Pentair SN Series, HN Series Owner's Manual

OWNER’S MANUAL

Shallow Well Jet Pumps

NOTICE D’UTILISATION

Pompes à éjecteur pour

puits peu profonds

MANUAL DEL PROPIETARIO

Bombas tipo “Jet” para

pozos poco profundos

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 888-782-7483

English ............................ Pages 2-14

2400 0496 NF

SN Series / Série SN / Serie SN

HN Series / Série HN / Serie HN

Installation/Fonctionnement/

Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

composer le 888-782-7483

Français ........................ Pages 15-27

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

llame al 888-782-7483

Español ....................... Paginas 28-40

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.STA-RITE.COM

PH: 888-782-7483

© 2012 Pentair, Inc. All Rights Reserved. S376 (11/05/12)

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of the

following signal words and be alert to the potential for

personal injury:

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which are

important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

California Proposition 65 Warning

This product and related accessories contain

chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm.

ELECTRICAL SAFETY

Capacitor voltage may be hazardous. To

discharge motor capacitor, hold insulated handle

screwdriver BY THE HANDLE and short capacitor terminals

together. Do not touch metal screwdriver blade or

capacitor terminals. If in doubt, consult a qualified

electrician.

GENERAL SAFETY

Do not touch an operating motor. Modern

motors are designed to operate at high temperatures. To

avoid burns when servicing pump, allow it to cool for 20

minutes after shut-down before handling.

Do not allow pump or any system component to freeze. To

do so will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on pumps.

Keep work area clean, uncluttered and properly lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

Pump body may explode if used as a booster

pump unless relief valve capable of passing full pump flow

at 75 psi is installed.

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect power

before working on pump,

motor or tank.

Wire motor for correct

voltage. See “Electri cal” section of this manual and motor

nameplate.

Ground motor before

connecting to power

supply.

Meet National Electri cal

Code, Canadian Elec tri cal

Code, and local codes for all

wiring.

Follow wiring instructions in this manual when connecting motor to power lines.

WARNING

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.

Table of Contents 3

Page

General Safety .....................................................................................................2

Warranty..............................................................................................................3

Installation (Well Pumps) .................................................................................4, 5

Connecting Discharge Piping...............................................................................6

Pressure Booster System .......................................................................................7

Electrical .......................................................................................................... 8, 9

Preparing To Start The Pump .............................................................................10

Repair Parts .................................................................................................11-13

Troubleshooting ................................................................................................. 14

Limited Warranty

STA-RITE warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free

from defects in material and workmanship for the Warranty Period shown below.

Product Warranty Period

Water Systems Products — jet pumps, small centrifugal pumps,

submersible pumps and related accessories

Pro-Source™ Composite Tanks 5 years from date of original installation

Pro-Source™ Steel Pressure Tanks 5 years from date of original installation

Pro-Source™ Epoxy-Lined Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products

Our warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication,

improper installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase

power through a phase converter will void the warranty. Note also that three phase motors must be protected by three-leg,

ambient compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and STA-RITE’s only duty, is that STA-RITE repair or replace defective products (at STA-RITE’s choice). You

must pay all labor and shipping charges associated with this warranty and must request warranty service through the installing

dealer as soon as a problem is discovered. No request for service will be accepted if received after the Warranty Period has

expired. This warranty is not transferable.

STA-RITE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE FOREGOING WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION EXPRESSLY PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an

implied warranty, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and

You may also have other rights which vary from state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

whichever occurs first:

12 months from date of original installation,

or 18 months from date of manufacture

12 months from date of original installation, or

18 months from date of manufacture

293 Wright Street • Delavan, WI U.S.A. 53115

Phone: 1-888-782-7483 • Fax: 1-800-426-9446 • Web Site: sta-rite.com

STA-RITE INDUSTRIES

Installation 4

REPLACING AN OLD PUMP

Hazardous voltage. Disconnect power to

pump before working on pump or motor.

1. Drain and remove the old pump. Check the old pipe

for scale, lime, rust, etc., and replace it if necessary.

2. Install the pump in the system. Make sure that all pipe

joints in the suction pipe are air-tight as well as water

tight. If the suction pipe can suck air, the pump will not

be able to pull water from the well.

