Pentair Myers BX Series, Myers BX6-12, Myers BX8-15 Installation And Service Manual

MODEL BX

INDUSTRIAL PUMPS

INSTALLATION AND SERVICE MANUAL

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Part # 13800A903 | © 2012 Pentair Pump Group, Ltd. | 11/12/12

GENERAL INSTRUCTIONS

Reciprocating pumps of both the plunger and piston

type are positive displacement in principle. Due to

positive displacement characteristics, problems may

arise through improper installation or application.

When new or unusual installations are planned, or

the material to be pumped is a liquid other than

cold water, the customer should consult the “Myers

Reciprocating Pump Manual” or factory for additional

information.

CAUTION: Positive Displacement Pumps must

have a proper size and operable type of pressure

regulating valve or pressure relief valve piped into

the discharge line. This is mandatory to prevent

damage to pump and piping or possible injury

to personnel. Do not install any valves or shutoff

devices in the bypass line from pressure regulator

to tank or supply.

CAUTION: All pumps should be installed level.

For mobile applications the maximum angle of

intermittent operation should be no more than

5 degrees in any one direction.

CALIFORNIA PROPOSITION 65 WARNING:

This product and related

accessories contain chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm.

1. INSTALLATION

A. If possible, install suction piping one pipe size

larger than suction tapping in pump. Reduce

piping size at pump with a reducer coupling.

A suction surge arrester will assure smoother

operation.

B. Keep suction piping as short and simple as

possible with a minimum of lift. Avoid any high

points in the suction line. Suction piping must not

have any air leaks. Check suction piping assembly

for leaks by using 20–80 PSI air pressure and soap

bubbles or submerging assembly under water.

C. Use suction strainer and screen with twice the

rating of the pump capacity to avoid restriction

of the pump suction. Strainer mesh should be

sufficiently small to prevent passage of trash

which may lodge under pump valves. Keep screen

clean with a regular maintenance schedule to

avoid starving of pump suction. A starved suction

condition is usually indicated by excessive pump

shock and noise. Many pump problems and many

packing or cup failures are directly traceable to a

starved suction condition.

D. When pumping liquids that are heated, reduce

pump speed to avoid suction problems. Consult

“Myers Reciprocating Pump Manual” or factory for

temperature and speed limitations.

E. Make sure that drive is adequate for horsepower

required and that drive is properly aligned and

tensioned. With belt drives, pulley on both motor

and pump should be located as close as possible

to bearing to reduce bearing and shaft bending

loads.

CAUTION: Be sure that pump belts and pulleys

are properly protected by guards according to

industrial code within state of application.

F. Make sure that all bolts, nuts, set screws and keys

are properly tightened.

G. Be sure that discharge line is properly protected

by means of a pressure regulating valve and a

discharge surge arrester of proper size, capacity

and pressure rating. The discharge line should be

of comparable size to discharge tapping in pump.

Average discharge line velocity should not exceed

5 feet per second for most satisfactory operation.

H. Nozzle capacity or demand should not exceed

90% of pump capacity for satisfactory regulating

valve operation. Nozzling in excess of this capacity

may cause unstable pressure regulator operation.

It is also preferred to nozzle in excess of 50% of

pump capacity to reduce rate of erosion or wear

on regulating valve and seat. When lower system

demands (than rated pump capacity) are required

in an installation, the pump speed should be

reduced by changing drive ratios. This will reflect

savings in power consumption, reduced regulating

valve wear and extended pump life.

I. Where line shock or water hammer is encountered

a second surge arrester should be installed in the

discharge line adjacent to spray gun or nozzles.

Under some conditions it may also be desirable

to isolate pump from piping with a suitable high

pressure hose. This will eliminate transmission of

line vibration to the pump, reducing possible failure

of piping, pipe threads, and/or pump casting.

J. Never pipe the bypass from a pressure regulating

valve back into the pump suction. When the

discharge line is shut off, the complete bypass is

circulated back into pump suction with a resulting

rapid temperature rise which will destroy the piston

packing. It is permissible to pipe the bypass from

an unloader into the suction because the pump

pressure is unloaded when discharge is shut off.

2. STARTING PUMP

A. Before starting read all instructions carefully!

1. Replace all drain plugs in pump and piping.

2. Fill pump crankcase with recommended oil to

the proper level. (See Lubrication Section.)

3. Inspect tank to be sure that no foreign material

is in tank or suction line.

4. Fill tank at least half full or connect suction to

water supply. Open valve (if present) in suction

line. If pumping from a pit, make sure that

suction line is completely submerged.

13800A903 11/12/12

2

5. Make sure all valves, including spray gun or

nozzles, are open in discharge line. Spray gun

may be anchored to discharge back into tank.

6. Completely back off pressure adjusting screw

on pressure regulating valve.

CAUTION: When pumping from a pit or under a

suction lift condition, if pump does not prime in

a short period, fill the discharge side of fluid end

with water to seal discharge valves. If pump still

does not prime remove suction hose and fill pump

with water. Dry operation will cause heating and

wear on cylinders and packing. Be sure that an

operating pressure gauge is located on discharge

line.

SAE 40 should be used. Use only good quality grade

oils with SAE designation MS, SC or SD. Maintain

level at mark on cover for the required RPM. Foaming

or milky discoloration of oil is an indication of water.

Oil should be replaced to preclude possible damage

to crankcase and components.

NOTE: Drain oil from crankcase after first 30 hours

of operation. It is best to always drain the oil when

it is still hot. Refill the new oil as mentioned above.

Run pump at full speed under no pressure for 2 or

3 minutes before returning to operation. Thereafter

change oil every 300 hours or immediately if water

droplets are found in crankcase. Check oil level

regularly and add oil as needed.

