Page 1

SYSTEM 3

®

MODULAR MEDIA FILTER

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

MODEL S8M600

Furnish this manual to the end user

of this filter; its use will reduce service calls and chance of injury and

will lengthen filter life.

Pentair Water Pool and Spa, Inc.

© 2008 Pentair Water Pool and Spa, Inc. All rights reserved. This document is subject to change without notice.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Trademarks and Disclaimers:

System 3

®

and Pentair Water Pool and Spa®are registered trademarks of Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the United States and/or other counties. Unless noted, names and brands of others that may be used in

this document are not used to indicate an affiliation or endorsement between the proprietors of these names and brands and

Pentair Water Pool and Spa, Inc. Those names and brands may be the trademarks or registered trademarks of those parties

or others. Printed in U.S.A.

February 4, 2008 S293S (Rev. A)

Protected by one or more of the following U.S. Patents and all corresponding foreign counterparts: U.S. Pat. No. 4,995,523, 5,190,651, 5,753,071 and 6,036,853.

Page 2

2

SYSTEM 3

®

MODULAR

MEDIA FILTERS:

To avoid unneeded service calls, prevent possible injuries, and get the most out of your filter, READ THIS

MANUAL CAREFULLY!

The Sta-Rite System 3

®

Modular Media Filter:

•Is designed to filter water for swimming pools, spas

and hot tubs.

•Is an excellent performer; durable, reliable.

Table of Contents

Safety Instructions ......................................................2

General Information .....................................................3

Installation ................................................................3-4

Specifications...............................................................4

Initial Startup ...............................................................5

Filter Disassembly/Assembly ......................................5

Filter Cleaning Procedure .........................................6-7

System Inspection/Winterizing .....................................7

Troubleshooting Guide.................................................8

Pressure Drop Curve ...................................................9

Repair Parts List ........................................................10

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your system or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury.

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on filter.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Incorrectly installed equipment may fail,

causing severe injury or property damage. Read and

follow operational parameters given below when installing equipment described in this owner’s manual.

1. Follow instructions and procedures in owner’s manual

for installation, operation, and maintenance of equipment.

2. Do not connect any part of pool or spa system to city

water system, well water system, or to any other type

of high pressure water system or supply.

3. Do not attempt to use pool or spa equipment in any

type of installation other than a pool or spa.

4. Trapped air under pressure in system can cause ex-

plosion and serious injury. Follow instructions in

owner’s manual or on equipment to make sure that

no air is trapped in the system before testing or operating equipment.

Equipment that is incorrectly pressure

tested may explode, causing severe injury or property

damage. Pressure testing should only be done by

trained pool professionals, following test parameters

given below when testing the equipment described in

this owner's manual.

1. Make physical check for correct tightness of all

clamps, bolts, lids, and system accessories prior to

test. See owner’s manuals covering equipment being

tested for this information.

2. Make sure there is no air entrapped in system.

Release all air in system before testing.

3. When using a Sta-Rite pump and trap, tighten pump

trap lid to 30 ft. lbs. (4.1 kg-m.) torque before testing.

4. Water pressure for testing must be 25 PSI (172 kPa)

or less.

5. Water temperature for testing must be 100°F (38°C)

or less.

6. Test length must be 24 hours or less.

7. After test, make visual check of system to make sure

that it is ready for operation. Remove Sta-Rite pump

trap lid and retighten hand-tight only.

8. Exceeding any one of limits 2 through 6 or omitting

physical checks specified in Steps 1 and 7 can result

in equipment and property damage or physical injury.

NOTICE: These parameters apply to Sta-Rite pool and

spa equipment only. For non-Sta-Rite equipment, consult manufacturer.

Page 3

3

GENERAL

INFORMATION

Hazardous pressure. Can cause severe

injury or major property damage from tank blow up.

Release all pressure and read instructions before working on filter.

Clean a new pool as well as possible before filling pool

and operating filter. Excess dirt and large particles of

foreign matter in the system can cause serious damage

to the filter and pump.

With a cartridge filter system in place and operating correctly, clean water is returned to the pool faster than the

pool water is being contaminated. A typical pool installation will require approximately one week to obtain and

maintain the sparkle that your filter is capable of giving

you.

Keep pool water pH at recommended level (7.2 to 7.6).

Be sure clamps are in place and knobs are securely

tightened before starting filter.

Maintain pressure gauge in good working order.

Replace gauge if it fails or is damaged.

