Pentair S060516G041, S060316G031, S060326G031, S060516G031, S060526G041 Instruction Manual

...Page 1

SPECTRACOOL™

Slim Fit Air ConditionerS

All modelS

INSTRUCTION MANUAL

Rev. I

© 2015 Pentair Equipment Protection 89116616

P/N 89116616

Page 2

TABLE OF CONTENTS

Pentair Cooling Sales and Service Contacts ....................................................................................................4

Warranty and Return Policy ............................................................................................................................. 4

General Information ......................................................................................................................................... 5

Standards, CE, Declaration of Conformity ...........................................................................................................................5

Receiving The Air Conditioner .......................................................................................................................... 6

Handling and Testing The Air Conditioner ....................................................................................................... 6

PHASE MONITOR (460v Only) .....................................................................................................................................6

How to Read Model Numbers ........................................................................................................................... 6

General Safety Information .............................................................................................................................. 7

General Technical Information ......................................................................................................................... 7

Sequence of Operation .........................................................................................................................................................7

Cooling ............................................................................................................................................................................7

Component Operation ...........................................................................................................................................................7

Smart Controller (General Alarms)...............................................................................................................................7

Remote Access Control (Optional) ................................................................................................................................7

Door Switch ....................................................................................................................................................................7

Active Condensate Management ...................................................................................................................................7

Mounting .......................................................................................................................................................... 8

Tools Required For Installation: ...........................................................................................................................................8

External Mounting ................................................................................................................................................................8

Partial Recessed Mounting (Not Applicable to 300W Unit) .................................................................................................8

Full Recessed Mounting .....................................................................................................................................................10

Electrical Installation ..................................................................................................................................... 11

Principles of Operation .................................................................................................................................. 11

Smart Controller ............................................................................................................................................ 12

Introduction .........................................................................................................................................................................12

Energizing The Controller ..................................................................................................................................................12

Control Status Indication ....................................................................................................................................................12

Displaying and Changing Program Variables ....................................................................................................................13

Models with °C Controller ........................................................................................................................................13

Operating Parameters .................................................................................................................................................13

Alarm Parameters .......................................................................................................................................................13

Models with °F Controller ........................................................................................................................................13

Operating Parameters .................................................................................................................................................13

Alarm Parameters .......................................................................................................................................................13

Displaying Temperature Sensor #2 ...................................................................................................................................14

Compressor Restart Time Delay ........................................................................................................................................14

Alarm Output Contact .........................................................................................................................................................14

Alarm Input Connection ......................................................................................................................................................14

Alarm Condition Display .....................................................................................................................................................14

Remote Access Control .................................................................................................................................. 15

Air Conditioner Unit Communication Features (Optional) ................................................................................................15

USB Communication ....................................................................................................................................................15

Ethernet Communication ............................................................................................................................................15

SOFTWARE AND CONFIGURATION FILE DOWNLOADS .........................................................................................15

Remote Access Control Pin-out ..................................................................................................................................15

Technical Information .................................................................................................................................... 16

S06 Models 300/500W .........................................................................................................................................................16

S06 Schematic 300/500W ............................................................................................................................................16

S06 Wire Diagram 300/500W .......................................................................................................................................17

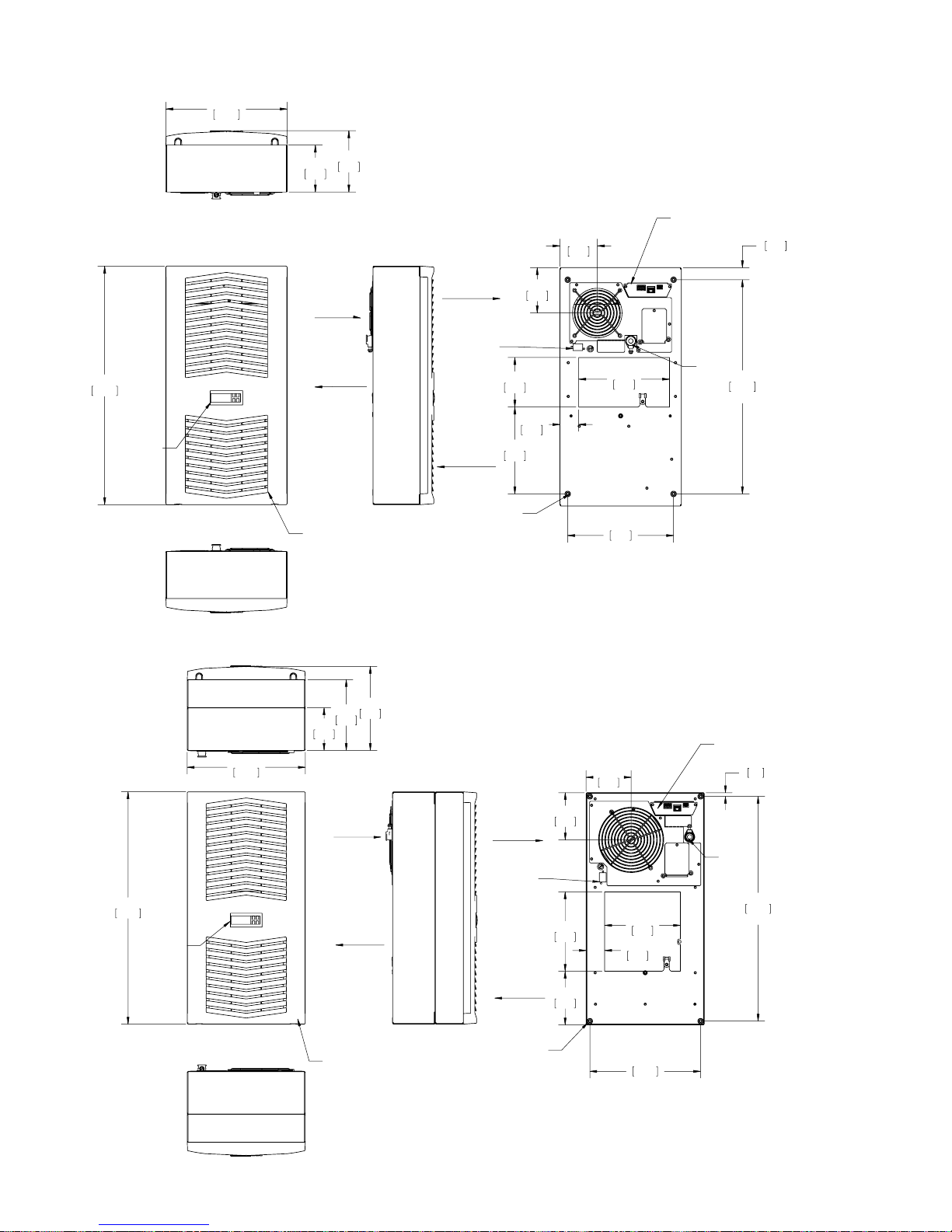

S06 Dimensional Drawings .........................................................................................................................................18

300W ..........................................................................................................................................................................18

500W ..........................................................................................................................................................................18

S06 Installation Instruction .........................................................................................................................................19

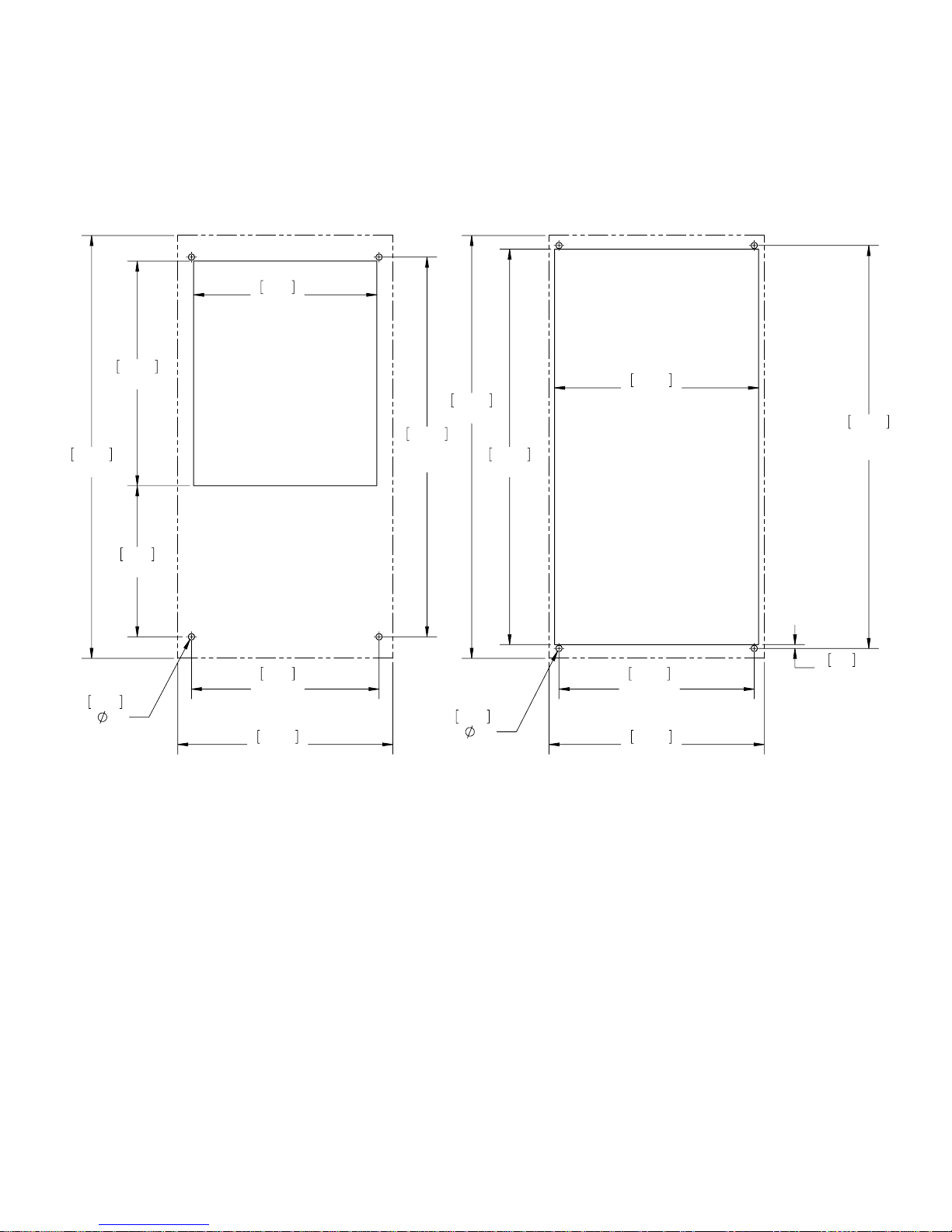

S06 300W Cutout Drawing ...........................................................................................................................................19

Surface Mount ..............................................................................................................................................................19

Full Recess Mount ........................................................................................................................................................19

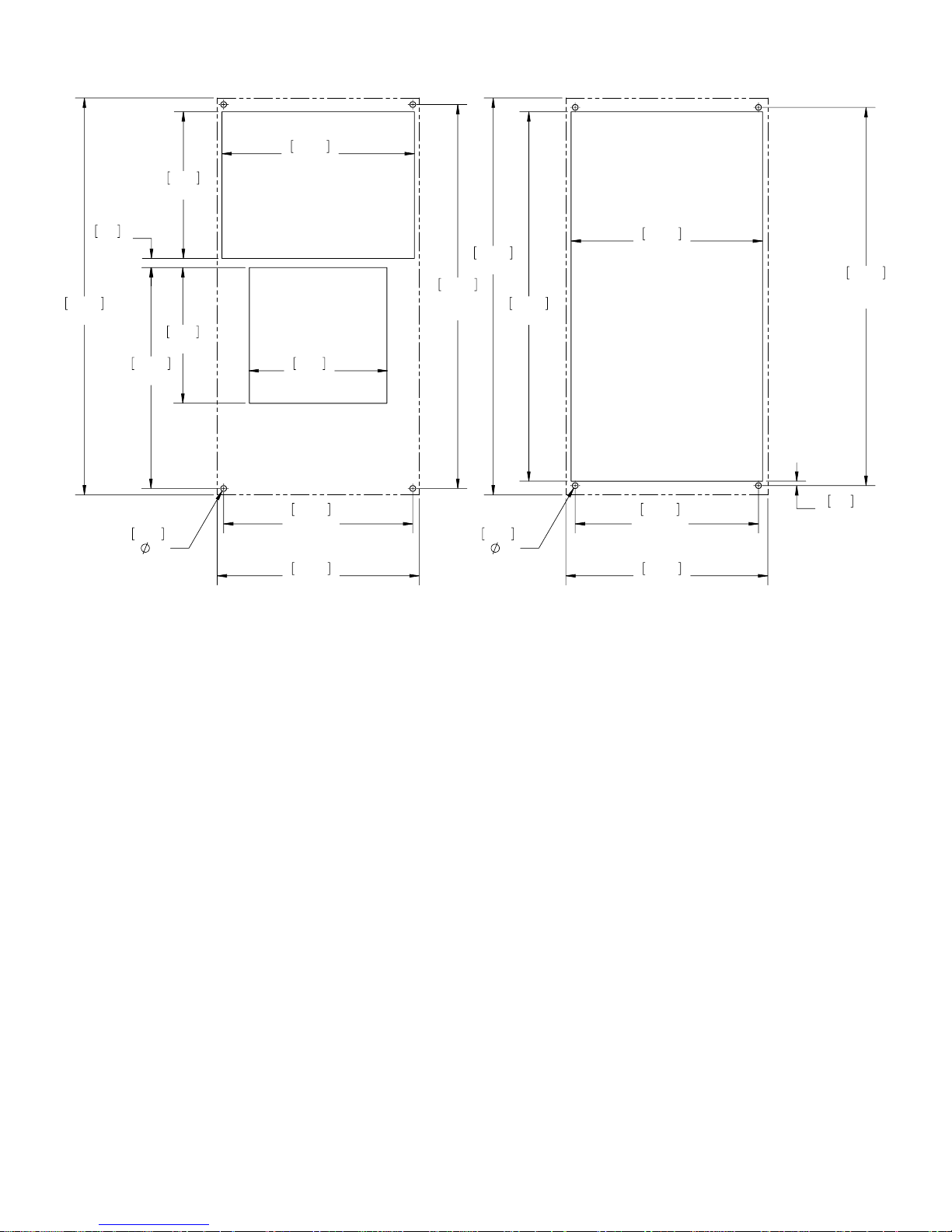

S06 500W Cutout Drawing ...........................................................................................................................................20

