should be coun terclock wise when looking at

the impeller. Correct improper

rotation on three phase pumps

by reversing any two line

leads. No rotation check is

nec es sary on single phase pumps.

8. Closed discharge gate valve.

9. Plugged impeller or pipeline.

10. Discharge head may be too

high. Check elevation against

design point of pump.

11. Floats not hanging free in

the sump.

12. Malfunctioning floats.

Disconnect power supply.

Checking Power Cord

To be sure wires are not burned

off or broken in cord, use ohmmeter for check. Set ohmmeter

scale pointer to R x 1 scale and

attach one meter lead to white

cord wire and one meter lead

to black cord wire, then place a

screw driv er blade across terminals

of plug. If cord is OK, meter

needle will go to zero and stay

there. If meter needle does not

move, this will indicate an open

wire and cord must be replaced.

Motor

Warning: Be certain power to

pump is off! Disconnect pump

power cord from terminals in

control panels (manual pump

models) and power source

(automatic models) and remove

pump from sump.

1. Clean any dirt or trash from

the outside of the pump

before dis man tling.

If the unit is being operated

by float or diaphragm switch,

unplug the pump from the

piggyback receptacle and

plug the pump directly into

the power source. If the pump

starts each time it is plugged

directly into the receptacle

and does not start each time

when plugged into the piggyback switch with the float

raised or the di a phragm switch

pressed into the start position,

replace the com plete piggyback switch assembly and

retest with new assembly.

2. If motor does not run when

tested as described above, the

capacitor and/or stator must

be checked.

Disconnect from power supply.

Remove plug (#6) from top of

housing and pour oil into

container, preferably clear, so

that oil can be observed.

3. If oil is clear, it will indicate

motor is not burned and there

has been no water leak into

the motor. If oil is cloudy, it

will indicate water in motor,

or, if oil is black, it will

indicate a burned stator.

4. After draining oil, carefully

loosen the power cord

assembly (#22) from the

motor housing (#2). With

power cord loose, remove the

four wire nuts and screws (#4)

and carefully lift off the motor

housing (#2) ex pos ing the

capacitor (#28) (1ø only) and

the motor assembly.

3

SPD50H

SPD100H

4

Loading...

Loading...