Make sure internal air bleed tube and air bleed filter

(Key Nos. 9 and 10, Page 10) are in place before operating filter. Clean air bleed periodically.

Cleaning interval is based on pressure differential, not

on length of time filter is operated. Different areas and

water conditions will have different normal cleaning intervals.

NOTICE: Some pool disinfectants may clog filter media.

To maximize media-life and filter cycle time, closely follow disinfectant manufacturers instructions when cleaning pool or filter.

If filter is improperly disassembled or assembled, it may explode under pressure! To avoid danger of severe injury or major property damage, always

follow service instructions in this manual when working

on filter!

NEVER operate this filter system at more

than 50 pounds per square inch (50 PSI/345kPa) pressure!

On a new pool installation, we recommend:

1. Disassemble the filter after the initial cleanup.

To prevent severe injury or major property damage, follow exactly “Filter

Disassembly/Assembly Procedure” on Page 5.

2. Hose down the element assembly to remove contaminants.

INSTALLATION GENERAL

Installation of filter should only be done by qualified,

licensed personnel.

Filter mount must

Provide space and lighting for easy access for routine

maintenance.

Provide adequate ventilation and drainage for pump.

Be protected from weather and reasonably level.

Be less than three feet above pool water level.

Be as close to pool as possible to reduce line loss from

pipe friction.

Piping

All piping must conform to local and state plumbing and

sanitary codes.

Never use pipe joint sealing compound on pipe and fittings that are plastic or may come into contact with plastic. Use only Teflon tape, Plasto-Joint Stik®or Silastic

732®** on PVC pipe and fittings; pipe joint compound

may cause stress cracking of plastic components. Use

pipe joint compounds only on metal-to-metal joints.

Support pipe independently to prevent strains on filter or

pump.

Use 2” or larger pipe to reduce pressure losses.

NOTICE: High flow rates may require larger pipe to produce adequate flow through filter.

Check local codes.

Fittings restrict flow; for best efficiency use fewest possible fittings.

Filter pumps require

hazardous voltage

which can shock, burn,

or cause death

BEFORE

WORKING

ON PUMP OR

MOTOR:

Disconnect

power to motor.

BEFORE WORKING

ON PUMP FILTER:

1. Stop pump.

2. Open air

release valve.

3. Release all pressure from system.

If filter clamps are

adjusted or removed

under pressure,

tank may explode,

causing severe injury or

major property damage.

Plasto-Joint Stik®is a registered trademark of La-Co Industries, Inc. and Silastic 732®is a registered trademark of Dow Corning Corp.

Page 4

4

Keep piping tight and free of leaks: pump suction line

leaks may cause trapped air in filter tank or loss of

prime at pump; pump discharge line leaks may show up

as dampness or jets of water.

Either plug drain fitting with a 2" NPT pipe plug or run

piping from drain fitting to an acceptable waste water

disposal point. Provide plug or valve for wastewater

line.

Valves

Provide isolation valves to allow for easy servicing of filter.

A check valve installed between pool and filter inlet will

prevent contaminants from draining back into pool.

A check valve installed between filter and heater will

prevent hot water from heater from backing up into the

filter and deforming filter elements.

NOTICE: Damaging filter elements through excessive

heat voids the warranty.

Do not use selector valves (i.e., slide or multiport etc.)

with this filter. Filter cannot be backwashed. See Page 6

for cleaning information.

Electrical

BE SURE filter grounding and bonding meets local and

National Electrical Code standards. All wiring, grounding and bonding of associated equipment must meet

local and National Electrical Code standards.

