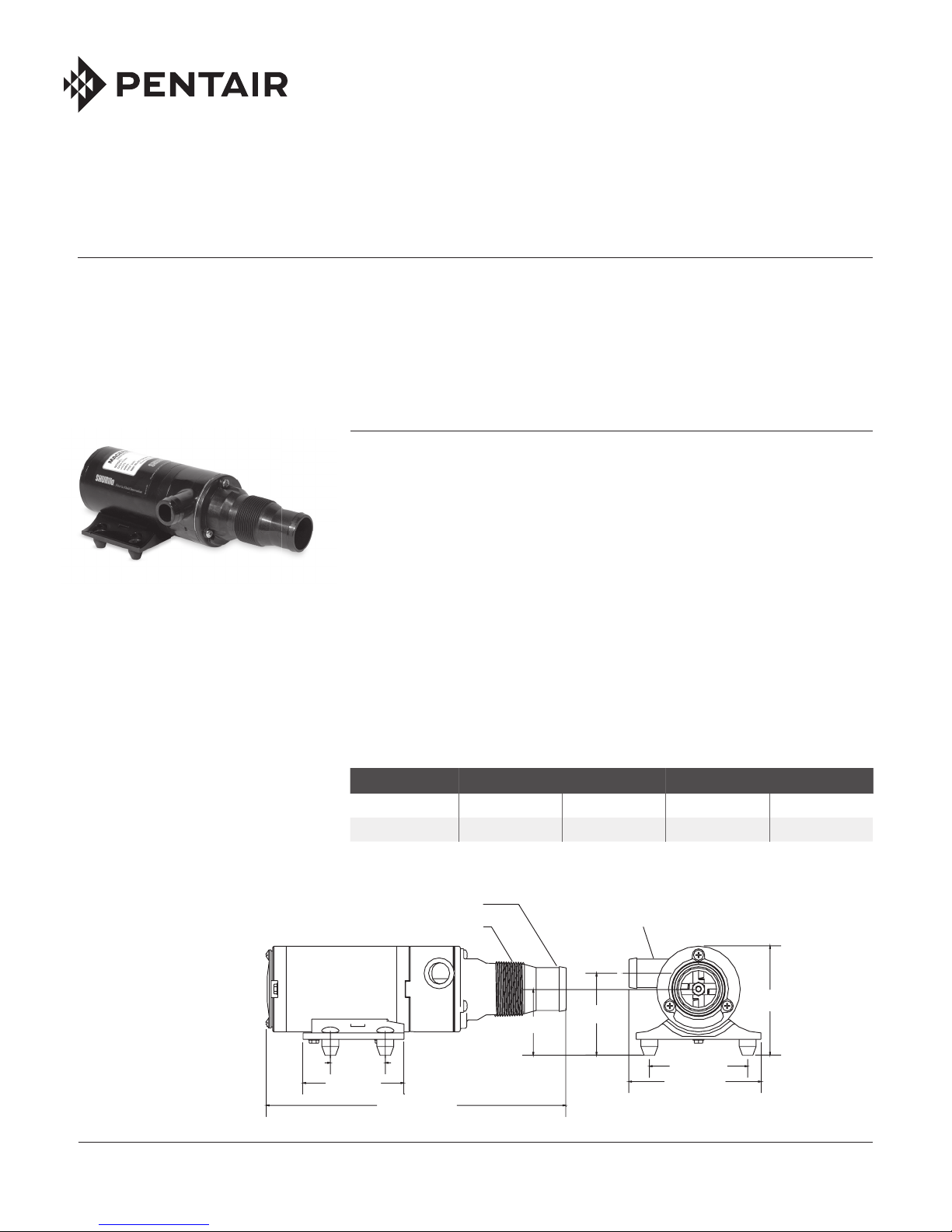

SHURFLO® 3200 MACERATOR PUMP

INSTALLATION, OPERATION & REPAIR MANUAL

SHURFLO’s macerator pump is designed to empty marine and RV holding tanks of normal waste. It is also an excellent choice

for emptying fi sh boxes of scales and residual waste. A fl ow rate of up to 13 gallons per minute conveniently empties any tank

in minutes. The unique dual-cut blade design ensures waste is ground up thoroughly. The pump is self-priming to a fi ve foot lift

when impeller is wet, four foot lift when impeller is dry, but for optimum performance and life, it should be mounted as close to

the tank as possible. Marine pump out must be in proper discharge zones only. This macerator will not handle hard objects, rags,

or feminine napkins.

