Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

VME System Subracks 7 U / 8 U

User Manual

Product Numbers:

20836-716

20836-719

20836-815

Doc-No: 63972-147

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Revision: R1.0, September 22, 2006

Rev. Date updated Change

R1.0 September 22, 2006 Initial Release

Impressum:

Schroff GmbH

D-75334 Straubenhardt, Germany

The details in this manual have been carefully compiled and

checked - supported by certified Quality Management System

to EN ISO 9001/2000

The company cannot accept any liability for errors or misprints.

The company reserves the right to amendments of technical

specifications due to further development and improvement of

products.

Copyright

© 2006

All rights and technical modifications reserved.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U

20836-716/-719/-815

Table of Contents

1 Safety................................................................................................................. 1

1.1 Indended Application........................................................................................... 1

1.2 Safety Instructions............................................................................................... 2

1.3 Safety Symbols used in this document................................................................ 2

1.4 General Safety Precautions................................................................................. 2

1.5 References and Architecture Specifications........................................................ 3

2 Product Definition............................................................................................. 4

2.1 Mechanical Overview........................................................................................... 5

2.2 Subrack................................................................................................................ 6

2.3 VME Backplane................................................................................................... 6

2.4 Power Supply....................................................................................................... 7

2.4.1 Grounding.............................................................................................. 7

2.5 Thermals............................................................................................................ 10

2.6 Fan Control Module (FCM)................................................................................ 11

2.7 Chassis Monitoring Module (CMM) -optional- ................................................... 12

2.8 Display Module.................................................................................................. 13

3 Installation....................................................................................................... 14

3.1 Unpacking.......................................................................................................... 14

3.1.1 Ensuring Proper Airflow....................................................................... 14

3.2 Rack-Mounting................................................................................................... 15

3.3 Assembly of additional Backplanes................................................................... 16

3.4 Basic Functional Check..................................................................................... 17

4 Service............................................................................................................. 18

4.1 Technical support and Return for Service Assistance....................................... 18

4.2 Declaration of Conformity.................................................................................. 18

4.3 Scope of delivery............................................................................................... 19

4.4 Accessories ....................................................................................................... 19

4.5 Spare Parts........................................................................................................ 19

5 Technical Data ................................................................................................ 20

6 Dimensions ..................................................................................................... 21

www.schroff.biz I R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U

20836-716/-719/-815

www.schroff.biz II R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Safety

20836-716/-719/-815

1 Safety

1.1 Indended Application

The VME system subrack, described in this manual, is indended as a platform

for a microcomputer system based on the VME bus system (VITA 1-1994).

The VME system subracks are designed for protection class IP 20 and can be

used only in the resp. environments.

For higher protection requirements, a.e. IP 54/55 you must install the system

subrack in a protective case.

VME system subracks are not end-products, so there is no valid approval for this

unit. In order to enable stand-alone functionality,additional elements are

required. An operational system is achieved only by way of appropiate VME

boards.

The completion and final testing of the units have been carried out, or at least

supervised, by qualified technicians. These instructions are directed exclusively

to these qualified technicians i.e.engineers, trained and qualified electricians

etc.

Make sure that:

• the assembled unit complies with the safety regulations currently applicable

in the country it is going to be used.

• the overall unit complies with all other regulations and specifications at the

place and country of use, e.g. interference limits, approval by the telecommunications authorities.

www.schroff.biz 1 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Safety

20836-716/-719/-815

1.2 Safety Instructions

The intended audience of this User’s Manual is system integrators and

hardware/software engineers.

1.3 Safety Symbols used in this document

Hazardous voltage!

This is the electrical hazard symbol. It indicates that there are dangerous

voltages inside the Shelf.

Caution!

This is the user caution symbol. It indicates a condition where damage of the

equipment or injury of the service personnel could occur. To reduce the risk of

damage or injury, follow all steps or procedures as instructed.

Danger of electrostatic discharge!

The Shelf contains static sensitive devices. To prevent static damage you must

wear an ESD wrist strap.

1.4 General Safety Precautions

Warning!

