SHURFLO

®

WATER BOOST MODULAR FILTRATION SYSTEMS

INTRODUCTION

Pentair® Shurflo® has applied its expertise and years of experience in pump technology to provide a safe and reliable

diaphragm pump. Every Pentair Shurflo pump is 100% tested for proper flow, pressure, and performance before it leaves

the factory. Although this tested design will provide years of trouble-free and economical operation, you should use care in

installing your system.

SYSTEM DESCRIPTION AND FUNCTION

The Pentair Shurflo water boost modular filtration system is designed to integrate both the water boost and water filtration

systems into one easy to install component, thus guaranteeing proper placement of the water boost system in relation to

the filtration system. The system consists of a Pentair Shurflo 8000 diaphragm pump and accumulator tank which function

together to boost the water pressure to the filtration system. The boosted water pressure not only assures an adequate water

supply to the fountain system but maximizes utilization of the filter elements throughout their service life.

The pump, accumulator tank and filtration system are NSF listed.

The system comes mounted on a steel panel which design includes Pentair Shurflo patented slide track design requiring

minimal steps for installation and startup.

FEATURES

• Pentair Shurflo patented slide track design for wall mounting or rack mounting

• NSF listed components

• 115 VAC

• All plumbing connections are located on the upper left of the unit

• City Water Inlet: 3/8" barb

• Water Outlet to Ice Maker Feeder (non-boosted, non-filtered): 3/8" barb

• Water Outlet (2): 3/8" barb

FOODSERVICE

SHURFLO WATER BOOST MODULAR FILTRATION SYSTEM INSTALLATION AND OPERATION GUIDE

SYSTEM IDENTIFICATION

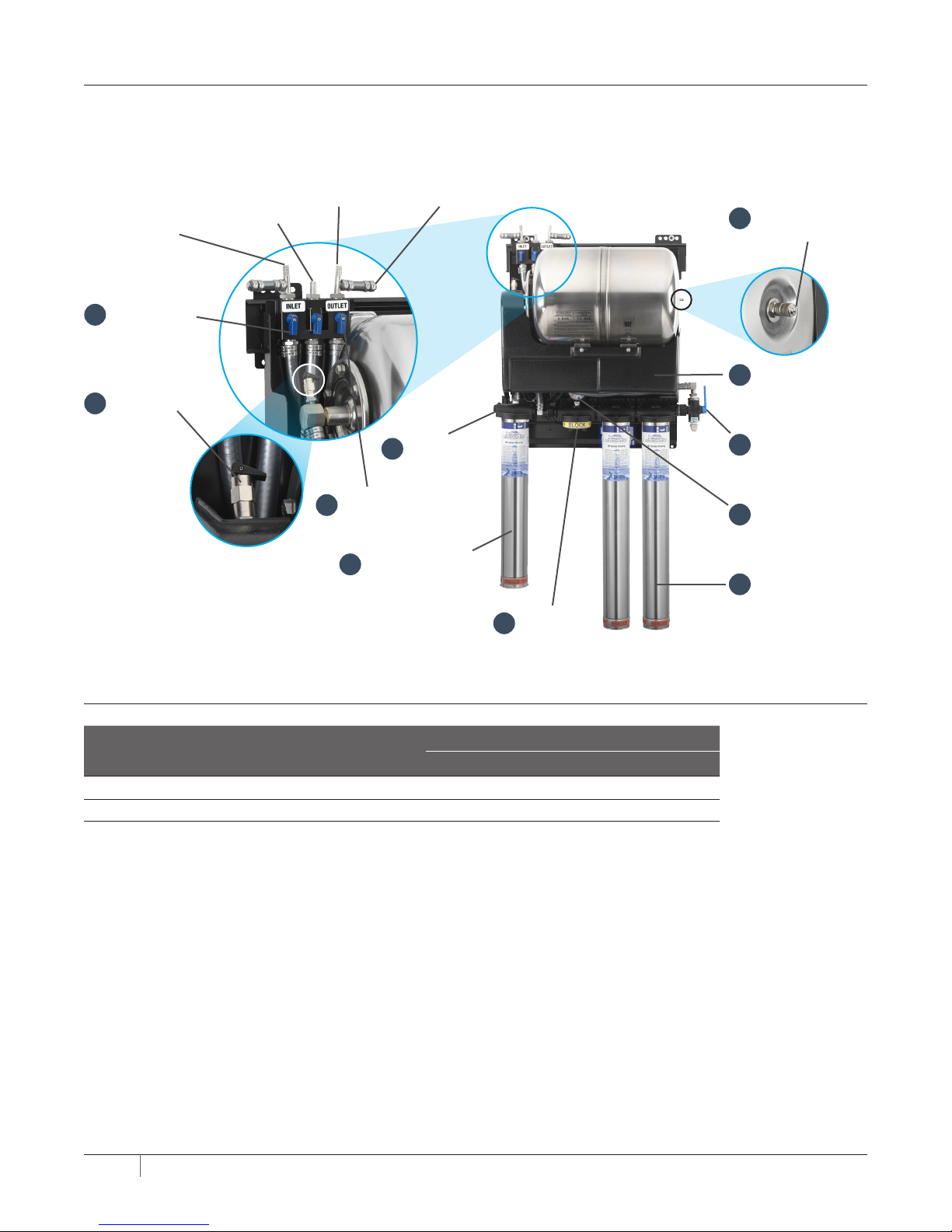

WATER BOOST MODULAR FILTRATION (WBMF) SYSTEM

Water Out

to Carbonator

Main City

Water Inlet

City Water In

1

Ball Valve

Pressure Relief

2

Valve

Ice Maker

Water Supply*

4

WBMF System Out

3

Ball Valve

Ice Filter Canister

11

stainless steel sump

*Ice Maker Water Supply is non-boosted/non-filtered

Water Out

Non-Carb System

Filter Head

Assembly

5

Bypass

Plug/Cap

Tank Pre-charge

10

Valve and Cap

Booster Pump

9

(behind shroud)

Purge Valve

8

w/o drain tubing

attached

Filtered Water

7

Pressure Gauge

Filter Canister

6

stainless steel sump

SYSTEM CONFIGURATIONS

WBMF Model #

WB6-M3-22-003-SS 6 3 in parallel bypass plug 122TO5 122TO5

WB6-M3-22-003-SSPLUS 6 3 in parallel 122PLUS 122PLUS 122PLUS

Tank

(gallons)

Filter System

Configuration

Head 1 Head 2 Head 3

Filter Media Elements

2 SHURFLO WATER BOOST MODULAR FILTRATION SYSTEM INSTALLATION AND OPERATION GUIDE

SYSTEM COMPONENTS

Filter System

Design

Modular filter head design with patented locking system and quick connect couplers for parallel or

series water flow

Inlet Port 3/8" barb

Outlet Port 3/8" barb

Pressure Gauge 0 –160 psi incremental pressure gauge (measures outlet pressure)

Min./Max. Operating Pressure 20 psi (1.4 bar) / 125 psi (8.6 bar)

Min./Max. Water Temperature 40˚F / 100˚F (4.4˚C / 37.8˚C)

