Page 1

RS-485 COMBO CONVERSION REPLACEMENT KIT

USA (P/N 476211) AND AUSTRALIA (P/N 462049)

FOR MASTERTEMP® AND MAX-E-THERM® POOL AND SPA HEATERS

INSTALLATION INSTRUCTIONS

FAILURE TO FOLLOW ALL INSTRUCTIONS AND WARNINGS CAN RESULT IN

SERIOUS BODILY INJURY OR DEATH. THIS PRODUCT SHOULD BE

INSTALLED AND SERVICED ONLY BY A QUALIFIED POOL SERVICE

PROFESSIONAL. INSTALLERS, POOL OPERATORS AND OWNERS MUST

READ THESE WARNINGS AND ALL INSTRUCTIONS IN THE HEATER

INSTALLATION AND USER’S GUIDE BEFORE USING THIS PRODUCT.

THESE INSTRUCTIONS MUST BE LEFT WITH THE POOL OWNER.

Pentair Water Pool and Spa heater related products are available at:

https://www.pentair.com/en/products/pool-spa-equipment/pool-heaters.html

Call (800) 831-7133 for additional free copies of these instructions.

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS - SAVE THESE INSTRUCTIONS

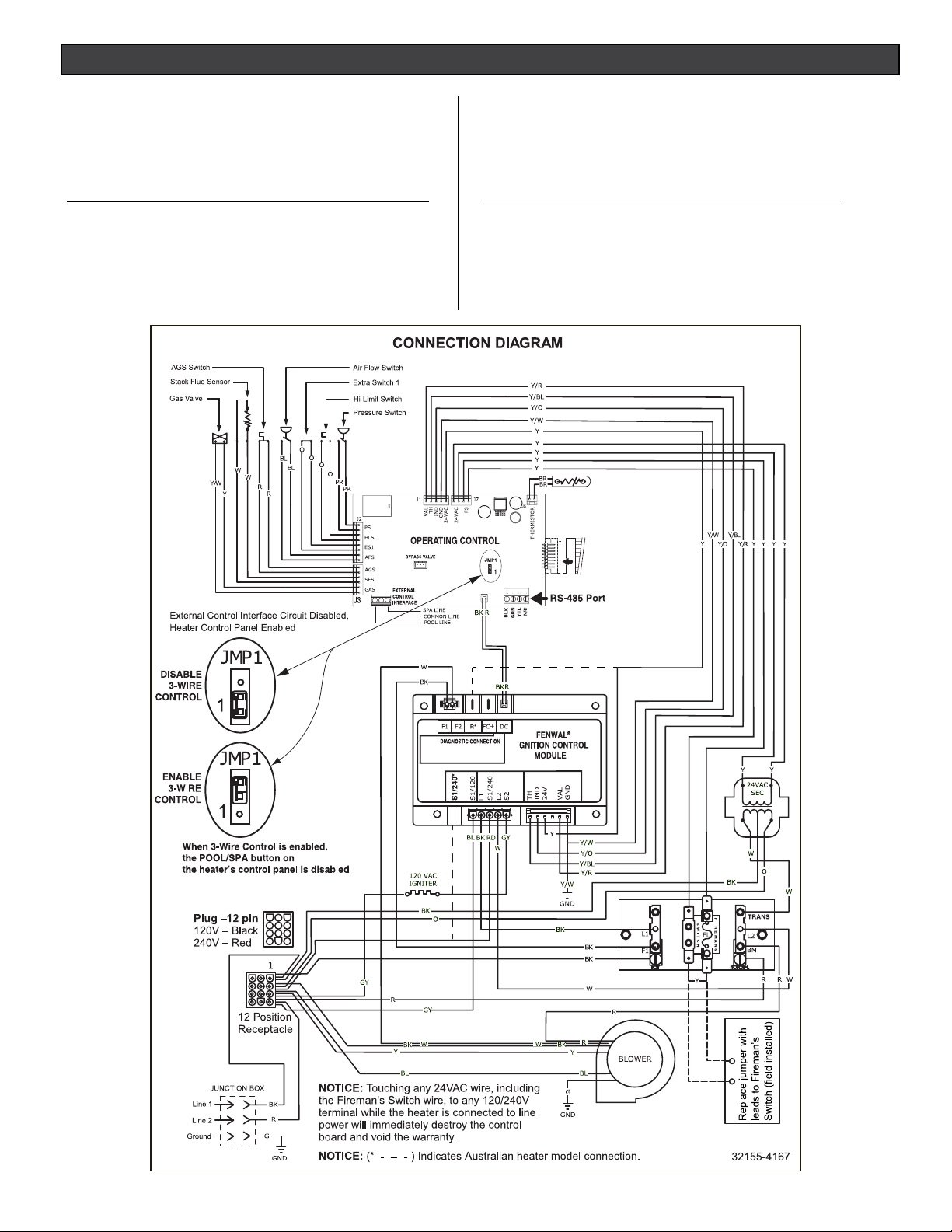

RS-485 Combo Conversion Instructions for USA and Australian heater models

The following instructions describe how to replace the PCBA, Membrane Pad, Ignition Control Module

(ICM) and Wiring Harness in a MasterTemp or Sta-Rite pool and spa heater (USA and Australia

models) that doesn’t have RS-485 communication capability.

Contents