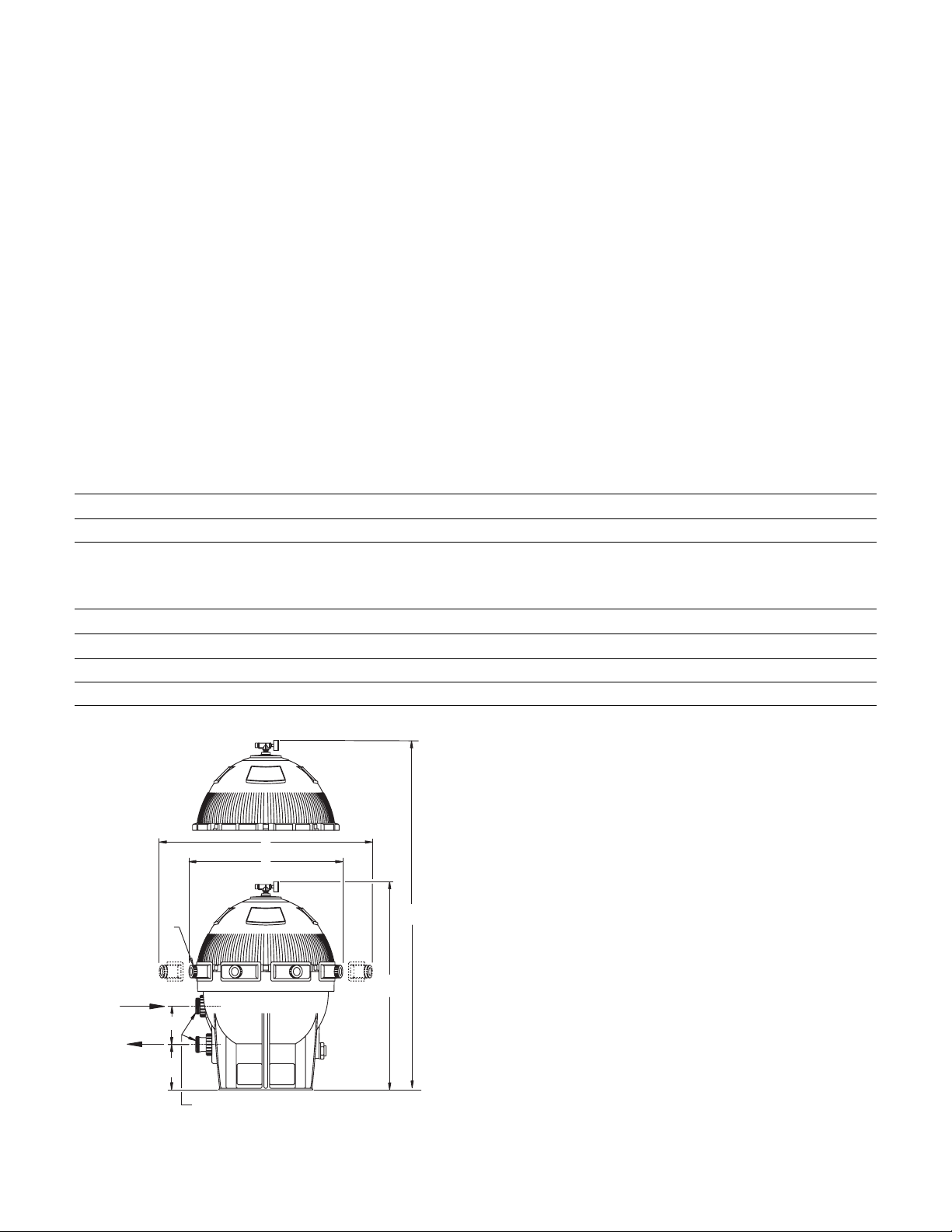

SPECIFICATIONS

TABLE I - SPACE REQUIREMENTS in inches (mm)

Model No. A B C* D E

S8M600 32-1/2 (826) 42-1/4 (1073) 8 40 (1020) 68 (1730)

* Number of clamps.

TABLE II - FILTER SPECIFICATIONS AND OPERATING INFORMATION

Filter Model: S8M600

Filter Area 600 Sq. Ft. (55.8 Sq. M)

Maximum Flow Rate 160 GPM (606 l/min.)

Max Operating Pressure 50 PSI (345 kPa)

Figure 1 - Dimensions in inches (mm)

A

B

C

D

E

INLET

OUTLET

7.812" (19.85 cm)

9.19" (23.3 cm)

F

2" (51mm) Sta-Rite Union Connectors

Page 5

5

INITIAL START-UP

Turn pump OFF before starting procedure.

Properly seat filter clamps and securely tighten clamp

knobs before proceeding.

Read “Warning Instructions For Clamp Assembly” decal

on tank.

Water pressure in filter must not exceed 50 PSI (345

kPa) under any circumstances.

1. Open air release valve (Key No. 3, Page 12) located

on top of filter tank head.

2. Start pump.

3. When a steady stream of water comes from air release valve, close valve.

4. After filter is operating, record filter pressure gage

reading in owner’s manual for future use.

NOTICE: When installed on a new pool, filter element

may need cleaning after approximately 48 hours of operation.

NOTICE: A new filter may discharge foam upon initial

start-up. This non-toxic foam is a normal consequence

of the microban treatment process and should disappear after a few minutes of operation.

