Pentair Myers MVPH-100, Myers MVPH-150, Myers MVPH-200, Berkeley 10MS, Berkeley 15MS Owner's Manual

...

OWNER’S MANUAL

Multi-Stage Deep Well Jet Pumps

60

40

20

80

100

MVPH-100 1 HP

MVPH-150 1-1/2 HP

MVPH-200 2 HP

Installation/Operation/Parts

For further operating, installation, or maintenance assistance:

Call 1-888-987-8677

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.FEMYERS.COM

PH: 888-987-8677

© 2013 Pentair, Ltd. All Rights Reserved. MY757 (Rev. 02/05/13)

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury:

warns about hazards that will cause serious

personal injury, death or major property damage if

ignored.

personal injury, death or major property damage if

ignored.

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Make workshops childproof; use padlocks and master

switches; remove starter keys.

California Proposition 65 Warning

This product and related accessories

contain chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

warns about hazards that can cause serious

warns about hazards that will or can cause

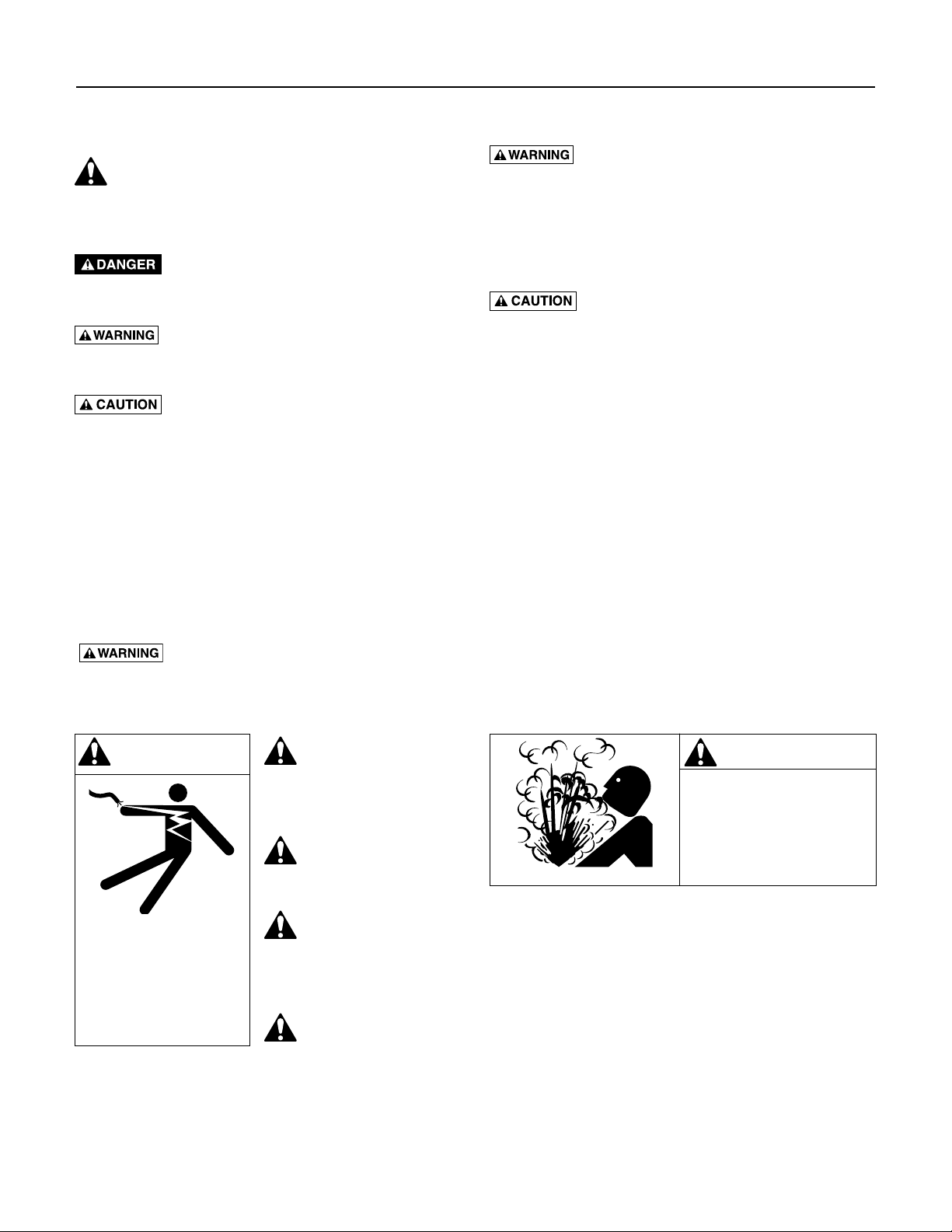

ELECTRICAL SAFETY

Capacitor voltage may be hazardous.

