Pentair SHURFLO BLASTER 4238, SHURFLO BLASTER 4338 Series Series Manual

SHURFLO® BLASTER™ II 3.5 GPM

MARINE WASH DOWN PUMP

MODEL SERIES 4238 & 4338

SHURFLO BLASTER™ II Designed for the toughest wash down applications.

SHURFLO’s BLASTER™ II wash down pump design was created with unique over-molded single-piece diaphragm, assuring long

life and top performance in all deck wash down plumbing systems. Designed as the next legendary pump to exceed the expectations of our customers, the BLASTER™ II pumps are designed for the toughest marine wash down applications. SHURFLO’s

quality reputation has been built on the reliability and dependability of every pump we build. The BLASTER™ II wash down automatic demand pumps are quiet, thermally protected and can run dry without damage.

FEATURES

❚ 4 independent chambers

❚ Co-Molded diaphragm

❚ Adjustable pressure switch

❚ Self-priming up to 6 feet

❚ Sealed switch

❚ Sealed motor

❚ Corrosion resistance electro coated

motor

❚ Thermally protected

❚ Ignition protected, CE

INSTALLATION TIPS

❚ Properly sized plumbing

❚ Properly sized wiring

❚ Mount in a dry location that allows

easy access if maintenance is required

❚ Mount higher than the outside water

level, the pump is capable of 6ft. vertical

prime above water line

❚ Use proper fuse size

❚ Install strainer on pump inlet

❚ Minimize plumbing elbows and valves

❚ Flexible high-pressure hose on inlet

and outlet

911-1047 REV. B 1

OPERATION TIPS

❚ Pump is design for intermittent operation only

❚ Turn off power to the pump when boat

is unattended

❚ Maintain your strainer clean for ultimate pump performance

❚ Pump will perform at best when

proper voltage is provided

APPLICATION

❚ Marine 12V DC or 24V DC systems –

see pump label for rated voltage

❚ Wash Down applications

❚ General water transfer

SHURFLO’s BLASTER™ II wash down

pump design was created with unique

over-molded single-piece diaphragm,

assuring long life and top performance

in all deck wash down plumbing systems. Designed as the next legendary

pump to exceed the expectations of our

customers, the BLASTER™ II pumps are

designed for the toughest marine wash

down applications. SHURFLO’s quality

reputation has been built on the reliability and dependability of every pump

we build. The BLASTER™ II wash down

automatic demand pumps are quiet,

thermally protected and can run dry

without damage.

