Pentair Myers MES100, Myers MES50 Installation And Operator's Manual

INSTALLATION AND

OPERATOR'S MANUAL

Submersible Sewage

Ejector Pump

INSTALLATION ET MANUEL

DE L'OPÉRATEUR

Pompe submersible

d'eauxd'egout

Installation/Operation/Parts

For further operating, installation, or

maintenance assistance:

Call 1-888-987-8677

English ..........Pages 2-12

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.FEMYERS.COM

PH: 888-987-8677 ORDERS FAX: 800-426-9446

490 PINEBUSH ROAD, UNIT 4, CAMBRIDGE, ONTARIO, N1T 0A5

PH: 800-363-7867 ORDERS FAX: 888-606-5484

© 2016 Pentair plc. All Rights Reserved. 23833A704 (05/25/16)

MES50/MES100

Installation/Fonctionnement/Pièces

Pour plus de renseignements concernant

l’utilisation, l’installation oul’entretien,

Composer le 1 (888) 987-8677

Français ........Pages 13-24

Safety 2

Contents

Important Safety Instructions .......................2

Installation .......................................3

Operation ........................................5

Maintenance ......................................5

Ground check .................................... 6

Reassembly ...................................... 7

Oil fill ........................................... 7

Troubleshooting ..................................8

Repair Parts ......................................9

Warranty .......................................11

Product Specifications ............................12

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product.

Save this manual for future reference.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury!

indicates a hazard which, if not avoided, will

result in death or serious injury.

indicates a hazard which, if not avoided,

could result in death or serious injury.

indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE

The manufacturer cannot anticipate every possible

circumstance that might involve a hazard. The warnings

in this manual, and the tags and decals affixed to the unit

are, therefore, not all-inclusive. If you use a procedure

or operating technique that the manufacturer does not

specifically recommend, you must satisfy yourself that it

is safe for you and others. You must also make sure that

the procedure or operating technique that you choose

does not render the system unsafe.

addresses practices not related to personal injury.

Electrically powered sewage pumps normally give many

years of trouble-free service when correctly installed,

maintained, and used. However, unusual circumstances

(interruption of power to the pump, large solids in

the sump, flooding that exceeds the pump’s capacity,

electrical or mechanical failure in the pump, etc.) may

prevent your pump from functioning normally. To prevent

possible damage, consult your dealer about installing

a secondary sewage pump or a high water alarm. See

Troubleshooting in this manual for information about

common sewage pump problems and remedies. For

more information, see your retailer, call Hydromatic

customer service at 1-888-957-8677 or visit our web site

at hydromatic.com.

Hazardous voltage - risk of electrical

shock. Shock can cause serious injury or death.

Failure to follow the warnings below can result in fatal

electricshock.

Burn Hazard.

high temperatures. Do not touch an operating motor. To do

so can cause personal injury.

Risk of flooding. If a flexible discharge hose

is used, pump may move around in sump when motor

starts. If it moves far enough so that the switch hits the

side of sump, the switch may stick and prevent the pump

from starting. Make sure the pump is secured so it cannot

move around in the sump.

Modern motors can operate at

Safety • Installation 3

Hazardous pressure and gas - risk of

explosion and personal injury. Failure to follow the

warnings that follow can result in personal injury.

1. If your basement has water or moisture on the floor,

do not walk on the wet area until all the power

has been turned off. If the shut-off box is in the

basement, call the electric company or the hydro

authority to shut off the service to the house, or call

your local fire department for instructions. Do not

handle the pump or pump motor with wet hands or

when standing on wet or damp surfaces.

2. Connect only to a properly grounded receptacle.

3. All wiring should be performed by a

qualifiedelectrician.

4. Protect the electrical cord from sharp objects, hot

surfaces, oils, and chemicals. Observe the Cord Lift

Warning shown below.

5. Risk of explosion and hazardous gas. Septic

tank must be vented in accordance with local

plumbingcodes.

Do not smoke or use sparkable electrical devices or

flame in a septic (gaseous) or possible septicsump.