Surface Mount ..............................................................................................................................................................20

Partial and Full Recess Mount ....................................................................................................................................20

S06 Unit Characteristics ..............................................................................................................................................21

S06 Components ..........................................................................................................................................................22

S10 Models 1000/1500W .....................................................................................................................................................23

- 2 -

© 2015 Pentair Equipment Protection

89116616

Page 3

S10 Schematics ............................................................................................................................................................23

1000W 115V, 230V .....................................................................................................................................................23

1000W 460V ...............................................................................................................................................................23

1500W 115V ..................................................................................................................................................................24

1500W 230V ..................................................................................................................................................................24

1500W 460V ..................................................................................................................................................................25

S10 Wire Diagrams ......................................................................................................................................................26

1000W 115V, 230V .....................................................................................................................................................26

1000W 460V ...............................................................................................................................................................27

1500W 115V ...............................................................................................................................................................28

1500W 230V ...............................................................................................................................................................29

1500W 460V ...............................................................................................................................................................30

S10 Dimensional Drawing ...........................................................................................................................................31

1000/1500W ..............................................................................................................................................................31

S10 Installation Instruction .........................................................................................................................................32

S10 1000/1500W Cutout Drawing ................................................................................................................................32

Surface Mount ..............................................................................................................................................................32

Partial and Full Recess Mount ....................................................................................................................................32

S10 Unit Characteristics (115V, 230V) .........................................................................................................................33

S10 Unit Characteristics (460V) ...................................................................................................................................34

S10 Components (1 Phase) ..........................................................................................................................................35

S10 Components (3 pHASE) ........................................................................................................................................36

S16 Models 2000/2500W .....................................................................................................................................................37

S16 Schematics ............................................................................................................................................................37

2000W 115V ...............................................................................................................................................................37

2000W 230V ...............................................................................................................................................................37

2000W 460V ...............................................................................................................................................................38

2500W 115V ...............................................................................................................................................................38

2500W 230V ...............................................................................................................................................................39

2500W 460V ...............................................................................................................................................................39

4000W 460V ...............................................................................................................................................................40

S16 Wire Diagrams .....................................................................................................................................................41

2000W 115V ...............................................................................................................................................................41

2000W 230V ...............................................................................................................................................................42

2000W 460V ...............................................................................................................................................................43

2500W 115V ...............................................................................................................................................................44

2500W 230V ...............................................................................................................................................................45

2500W 460V ...............................................................................................................................................................46

4000W 460V ...............................................................................................................................................................47

S16 Dimensional Drawing ...........................................................................................................................................48

2000/2500W ..............................................................................................................................................................48

4000W ........................................................................................................................................................................49

S16 Installation Instruction .........................................................................................................................................50

S16 2000/2500W Cutout Drawing ................................................................................................................................50

Surface Mount ..............................................................................................................................................................50

Partial and Full Recess Mount ....................................................................................................................................50

S16 4000W Cutout Drawing .........................................................................................................................................51

Surface Mount ..............................................................................................................................................................51

Partial Recess Mount ...................................................................................................................................................51

S16 Unit Characteristics (115V, 230V) .........................................................................................................................52

S16 Unit Characteristics (460V) ...................................................................................................................................53

S16 Components )115V, 230V) .....................................................................................................................................54

S16 Components (460V) ...............................................................................................................................................55

Maintenance ................................................................................................................................................... 56

Compressor .........................................................................................................................................................................56

Inlet Air Filter (Field Installed Option) ................................................................................................................................56

How To Remove, Clean or Install an optional Inlet Air Filter ............................................................................................56

Condenser and Evaporator Air Movers ..............................................................................................................................56

Maintenance / Inspection Recommendations ............................................................................................................57

Basic Air Conditioning Trouble Shooting Check List - Remote Access Control Version ................................. 59

Basic Air Conditioning Trouble Shooting Checklist ...........................................................................................................60

3-Phase Basic Air Conditioning Trouble Shooting Check List - Remote Access Control Version ...................................61

3-Phase Symptoms and Possible Causes - Remote Access Control Version ..................................................................62

89116616

© 2015 Pentair Equipment Protection

- 3 -

Page 4

PENTAIR COOLING SALES AND SERVICE CONTACTS

EUROPE:

Deutschland (Germany) +49 (0) 7082 794 0

France +33 (0) 3 88 90 64 90

Italia (Italy) +39 02 932 714-1

Polska (Poland) +48 22 209 98 37

Россия (Russia) +7 495 926 18 85

Sverige (Sweden) +46 (0) 8 683 6100

United Kingdom +44 (0) 1442 240 471

MIDDLE EAST:

UAE +971 4 378 1700

NORTH AMERICA:

México +52 555 280 1449

US & Canada +1 763 421 2240

SOUTH AMERICA:

Brasil (Brazil) +55 15 3363 9100

ASIA/SOUTH PACIFIC:

中国 (China) +86 400 820 1133

India +91 80 2845 4640

日本 (Japan) +81 (0) 45 476 02 81

Singapore +65 6768 5800

Or visit PentairProtect.com

WARRANTY AND RETURN POLICY

Visit www.pentairprotect.com/en/na/warranty for product warranty and return policy.

- 4 -

© 2015 Pentair Equipment Protection

89116616

Page 5

GENERAL INFORMATION

STANDARDS, CE, DECLARATION OF CONFORMITY

PENTAIRTECHNICALSOLUTIONS

Minneapolis,MN55303‐1745,USA

2100HoffmanWay

+1.763.421.2240main

DeclarationofConformity

Issued by Manufacturer

Pentair Technical Products China dba Hoffman

declare at our sole responsibility, that these devices are designed and constructed according to the fundamental safety and health

requirements of the relevant EC directives.

Equipment Description: S0603X6GXXX, S0605X6GXXX, S1010X6GXXX, S1015X6GXXX, S1620X6GXXX,

S1625X6GXXX, S1640X6GXXX

Product Name: “ SpectraCool SLIM Fit” Control Cabinet Air-Conditioner

First Year of CE Marking: 2014

Ingress Protection: IP 34 – Ambient Side, IP 54 Enclosure Side

Applicable Directives: Directive /95/EC Low Voltage Directive

Laws for electrical equipment within certain voltage limits

Directive /108/EC EMC Directive relating to

Electromagnetic compatibility

Directive /65/EU on the restriction of the use of certain hazardous substances in

electrical and electronic equipment

Applicable Standards:

EN 378-1 and -2 Refrigerating systems and heat pumps-safety and environmental

requirements

EN 12100-1 and -2 Safety of machinery, equipment and facilities

EN ISO 13857 Safety of machinery-safety distances to prevent hazard zones being

reached by upper and lower limbs

EN 60335-1 and -2-40 Appliances-Safety, Particular requirements for electrical heat

pumps, air-conditioners and dehumidifiers

DIN EN 14511-2 (4) Air conditioner, Test conditions

DIN EN 14511-3 (4) Air Conditioner, Test methods

DIN EN 14511-4 (4.2, 4.5, 4.6) Air Conditioner, operating requirements

DIN 3168-4.5 Coolers for distribution boxes, concepts testing, marking

EN 61000-6-2 Electromagnetic compatibility (EMC)- Part 6-2: Generic standards -

Immunity for industrial environments

EN 61000-6-3 Electromagnetic compatibility (EMC)- Part 6-3: Generic standards –

Emission standard for residential, commercial, and light industrial environments

EN 60529, IEC 60529 Degrees of protection provided by enclosures (IP code)

EN 50581: Technical documentation for the assessment of electrical and electronic

products with respect to the restriction of hazardous substances

DIN 45635 Measurement of noise emitted by machines, airborne noise emission

For official DoC, go to http://www.pentairprotect.com/en/na/Compliance

Air Port Industrial Zone

Shuangyuan Road South

Chengyang District

Qingdao,

Shandong 266108 China

Authorizedby:

Manager,Lab&Certifications

Subject to Change Without Notice DOC: 00001 -A

89116616

7/15/2014

Tom Hurney Date

© 2015 Pentair Equipment Protection

- 5 -

Page 6

RECEIVING THE AIR CONDITIONER

Inspect the air conditioner. Check for concealed damage that may have occurred during shipment. Look for dents,

scratches, loose assemblies, evidence of oil, etc. Damage evident upon receipt should be noted on the freight bill.

Damage should be brought to the attention of the delivering carrier -- NOT to Pentair Equipment Protection -within 15 days of delivery. Save the carton and packing material and request an inspection. Then file a claim with

the delivering carrier.

Pentair Equipment Protection cannot accept responsibility for freight damages; however, we will assist you in any

way possible.

HANDLING AND TESTING THE AIR CONDITIONER

If the air conditioner has been in a horizontal position, be certain it is placed in an upright, vertical or mounting

position for a minimum of five (5) minutes before operating.

CAUTION

Do not attempt to operate the air conditioner while it is horizontal or

on its side, back or front. The refrigeration compressor is filled with

lubricating oil. This will cause permanent damage to the air conditioner

and also voids the warranty.

TEST FOR FUNCTIONALITY BEFORE MOUNTING THE AIR CONDITIONER TO THE ENCLOSURE.

Refer to the nameplate for proper electrical current requirements, and then wire the unit to a properly grounded

power supply using copper conductors only. Power supply wiring should be restrained after field installation to

ensure no contact with internal fan. Minimum circuit ampacity should be at least 125% of the amperage shown on

the unit nameplate. No other equipment should be connected to this circuit to prevent overloading.

Electrical circuit should be fused with slow blow or heating, air conditioning and refrigeration (HACR) rated circuit

breaker. Use a higher ampere rated circuit breaker or time-delay fuse that is closest to the nominal ampere

rating of the air conditioner, or sum of the individual component ampere ratings, to protect system electrical

circuits from short circuit or overload.

PHASE MONITOR (460V ONLY)

Note Location: Rear access panel, D-shaped sight port.

Reference S10 Dimensional Drawing on page 31; S16 Dimensional Drawing,

2000/2500W on page 48; S16 Dimensional Drawing, 4000W on page 49

This product is equipped with Phase/Voltage Protection. Please verify correct phasing and voltage before

operating. Note the fans may still operate if phasing is incorrect, but the compressor will not, so the unit

will not cool. Illuminated light on Phase Monitor indicates phase is correct.

If the light is not illuminated, disconnect power from the unit and swap any two power leads at the

terminal block. This should correct the phasing. The light should now illuminate when power is reapplied.

Immediately after applying power, the evaporator blower (enclosure air) should start running. Operate the air

conditioner with the compressor running for five (5) to ten (10) minutes. You will need to set the cooling controller

setpoint below the ambient temperature to operate the compressor.

Condenser air temperatures should be warmer than normal room temperatures within a few minutes after the

condenser impellers start.

See Sequence of Operation on page 7 for specifics on how the unit operates when powered up.

HOW TO READ MODEL NUMBERS

S10 15 2 6 G031

1 2 3 4 5

1. Identifies the type/family of air conditioner and the approximate height (i.e. S10 = Slim Fit family

about 1000mm high (10x100).

2. This is the air conditioner’s listed capacity in Watts at rated conditions. (i.e. 15=1500W (15x100) at

35/35 C)

3. 1 = 115 Volt, 2 = 230 Volt, 4 = 400/460 Volt.

4. 5 = 50 Hz only, 6 = 50/60 Hz or 60 Hz only.

5. Unique set of numbers for each air conditioner which identifies the accessories on a model.

- 6 -

© 2015 Pentair Equipment Protection

89116616

Page 7

GENERAL SAFETY INFORMATION

Please observe the following general safety instructions when assembling and operating the unit:

• Assembly,installation and servicing may only be performed by properly trained specialists.

• When transporting the enclosure with the cooling unit externally mounted, always use an additional shipping brace

to support the cooling unit.

GENERAL TECHNICAL INFORMATION

The evaporator outlet sensor monitors the enclosure return air temperature to prevent ice buildup on the

evaporator coil. If the air temperature drops below -1°C, the compressor and condenser air mover(s) shut off.

They turn back on when the temperature rises above 15°C.

The compressor and the air movers are equipped with overload protection to guard against excess current and

temperatures.

SEQUENCE OF OPERATION

The air conditioner comes standard with smart controller. During cooling modes, the evaporator fan will be

running.

COOLING

When the enclosure temperature is above the cooling setpoint, power is applied to the compressor and

condenser air mover(s).

Operating the air conditioner below the minimum ambient temperature or above the maximum

ambient temperatures indicated on the nameplate voids all warranties. DO NOT adjust the setpoint to a

temperature lower than 20°C. Doing so can increase the likelihood of frost buildup on the evaporator coil.

The moisture that the sealed enclosure air can contain is limited. If moisture flows from the drain tube

continuously this can only mean that ambient air is entering the enclosure. Be aware that frequent

opening of the enclosure’s door admits humid air that the air conditioner must then dehumidify.

COMPONENT OPERATION

NOTE: Do not reduce the time delay setting on the controller to less than 120 seconds. This may

cause the compressor to cycle too rapidly, shortening the life of the compressor.

SMART CONTROLLER (GENERAL ALARMS)

See Smart Controller on page 12

REMOTE ACCESS CONTROL (OPTIONAL)

See Remote Access Control on page 15

DOOR SWITCH

Several door switches may be connected in series and operated on one cooling unit. The door switch

only supports a floating connection, no external voltages. Remove jumper from terminals 3 and 4 of the

connector and connect the door switch to the two terminals if a door switch is available.

NOTE: The alarm code “TP” will appear on the controller display if this jumper wire is removed

without the addition of a customer installed door switch.

ACTIVE CONDENSATE MANAGEMENT

At low temperatures and high humidity levels inside the enclosure, condensation may form on the

evaporator coil.