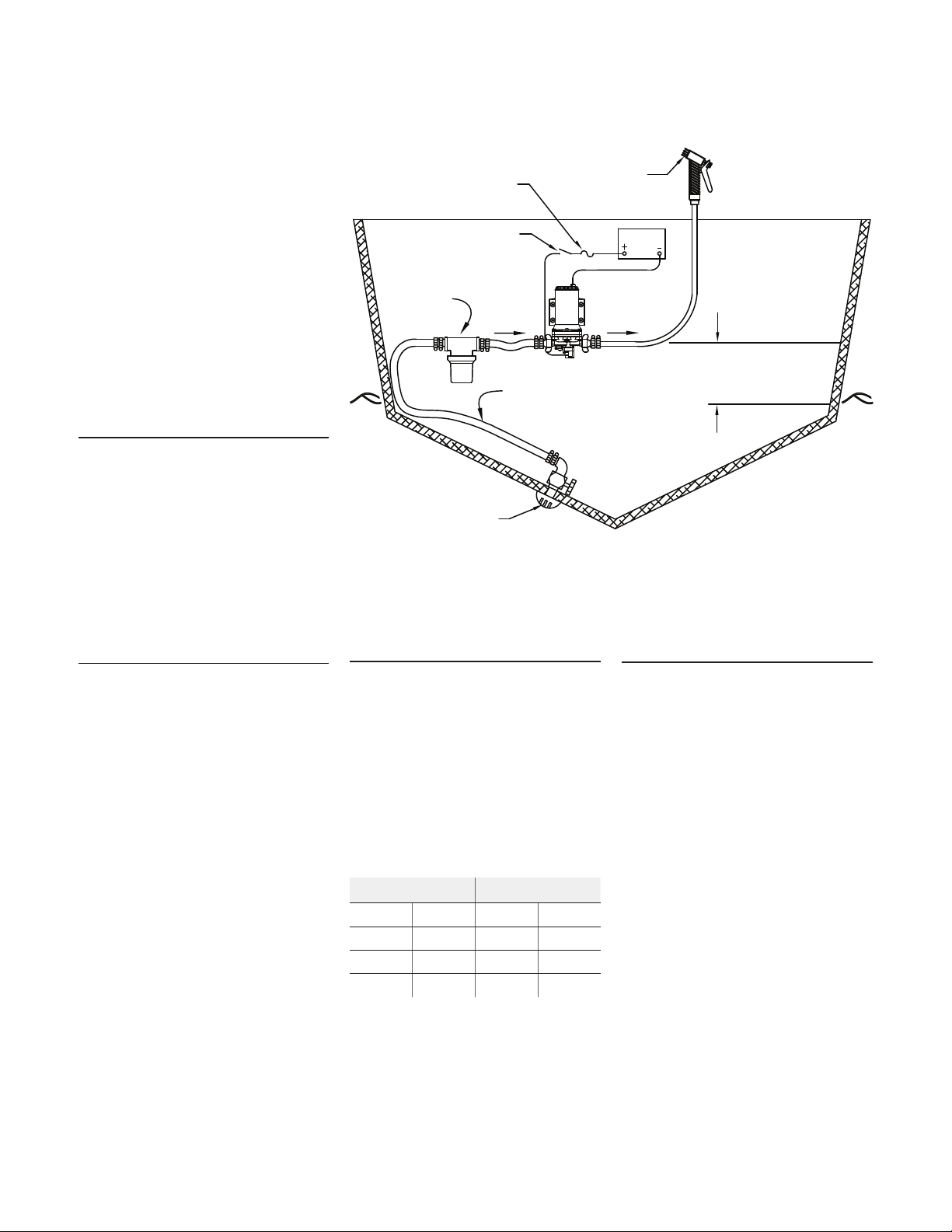

DUTY CYCLE

See pump label for fuse size

Ignition protected

U/L marine switch

SHURFLO

strainer

Inlet

SHURFLO

spray nozzle

Battery

Black

Red

Use flexible high pressure tubing

from thru-hull fitting, strainer,

and pump. Tubing should be rated

for below water line use.

PumpSHURFLO

Outlet

6 ft. max [1.82 m]

Verical lift from

outside water lavel

to pump inlet port

Wash down pumps are rated for intermittent duty ONLY, as they operate at

higher than average pressures. Operating a wash down pump continuously for

more than 20 minutes, within an hour

period, is NOT recommended. Actual

duty cycle is determined by amp draw

and temperature.

MOUNTING

❚ Consider a DRY location that allows

easy access if maintenance is required.

The pump should not be located in an

area of less than one cubic foot unless adequate ventilation is provided.

Excessive heat may trigger the thermal

protector and interrupt operation. When

the temperature drops the thermal

breaker will automatically reset and

start operation.

❚ Mount higher than the water level.

The pump is capable of a 6 ft. [1.82

Meter] vertical prime. The pump can be

mounted in any position. If mounting the

pump vertically, the pump head should

be in the down position.

CAUTION: Do not drive screws through

the vessels’ hull. Use #8 stainless steel

screws to fasten the pump. Choose a

solid surface (bulkhead or stringer)

that will not amplify pump sound. The

mounting feet are intended to isolate

the pump from the mounting surface;

over-tighten, flattening or oversized

screws will reduce the mounting ability

to isolate vibration and noise.

Sea-cock

valve

Through

hull fitting

ELECTRICAL

❚ The pump should be on a dedicated

(individual) circuit protected by the

specified fuse on the motor label.

❚ A UL marine duty switch (ignition

protected) rated for 15 amps or higher is

recommended, and must interrupt current flow on the positive (+ red) lead.

❚ SHUT OFF POWER TO THE PUMP

WHEN LEAVING THE BOAT UNATTENDED.

Ft. [m] AWG [mm2]

0-20 [0-6] 14 [2.5]

20-50 [6-15] 12 [4]

50-70 [15-21] 10 [6]

70-100 [21-30] 8 [8]

Minimum Wire Size for a 10% voltage drop on a 12VDC, 15 Amp

Circuit. Length is the distance from the power source to pump

and back to ground.

NOTES

❚ To prevent cavitation, through hull

fittings should be located at least 12

inches [304 mm] off the centerline of the

water pick-up for the motor.

❚ The through hull fitting must have a

seacock valve to shut-off in case of an

emergency.

❚ Always use high quality non-corrosive

fittings, valves and hardware to assure

long-term reliability.

❚ Properly seal all pipe threads before

the strainer to prevent unforeseen

leaks. Never use Teflon tape or sealing

compounds on SHURFLO pump threads

or fittings. Sealer may enter the pump

causing a failure not covered under

warranty.

2

Loading...

Loading...