To discharge motor capacitor, hold insulated handle

screwdriver BY THE HANDLE and short capacitor

terminals together. Do not touch metal screwdriver

blade or capacitor terminals. If in doubt, consult a

qualified electrician.

GENERAL SAFETY

Do not touch an operating motor. Modern

motors are designed to operate at high temperatures. To

avoid burns when servicing pump, allow it to cool for 20

minutes after shut-down before handling.

Do not allow pump or any system component to freeze.

Freezing may damage system, leading to injury or

flooding. Allowing pump or system components to freeze

will void warranty.

Relief valve must be capable of passing full pump flow at

75 PSI.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on pumps.

Keep work area clean, uncluttered and properly lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect power

before working on pump,

motor or tank.

Wire motor for correct

voltage. See

“Electrical” section of

this manual and motor

nameplate.

Ground motor before

connecting to power

supply.

Meet National

Electrical Code,

Canadian Elec tri cal

Code, and local codes

for all wiring.

Follow wiring

instructions in this

manual when

connecting motor to

power lines.

WARNING

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.

Table of Contents 3

Page

General Safety .....................................................................................................2

Warranty..............................................................................................................3

Installation ........................................................................................................4-7

Electrical ...........................................................................................................8-9

Operation .....................................................................................................10-11

Maintenance .................................................................................................12-13

Troubleshooting ................................................................................................. 14

Repair Parts .................................................................................................15-16

Limited Warranty

F.E. MYERS warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free

from defects in material and workmanship for the Warranty Period shown below.

Product Warranty Period

Jet pumps, small centrifugal pumps, submersible pumps and relatedaccessories

Fibrewound Tanks 5 y

Steel Pressure Tanks 5 years from date of original installation

Sump/Sewage/Effluent Products

Our warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication, improper

installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase power

through a phase converter will void the warranty. Note also that three phase motors must be protected by three-leg, ambient

compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and F.E. MYERS’s only duty, is that F.E. MYERS repair or replace defective products (at F.E. MYERS’s choice). You

must pay all labor and shipping charges associated with this warranty and must request warranty service through the installing

dealer as soon as a problem is discovered. No request for service will be accepted if received after the Warranty Period has

expired. This warranty is not transferable.

F.E. MYERS SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an

implied warranty, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You

may also have other rights which vary from state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

F.E. MYERS

293 Wright Street, Delavan, WI 53115

Phone: 888-987-8677 • Fax: 800-426-9446 • www.femyers.com

In Canada: P. O. Box 9138, 269 Trillium Dr., Kitchener, Ontario N2G 4W5

Phone: 519-748-5470 • Fax: 888-606-5484

whichever occurs first:

12 months from date of original installation,

or 18 months from date of manufacture

ears from date of original installation

12 months from date of original installation,

or 24 months from date of manufacture

Installation 4

Be sure

entire

well

point is

below

water.

Drive

Coupling

Drive

Point

Check

Valve

1" NPT

Plug

Well

Casing

1" NPT

Plug

Foot

Valve &

Strainer

Shallow well is less

than 25' (7.6M)

to water with

pump running.

Dirt and Scale Plug Pump and Pipes!

Use New Pipe for Best Results.

Pump

Body

Clean Flow!