3. Adjust the pump mounting height so that the plumbing

connections do not put a strain on the pump body.

Support the pipe so that the pump body does not take

the weight of piping or fittings.

You have just completed the well plumbing for your

new shallow well jet pump. Please go to Page 6 for

discharge pipe and tank connections.

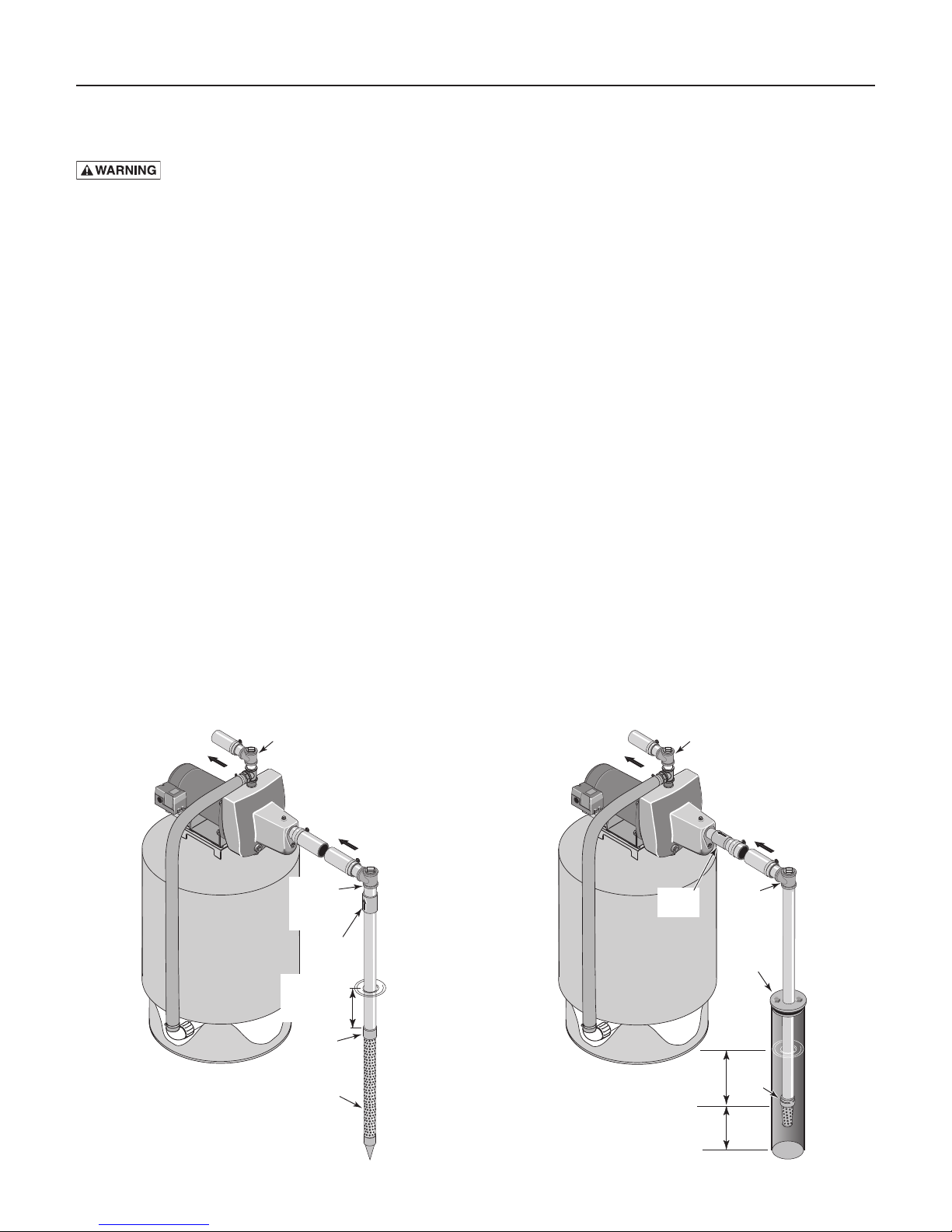

WELL POINT (DRIVEN POINT)

INSTALLATION (FIGURE 1)

1. Drive the well, using “drive couplings” and a

“drive cap”. “Drive fittings” are threaded all the way

through and allow the pipe ends to butt against each

other so that the driving force of the maul is carried

by the pipe and not by the threads. The ordinary

fittings found in hardware stores are not threaded

all the way through the fitting and can collapse

under impact. “Drive fittings” are also smoother

than standard plumbing fittings, making ground

penetration easier.