Slim Fit air conditioners continuously evaporate the water that may be in the drain pan due to

condensation from the evaporator coil into the external air stream. Excess condensate is routed

downwards out of the air conditioner via a barbed fitting at the bottom of the condenser side of the unit. A

10 mm (.40) inside diameter tube can be attached to the fitting and routed to a nearby drain.

89116616

© 2015 Pentair Equipment Protection

- 7 -

Page 8

MOUNTING

TOOLS REQUIRED FOR INSTALLATION:

• #2 Phillips screwdriver

• 6.5 mm slotted screwdriver

• 13 mm wrench or socket

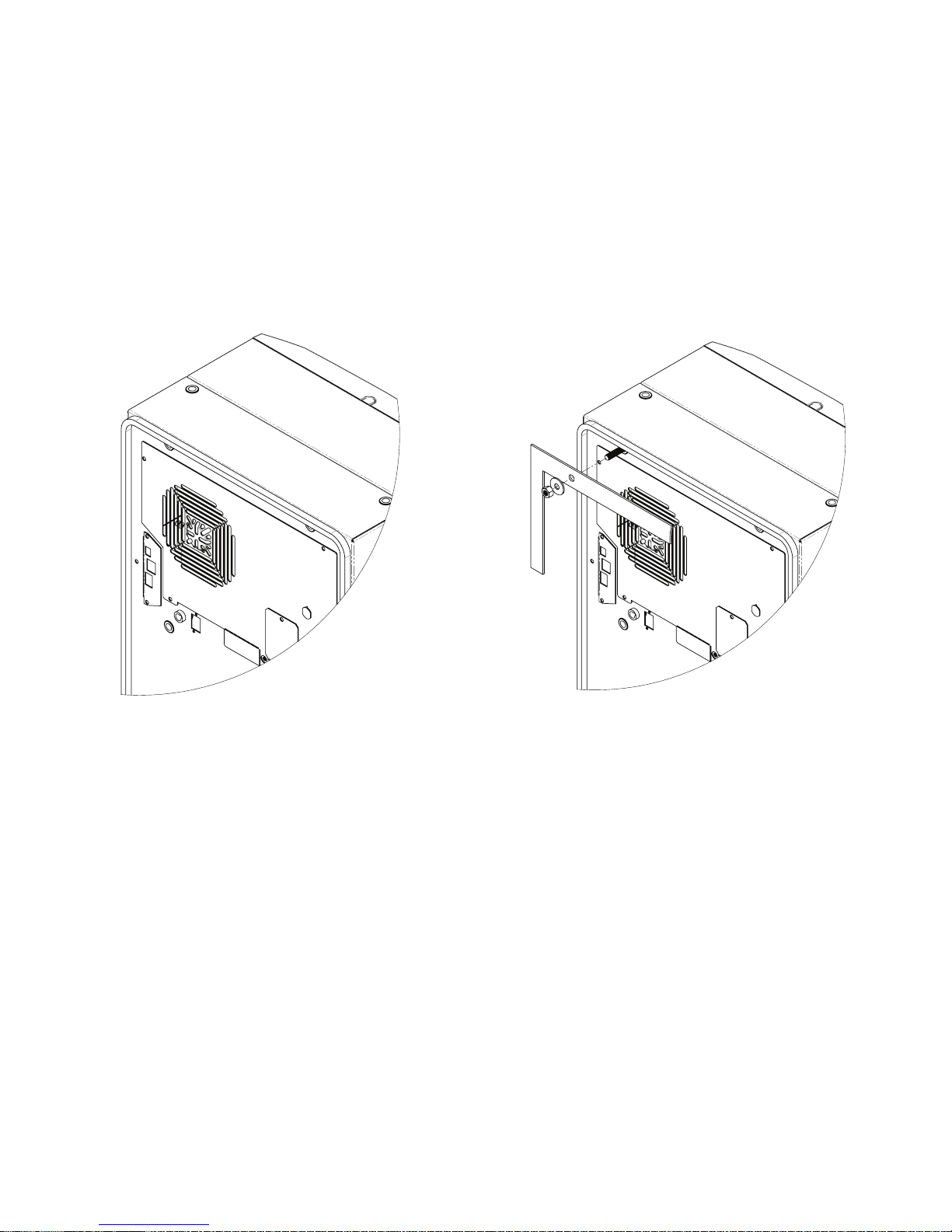

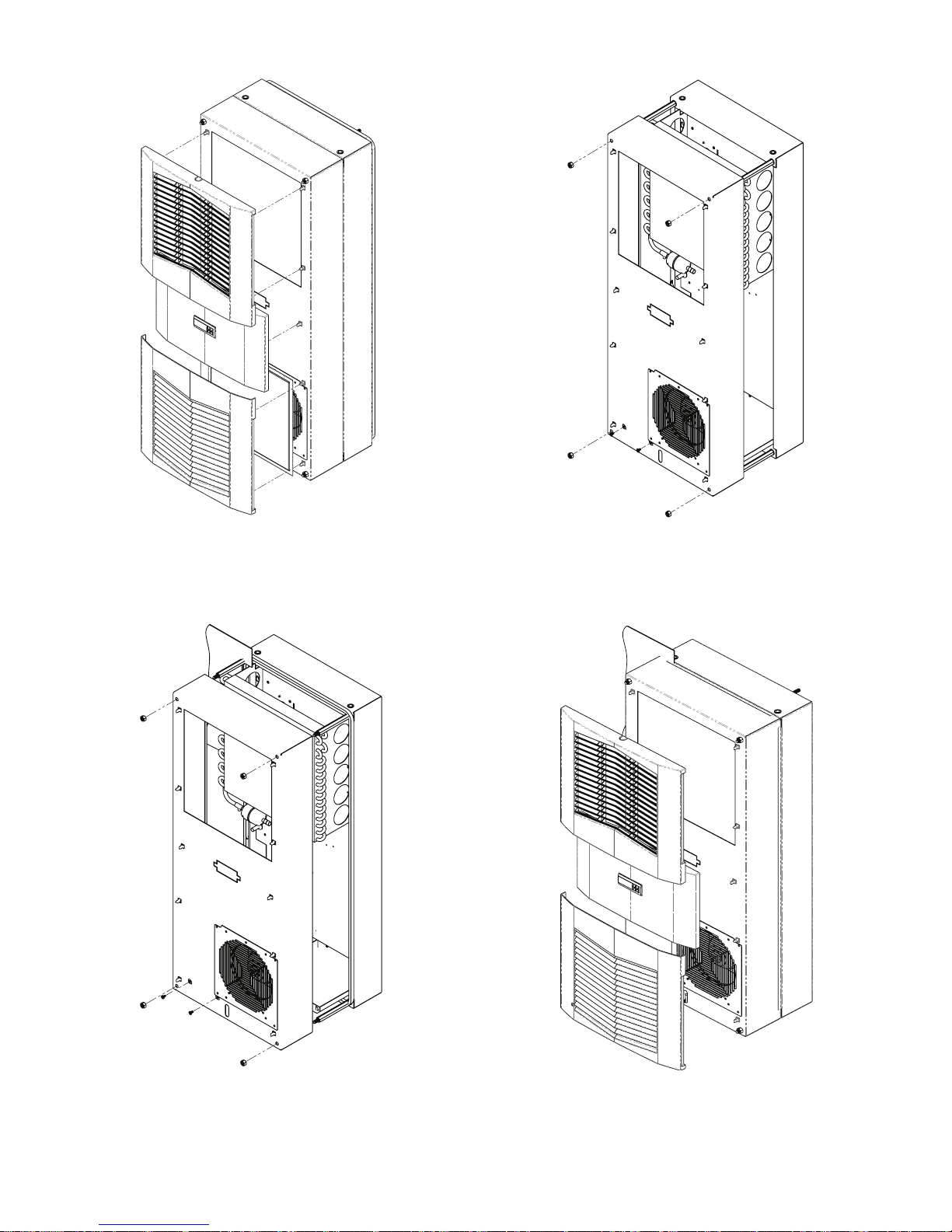

EXTERNAL MOUNTING

1. Using the mounting gasket kit provided with the unit, install gasket to the air conditioner, see Figure

1.

2. Screw the supplied grub screws into the blind nuts on the rear of the unit, see Figure 2.

3. Secure the unit to the enclosure using the supplied washers and nuts. Use caution to avoid damaging

the gasket while positioning the unit.

Figure 1 Figure 2

PARTIAL RECESSED MOUNTING (NOT APPLICABLE TO 300W UNIT)

1. Carefully remove the louvered grille, and where applicable, remove the center panel from the

enclosure by pulling forwards. See Figure 3 on page 9.

2. Carefully disconnect the connectors from the rear of the smart controller.

3. Remove the two front screws.

4. Remove the four nuts on the front panel and pull the panel assembly forward approximately 5 cm.

See Figure 4 on page 9.

5. Disconnect the fan electrical connection.

6. Remove the front panel.

7. Remove the four standoffs, leaving the grub screws in place.

8. Push the rear enclosure half into the mounting cutout and secure it with the four standoffs. See

Figure 5 on page 9.

9. Push the smart controller cables through the rectangular hole in the front panel.

10. Reconnect the fan electrical connector.

11. Mount the front panel using the nuts removed in step 4.

12. Install two front screws.

13. Carefully reconnect the smart controller connectors .

14. Push the louvered grille and, where applicable, the center panel, onto the front panel. See Figure 6

on page 9.

- 8 -

© 2015 Pentair Equipment Protection

89116616

Page 9

Figure 3

Figure 4

Figure 5 Figure 6

89116616

© 2015 Pentair Equipment Protection

- 9 -

Page 10

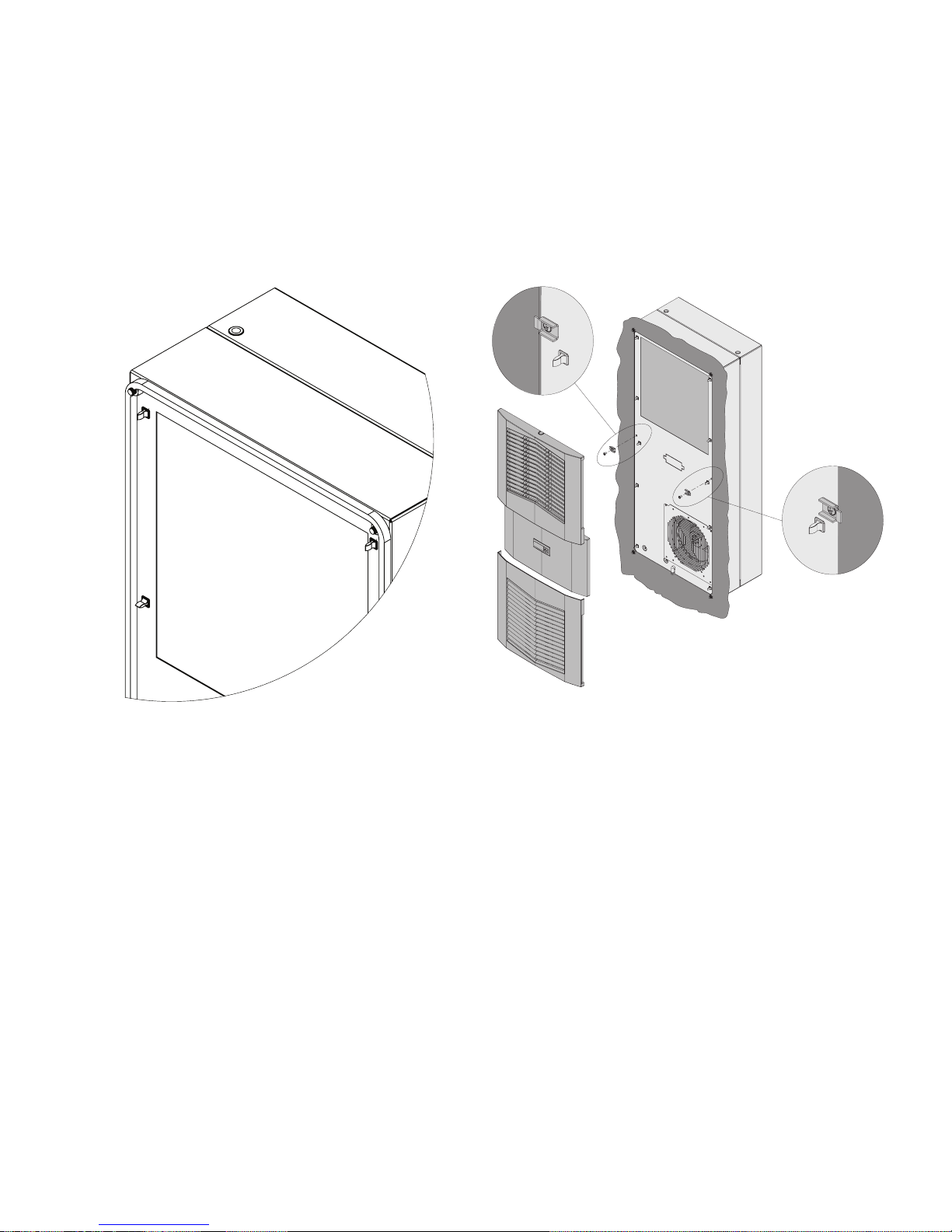

FULL RECESSED MOUNTING

1. Carefully remove the louvered grille, and where applicable, remove the center panel from the

enclosure by pulling forwards.

2. Carefully disconnect the connectors from the rear of the smart controller.

3. Using the mounting gasket kit provided with the unit, install gasket to the air conditioner front panel.

See Figure 7.