RS-485 Combo Conversion Replacement (USA) page 2-5

RS-485 Combo Conversion Replacement (Australia) page 6-8

P/N 476251.A 9/2020

1

Page 2

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (USA)

476211 RS-485 COMBO CONVERSION (USA)

Parts List

P/N Description Qty.

466225 WH HRN US W/ FC 1

476221 ICM W/ FLAME SENSE US 1

476201 MEM PAD MT 6 BUTTONS 1

476199 PCBA MT/MET HTR W/RS485 1

476251 INSTALLATION INSTRUCTIONS 1

462049 RS-485 COMBO CONVERSION (AUSTRALIA)

Parts List

P/N Description Qty.

476226 WH HRN AUSTRALIA W/ FC 1

476222 ICM W/ FLAME SENSE AU 1

476251 INSTALLATION INSTRUCTIONS 1

476201 MEM PAD MT 6 BUTTONS 1

476199 PCBA MT/MET HTR W/RS485 1

2

Page 3

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (USA)

When installing this kit, basic safety precautions should always be followed. Read and follow all instructions.

Required installation tools:

• Powered socket/nut driver

• 1/4” nut driver bit

• 5/16” socket and nut driver

• 3/8” nut driver

CAUTION! Before starting: Always disconnect AC power to the heater before proceeding with

the wire harness replacement instructions.

CAUTION!: Before unplugging ICM connector plugs, be sure to match the

wire identication on both the existing and replacement wire harnesses.