To Household

Water System

Pump Priming

Tee and Plug

2. Mount the pump as close to the well as possible.

3. Use the fewest possible fittings (especially elbows)

when connecting the pipe from the well point to

the pump suction port. The suction pipe should be

at least as large as the suction port on the pump

(include a check valve if your pump is not equipped

with one – see Figure 1). Support the pipe so that

there are no dips or sags in the pipe, so it doesn’t

strain the pump body, and so that it slopes slightly

upward from the well to the pump (high spots can

cause air pockets which can air lock the pump). Seal

the suction pipe joints with PTFE pipe thread sealant

tape. Joints must be air- and water-tight. If the suction

pipe can suck air, the pump cannot pull water from

the well. If one well point does not supply enough

water, consider connecting two or three well points

to one suction pipe.

You have just completed the suction piping for your

new shallow well jet pump. Please go to Page 6 for

discharge pipe and tank connections.

CASED WELL INSTALLATION, 2” OR

LARGER CASING (FIGURE 2)

1. Mount the pump as close to the well as possible.

2. Assemble the foot valve, strainer, and well pipe (see

Figure 2). Make sure that the foot valve works freely.

3. Lower the pipe into the well until the strainer is five

feet above the bottom of the well. It should also be

at least 10 feet below the well’s water level while the

pump is running in order to prevent the pump from

sucking air. Install a sanitary well seal.

To Household

Water System

Pump Priming

Tee and Plug

Suction Pipe

From Well

Priming

Tee and

Plug

Check

Valve

Drive point

below water

level

Drive

Coupling

Not

to

Scale

Figure 1: Driven Point Installation

Drive

Point

Check

Valve

10'

Not

Min.

to

Scale

Figure 2: Cased Well Installation

5–10'

Suction Pipe

From Well

Priming

Tee and

Plug

Sanitary

Well Seal

Well

Casing

Foot

Valve

Installation 5

To Household

Pump Priming

4. Install a priming tee, priming plug, and suction pipe

to the pump (see Figure 2). Connect the pipe from

the well to the pump suction port, using the fewest

possible fittings – especially elbows – as fittings

increase friction in the pipe (however, include a

foot valve – see Figure 2). The suction pipe should

be at least as large as the suction port on the pump.

Use PTFE pipe thread sealant tape on threaded pipe

joints. Support the pipe so that there are no dips or

sags in the pipe, so it doesn’t strain the pump body,

and so that it slopes slightly upward from the well to

the pump (high spots can cause air pockets which

can air lock the pump). Seal the suction pipe joints

with PTFE pipe thread sealant tape. Joints must be

air- and water-tight. If the suction pipe can suck air,

the pump cannot pull water from the well.

You have just completed the suction piping for your

new shallow well jet pump. Please go to Page 6 for

discharge pipe and tank connections.