4. Remove the four nuts on the front panel.

5. Push the unit into the mounting cutout and secure it using the nuts removed in step 4.

6. Carefully reconnect the smart controller.

7. Push the louvered grille and, where applicable, the center panel, onto the front panel. See Figure 8.

- 10 -

Figure 7

© 2015 Pentair Equipment Protection

Figure 8

89116616

Page 11

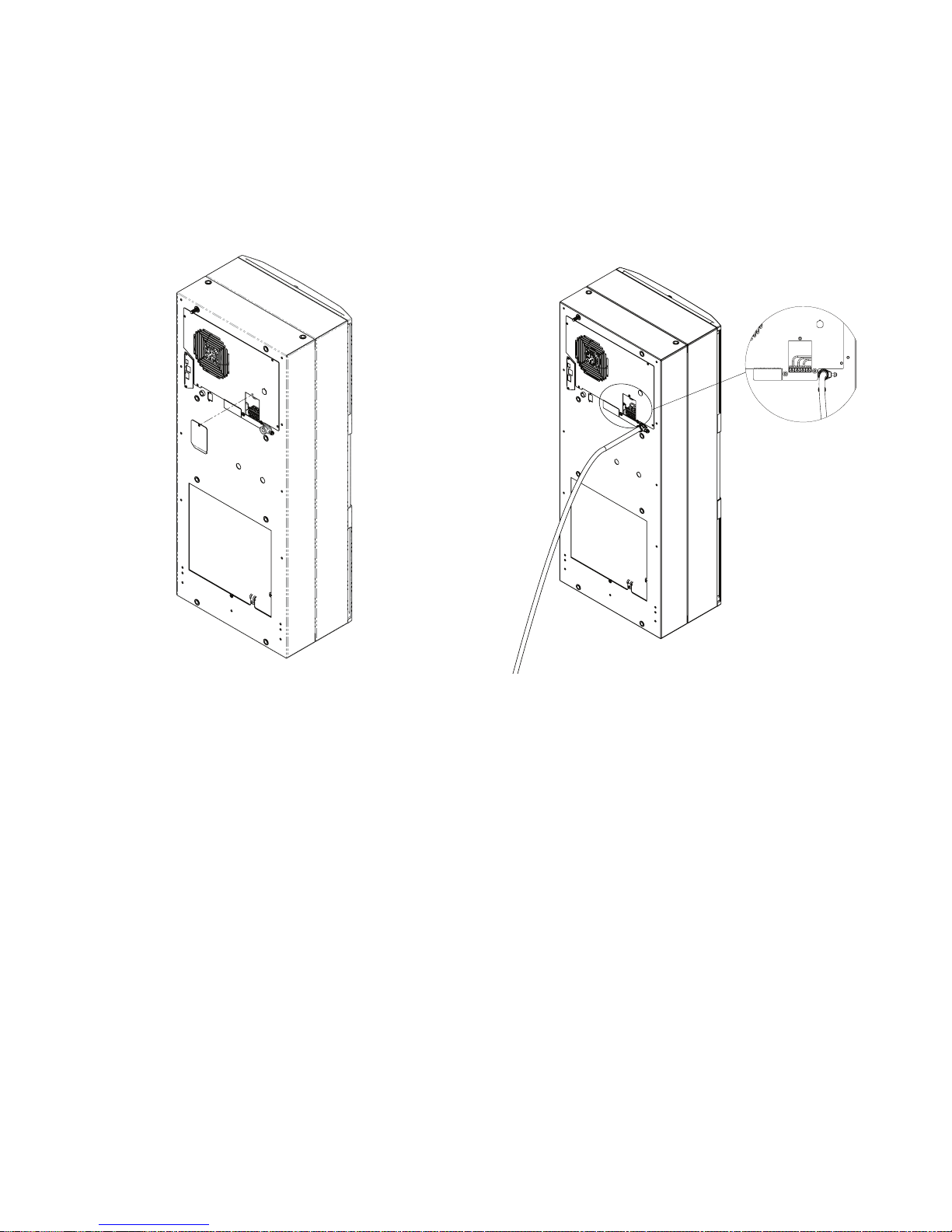

ELECTRICAL INSTALLATION

1. Loosen the screw on the evaporator access panel and remove the power access panel. See Figure 9.

2. Push the power supply wire through the strain relief.

3. Connect the wire to the terminal block per the label.

4. Reinstall the power access panel and screw.

5. Tighten the screw on the strain relief to secure the supply wire, see Figure 10.

NOTE: Use a higher ampere rated circuit breaker, or time-delay fuse, that is closest to the

nominal ampere rating of the air conditioner, or sum of the individual component ampere ratings,

to protect the system electrical circuits from short circuit or overload.

Figure 9

Figure 10

PRINCIPLES OF OPERATION

If electrical power to the air conditioner is interrupted and reapplied, the compressor may take up to five (5)

minutes to restart due to the high back pressure of the compressor.

NOTE: The controller includes a nominal time delay setting of 5 minutes. Do not decrease the

time delay setting to less than 2 minutes, as this may cause rapid cycling of the compressor,

which may reduce the life of the compressor.

89116616

© 2015 Pentair Equipment Protection

- 11 -

Page 12

SMART CONTROLLER

INTRODUCTION

The smart controller is a parametric controller for the complete management of air conditioners. All settings are

pre-programmed at the factory. Cooling set-points, cooling differential and high/low temperature alarm setpoints can be adjusted by the user. Alarms are outputted through a relay contact.

NOTE: The polyester tape on the top side and the neoprene seal around the connectors

assure IP34 protection for the controller. Do not remove.

ENERGIZING THE CONTROLLER

The controller is wired and programmed at the factory to be energized when power is applied to the air

conditioner.

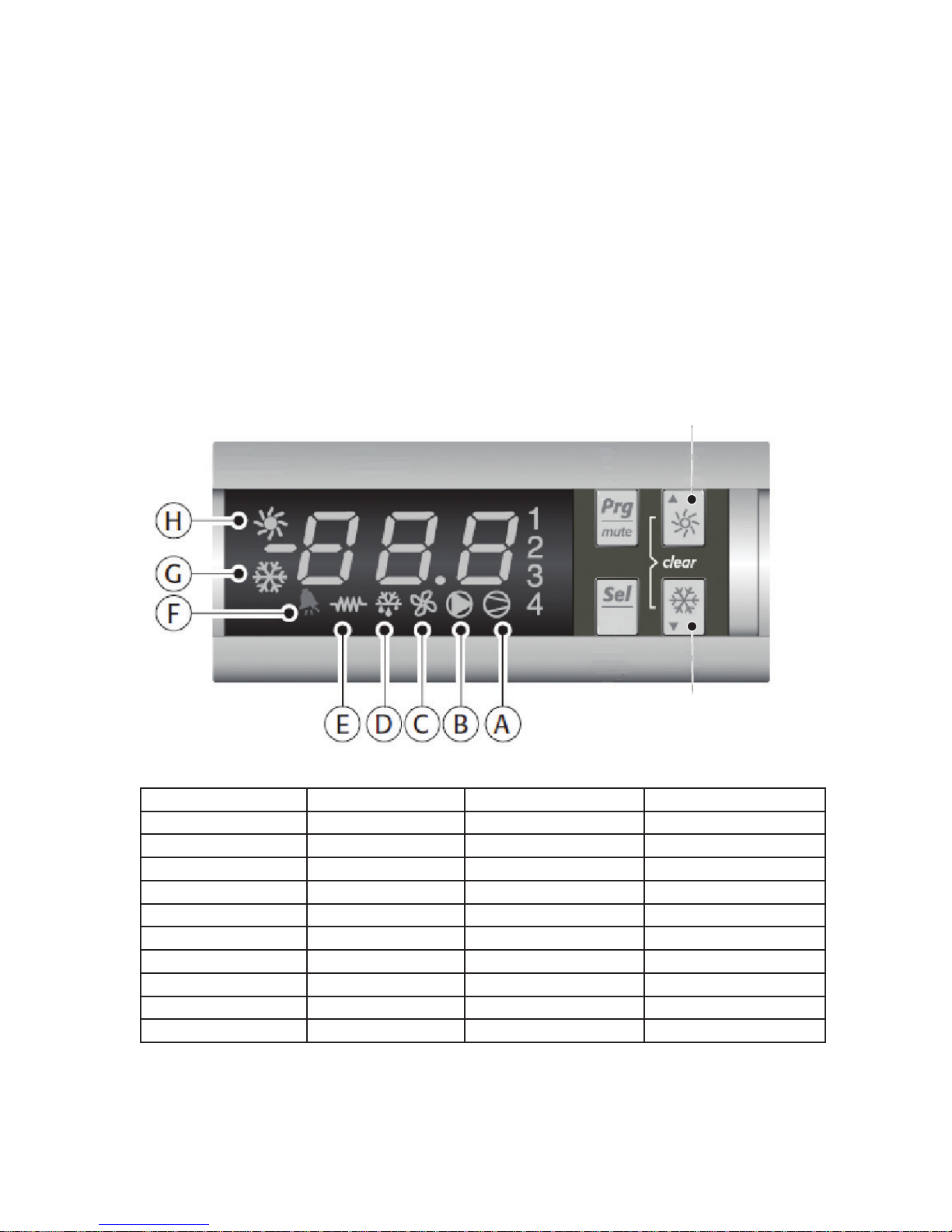

CONTROL STATUS INDICATION

The display has numerous symbols that indicate if the controller is heating, cooling, alarming, if the compressor

is enabled, and if the ambient fan is enabled. The 3 alpha-numeric characters further describe alarms and show

the cabinet temperature by default.

NOTE: The Slim Fit air conditioners do not come standard with a heating option.

Heating (sun)

Cooling

(snowake)

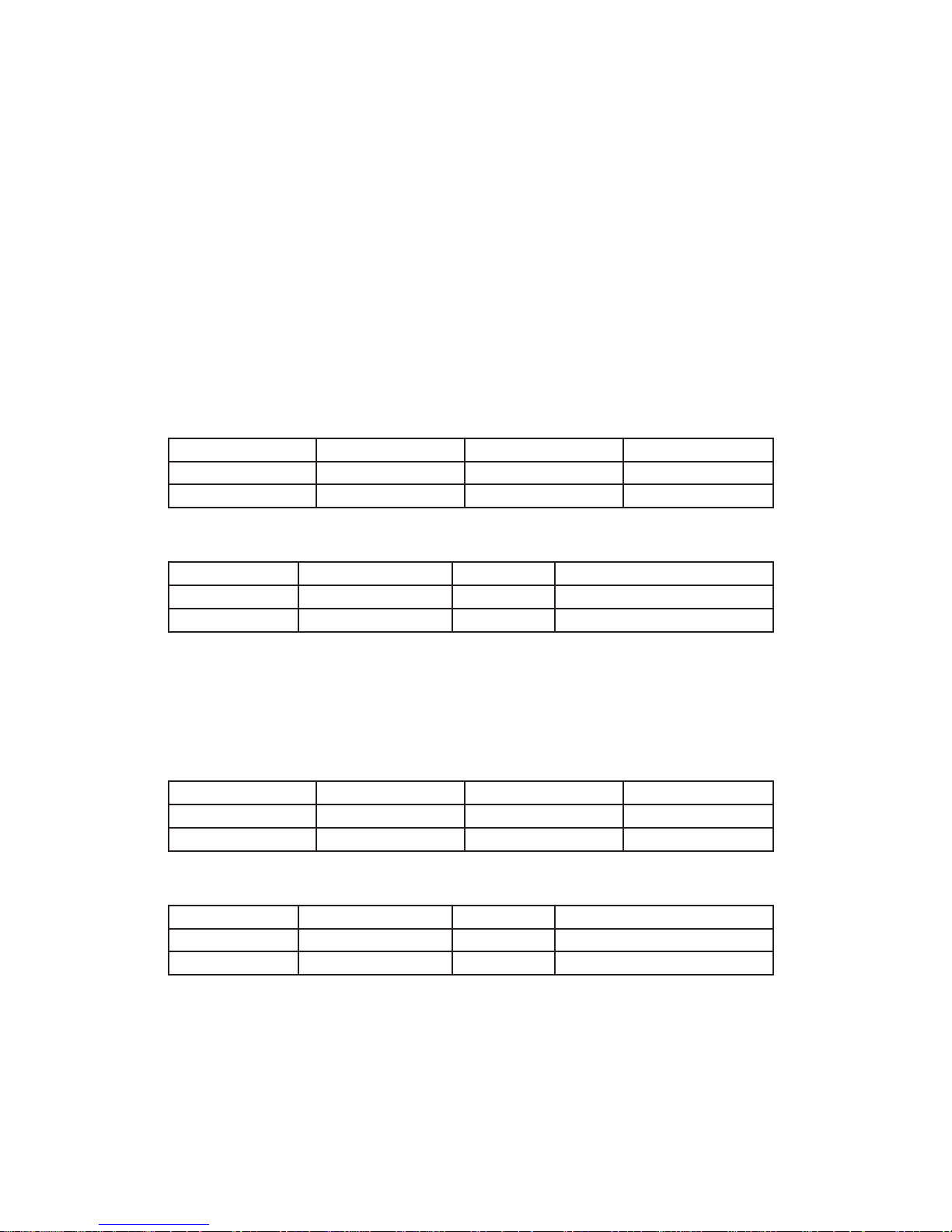

SYMBOL COLOR ICON ON ICON FLASHING

1 AMBER Compressor On Start-up Request

2,3,4 AMBER Not Used Not Used

A AMBER Compressor On Not Used

B AMBER Evaporator Fan On Not Used

C AMBER Not Used Not Used

D AMBER Not Used Not Used

E AMBER Not Used Not Used

F RED Alarm Active Not Used

G AMBER Controller Active Not Used

H AMBER Not Used Not Used

NOTE: On the smart controller, the display symbols for “H” and “E” are not suppose to

turn ON. If they do turn on, simply hold the “Heating” button for 5 seconds to disable

them. Then hold the “Cooling” button for 5 seconds until the snowflake symbol (“G”)

displays.

- 12 -

© 2015 Pentair Equipment Protection

89116616

Page 13

DISPLAYING AND CHANGING PROGRAM VARIABLES

Access: To view and/or change parameters, press and hold the Prg and Sel buttons for greater than 5 seconds.

Press the up or down arrow buttons until 22 is displayed, then press Sel button. When S-P is displayed, press Sel.

Navigation: Press up or down arrows to display sub-menus then press Sel to select the desired sub-menu. In the

sub-menu, use up or down arrows to display parameters for viewing or changing and press Sel. Use Prg button to

back out of menu levels as desired.

Adjust: Use the up or down arrows to change the parameter value then push Sel to save that setting. If Sel is not

pressed, the change to the value will not be saved. Navigate to and change other parameters as desired. When

finished, push Prg to back out of the sub-menus to the main menu.