From

Well

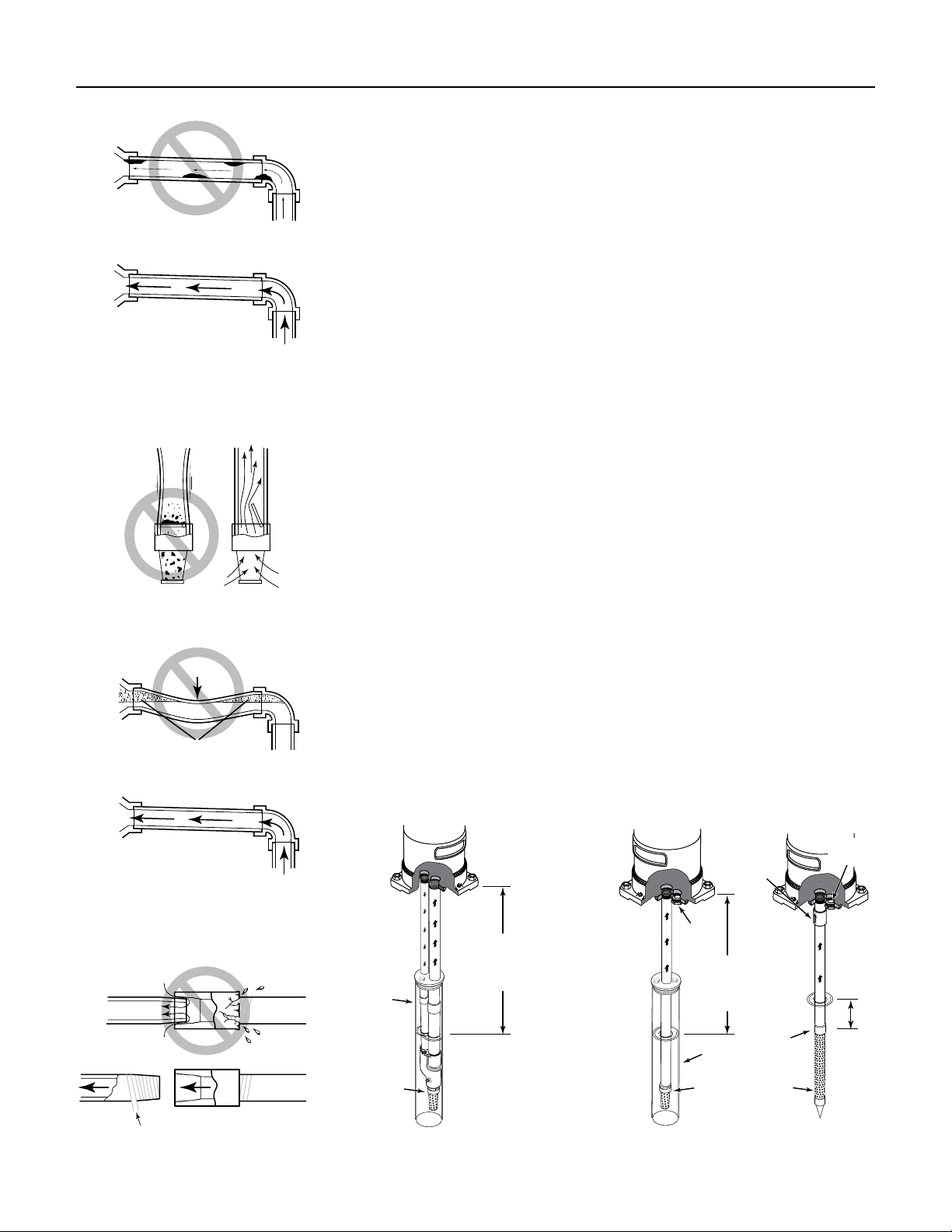

Figure 1: No Dirt or Scale in Suction

Pipe

Figure 2: Foot Valve Must Work Freely

No Sags

Sags Allow Air Pockets

If Air Pockets Form, Water Won’t Flow.

BEFORE YOU INSTALL YOUR PUMP

NOTE: For proper performance, pump MUST be matched to ejector and

to well depth. Use shallow well installation for wells up to 25 ft depth to

water and deep well ejector for depths up to 130 ft.

Step 1. Long runs and many fittings increase friction and reduce flow.

Locate pump as close to well as possible: use as few elbows and

fittings as possible.

Step 2. Be sure well is clear of sand. Sand will plug the pump and void the

warranty.

Step 3. Protect pump and all piping from freezing. Freezing will split

pipe, damage pump and void the warranty. Check locally for frost

protection requirements (usually pipe must by 12” below frost line

and pump must be insulated).

Step 4. Be sure all pipes and foot valve are clean and in good shape.

Step 5. No air pockets in suction pipe.

Step 6. No leaks in suction pipe. Use PTFE pipe thread sealant tape to seal

pipe joints.

Step 7. Match pump to well.

IMPORTANT: Flow into well must at least equal flow out through

pump!

Step 8. Unions installed near pump and well will aid in servicing. Leave

room to use wrenches.

Step 9. Plug 1” drive port when installing on shallow well.