Voltages over 60 VDC can be present in this equipment. This equipment is

intended to be accessed, to be installed and maintained by qualified and

trained service personnel only.

This equipment is designed in accordance with protection class 1!

It must therefore be operated only with protective GND/earth connection!

• Service personnel must know the necessary electrical safety, wiring and

connection practices for installing this equipment in a telecommunication

environment.

• Install this equipment only in compliance with local and national electrical

codes.

www.schroff.biz 2 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Safety

20836-716/-719/-815

1.5 References and Architecture Specifications

• User Manual VME Backplanes

Order no.: 73972-103

• Short Form User Manual VME J1/J2 Monolithic Backplanes

Order no.: 73972-128

• User Manual Fan Control Module (FCM)

Order no.: 73972-083

For more information see the catalogue „Electronic Packaging“ and at

www.schroff.biz

www.schroff.biz 3 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Product Definition

20836-716/-719/-815

2 Product Definition

The Schroff VME subrack system consists of:

• A shielded 19“ subrack with front assembly area for

6 U front boards according to VME Standard (VITA 1-1994)

• A VME (VITA 1-1994) Backplane

• An open frame power supply with wide range input

• Speed controlled fans for cooling the boards

• Fan Control Module (FCM) for fan monitoring/controlling

• Display module

• Mains/line switch

• Rear assembly area for three 6 U, 4 HP Rear Transition Modules

The fans and the power supply are assembled on the bottom-hinged rear panel.

