Page 1

SPECTRACOOL

Air Conditioner, HAzArdous LoCAtions

nHz28 ModeL

INSTRUCTION MANUAL

Rev. F

© 2015 Pentair Equipment Protection 89117141

P/N 89117141

Page 2

TABLE OF CONTENTS

General Safety Information ............................................................................................................................................................................... 3

Receiving the Air Conditioner ........................................................................................................................................................................... 3

Handling and Testing the Air Conditioner ........................................................................................................................................................ 4

How to Read Model Numbers ........................................................................................................................................................................... 4

Technical Information ........................................................................................................................................................................................ 4

General ....................................................................................................................................................................................................................4

Sequence of Operation ............................................................................................................................................................................................4

Cooling .............................................................................................................................................................................................................4

Standard and Optional Component Operation .......................................................................................................................................................5

SMART CONTROLLER ....................................................................................................................................................................................5

For cooling (75-100 F range) ..........................................................................................................................................................................5

Remote Access Control (optional) ..................................................................................................................................................................5

Head Pressure Control (optional) ...................................................................................................................................................................5

115V/230V to 10V Transformer (optional) ......................................................................................................................................................5

Door Switch .............................................................................................................................................................................................................5

Active Condensate Management ............................................................................................................................................................................5

When Used With Purge and Pressurized Enclosures ...........................................................................................................................................5

Schematics and Wiring Diagrams ..........................................................................................................................................................................6

Generic 115V Schematic (actual unit options may vary) ...............................................................................................................................6

Generic 230V Schematic (actual unit options may vary) ...............................................................................................................................6

Generic 460V Schematic (actual unit options may vary) ...............................................................................................................................7

Generic 115V Wire Diagram (actual unit options may vary) ..........................................................................................................................8

Generic 230V Wire Diagram (actual unit options may vary) ..........................................................................................................................9

Dimensional Drawing ...................................................................................................................................................................................... 11

General Safety Information ............................................................................................................................................................................. 12

Installation Instructions .................................................................................................................................................................................. 12

Smart Controller ............................................................................................................................................................................................. 14

Remote Access Control ................................................................................................................................................................................... 17

Remote Access Control Pin-out ...................................................................................................................................................................... 20

General Safety Information ............................................................................................................................................................................. 20

Maintenance .................................................................................................................................................................................................... 21

Service Data ..................................................................................................................................................................................................... 24

Trouble Shooting .............................................................................................................................................................................................. 28

Warranty .......................................................................................................................................................................................................... 30

Generic 460V Wire Diagram (actual unit options may vary) ........................................................................................................................10

Introduction ...........................................................................................................................................................................................................14

Energizing the Controller .....................................................................................................................................................................................14

Control Status Indication ......................................................................................................................................................................................14

Displaying and Changing Program Variables ......................................................................................................................................................15

Operating Parameters ..........................................................................................................................................................................................15

Alarm Parameters ................................................................................................................................................................................................15

Displaying Temperature Sensor #2 ......................................................................................................................................................................15

Compressor Restart Time Delay ..........................................................................................................................................................................15

Alarm Output Contact ...........................................................................................................................................................................................15

Alarm Input Connection ........................................................................................................................................................................................16

Alarm Condition Display .......................................................................................................................................................................................16

Air Conditioner Unit Communication Features ...................................................................................................................................................17

USB Communication.....................................................................................................................................................................................17

Ethernet Communication .............................................................................................................................................................................17

Using the PC Interface Tool ..................................................................................................................................................................................18

USB COMMUNICATION MODE .....................................................................................................................................................................18

Ethernet Communication Mode ...................................................................................................................................................................19

Compressor ...........................................................................................................................................................................................................21

Inlet Air Filter ........................................................................................................................................................................................................21

How To Remove, Clean or Install a New Inlet Air Filter ......................................................................................................................................21

Condensate Management and Drain Trap Maintenance .....................................................................................................................................21

Condenser and Evaporator Air Movers ................................................................................................................................................................22

Refrigerant Loss....................................................................................................................................................................................................22

Refrigerant Properties Chart (R134a) ..................................................................................................................................................................22

Unit Characteristics ..............................................................................................................................................................................................23

Functional Data .....................................................................................................................................................................................................23

Components List ...................................................................................................................................................................................................24

NHZ280416GXXX Pressure Tables ........................................................................................................................................................................25

NHZ280426GXXX Pressure Tables ........................................................................................................................................................................26

Basic Air Conditioning Trouble Shooting Check List - SMART CONTROLLER ...................................................................................................28

Symptoms and Possible Causes - Remote Access Control Version ...................................................................................................................29

Return and Repair Policy ......................................................................................................................................................................................30

Limitation of Liability ............................................................................................................................................................................................31

- 2 -

© 2015 Pentair Equipment Protection

89117141

Page 3

GENERAL SAFETY INFORMATION

Please observe the following general safety instructions when assembling and operating the unit:

• Assembling, installing and servicing must only be performed by properly trained specialists.

• When transporting the enclosure with the cooling unit externally mounted, always use an additional shipping brace

to support the cooling unit.

• Do not attempt to operate the air conditioner while it is horizontal or on its side, back or front.

• Operation of air conditioner in areas containing airborne caustics or chemicals can rapidly degrade sealing

properties of materials, deteriorate filters, refrigeration coils, blowers and motors. Contact Pentair Equipment

Protection for special recommendations. See Maintenance on page 21.

DANGER

Danger: explosion hazard - do not energize, disconnect, or troubleshoot equipment

unless power has been switched off or the area is known to be non-hazardous.

Unit to be installed and maintained by properly trained personnel only.

Danger : Risque d’explosion – Ne pas alimenter, déconnecter ni dépanner

l’équipement si l’alimentation n’a pas été coupée ou si la zone n’est pas reconnue

comme non dangereuse.

RECEIVING THE AIR CONDITIONER

Inspect the air conditioner. Check for concealed damage that may have occurred during shipment. Look for dents,

scratches, loose assemblies, evidence of oil, etc. Damage evident upon receipt should be noted on the freight bill.

Damage should be brought to the attention of the delivering carrier -- NOT to Pentair Equipment Protection -within 15 days of delivery. Save the carton and packing material and request an inspection. Then file a claim with

the delivering carrier.

Pentair Equipment Protection cannot accept responsibility for freight damages; however, we will assist you in any

way possible.

CAUTION

This air conditioner is suitable for use in Class 1, Division 2, Groups A,B,C, D T4A hazardous locations,

or non-hazardous locations only. It is meant to be installed in an enclosure such that the field wiring and

controls are only accessible with the use of a tool.

Do not attempt to operate the air conditioner while it is horizontal or on its side, back or front. The

refrigeration compressor is filled with lubricating oil. This will cause permanent damage to the air

conditioner and also voids the warranty.

Ce climatiseur peut être utilisé dans des zones dangereuses de Classe 1, Division 2, Groupes A, B, C, D

T4A ou des zones non dangereuses uniquement. L’installation doit être effectuée dans une armoire de telle

sorte que le câblage et les commandes sur le terrain ne soient accessibles qu’à l’aide d’un outil.

Ne pas essayer de faire fonctionner le climatiseur en position horizontale, ou posé sur le côté, l’arrière ou

l’avant. Le compresseur de réfrigération est rempli d’huile lubrifiante. Cela endommagerait le climatiseur

de manière permanente et annulerait la garantie.

MISE EN GARDE

89117141

© 2015 Pentair Equipment Protection

- 3 -

Page 4

HANDLING AND TESTING THE AIR CONDITIONER

If the air conditioner has been in a horizontal position, be certain it is placed in an upright, vertical or mounting

position for a minimum of five (5) minutes before operating.

TEST FOR FUNCTIONALITY BEFORE MOUNTING THE AIR CONDITIONER TO THE ENCLOSURE.

Refer to the nameplate for proper electrical current requirements, and then wire the unit to a properly grounded

power supply using copper conductors only. Power supply wiring should be restrained after field installation to

ensure no contact with internal fan. Minimum circuit ampacity should be at least 125% of the amperage shown on

the unit nameplate. No other equipment should be connected to this circuit to prevent overloading

Immediately after applying power, the evaporator blower (enclosure air) should start running. Operate the

air conditioner with the compressor running for five (5) to ten (10) minutes. You will need to set the cooling

thermostat or controller setpoint below the ambient temperature to operate the compressor.

Condenser air temperatures should be warmer than normal room temperatures within a few minutes after the

condenser impellers start.

See Sequence of Operation on page 4 for specifics on how the unit operates when powered up.

