Pentair ONGA INTELLIMASTER INJ-4500L 075, ONGA INTELLIMASTER INJ-4500L 022, ONGA INTELLIMASTER INJ-4500L 015 User Quick Manual

Page 1

USER QUICK MANUAL

ONGA

R

Page 2

SAFETY INSTRUCTIONS

Please read the IMPORTANT SAFETY INFORMATION below, and all Warning and

Caution information elsewhere.

Intellimaster series is intended for professional incorporation into complete equipment or systems as part of a fixed

installation. If installed incorrectly it may present a safety hazard. The Intellimaster series uses high voltages and

currents, carries a high level of stored electrical energy, and is used to control mechanical plant that may cause injury.

Close attention is required to system design and electrical installation to avoid hazards in either normal operation or in

the event of equipment malfunction. Only qualified electricians are allowed to install and maintain this product.

System design, installation, commissioning and maintenance must be carried out only by personnel who have the

necessary training and experience. They must carefully read this safety information and the instructions in this Guide

and follow all information regarding transport, storage, installation and use of the Intellimaster series, including the

specified environmental limitations.

Electric shock hazard! Disconnect and ISOLATE the Intellimaster series before attempting any work on it. High

voltages are present at the terminals and within the drive for up to 10 minutes after disconnection of the electrical

supply. Always ensure by using a suitable multimeter that no voltage is present on any drive power terminals prior to

commencing any work.

Where supply to the drive is through a plug and socket connector, do not disconnect until 10 minutes have elapsed

after turning off the supply.

The STOP function does not remove potentially lethal high voltages. ISOLATE the drive and wait 10 minutes before

starting any work on it. Never carry out any work on the Drive, Motor or Motor cable whilst the input power is still applied.

The entry of conductive or flammable foreign bodies should be prevented. Flammable material should not be placed

close to the drive Relative humidity must be less than 95% (non-condensing).

Ensure that the supply voltage, frequency and single phase input correspond to the rating of the Intellimaster as delivered.

Never connect the mains power supply to the Output terminals U, V, W.

Do not install any type of automatic switchgear between the drive and the motor.

The driven motor can start at power up if the enable input signal is present.

Do not perform any flash test or voltage withstand test on the Intellimaster series. Any electrical measurements

required should be carried out with the Intellimaster series disconnected.

Danger : Indicates a risk of electric shock, which,

if not avoided, could result in damage to the

equipment and possible injury or death.

Danger : Indicates a potentially hazardous

situation other than electrical, which if not

avoided, could result in damage to property.