NOTE: The display will revert to normal temperature display mode if no buttons are pressed for

60 seconds.

MODELS WITH °C CONTROLLER

Cooling turns on at r01 (Setpoint), and off at r01 (Setpoint) - r02 (Differential).

For example, using default values from the table below, cooling will turn on at 35 °C (setpoint), and turn

off at 30 °C (setpoint – differential).

OPERATING PARAMETERS

Parameter Description Default Value Range

r01 Cooling set-point 35°C 20°C to 55°C

r02 Cooling differential 5°C -

ALARM PARAMETERS

Parameter Default Value Range Description

P16 55°C - High Temperature Alarm

P19 14°C - Low Temperature Alarm

MODELS WITH °F CONTROLLER

Cooling turns on at r01 (Setpoint) + r02 (Differential), and off at r01 (Setpoint).

For example, using default values from the table below, cooling will turn on at 87 °F (setpoint +

differential), and turn off at 80 °F (setpoint).

OPERATING PARAMETERS

Parameter Description Default Value Range

r01 Cooling set-point 80°F 72°F to 120°F

r02 Cooling differential 7°F -

ALARM PARAMETERS

Parameter Default Value Range Description

P16 125°F - High Temperature Alarm

P19 40°F - Low Temperature Alarm

89116616

© 2015 Pentair Equipment Protection

- 13 -

Page 14

DISPLAYING TEMPERATURE SENSOR #2

Sensor number 2, the air outlet or evaporator coil sensor, can be viewed at any time by pressing the up or down

arrow button on the front panel of the controller display. The display will revert to displaying temperature sensor

number 1 (the evaporator air inlet temperature) after 60 seconds. Both sensors can also be read through the

Ethernet and USB connections with the optional communications board.

COMPRESSOR RESTART TIME DELAY

A factory set 5 minute (300 second) restart delay exists to reduce residual back pressure before allowing the

compressor to restart. The compressor will stay off for the entire restart duration after the compressor is

disabled. A flashing 1 on the controller display will indicate the unit is in a compressor restart delay while calling

for cooling. If the time delay is reduced to less than five (5) minutes, this may cause reduced compressor life.

ALARM OUTPUT CONTACT

The smart controller has a normally open dry contact alarm output with a resistive load rating of 250 VAC at 3

amps. A connector located on the enclosure side of the unit provides a 2 pin connection to this output marked

YEL/ALARM.

ALARM INPUT CONNECTION

The smart controller can accept a dry contact/switch input via the connector terminals marked WHT/DS1 and

WHT/DS2 located on the enclosure side of the unit. This input is associated with the controller display alarm

mnemonic TP (door open and/or smoke detected). To use this feature, remove the jumper wire connecting

terminals DS1 and DS2 and replace with customer supplied wires from the enclosure door switch to DS1 and DS2

terminals.

ALARM CONDITION DISPLAY

There are seven possible non-latching alarm conditions detectable by the controller and are indicated on the

controller display. All alarms can also be accessed through the Ethernet and USB connections with the optional

communications board.

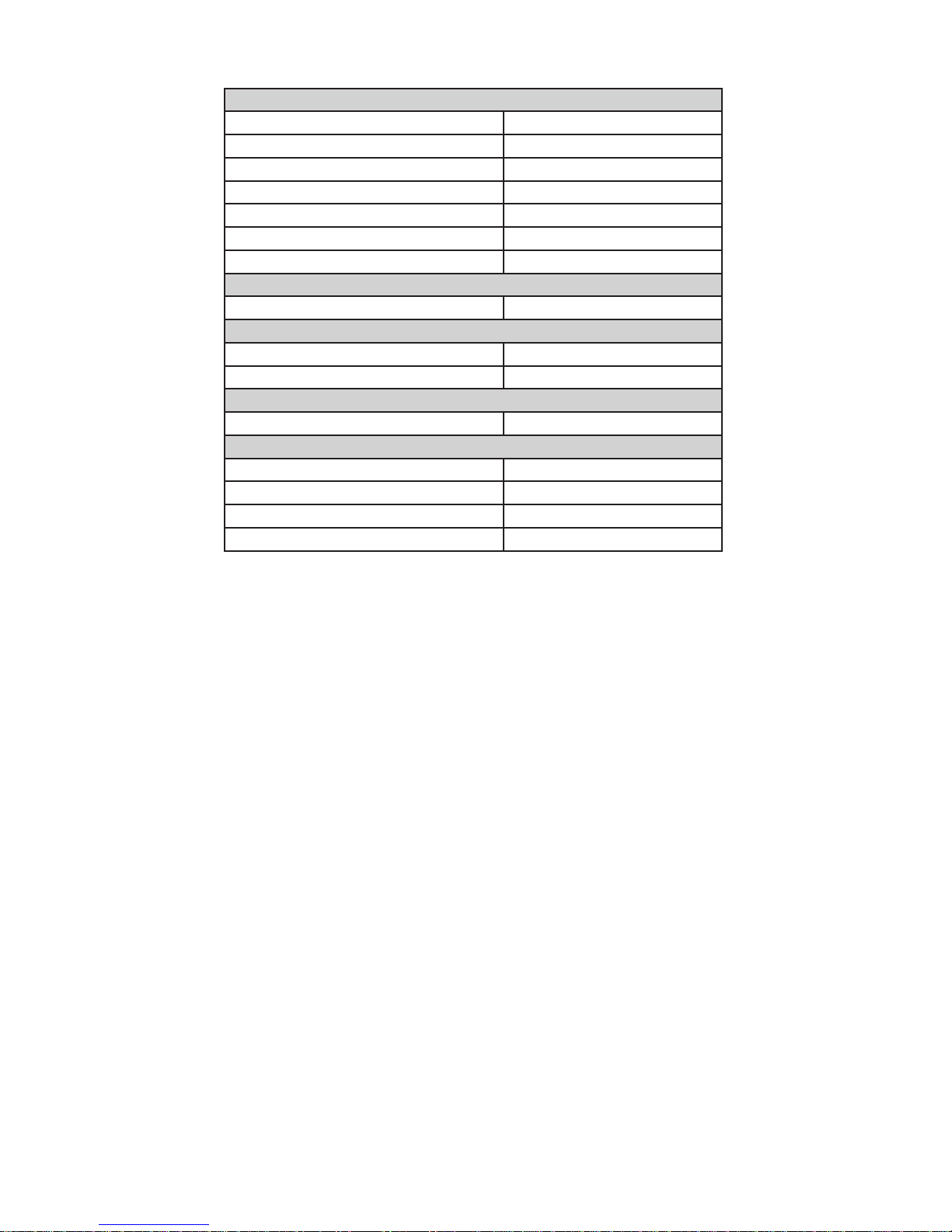

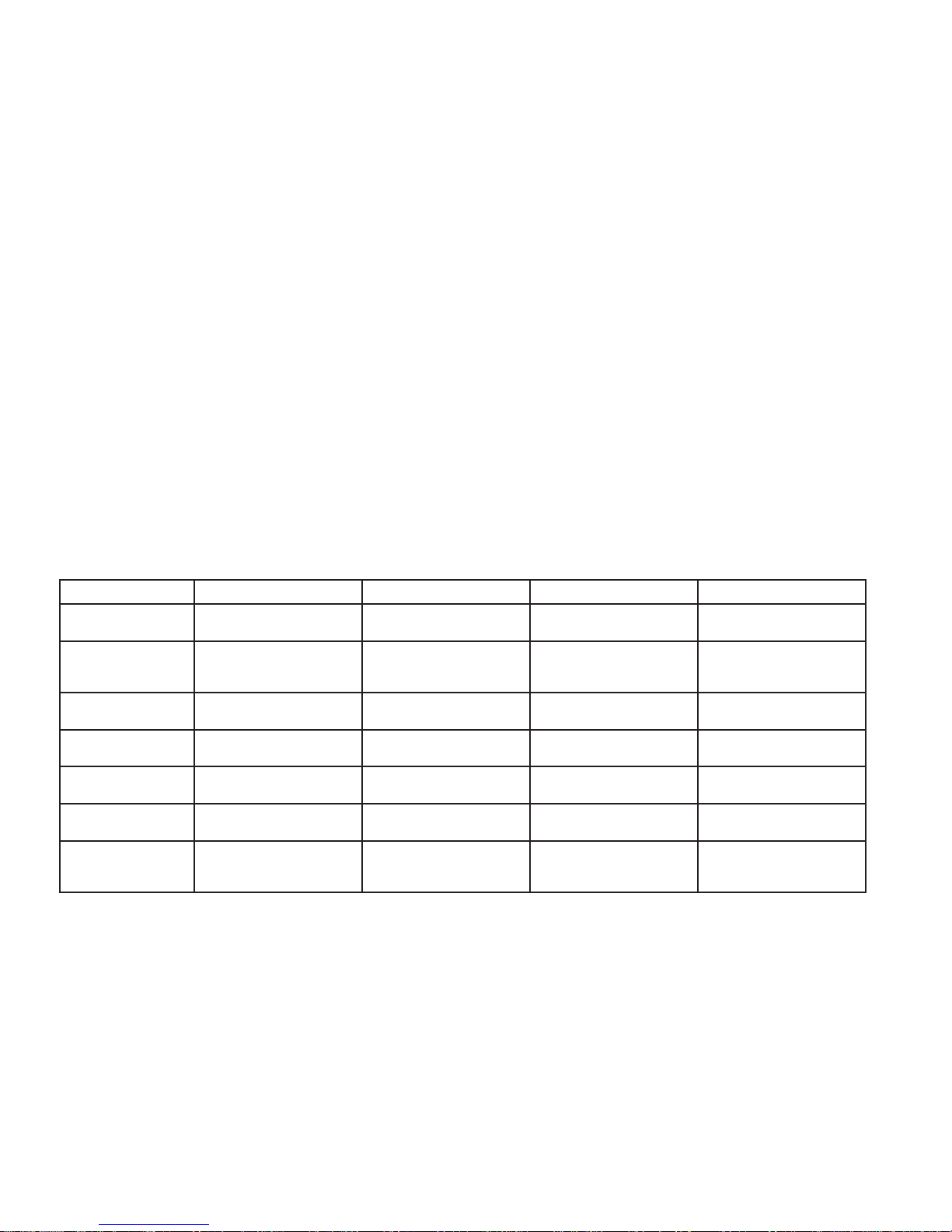

Alarm Mnemonic Description Cause Result Alarm Relay

TP General Alarm

LA High Pressure Warning

E1

E2

Ht

Lt

A1 Frost Alarm

NOTE 1: Air inlet temperature sensor will default to air outlet temperature sensor. Cooling set point defaults to 10°C.

NOTE 2: Unit continues to operate without evaporator freeze protection.

NOTE 3: The MALF high pressure switch is optional.

Air Inlet Temperature

Sensor Alarm

Air Outlet Temperature

Sensor Alarm

High Temperature Alarm

Default = 55°C

Low Temperature Alarm

Default = 14°C

Door open and/or smoke

detected

MALF high pressure

switch opens (See Note 3

below)

Sensor Failure See Note 1 below Relay Contacts Close

Sensor Failure See Note 2 below Relay Contacts Close

Air inlet temperature

greater than 55°C

Air inlet temperature less

than 14°C

Air outlet temperature

less than or equal to

-1.0°C

Unit turns off for duration

of alarm

No effect on function N/A

No effect on function Relay Contacts Close

No effect on function Relay Contacts Close

Compressor and

Condenser fan off for

duration of alarm

Relay Contacts Close

Relay Contacts Close

- 14 -

© 2015 Pentair Equipment Protection

89116616

Page 15

REMOTE ACCESS CONTROL

AIR CONDITIONER UNIT COMMUNICATION FEATURES (OPTIONAL)

An optional communication board offers capabilities that include SNMP, EtherNet/IP, Modbus TCP and Profinet

protocols through Ethernet and Modbus RTU protocol via USB. Pentair has a PC Interface Tool available for

download that can utilize either mode to communicate with the air conditioner unit.

USB COMMUNICATION

This communication mode allows direct connection of a PC to the air conditioner unit. The protocol

supported is Modbus RTU. Use the Pentair AC monitor to communicate with the air conditioner unit. A

MINI-b USB connection is included with this option.

ETHERNET COMMUNICATION

This communication mode allows remote connection to the air conditioner unit using SNMP, EtherNet/IP

and Modbus/TCP, and Profinet protocols. Customers using their own software can download a MIB file for

SNMP, EDS file or EtherNet_IP Object file for EtherNet/IP, Coil Register file for Modbus TCP and GSDML

file for Profinet.

Note: ACU has a default IP Address of 192.168.1.2

Both Ethernet and USB communication modes allow the ability to:

• Read ACU inlet and outlet air temperatures

• Read and change Cooling Set-point and Cooling Differential

• Read and change High and Low Temperature Alarm Settings

• Read and change Gateway IP Address, Device IP Address, Subnet Mask, Trap IP Address and SNMP Community

• Read and change Unit Identification

• Read and change the type of IP addressing (static or dynamic)

• Read current Alarm Status

• Read MAC address

SOFTWARE AND CONFIGURATION FILE DOWNLOADS

The Pentair AC monitor, MIB file, EDS file, EtherNet_IP Object file, Coil Register file and GSDML file for

Profinet can be downloaded from www.pentairprotect.com/en/na/Product-EnclosureCoolingHeating.