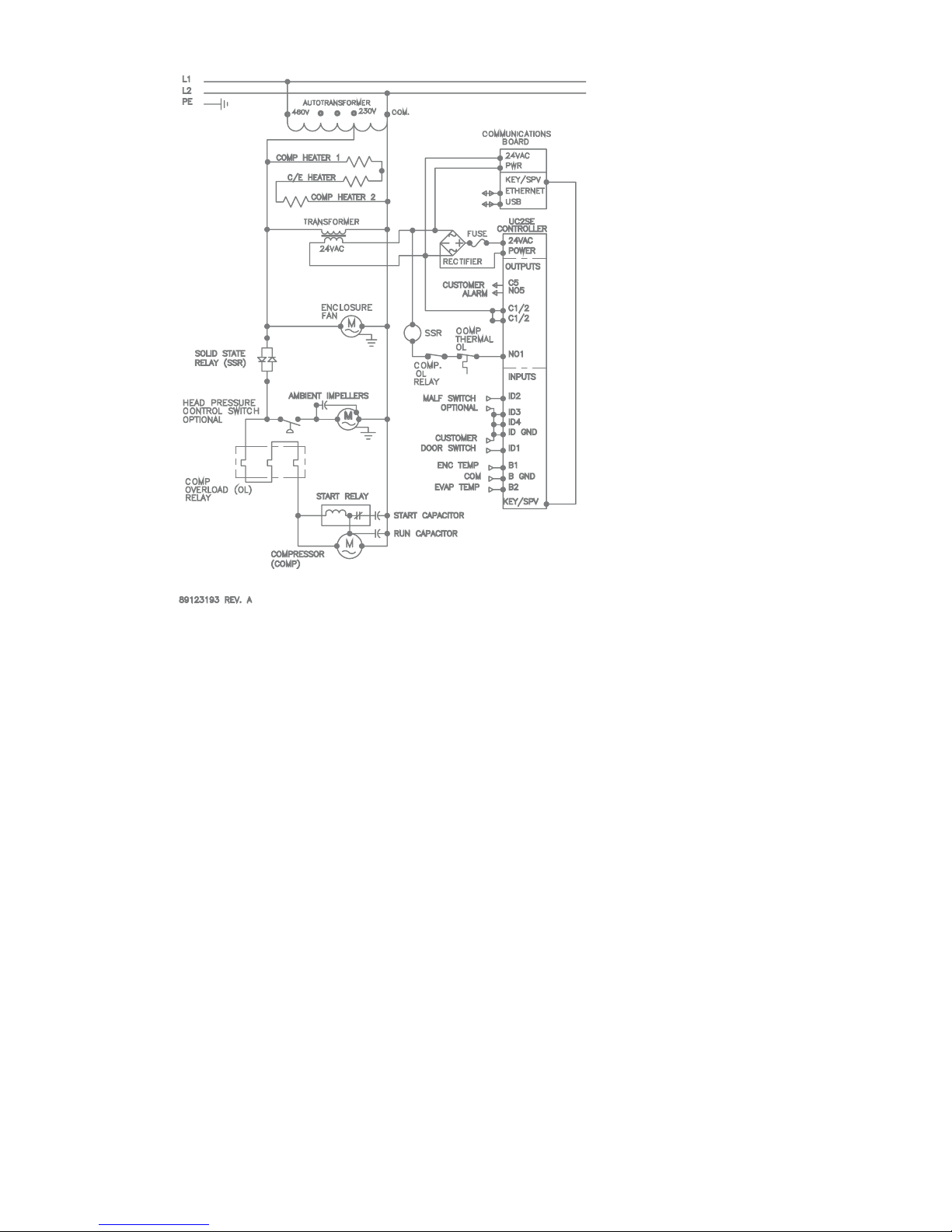

HOW TO READ MODEL NUMBERS

NHZ28 04 2 6 G300

1 2 3 4 5

1. Identifies the type/family of air conditioner and the approximate height (i.e. NHZ28 = Narrow

Hazardous Location family about 28 inches high).

2. This is the air conditioner’s listed capacity in BTU/Hr. at rated conditions. (i.e. 06=6,000 BTU/Hr. at

131/131 F)

3. 1 = 115 Volt, 2 = 230 Volt, 4 = 460 Volt.

4. 6 = 50/60 Hz or 60 Hz only.

5. Unique set of numbers for each air conditioner which identifies the accessories on a model.

TECHNICAL INFORMATION

GENERAL

Sensor 2 monitors the enclosure return air temperature to prevent ice buildup on the evaporator coil. If the air

temperature drops below -1 C, the compressor and condenser air mover(s) shut off. They turn back on when the

temperature rises above 15 C.

The compressor and the air movers are equipped with overload protection to guard against excess current and

temperatures.

SEQUENCE OF OPERATION

The air conditioner comes standard with smart controller. During cooling modes, the evaporator fan will be

running.

COOLING

When the enclosure temperature is above the cooling set-point plus the cooling differential, the smart

controller will call for cooling. The compressor is then energized through a solid state relay or contactor.

The condenser impellers will start immediately if the unit is not equipped with an optional head pressure

control switch. If the unit is equipped with an optional head pressure control switch, the condenser

impellers will start once the refrigerant pressure reaches the pressure setting of the switch. Component

specific information is listed below.

Operating the air conditioner below the minimum ambient temperature or above the maximum ambient

temperatures indicated on the nameplate voids all warranties. DO NOT adjust cooling set-point to a

temperature lower than 70 F. Doing so can increase the likelihood of frost buildup on the evaporator coil.

The moisture that the enclosure air can contain is limited. If moisture flows from the drain tube

continuously this can only mean that ambient air is entering the enclosure. Be aware that frequent

opening of the enclosure’s door admits humid air that the air conditioner must then dehumidify.

- 4 -

© 2015 Pentair Equipment Protection

89117141

Page 5

STANDARD AND OPTIONAL COMPONENT OPERATION

SMART CONTROLLER

The standard NHZ28 air conditioner uses our standard smart controller. The setpoint equals the

temperature that the air conditioner turns off. The controller has a 7 F differential from setpoint until it

calls for cooling. An example of operation is shown below.

FOR COOLING (75100 F RANGE)

• Thermostat setpoint = 80 F

• Cooling turns on at 87 F

• Cooling turns off at 80 F

REMOTE ACCESS CONTROL (OPTIONAL)

See Remote Access Control on page 17

HEAD PRESSURE CONTROL (OPTIONAL)

Unit is set at the factory, no adjustment necessary.

At a saturated condenser temperature of 85 F (95 psig), the condenser fans will power off. At a saturated

condenser temperature of 117 F (165 psig), the condenser fans will power on.

115V/230V TO 10V TRANSFORMER (OPTIONAL)

This transformer powers the thermal display.

DOOR SWITCH

Several door switches may be connected in series and operated on one cooling unit. The door switch only

supports a floating connection,no external voltages. Remove jumper from terminals 3 and 4 of the connector and

connect the door switch to the two terminals if a door switch is available.

ACTIVE CONDENSATE MANAGEMENT

At low temperatures and high humidity levels inside the enclosure, condensation may form on the evaporator coil.

The air conditioner will continuously evaporate the water that may be in the drain pan due to condensation from

the evaporator coil into the external air stream. Excess condensate is routed downwards out of the air conditioner

via a tube fitting at the bottom of the condenser side of the unit. A 10 mm inside diameter tube can be attached to

the fitting and routed to a nearby drain.

WHEN USED WITH PURGE AND PRESSURIZED ENCLOSURES

This air conditioner will operate safely in a Class 1 Division 2 Groups A, B, C and D hazardous location on both

exterior and interior sides. It does not require a purge and pressurized enclosure, but if it is to be installed on one,

the following should be considered.

The active condensate management system functionally described above is possible due to a drain trap directly

connecting and routing condensation from the evaporator coil pan to the ambient side where it collects in the

condensate evaporator pan.

During initial purging of an enclosure or after long periods of operation in a pressurized system utilizing a dry

protective and/or inert gas supply, the drain trap can eventually dry out and allow a small amount of protective

gas to leak outward of the enclosure through the drain trap. A leakage should not immediately be associated with

a hazardous condition. If continuous positive pressure is maintained inside an enclosure, the protective gas will

leak out to ambient and prevent hazardous gasses from entering. A typical enclosure pressurization system can

compensate for this and maintain proper enclosure pressure.

If the pressurization system cannot compensate for the additional leakage, a drain trap seal can be created by

priming the air conditioner drain. This can be done by de-energizing and opening the enclosure for access to the

evaporator coil, and carefully pouring clean water (approx. 1 cup) into the face of the coil. With water present, the

drain trap should be fully primed and sealed. Opening the enclosure can also introduce humidity back into the

enclosure which will eventually condense on the evaporator coil and become part of the seal in the drain trap.

