Pentair MYERS MG200 Series Installation And Service Manual

MG200 SERIES

GRINDER PUMPS

INSTALLATION AND SERVICE MANUAL

2 HP Grinder Pump for Residential and Pressure Sewer Applications.

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Part # 23833A664 | © 2014 Pentair Ltd. | 07/16/14

USAGE

n CAUTION!

The MG200 Series is a submersible wastewater

grinder pump designed specifically for individual

residential and pressure sewer applications. The

pumps are to be used for domestic sewage only

and are not to be used for pumping commercial or

industrial sewage such as from motels, schools,

apartments, factories, etc. THIS PUMP IS NOT FOR

USE IN HAZARDOUS LOCATIONS!

INSPECTING PUMP

Before making any piping or electrical connections,

check the pump for shipping damage or cracks.

Using a flat screwdriver placed in the slot on the

shaft end, turn shaft and impellers to be sure they are

free. DO NOT TURN IMPELLER WITH FINGERS AS

EDGES ARE SHARP.

POWER SUPPLY

The MG200 Series grinder pump should be connected

only to a 230 volt, single phase, 60 Hz power source.

The pump will draw approximately 9.1 amperes at

minimum flow and 15.0 full load amperes. The pump

must be connected to a grounded power socket. DO

NOT cut off the ground pin from the power cord plug.

POWER CORD

A 20 foot power cord is attached to the grinder pump

via three insulated quick-disconnect terminals. To

replace a cord simply unscrew (turn counterclockwise)

cord nut from top of motor housing. Once cord nut

is completely loosened from housing, gently pull

cord upward away from housing. While cord is being

pulled, it may be necessary to shift cord leads back

and forth to guide the insulated terminals through

the hole in the motor housing. Once the terminals

have cleared the hole, gently pull cord until terminals

are completely outside motor housing. Then simply

disconnect terminals to remove cord.

To install new cord, reconnect terminals (black to

black, white to white, green to green), and guide

terminals back through hole in motor housing. Once

terminals have passed through the hole, retighten the

cord nut into housing. Tighten nut firmly but do

not overtighten.

The power cord should be replaced if it has

been damaged in any way or the cord jacket

has become brittle.

MOTOR TYPE

The MG200 Series grinder pump contains a 3/4

frame, 2 HP, single phase, 60 Hz, 3450 RPM, capacitor

start, capacitor run motor with Class F insulation and

built-in, on-winding overload protection. Motor has

upper and lower ball bearings and is oil-cooled

and lubricated.

THE MG200 SERIES GRINDER PUMP SHOULD

NEVER BE WORKED ON WITHOUT FIRST

DISCONNECTING THE POWER CORD.

OIL TYPE

The motor housing contains dielectric transformer oil

to provide good heat transfer and lubrication of ball

bearings; no other lubrication is required. Oil level

may be checked by removing the nut and washers

from the top of the motor housing. The oil level

should be filled to the bottom of the end shield. Do

not overfill with oil. Only dielectric transformer oil

obtained from a Myers

should be used.

®

authorized service center

PUMP SWITCH INSTALLATION

INSTRUCTIONS

NOTE: In accordance with third party approval, pump

must be submerged a minimum of 8-1/2" from bottom

of the legs on volute case during operation.

Mounting the Switch

1. Determine pumping range for installation. Do not

tether less than 3-1/2" from pipe.

2. Tighten strap around discharge pipe keeping

switch cable between strap and pipe to prevent

slippage.

3. Space small ties at least 1" apart. To readjust ties,

press small tie tabs down.

4. To lock releasable tab, run remaining

strap between tab and head. Tuck strap back

through head.