If a septic sump condition exists and if entry into

sump is necessary, then (1) provide proper safety

precautions per OSHA requirements and (2) do

not enter sump until these precautions are strictly

adhered to.

Do not install pump in location classified as

hazardous per N.E.C., ANSI/NFPA 70- 2001.

6. Know the pump application, limitations and

potential hazards.

7. Wear safety glasses at all times when working with

the pump.

Keep the work area clean, uncluttered and properly

8.

lighted - secure all unused tools and equipment.

9. Keep visitors at a safe distance from working area.

10. Make the workshop child-proof - with padlocks,

master switches, and by removing starter keys.

11. Release all pressure within the system before

servicing any component.

12.

Provide a means of pressure relief for pumps whose

discharge line can be shut-off or obstructed.

13. Periodically inspect the pump and system

components. Perform routine maintenance

asrequired.

14. Drain all the liquid from the system beforeservicing.

California Proposition 65 Warning

This product and related accessories contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Installation

Thank you for purchasing this Hydromatic® pump. To

help ensure years of trouble-free operation, please read

the manual carefully.

Before installation, check your local electrical and

plumbing codes. Typical sewage pump installations are

shown on the next page.

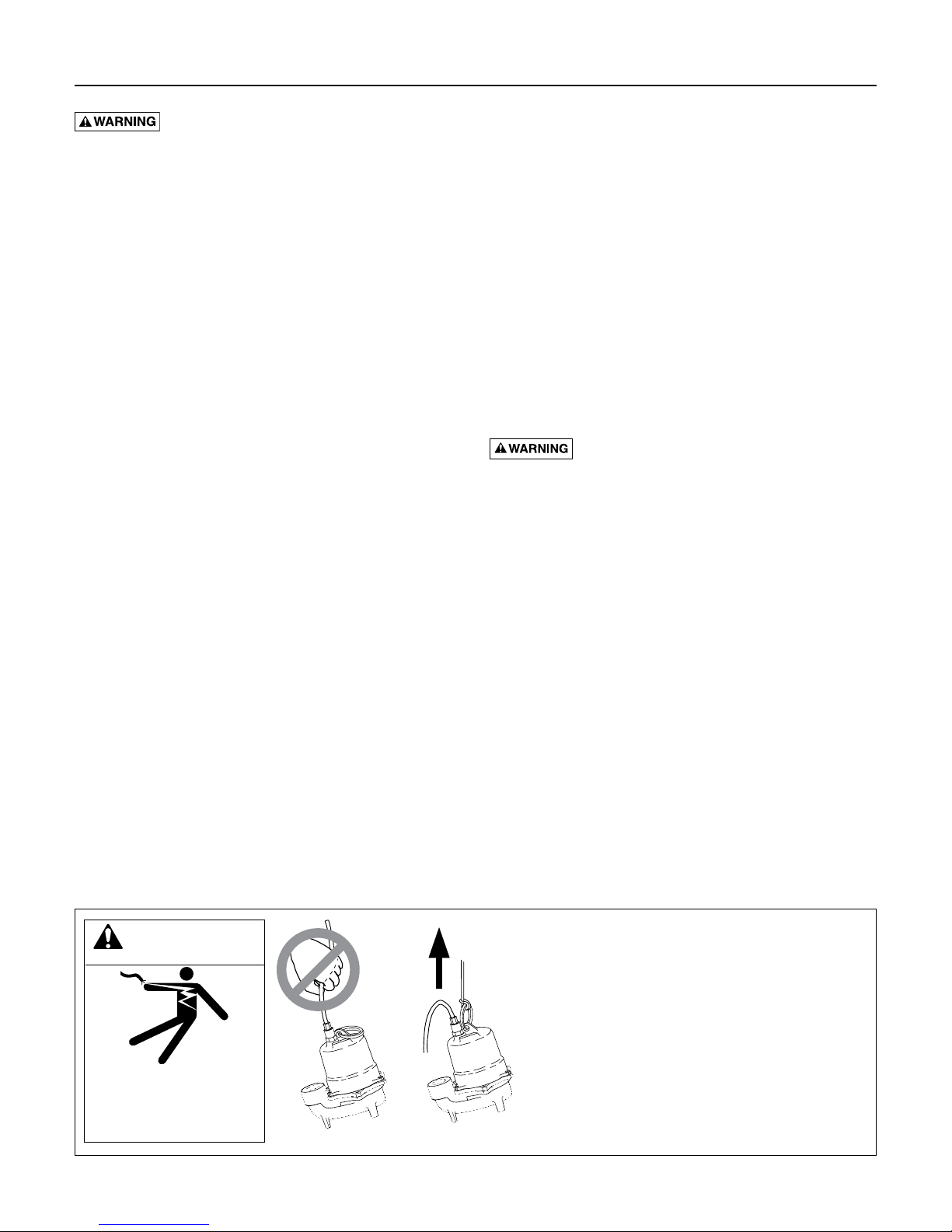

WARNING

Risk of electrical shock.

Can burn or kill.

Do not lift pump by

powercord.

Cord Lift Warning

Risk of electrical shock and fire.

1. Attempting to lift or support the pump by

the power cord can damage cord and cord

connections, expose bare wires, and cause

a fire or electrical shock.

2. Use handle on top of pump for all lifting or

lowering of pump. Disconnect the power

to the pump before doing any work on it

or attempting to remove it from the pit.

3. Lifting or supporting the pump by the

power cord will void the warranty.

Installation 4

Typical Single Phase Switch Operated Installation

Typical Three Phase Simplex Installation with float

Installation • Operation • Maintenance 5

Follow these guidelines for installation:

1. Provide properly sized pit (see Specifications) on

sewage tank. Minimum pump run time is two

minutes. For maximum pump life, three minutes

isrecommended.

2. Make sure sump is free of string, cloth, nails, gravel,