SHALLOW WELL/CENTRIFUGAL INSTALLATION

No ejector is used in this case, plug the smaller of the two inlet ports,

using the larger for the suction pipe. Refer to Figure 6 for installation tips.

Maximum depth to water for shallow well/centrifugal operation is 25 feet.

NOTE: To avoid pump overloading and motor failure, install a flow control

valve at the discharge to limit flow to 20 gallons per minute.

Keep Pipe Straight and Angled up to Pump.

Figure 3: No Air Pockets in Suction

Pipe

Pipe Joint

No Air Leaks

in Suction Pipe.

If Air Flows

Water Won’t

Use PTFE Tape

Figure 4: Suction Pipe Must Not Leak

Compound Will

Damage Plastic.

Deep well is more

than 25' (7.6M)

Foot

Valve &

Strainer

to water with

pump running.

Well

Casing

Figure 5: Double Pipe Deep Well

Check

Valve

1" NPT

Plug

Shallow well is less

than 25' (7.6M)

to water with

pump running.

Drive

Well

Casing

Foot

Valve &

Strainer

Coupling

Drive

Point

Figure 6: Cased Shallow Well

and Drive Point Shallow Well

1" NPT

Plug

Be sure

entire

well

point is

below

water.

Installation 5

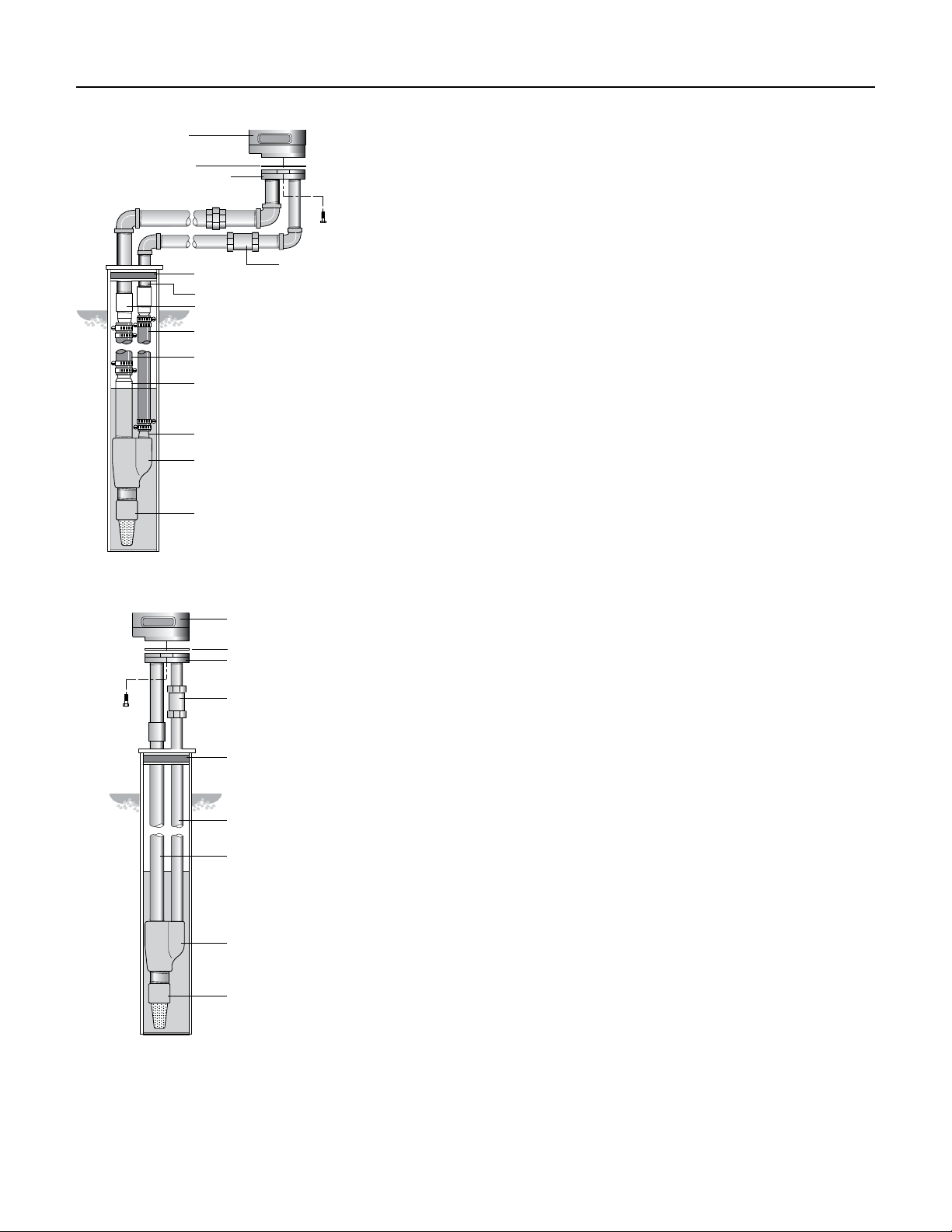

Pump

Gasket

Adapter Flange

Sanitary

Well Seal

1" Drive Pipe

Ejector Assembly

Foot Valve & Strainer

1-1/4" Suction Pipe

Threadless Coupling

PLASTIC PIPE SHOWN

B-OVER THE WELL INSTALLATION

STEEL PIPE SHOWN

Pump

Gasket

Adapter Flange

Sanitary

Well Seal

Steel Pipe Nipple

Coupling

1" Plastic Drive Pipe

1-1/4" Plastic Suction Pipe

Special 1-1/4" Plastic Pipe

Adapter. (Supplied with Ejector)

1" Plastic Pipe Adapter

Ejector Assembly

Foot Valve & Strainer

A-OFFSET INSTALLATION

B-OVER THE WELL INSTALLATION

STEEL PIPE SHOWN

Figure 7

Threadless

Coupling

Gasket

Adapter Flange

Threadless Coupling

Sanitary

Well Seal

1" Drive Pipe

1-1/4" Suction Pipe

Ejector Assembly

Foot Valve & Strainer

PIPING IN THE DEEP WELL

See Figures 7 and 8.

NOTE: Deep well installations are either single pipe (2” wells) or double

pipe (4” and larger wells). In a double pipe installation, the larger pipe is

the suction pipe and the smaller pipe is the drive pipe (very deep wells

may use suction and drive pipes of the same diameter).

Plastic pipe is ideal for double pipe installations. Due to its light weight,

it is easy to handle and does not usually require a block and tackle for

installation and removal.