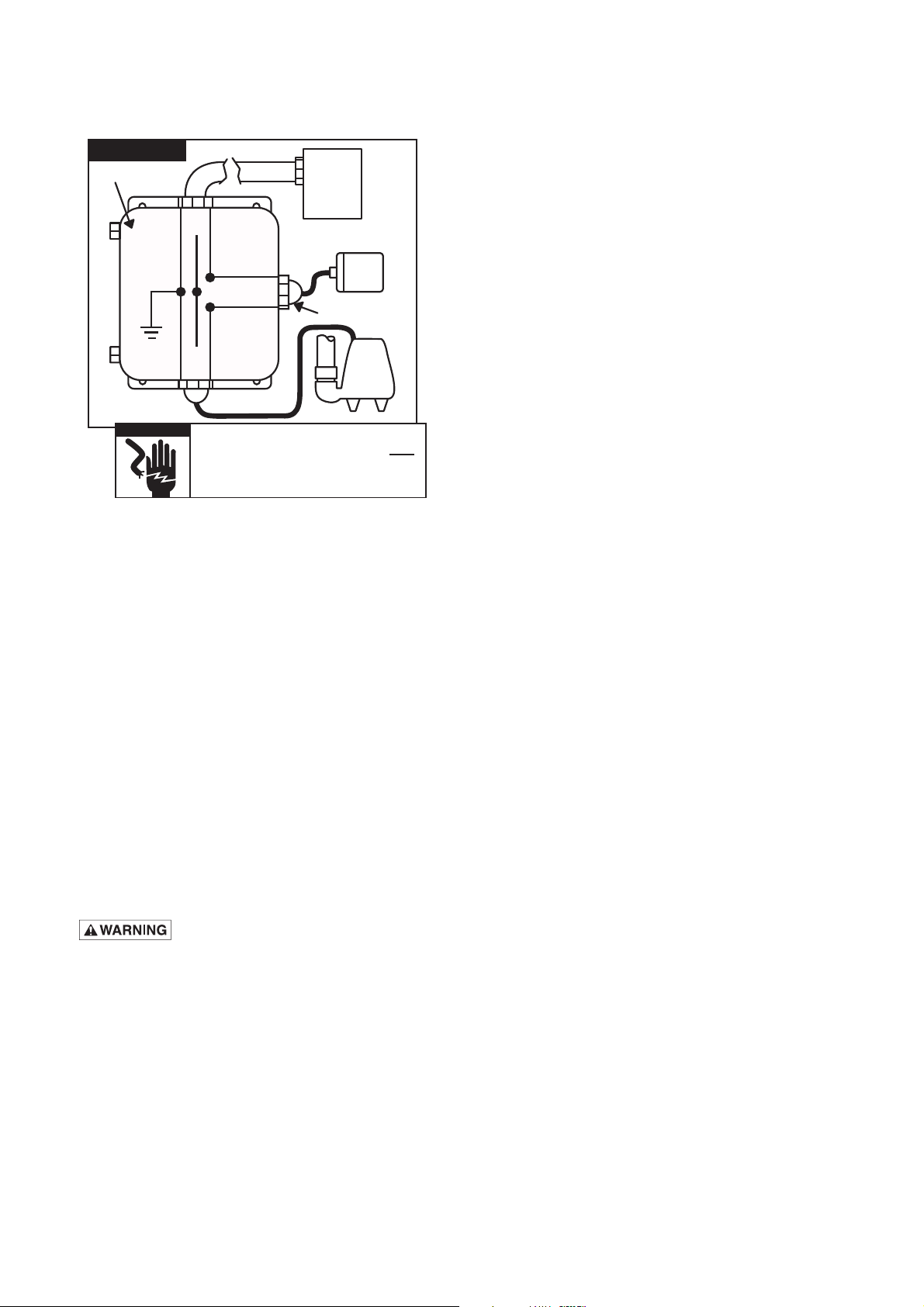

Piggyback Plug Install

n

Electrical outlet must not be located

in pump chamber.

n Electrical outlet voltage, piggyback plug voltage,

and pump voltage must match.