etc., before installing pump.

3. Do not set pump directly on the bottom of sump pit

if it is not solid. Raise the pump by using bricks or

concrete blocks underneath it.

4. Do not remove ground pin from electrical plug.

5. Do not use an extension cord to operate thispump.

6. For proper automatic operation, make sure the pump

power cord is plugged into the piggyback receptacle

on the switch cord. Three phase models must be

properly connected to a suitable controlpanel.

Do not cut, crimp, or bend single phase switch

power cord. This may cause pump failure and

voidwarranty.

7. Use steel or plastic pipe for all connecting lines

between pump and sewer outlet.

NOTICE: Some city regulations do not

allow installing a pump with plastic pipe.

Checklocalregulations.

8. Use PTFE pipe thread sealant tape on pipe

connections. Do not use ordinary pipe joint

compound on plastic pipe or pump. Pipe joint

compound can attack plastics and damage pump.

9. In applications where the pump may sit idle for

months at a time, it is recommended that the

pump(s) be cycled every month to ensure the

pumping system is working properly whenneeded.

10. A check valve should be installed horizontally in the

discharge pipe.

11. The optional Hydromatic Q Alert is an audible

alarm system for high water conditions. It should be

installed in every sump for greater protection.

NOTICE: Q Alert is for indoor use only. Other

Q Alarm and control panels are available for

outdoor use. Contact your Hydromatic distributor

forapplications.

12. Use pump partially or completely submerged for

pumping waterlike liquids. The pump will pump

solid materials up to 3/4” (spherical) in diameter.

liquids. Strong chemicals or salt water should not

be pumped without consulting your Hydromatic

distributor for proper seals and coatings.

Risk of fire. Do not pump flammable

Operation

NOTICE: Do not allow pump to run in a dry sump.

Doing so will void the warranty and may damage

thepump.

An automatic overload protector in the motor will

protect the motor from burning out due to overheating/

overloading. When the motor cools down, the overload

protector will automatically reset.

If overload trips frequently, check for the cause. It could

be a stuck impeller, wrong/low voltage, or electrical

failure in motor. If an electrical failure in the motor is

suspected, have it serviced by a competent repairman.