To replace the membrane pad PCBA on a MasterTemp

®

Heater

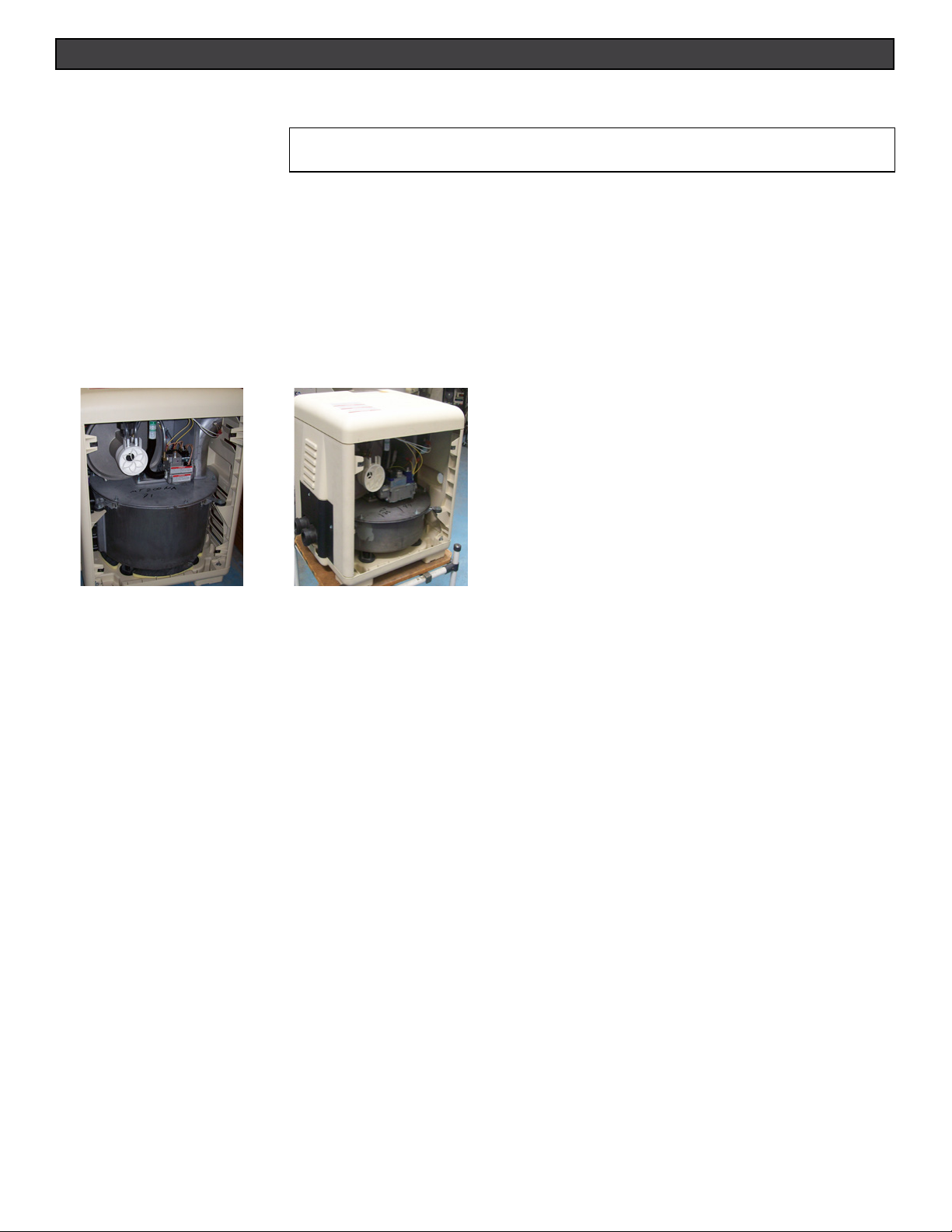

To open the heater:

1. Remove left side panel from the heater (Fig. 1 and Fig. 2). Remove the four (4) wing nuts holding the top in place.

FIG. 1.

MasterTemp

2. Disconnect the wire harness from the back of the PCBA.

3. Disconnect the membrane pad from the PCBA.

4. Remove the four (4) screws holding the PCBA and remove the PCBA.

5. Peel the membrane pad from the top panel by pulling one of the corners. Set the panel aside.

6. Disconnect the wires from the ICM. Remove the two (2) screws that secure the ICM to the junction box.

7. Route the membrane pad connector through the top panel slot in order to connect it to the control board. Peel off the membrane

pad backing off the new membrane.

8. Align the membrane pad with the bottom of the recess in the lid and press firmly into place. Smooth the membrane pad with your

hand.

9. Place new PCBA into underside of cover and secure with four (4) mounting screws.

10. Reconnect the membrane pad to the PCBA (note the arrow on the membrane connector should be on the bottom)the upper jackets

halves from the heater (Fig. 3).

11. Place lid assembly aside and continue with replacing the ICM and Wire Harness.

STD Heater

FIG. 2.

MasterTemp 125 Heater

3

Page 4

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (USA)