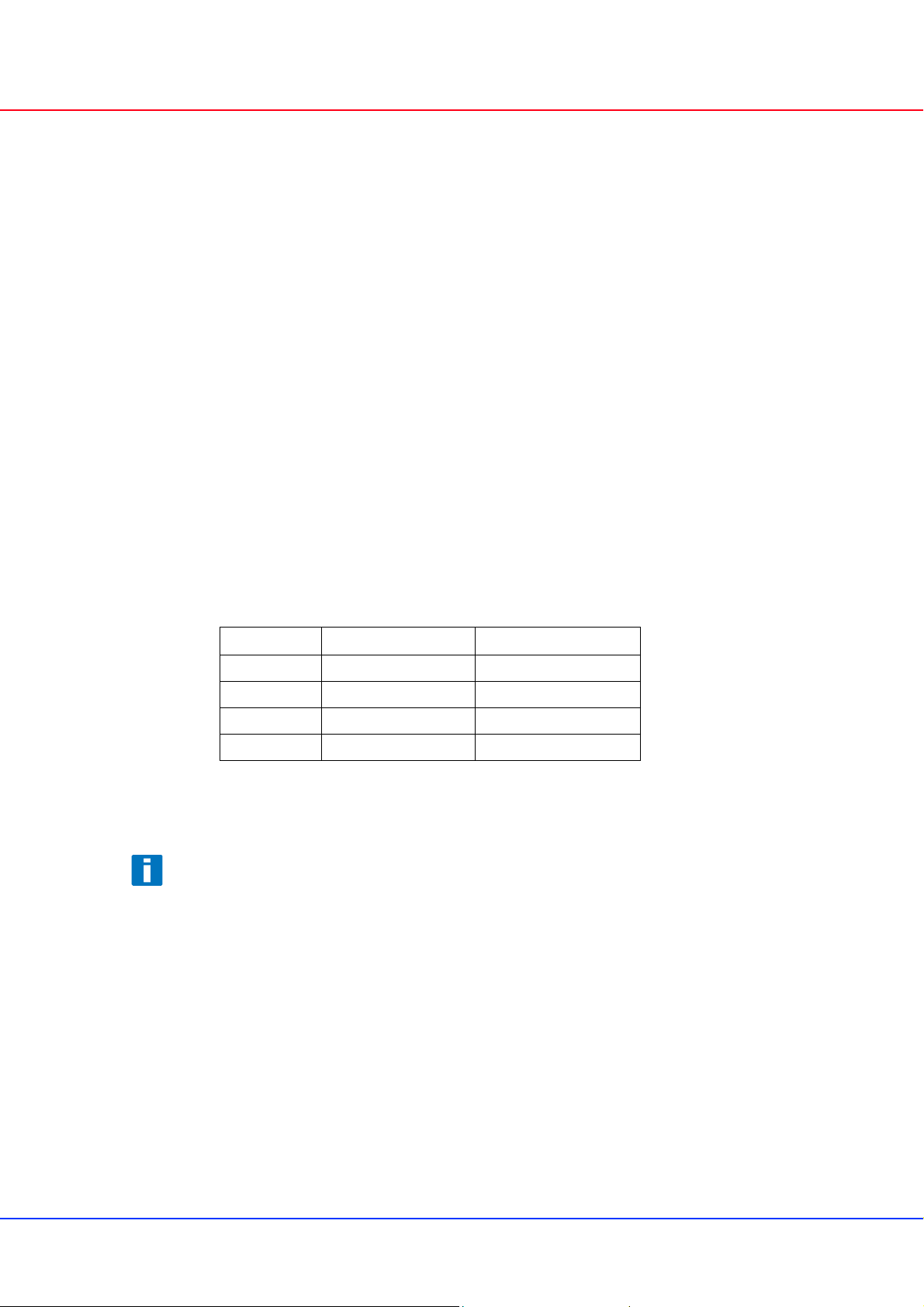

System differences:

The subracks 20836-716/-719 are identical in their construction. The only

difference is the depth (355 mm/475 mm).

The subrack 20836-815 is identical to 20836-716 with the following exceptions:

20836-717 20836-815

Power supply 5 V / 60 A 5 V / 120 A

Fans 3 x 170 m³/h (100 cfm) 3 x 237 m³/h (140 cfm)

Backplane 12-Slot 21-Slot

Height 7 U 8 U

The 7 U system has a 0,5 U bottom plenum and a 0,5 U upper plenum. The 8 U

system has a 1 U bottom plenum and a 1 U upper plenum for more efficient

airflow and cooling.

Variations

The Schroff assembly service can customize your subrack system with:

• Different Backplane configurations

• Drive mounting cassettes

• Special power supplies

• A Chassis Monitoring Module (CMM)

More information in the catalogue or at www.schroff.biz

www.schroff.biz 4 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Product Definition

20836-716/-719/-815

2.1 Mechanical Overview

Figure 1: Mechanical Overview (Shown at 7 U System)

10006813

1 Front card cage with guide rails 7 Fan Control Module (FCM)

2 Front panel 6 U / 36 HP

8 Display module

(Only 7 U system)

3 Space for Rear Transition Modules 9 Power supply

4 Bottom-hinged rear panel 10 AC terminal with line filter

5 VME Backplane 11 Mains/line switch

6 Axial fans

www.schroff.biz 5 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Product Definition

20836-716/-719/-815

2.2 Subrack

The 7 U / 8 U 19“ system based on the Schroff europacPro System with EMC

shielding. The front card cage provides space for the installation of 12 or 21 VME

Boards (6 U, 4 HP, 160 mm deep).

The lower guide rails are fitted with ESD clips.

The front card cage at the 7 U system is upgradeable to 21 slots.

The horizontal assembly area allows the installation of 3 Rear Transition

Modules (6 U, 4 HP). The depth depends on the system. The subrack system

20836-716 and 20836-815 allows Rear Transition Modules with a depth of 120

mm, the subrack system 20836-719 allows up to 240 mm depth.

2.3 VME Backplane

The 6 U Backplane (J1/J2 Monolithic) is compliant to:

• VITA 1-1994

• VITA 38 Systemmanagement for VME

The subrack systems 20836-716/-719 have a 12-Slot Backplane as standard,

the subrack system 20836-815 has 21-Slot Backplane. You can customize your

system with different Backplanes.

For more information see the Backplane’s User Manual, Order No. : 73972-103/

-128, in the catalogue and at www.schroff.biz

1 Slot = 4 HP = 20,32 mm

www.schroff.biz 6 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Product Definition

20836-716/-719/-815

2.4 Power Supply

Hazardous voltage!