Maintenance

Read the following instructions carefully before replacing

any parts. Reasonable care and safe methods should be

practiced. Check local codes and requirements before

installation. Only a competent plumber/electrician

should make the installations.

Submerge pump in a disinfectant solution (dilute chlorine

bleach) for at least one hour before disassembling pump.

The following steps should be performed only by an

authorized service center.

NOTICE: Read all directions before replacing any

parts. Remove pump and switch from power source

beforeservicing.

The numbers in parentheses, such as "(3)" or "(16)", refer

to item numbers used on the Repair Parts diagram.

Checking power cord

To be sure wires are not burned off or broken in cord,

use ohmmeter for check. Set ohmmeter scale to RX1

scale and check meter by putting both meter leads

together and adjusting the needle knob until meter reads

zero. If meter cannot be adjusted to zero, the batteries in

meter must be replaced.

NOTICE: Always reset meter to zero [0] when going to a

new scale before making any checks on motor.

Attach one meter lead to white cord wire and one meter

lead to black cord wire, then place a screwdriver blade

across terminals of plug. If cord is OK, meter needle

will go to zero and stay there. If meter needle does not

move, the cord has an open wire and the cord must

bereplaced.

Maintenance 6

Checking motor operation

If the unit is being operated by float switch, unplug

the pump from the piggyback receptacle and plug the

pump directly into the power source. Motor should start

and run smoothly. If motor does not start each time it is

plugged directly into the receptacle and does not start

each time when plugged into the piggyback switch with

the float raised, replace the complete piggyback switch

assembly and retest with new assembly.

If motor does not run when tested with functional switch,

the capacitor and/or stator must be checked.

Checking motor stator

1. Remove plug (6) from top of housing (2) and pour

oil into a clean glass container. If oil is clear, it

will indicate motor is not burned and there has

been no water leak into the motor. If oil is black,

it will indicate a burned stator. If oil is cloudy, it

will indicate water in motor oil, so all seals should

bereplaced.

2. After draining oil, carefully loosen the power cord

assembly (22) from the motor housing (2). With

power cord loose, remove the screws (4) and

carefully lift off the motor housing (2) exposing the

motor assembly.

3. On single phase (1ø) units, check capacitor (28)

using ohmmeter. With ohmmeter scale set at

Rx1000, attach meter leads to capacitor leads.

The meter needle should go to zero and come

back slowly. If it does not, the capacitor should

bereplaced.

4. To check motor stator, remove power cord leads

from terminals on top of motor (1ø) or remove

splice connectors (3ø). If stator is visibly burned,

motor assembly must be replaced. If stator is not

burned but the oil shows signs of water, stator can be

checked with the ohmmeter to see if it can be used.

Ground check

Set ohmmeter scale to R X 100K scale. Connect one

meter lead to one blade terminal of stator and touch

other meter lead to motor housing (2). If the resistance

to the ground is less than 500,000 ohms, stator must be

dried out before retesting. To dry out, place pump in 220

degree oven for four hours. Recheck after motor cools.

If motor is thoroughly dry, needle of ohmmeter will not

move on the ground check. This indicates a reading of

50 megohms or higher. When making the ground check,

if the needle goes to zero, the motor has a wire touching

the stator shell at some place and the stator will have to

be replaced. Repeat for each leg or wire lead.

NOTICE: If motor shows a satisfactory ground check then

the winding resistance must be checked.

Winding resistance test

1. Use ohmmeter with scale set to RX1 scale. On this

scale, meter reads directly in ohms. Recheck to zero

[0] before making a reading on thewinding.

NOTICE: If water is found in motor, seal should

bereplaced.

2. For single phase pumps, connect one meter lead to

the white wire terminal and the other meter lead to

the black wire terminal. This reading is for the main

winding. If the readings obtained do not agree with

those given below, the stator is defective and the

motor assembly must bereplaced.

Reconnect the wires as they were removed.