89117141

© 2015 Pentair Equipment Protection

- 5 -

Page 6

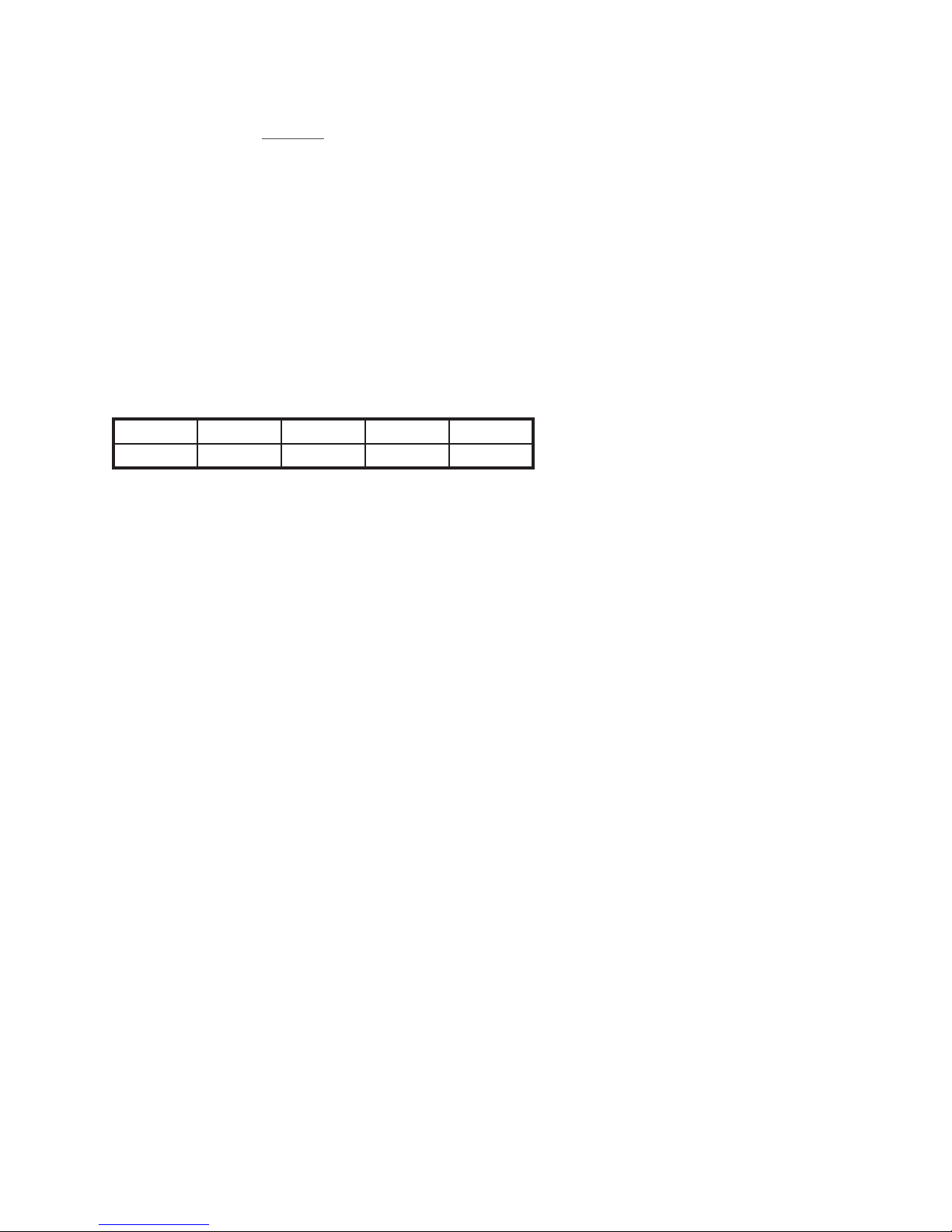

SCHEMATICS AND WIRING DIAGRAMS

GENERIC 115V SCHEMATIC (ACTUAL UNIT OPTIONS MAY VARY)

GENERIC 230V SCHEMATIC (ACTUAL UNIT OPTIONS MAY VARY)

- 6 -

© 2015 Pentair Equipment Protection

89117141

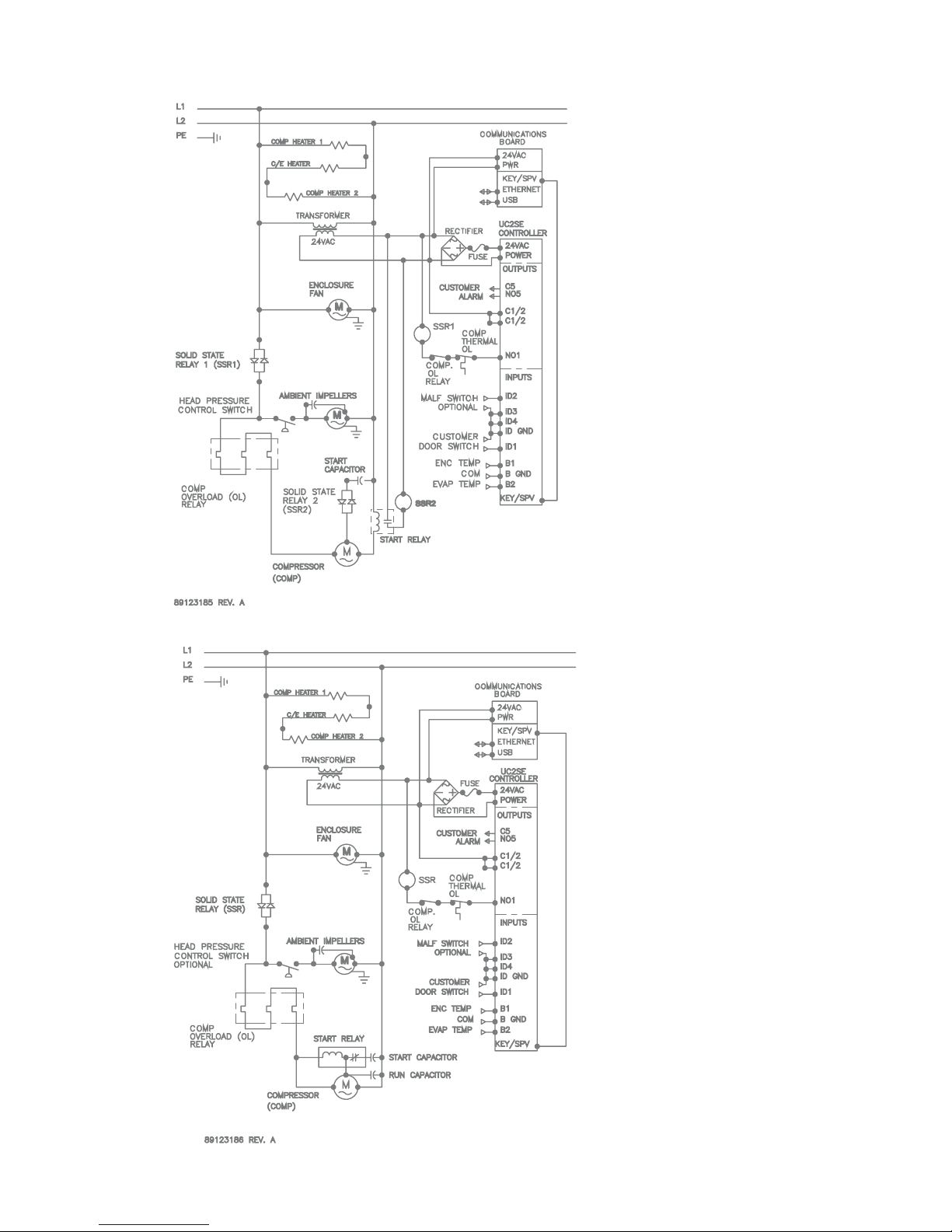

Page 7

GENERIC 460V SCHEMATIC (ACTUAL UNIT OPTIONS MAY VARY)

89117141

© 2015 Pentair Equipment Protection

- 7 -

Page 8

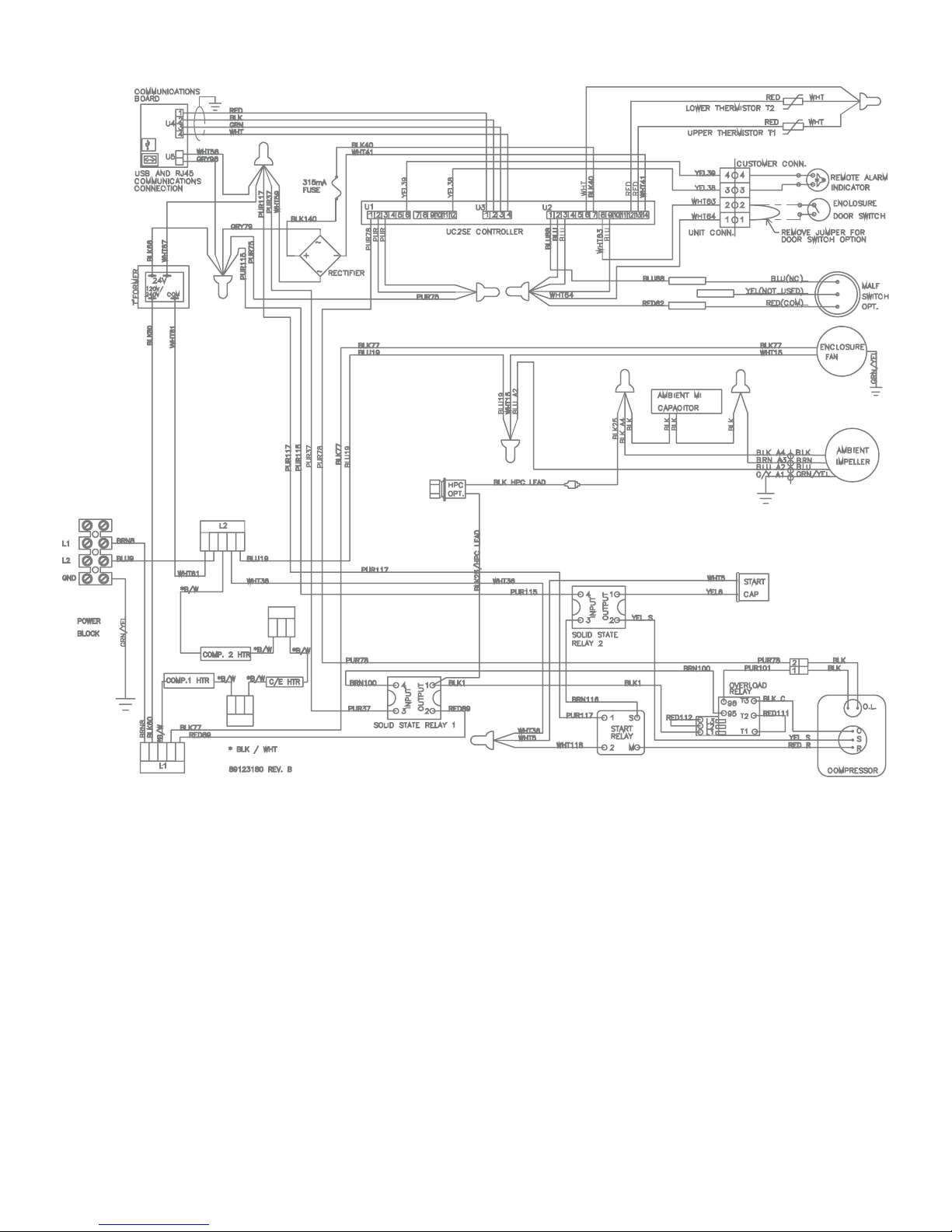

GENERIC 115V WIRE DIAGRAM (ACTUAL UNIT OPTIONS MAY VARY)