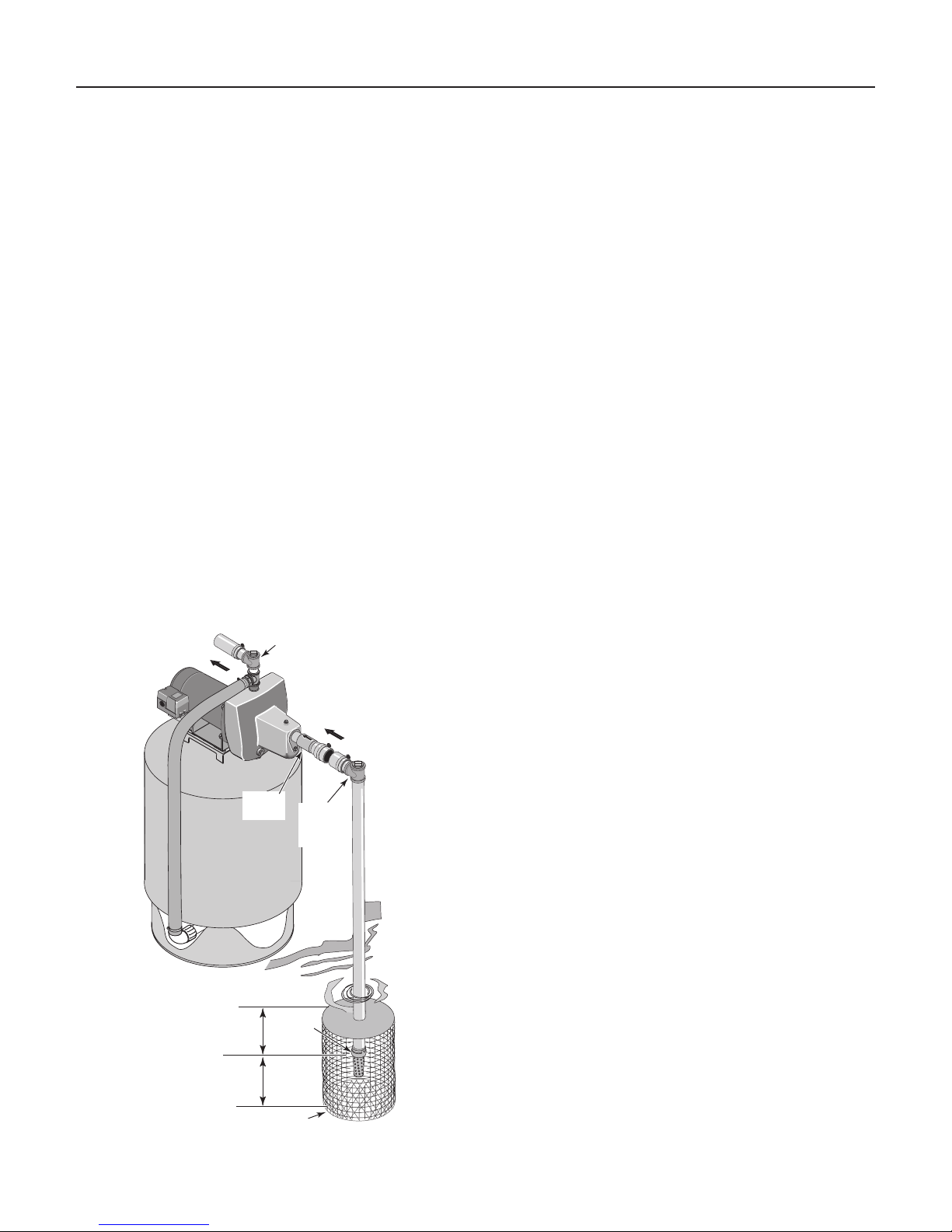

INSTALLATION FOR SURFACE WATER

(FIGURE 3)

1. The pump should be installed as close to the water as

possible, with the fewest possible fittings (especially

elbows) in the suction pipe. The suction pipe should

be at least as large as the suction port on the pump.

2. Assemble a foot valve and suction pipe (Figure 3).

Make sure that the foot valve works freely. Use PTFE

pipe thread sealant tape on threaded pipe joints.

Protect the foot valve assembly from fish, trash, etc,

by installing a screen around it (see Figure 3).

3. Lower the pipe into the water until the strainer is

five feet above the bottom. It should also be at least

10 feet below the water level in order to prevent the

pump from sucking air.

4. Install a priming tee, priming plug, and suction pipe

to the pump (see Figure 3). Support the pipe so that

there are no dips or sags in the pipe, so it doesn’t

strain the pump body, and so that it slopes slightly

upward from the well to the pump (high spots can

cause air pockets which can air lock the pump). Seal

the suction pipe joints with PTFE pipe thread sealant

tape. Joints must be air- and water-tight. If the suction

pipe can suck air, the pump cannot pull water from

the well.

You have just completed the plumbing for your

new shallow well jet pump. Please go to Page 6 for

discharge pipe and tank connections.

Water System

Not

to

Scale

Check

Valve

10'

Min.

5–10'

Tee and Plug

Suction Pipe

From Well

Priming

Tee and

Plug

Foot

Valve

Screen

Figure 3: Surface Water Installation

Loading...

Loading...