Replacing seal

A milky appearance to the oil collected earlier indicates

that water has entered through worn or damaged seals

or O-rings. In this case, the mechanical seal (14) and

the O-ring (19) will have to be replaced. The seal (14)

consists of a ceramic stationary seat and a carbon

rotating ring. To check seal:

1. Remove bottom plate (12) and impeller (11).

2. Remove the rotating carbon ring and stainless

steelspring.

3. Remove the hex head stator bolts and lift the stator

(3). A screwdriver can be inserted under the stator

shell in order to remove the stator.

4. Tap the end of the shaft with a plastic or rubber

hammer. This will push the rotating half of the

mechanical seal from the shaft and also push the

lower bearing from the seal plate. Now remove

the shaft, rotor, and bearing assembly from the

sealplate.

5. Turn the bearing by hand: if it feels rough when

turned or looks rusted, it should be replaced. Use a

bearing puller to remove the bearing.

Maintenance 7

Reassembly

1. Thoroughly clean the seal (14) and bearing pockets

in the volute. All sand and dirt must beremoved.

2. If the stationary seal half was removed, use a plastic

pusher to press it into the housing. Make sure the

rubber ring goes in first. Do not use any sharp

objects that may damage the seal.

3. When installing a replacement bearing, press only

on the inner face and make sure the bearing is flush

against the snap ring. If a press is not available, the

bearing can be tapped onto the shaft using a sleeve

that bears only on the inner face. Pressing on the

outer face will ruin the bearing.

4. Push the shaft, rotor and ball bearing assembly into

the seal plate, being careful not to chip the ceramic

of the stationary seal half.

5. Replace wavy washer.

6. Replace the motor if it is visibly burned or if the

ground resistance test or the winding resistance test

has failed. Note that the replacement stator must be

of the same manufacture as the existing rotor, or vice

versa. Replace the four stator bolts.

7. Remove the old O-ring (19), regardless of condition,

and replace. Place the new O-ring over the seal plate

shoulder. Do not “roll” it. If twisted, water may enter

chamber and cause failure.

8. Reattach power wires and ground.

9. Clean the motor housing (2) thoroughly, then

position it onto the seal plate.

10. Press the new ceramic seal (14) in place with

the rubber ring facing the impeller. This should

have a thin oil (dielectric, same as in motor

housing)coating.

NOTICE: Ceramic must be kept clean. Any dirt

will cause seal failure. Also, mixing old and new

seal parts will cause immediate seal failure. When

replacing seal, replace both the rotating and the

stationary seal halves.

11. Reassemble the lower seal as described.

12. Add a drop of 2Loctite® #243 to the impeller threads

and screw the impeller hand tight. The impeller will

force the ceramic seal into position. The shaft should

be free of dirt, grease, etc., or the Loctite® will not

hold as designed. Replace impeller washer and

impeller screw to the shaft on three phase models.

2

Henkel Corporation, Germany

NOTICE: Loctite® overrun onto the seal or bearing

will result in shaft seizure.

13. Install bottom plate (12) and gasket (15).

14. To replace the power cord (22) on single phase

pumps, first slip the stator lead wires through the

holes in the wire seal assembly. Coat the cord grip

threads with PTFE pipe thread sealant tape and

screw the new power cord assembly into the motor

housing. Referring to wiring diagrams in this manual,

secure wires together with wire nuts.

NOTICE Do not tape leads together as the hot oil

will deteriorate the tape and cause failure.

15. Before filling the motor housing with oil, a seal leak

test should be performed. Apply 7 to 8 pounds of

air pressure in the 1/4" NPT tap (6) on the top of the

motor cover and seal chamber.

NOTICE Too much pressure will damage the seal.

Seal would have to be replaced.

Then submerge the pump in water and check for

leaks. If a leak occurs, isolate where it is coming

from and correct the problem by replacing the

failedpart.

Hydromatic pumps have a small air vent hole in

the impeller cavity to let out trapped air. If this hole

becomes plugged, pump may air lock. To break the

air lock, use a small screwdriver to clear hole in the

impeller cavity.