- 8 -

© 2015 Pentair Equipment Protection

89117141

Page 9

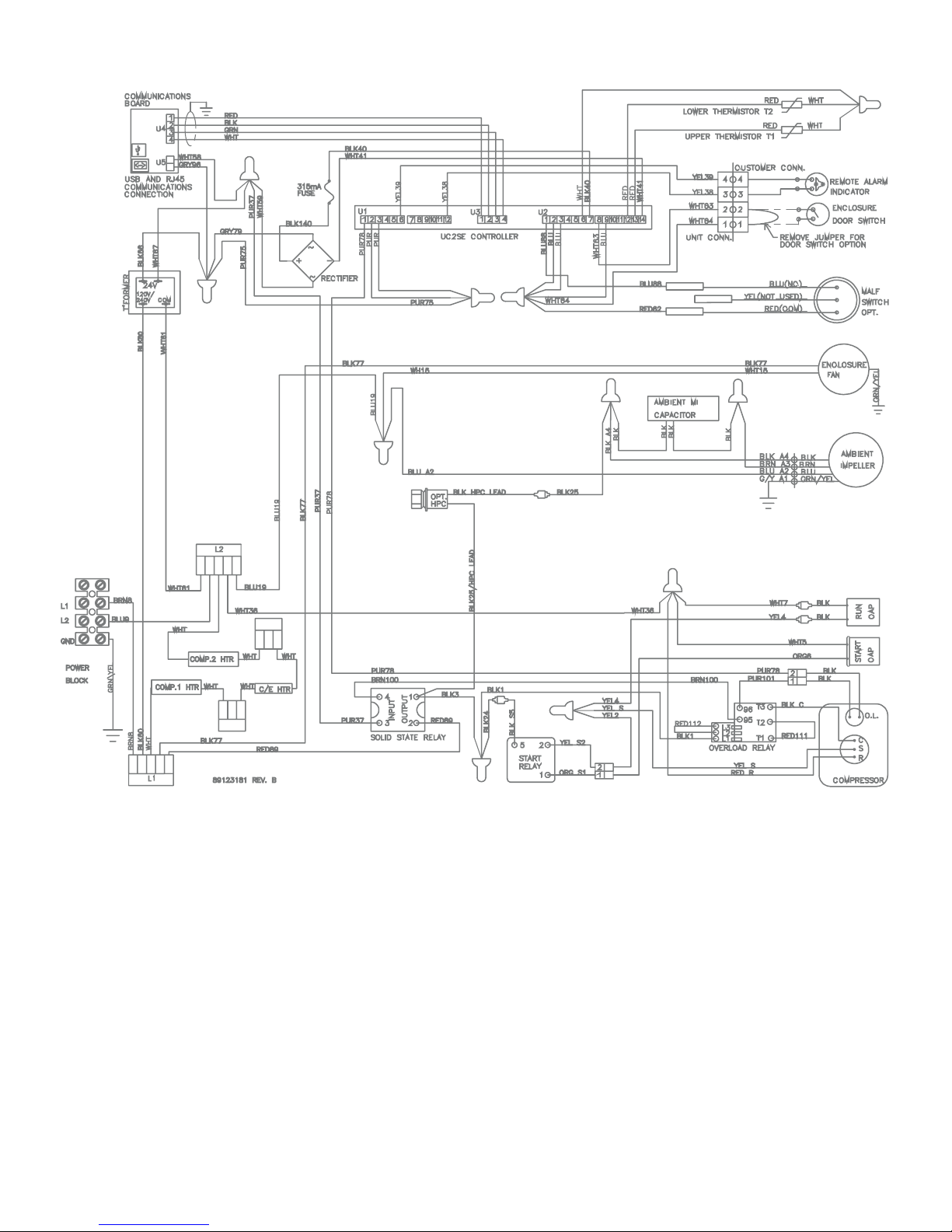

GENERIC 230V WIRE DIAGRAM (ACTUAL UNIT OPTIONS MAY VARY)

89117141

© 2015 Pentair Equipment Protection

- 9 -

Page 10

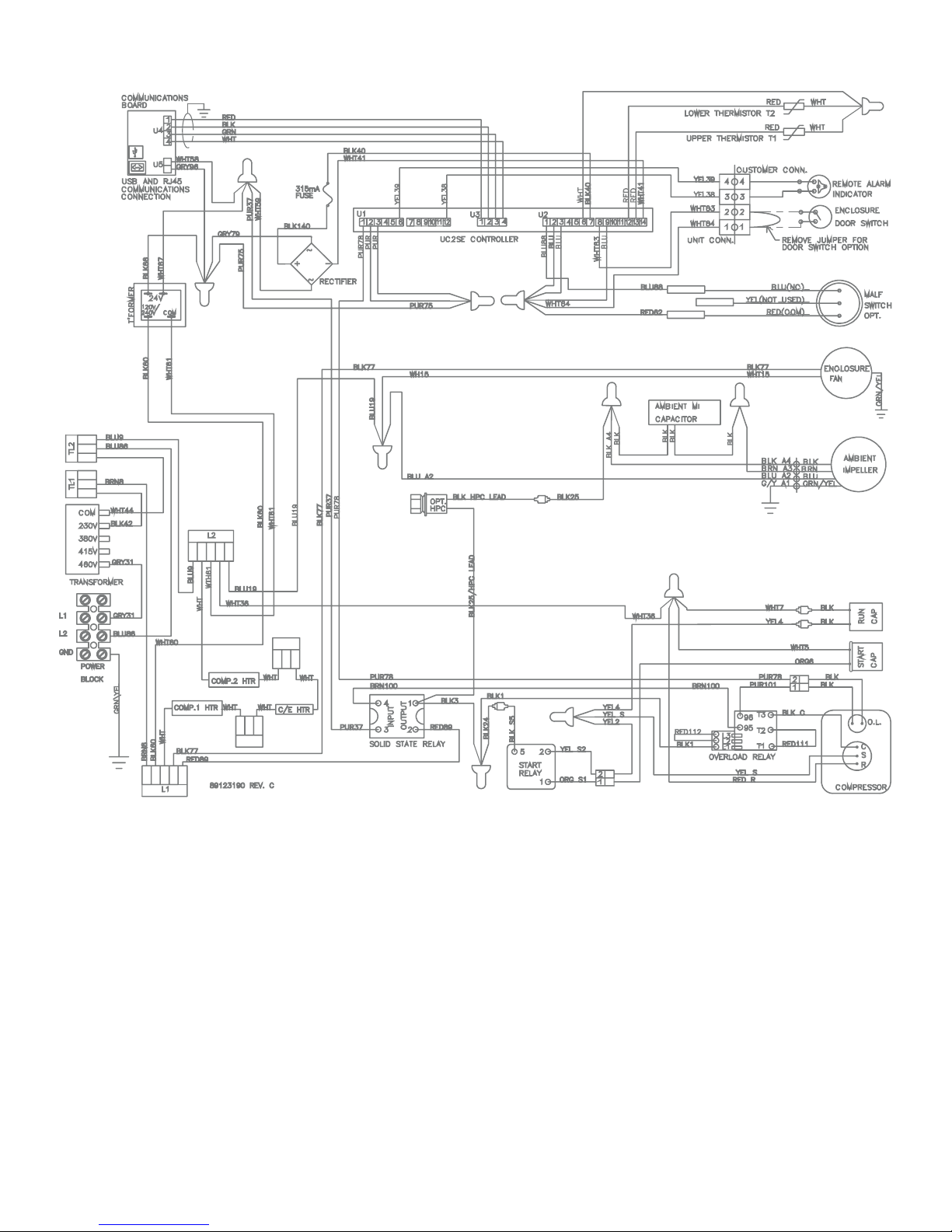

GENERIC 460V WIRE DIAGRAM (ACTUAL UNIT OPTIONS MAY VARY)

- 10 -

© 2015 Pentair Equipment Protection

89117141

Page 11

DIMENSIONAL DRAWING

AIR IN

AIR IN

CONTROLLER

CONNECTOR

CONTROLLER

COOL

89117141

© 2015 Pentair Equipment Protection

- 11 -

Page 12

GENERAL SAFETY INFORMATION

Please observe the following general safety instructions when assembling and operating the unit:

• Assembling, installing and servicing must only be performed by properly trained specialists.

• When transporting the enclosure with the cooling unit externally mounted, always use an additional shipping brace

to support the cooling unit.

• Do not attempt to operate the air conditioner while it is horizontal or on its side, back or front.

• Operation of air conditioner in areas containing airborne caustics or chemicals can rapidly degrade sealing

properties of materials, deteriorate filters, refrigeration coils, blowers and motors. Contact Pentair Equipment

Protection for special recommendations. See Maintenance on page 21.

DANGER

Danger: explosion hazard - do not energize, disconnect, or troubleshoot equipment

unless power has been switched off or the area is known to be non-hazardous.

Unit to be installed and maintained by properly trained personnel only.

Danger: Risque d’explosion – Ne pas alimenter, déconnecter ni dépanner

l’équipement si l’alimentation n’a pas été coupée ou si la zone n’est pas reconnue

comme non dangereuse.

INSTALLATION INSTRUCTIONS

1. Refer to nameplate for hazardous location rating.

2. Install a suitable switch to de-energize the air conditioner for repairs or remove the fuse.

3. Inspect the air conditioner and verify correct functionality before mounting the air conditioner. See

Handling and Testing the Air Conditioner on page 4.

4. Using the mounting gasket kit provided with the unit, install gaskets to the air conditioner.

5. When considering a location for the unit, it is recommended that a six (6) inch clearance be

maintained on at least one side of the air conditioner. It is also recommended that twenty (20)

inches of clearance be allowed from the front of the unit for cover removal.

6. Figure 1 and the cutout template included with the unit will assist in preparing the enclosure for

installation of the unit. NOTE: Mount the unit within 3° from vertical.

7. Mount air conditioner on enclosure taking care not to damage the mounting gasket. The

mounting gasket is the seal between the air conditioner and the enclosure. Avoid dragging the air

conditioner on the enclosure with the mounting gasket attached as this could cause rips or tears

in the gasket and risk losing the water tight seal.