1. Follow steps 1 through 4 of “Mounting the Switch.”

2. Insert switch’s piggyback plug into outlet.

3. Plug pump into piggyback plug.

4. Check installation. Allow system to cycle to ensure

proper operation.

Direct Wire Install

1. Follow steps 1 through 4 of “Mounting the Switch.”

2. Further wiring of switch should be done by

qualified professionals only.

3. Check installation. Allow system to cycle to ensure

proper operation.

2

230 VAC

junction

box

REPLACING GRINDER IMPELLER AND

230V

power

source

G

L1

L2

GRINDER SHREDDING RING

All repairs must be done at the factory or at an

authorized Myers

®

service facility.

black

G

n WARNING

white

G

L1

L2

In 230 VAC pump installations, one side of

the line going to the pump is always HOT.

This condition exists if the switch is on or

off. Install double pole disconnect on all

230 VAC pump circuits.

liquid-tight

connector

230V

pump

SAFETY WARNINGS

n WARNING! Risk of electrical shock. Pumps are

supplied with a grounding conductor and groundingtype attachment plug on the power cord (except

MG200-21L/P). To reduce the risk of electrical

shock, be certain that it is connected only to properly

grounded, grounding-type receptacle. DO NOT cut

off ground pin or use an adapter fitting. DO NOT

use an extension cord with this pump. When wiring

this pump follow all local electrical, safety codes and

ordinances as well as most recent National Electric

Code (NEC-ANSI/NFPA).

The MG200 Series grinder pumps have a GROUND

WIRE that is connected to a screw in the metal motor

housing. This wire goes to the receptacle or control

box which must be connected to a good outside

GROUND such as a metal water pipe or GROUND

STAKE driven at least 8 feet into the ground.

CALIFORNIA PROPOSITION 65 WARNING:

This product and related

accessories contain chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm.

DISMANTLING PUMP FOR

REPLACEMENT PARTS

Before dismantling pump for replacement parts, clean

pump thoroughly.

n CAUTION!

DISCONNECT ALL POWER AND CONTROL

WIRES TO MOTOR AT CONTROL PANEL BEFORE

STARTING DISASSEMBLY OPERATIONS. NEVER

RELY ON OPENING CIRCUIT BREAKER ONLY.

DISASSEMBLY OF SHREDDING RING

AND GRINDER IMPELLER

1. Remove three screws from grinder ring flange.

Grinder ring is pressed into flange for easy

removal.

2. Using Allen head socket wrench, thread two

screws into tapped back-off holes in flange. Evenly

tighten screws to guide grinding ring out of pump

volute case.

3. Hold grinder impeller by prying against impeller

cutting bar and remove cap screw from end

of shaft.

4. Use large screwdriver in slot in end of shaft

and bump on cutter vane with plastic hammer.

Bump in counterclockwise direction as thread

is right-hand. It may take several bumps to

loosen impeller.

DO NOT CONTINUE TO POUND ON IMPELLER

AS IMPELLER AND SHAFT MAY BE DAMAGED.

5. If impeller comes off easily, clean and replace

if worn.

6. Be sure pump impeller has not loosened when

grinder impeller is removed. This can be checked

on reassembly of grinder impeller and shredding

ring. Tips of impeller cutter vanes should extend

about 1/8" below bottom of shredding ring. If

distance is more, it means the pump impeller has

loosened, and if it is less, it means the shredding

ring is not properly seated.

If the pump impeller has loosened, remove grinder

impeller and shredding ring as described above

and remove bolts from volute case and remove

case. Plastic hammer can be used to bump on

casing discharge to loosen. Place gasket in oil

to prevent drying out. DO NOT loosen the pump

impeller further – it is the seat for the seal spring.

7. After case is removed, wrap emery paper around

shaft and hold with vice grip pliers. Use cloth

on impeller and screw up against shoulder. Now

pump can be reassembled.

8. Clean all threads with wire brush and file; smooth

any threads that may have been nicked.

3

Loading...

Loading...