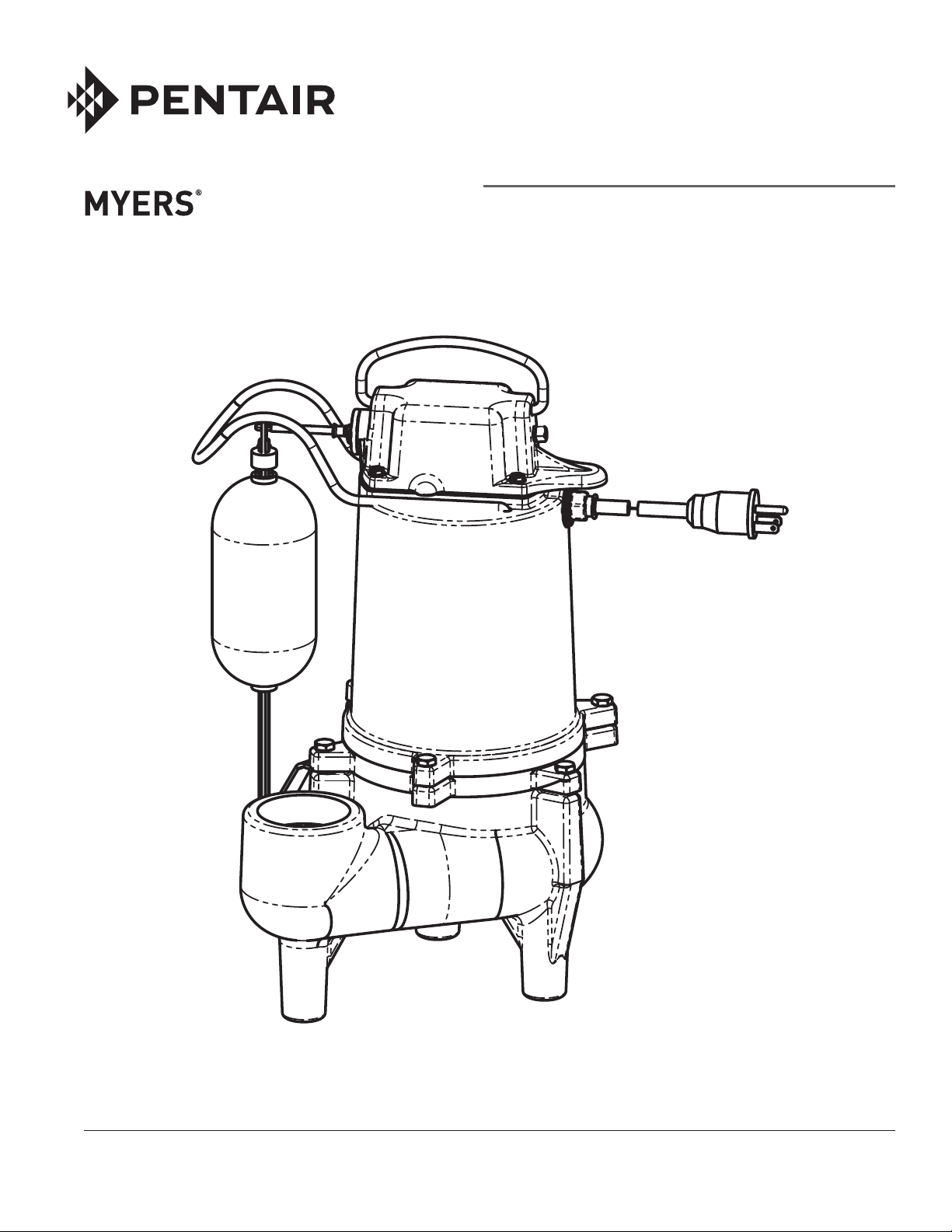

Pentair MYERS MSE50 Series, MYERS MSE5012P20, MYERS MSE5012P10, MYERS MSE5022P10, MYERS MSE5022P20 Installation And Service Manual

INSTALLATION AND SERVICE MANUAL

MSE50 Submersible Sewage

Ejec tor Pump

MODELS

MSE5012P10, MSE5012P20

MSE5022P10, MSE5022P20

NOTE! TO THE INSTALLER: Please make sure you provide this manual to the owner of the pumping equipment or to

the responsible party who maintains the system.

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.FEMYERS.COM

PH: 888-987-8677 Fax: 800-426-9446

© 2018 Pentair plc. All Rights Reserved. MY1004 (Rev. 02/08/18)

490 PINEBUSH ROAD, UNIT 4, CAMBRIDGE, ONTARIO N1T 0A5

PH: 800-387-4386 ORDERS FAX: 888-606-5484

General

Information

Thank you for purchasing your

Myers® pump. To help ensure

years of trouble-free

op er a tion, please read the

fol low ing manual carefully.

Before Operation:

Read the following in structions care ful ly. Reasonable care

and safe meth ods should be

practiced. Check local codes and

requirements before installation.

Attention:

This manual contains

important information for the

safe use of this product. Read

this manual completely before

using this product and refer

to it often for con tin ued safe

product use.