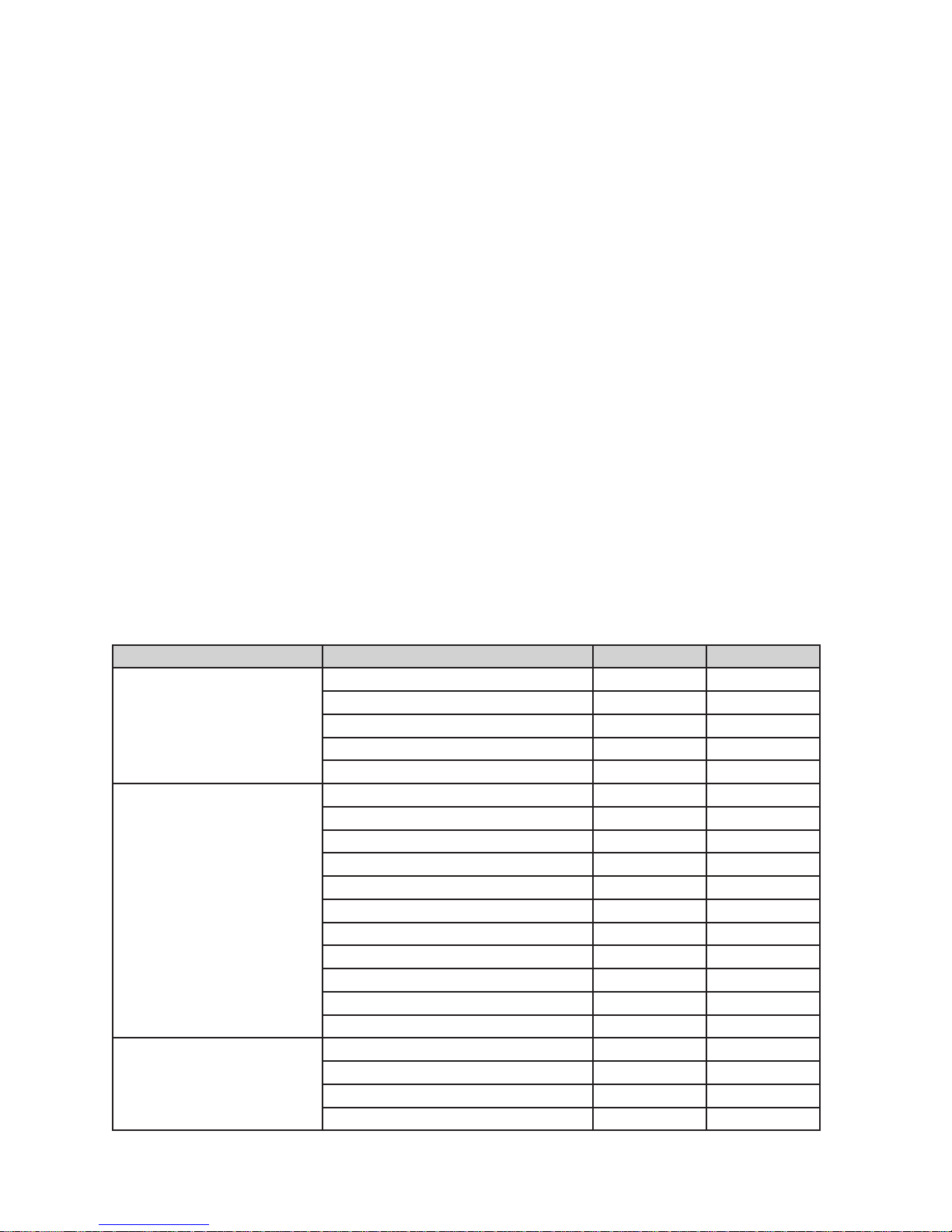

REMOTE ACCESS CONTROL PINOUT

U1 OUTPUTS

U2 INPUTS

U3 DATA

FUNCTION NAME PIN #

COOL No1 1

C1/2 2

C1/2 3

ALARM RELAY OUTPUT No5 12

C5 6

ENCLOSURE DOOR SWITCH ID1 8

MALFUNCTION NC SWITCH ID2 1

NA ID3 (na) 9

NA ID4 (na) 2

DIGITAL INPUT GROUND ID GND 3

T1, EVAP IN THERMISTOR B1 13

T2, EVAP OUT THERMISTOR B2 12

T1, T2 GND GND 6

NA B3 11

CONTROLLER POWER G 7

CONTROLLER POWER G0 14

POWER 1

GROUND 2

DIRECTION 3

DATA 4

89116616

© 2015 Pentair Equipment Protection

- 15 -

Page 16

TECHNICAL INFORMATION

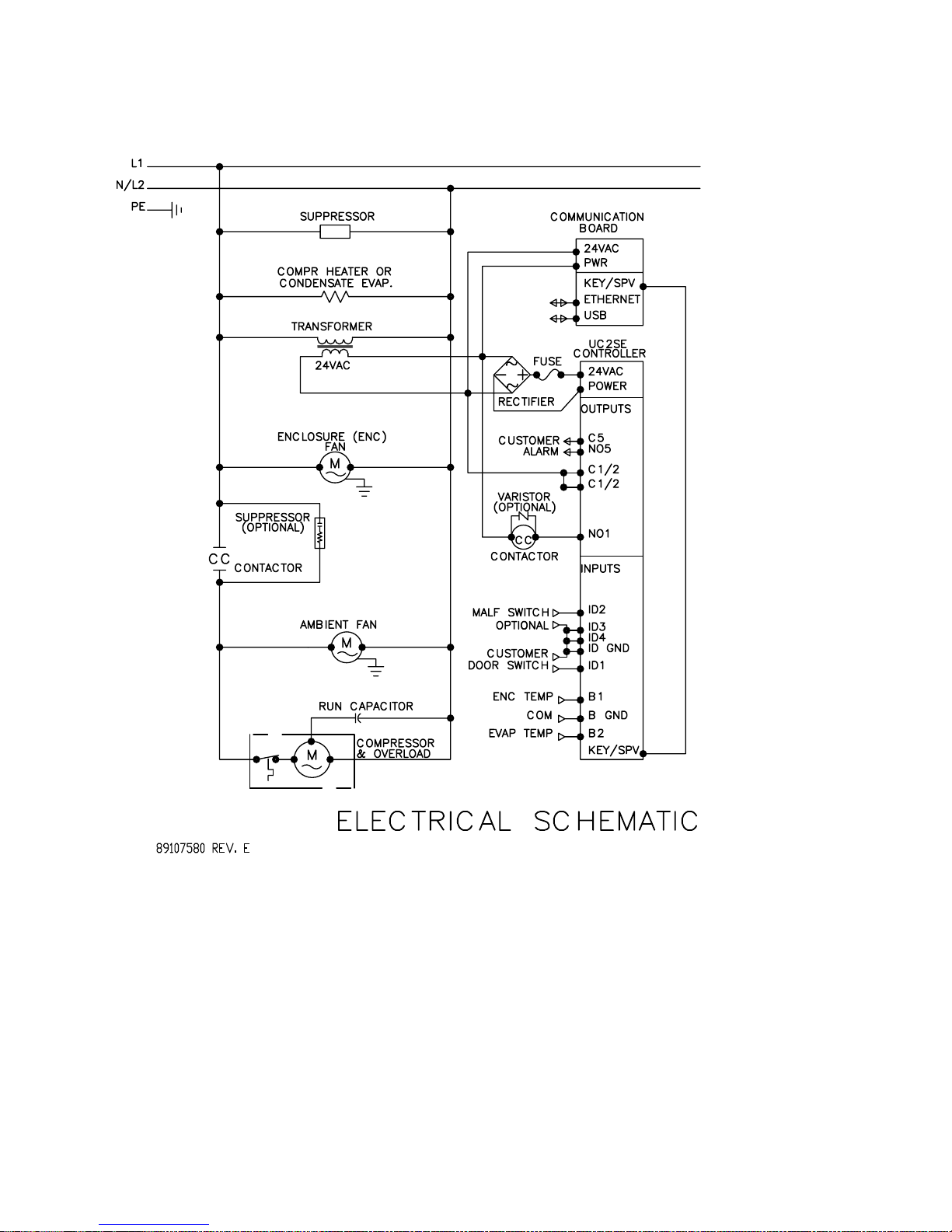

S06 MODELS 300/500W

S06 SCHEMATIC 300/500W

- 16 -

© 2015 Pentair Equipment Protection

89116616

Page 17

S06 WIRE DIAGRAM 300/500W

89116616

© 2015 Pentair Equipment Protection

- 17 -

Page 18

S06 DIMENSIONAL DRAWINGS

300W

280

11.02

108

4.27

5.57

142

3.39

OPTIONAL COMMUNICATION

86

BOARD CONNECTIONS

1.10

28

(2)

550

21.65

ELECTRONIC

CONTROLLER

500W

280

11.02

WARM

ENCLOSURE

AIR IN

COOL

AIR OUT

OPTIONAL FIELD-INSTALLED,CLEANABLE

REUSABLE, ALUMINUM INLET FILTER MOUNTS

BEHIND PLASTIC LOUVER

199

167

7.82

6.58

101

3.97

AIR OUT

ENCLOSURE DOOR

SWITCH SHUT DOWN

AND ALARM OUTPUT

CONNECTOR

114

4.50

M6 MOUNTING

THREADS(4)

200

7.88

AMBIENT

AIR IN

1.70

105

4.13

210

8.25

43

244

9.61

(2)

107

4.20

INPUT

494

POWER

19.44

(2)

OPTIONAL COMMUNICATION

BOARD CONNECTIONS

9

.35

(2)

550

21.65

ELECTRONIC

CONTROLLER

- 18 -

ENCLOSURE

AIR IN

COOL

AIR OUT

OPTIONAL FIELD-INSTALLED,CLEANABLE

REUSABLE, ALUMINUM INLET FILTER MOUNTS

BEHIND PLASTIC LOUVER

© 2015 Pentair Equipment Protection

WARM

AIR OUT

ENCLOSURE DOOR

SWITCH SHUT DOWN

AND ALARM OUTPUT

CONNECTOR

AMBIENT

AIR IN

M6 MOUNTING

THREADS(4)

112

4.40

188

7.40

127

5.00

1.73

179

7.06

44

10.32

262

INPUT

POWER

532

20.94

(2)

(2)

89116616

Page 19

S06 INSTALLATION INSTRUCTION

1. See Receiving The Air Conditioner and Handling and Testing The Air Conditioner on page 6.

2. Using the cutout template provided with the unit, prepare the enclosure. See Figure 11 and Figure 12.

The front of the unit requires a half meter clearance for proper airflow. Five centimeters is required

on each side of the unit. To avoid condensate overflow, unit must be mounted within 3° of level.

3. Refer to mounting instructions on page 8.

4. Adjust controller to desired cabinet temperature. Refer to Displaying and Changing Program

Variables on page 13 for controller adjustment and operation.

9.38

238

21.65

550

.315

(4)

8

11.50

292

7.74

196

9.61

244

(2)

11.02

280

19.44

494

(2)

21.65

550

.315

(4)

8

20.25

514

10.44

265

10.00

254

(2)

11.02

280

20.63

524

(2)

.19

5

Surface Mount Full Recess Mount

Dashed Lines Represent The Air Conditioner

89116616

Figure 11

S06 300W Cutout Drawing

© 2015 Pentair Equipment Protection

- 19 -

Page 20

8.00

203

10.50

267

21.65

550

.50

13

12.05

306

.315

8

(4)

10.44

265

10.00

254

(2)

11.02

280

7.40

188

7.56

192

10.32

262

(2)

11.02

280

20.94

532

(2)

21.65

550

20.15

512

.315

8

(4)

Surface Mount Partial and Full Recess Mount

20.63

524

(2)

.24

6

Figure 12

S06 500W Cutout Drawing

Dashed Lines Represent The Air Conditioner

- 20 -

© 2015 Pentair Equipment Protection

89116616

Page 21

S06 UNIT CHARACTERISTICS

UNIT 300W 115V 300W 230V 500W 115V 500W 230V

CATALOG NUMBER

Indoor Model without Communications Board (°C Controller) S060316G031 S060326G031 S060516G031 S060526G031

Indoor Model with Communications Board (°C Controller) S060316G041 S060326G041 S060516G041 S060526G041

Indoor Model without Communications Board (°F Controller) S060316G050 S060326G050 S060516G050 S060526G050

Indoor Model with Communications Board (°F Controller) S060316G060 S060326G060 S060516G060 S060526G060

COOLING PERFORMANCE

Total L35 L35, 50Hz, according to DIN EN 14511 (Watt) 370 370 550 550

Cooling performance L35 L35 (Watt) 50/60Hz 370 / 420 370 / 420 550 / 640 550 / 640

Cooling performance L35 L50 (Watt) 50/60Hz 190 / 230 190 / 230 320 / 380 320 / 380

Refrigerant R134a R134a R134a R134a

Refrigerant Charge (g) 133 128 162 162

Max. allowable operating pressure (p. max.) bar 28 28 28 28

Operating Temperature Range (Min/Max °C)

Operating Temperature Range (Min/Max °F)

Setting Temperature Range (Min. / Max. °C Controller ) 20 / 55 20 / 55 20 / 55 20 / 55

Setting Temperature Range (Min. / Max. °F Controller) 72 / 120 72 / 120 72 / 120 72 / 120

Airflow at 0 Static Pressure:

Internal loop (m³/h) 109 / 124 109 / 124 197 / 233 197 / 233

External loop (m³/h) 129 / 156 129 / 156 189 / 219 189 / 219

Duty Cycle 100% 100% 100% 100%

ELECTRICAL DATA

Rated Voltage (Volt) 100 / 115 230 115 230

Phase 1~ 1~ 1~ 1~

Frequency (Hz) 50/60 50/60 50/60 50/60

Operating Range +/- 10% +/- 10% +/- 10% +/- 10%

Max power Consumption 50/60Hz L35 L35 (Watt) 270 / 300 300 / 320 450 / 470 450 / 480

Max power Consumption 50/60Hz L35 L50 (Watt) 280 / 320 330 / 350 490 / 540 510 / 540

Max. Nominal Current (Amps) 4.0 / 3.8 1.8 / 1.7 6.5 / 6.1 2.6 / 2.9

Starting Current (Amps) 13 / 13 6.0 / 6.0 21 / 20 9.0 / 6.0

Pre-fuse T (Amps) 15 15 15 15

Agency Approvals UL listed, cUL listed, GOST, CE

Power Input Description Terminal Block

PERFORMANCE FACTOR (EER), 50Hz, DIN EN 14511

Cooling Performance L35 / L35 1.37 / 1.40 1.23 / 1.31 1.22 / 1.36 1.24 / 1.35

Cooling Performance L35 / L50 0.68 / 0.70 0.58 / 0.65 0.64 / 0.70 0.62 / 0.70

ENCLOSURE PROTECTION

IP Code (External loop / Internal loop) IP34 / IP54 IP34 / IP54 IP34 / IP54 IP34 / IP54