NOTICE: A new or recently cleaned filter element may

pass some foreign material until it builds up a sufficient

coating to stop all “fines”. This is normal; a short operational period should correct the condition.

Check pressure gauge; if pressure has risen more than 10

PSI (70 kPa) above startup pressure, remove and clean element.

FILTER DISASSEMBLY/

ASSEMBLY PROCEDURE

Before Disassembling Filter:

1. STOP PUMP.

2. OPEN air release valve.

3. WAIT until all pressure is released

from filter tank and system before loosening clamp

knobs.

Disassembly:

1. Stop pump.

2. Open air release valve (Key No. 2, Page 10) on top

of filter tank to release all pressure from inside of

tank and system.

3. Close plumbing inlet and return valves to prevent

flooding.

4. Remove filter drain plug (Key No. 17 or 18, Page 10)

and drain all water from tank.

5. To equalize flange stresses, loosen clamps alternately (that is, on opposite sides of tank) around

tank. Remove clamps.

6. Being careful not to damage Cord ring (Key No. 23,

Page 10), lift upper tank half (Key No. 24, Page 10)

off of lower tank half (Key No. 22, Page 10).

Assembly:

1. Remove Cord Ring slowly to avoid stretching or tearing

it.

2. Inspect Cord Ring (Key No. 23, Page 10) for cuts,

nicks, etc. If damaged, replace with a new one.

3. Clean Cord Ring area of tank half (both halves) and

Cord Ring.

4. Carefully install Cord Ring and upper tank half (Key

No. 24, Page 10).

NOTICE: Be sure upper tank half contacts Cord Ring

surface evenly and seal area is clean and free from dirt.

Do not lubricate Cord Ring; lubricants may cause the

Ring to swell.

5. Install clamps. Do not tighten clamps yet.

6. See Figure 3 for clamp tightening sequence. Tighten

all clamp knobs securely hand tight.

NOTICE: To equalize stresses on tank, be sure to

tighten clamps in sequence shown. DO NOT work your

way around the filter tightening adjacent clamps.

7. Open isolation valves.

8. Follow directions under “Initial Startup”.

Figure 2 - 25" Filter clamp tightening sequence.

1

7

4

6

2

8

3

5

25" Filter

Page 6

FILTER CLEANING PROCEDURE

NOTICE: When sanitizing your pool using PHMB (polyhexamethylene biquanide based) cleaners, use only

PHMB cleaners to clean the module. When using

PHMB sanitizers, the filter module MUST be cleaned

more thoroughly and frequently than for a pool using

chlorine. Follow manufacturer’s instructions carefully.

Use of any other type of cleaners with PHMB pool sanitizers will void the filter’s warranty.

With hose, wash foreign material from inside of tank.

Avoid washing debris into outlet port.

Be sure inside surface of tank is clean.

Keep track of filter operating pressure. When pressure

reaches 10 PSI (70 kPa) above initial operating pressure, clean filter element.

If filter is used with a spa, soak element (see “Special

Cleaning Instructions,” Page 9) at each regular cleaning.

Filter elements are too heavy for safe lifting

when wet and dirty. To avoid back injury, clean and

drain elements as far as possible in operating position

in filter tank. Have two people lift elements and lift with

care. Follow cleaning procedure given below.

A. Cleaning in Place Procedure:

1. Follow steps one through six under

“Disassembly”, Page 5.

2. With a garden hose, hose as much dirt as possible

off of filter elements while they are still in place inside the tank (See recommendations, below, right).

Allow tank to drain completely. Make sure that waste

water disposal complies with local codes and ordinances.

3. Lift out center element and hose it down thoroughly. Allow to drain.

4. With large element still in tank, hose down both

inner and outer pleats

5. Inspect large element. If it is still dirty, allow it to

drain thoroughly, lift it out of tank and repeat washing operation; then go to Step 6. If it is clean, got to

Step 7.

Filter elements are heavy when wet and

dirty. To avoid back injury, allow filter element to

drain completely before removing from tank. Have

two people lift element and lift with care.

6. Once it is clean, allow large element to drain thoroughly, then reinstall in filter tank.

NOTICE: If this cleaning method does not remove

stubborn deposits, use “Special Cleaning

Instructions”, at right.

7. Reinstall center element

8. Follow steps one through eight under “Assembly”,

Page 5.