DO NOT THROW AWAY OR

LOSE THIS MAN U AL. Keep it

in a safe place so that you may

refer to it often.

WARNING: Before handling

these pumps and controls,

always disconnect the power

first. Do not smoke or use

sparkable electrical devices

or flames in a septic

(gaseous) or possible septic

sump.

California Proposition 65

Warning

This product and

related accessories contain

chemicals known to the

State of California to cause

cancer, birth defects or other

reproductive harm.

Pump Warning

To reduce risk of electrical

shock:

1. Risk of Electrical Shock:

This pump has not been

in ves ti gat ed for use in

swimming pool areas.

2.Risk of Electrical Shock:

Connect only to a properly

ground ed receptacle.

Septic tank to be vented

in ac cor dance with local

plumbing codes.

Do not smoke or use

sparkable electrical

devices or flame in a septic

(gaseous) or possible septic

sump.

If a septic sump condition

exists and if entry into

sump is necessary, then

(1) provide proper safety

precautions per OSHA

re quire ments and (2) do not

enter sump until these

precautions are strictly

adhered to.

Do not install pump in

location clas si fied as

hazardous per N.E.C.,

ANSI/NFPA 70 - 2001.

Failure to heed above

cautions could result in

injury or death.

Pump Installation

These important instructions

must be followed for

satisfactory performance

of your pump. Before

installation, check your local

electrical and plumbing codes.

1. Provide proper sump size

to allow the pump to

operate without

restrictions. A two- to

five-minute run time is

recommended. Also,

minimum 24" diameter

recommended.

2. Make sure sump is free of

string, cloth, nails, gravel,

etc. before installing pump.

3. Do not set pump directly

on the bottom of sump pit

if it is not solid. Raise the

pump by placing bricks or

concrete blocks underneath

it.

4. Use steel or plastic pipe

for all connecting lines

between pump and sewer

outlet.

NOTE: Some city

regulations do not allow

installing a pump with

plastic pipe. Check local

regulations.

5. In applications where

the pump may sit idle for

months at a time, it is

recommended that the

pump(s) be cycled every

month to ensure the

pumping system is working

properly when needed.

6. A check valve should be

installed in discharge

pipe, at least 12" above

the discharge outlet of the

pump.

NOTE: If pumping raw

sewage, the check valve

must be installed in the

horizontal position

7. An audible alarm system,

for high water conditions

should be installed in

every pump for greater

protection.

8. Connect to power source

using 3-prong grounded

AC receptacle. Do not

remove ground pin from

electrical plug. Do not use

an extension cord.

9. Use pump partially or

completely submerged for

pumping (temperature to

140° F). The MSE50 will

pump solid materials up to

2" (spherical) in diameter.

CAUTION: Do not pump

flammable liquids, strong

chemicals or salt water.

2

Pump

Servicing

Servicing should be performed

only by knowledgeable pump

service contractors or

authorized service stations.

1. Remove pump from sump.

Before removing pump

from sump pit for repair,

check if the trouble could

simply be a blown fuse,

tripped circuit breaker, or a

power cord not completely

inserted into the receptacle.

2. Check switch.

3. Check for impeller blockage.

Disconnect pump from

power source. Check for an

obstruction in the impeller

cavity by laying the pump

on its side and inserting a

screwdriver into impeller.

Impeller should turn freely.

If impeller is stuck, then

turn the pump on its side,

DRAIN THE OIL through

the oil fill plug on top of

the pump. Drain oil into

a clean, dry container. A

milky appearance to the

oil indicates that water

has entered through either

worn out or damaged seals

(7) or seal ring. Remove the

3 screws (9) to remove the

volute (2). If the impeller (8)

does not rotate freely, clear

the impeller and cavity walls

before reassembling the

base. Repeat Step 2.

4. Check power cord. If the

above tests have not

resolved the problem, it

may be in the electrical

components of the pump.

Starting with the power

cord (19), inspect for cuts or

nicks in the insulation. If the

cord is damaged – replace

it!

5. Remove the motor cover.

Use a screw driver to

pry the motor cover (10)

from the seal plate (1) at

the fastening ears, being

careful not to cut the seal

ring with the screwdriver

or crack the motor cover.

Lift the motor cover until it

clears the stator (3).

6. Check for short. Disconnect

the stator leads from

the connector. Use an

ohmmeter to check the

continuity of the stator. If

stator fails to pass the

continuity test, it must

be replaced.

Ground check. Set

ohmmeter scale pointer to

R X 100K scale and check

meter by putting both

meter leads together and

adjusting the

needle knob until meter

reads zero. If meter cannot

be adjusted to zero it will

indicate that batteries in

meter must be replaced.

Always make this test

with the meter when scale

pointer is set to a new scale

before making any checks

on motor.

Now connect one meter

lead to one blade terminal

of stator and touch other

meter lead

to motor stator shell (3).

If needle reads below 5

(500,000 ohms) stator

must be dried out before

reusing. To dry out, bake

in 220° oven for 4 hours.