F

I

L

T

E

R

PUMP

AUX

1

AUX

2

H

IG

H

SPE

ED

L

OW

S

PE

ED

BOOS

TE

R P

UM

P

Retaining

Pins

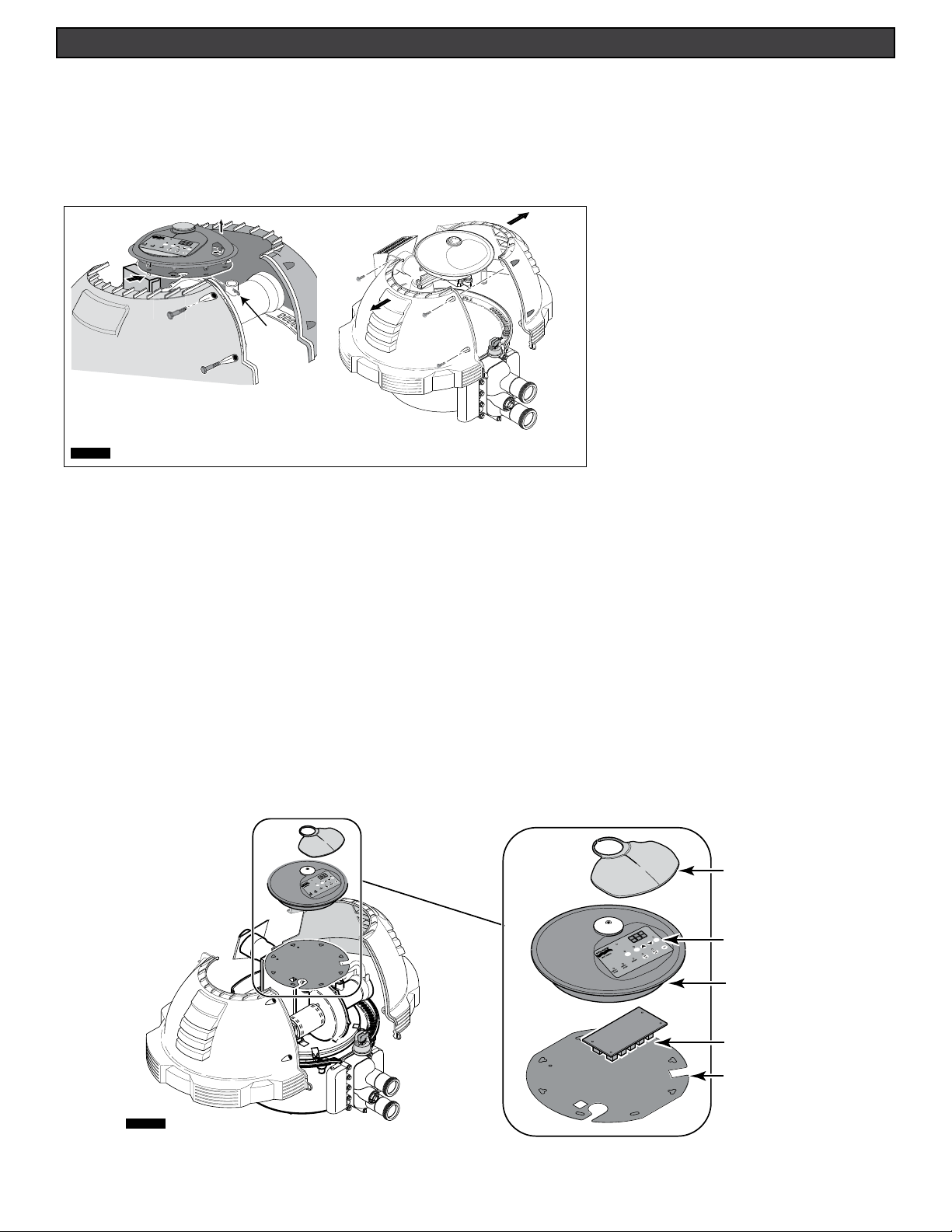

To replace the membrane pad and PCBA on a Sta-Rite Max-E-Therm

1. Unbolt the four bolts and separate the jackets halves. Pull hair pin clips. (Fig. 3).

2. Press the plastic clips on the control panel assembly.

3. Lift control panel assembly off of support plate.

4. Disconnect the connectors from the control panel assembly.

FIG. 3.

Max-E-Therm Heater

5. Disconnect the wire harness from the back of the PCBA.

6. Disconnect the membrane pad from the PCBA.

7. Remove the four (4) screws holding the PCBA and remove the PCBA

8. Peel the membrane pad from the top panel by pulling one of the corners.

9. Route the membrane pad connector through the top panel slot in order to connect it to the control board. Peel off the membrane

backing

10. Align the membrane pad with the bottom of the recess in the lid and press firmly into place. Smooth the membrane pad with your

hand.

11. Place new PCBA into underside of cover and secure with four (4) mounting screws.

12. Reconnect the membrane pad to the PCBA (note the arrow on the membrane connector should be on the bottom)the upper

jackets halves from the heater (Fig. 3).

13. Route the membrane pad connector through the top panel slot to connect to the control board. Peel of the membrane backing.

Align the membrane pad properly onto the area of the top panel.