PRODUCT SPECIFICATIONS

Motor: Seamless can motor, 1/8 hp Thermally protected

Lead Wires: 14 GA

Fuse: See motor label for fuse size

Pump Type: Flexible Impeller

Duty Cycle: Intermittent duty only

Ports: Inlet: 1-1/2” hose barb &

1-1/2” NPT Male

Outlet: 1” hose barb

Impeller: Brandonite

Blade: 316 stainless “Double-cut”

Dimensions: See drawing

Weight: 5 lbs.

Approvals: Ignition protected, ISO 8846, CE, and CSA, models available

Typical Flow: Dependent on fl uid viscosity (Chart below based on water)

®

911-566 REV. P 1

HEAD FLOW GPM [LPM] MAX. DC AMPS

Ft. [m] 12 V 24 V 12 V 24 V

0 [0] 13 [49] 13 [49] 17 9

Max. Operating Head = 30 feet

1-1/2" Hose Barb

1-1/2" NPT Male

2.0 [50.0]

3.6 [91.9]

10.8 [273.3]

2.3 [58.4]

1" Hose Barb

3.8 [97.3]

2.9 [72.9]

3.5 [89.7]

4.8 [120.9]

ELECTRICAL CONNECTIONS

WARNING: If the pump is operated in an

area containing flammable vapors, the

wire leads must be joined by insulated

mechanical locking connectors. Loose

or inadequate wire connections can

spark, resulting in an explosion resulting in property damage, injury, or death.

All electrical installations should be

done by a qualified electrician.

❚ Pump must be protected with proper

size fuse as specified on the motor

label.

❚ Pump should be operated on a separate circuit.

❚ Pump should be connected to properly

sized momentary switch. This prevents

pump from damage due to long periods

of dry run condition.

❚ Switch should be near pump. This will

allow operator to hear change in pump

sound when tank is empty.

AVERTISSEMENT: Si la pompe est

utilisée dans une zone contenant des

vapeurs inflammables, les fils doivent

être reliés par des raccords à verrouillage mécanique isolés. Des raccordements de fils desserrés ou inadéquats

peuvent produire des étincelles et

provoquer une explosion entraînant des

dommages matériels, des blessures ou

la mort. Toutes les installations électriques doivent être effectuées par un

électricien qualifié.

❚ La pompe doit être protégée par un

fusible de calibre approprié comme

précisé sur l’étiquette du moteur.

❚ La pompe devrait être utilisée sur un

circuit distinct.

❚ La pompe devrait être raccordée à un

interrupteur à rappel calibré correctement. Cela protège la pompe contre les

dommages attribuables à de longues

périodes de tournage à sec.

❚ L’interrupteur devrait se trouver

près de la pompe. Cela permettra à

l’utilisateur d’entendre un changement

dans le son de la pompe lorsque le

réservoir est vide.

NOTE: For proper operation motor must

rotate counterclockwise when viewed

from pump end.