Recheck after motor

cools. If motor is new or

thoroughly dry, needle of

ohmmeter will not move

on the ground test. This

indicates a reading of 50

megohms or higher. One

megohm is one million

ohms.

When making the ground

test, if the needle goes

clear to zero the motor

probably has a wire

touching the stator at some

point and the stator will

have to be replaced.

7. Remove the stator. To

remove the stator, remove

the four hex head screws

(4) and disconnect the

capacitor leads from the

capacitor. Lift the stator off

the seal plate (1) and set

aside.

8. Remove the impeller. To

remove the impeller (8),

hold the rotor shaft (5)

with a screwdriver at the

center of the impeller and

tap the impeller with a

plastic or rubber mallet

so as to turn the impeller

counterclockwise.

9. Check the seal. Remove the

rotating portion of seal

(7) from shaft by inserting a

screwdriver under the edge

of the seal and lifting it off.

Inspect the seal face for any

nicks or an uneven seating

of seal face. If any are

present, replace the seal.

(See Step 14.)

Full Load Amps:

115 Volt ....................... 9 Amps

230 Volt .................... 4.6 Amps

10. Remove rotor. Tap the rotor

shaft (5) at the impeller

end of the shaft with a

plastic mallet to remove

the rotor and shaft. Inspect

the bearings. If they do not

rotate freely and smoothly,

they should be replaced.

3

11. Remove seal. Remove the

old stationary portion of the

seal (7) from the seal plate

by inserting a screwdriver

into the seal housing of the

seal plate from the top of

the case and tapping lightly

with a hammer. Clean the

seal area of the seal plate

(1) with a clean cloth.

12. Reinstall the rotor and shaft

assembly. Push on outer

face to seat bearing in seal

plate.

13. Reinstall seal. Apply a good

lubricant to the new

stationary portion of the

seal (7) and press into the

seal plate. Coat the new

rotating portion of seal with

lubricant and press into

place on the rotor shaft

with

the rubber ring facing

the impeller.

14. Reinstall impeller. Add a

drop of Loctite 222 to

the shaft and screw the

impeller on hand tight.

The impeller will force the

rotating portion of seal into

position.

15. Replace seal ring. Remove

the old square seal ring

from the seal plate and

stretch on a new ring

coated with O-ring lube.

Do not roll the ring onto

the seal plate or improper

seating and water leakage

into the motor housing will

result.

16.Reinstall the stator. Place

the stator (3) in the seal

plate (1) so the stator

bolt holes line up. Lay the

stator plate on the stator

(3) and line up with stator

bolt holes. Slide the ring

terminal of the ground

lead wire over one of the

stator bolts. Put in the

stator bolts and tighten

evenly to prevent cocking

of the stator. Connect the

capacitor to the capacitor

leads. Push the connectors

of the two black stator leads

onto the power cord pin

terminals. Push the ground

wire sleeve terminal over

the ground pin terminal.

(identified with the 'bump'

on the molded terminal

housing)

17. Reassemble pump. Replace

the motor cover (10) on

the seal plate (1). Place

the assembly on the volute

(2). Insert the three cap

screws (9) through the

motor housing ears, into

the tapped holes in the

volute. Tighten them evenly

to prevent cocking the

motor housing and causing

an uneven seal on the seal

ring.

18. Oil. Fill the motor cap with

high grade transformer oil

just covering over stator

end cap.

Do not fill the motor

housing

completely – allow airspace

for oil expansion. Make

sure the stator is fully

immersed. You will have

to peer through the oil

plug hole to be sure of the

correct oil level.

19. Reinstall oil pipe plug. Coat

pipe threads with thread

sealant before installing.

Plug into housing (14).

20. Check pump. Plug the

power cord into a grounded

outlet and start pump

by raising the switch rod

extending out of the switch

housing. Motor should run

smoothly, be free

of vibration and stop when

pressure is removed from

diaphragm switch.

21. Check for air lock. Myers

pumps have a small air

vent hole in the impeller

cavity to let out trapped

air. If this hole becomes

plugged, pump may air

lock. To break the air

lock, use a small

screwdriver to clear hole in

the

impeller cavity.

Switch

Replacement

As a secondary precaution

in installations of this type

— 1⁄16" hole should be

drilled in the discharge

pipe below the check valve.

The check valve should be

12 to 18 inches above pump

discharge. Do not put check

valve directly into pump

discharge opening.

NOTE: In basins where the

pump is operating daily,

air locking rarely occurs.

1. Disconnect power to the

pump.

2. Remove the pump from the

sump. Disinfect it for one

hour with chlorine bleach.

Wear rubber gloves when

handling the pump.

3. Remove the bottom tether

strap from the float rod, lift

the float and swing it

sideways, and remove it

from the switch arm.

4. Remove the four screws

that secure the switch

to the top of the motor

housing and lift the switch

off the motor. The switch

guard may come off with it.

44

5. Disconnect four wires that

222 0

connect the switch to the

motor housing.

6. Remove and discard the

gasket between the switch

and the pump. Clean the

gasket surface on the

motor housing.