CONTROLLER

Description Smart controller with display

Controller Location Ambient side

Factory Default Setpoint (°C Controller) 35 35 35 35

Factory Default Setpoint (°F Controller) 80 80 80 80

SOUND LEVEL

At 1 M (dBA) 66 66 70 70

UNIT CONSTRUCTION

Material Steel Steel

Finish RAL 7035 RAL 7035

UNIT DIMENSIONS

Height (mm)

Width (mm)

Depth (mm)

Weight (kg)

10 / 52 (50Hz)

10 / 55 (60Hz)

50 / 126 (50Hz)

50 / 131 (60Hz)

550 550 550 550

280 280 280 280

140 140 206 206

13 13 15 15

10 / 55 10 / 55 10 / 55

50 / 131 50 / 131 50 / 131

89116616

© 2015 Pentair Equipment Protection

- 21 -

Page 22

S06 COMPONENTS

Item Model Series 300W 115V 300W 230V 500W 115V 500W 230V

Part Descriptions Part Numbers

1 Capacitor, Compressor, Run 52603209SP 52603210SP 89107709SP 89106525SP

2 Capillary Tube 99042047SP 99042047SP 99054030SP 99054030SP

3 Coil, Condenser 89110804SP 89110804SP 89107198SP 89107198SP

4 Coil, Evaporator 89107600SP 89107600SP 89107023SP 89107023SP

5 Communication Board (optional) 89109039SP 89109039SP 89109039SP 89109039SP

6 Compressor 10101682SP 101026101SP 89109026SP 89108369SP

7 Contactor Compressor 10100536SP 10100536SP 10100536SP 10100536SP

Smart Controller °C 89110301SP 89110301SP 89110301SP 89110301SP

8

Smart Controller °F 90236204SP 90236204SP 90236204SP 90236204SP

9 Drain Tube Kit (optional) 101027177SP 101027177SP 101027177SP 101027177SP

10 Filter Air, Reusable (optional) 89106978SP 89106978SP 89106978SP 89106978SP

11 Filter/Dryer 52602803SP 52602803SP 52602803SP 52602803SP

12 Fan, Condenser 89117829SP 89117830SP 89117829SP 89117830SP

13 Fan, Evaporator 13101501SP 13101502SP 12101201SP 12101202SP

14 Thermal Overload, Compressor 10100767SP 10100768SP 90238423SP 89112627SP

15 Thermistor 89075654SP (2) 89075654SP (2) 89075654SP (2) 89075654SP (2)

16 Transformer, 24V 10100694SP 10100693SP 10100694SP 10100693SP

17 Fuse (Controller) 89085114SP 89085114SP 89085114SP 89085114SP

Accessories

18 Installation Kit 90221634QDSP 90221634QDSP 90221634QDSP 90221634QDSP

19 Unit Mounting Gasket 90241618SP 90241618SP 90241618SP 90241618SP

20 Mounting standoffs NA NA 89105488SP (4) 89105488SP (4)

Structural Parts

21 Louvered Grill Panel 89105442SP 89105442SP 89105442SP 89105442SP

22 Panel Strike Clip (Pkg. 4) 90245472SP 90245472SP 90245472SP 90245472SP

23 Body Catch Clip (Pkg. 4) 89105486SP 89105486SP 89105486SP 89105486SP

24 Body Front Shell NA NA 89104023SP 89104023SP

8

21

13

15

14

24

5

7

1

1716

6

2

10

11

20

3

15

4

22

23

12

18

- 22 -

© 2015 Pentair Equipment Protection

89116616

Page 23

S10 MODELS 1000/1500W

S10 SCHEMATICS

1000W 115V, 230V

1000W 460V

89116616

© 2015 Pentair Equipment Protection

- 23 -

Page 24

1500W 115V

1500W 230V

- 24 -

© 2015 Pentair Equipment Protection

89116616

Page 25

1500W 460V

89107589 REV. G

89116616

© 2015 Pentair Equipment Protection

- 25 -

Page 26

S10 WIRE DIAGRAMS

1000W 115V, 230V

- 26 -

© 2015 Pentair Equipment Protection

89116616

Page 27

1000W 460V

89116616

© 2015 Pentair Equipment Protection

- 27 -

Page 28

1500W 115V

- 28 -

© 2015 Pentair Equipment Protection

89116616

Page 29

1500W 230V

89116616

© 2015 Pentair Equipment Protection

- 29 -

Page 30

1500W 460V

89107588 REV. H

- 30 -

© 2015 Pentair Equipment Protection

89116616

Page 31

S10 DIMENSIONAL DRAWING

1000/1500W

260

222

10.22

8.75

105

4.14

951

37.44

M8 LIFT

ELECTRONIC

CONTROLLER

LUGS

400

15.75

ENCLOSURE

AIR IN

COOL

AIR OUT

OPTIONAL,FIELD-INSTALLED, CLEANABLE

REUSABLE,ALUMINUM INLET FILTER MOUNTS

BEHIND PLASTIC LOUVER

WARM

AIR OUT

OPTIONAL COMMUNICATION

BOARD CONNECTIONS

ENCLOSURE DOOR SWITCH

SHUT DOWN AND ALARM

OUTPUT CONNECTOR

AMBIENT

AIR IN

M8 MOUNTING

THREADS(8)

129

5.07

273

10.75

100

3.92

128

5.06

PHASE MONITOR (460V ONLY)

D-SHAPED SIGHT PORT

45

1.78

298

11.75

250

9.84

(4)

INPUT

POWER

15

.61

(2)

280

11.02

(2)

255

10.04

(2)

385

15.16

(2)

89116616

© 2015 Pentair Equipment Protection

- 31 -

Page 32

S10 INSTALLATION INSTRUCTION

1. See Receiving The Air Conditioner and Handling and Testing The Air Conditioner on page 6.

2. Using the cutout template provided with the unit, prepare the enclosure. See Figure 13. The front of

the unit requires a half meter clearance for proper airflow. Five centimeters is required on each side

of the unit. To avoid condensate overflow, unit must be mounted within 3° of level.

3. Refer to mounting instructions on page 8.

4. Adjust controller to desired cabinet temperature. Refer to Displaying and Changing Program

Variables on page 13 for controller adjustment and operation.

37.44

951

14.14

359

.375

10

(8)

10.00

254

11.50

292

10.75

273

14.00

356

12.19

310

9.84

250

(4)

11.02

280

(2)

10.04

255

(2)

15.16

385

(2)

37.44

951

.375

10

(4)

[.47]

12 X 45

(4 PLACES)

14.88

378

.14

4

14.56

370

(2)

36.22

920

(2)

35.94

913

15.75

400

Surface Mount Partial and Full Recess Mount

Dashed Lines Represent The Air Conditioner

- 32 -

Figure 13

S10 1000/1500W Cutout Drawing

© 2015 Pentair Equipment Protection

15.75

400

89116616

Page 33

S10 UNIT CHARACTERISTICS (115V, 230V)

UNIT 1000W 115V 1000W 230V 1500W 115V 1500W 230V

CATALOG NUMBER

Indoor Model without CommuNnications Board (°C Controller) S101016G031 S101026G031 S101516G031 S101526G031

Indoor Model with Communications Board (°C Controller) S101016G041 S101026G041 S101516G041 S101526G041

Indoor Model without CommuNnications Board (°F Controller) S101016G050 S101026G050 S101516G050 S101526G050

Indoor Model with Communications Board (°F Controller) S101016G060 S101026G060 S101516G060 S101526G060

COOLING PERFORMANCE

Total L35 L35, 50Hz, according to DIN EN 14511 (Watt) 1300 1300 1800 1800

Cooling performance L35 L35 (Watt) 50/60Hz 1300 / 1380 1300 / 1380 1800 / 1880 1800 / 1880

Cooling performance L35 L50 (Watt) 50/60Hz 900 / 1000 900 / 1000 1300 / 1380 1300 / 1380

Refrigerant R134a R134a R134a R134a

Refrigerant Charge (g) 425 283 425 425

Max. allowable operating pressure (p. max.) bar 28 28 28 28

Operating Temperature Range (Min/Max °C) 10 / 55 10 / 55 10 / 55 10 / 55

Operating Temperature Range (Min/Max °F) 50 / 131 50 / 131 50 / 131 50 / 131

Setting Temperature Range (Min. / Max. °C Controller) 20 / 55 20 / 55 20 / 55 20 / 55

Setting Temperature Range (Min. / Max. °F Controller) 72 / 120 72 / 120 72 / 120 72 / 120

Airflow at 0 Static Pressure:

Internal loop (m³/h) 350 / 391 350 / 391 342 / 391 342 / 391

External loop (m³/h) 567 / 584 567 / 584 576 / 579 576 / 579

Duty Cycle 100% 100% 100% 100%

ELECTRICAL DATA

Rated Voltage (Volt) 115 230 115 230

Phase 1~ 1~ 1~ 1~

Frequency (Hz) 50/60 50/60 50/60 50/60

Operating Range +/- 10% +/- 10% +/- 10% +/- 10%

Max power Consumption 50/60Hz L35 L35 (Watt) 810 / 1010 670 / 800 850 / 1040 850 / 1040

Max power Consumption 50/60Hz L35 L50 (Watt) 950 / 1120 780 / 950 990 / 1160 960 / 1170

Max. Nominal Current (Amps) 9.6 / 10.2 4.1 / 5.5 9.6 / 10.2 5.1 / 6.7

Starting Current (Amps) 32 / 34 14 / 18 32 / 34 17 / 22

Pre-fuse T (Amps) 15 15 15 15

Agency Approvals UL Listed, cUL Listed, GOST, CE

Power Input Description Terminal Block

PERFORMANCE FACTOR (EER), 50Hz, DIN EN 14511

Cooling Performance L35 / L35 1.60 / 1.37 1.94 / 1.73 2.12 / 1.81 2.12 / 1.81

Cooling Performance L35 / L50 0.95 / 0.89 1.15 / 1.05 1.31 / 1.19 1.35 / 1.18

ENCLOSURE PROTECTION

IP Code (External loop / Internal loop) IP34 / IP54 IP34 / IP54 IP34 / IP54 IP34 / IP54

CONTROLLER

Description Smart Controller with display

Controller Location Ambient Side

Factory Default Setpoint (°C Controller) 35 35 35 35

Factory Default Setpoint (°F Controller) 80 80 80 80

SOUND LEVEL

At 1 M (dBA) 71 71 73 73

UNIT CONSTRUCTION

Material Steel Steel

Finish RAL 7035 RAL 7035

UNIT DIMENSIONS

Height (mm)

Width (mm)

Depth (mm)

Weight (kg)

950 950 950 950

400 400 400 400

259 259 259 259

39 39 43 43

89116616

© 2015 Pentair Equipment Protection

- 33 -

Page 34

S10 UNIT CHARACTERISTICS (460V)

UNIT 1000W 460V 1500W 460v

CATALOG NUMBER

Indoor Model without Communications Board (°C Controller) S101046G031 S101546G031

Indoor Model with Communications Board (°C Controller) S101046G041 S101546G041

Indoor Model without Communications Board (°F Controller) S101046G050 S101546G050

Indoor Model with Communications Board (°F Controller) S101046G060 S101546G060

COOLING PERFORMANCE

Total L35 L35, 50Hz, according to DIN EN 14511 (Watt) 1300 1800

Cooling performance L35 L35 (Watt) 50/60Hz 1300 / 1380 1800 / 1880

Cooling performance L35 L50 (Watt) 50/60Hz 900 / 1000 1300 / 1380

Refrigerant R134a R134a

Refrigerant Charge (g) 283 510

Max. allowable operating pressure (p. max.) bar 28 28

Operating Temperature Range (Min/Max °C) 10 / 55 10 / 55

Operating Temperature Range (Min/Max °F) 50 / 131 50 / 131

Setting Temperature Range (Min. / Max. °C Controller) 20 / 55 20 / 55

Setting Temperature Range (Min. / Max. °F Controller) 72 / 120 72 / 120

Airflow at 0 Static Pressure:

Internal loop (m³/h) 350 / 391 342 / 391

External loop (m³/h) 567 / 584 576 / 579

Duty Cycle 100% 100%

ELECTRICAL DATA

Rated Voltage (Volt) 400 / 460 400 / 460

Phase 1~ 3~

Frequency (Hz) 50/60 50/60

Operating Range +/- 10% +/- 10%

Max power Consumption 50/60Hz L35 L35 (Watt) 750 / 960 930 / 1130

Max power Consumption 50/60Hz L35 L50 (Watt) 870 / 1090 970 / 1210

Max. Nominal Current (Amps) 2.1 / 2.4 2.1 / 2.4

Starting Current (Amps) 7 / 8 7 / 8

Pre-fuse T (Amps) 15 15

Agency Approvals UL Listed, cUL Listed, GOST, CE

Power Input Description Terminal Block

PERFORMANCE FACTOR (EER), 50Hz, DIN EN 14511

Cooling Performance L35 / L35 1.73 / 1.44 1.94 / 1.66

Cooling Performance L35 / L50 1.03 / 0.92 1.34 / 1.14

ENCLOSURE PROTECTION

IP Code (External loop / Internal loop) IP34 / IP54 IP34 / IP54

CONTROLLER

Description Smart Controller with display

Controller Location Ambient Side

Factory Default Setpoint (°C Controller) 35 35

Factory Default Setpoint (°F Controller) 80 80

SOUND LEVEL

At 1 M (dBA) 71 73

UNIT CONSTRUCTION

Material Steel Steel

Finish RAL 7035 RAL 7035

UNIT DIMENSIONS

Height (mm)

Width (mm)

Depth (mm)

Weight (kg)

950 950

400 400

259 259

45 43

- 34 -

© 2015 Pentair Equipment Protection

89116616

Page 35

S10 COMPONENTS (1 PHASE)