2

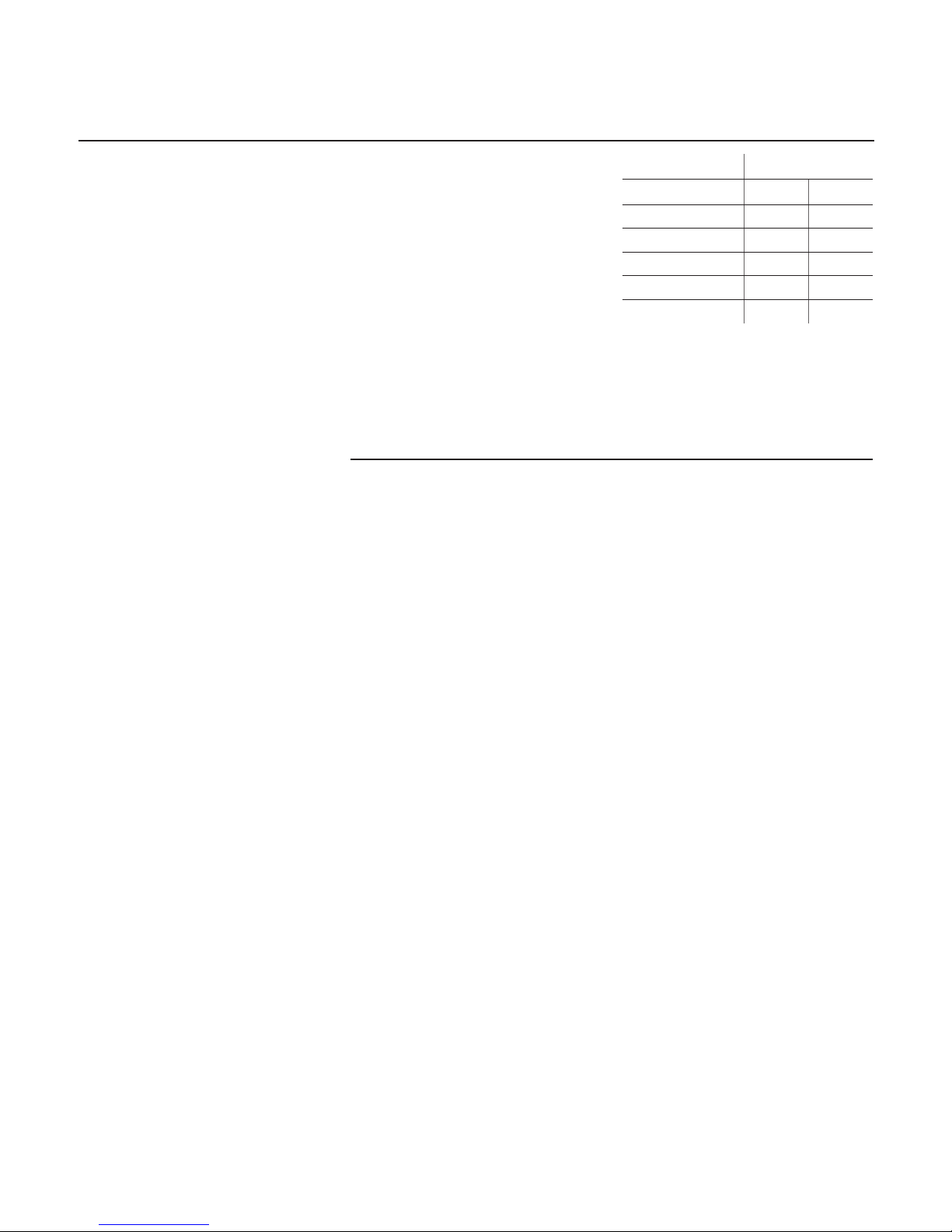

ELECTRICAL INSTALLATION CHECKLIST

√ Separate circuit from power source

√ Proper size momentary switch

mounted near pump

√ Proper wire size to length

√ Proper fuse size and type

√ Insulated wire connectors

12 Volt System Min. Wire Size (20 Amps)

Total Wire Length* 3% Drop 10% Drop

Feet [m] GA GA

1-10 [.3-3] #10 #16

11-20 [3.3-6] #8 #14

21-30 [6.4-9.1] #6 #12

30-60 [9.1-18.2] #4 #10

*length from power source to motor and

back to ground.

PLUMBING CONNECTIONS

Pump should be mounted as near as possible to tank to minimize dry run. Pump is

self-priming to a five-foot lift when impeller is wet, four foot lift when impeller is dry.

Pump is more efficient if mounted near the holding tank. Installations should be

done by qualified marine tech.

INLET: Always install pump with a shut-off valve between pump and holding

tank.

Hose: Use 1-1/2” ID [non-collapsible vacuum rated] hose on inlet [suction]

side. Use stainless steel hose clamps on all sanitation connections.

Flange: To mount to 1-1/2” female flange, inlet barb must be cut off just before

threads. Seal threads and hand tighten.

WARNING: Any air leak on inlet side can cause pump to run dry and can damage

impeller and impeller housing. Check all inlet side connections, even those on deck

plates. All runs should be smooth with no kinks or sharp angles.

AVERTISSEMENT: Une fuite d’air sur le côté aspiration peut causer le tournage à

sec de la pompe et endommager la turbine et le boîtier de turbine. Vérifier tous les

raccordements sur le côté aspiration, même ceux sur les plaques de plateforme.

Tous les parcours doivent être lisses, sans tortillement ni angle aigus.

OUTLET: Use 1” minimum ID hose on discharge side of pump. Connect to thru

hull fitting above highest heeled point above waterline. Vented loop

installations must vent at least 10” above highest heeled point above

waterline. Use stainless steel hose clamps on all sanitation connec-

tions.

Operation: INTERMITTENT DUTY ONLY!

Pump switch must be near pump and tank so operator can hear pump running.

Make sure shut-off valve to pump and dump valve [if equipped] are both open. Turn

on momentary switch and pump out tank. When tank is empty, pump will get louder

with a high pitch sound. Immediately turn pump off, or damage to impeller and

housing will occur. Do not run pump dry for more than 15 – 20 seconds. Flush tank

and pump with water after each use. This macerator will handle normal waste, tissues, cigarettes, fish scales, etc. It is not designed to handle large hard objects such

as large bones or fruit pits.

Periodic Maintenance and Storage: Flush with water after each use. Check wire

connections occasionally. After periods of non-use, impeller can stick. To loosen,

open rear shaft cover and turn motor shaft clockwise with a flat tip screwdriver.

Then replace shaft cover. For extended periods of non-use, pump impeller can be

lubricated by running a small amount of mineral oil through holding tank system.

Loading...

Loading...