8. Allow unit to remain upright for a minimum of five (5) minutes before starting. CAUTION! Air

conditioner must be in upright position during operation.

9. Refer to the nameplate for electrical requirements. Wire the unit to a properly grounded power

supply. Electrical circuit should be fused with slow blow or HACR circuit breaker.

10. Adjust the controller to the desired cabinet temperature. Refer to Displaying and Changing

Program Variables on page 15 for controller adjustments and operation.

The unit is meant to be installed in an enclosure suitable for the environment listed previously and such that

the field wiring and controls are only accessible with the use of a tool.

When installed on an enclosure, only the front/face side, ambient air in, and ambient air out can be exposed

to the environment.

L’unité doit être installée dans une armoire adaptée à l’environnement susmentionné et de telle sorte que

le câblage et les commandes sur le terrain ne soient accessibles qu’à l’aide d’un outil.

Lors d’une installation sur une armoire, seule la face avant/latérale, l’entrée d’air ambiant et la sortie d’air

ambiant peuvent être exposées à l’environnement.

- 12 -

CAUTION

© 2015 Pentair Equipment Protection

MISE EN GARDE

89117141

Page 13

Surface Mount

Figure 1

Cut-out Drawing

89117141

© 2015 Pentair Equipment Protection

- 13 -

Page 14

SMART CONTROLLER

INTRODUCTION

The smart controller is a parametric controller for the complete management of air conditioners. All settings are

pre-programmed at the factory. Cooling set-points, cooling differential and high/low temperature alarm setpoints can be adjusted by the user. Alarms are outputted through a relay contact.

ENERGIZING THE CONTROLLER

The controller is wired and programmed at the factory to be energized when power is supplied to the air

conditioner.

CONTROL STATUS INDICATION

The display has numerous symbols that indicate if the controller is cooling or alarming, if the compressor is

enabled, and if the ambient fan is enabled. The 3 alpha-numeric characters further describe alarms and show the

cabinet temperature by default.

SYMBOL COLOR ICON ON ICON FLASHING

1 AMBER Compressor On Start-up Request

2,3,4 AMBER Not Used Not Used

A AMBER Compressor On Not Used

B AMBER Evaporator Fan On Not Used

C AMBER Not Used Not Used

D AMBER Not Used Not Used

E AMBER Heater Active Not Used

F RED Alarm Active Not Used

G AMBER Controller Active Not Used

H AMBER Not Used Not Used

- 14 -

© 2015 Pentair Equipment Protection

89117141

Page 15

DISPLAYING AND CHANGING PROGRAM VARIABLES

Access: To view and/or change parameters, press and hold the Prg and Sel buttons for greater than 5 seconds.

Press the up or down arrow buttons until “22” is displayed, then press Sel button. When “S-P” is displayed, press

Sel.

Navigation: Press up or down arrows to display sub-menus then press Sel to select the desired sub-menu. In the

sub-menu, use up or down arrows to display parameters for viewing or changing and press Sel. Use Prg button to

back out of menu levels as desired.

Adjust: Use the up or down arrows to change the parameter value then push Sel to save that setting. If Sel is not

pressed, the change to the value will not be saved. Navigate to and change other parameters as desired. When

finished, push Prg to back out of the sub-menus to the main menu.

NOTE: The display will revert to normal temperature display mode if no buttons are pressed

for 60 seconds.

OPERATING PARAMETERS

Parameter Default Value Range Description

r01 80 F 72 F to 120 F Cooling set-point

r02 7 F - Cooling differential

A04 50 F* 32 F to 60 F Heating set-point*

A05 7 F* - Heating differential*

Cooling turns on at r01 + r02, and off at r01

Heating turns on at A04, and off at A04 + A05

*Functional only on units with heater option

ALARM PARAMETERS

Parameter Default Value Description

P16 125 F High Temperature Alarm

P19 40 F Low Temperature Alarm

DISPLAYING TEMPERATURE SENSOR #2

Sensor number 2, the air outlet or condenser coil sensor, can be viewed at any time by pressing the up or down

arrow button on the front panel of the controller display. The display will revert to displaying temperature sensor

number 1 (the AC inlet temperature) after 60 seconds. Both sensors can also be read through the Ethernet and

USB connections.

COMPRESSOR RESTART TIME DELAY

A factory set 6 minute (360 second) restart delay exists to reduce residual back pressure before allowing the

compressor to restart. The compressor will stay off for the entire restart duration after the compressor is

disabled. A flashing one (1) on the controller display will indicate the unit is in a compressor restart delay while

calling for cooling. If the time delay is reduced to less than five (5) minutes, this may cause reduced compressor

life.

ALARM OUTPUT CONTACT

The smart controller has a normally open, dry contact, alarm output with a resistive load rating of 24 VAC at

261 mA. A connector located on the enclosure side of the unit provides a 2-pin connection to this output marked

YEL/ALARM.

89117141

© 2015 Pentair Equipment Protection

- 15 -

Page 16

ALARM INPUT CONNECTION

The smart controller can accept a dry contact/switch input via the connector terminals marked WHT/DS1 and

WHT/DS2 located on the enclosure side of the unit. This input is associated with the controller display alarm

mnemonic TP (door open and/or smoke detected). To use this feature, remove the jumper wire connecting

terminals DS1 and DS2 and replace with customer supplied wires from the enclosure door switch to DS1 and DS2

terminals.

ALARM CONDITION DISPLAY

There are seven possible non-latching alarm conditions detectable by the controller and are indicated on the

controller display. All alarms can also be accessed through the Ethernet and USB connections with the optional

communications board.

Alarm Mnemonic Description Cause Result Alarm Relay

TP General Alarm

LA

E1

E2

Ht

Lt

A1 Frost Alarm

High Pressure

Warning

Air Inlet Temperature

Sensor Alarm

Air Outlet Temperature

Sensor Alarm

High Temperature

Alarm

Default = 125 F

Low Temperature

Alarm

Default = 40 F

Door open and/or

smoke detected

MALF high pressure

switch opens

Sensor Failure

Sensor Failure

Cabinet over

temperature

Alarm clears at default

setting -2 F

Cabinet under

temperature

Alarm clears at default

setting +27 F

Evaporator coil frozen

Alarm clears at 59 F

Unit turns off for

duration of alarm

No effect on function N/A

Unit turns off for

duration of alarm

Unit turns off for

duration of alarm

No effect on function Relay Contacts Close

No effect on function Relay Contacts Close

Compressor fan off for

duration of alarm

Relay Contacts Close

Relay Contacts Close

Relay Contacts Close

Relay Contacts Close

- 16 -

© 2015 Pentair Equipment Protection

89117141

Page 17

REMOTE ACCESS CONTROL

AIR CONDITIONER UNIT COMMUNICATION FEATURES

Air conditioner units equipped with communication capabilities provide SNMP, EtherNet/IP, Modbus TCP and

Profinet protocols through Ethernet and Modbus RTU protocol via USB. Hoffman Cooling has a PC Interface Tool

available for download that can utilize either mode to communicate with the air conditioner unit.

USB COMMUNICATION

This communication mode allows direct connection of a PC to the air conditioner unit. The protocol

supported is Modbus RTU. Use the PC Interface Tool to communicate with the air conditioner unit. A

MINI-b USB connection is provided.

ETHERNET COMMUNICATION

This communication mode allows remote connection to the air conditioner unit using SNMP, EtherNet/

IP, Modbus TCP and Profinet protocols. Customers using their own software can download a MIB file for

SNMP, EDS file or EtherNet_IP Object file for EtherNet/IP and Coil_Register file for Modbus TCP and

GSDML file for Profinet.

Note: ACU has a default IP Address of 192.168.1.2

Both Ethernet and USB communication modes allow the ability to:

• Read ACU inlet and outlet air temperatures

• Read and change Cooling Set-point and Cooling Differential

• Read and change Heating Set-point, Heating Differential

• Read and change High and Low Temperature Alarm Settings

• Read and change Gateway IP Address, Device IP Address, Subnet Mask, Trap IP Address and Community

• Read and change Unit Identification

• Read and change the state of IP addressing (static or dynamic)

• Read current Alarm Status

SOFTWARE AND CONFIGURATION FILE DOWNLOADS

The PC Interface Tool, MIB file, EDS file, EtherNet_IP Object file, Coil_Register file and GSDML file for

Profinet can be downloaded from:

www.pentairprotect.com/en/na/Product-Enclosure-Cooling-Heating

89117141

© 2015 Pentair Equipment Protection

- 17 -

Page 18

USING THE PC INTERFACE TOOL

The PC Interface Tool gives the user the ability to communicate with the air conditioner unit to read/write

parameters using either Ethernet or USB connections.

USB COMMUNICATION MODE

NOTE: Before connecting unit to the PC, make note of the comm ports present. After the unit

is connected to the PC, a new comm port will be added to the list. Use this new comm port.

• From Tools menu select Use Ethernet

• When Use Ethernet is unchecked, then Comm Port menu is enabled, Device IP and Community boxes are not

shown, and USB communication can be used

• To set the comm port, choose Comm Port from the Tools menu and then select the comm port from the combo box

VIEWING AIR CONDITIONER UNIT VALUES

To view Air Conditioner Unit values

• Select the ACU Values tab

• Select the Enable Comm button (the PC Interface will now be communicating with unit)

• To stop communication select the Disable Comm button

CHANGING AIR CONDITIONER UNIT VALUES

To change ACU Values

• Select the Settings tab

• Select the value to change

• Make the change to the value

• Select the Change Setting button

• Change can be verified in ACU Values tab

VIEWING AND CHANGING ETHERNET INFORMATION

To view and change Ethernet Information

• Select Ethernet Info tab

To view Ethernet Information

• Click Read Ethernet Info button

To change to dynamically assigning IP Address Mode

• Check Use DHCP Server checkbox

• Enter Trap IP Address and Community

• Click Load Ethernet Info button

To change to statically assigning IP Address Mode

• Uncheck Use DHCP Server checkbox

• Enter Device IP Address, Subnet Mask, Gateway IP Address, Trap IP Address and Community

• Click Load Ethernet Info button

- 18 -

© 2015 Pentair Equipment Protection

89117141

Page 19

ETHERNET COMMUNICATION MODE

• From Tools menu select Use Ethernet

• When Use Ethernet is checked, Comm Port selection is disabled, Device IP and Community boxes are shown and

Ethernet communication can be used.