14. Set the lid assembly aside and continue replacing the ICM and wire harness replacing it with the new Control Board with RS-485

communication. Note: The PCBA is not serviceable.

Control Panel

FIG. 3b

AUX

2

EED

SP

W

LO

PUMP

TER

OS

BO

D

UX

PEE

S

A

IGH

1

H

ER

LT

FI

P

PUM

Heater Display

Cover

AUX

2

D

SPEE

W

LO

P

M

PU

TER

BOOS

D

E

AUX

H SPE

G

1

HI

FILTER

ON

F

F

O

NT

VE

SS

E

PR

B

TA

T

LO

I

P

PUMP

Membrane Pad

(Included with Kit)

Control Board

Enclosure Kit

Control Board

Index Plate

FIG. 4.

4

Page 5

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (USA)

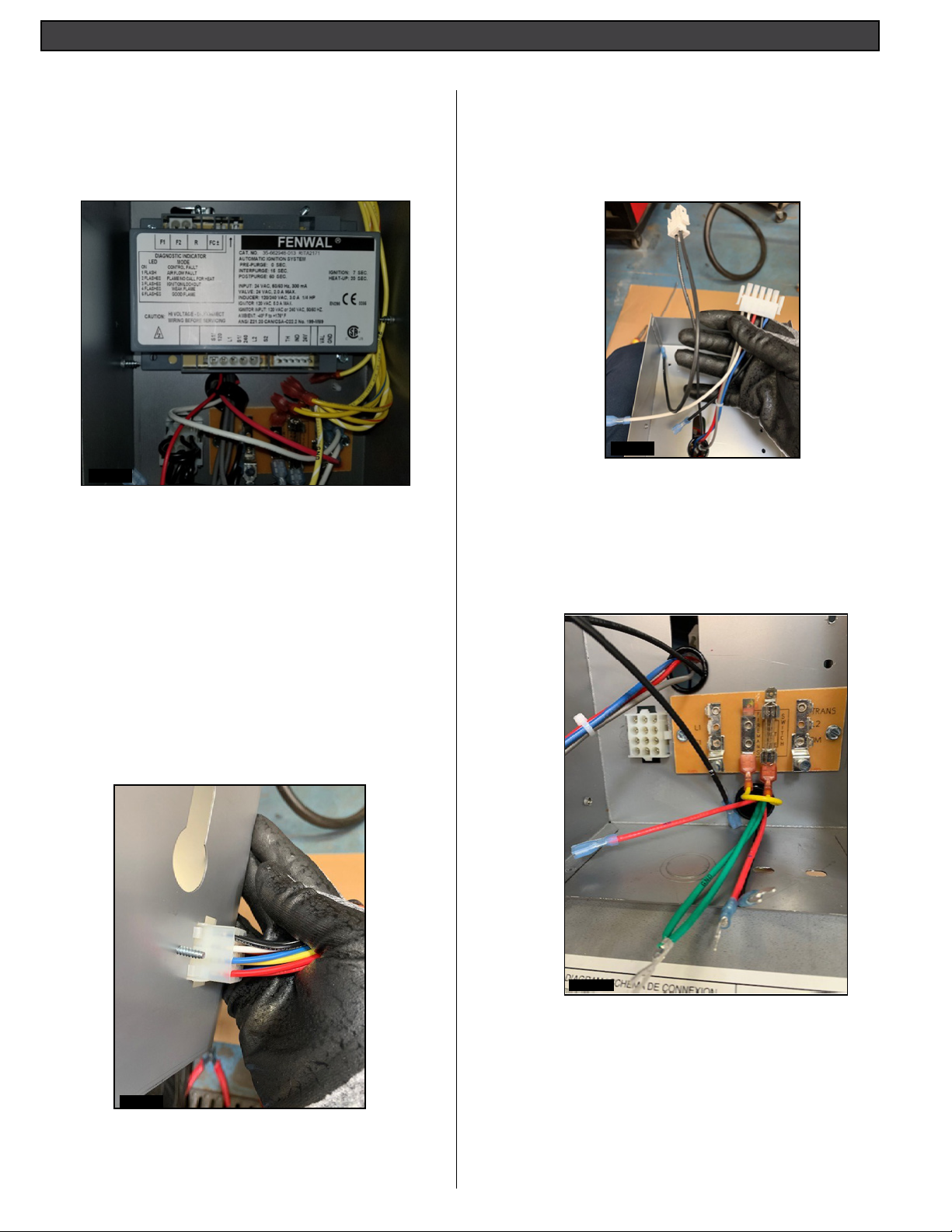

To replace the Ignition Control Module:

1. Disconnect all connector plugs and wires from the legacy

ICM. Remove the screws from the legacy ICM. Remove

ICM from the heater. (Fig. 5).