B. Starting Unit:

1. After starting, close discharge valve or gun

slowly while watching pressure gauge to

make sure relief valve or unloader is operating

properly.

2. Adjust relief valve to desired pressure. See

regulator instructions.

3. Cycle nozzles or gun on and off to be sure that

pressure adjustment and regulator operation is

satisfactory.

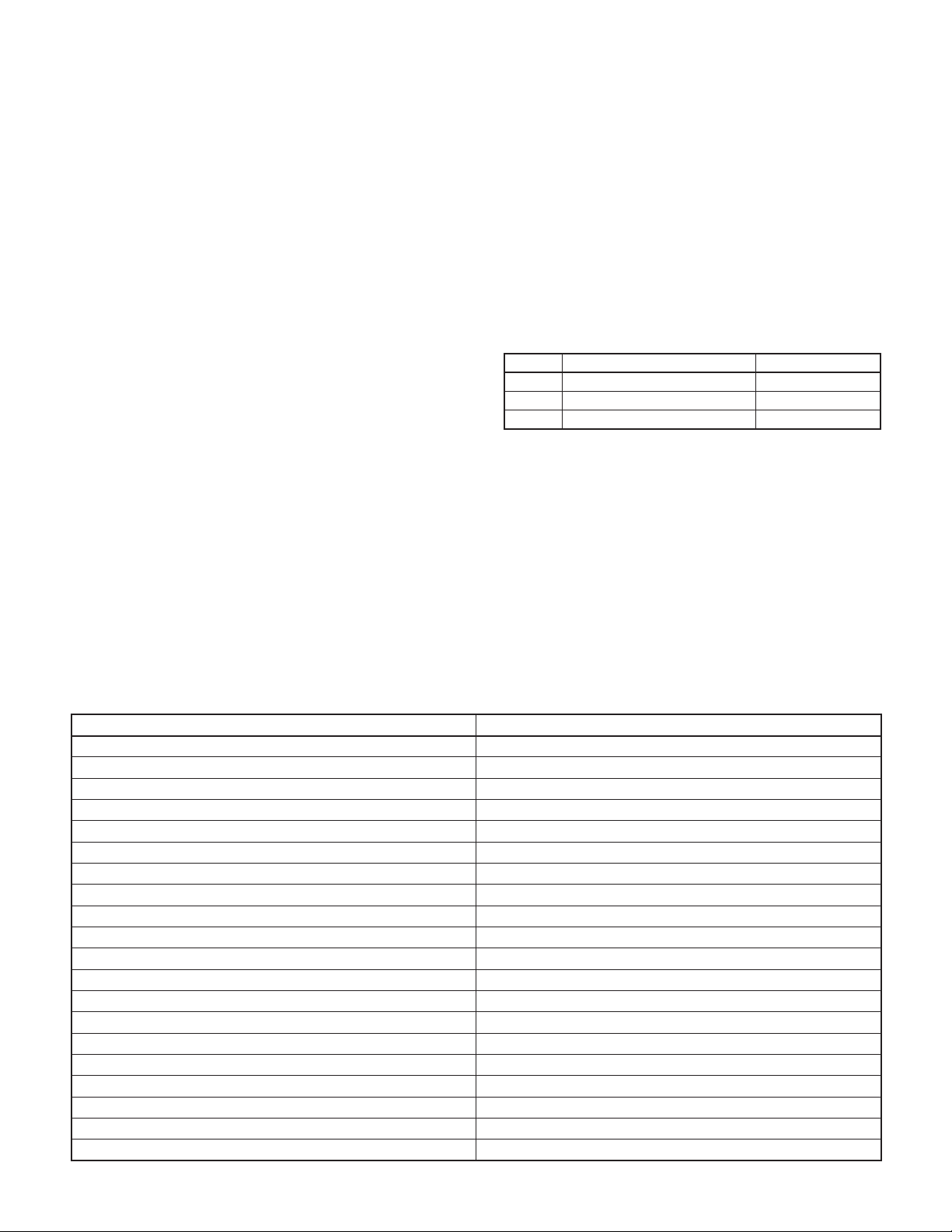

LUBRICATION

Pump-Crankcase must be filled with 2 to 3 pints

depending on RPM (See Table) of SAE 30 oil unless

ambient temperature exceeds 90 degrees F when

RPM OIL LEVEL LOCATION OIL CAPACITY

800 Add Level Mark 32 oz.

700 Between Add & Full Mark 40 oz.

600 Full Mark 48 oz.

Speeds of 400 to 600 RPM require 48 ounces of oil.

For speeds less than 400 RPM consult factory for

recommendations.

Avoid Freezing by draining all water from pump

and system in cold weather. This can be done by

breaking suction connections and turning crankshaft

over 4 or 5 times, or the fluid end can be removed to

completely drain cylinders and fluid end.

SPECIFICATIONS

TYPE TRIPLEX – SINGLE ACTING

Rated Capacity GPM @ 800 RPM 8 GPM

Pressure Rating: Continuous/Intermittent 1,000 PSI/1,200 PSI

Required BHP @ 800 RPM and Rated Pressure 6.3

Temperature Rating (Max.) 140˚ F

Cylinder Bore 1"

Stroke 1-1/16"

Suction Size 1 NPT (Bottom)

Discharge 3/4" NPT (Top)

Crankshaft Diameter 1"

Keyway 1/4 x 1/8

Cylinder Material Alumina Ceramic

Fluid End Material Brass

Packing Material High Acrylic Nitrile

Valve Material Stainless Steel

Seat Material Stainless Steel

Piston Material Brass

Approximate Shipping Weight 50 lbs.

Recommended Regulator 22900B000

Recommended Unloader 19280C000

Recommended Discharge Surge Suppressor 6CU

3

13800A903 11/12/12

Loading...

Loading...