Page 3

DISPLAY

2> LCD Color

1> LCD Display

<Alarm is Red><Stop is Purple><Operation is Blue>

Sensor Alarm

VFD Alarm

Pump Alarm

Parameter 1

Parameter 2

VFD Operation

VFD Stop

Page 4

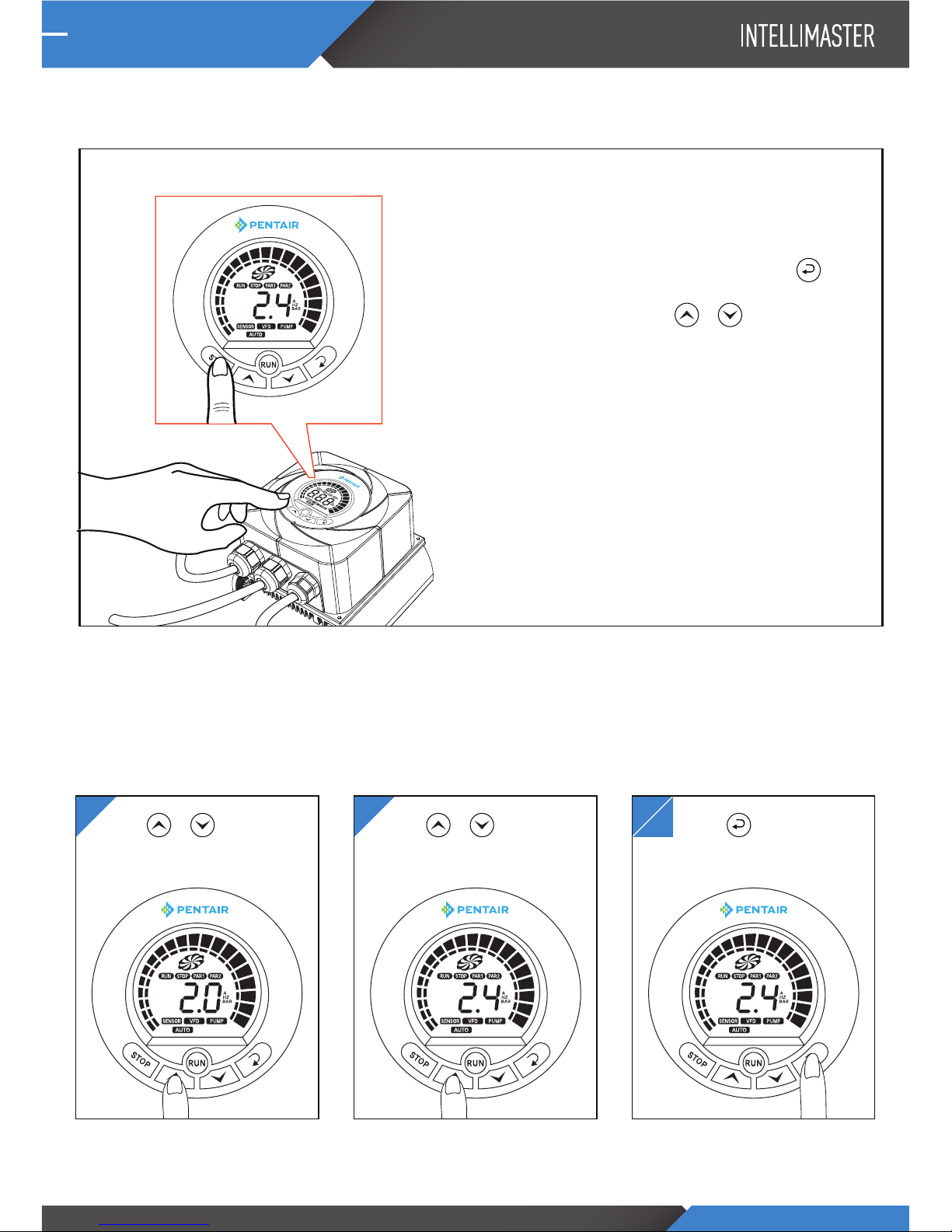

Changing to Constant Speed(MANUAL OPERATION MODE)

• To set to MANUAL OPERATION MODE, press down on

the STOP button for 3 seconds. The AUTO indication will

disappear. In MANUAL OPERATION MODE, press the

and once the indication is on Hz, change the constant speed

required by pressing either the or and press the

run button once the Hz is selected.

Changing to Constant Pressure(AUTO OPERATION MODE)

• To set to AUTO OPERATION MODE, press down on the

STOP button for 3 seconds. The AUTO indication will

appear. In AUTO OPERATION MODE, the pump will operate

according to the set pressure.

*NOTE: THIS IS THE CURRENT DEFAULT SETTING

21

SETTING

1> Switching to Constant Pressure or Constant Speed

2> Setting the pressure

Press or

button for 2 seconds.

Press or

button to set the desired pressure.

3

4

Press button to

complete the pressure setting.

STOP

RUN

Page 5

SETTING PARAMETER

1> Parameter1

Inverter Parameter

2> Parameter2

Booster Parameter

First, stop the inverter, then press the and button stimultaneously.

First, stop the inverter, then press the and button stimultaneously.

50

50

240

25

120

1.5

15

3

3

1

2

150

10

120

60

8

428

5.0 ~ 70.0 Hz

5.0 ~ 70.0 Hz

50 ~ 240 VAC

5.0 ~ 70.0 Hz

3 ~ 220 VAC

0.1 ~ 20.0 Hz

3 ~ 100 VAC

3.0 ~ 99.9 Sec

3.0 ~ 99.9 Sec

0 : Deceleration to stop

1 : Coast to stop

0 : 1 HP (3.1A)

1 : 1.5 HP (4.3A)