2. Install the new ICM into the heater Control Box compartment. Secure the unit with the two (2) screws.

FIG. 5.

To replace the wire harness:

- LEGACY WIRE HARNESS (USA) (P/N 42001-0104):

Disconnect all connector plugs and wires from all heater

components. Remove the wire harness from the heater.

- Install wire harness (USA) (P/N 476221):BEFORE

YOU START, LAY OUT THE WIRING HARNESS.

3. Bring the Flat 5-pin plug, 2-pin plug and multi-pin

connector into the control box. Install the bushing in the

hole. Also, bring the Flame current cable into the control

box. (Fig. 7).

FIG. 7.

4. Route the Red and Green wires into the Control Box

through the bottom hole. Plug the Fireman’s jumper into

the terminal board. Install bushing. Be sure the bushings

are install when routing the wires into the Junction box.

(Fig. 8). Note: The plugs are shown in the control box and

the Fireman’s jumper installed.

1. Cut one tie to release two jumpers.

2. Route the 12-pin plug in the control box from the back.

The plug is shown from outside the Control Box. (Fig. 6.)

Note: Narrow key hole in the upper right corner of the

plug.

FIG. 6.

FIG. 8.

5

Page 6

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (USA)

5. Connect BLACK and RED wires to terminal board

connections. Match wire identification with terminal

marking. (Fig. 9).

FIG. 9.

6. From outside the Control Box, push the clip through its

hole in the back of the box. (Fig. 10).

8. Connect the 2-pin connector to F1 / F2 at the upper

right side of the ICM. (Fig. 12)

FIG. 12.

9. Connect 5-pin connector to lower right side of the

ICM and connect multi-pin connector next to 5-pin

connector. (Fig. 13).

FIG. 10.

7. Install the bushing in the top of the control box. Use

(Fig. 11)

FIG. 13.

10. Mount the bundle of wires on the blower. Plug in the

blower motor. (Fig. 14).

FIG. 14.

FIG. 11.

6

Page 7

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (USA)

11. Connect the Stack Flu sensor. (Fig. 15)

FIG. 15.

12. Connect the Gas Valve. (Fig. 16)

14. Connect the Blower assembly. (Fig. 18).

FIG. 18.

15. Plug in the Transformer. (Fig. 19).

FIG. 16.

13. Connect the Air Flow Switch. (Fig. 17).

FIG. 17.

FIG. 19.

16. Route wires (HL, AGS, WP, etc) to the manifold. (Fig. 20).

FIG. 20.

7

Page 8

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (USA)

17. Connect the Thermistor sensor and High Limit Switch.

Note: The Thermistor sensor is located at the top of the

manifold. The High Limit switch is located at the bottom of

the manifold. (Fig. 21).

FIG. 21

18. Connect the Water Pressure Switch and AGS switch.

The AGS is located on the right side. (Fig. 22).

20. Connect one end of the flame cable (Red/Black wires)

to Control Board and the other end to the upper left

side of the ICM. (Fig 24)

FIG. 24.

21. Reassemble the heater control panel assembly. Be sure

that the control panel can be adjusted without having to

lean over the exhaust vent.

22. Replace hair pin clips. See Fig. 2, 3) page 3.

23. Replace jacket halves and bolts and tighten.

FIG. 22.

19. Plug the harness into the back of the circuit board.

(Fig. 23).

FIG. 23.

8

Page 9

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (AUSTRALIA)

When installing this kit, basic safety precautions should always be followed. Read and follow all instructions.

Required installation tools:

• Powered socket/nut driver

• 1/4” nut driver bit

• 5/16” socket and nut driver

• 3/8” nut driver

CAUTION! Before starting: Always disconnect AC power to the heater before proceeding with

the wire harness replacement instructions.

CAUTION!: Before unplugging ICM connector plugs, be sure to match the

wire identication on both the existing and replacement wire harnesses.