Parts of the power supply may be exposed with hazardous voltage. Always

remove mains/line connector before carry out any assembly work.

Caution!

Your system has not been provided with a AC power cable. Purchase a

AC power cable that is approved for use in your country. The AC power cable

must be rated for the product and for the voltage and current marked on the

product's electrical ratings label. The voltage and current rating of the cable

should be greater than the ratings marked on the product.

The subrack system has a open frame AC power supply with wide range input.

The power supply is assembled on the bottom-hinged rear panel.

The power input is provided by a AC mains/line module with IEC 320-C14

connector, integrated mains/line fuses and line filter.

A mains/line switch is located at the lower front side.

Maximum fuse values are:

• 8 A (Power supply MP4 in 7 U Systems)

• 10 A (Power supply MP6 in 8 U Systems)

Warning!

The fuse value has been determined in factory for the maximum power

delivered by the power supply. The fuse value must be changed to the actua l

current of the complete equipped system.

2.4.1 Grounding

Caution!

The unit is designed in accordance with protection class 1! It must therefore be

operated with protective earth/GND connection. Use only a three conductor

AC power cable with a protective earth conductor that meets the IEC safety

standards!

There is a 6,3 mm faston connector at the right side panel. This co nnector is only

for equipotential bonding. Grounding is achieved through the protective earth

conductor of the power cable!

www.schroff.biz 7 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Product Definition

20836-716/-719/-815

Figure 2: AC Power Supply

10006819

T able 1: Data AC Power Supply

e

Power supply MP4 (7 U Systems) Power supply MP6 (8 U Systems

Input voltage nominal 100 - 240 VAC 100 - 240 VAC

Mains Frequency 50 / 60 / 400 Hz 50 / 60 / 400 Hz

Output (max.) 444 W (400 W if U < 200 VAC) 744 W (600 W if U < 200 VAC)

Output voltages 5.0

12.0

-12.0

V

V

V

A

10

A

4

-

A

60

-

5.0

12.0

-12.0

A

10

-

V

A

4

-

V

A

120

-

V

Ripple < 1 % < 1 %

Dynamic response < 2 % or 100 mV with 25 % load

step

< 2 % or 100 mV with 25 % load

step

Recovery time to within 1% < 300 µsec < 300 µsec

Overvoltage protection for all voltages

110 – 120 % U > 5 V or

122 – 134 % U < 5 V

for all voltages

110 – 120 % U > 5 V or

122 – 134 % U < 5 V

Overcurrent protection 105 – 120 % of rated output current 105 – 120 % of rated output current

Hold-up time >= 20 ms >= 20 ms

www.schroff.biz 8 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Product Definition

20836-716/-719/-815

Figure 3: Block Diagram

10006820

www.schroff.biz 9 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Product Definition

20836-716/-719/-815

2.5 Thermals

The front boards are cooled by forced air convection through 3 speed controlled

24 VDC axial fans.

• 7 U System: each fan 170 m³/h (100 cfm).

• 8 U System: each fan 237 m³/h (140 cfm).

The fans are assembled on the bottom-hinged rear panel.

The air enters the subrack at the lower front into the bott om air plenum and turns

90° upward. As the air passes across the hot components on the Front Boards,

heat is carried away by forced convection. The air exits the Subrack a t th e top,

is drawn into the upper plenum, turns 90°, and is exhausted out the rear of the

subrack by fans.

The fan speed is controlled by the Fan Control Module (FCM) depending on the

exhaust temperature. The average temperature increase at full load is 10 K.

Caution!

To maintain proper airflow, all open slots must be covered with filler panels.

The filler panel should include an airflow baffle that extends to backplane.

Figure 4: Airflow

10002057

www.schroff.biz 10 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Product Definition

20836-716/-719/-815

2.6 Fan Control Module (FCM)

The Fan Control Module (FCM):

• Monitors and controls up to four fans

• Monitors the signals from up to four temperature sensors

• Controls the Display Module

• Speed up the fans in case of a failure of one fan

• Is able to communicate with the optional Chassis Monitoring Module (CMM)

Up to four NTC temperature sensors can be connected to the FCM. The highest

temperature level is the reference for the fan speed. If one ore more sensors

exceed 60° C the output for the temperature fail LED and a digital output are

activated. Since the fan speed is temperature controlled by the FCM, the fans

rotate with the lowest speed possible. Lower speeds reduce acoustic noise and

increase the longevity of the fans.