• Enter unit’s IP Address and Community string in Device IP and Community boxes at the bottom of the PC Interface

Tool.

Each unit has two community strings. One is a Read/Write community string (defaulted to

‘private’) that can be changed by the customer (must be 4 to 8 characters long). The other is a

Read-Only community string (‘public’) and cannot be changed.

VIEWING AIR CONDITIONER UNIT VALUES

To view Air Conditioner Unit values

• Select the ACU Values tab

• Select the Enable Comm button (the PC Interface will now be communicating with unit)

• To stop communication select the Disable Comm button

CHANGING AIR CONDITIONER UNIT VALUES

To change ACU Values

• Select the Settings tab

• Select the value to change

• Make the change to the value

• Select the Change Setting button

• Change can be verified in ACU Values tab

VIEWING AND CHANGING ETHERNET INFORMATION

To view and change Ethernet Information

• Select Ethernet Info tab

To view Ethernet Information

• Click Read Ethernet Info button

To change to dynamically assigning IP Address Mode

• Check Use DHCP Server checkbox

• Enter Trap IP Address and Community

• Click Load Ethernet Info button

To change to statically assigning IP Address Mode

• Uncheck Use DHCP Server checkbox

• Enter Device IP Address, Subnet Mask, Gateway IP Address, Trap IP Address and Community

• Click Load Ethernet Info button

ALARM LOG ACCESSIBLE WITH SNMP

• Using custom software with the provided MIB file gives the ability to view a log of the last 25 alarms

89117141

© 2015 Pentair Equipment Protection

- 19 -

Page 20

REMOTE ACCESS CONTROL PINOUT

U1 OUTPUTS

ALARM RELAY OUTPUT No5 12

ENCLOSURE DOOR SWITCH ID1 8

MALFUNCTION NC SWITCH ID2 1

DIGITAL INPUT GROUND ID GND 3

U2 INPUTS

U3 DATA

T1, EVAP IN THERMISTOR B1 13

T2, EVAP OUT THERMISTOR B2 12

CONTROLLER POWER G 7

CONTROLLER POWER G0 14

FUNCTION NAME PIN #

COOL No1 1

C1/2 2

C1/2 3

C5 6

NA ID3 (na) 9

NA ID4 (na) 2

T1, T2 GND GND 6

NA B3 11

POWER 1

GROUND 2

DIRECTION 3

DATA 4

GENERAL SAFETY INFORMATION

Please observe the following general safety instructions when assembling and operating the unit:

• Assembling, installing and servicing must only be performed by properly trained specialists.

• When transporting the enclosure with the cooling unit externally mounted, always use an additional shipping brace

to support the cooling unit.

• Do not attempt to operate the air conditioner while it is horizontal or on its side, back or front.

• Factory-supplied replacement parts must be used.

• Repaired/replaced components must be located and wired in the identical location as the original components.

• Hazardous Location rating may be compromised if the above are not followed.

• Operation of air conditioner in areas containing airborne caustics or chemicals can rapidly degrade sealing

properties of materials, deteriorate filters, refrigeration coils, blowers and motors. Contact Pentair Equipment

Protection for special recommendations.

DANGER

Danger: explosion hazard - do not energize, disconnect, or troubleshoot equipment

unless power has been switched off or the area is known to be non-hazardous.

Unit to be installed and maintained by properly trained personnel only.

Danger: Risque d’explosion – Ne pas alimenter, déconnecter ni dépanner

l’équipement si l’alimentation n’a pas été coupée ou si la zone n’est pas reconnue

comme non dangereuse.

- 20 -

© 2015 Pentair Equipment Protection

89117141

Page 21

MAINTENANCE

COMPRESSOR

The compressor requires no maintenance. It is hermetically sealed, properly lubricated at the factory and should

provide years of satisfactory operating service.

Under no circumstances should the access fitting covers be loosened, removed or tampered with.

Breaking of seals on compressor access fittings during warranty period will void warranty on hermetic system.

Recharging ports are provided for the ease and convenience of reputable refrigeration repair service personnel

for recharging the air conditioner.

INLET AIR FILTER

This air conditioner was designed with a dust resistant condenser coil. This allows it to be run filterless in most

applications. The air conditioner is shipped with a filter in place for your convenience. For filterless operation,

simply remove the filter. Should you decide the filter is necessary in your application, regular maintenance to

clean this filter will assure normal operation of the air conditioner. The easily removable inlet air filter is located

behind the inlet of the front cover. If necessary filter maintenance is delayed or ignored, the maximum ambient

temperatures under which the unit is designed to operate will be decreased.

If the compressor’s operating temperature increases above designed conditions due to a dirty or clogged filter

(or plugged condenser coil), the air conditioner’s compressor will stop operating due to actuation of the thermal

overload cut-out switch located on the compressor housing. As soon as the compressor temperature has dropped

to within the switch’s cut-in setting, the compressor will restart automatically. However the above condition will

continue to take place until the filter or coil has been cleaned. It is recommended that power to the air conditioner

be interrupted intentionally when abnormally high compressor operating temperature causes automatic shutdown of the unit. The above described shut-down is symptomatic of a clogged or dirty filter, thus causing a

reduction in cooling air flow across the surface of the compressor and condenser coil.

HOW TO REMOVE, CLEAN OR INSTALL A NEW INLET AIR FILTER

RP aluminum washable air filters are designed to provide excellent filtering efficiency with a high dust holding

capacity and a minimum amount of resistance to air flow. Because they are constructed entirely of aluminum

they are lightweight and easy to service. To achieve maximum performance from your air handling equipment, air

filters should be cleaned on a regular basis.

The inlet air filter is located behind the condenser air inlet grille. To access the filter, simply slide it out. The filter

may now be cleaned or a new filter installed.

Cleaning Instructions:

1. Flush the filter with warm water from the exhaust side to the intake side. DO NOT USE CAUSTICS.

2. After flushing, allow filter to drain. Placing it with a corner down will assure complete drainage.

CONDENSATE MANAGEMENT AND DRAIN TRAP MAINTENANCE

The drain trap can be cleaned by pouring soapy water into the face of the evaporator coil. An alternate method is

to remove the panel underneath the condenser coil, locate the drain trap above the condensate evaporator pan,

and blow compressed air through the tube.

89117141

© 2015 Pentair Equipment Protection

- 21 -

Page 22

CONDENSER AND EVAPORATOR AIR MOVERS

Impeller motors require no maintenance. All bearings, shafts, etc. are lubricated during manufacturing for the

life of the motor.

If the condenser impeller motors (ambient impellers) should fail, it is not necessary to remove the air conditioner

from the cabinet or enclosure to replace the blower. The condenser impeller is mounted on its own bracket and is

easily accessible by removing the front cover.

If the evaporator impeller motor should fail, it may require dismounting the unit from the enclosure because

access to the evaporator is through the enclosure side. After it is repaired, refer to Installation Instructions on

page 12 for mounting the unit back onto the enclosure. Replace the mounting gasket if damaged.

CAUTION

MISE EN GARDE

Operation of air conditioner in areas containing airborne caustics or chemicals can rapidly degrade sealing

properties of materials, deteriorate filters, refrigeration coils, blowers and motors.

Contact Pentair Equipment Protection for special recommendations.

Le fonctionnement du climatiseur dans des espaces contenant des produits caustiques ou chimiques en

suspension dans l’air peut rapidement dégrader les propriétés d’étanchéité des matériaux, détériorer les filtres,

les serpentins du condenseur, les ventilateurs et les moteurs.

Communiquer avec Pentair Equipment Protection pour connaître les recommandations spéciales.

REFRIGERANT LOSS

Each air conditioner is thoroughly tested prior to leaving the factory to insure against refrigeration leaks. Shipping

damage or microscopic leaks not found with sensitive electronic refrigerant leak detection equipment during

manufacture may require repair or recharging of the system. This work should only be performed by qualified

professionals, generally available through a local, reputable air conditioning repair or service company.

Should the refrigerant charge be lost, access ports on the suction and discharge sides of the compressor are

provided for recharging and/or checking suction and discharge pressures.

Refer to the data on the nameplate which specifies the type of refrigerant and the charge size in ounces.

Before recharging, make sure there are no leaks and that the system has been properly evacuated into a deep

vacuum.

REFRIGERANT PROPERTIES CHART (R134A)

°F °C Pressure °F °C Pressure

-40 -40 -14.7 60 15.6 58

-35 -37.2 -12.3 65 18.3 64

-30 -34.4 -9.7 70 21.1 71.5

-25 -31.7 -6.8 75 23.9 78

-20 -28.9 -4 80 26.7 86.7

-15 -26.1 0 85 29.4 95

-10 -23.3 2 90 32.2 105

-5 -20.6 4 95 35 113.3

0 -17.8 7.5 100 37.8 125

5 -15 9 105 40.6 135

10 -12.2 12 110 43.3 146.7

15 -9.4 15 115 46.1 157.5

20 -6.7 18.5 120 48.9 170

25 -3.9 22 125 51.7 185

30 -1.1 26

35 1.7 30

40 4.4 35

45 7.2 40

50 10 45.5

55 12.8 51.5

- 22 -

© 2015 Pentair Equipment Protection

89117141

Page 23

UNIT CHARACTERISTICS

Model

NHZ280416GXXX NHZ280426GXXX NHZ280446GXXX

Dimensional Data

Height 28” / 711.2 mm

Width 11.5” / 292.1 mm

Depth 14” / 355.6 mm

Unit Weight 84 lbs / 38 kg 84 lbs / 38 kg 98 lbs / 44 kg

Unit Protection Rating

Class 1 Division 2 Groups A, B, C, D T4A

Cooling Data

Refrigerant R134a

Refrigerant Charge 10 oz. 11 oz. 11 oz.