To replace the membrane pad PCBA on a MasterTemp

1. MasterTemp Heater: Remove left side panel from the heater (Fig. 1

and Fig. 2).

FIG. 1.

MasterTemp

2. Disconnect the wire harness from the back of the PCBA.

3. Disconnect the membrane pad from the PCBA.

4. Remove the four (4) screws holding the PCBA and remove the PCBA.

5. Peel the membrane pad from the top panel by pulling one of the corners. Set the panel aside.

6. Disconnect the wires from the ICM. Remove the two (2) screws that secure the ICM to the junction box.

7. Route the membrane pad connector through the top panel slot in order to connect it to the control board. Peel off the membrane

pad backing

8. Align the membrane pad with the bottom of the recess in the lid and press firmly into place. Smooth the membrane pad with your

hand.

9. Place new PCBA into underside of cover and secure with four (4) mounting screws.

10. Reconnect the membrane pad to the PCBA (note the arrow on the membrane connector should be on the bottom)the upper jackets

halves from the heater (Fig. 3).

11. Place lid assembly aside and continue with replacing the ICM and Wire Harness.

STD Heater

FIG. 2.

MasterTemp 125 Heater

®

Heater

9

Page 10

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (AUSTRALIA)

F

I

L

T

E

R

PUMP

AUX

1

AUX

2

H

IG

H

SPE

ED

L

OW

S

PE

ED

BOOS

TE

R P

UM

P

Retaining

Pins

To replace the membrane pad and PCBA on a Sta-Rite Max-E-Therm

1. Unbolt the four bolts and separate the jackets halves. Pull hair pin clips. (Fig. 3).

2. Press the plastic clips on the control panel assembly.

3. Lift control panel assembly off of support plate.

4. Disconnect the connectors from the control panel assembly.

FIG. 3.

Max-E-Therm Heater

5. Disconnect the wire harness from the back of the PCBA.

6. Disconnect the membrane pad from the PCBA.

7. Remove the four (4) screws holding the PCBA and remove the PCBA

8. Peel the membrane pad from the top panel by pulling one of the corners.

9. Route the membrane pad connector through the top panel slot in order to connect it to the control board. Peel off the membrane

backing

10. Align the membrane pad with the bottom of the recess in the lid and press firmly into place. Smooth the membrane pad with your

hand.

11. Place new PCBA into underside of cover and secure with four (4) mounting screws.

12. Reconnect the membrane pad to the PCBA (note the arrow on the membrane connector should be on the bottom)the upper

jackets halves from the heater (Fig. 3).

13. Route the membrane pad connector through the top panel slot to connect to the control board. Peel of the membrane backing.

Align the membrane pad properly onto the area of the top panel.

14. Set the lid assembly aside and continue replacing the ICM and wire harness replacing it with the new Control Board with RS-485

communication. Note: The PCBA is not serviceable.

Control Panel

FIG. 3b

AUX

2

EED

SP

W

LO

PUMP

TER

OS

BO

D

UX

PEE

S

A

IGH

1

H

ER

LT

FI

P

PUM

Heater Display

Cover

AUX

2

D

SPEE

W

LO

P

M

PU

TER

BOOS

D

E

AUX

H SPE

G

1

HI

FILTER

ON

F

F

O

NT

VE

SS

E

PR

B

TA

T

LO

I

P

PUMP

Membrane Pad

(Included with Kit)

Control Board

Enclosure Kit

Control Board

Index Plate

FIG. 4.

10

Page 11

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (AUSTRALIA)

To replace the wire harness on a MasterTemp® or Max-E-Therm® Heater:

To replace the Ignition Control Module:

1. Disconnect all connector plugs and wires from the legacy

ICM. Remove the screws from the legacy ICM. Remove

ICM from the heater. (Fig 5.)

2. Install the ICM onto the heater junction box compartment.

Secure the unit with the two (2) screws.

3. Reconnect the membrane pad to the PCBA. Note the

arrow on the membrane connector should be on the

bottom.

2. Place the 12-pin plug in the control box from the back.

The plug is shown from the inside the control box. Note:

narrow key in upper right corner of plug. (Fig. 6.)

FIG. 6.

3. Bring the Flat 5-pin plug, 2 -pin plug into the control box.

Install the bushing. If heater has new Control Board bring

flame current cable as well.