PLASTIC PIPE INSTALLATION – DOUBLE PIPE

NOTE: Use PTFE pipe thread sealant tape on all male threads on plastic

pipe and fittings to prevent air leaks in suction piping.

Step 1. Inspect ejector to make sure that nozzle and venturi openings are

clean and clear.

Step 2. Inspect pipe for any foreign matter or obstructions.

IMPORTANT: Make sure that no foreign matter enters pipe

openings while installing pump.

Step 3. Make sure foot valve operates freely: attach to ejector with a close

nipple. Use PTFE pipe thread sealant tape on male threads.

Step 4. Install nozzle and venturi in deep well ejector.

Step 5. Using PTFE pipe thread sealant tape on male threads, install

special plastic pipe adapter (supplied with ejector) by screwing

adapter into 1-1/4” tapped hole in ejector body (see Figure 7A).

Step 6. Thread a 1” plastic pipe adapter into the 1” tapped hole in ejector

body (see Figure 7A).

Step 7. Install sufficient plastic pipe in well casing to place ejector at the

proper depth. (Your well driller should supply this information.)

IMPORTANT: as a guide, the ejector should be set at least 10

to 20 feet below the lowest water level with pump running, if

possible, but always at least five feet from the bottom of the well.

Step 8. Tighten all hose clamps securely on plastic pipe. Use two clamps

Step 9. Install sanitary well seal on top of well casing; use steel nipple

IMPORTANT: align locating lugs on adapter flange and pump

Step 10. Install 1” nipple in one side of adapter flange. Slide threadless

Step 11. Slide threadless coupling up and secure nipple to drive pipe.

Step 12. Remove paper backing from adhesive gasket. Apply gasket to

Step 13. Align locating lugs on pump base with locating lugs on adapter

Step 14. See “Discharge Pipe Sizes” for information regarding correct

per joint to prevent air leaks into suction pipe. Clamp screws

should be on opposite sides of the pipe. Fill pipes with water to

make sure that foot valve and connections do not leak.

through well seal as shown in Figure 7A.

base so that pump discharge will be aligned with piping.

coupling down over drive pipe from well. Thread adapter flange

onto suction pipe from well and align nipple and drive pipe.

adapter flange, making sure that holes line up.

flange; attach pump to flange with cap screws provided.

discharge pipe size.

Loading...

Loading...