7. Remove old switch and

replace.

8. Make sure the fork on the

rod fits over the switch

lever.

9. Set the new gasket on

the motor housing, then

connect the four wires on

the new switch to the four

terminals in the motor

housing

(see Figure)

10. With the switch guard in

place, set the switch on

the motor housing with

the switch arm pointed

toward the discharge side

of the pump and install and

tighten the four screws

which secure the switch to

the pump.

11. Holding the float out

sideways, hook the float

rod on to the switch arm

and swing the float rod

down.

12. Insert the float rod in the

hole in the tether strap.

13. Reinstall the pump in the

sump, check all piping

connections, and reconnect

the power. Run the pump

through one complete

operating cycle to check for

proper operation. Failure

to make this operational

check may lead to flooding

and will void the warranty.

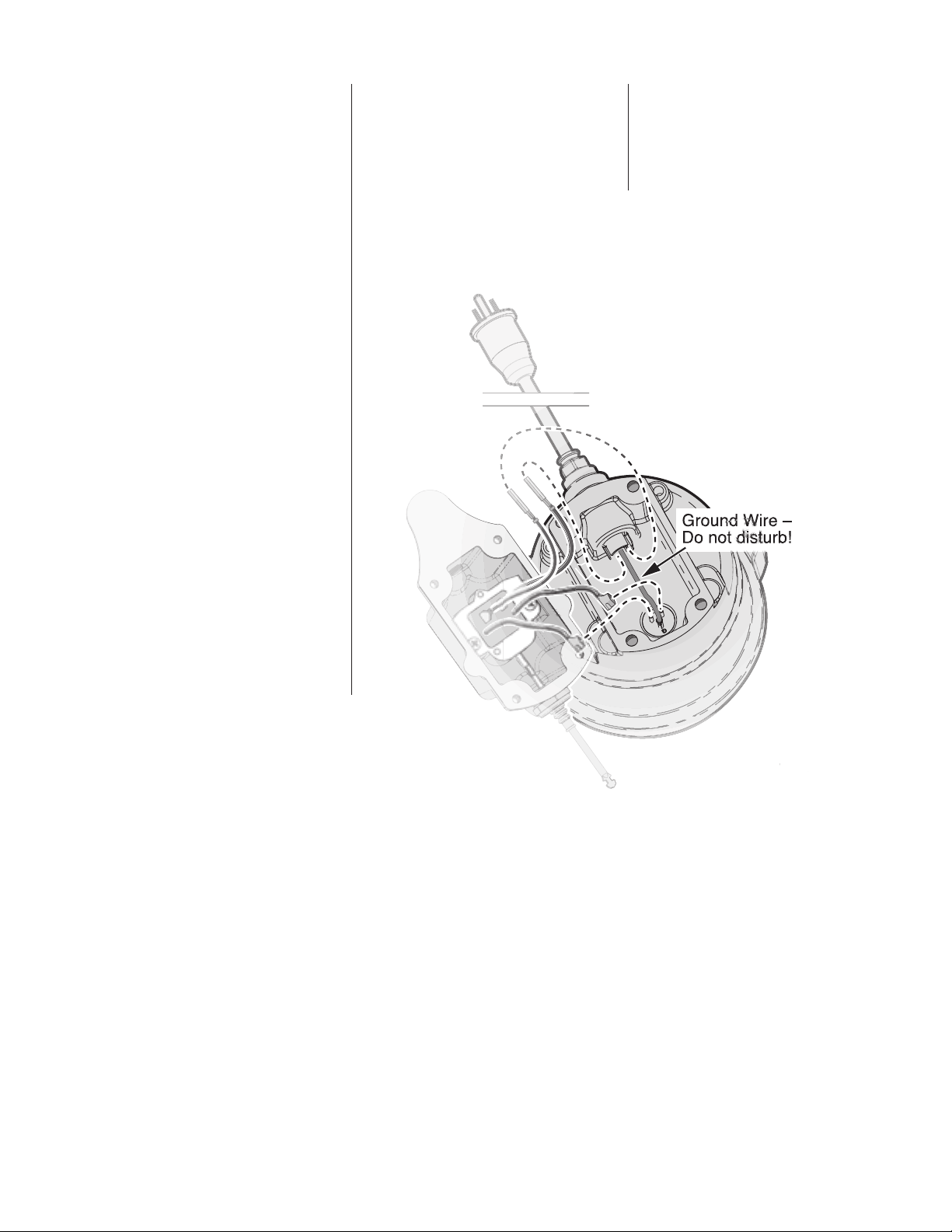

NOTICE: When you connect

the two power wires to the

cord terminals, make sure

that the wire ends don’t

lodge between the cord pin

and the side of the cord

plug. The connector must

be on the pin.