(Fig. 7.)

FIG. 5.

To replace the wire harness:

- LEGACY WIRE HARNESS (USA) (P/N 474163): Discon-

nect all connector plugs and wires from all heater components. Remove the wire harness from the heater.

- Install wire harness (USA) (P/N 476222):BEFORE YOU

START, LAY OUT THE WIRING HARNESS.

1. Cut one tie to release two jumpers.

FIG. 7.

11

Page 12

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (AUSTRALIA)

4. Route the Red and Green wires into the Control Box

through the bottom hole. Plug the Fireman’s jumper into

the terminal board. Install bushing. Be sure the bushings

are install when routing the wires into the Junction box.

(Fig. 8). Note: The plugs are shown in the control box and

the Fireman’s jumper installed.

FIG. 8.

7. From outside the Control Box, push the clip through its

hole in the back of the box. (Fig. 11).

FIG. 11.

5. Install the bushing in the top of the control box. (Fig. 9)

FIG. 9.

6. Connect wires to terminal board connections. Match wire

identification with terminal marking. (Fig. 10)

8. Connect the 2-pin connector to F1 / F2 at the upper

right side of the ICM. (Fig. 12)

FIG. 12.

9. Connect 5-pin connector to lower left side of the ICM.

(Fig. 13).

FIG. 10.

FIG. 13.

12

Page 13

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (AUSTRALIA)

10. Connect S1/240, located on the left side of the 5-pin

connector. (Fig. 14).

FIG. 14.

11. Plug in the transformer. (Fig. 15).

14. Connect the Orange/Yellow wire to IND ¼” tab at ICM.

(Fig. 18)

FIG. 18.

15. Connect the Red/yellow wire to VAL ¼” tab at the ICM,

(Fig. 19)

FIG. 15.

12. Connect the Air Flow sensor. (Fig. 16).

FIG. 16.

13. Connect the Blue/Yellow wire to TH ¼” tab at ICM.

(Fig. 17)

FIG. 19.

16. Connect the White/Yellow wire to GND ¼” tab at the ICM.

(Fig. 20)

FIG. 17.

FIG. 20.

13

Page 14

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (AUSTRALIA)

17. Connect the 24 VAC plug at the upper right side as

shown in Fig. 21.

FIG. 21.

18. Connect the Blower assembly.(Fig. 22).

20. Connect the Thermistor sensor and High Limit Switch. Note:

The Thermistor sensor is located at the top of the manifold.

The High Limit switch is located at the bottom of the manifold.

(Fig. 24).

FIG. 24.

21. Connect the Flu Sensor. (Fig. 25).

FIG. 22.

19. Route wires (HL, AGS, WP, etc) to the manifold. (Fig. 23).

FIG. 23.

FIG. 25.

22. Connect the Gas Valve. (Fig. 26).

FIG. 26.

14

Page 15

RS-485 COMBO CONVERSION REPLACEMENT INSTRUCTIONS (AUSTRALIA)

23. Connect the cables that supply power to the heater. (Fig. 27).

FIG. 27.

24. Connect the Water Pressure Switch and AGS switch.

The AGS is located on the right side. (Fig. 28).

26. Connect one end of the flame cable (Red/Black wires

to Control Board and the other end to the upper left

side of the ICM. (Fig 30).

FIG. 30.

27. Reassemble the heater control panel assembly. Be sure

that the control panel can be adjusted without having to

lean over the exhaust vent.

28. Replace hair pin clips. See Fig. 2, 3) page 3.

29. Replace jacket halves and bolts and tighten.

FIG. 28.

25. Plug the harness into the back of the circuit board.

(Fig. 29).

FIG. 29.

15

Page 16

1620 HAWKINS AVE., SANFORD, NC 27330 • (919) 566-8000

10951 WEST LOS ANGELES AVE., MOORPARK, CA 93021 • (805) 553-5000

Technical Support: 800.831.7133

www.pentair.com

All indicated Pentair trademarks and logos are property of Pentair Inc. or its global aliates in the U.S.A. and/or other countries. Third

party registered and unregistered trademarks and logos are the property of their respective owners

© 2020 Pentair. All rights reserved. This document is subject to change without notice.

* 476251*

P/N 476251.A 9/2020

Loading...

Loading...