The FCM also controls a Display Module. 3 green LEDs signal the 3 VME

voltages, two red LEDs signal over-temperature and fan fail events.

Figure 5: Diagram fan speed/temperature

8

FanSpeed

(%)

Over-Temp.

100

60

10006807

For more information see the FCM’s User Manual, Order No.: 73972-083 and at

www.schroff.biz

www.schroff.biz 11 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Product Definition

20836-716/-719/-815

2.7 Chassis Monitoring Module (CMM) -optional-

The Chassis Monitoring Module (CMM)

• monitors the three VME voltages

• can monitor two additional voltages with a range of ±24 V

• can monitor up to seven NTC temperature sensors

• can communicate with the Fan Control Module (FCM)

• provides 16 digital inputs

• provides 10 digital outputs

The CMM is an optional assembly and not included with the subrack by default.

The CMM is a pluggable unit in the 3 U euroboard format with a

3 U/1 HP front panel and can be assembled at the front or rear side.

The CMM allows communication and remote monitoring via RS-232 or Eth ernet

interface. The front panel provides a RJ45 connector (Ethernet) an a D-Sub9

connector (RS-232).

A user interface via HTML page is available.

DC

The CMM can monitor the 3 VME voltages and two additional voltages (up to

±24 V

). The error status can be displayed by LEDs, through the RS-232 serial

DC

interface or via ethernet as a HTML page.

Up to 7 NTC temperature sensors can be connected to the CMM.Two alarm

thresholds between 20° C and 70° C can be set.

The CMM provides 16 digital inputs and 10 digital outputs for custom specific

applications. Four digital outputs are open collector outputs, isolated by optocouplers, six digital outputs are TTL-compatible non-isolated.

The CMM is connected to the FCM. The temperature values and the fan speeds

are transferred to the CMM.

For more information see the CMM’s User Manual, Order No.: 73972-084 and

at www.schroff.biz

www.schroff.biz 12 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Product Definition

20836-716/-719/-815

2.8 Display Module

Figure 6: Display Module

10006821

The Display Module is located at the upper front side of the subrack. 3 green

LEDs signal the 3 VME voltages, two red LEDs signal over-temperature and fan

fail events.

The Display Module is controlled by the FCM.

When a CMM is present, the Display Module is controlled by the CMM.

www.schroff.biz 13 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Installation

20836-716/-719/-815

3 Installation

3.1 Unpacking

Caution!

When opening the shipping carton, use caution to avoid damaging the system.

Consider the following when unpacking and storing the system:

• Leave the system packed until it is needed for immediate installation.

• After unpacking the system, save and store the packaging material in case

the system must be returned.

If the packaging is damaged and possible system damage is present, report to

the shipper and analyze the damage.

3.1.1 Ensuring Proper Airflow

• Install the system in an open rack whenever possible. If installation in an

enclosed rack is unavoidable, ensure that the rack has adequate ventilation.

• Maintain ambient airflow to ensure normal operation. If the airflow is blocked

or restricted, or if the intake air is too warm, an over temperature condition

can occur.

• Ensure that cables from other equipment do not obstruct the airflow through

the systems.

• Use filler panels to cover all empty chassis slots. The filler panel prevents

fan air from escaping out of the front of an open slot.

Caution!

To maintain proper airflow, all open slots must be covered with filler panels.

The filler panel should include an airflow baffle that extends to backplane.

www.schroff.biz 14 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Installation

20836-716/-719/-815

3.2 Rack-Mounting

Warning!

Do NOT move the a full equipped system by yourself. Due to the weight at

least two persons are needed to accomplish this task

Warning!

Do NOT stack the system on top of any other equipment. If the system falls, it

can cause severe bodily injury and damage the equipment.