B. Special Cleaning Instructions:

Use this procedure to clean scale or oils which are not

removed by simply hosing down and scrubbing element. Be sure to dispose of spent chemicals according

to all applicable codes and waste disposal ordinances.

Use a soft stream nozzle to minimize flying water and

spray.

6

Figure 3 - Hose down elements thoroughly.

Figure 4 - Clean inside as well as outside of elements.

Follow these recommendations for easier cleaning with a

garden hose:

1. Prepare to get wet!

2. Use a soft flow nozzle which will reduce spray around filter.

3. Move around element while spraying to reach entire surface.

4. Repeat wash-down process for inside of element. Hold

nozzle as close to inside of pleats as possible.

NOTICE: BE SURE all dirt and foreign material is washed

away from INSIDE pleats of element.

5. Drain elements as much as possible before trying to lift

them.

Page 7

7

1. Clean filter elements first according to cleaning

procedure above.

2. Use one of the commercial filter cleaners listed

(see Table III)

Risk of fire or explosion. Isolate filter from

system before chemical cleaning; rinse filter and elements completely before returning to service. If filter

cannot be isolated, remove media and clean at another

location. Follow chemical manufacturer’s instructions for

use. Do not mix chemicals except as directed by manufacturer. Do not allow cleaning chemicals to mix or to

come in contact with chlorines, bromines, other chemicals, or chemical feed devices.

3. Sponge or spray elements according to chemical

manufacturer’s directions. Leave elements in operating position or remove and clean elsewhere, depending on filter location, chemicals used, and

chemical manufacturers instructions (see warning

above).

4. If soaking is required, remove elements from filter

body and submerge in a separate tank. Follow

cleaner manufacturer’s instructions to mix enough

chemical cleaner to soak element. Soaking may

require four to six hours or more.

5. After soaking, drain and rinse elements completely. Dispose of cleaners in accordance with

codes and waste disposal ordinances.

6. Rinse inside of filter tank completely and re-install

elements (have two people lifting - lift with care).

7. Follow instructions under “Assembly”, Page 5.

8. Restore valving and other plumbing to service position; return system to service (see “Initial

Startup”, Page 5).

SYSTEM INSPECTION

General

Wash outside of filter with a mild detergent and water.

Rinse off with hose.

NOTICE: DO NOT use solvents to clean filter; solvents

may damage plastic components in system.

NOTICE: Open air bleed valve and bleed all air from filter each time pump is stopped and restarted.

Weekly Inspection:

1. Skimmer basket - remove debris.

2. Stop pump, release all pressure. Remove trap cover

and basket, remove debris.

3. Bleed air from filter each time system is started.

4. Check pump for leaks. If found, see pump owner’s

manual.

5. Check pump strainer lid for tightness. Do not overtighten!

NOTICE: Filter must be protected from the weather

and drained if freezing is anticipated. Allowing filter to

freeze can cause damage to filter and WILL VOID

THE WARRANTY!

Winterizing

1. Stop pump.

2. Open air release valve.

3. Remove both drain plugs from lower tank half; loosen

union connection to inlet and outlet ports to allow internal piping to drain. Leave unions loose over winter.

4. Drain ALL piping to and from filter.

5. Disassemble filter.

To avoid severe injury or major property damage, exactly follow instructions under “Disassembly” (Page 5)!

6. Remove filter elements and store in a warm, dry

area.

Do not remove or damage safety and

instruction labels during cleaning. Replace any decals which may have been damaged.

TABLE III - Specialty Filter Cleaners

(for Degreasing and Scale Removal)

Filter Cleanse

TM

Filter Kleen

TM

KleenItTMor .

Strip Kwik

®

Filter Cleanse™ is a trademark of Advantis Technologies, Inc.,

Filter Kleen™ is a trademark of Haviland Consumer Products, Inc.,

Strip-Kwik

®

and KleenIt®are trademarks and/or registered trade-

marks of Bio-Lab, Inc..

Page 8

8

TROUBLESHOOTING

GUIDE

A. Short Cycle:

Time between cleanings will vary with each installation and between different areas of the country. The

following causes and remedies are for cycle times

shorter than normal for your area.

NOTICE: Some pool disinfectants may clog filter

media. To maximize media-life and filter cycle time,

closely follow disinfectant manufacturers instructions

when cleaning pool or filter.

1. Chlorine residual too low; maintain proper residual

(consult pool professional for recommendation).

2. Flow rate too high; restrict flow to rated capacity of

filter (see instruction decal on filter).