Item Model Series 1000W 115V 1000W 230V 1000W 460V 1500W 115V 1500W 230V

Part Descriptions Part Numbers

1 Capacitor, Compressor, Run 90235721SP 89107715SP 89107715SP 90235721SP 89107716SP

2 Capacitor, Condenser Blower 52603213SP 52603214SP 52603214SP 52603213SP 52603214SP

3 Capacitor, Evaporator Blower 52603215SP 52603214SP 52603214SP 52603215SP 52603214SP

4 Coil, Condenser 89102610SP 89102610SP 89102610SP 89102610SP 89102610SP

5 Coil, Evaporator 89102609SP 89102609SP 89102609SP 89102609SP 89102609SP

6 Communication Board (optional) 89109039SP 89109039SP 89109039SP 89109039SP 89109039SP

7 Compressor 89111874SP 89107239SP 89107239SP 89111874SP 89105607SP

8 Contactor Compressor 89088986SP 89088986SP 89088986SP 89088986SP 89088986SP

Smart Controller °C 89110301SP 89110301SP 89110301SP 89110301SP 89110301SP

9

Smart Controller °F 90236204SP 90236204SP 90236204SP 90236204SP 90236204SP

10 Drain Tube Kit (optional) 101027177SP 101027177SP 101027177SP 101027177SP 101027177SP

11 Filter Air, Reusable (optional) 89106977SP 89106977SP 89106977SP 89106977SP 89106977SP

12 Filter/Dryer 52602800SP 52602800SP 52602800SP 52602800SP 52602800SP

13 Impeller, Condenser 89107374SP 89107375SP 89107375SP 89107374SP 89107375SP

14 Impeller, Evaporator 101091121SP 101091122SP 101091122SP 101091121SP 101091122SP

15 Thermal Expansion Valve 89063955SP 10104042SP 10104042SP 89063955SP 10104042SP

16 Thermal Overload, Compressor 90238424SP 89112628SP 89112628SP 90238424SP NA

17 Thermistor 89075654SP (2) 89075654SP (2) 89075654SP (2) 89075654SP (2) 89075654SP (2)

18 Transformer, 24V 10100694SP 10100693SP 10100693SP 10100694SP 10100693SP

19 Transformer, 230/460V NA NA 101006111SP NA NA

20 Fuse (Controller) 89085114SP 89085114SP 89085114SP 89085114SP 89085114SP

Accessories

21 Installation Kit 90221633QDSP 90221633QDSP 90221633QDSP 90221633QDSP 90221633QDSP

22 Unit Mounting Gasket 90241618SP 90241618SP 90241618SP 90241618SP 90241618SP

23 Mounting standoffs 89105489SP (4) 89105489SP (4) 89105489SP (4) 89105489SP (4) 89105489SP (4)

Structural Parts

24 Louvered Grill Panel 89105410SP (2) 89105410SP (2) 89105410SP (2) 89105410SP (2) 89105410SP (2)

25 Controller Bezel Panel 89105411SP 89105411SP 89105411SP 89105411SP 89105411SP

26 Panel Strike Clip (Pkg. 4) 90245472SP 90245472SP 90245472SP 90245472SP 90245472SP

27 Body Catch Clip (Pkg. 4) 89105486SP 89105486SP 89105486SP 89105486SP 89105486SP

28 Body Front Shell 89102598SP 89102598SP 89102598SP 89102598SP 89102598SP

16

7

24

25

9

24

89116616

17

15

27 26

11

8

3

18

2

12

23

21

1

28

© 2015 Pentair Equipment Protection

14

6

20

17

5

4

13

- 35 -

Page 36

S10 COMPONENTS (3 PHASE)

Item Model Series 1500W 460V

Part Descriptions Part Numbers

2 Capacitor, Condenser Blower 52603214SP

3 Capacitor, Evaporator Blower 52603214SP

4 Coil, Condenser 89108399SP

5 Coil, Evaporator 89102609SP

6 Communication Board (optional) 89109039SP

7 Compressor 89107888SP

8 Contactor Compressor 89107296SP

Smart Controller °C 89110301SP

9

Smart Controller °F 90236204SP

10 Drain Tube Kit (optional) 101027177SP

11 Filter Air, Reusable (optional) 89106977SP

12 Filter/Dryer 52602800SP

13 Impeller, Condenser 89107375SP

14 Impeller, Evaporator 101091122SP

15 Thermal Expansion Valve 89063955SP

16 Thermal Overload, Compressor 90238425SP

17 Thermistor 89075654SP (2)

18 Transformer, 24V 10100693SP

19 Transformer,460/230V 101006128SP

20 Fuse (Controller) 89085114SP

Accessories

21 Installation Kit 90221633QDSP

22 Unit Mounting Gasket 90241618SP

23 Mounting standoffs 89105489SP (4)

Structural Parts

24 Louvered Grill Panel 89105410SP (2)

25 Controller Bezel Panel 89105411SP

26 Panel Strike Clip (Pkg. 4) 90245472SP

27 Body Catch Clip (Pkg. 4) 89105486SP

28 Body Front Shell 89102598SP

29 Relay, Overload 89098323SP

30 Relay, Phase Monitor 89097986SP

- 36 -

© 2015 Pentair Equipment Protection

89116616

Page 37

S16 MODELS 2000/2500W

S16 SCHEMATICS

2000W 115V

2000W 230V

89116616

© 2015 Pentair Equipment Protection

- 37 -

Page 38

2000W 460V

2500W 115V

89107589 REV. G

- 38 -

© 2015 Pentair Equipment Protection

89116616

Page 39

2500W 230V

2500W 460V

89107593 REV. G

89116616

© 2015 Pentair Equipment Protection

- 39 -

Page 40

4000W 460V

- 40 -

© 2015 Pentair Equipment Protection

89116616

Page 41

S16 WIRE DIAGRAMS

2000W 115V

89116616

© 2015 Pentair Equipment Protection

- 41 -

Page 42

2000W 230V

- 42 -

© 2015 Pentair Equipment Protection

89116616

Page 43

2000W 460V

89107588 REV. H

89116616

© 2015 Pentair Equipment Protection

- 43 -

Page 44

2500W 115V

- 44 -

© 2015 Pentair Equipment Protection

89116616

Page 45

2500W 230V

89116616

© 2015 Pentair Equipment Protection

- 45 -

Page 46

2500W 460V

89107592 REV. H

- 46 -

© 2015 Pentair Equipment Protection

89116616

Page 47

4000W 460V

89116616

© 2015 Pentair Equipment Protection

- 47 -

Page 48

S16 DIMENSIONAL DRAWING

2000/2500W

146

5.74

400

15.75

1580

62.19

ELECTRONIC

CONTROLLER

258

10.15

ENCLOSURE

AIR IN

295

11.61

COOL

AIR OUT

WARM

AIR OUT

OPTIONAL COMMUNICATION

BOARD CONNECTIONS

ENCLOSURE DOOR SWITCH

SHUT DOWN AND ALARM

OUTPUT CONNECTOR

137

5.38

252

9.94

128

5.06

PHASE MONITOR (460V ONLY)

D-SHAPED SIGHT PORT

INPUT

POWER

45

1.78

298

11.75

380

14.96

(2)

550

21.65

(2)

325

12.80

(2)

25

.98

(2)

M8 LIFT LUGS

AMBIENT

AIR IN

OPTIONAL,FIELD-INSTALLED,CLEANABLE

REUSABLE,ALUMINUM INLET FILTER MOUNTS

BEHIND PLASTIC LOUVER.

M8 MOUNTING

THREADS(10)

341

13.43

280

11.02

(5)

275

10.82

(2)

- 48 -

© 2015 Pentair Equipment Protection

89116616

Page 49

4000W

W,^DKE/dKZ;ϰϲϬsKE>zͿ

Ͳ^,W^/',dWKZd

89116616

© 2015 Pentair Equipment Protection

- 49 -

Page 50

S16 INSTALLATION INSTRUCTION

1. See Receiving The Air Conditioner and Handling and Testing The Air Conditioner on page 6.

2. Using the cutout template provided with the unit, prepare the enclosure. See Figure 14 and Figure 15.

The front of the unit requires a half meter clearance for proper airflow. Five centimeters is required

on each side of the unit. To avoid condensate overflow, unit must be mounted within 3° of level.

3. Refer to mounting instructions on page 8.

4. Adjust controller to desired cabinet temperature. Refer to Displaying and Changing Program

Variables on page 13 for controller adjustment and operation.

.625

R

16

(4)

14.88

378

12.44

316

14.00

356

14.96

380

(2)

21.65

550

(2)

12.80

325

(2)

10.82

275

(2)

.375

(4)

10

62.19

1580

14.56

370

(2)

15.75

400

60.69

1542

61.34

1558

(2)

.33

8

62.19

1580

21.83

554

.375

10

(10)

25.63

651

9.44

240

12.19

310

11.02

280

(5)

15.75

400

Surface Mount Partial and Full Recess Mount

Dashed Lines Represent The Air Conditioner

- 50 -

Figure 14

S16 2000/2500W Cutout Drawing

© 2015 Pentair Equipment Protection

89116616

Page 51

Surface Mount Partial Recess Mount

Dashed Lines Represent The Air Conditioner

89116616

Figure 15

S16 4000W Cutout Drawing

© 2015 Pentair Equipment Protection

- 51 -

Page 52

S16 UNIT CHARACTERISTICS (115V, 230V)

UNIT 2000W 115V 2000W 230V 2500W 115V 2500W 230V

CATALOG NUMBER

Indoor Model without Communications Board (°C Controller) S162016G031 S162026G031 S162516G031 S162526G031

Indoor Model with Communications Board (°C Controller) S162016G041 S162026G041 S162516G041 S162526G041

Indoor Model without Communications Board (°F Controller) S162016G050 S162026G050 S162516G050 S162526G050

Indoor Model with Communications Board (°F Controller) S162016G060 S162026G060 S162516G060 S162526G060

COOLING PERFORMANCE

Total L35 L35, 50Hz, according to DIN EN 14511 (Watt) 2200 2200 2680 2680

Cooling performance L35 L35 (Watt) 50/60Hz 2200 / 2400 2200 / 2400 2680 / 2800 2680 / 2800

Cooling performance L35 L50 (Watt) 50/60Hz 1820 / 1900 1820 / 1900 2200 / 2300 2200 / 2300

Refrigerant R134a R134a R134a R134a

Refrigerant Charge (g) 709 709 737 737

Max. allowable operating pressure (p. max.) bar 28 28 28 28

Operating Temperature Range (Min/Max °C) 10 / 55 10 / 55 10 / 55 10 / 55

Operating Temperature Range (Min/Max °F) 50 / 131 50 / 131 50 / 131 50 / 131

Setting Temperature Range (Min. / Max. °C Controller) 20 / 55 20 / 55 20 / 55 20 / 55

Setting Temperature Range (Min. / Max. °F Controller) 72 / 120 72 / 120 72 / 120 72 / 120

Airflow at 0 Static Pressure:

Internal loop (m³/h) 454 / 484 454 / 484 447 / 466 447 / 466

External loop (m³/h) 634 / 654 634 / 654 1104 / 1143 1104 / 1143

Duty Cycle 100% 100% 100% 100%

ELECTRICAL DATA

Rated Voltage (Volt) 115 230 115 230

Phase 1~ 1~ 1~ 1~

Frequency (Hz) 50/60 50/60 50/60 50/60

Operating Range +/- 10% +/- 10% +/- 10% +/- 10%

Max power Consumption 50/60Hz L35 L35 (Watt) 930 / 1090 940 / 1140 1230 / 1420 1320 / 1650

Max power Consumption 50/60Hz L35 L50 (Watt) 1280 / 1410 1070 / 1320 1500 / 1970 1500 / 1910

Max. Nominal Current (Amps) 11.1 / 12.5 5.7 / 7.2 16.1 / 16.9 8.0 / 10.1

Starting Current (Amps) 37 / 41 19 / 24 53 / 56 26 / 33

Pre-fuse T (Amps) 15 15 20 15

Agency Approvals UL Listed, cUL Listed, GOST, CE

Power Input Description Terminal Block

PERFORMANCE FACTOR (EER), 50Hz, DIN EN 14511

Cooling Performance L35 / L35 2.37 / 2.20 2.34 / 2.11 2.18 / 1.97 2.03 / 1.70

Cooling Performance L35 / L50 1.42 / 1.35 1.70 / 1.44 1.47 / 1.17 1.47 / 1.20

ENCLOSURE PROTECTION

IP Code (External loop / Internal loop) IP34 / IP54 IP34 / IP54 IP34 / IP54 IP34 / IP54

CONTROLLER

Description Smart controller with display

Controller Location Ambient Side

Factory Default Setpoint (°C Controller) 35 35 35 35

Factory Default Setpoint (°F Controller) 80 80 80 80

SOUND LEVEL

At 1 M (dBA) 70 70 72 72

UNIT CONSTRUCTION

Material Steel Steel

Finish RAL 7035 RAL 7035

UNIT DIMENSIONS

Height (mm)

Width (mm)

Depth (mm)

Weight (kg)

1580 1580 1580 1580

400 400 400 400

295 295 295 295

68 68 70 70

- 52 -

© 2015 Pentair Equipment Protection

89116616

Page 53

S16 UNIT CHARACTERISTICS (460V)

UNIT 2000W 460V 2500W 460V 4000W 460V

CATALOG NUMBER

Indoor Model without Communications Board (°C Controller) S162046G031 S162546G031 S164046G031

Indoor Model with Communications Board (°C Controller) S162046G041 S162546G041 S164046G041

Indoor Model without Communications Board (°F Controller) S162046G050 S162546G050 S164046G050

Indoor Model with Communications Board (°F Controller) S162046G060 S162546G060 S164046G060

COOLING PERFORMANCE

Total L35 L35, 50Hz, according to DIN EN 14511 (Watt) 2200 2680 4000

Cooling performance L35 L35 (Watt) 50/60Hz 2200 / 2400 2680 / 2800 4000 / 4500

Cooling performance L35 L50 (Watt) 50/60Hz 1820 / 1900 2200 / 2300 3050 / 3450

Refrigerant R134a R134a R134a

Refrigerant Charge (g) 709 850 1247

Max. allowable operating pressure (p. max.) bar 28 28 28