This subrack system can be installed in 19“ equipment racks. The rack must be

accessible from the front and rear for equipment installation.

Mounting brackets and a rack mount kit come with the system. Allow sufficient

clearance around the rack for system maintenance.

Mounting Instructions:

• Ensure that the rack is constructed to support the weight and dimensions of

the Shelf.

• Install any stabilizers that came with your equipment rack before mounting

or servicing the system in the rack.

• Load the rack from the bottom to the top, with the heaviest system at the

bottom, avoid uneven mechanical loading of the rack.

• We recommend to use also chassis support brackets.

www.schroff.biz 15 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Installation

20836-716/-719/-815

3.3 Assembly of additional Backplanes

With the subrack systems 20836-716/-719 you can assemble an additional

Backplane.

Obey the following instructions:

1 Disconnect the System from the line/mains power supply.

2 Remove the front panel.

3 Mount the guide rails.

4 Remove the back panel.

Note: Open the back panel to an angle of 135°. At this angle you can

separate the hinges and remove the back panel completely.

5 Attach the new Backplane with two M2.5 screws and isolating washers at

the top and the bottom, but do not tighten the screws.

6 To align the Backplane, insert a VME board in the outer guiderails at the left

and the right.

7 Attach the Backplane using M2.5 screws and isolating washers.

Note: Use at least every second mounting hole at the top and the bottom.

8 Connect the Backplane to the system power.

9 Attach the rear panel.

10Power-up the systems without the VME boards and check all VME voltages

at the backplane connectors.

Note: For instructions see Chapter3.4, "

Basic Functional Check".

For more information and further assembly instruction see the Backplanes

User manual.

www.schroff.biz 16 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Installation

20836-716/-719/-815

3.4 Basic Functional Check

Warning!

Voltages over 60 VDC can be present in this equipment. This equipment is

intended to be accessed, to be installed and maintained by qualified and

trained service personnel only.

This eqipment is designed in accordance with protection class 1!

It must therefore be operated only with protective GND/earth connection!

Before starting the system with VME boards the following tests have to be done:

• Ensure that the unit does not get damaged during tranport.

• Check the Protective Earth (PE) resistance, should be < 0,1 Ohm.

• Switch on the system and check all VME voltages on the Backplane

connectors before you plug in the VME boards.

Note: The +12 V output requires 10% minimum load, i.e. a resistor

12 Ohm / 12 W.

• Plug in the VME boards.

• Cover all open Slots with filler panels.

• Tighten the rear panel mounting screws.

• Power-on the system and determine the actual current consumtion.

• Replace the mains fuses suitable to the actual current.

The fuse value has been determined in factory for the maximum power

delivered by the power supply. The fuse value must be adjusted to the actual

current consumtion of the completed system.

Maximum values are 8 A slow (MP4) or 10 A slow (MP6).

Figure 7: Mains Fuses

10006815

1 Fuse 2 Power Socket

www.schroff.biz 17 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Service

20836-716/-719/-815

4 Service

4.1 Technical support and Return for Service Assistance

For all product returns and support issues, please contact your Schroff sales

distributor or www.schroff.biz

We recommend that you save the packing material. Shipping without the original

packing material might void the warranty.

4.2 Declaration of Conformity

Microcomputer packaging systems are not complete units which can be

delivered directly to the end user, other items need to be fitted.

.

As it is defined in the EMC standard, it is not designated as a device.

A CE symbol is therefore not required. However, the systems comply with all

requirements. Each individual component complies to the EMC standard

89/336/EWG and to the low frequency standard 73/23/EWG.

These systems are generally equiped with power supplies having the

CE symbol (EN 60950, EN 61000-6-3, EN 61000-6-2).

The choice of the mains filter is carried out by considering the limited values‘

curve, according to EN 55022 class B.

To warrant the interference immunity according to EN 61000-6-2, the shielding

attenuation is measured in the frequency range from 30 MHz to 1000 MHz

according to VG 95 373, Part 15.