Cooling Capacity at 95 F Enclosure

95 F Ambient (BTU/Hr.)

Cooling Capacity at Max Conditions

(BTU/Hr.)

3300/3500 3690 3690

3487/3680 4279/4681 4279/4681

Maximum Ambient Temp 125 F / 52 C

Minimum Ambient Temp -40 F / -40 C

Enclosure Airflow 143 CFM

External Airflow 288 CFM

Condensate Management Hose discharge / Optional powered C/E

Electrical Data

Rated Voltage (50/60 Hz) 115 V 230 V 460 V

Rated Frequency 50 / 60 Hz 50 / 60 Hz 50 / 60 Hz

Voltage Range +/- 10% of rated

Cooling Amps at Max Conditions 10.2/9.4 4.9/5.0 2.4/2.5

Compressor RLA / LRA 8.1/40.0 24.5 24.5

Evaporator Fan RLA .38/.36 .19 .19

Condenser Fan RLA .78/.93 .53 .53

Type 12/4/4X/3R

Unit

NHZ280416GXXX

NHZ280426GXXX

NHZ280425GXXX

NHZ280446GXXX

89117141

Evaporator. Air

In(°F)

65-80 7.3-8.9 15-23 22-31

80-100 7.9-9.9 17-26 25-31

65-80 4.7-5.8 14-23 21-32

80-100 4.8-6.3 17-28 26-38

65-80 3.2/4.5 14-22 19-29

80-100 3.5/5.2 16-26 23-35

65-80 2.4-2.9 14-23 21-32

80-100 2.4-3.2 17-28 26-38

FUNCTIONAL DATA

Amps(A)

© 2015 Pentair Equipment Protection

Condenser

Delta(°F)

Evaporator

Delta(°F)

- 23 -

Page 24

SERVICE DATA

COMPONENTS LIST

Part Description

Capacitor, Compressor, Start 89074579SP 89074578SP 89074578SP

Capacitor, Condenser Impeller 52603213SP 52603214SP 52603214SP

Coil, Condenser 89068416SP 89068416SP 89068416SP

Coil, Evaporator 89068414SP 89068414SP 89068414SP

Coil, Evaporator E-coated 89106893SP 89106893SP 89106893SP

Compressor (see note below) 89111751SP 89111752SP 89111752SP

Filter, Air, Reusable 89068420SP 89068420SP 89068420SP

Filter/Dryer 52602800SP 52602800SP 52602800SP

Head Pressure Control Switch 89112571SP 89112571SP 89112571SP

Impeller, Condenser 89114225SP 89114226SP 89114226SP

Fan, Evaporator 12101201SP 12101202SP 12101202SP

Relay, Compressor Start 89115078SP 89114206SP 89114206SP

Capillary Tube 99054039SP 99064045SP 99064045SP

Transformer, Input Power N/A N/A 101006111SP

Controller, Basic 89099443SP 89099443SP 89099443SP

Thermistor 89075654SP 89075654SP 89075654SP

Bridge Rectifier 89087424SP 89087424SP 89087424SP

Controller Wires with pins (24) 89083091SP 89083091SP 89083091SP

Communication Board 89109039SP 89109039SP 89109039SP

Communication Cable 89080313SP 89080313SP 89080313SP

Fuse, Controller (315mA) 89085114SP 89085114SP 89085114SP

Encapsulated Compressor Overload 89114216SP 89114217SP 89114217SP

Solid State Relay 89114223SP 89114223SP 89114223SP

Overload Relay 89115269SP 89115544SP 89115544SP

Mounting Gasket 89114209SP 89114209SP 89114209SP

Mounting Kit 89068421SP 89068421SP 89068421SP

Stainless Steel Mounting Kit 89116252SP 89116252SP 89116252SP

115 V 230 V 460 V

Part Number

Danger: explosion hazard - Substition or incorrect installation of components may

void the suitability for hazardous location use.

Danger: Risque d’explosion – Le remplacement ou une mauvaise installation

des composants peuvent rendre l’équipement inadapté à une utilisation en zone

dangereuse.

Note: This design utilizes an encapsulated compressor overload, which is mounted on the

side of the compressor body. If the compressor is replaced, the standard overload (included

with the compressor) must be discarded and not used. An encapsulated overload must be

mounted and wired identical to the original.

- 24 -

DANGER

© 2015 Pentair Equipment Protection

89117141

Page 25

NHZ280416GXXX PRESSURE TABLES

NHZ280416GXXX 50hz

°F

L H L H L H L H L H L H L H L H

70 23 118 25 121 27 124 28 125 28 127 31 131 32 133 33 134

80 25 145 27 149 29 153 30 154 31 156 34 161 35 163 36 165

90 28 173 30 177 32 181 33 183 34 185 37 190 39 193 40 195

95 29 186 31 191 34 195 35 197 36 199 39 205 41 208 42 210

100 30 200 32 205 35 209 36 212 37 214 40 220 42 223 43 226

113 33 235 36 241 39 246 40 249 41 252 45 259 47 263 48 265

120 35 254 38 260 40 266 42 269 43 272 47 280 48 284 50 287

Ambient Temperature (°F)

125 36 268 39 274 41 280 43 283 44 287 48 295 50 299 51 302

NHZ280416GXXX 60hz

°F

L H L H L H L H L H L H L H L H

70 22 122 23 124 24 127 24 128 25 129 26 132 27 134 27 135

80 24 149 25 153 26 156 27 157 27 159 29 163 29 165 30 166

90 26 177 27 181 29 184 30 186 30 188 32 193 33 195 34 197

95 27 191 29 194 30 198 31 200 32 202 34 207 35 210 36 212

100 28 204 30 209 31 213 32 215 33 217 35 223 36 226 37 228

113 31 240 33 245 35 250 36 253 37 255 39 262 41 266 42 268

120 32 259 34 265 36 271 37 273 39 276 41 284 43 287 44 290

Ambient Temperature (°F)

125 33 273 35 279 38 285 39 288 40 290 43 298 45 302 46 305

L = Suction (±5PSIG); H=Head (-10/+20PSIG)

Enclosure Temperature (°F)

70 80 90 95 100 113 120 125

L = Suction (±5PSIG); H=Head (-10/+20PSIG)

Enclosure Temperature (°F)

70 80 90 95 100 113 120 125

89117141

© 2015 Pentair Equipment Protection

- 25 -

Page 26

NHZ280426GXXX PRESSURE TABLES

NHZ280426GXXX 50hz

°F

L H L H L H L H L H L H L H L H

70 25 119 29 125 32 131 34 134 36 136 41 144 43 148 45 151

80 28 145 32 152 35 158 37 162 39 165 44 173 47 178 48 181

90 31 171 35 179 38 186 40 190 42 193 47 203 50 208 52 211

95 32 184 36 192 40 200 42 204 44 207 49 217 52 223 54 226

100 34 198 38 205 42 213 44 217 46 221 51 231 54 237 55 241

113 37 232 41 240 46 249 48 253 50 258 55 269 58 275 60 280

120 39 250 43 259 47 268 50 273 52 278 57 290 60 296 62 301

Ambient Temperature (°F)

125 41 263 45 273 50 282 52 287 54 292 59 304 62 311 64 316

NHZ280426GXXX 60hz

°F

L H L H L H L H L H L H L H L H

70 23 124 26 130 29 135 31 138 32 141 36 148 38 152 40 155

80 26 151 29 157 32 163 34 167 36 170 40 178 42 183 44 186

90 28 177 32 185 35 192 37 196 39 199 43 209 46 214 47 217

95 30 191 33 198 37 206 38 210 40 214 45 224 47 229 49 233

100 31 204 35 212 38 220 40 224 42 228 47 239 49 244 51 248

113 35 239 39 248 42 257 44 262 46 266 51 278 54 284 56 289

120 37 258 40 267 44 277 46 281 48 286 53 298 56 305 58 310

Ambient Temperature (°F)

125 38 271 42 281 46 291 48 296 50 301 55 314 58 321 60 326

L = Suction (±5PSIG); H=Head (-10/+20PSIG)

Enclosure Temperature (°F)

70 80 90 95 100 113 120 125

L = Suction (±5PSIG); H=Head (-10/+20PSIG)

Enclosure Temperature (°F)

70 80 90 95 100 113 120 125

- 26 -

© 2015 Pentair Equipment Protection

89117141

Page 27

NOTES

89117141

© 2015 Pentair Equipment Protection

- 27 -

Page 28

TROUBLE SHOOTING

Repair or Replace

defective part

Wait and/or heat

enclosure thermistor T1

BASIC AIR CONDITIONING TROUBLE SHOOTING CHECK LIST SMART CONTROLLER

1. Check manufacturer’s nameplate located on the unit for correct power supply.

2. Turn on power to the unit. The controller will display a start up sequence then revert to the normal

temperature display mode. Is the correct enclosure temperature displayed?

Note: The temperature may be alternating with an alarm code.

YES, proceed to step 3.

NO, possible problem:

• Open controller fuse

• Controller in alarm condition. See Alarm

Condition Display on page 16.

• Defective controller

• Defective thermistor - check by blowing

warm air across the thermistor. If display

temperature rises, thermistor is operable.

3. The cooling status indication (symbol G) should be on. Is the symbol on? If not, press and hold the

lower right “snowflake” button for greater than five seconds. Is the cooling mode symbol now on?

YES, proceed to step 4.