7222 0717 7

717

55

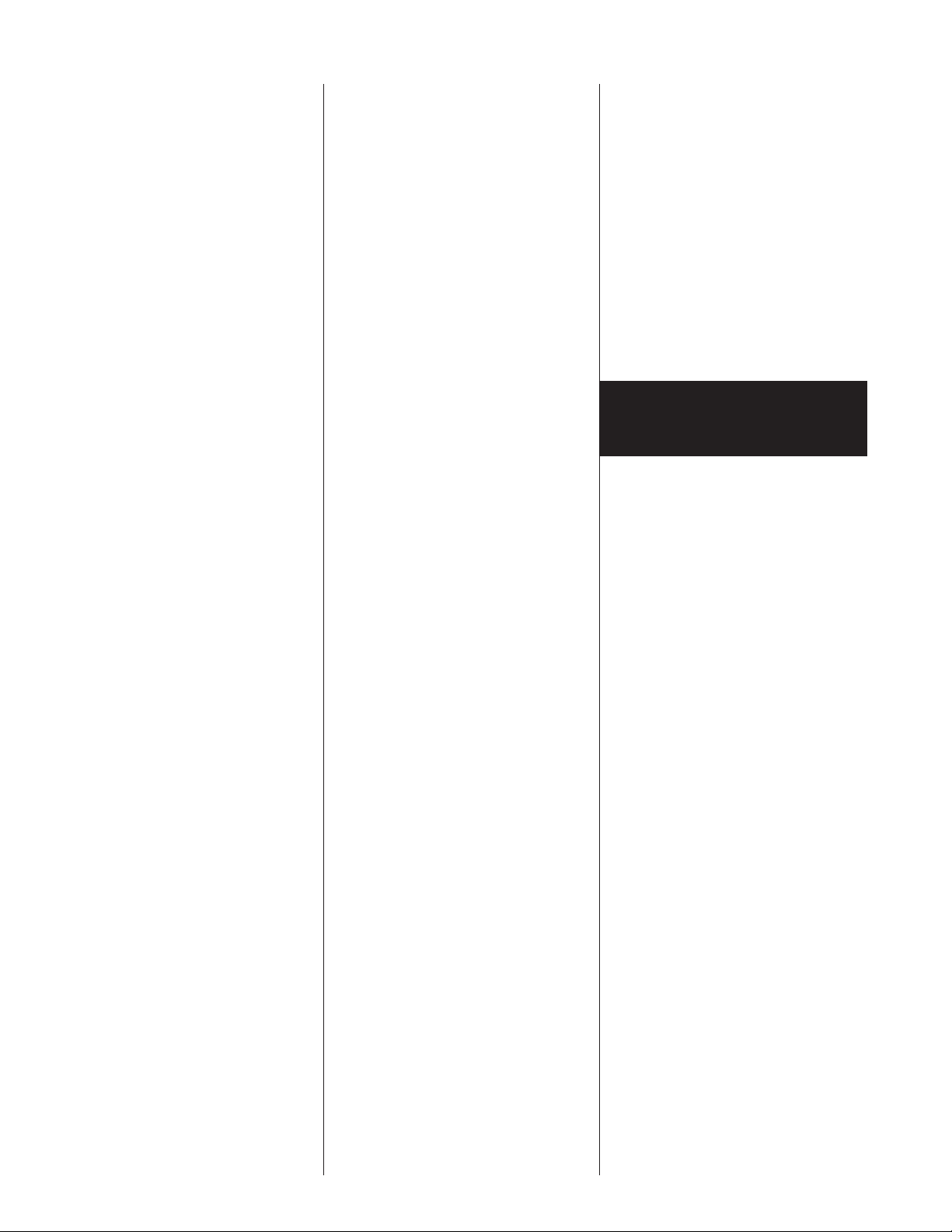

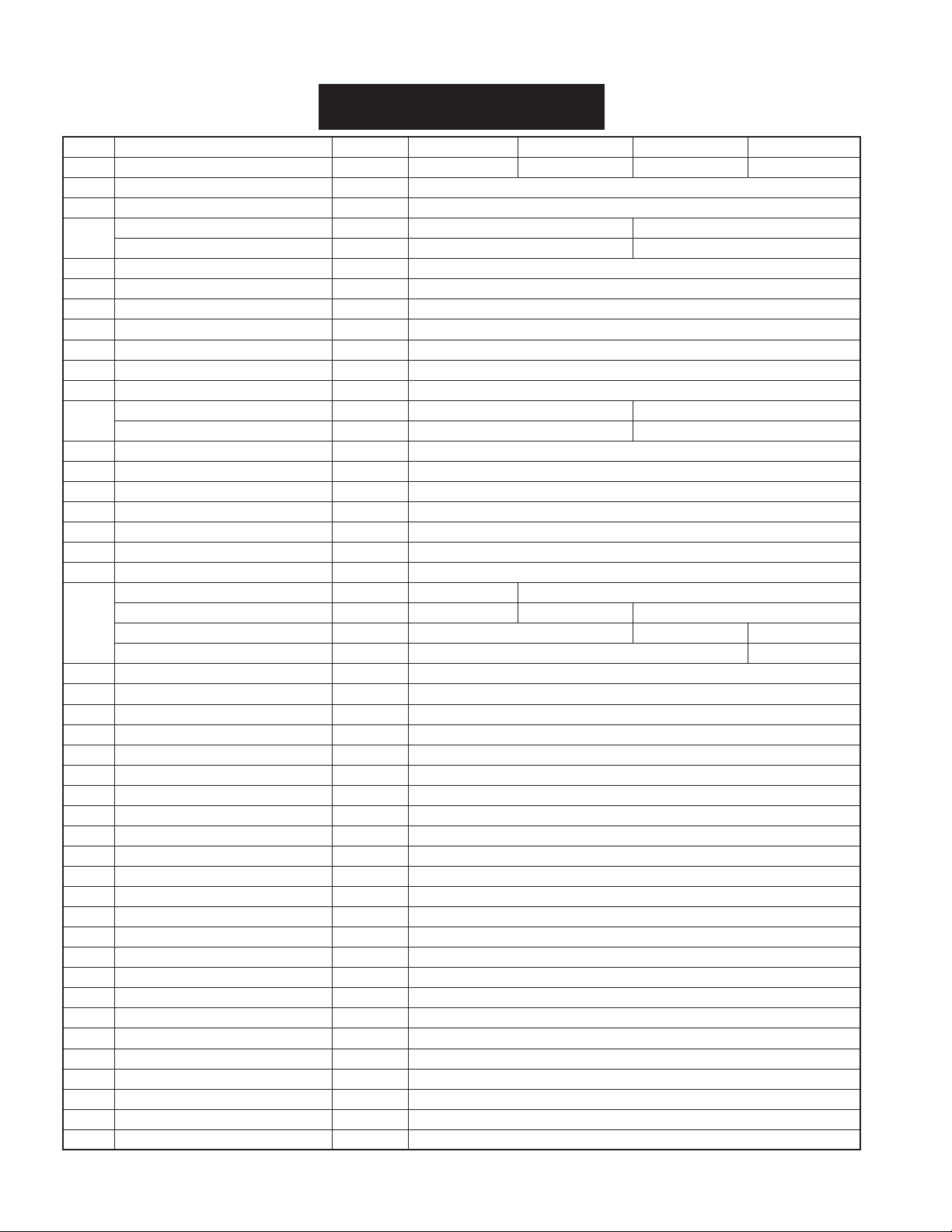

MSE50 - Parts List

MSE5012P10 MSE5012P20 MSE5022P10 MSE5022P20

Ref. No. Description Quantity Part Number Part Number Part Number Part Number

1 SEAL PLATE 1.000 PW3-1421

2 VOLUTE,SEWAGE .2" DISCH 2" 1.000 21612D000

STATOR 4/10HP, 115V 1PH 1.000 26165B010

3

STATOR 4/10HP 230V 1PH 1.000 26165B011

4 SCREW-MACH(HEX HD)8-32X 3-3/16 4.000 001450101

5 ASSEMBLY ROTOR 1/2 HP 1.000 27479A001

6 BEARING-BALL 1.000 650241

7 1/2 SHAFT SEAL 1.000 21607A015

8 IMPELLER 1.000 21542B000

9 HEX CAP SCREW 6.000 19099A012

10 MOTOR COVER 1.000 PW18-1691

RUN CAPACITOR 15MFD 1.000 U17-1540

11

RUN CAPACITOR 4MFD 1.000 U17-2150

12 SCREW 1.000 U30-985SS

13 O-RING 1.000 U9-339

14 PLUG 1.000 U78-94SST

15 GREEN WIRE W/TERMINALS 1.000 PS17-2149

16 CORD CONNECTOR 2.000 PS17-1508

17 O-RING 2.000 U9-356

18 INSULATING DISK 1.000 PS18-82

CORD, POWER 10FT 115V 1.000 PW117-237-TSE

CORD, POWER 20FT 115V 1.000 PW117-122-TSE

19

CORD, POWER 10FT 230V 1.000 PW117-2126-TSE

CORD, POWER 20FT 230V 1.000 PW117-218-TSE

20* GASKET, SWITCH COVER 1.000 PS20-126

21* SWITCH COVER 1.000 PW70-85