The systems are developped and manufactured according to EN 60950. Highvoltage tests, protective earth tests and functions tests are done on each series

system.

www.schroff.biz 18 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Service

20836-716/-719/-815

4.3 Scope of delivery

Quantity Description

1 19" subrack, shielded, with plain top and base covers and front handles. (front handles: RAL

7016; 19"-brackets, top and base covers: RAL 9006)

1 VME Backplane J1/J2 monolithic (VITA 1-1994); 12-Slot 6 U (7 U Systems);

21-Slot 6 U (8 U Systems);

1 Front assembly area for

- max. 12 Boards 6 U 160mm deep (7 U Systems)

- max. 21 Boards 6 U 160mm deep (8 U Systems)

guide rails incl. ESD-Clips (ESD-Clips assembled at front bottom)

1 Rear assembly area for the installation of max. 3 Rear I/0 Boards 6 U, 4 HP.

(max. depth aprox. 120 mm/240 mm, depending on the subrack)

The rear assembly area is covered with a panel 6 U, 12 HP.

1 AC mains/line mo dule with IEC 320-C14 connector, mains fuses and line filter

1 Open Frame power supply 444 W (7 U) orr 744 W (8 U) with wide range input 100 VAC to

240 VAC (with 3 voltages: 5 V / 60/120 A; 12 V / 10 A, -12 V / 4 A)

1 Complete AC/DC wiring

1 Display module and mains switch

3 Speed controlled fans, assembeld on bottom-hinged rear panel

1 FCM-Module for fan monitoring and controlling

1 Front plate 6 U, 36 U assembled at the right front side (only 7 U Systems)

4.4 Accessories

Parts-No. Description

23207-022 Chassis Monitoring Module (CMM)

20848-7xx Filler panel with EMC front plate for empty Slots, dimensions see catalogue

34562-8xx Filler panel for empty Slots, dimensions see catalogue

24579-03x Printed Circuit Board covers, dimensions see catalogue

20836-750 19“ case for 7 U system (Only for 20836-716)

20836-950 19“ case for 8 U system

4.5 Spare Parts

On request.

www.schroff.biz 19 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Technical Data

20836-716/-719/-815

5 Technical Data

Table 2: Technical Data

Dimensions

Height 7 U Systems 310.5 mm (7 U)

Height 8 U System 355 mm (8 U)

Width 483 mm (19“)

Depth (20836-716/-815) 355 mm

Depth (20836-719) 475 mm

Weight

(20836-716) 17 Kg

(20836-815) 18 kg

(20836-719) 20 kg

Power supply

Input voltage 100 VA C to 240 VAC

Mains frequency 50 / 60 / 400 Hz

Power consumption (20836-716/-719) up to 444 W

Power consumption (20836-815) up to 744 W

Cooling

3 x 24 VDC Fans (20836-716/-719) Each 170 m³/h (100 cfm)

3 x 24 VDC Fans (20836-815) Each 237 m³/h (140 cfm)

Ambient Temperature

Operating 0 °C to +40 °C

Storage -40 °C to +85 °C

Humidity

permissable Humidity 30 % to 80 %, non condensing

EMC, the system meets the

requirements for:

Emitted Interference EN 55022

Interference Resistance EN 55024

Safety

Test voltage according to EN 60950 Input - Output:

Input- PE:

Output - PE:

Output - Output:

Shock and Vibration: EN 60068-2-6 and EN 60068-2-27

4,3 kVDC

2,2 kVDC

0,7 kVDC

0,7 kVDC

Electromagnetic Shielding

Shielding attenuation typ. 40 dB at 1 GHz if shielded front

panels are used.

www.schroff.biz 20 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Dimensions

20836-716/-719/-815

6 Dimensions

Figure 8: Dimensions

10006822

1 HE = 1 U

1 TE = 1 HP

www.schroff.biz 21 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

VME System Subracks 7 U / 8 U Dimensions

20836-716/-719/-815

www.schroff.biz 22 R1.0, September 22, 2006

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SCHROFF GMBH www.schroff.biz

Langenalberstr. 96-100 Tel.: + 49 (0) 7082 794-0 Fax: +49 (0) 7082 794-200

D-75334 Straubenhardt

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Loading...

Loading...