NO, possible problem:

Replace part

• Defective controller

Replace part

4. The evaporator (Enclosure or “COLD” air) fan/impeller should turn on. Is there airflow?

YES, proceed to step 5.

NO, possible problem:

• Controller in alarm condition. See Alarm

Condition Display on page 16.

• Open motor winding

• Stuck fan/impeller

• Obstructed blades/wheel

• Defective motor capacitor

5. Start the cooling cycle by changing the cooling setpoint parameter (r01) to the low limit of 72 F (22

C). Symbol 1 should be displayed indicating a call for cooling. If symbol 1 is flashing, the unit is in

Restart Time Delay mode. Within 6 minutes, symbol 1 should display without flashing. Is symbol 1

displayed without flashing?

YES, proceed to step 8.

NO, possible problem:

• Unit still in Recycle Time Delay mode

• Enclosure temperature below cooling

setpoint temperature

6. The compressor and the condenser (Ambient or “HOT” air) impeller(s) should turn on. Is there

adequate airflow?

- 28 -

© 2015 Pentair Equipment Protection

89117141

Page 29

YES, proceed to step 7.

Repair or Replace

defective part

Reset, Repair or Replace

defective part

Repair or Replace

defective part

NO, possible problem:

• Open motor winding(s)

• Stuck impeller(s)

• Obstructed wheel(s)

• Defective motor capacitor(s)

7. Carefully check the compressor for proper operation - motor should cause slight vibration and the

outer case of the compressor should be warm. Is the compressor showing signs of this?

YES, wait 5 minutes, proceed to step 8.

NO, possible problem:

• Defective start or run capacitor

• Defective overload

• Defective start relay

• Defective contactor

• Defective compressor

• Tripped overload relay

8. Make sure the coils are clean then check the evaporator “air in” and “air out” temperatures. If the

temperatures are the same:

• Possible loss of refrigerant

• Possible bad valves in compressor

SYMPTOMS AND POSSIBLE CAUSES REMOTE ACCESS CONTROL VERSION

SYMPTOM POSSIBLE CAUSE

Clogged fins on coil(s)

Dirty filter

Unit won’t cool

Compressor tries to start but won’t run

Unit blows breakers

Getting water in enclosure

Impellers not running

Compressor not running

Compressor runs, but has bad valves

Loss of refrigerant

Low line voltage at start. Should be +/-10% rated voltage.

Compressor motor stuck

Bad contactor

Bad overload switch

Bad run/start capacitor

Undersized breaker/fuse or not time delayed

Short in system

Drain plugged

Drain tube kinked

Enclosure not sealed (allowing humidity in)

Mounting gasket damaged

For additional technical support, contact Pentair Equipment Protection at 800-896-2665.

89117141

© 2015 Pentair Equipment Protection

- 29 -

Page 30

WARRANTY

Pentair Equipment Protection warrants that the Goods manufactured by Pentair Equipment Protection

will be free from defects in material and workmanship for a period of one (1) year from the date of

shipment by Pentair Equipment Protection, subject to the following conditions and exclusions:

A. Conditions. All Goods must be installed and operated according to the following specifications:

1. Maximum voltage variation no greater than plus or minus 10% of nameplate nominal rating;

2. Maximum frequency variation no greater than plus or minus 3 Hz of nameplate nominal rating;

3. Must not exceed minimum and maximum stated temperatures on the nameplate;

4. Must not exceed (BTU/Hr) rating, including any heat sink as indicated on the nameplate;

5. Refrigerant bearing Goods must not be restarted for a period of one (1) minute after intentional or

accidental shut-off;

6. The filters (if applicable) must be cleaned regularly;

7. The Goods and any parts thereof must not be modified, unless prior written authorization is

received from Pentair Equipment Protection; and

8. All Goods must be installed and grounded in accordance with all relevant electrical and safety

codes, as well as the National Electric Code and OSHA rules and regulations.

9. All Goods must be installed in a stationery application, free of vibration.

A violation of any one of these conditions shall render the warranty hereunder void and of no effect.

B. Exclusions. This warranty shall be void if product is misapplied in any way or:

1. Buyer specified product is inappropriate for system or environment in which it is operating.

2. Goods are not installed in accordance with Pentair Equipment Protection specifications.

3. Removal or modification of Pentair Equipment Protection label affixed to product without written

Pentair Equipment Protection approval.

Pentair Equipment Protection must be notified of a claim in writing not later than fourteen (14) days from

the date when Buyer has become aware of such occurrence, or where the defect is such that it may cause

damage, immediately, such notice containing a description of how the defect manifests itself. Failure to

provide such prompt notice to Pentair Equipment Protection shall result in forfeiture of Buyer’s rights

under this warranty.

In the event of a warranty claim, Buyer is to return defective goods to Pentair Equipment Protection in

accordance with Pentair Equipment Protection Return Policy. Warranty period for repaired goods remains

at 1 year from shipment of original goods. Pentair Equipment Protection sole obligation to Buyer under

this warranty will be, at Pentair Equipment Protection option:

A. Repair or replace Pentair Equipment Protection products or parts found to be defective in material or

workmanship.

B. Issue credit for the purchase price paid by Buyer relating to such defective Goods or part.

THIS WARRANTY CONSTITUTES THE ENTIRE WARRANTY WITH RESPECT TO THE GOODS AND IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY AND IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

RETURN AND REPAIR POLICY

Pentair Equipment Protection products that: (i) are made to order, (ii) have been modified by Buyer, (ii)

have special finishes, or (iv) are determined by Pentair Equipment Protection to constitute “custom”

products that cannot be returned to stock or resold to other Buyers, will not be accepted for return by

Pentair Equipment Protection.

All returns require a Return Material Authorization number (RMA #), regardless of reason for return,

whether it be for warranty or out of warranty repair. Returns without an RMA # will be refused by our

Receiving Department. An RMA # is valid for 30 days.

- 30 -

© 2015 Pentair Equipment Protection

89117141

Page 31

A. An RMA # will be issued by our Product Return Department in Anoka, MN at 763-422-2211. Buyer

should have following information available at time of RMA request:

1. Complete Model Number, Serial Number and description of damaged unit being returned.

2. Original Buyer Purchase Order number and date product was received by Buyer.

3. Quantity to be returned and a brief description of failure for each unit, if different.

4. Contact information of Buyer that must include: name of company, billing and shipping address,

phone, number, fax number, freight carrier and the name and phone number of a Buyer contact

who can elaborate on the claimed defect in detail.

5. Buyer must provide a Repair Purchase Order number for both warranty and out of warranty

repairs. The PO will not exceed 50% of a new unit. Buyer will be notified of repair charges that

exceed approved PO amount.

B. All returns to Pentair Equipment Protection must be securely packed, using original cartons if

possible. All returns must have the RMA number visible on the outside of the carton. Pentair

Equipment Protection is not responsible for material damaged in transit. Any refrigerant-bearing

Goods must be shipped upright for return.

C. Shipping cost for all non-warranty repairs is the responsibility of the sender and must be shipped

prepaid. Shipping costs for all warranty related repairs will be covered by Pentair Equipment

Protection provided the goods are returned using a Pentair Equipment Protection approved carrier.

If after diagnoses the product is determined by Pentair Equipment Protection not be covered under

warranty, Buyer will be responsible for all shipping charges and will be billed accordingly.

D. Non-warranty repairs are subject to a $105 minimum analysis fee. If approval is not received within

30 days, material will be scrapped and all shipping expenses and corresponding analysis fees will be

billed to Buyer.

E. At Buyer’s request, Failure Analysis can be provided by Pentair Equipment Protection for warrantable

goods at no charge. Failure analysis for non-warranty repairs are subject to a $150 per hour

Engineering charge plus any other incurred testing costs.

F. All returned merchandise must be sent to the following address: Pentair Equipment Protection, 2100

Hoffman Way, Anoka, MN 55303-1745.

G. Credit for accepted returns shall be at the original selling price or the current selling price, whichever

is lower, less the restocking charge indicated as follows:

1. Within 60 days of invoice date - 20% of applicable selling price.

2. Within 61-120 days of invoice date - 30% of applicable selling price.

3. Within 121-180 days of invoice date - 40% of applicable selling price.

4. Beyond 180 days - subject to individual review by Pentair Equipment Protection.

If product being returned for credit requires repair or modification, the cost of any labor or material

necessary to bring product into saleable condition will be deducted from credit. Buyer may not take credit

against returns without prior written Pentair Equipment Protection approval.

LIMITATION OF LIABILITY

PENTAIR EQUIPMENT PROTECTION WILL NOT BE LIABLE UNDER ANY CIRCUMSTANCES FOR ANY

INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES, INCLUDING WITHOUT LIMITATION ANY LOST

PROFITS OR LABOR COSTS, ARISING FROM THE SALE, USE OR INSTALLATION OF THE GOODS, FROM

THE GOODS BEING INCORPORATED INTO OR BECOMING A COMPONENT OF ANOTHER PRODUCT,

FROM ANY BREACH OF THIS AGREEMENT OR FROM ANY OTHER CAUSE WHATSOEVER, WHETHER

BASED ON WARRANTY (EXPRESSED OR IMPLIED) OR OTHERWISE BASED ON CONTRACT, OR ON TORT

OR OTHER THEORY OF LIABILITY, AND REGARDLESS OF ANY ADVICE OR REPRESENTATIONS THAT

MAY HAVE BEEN RENDERED BY PENTAIR EQUIPMENT PROTECTION CONCERNING THE SALE, USE OR

INSTALLATION OF THE GOODS.

89117141

© 2015 Pentair Equipment Protection

- 31 -

Page 32

Pentair Equipment Protection

2100 Homan

Way

M

Pe

inneapolis, MN 55303 USA

+1.763.422.2211

+1.763.576.3200

ntairProtect.com

Rev. F

© 2015 Pentair Equipment Protection 89117141

P/N 89117141

Loading...

Loading...