3. Filter too small; install larger filter or additional filter.

4. Unstable water; consult pool professional.

5. Filter element not cleaned properly or plugged with

algae, iron, calcium, etc. - see “Special Cleaning

Instructions”, Page 6.

6. Iron in water - use oversize filter running at a flow

rate of 3/8 to 1/2 GPM/sq. ft.; see cleaning instructions, Page 6.

7. Heavy or improper application of powdered chlorine or chlorine pills using a binder; see “Special

Cleaning Instructions”, Page 6.

8. Algae in pool - Apply heavy dose of chlorine or algaecide as recommended by pool manufacturer.

Continue until algae is controlled.

B. Low flow:

1. Element is plugged; see “Special Cleaning

Instructions”, Page 6.

2. Pipe blocked downstream from filter; remove obstruction.

3. Piping too small; replace with larger pipe (consult

dealer for recommendation).

4. Pump hair and lint trap is plugged - empty and

clean.

5. Pump impeller and diffuser worn - replace with new

parts. Consult pump owner’s manual for information.

6. Pump too small for system - consult pool professional; if recommended, replace pump with larger

pump.

C. Pool Water Not Clear:

1. Chlorine dosage too low; maintain adequate

chlorine residual (consult pool professional for

recommendation).

2. Element cloth torn or punctured; replace element.

3. Filter too small, flow too low, or daily operating

time too short, giving inadequate turnover rate;

consult dealer to verify that equipment is properly

sized for your pool.

4. Pump too large - overpumping - reduce flow rate.

5. Filter installed backward - replumb.

D. Long Recovery Time After Heavy Usage:

1. Residual Chlorine level is too low - add chlorine.

2. Filter too small - replace with larger unit.

3. Pump too large - reduce flow rate.

E. Filter Bypasses Dirt:

To avoid severe injury or major property damage, exactly follow instructions under “Disassembly” and

“Assembly” (Page 5)!

1. Air bleed tube and/or tube filter not in position.

Exactly follow instructions in “Filter

Disassembly/Assembly Procedure”, Page 5, and

reinstall correctly.

2. Element cloth torn or punctured; replace element.

3. Filter element is not seated properly in lower tank

half; follow instructions under “Filter

Disassembly/Reassembly”, Page 5, and reposition

properly.

4. Filter is plumbed backwards and element cloth is

ruptured - replumb properly and replace element.

5. Colloidal fines (very small suspended dirt particles)

are present and passing through element covering. Floc with alum, or if fines have already settled,

vacuum to waste.

Page 9

9

Page 10

Model No.

Key S8M600

No. Part Description Qty. 600 Ft2Filters

1 2 Inch Gauge 1 33600-0023T

2 Air Release Valve 1 WC212-120P

3 Close Nipple 1/4 In. 1 35202-0959

4 Adapter Bushing 1 24900-0504

5 O-Ring 1 35505-1423

6 Large Cartridge 1 25022-0228S

7 Small Cartridge 1 25021-0225S

8 Air Bleed Filter 1 WC8-126

9 Air Bleed Tube 1 25021-0003

10 Baffle and Bulkhead Fitting 1 25021-0101

11 O-Ring 1 35505-1428

12 O-Ring 1 35505-1429

13 Elbow and Bulkhead Assembly 1 25021-0102

14 O-Ring 2 35505-1425

15 O-Ring 2 35505-1424

16 Adapter Fitting 1 24900-0509

17 1-1/2" NPT Plug 1 27001-0022S

18 Drain Plug 1 24900-0503

19 Bulkhead Retaining Nut 2 24752-0050

20 Clamp Assembly 8 24850-0200

21 Clamp Bolt 8 24850-0010

22 Lower Tank Half 1 24851-0103S

23 Cord Ring 1 24850-0009

24 Upper Tank Half Kit** 1 24851-9001

25 Valve and Gauge Assembly

(Includes Key Nos. 1-5) 1 24850-0105

* Model Plate 1 32155-4178

* Instruction Label 1 32155-4039

* Warning Label 1 32165-4005

* 2" Slip 1/2 Union Kit 1 PKG 188

* Not Illustrated ** Includes all decals and labels.

10

REPAIR PARTS LIST

23

2860 0597

0

5

1

0

1

5

2

0

2

5

1

3

2

4

5

24

20

21

14

7

6

10

11

12

14

13

22

19

17

16

15

18

15

8

9

25

Page 11

11

Blank Page

Page 12

S293S (Rev. A)

Loading...

Loading...