As a secondary precaution in installations of this

type, an 1⁄8” hole should be drilled in the discharge

pipe just above the volute. The check valve should

be at least 12 inches above pump discharge and

mounted horizontally. Do not put check valve

directly into pump discharge opening.

NOTICE: In sumps where the pump is operating

daily, air locking rarely occurs.

Oil fill

1. After seal leak test is satisfactory, remove unit from

water and wipe or blow off any excess water.

2. Do not put oil in motor with any water present in

motor cavity.

3. Use refined paraffinic transformer oil, 3Shellflex™

2210 or equivalent.

3

Shell Oil Company, Texas

4. Slowly fill oil to 1/8" over windings in motor housing

through opening (6). Use an oil fill tube that will go

into holes so that air can escape. Replace plug (6).

NOTICE Do not fill the motor housing completely –

allow air space for expansion.

5. Connect power cord wires to terminals in panel, or

connect power source, and check pump running.

Motor should run smoothly and be free of vibration.

Pump is ready for operation.

Troubleshooting 8

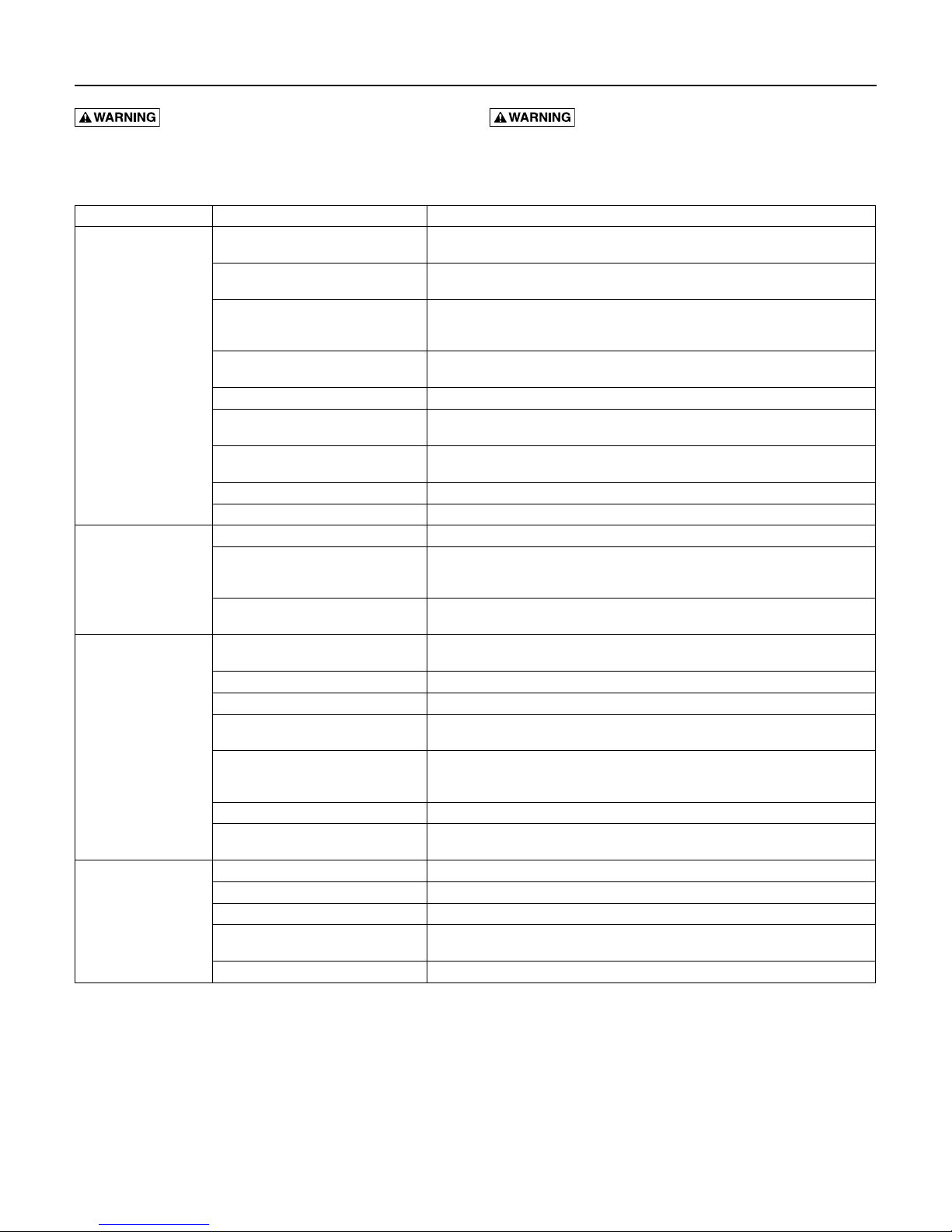

Troubleshooting

kill. Disconnect power before attempting any service or

repair work on pump.

Symptom Possible Cause(s) Corrective Action

Motor not running

Pump runs continuously

Little or no effluent

delivered from pump

Pump cycles constantly

Hazardous voltage. Can shock, burn, or

Motor protector tripped.

Open circuit breaker or blown fuse.

Impeller clogged or binding.

Power cable damaged.

Bad control panel. Inspect control panel wiring. Call a licensed electrician.

Defective liquid level switch.

Not enough liquid in wet well to activate

controls.

Liquid level cords tangled Untangle cords for free operation.

Automatic controls defective Try running pump in manual mode. If it runs, the automatic control is at fault.

Liquid level control cords tangled Untangle cords for free operation.

Pump is airlocked.

Flow in matches or exceeds the pump’s

capacity.

Check valve plugged, stuck shut, or

installed backwards.

System head excessive. Consult dealer.

Pump suction plugged. DISCONNECT POWER, pull pump, inspect, and clear as needed.

Wrong voltage or not wired correctly.

Pump is air locked.