22* MACH SCREW 4.000 U30-482SS

23* FLOAT SWITCH 1.000 PS17-1511

24* SCREW 8-32 X 5/8 HEX HD 2.000 U30-951PSW

25* FLOAT PIVOT ARM 1.000 PS41-5

26* E-RING, EXTERNAL 1.000 U9-472SS

27* VITON SHAFT BELLOWS SEAL 1.000 U9-483

28* RETAINING RING C-CLIP 1.000 U9-461

29* BELLOWS RETAINER 1.000 PW19-142

30* SCREW 2.000 U30-957SS

31* WIRE, GROUND (NOT SHOWN) 1.000 PS17-1509

32* WIRE, CORD ENTRY TO SWITCH (NOT SHOWN) 2.000 PS17-1510

33 FLOAT BODY 1.000 PS28-36P

34 RUBBER STANDOFF 1.000 PW19-141

35 FLOAT ROD 1.000 PW28-39

36 FLOAT ROD STOP 1.000 U9-463

37* PIPE PLUG 1.000 M15743

38 FLOAT PROTECTOR BRACKET 1.000 U97-194SS

39* HANDLE 1.000 U97-193SS

40 OIL (NOT SHOWN) 0.227 PO00VEL6

41 WASHER 1.000 U43-144SS

42 NYLON WASHER 1.000 U43-184

* SWITCH KIT 1.000 PW17-2130REP

66

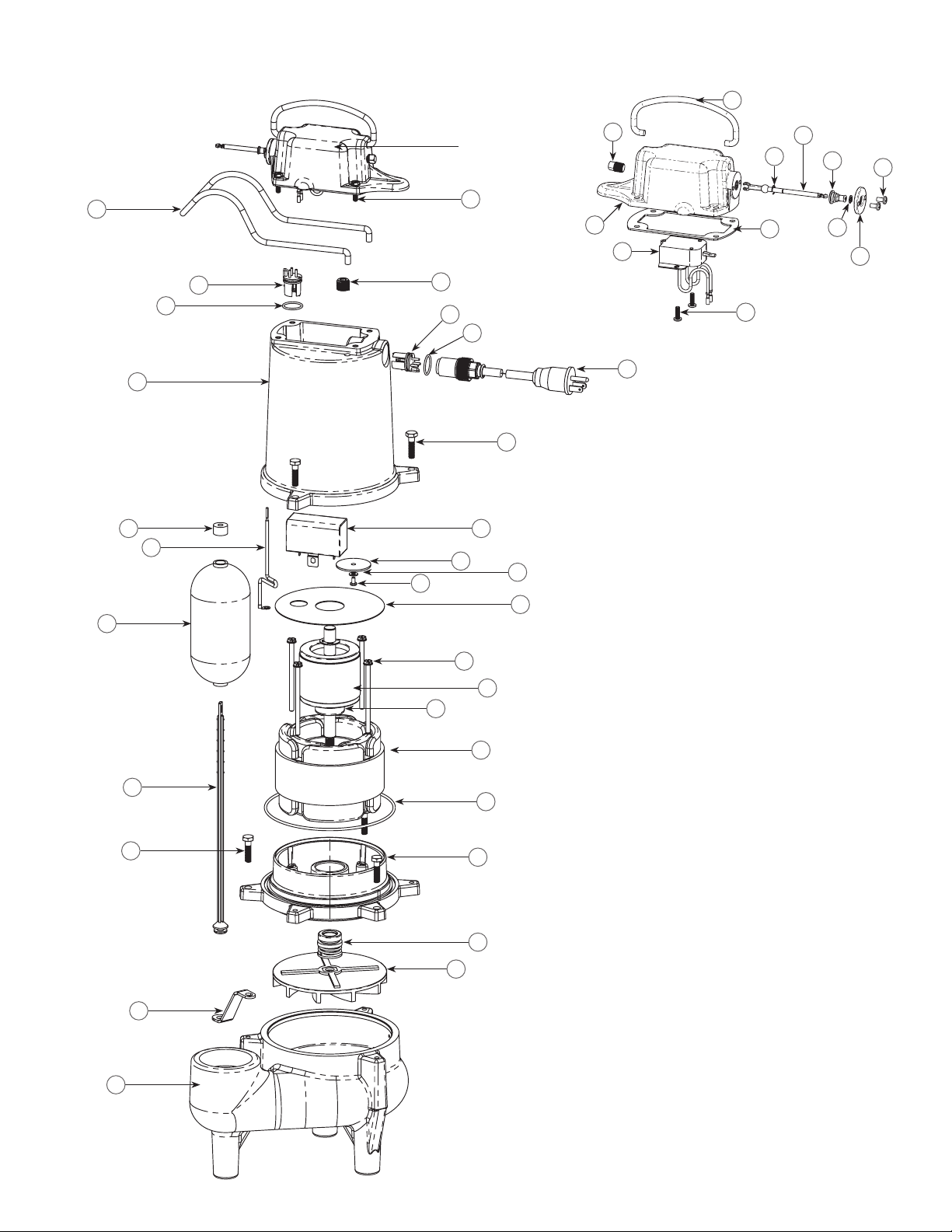

MODEL – MSE50

39

PW17-2130 REP

38

16

17

10

36

15

12

33

22

14

16

17

9

11

42

41

18

37

21

23

24

19

25

28

20

27

30

26

29

4

5

6

3

35

9

34

2

13

1

7

8

7

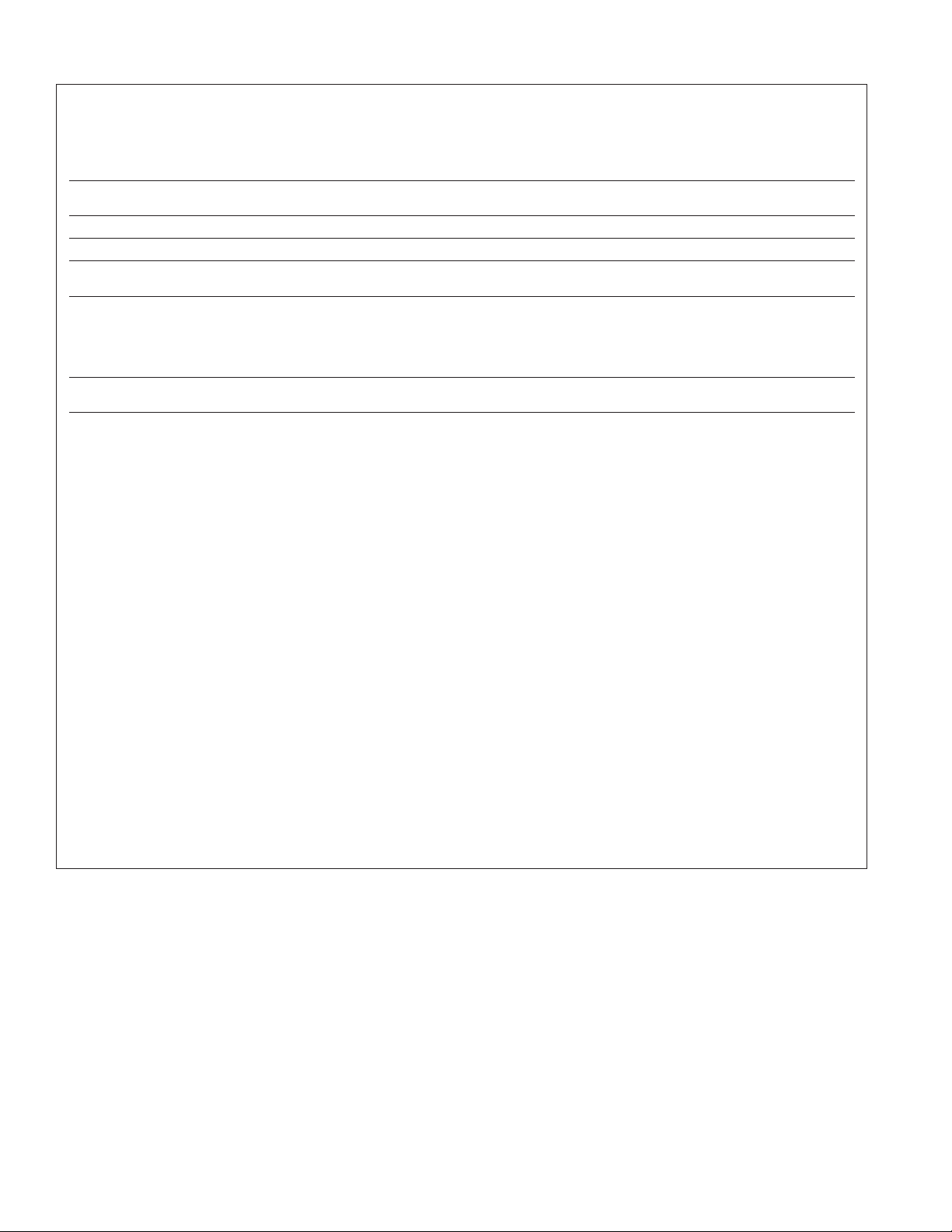

Limited Warranty

Myers® warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free from