Filter Element Housing

Design Bayonet style dry sump

Materials of Construction 304 Stainless steel

Filter Element

Design Sealed replacement dry sump style filter element

Materials of Construction Polypropylene

SPECIFICATIONS

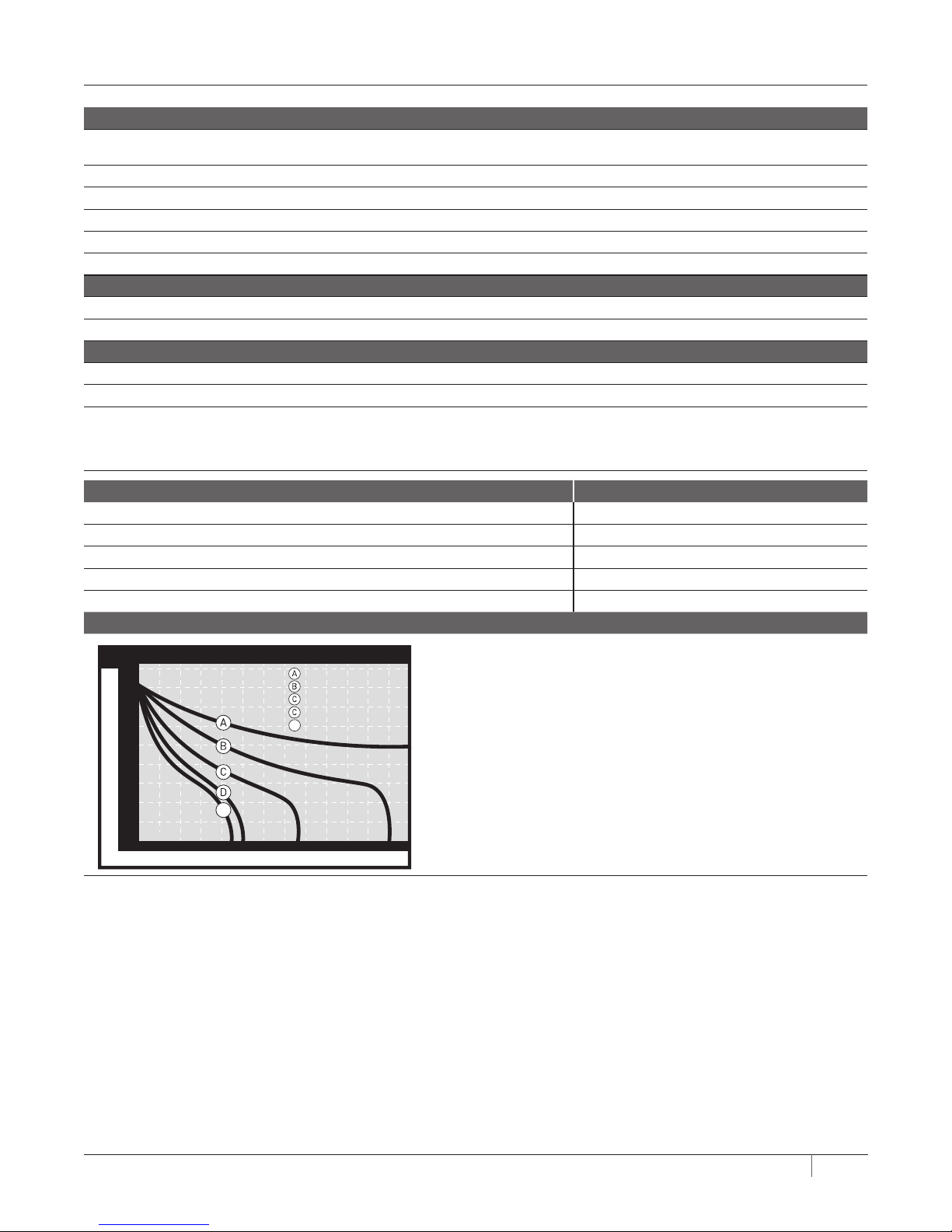

Water Boost System WB6 - Series System Dimensions and Weights

Booster Pump 90 psi, 115 VAC diaphragm design pump Triple

Booster Pump Materials Viton® valves, Santoprene® diaphragm, nylon housing Shipping Weight 44 lbs

Accumulator Tank Materials Stainless steel housing with butyl rubber bladder Operating Weight 61 lbs

Accumulator Tank Size 6 gallons (WB6 – series) Overall Dimensions* 18.5" x 41"x 12.5"

Accumulator Tank Pre-charge 50 psi

WB6 – Series Water Boost performance

100

6.9

90

6.2

80

5.5

70

4.8

60

4.1

50

3.4

40

2.8

Pressure (PSI/Bar)

30

2.1

20

1.4

10

0.7

6 Gallon Maxi Water Boost

Flow Rate

E

E

10 20 30 40 50 7060 80 90 100 110 120

Time (Seconds)

4.0 oz p/sec (118 ml p/sec)

6.0 oz p/sec (177 ml p/sec)

8.0 oz p/sec (237 ml p/sec)

10.0 oz p/sec (296 ml p/sec)

12.0 oz p/sec (355 ml p/sec)

*Allow an additional 3” vertical clearance below housing for filter element change.

3 SHURFLO WATER BOOST MODULAR FILTRATION SYSTEM INSTALLATION AND OPERATION GUIDE

PERFORMANCE DATA

Important Notice: Read this performance data and compare the capabilities of this system with your actual water treatment

needs. It is recommended that, before installing a water treatment system, you have your water supply tested to determine