50 ~ 200 %

2.0 ~ 99.9 Sec

100 ~ 200 %

50 ~ 90 %

3.0 ~ 15.0 Hz

444 - Reset setting

422 - Reset for 220VAC

424 – Reset for 240VAC

Max Frequency

Max Voltage Frequency

Max Voltage

Mid-Point Frequency

Mid-Point Voltage

Min Frequency

Min Voltage

ACC Time

DEC Time

Stop Mode

Pump HP

Overload Rate

Overload Time

Over-Voltage application Rate

Low-Voltage application Rate

Carrier Frequency

TEST

Version information

P 00

P 01

P 02

P 03

P 04

P 05

P 06

P 07

P 08

P 09

P 10

P 11

P 12

P 13

P 14

P 15

P 16

0.3 ~ 6.0 Bar

-3.0 ~ -0.2 Bar

1.0 ~ 16.0 Bar

-9.9 ~ 9.9 Bar

0.2 ~ 2.0 Bar

0 : Not use

1 ~ 999 Sec

0.5 ~ 5.0 A

0 : Not use

1 ~ 999 Sec

0 : CW 1 : CCW

1 ~ 200

1 ~ 200

1 ~ 200

0 ~ 20 ( OC,OL,OV,LV inverter err only)

0:Stop, 1:Run, 2:Last Key state

1, XX

Set Press

Run deviation

Sensor type

Sensor Adjust

Low press

Stop Time of

Low press

Low Current

Stop Time of

Low Current

Pump Direction

P

I

D

Auto Reset

The initial operation status

3.5

-0.5

16

0

0.5

20

3.3

10

0

25

40

40

5

2

-

-

-

Version information

B 00

B 01

B 02

B 03

B 04

B 05

B 06

B 07

B 08

B 09

B 10

B 11

B 12

B 13

B 14

B 15

B 16

B 17

P 17

Display Description Value Default (240V)

Display Description Value Default (240V)

Page 6

SPECIFICATION

Model Number 075 015 022

Insulation Class IP55

2Phase(2line)220/240V(±10%), 50/60Hz(±5%)

3Phase220/240V

PWM Type

0~120Hz

V/F Control (Regular Torque, Low Deceleration Torque)

150% of rated current for 1 minute

0.1~60 seconds (Independent settings for Accel/Decel Time)

0.1-25kg/cm

2

RESS-SEN (4-20mA Pressure Transmitter) , 1-5V voltage type(option)

Over-Current, Over Voltage, Under Voltage, Overheating, Overload, Low Pressure,

High Pressure, Water Low Level

PID Control, Auto Restart, Alarm Auto Reset, RS-485 Communication

Max. Applicable

Motor Output

KW

HP

0.75 1.1

1 2

3

2.2

3

5 7 10

Max linkage inverter

Rated Input AC Voltage

Rated Output Voltage (V)

Rated Output Current (A)

Control System

Output Frequency Range

Torque Characteristics

Overload Endurance

Accel/Decel Time

Pressure sensor Range

Analog Input Signal

Protections

Other Functions

Heat Sink

2.5kg

Cooling Methods

Weight (kg)

INJ-4500L

Page 7

ALARM LOG & CONFIRMATION

Alarm Log (Max 20 logs)

In Main display, Press the

and

button longer and together.

Over current

Low voltage

Over voltage

Over load

Fail

communication

Error of sensor

Stop for

low current

Low Pressure

Over-current on the inverter/

Abnormal operation of the motor/

Short of the motor’s output line

Low-voltage on the inverter

Over-voltage on the inverter,

when excessive voltage is

inputted to the inverter

Overload on the inverter/

Abnormal operation of the

motor/pump

Master and slave are

communication fail

Sensor fail to connect

When the water level

of the tank is low/

When air enters the pumps

When the pressure drops

below the set “Low press’

If problem repeats/

Check the pump/motor

Check the input voltage

Check the input voltage

Check the pump/motor

Check communication line

Check the connection

of the sensor/

Change the sensor

Check the tank/

Remove air from the pump

Lower the “Low press”/

Adjust the setting

for pump operation

AlarmDisplay Reason Countermeasures

Page 8

NOTES

Page 9

NOTES

Page 10

NOTES

Page 11

NOTES

Page 12

Loading...

Loading...