defects in material and workmanship for the Warranty Period shown below.

Product

Jet pumps, small centrifugal pumps, submersible pumps and

relatedaccessories

Fibrewound Tanks 5 years from date of original installation

Steel Pressure Tanks 5 years from date of original installation

Sump/Sewage/Effluent Products

Battery Backup Units

MBSP-2, MBSP-2C

MBSP-3, MBSP-3C

Wastewater Solids Handling Pumps

Our warranty applies only where such products are used in compliance with the requirements of the applicable product catalog

and/or manuals. For additional information, please refer to the applicable standard limited warranty featured in the product

manual.

Our warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication, improper

installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase power

through a phase converter will void the warranty. Note also that three phase motors must be protected by three-leg, ambient

compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and MYERS’s only duty, is that MYERS repair or replace defective products (at MYERS’s choice). You must pay

all labor and shipping charges associated with this warranty and must request warranty service through the installing dealer as

soon as a problem is discovered. No request for service will be accepted if received after the Warranty Period has expired. This

warranty is not transferable.

MYERS SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an

implied warranty, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You

may also have other rights which vary from state to state.

Warranty Period

whichever occurs first:

12 months from date of original installation,

or 18 months from date of manufacture

12 months from date of original installation,

or 36 months from date of manufacture

12 months from date of original installation,

or 18 months from date of manufacture

24 months from date of original installation,

or 30 months from date of manufacture

12 months from date of shipment from factory

or 18 months from date of manufacture

This Limited Warranty is effective April 1, 2014 and replaces all undated warranties and warranties dated before April 1, 2014.

F.E. MYERS

293 Wright Street, Delavan, WI 53115

Phone: 888-987-8677 • Fax: 800-426-9446 • www.femyers.com

In Canada: 490 Pinebush Road, Unit 4, Cambridge, Ontario N1T 0A5

Phone: 800-363-7867 • Fax: 888-606-5484