your actual water treatment needs.

This system has been tested according to NSF/ANSI 42 for the reduction of the substances listed below. The concentration

of the indicated substances in the water entering the system was reduced to the concentrations less than or equal to the

permissible limit for water leaving the system, as specified in NSF/ANSI 42.

MOD30422/MOD122TO5

Substance

Standard 42 Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥50% 97.4%

Particulate Class III

particles 0.5 to <1 m

Flow Rate = 7.5 gpm (26.87 lpm) Capacity = 60,000 Gallons (227,124.7 liters)

Influent Challenge

Concentration

at least 10,000

particles/mL

Maximum Permissible

Product Water

Concentration Reduction Requirements Average Reduction

≥85% 99.8%

MOD30422/MOD122PLUS

Maximum Permissible

Product Water

Concentration Reduction Requirements Average Reduction

Substance

Standard 42 Aesthetic Effects

Chloramines

1

Influent Challenge

Concentration

3.0 mg/L ± 10% 0.5 mg/L 97.81%

Chlorine 2.0 mg/L ± 10% ≥50% 97.81%

1

As monochloramine (measured as Cl2 /L) Flow Rate = 5.1 gpm (19.3 lpm) Capacity = 6,450 Gallons (24,415.9 liters)

TEST CONDITIONS OPERATING REQUIREMENTS

Inlet Pressure = 60 ± 3 psig (4.13 bar) Pressure = 20-125 psi (1.4-8.62 bar)

pH = 7.5 ± 0.5 Temperature = 40-100° F (4.4-37.8° C)

Temperature = 68 ± 5°F (20 ± 3°C)

Testing was performed under standard laboratory conditions, actual performance may vary.

4 SHURFLO WATER BOOST MODULAR FILTRATION SYSTEM INSTALLATION AND OPERATION GUIDE

Loading...

Loading...