Worn or damaged impeller. DISCONNECT POWER, pull pump and inspect impeller. Replace if necessary.

Liquid level controls incorrectly installed

or defective.

No discharge check valve installed. Install discharge check valve.

Discharge check valve stuck open. Repair or replace check valve as necessary.

Sewage wetwell too small. Consult dealer.

Liquid level controls incorrectly installed

or defective.

Pump too small for inlet flow. Consult dealer about larger pump or second pump.

which can cause loss of fingers. Keep hands away from

pump suction inlet when working on or servicing pump.

Allow motor to cool. Make sure pump is completely submerged. Clear debris from volute

and impeller. Check for high amp draw.

Replace fuse or reset breaker. If circuit breaker opens repeatedly, don’t reset it - call a

licensed electrician.

Check amp draw. If it is more than twice the nameplate amps, the impeller is locked.

Bearings and shaft may be damaged. DISCONNECT POWER, clear debris from volute,

impeller, and cutter as needed.

Resistance between power cable and ground should be infinity. If any reading is less than

infinity, call a licensed electrician.

With switch disconnected from power, check continuity through switch while activating

liquid level switch. Replace switch if necessary.

Allow the liquid to rise several inches above the switch-on level.

Stop pump for about one minute, then restart. Repeat stopping and starting until the

airlock clears. If the airlock persists, DISCONNECT POWER, pull the pump and drill a

1/8” hole in the discharge pipe between the pump discharge and the check valve.

A larger pump or more pumps may be needed.

Make sure check valve is installed correctly (flow arrow should point away from pump)

and functioning correctly.

Check pump’s rotation; check nameplate voltage against supply voltage (they must

match); consult a licensed electrician.

Stop pump for about one minute, then restart. Repeat stopping and starting until the

airlock clears. If the airlock persists, DISCONNECT POWER, pull the pump and drill a

1/8” hole in the discharge pipe between the pump discharge and the check valve.

Reposition or replace as necessary.

Reposition or replace as necessary.

Hazardous impellers and unexpected starts

Loading...

Loading...