Pentair Mi Series Installation, Maintenance And Operation Manual

Mineral insulated (Mi)

series Heating systeMs

Installation,

Maintenance and

Operation Manual

THERMAL MANAGEMENT

EN-PyrotenaxMI-IM-DOC586 R4

2

1

2

3

4

5

6

7

8

9

10

11

General information 4

Heating cable selection and storage 7

Heating cable installation 9

Components selection and installation 23

Temperature control and limitation 24

Thermal insulation and marking 27

Power supply and electrical protection 31

System testing 32

Operation, maintenance and repairs 33

Trouble Shooting 34

Installation Record Sheet 35

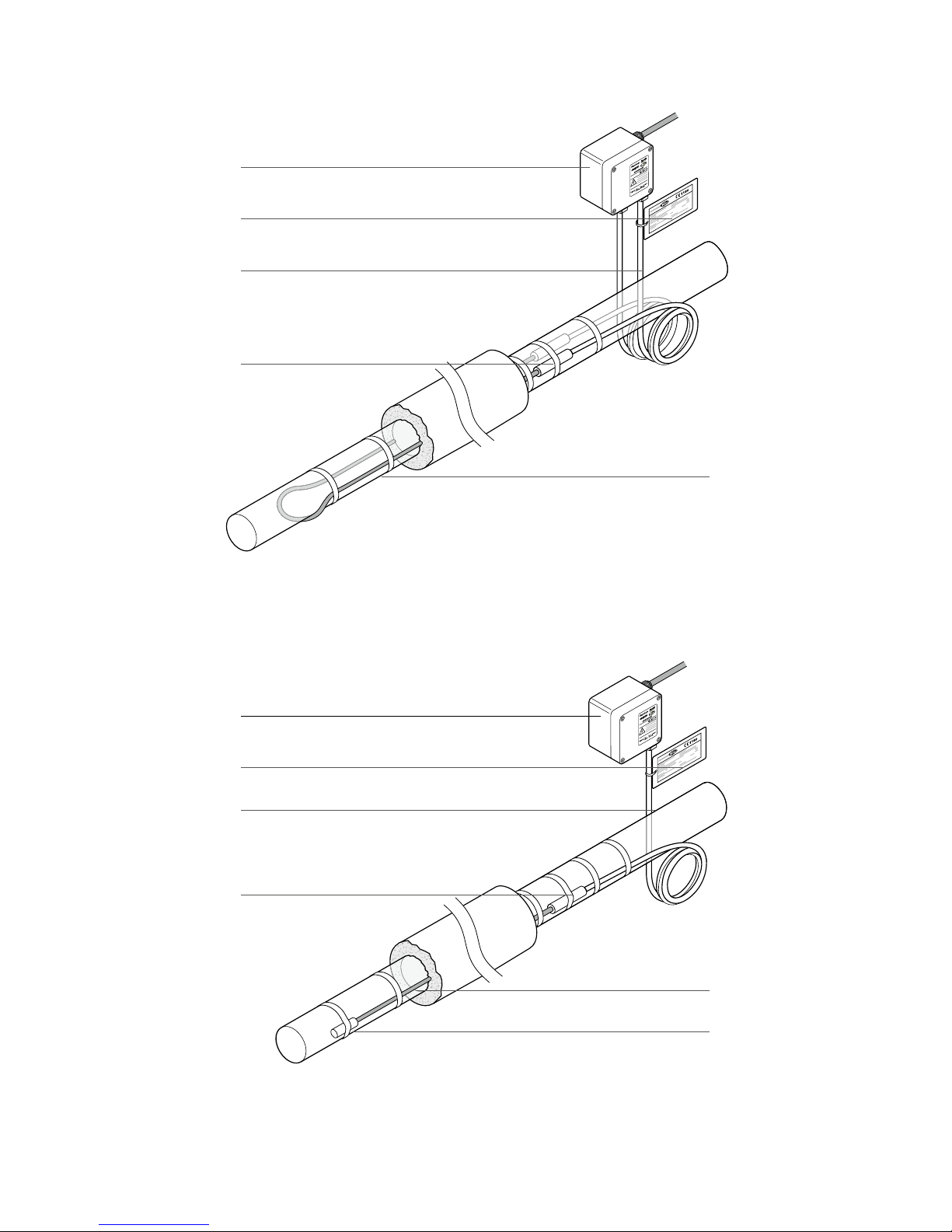

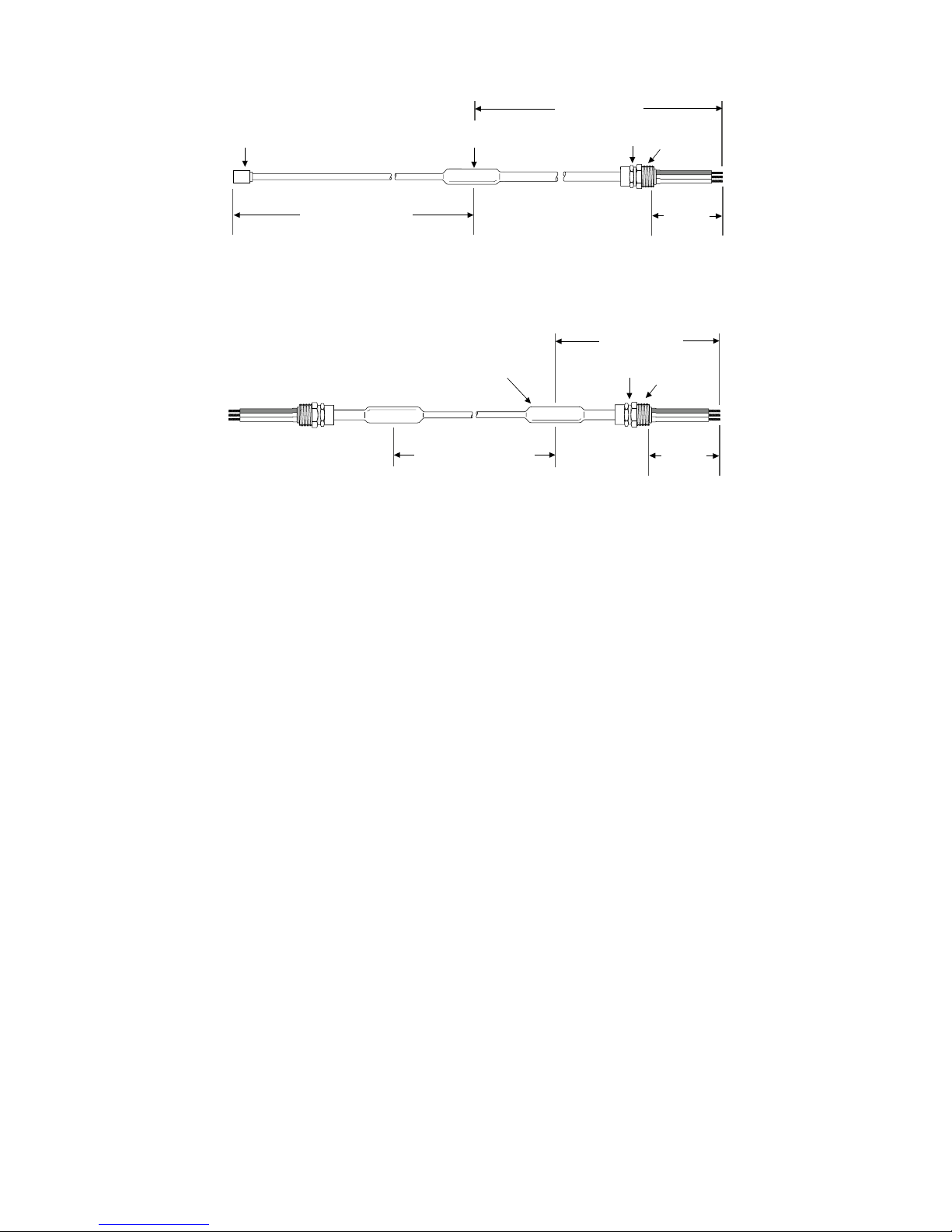

Typical configuration for MI-heating cable system

(single conductor)

Typical configuration for MI-heating cable system

(dual conductor)

Junction box

MI cold lead cable (single conductor)

Circuit identification tag

Hot/cold joint

MI cold lead cable (dual conductor)

Hot/cold joint

Circuit identification tag

Junction box

Dual conductor

MI heating cable

End cap

Loop of MI heating cable

(single conductor)

3

1 GENERAL INFORMATION

Use of the manual

This Installation and Maintenance manual applies to Pentair Thermal

Management Mineral Insulated (MI) series resistance heating cable systems

installed on thermally insulated pipes and vessels and associated equipment.

In particular it refers to mineral insulated (MI) series heating systems, which

feature a specific power output depending on various design parameters,

in particular, cable length and voltage. This manual provides general

information and shows an overview of the most common installations and

applications on MI as well as typical examples. In any case the information

provided for specific projects will take precedence over this manual. In case of

conflicts, please contact your Pentair Thermal Management representative.

Pentair Thermal Management offers two different cable constructions for

electrical heat-tracing purposes: single conductor cables, which are typically

laid in loop configurations and dual conductor cables, which are typically laid

in single runs.

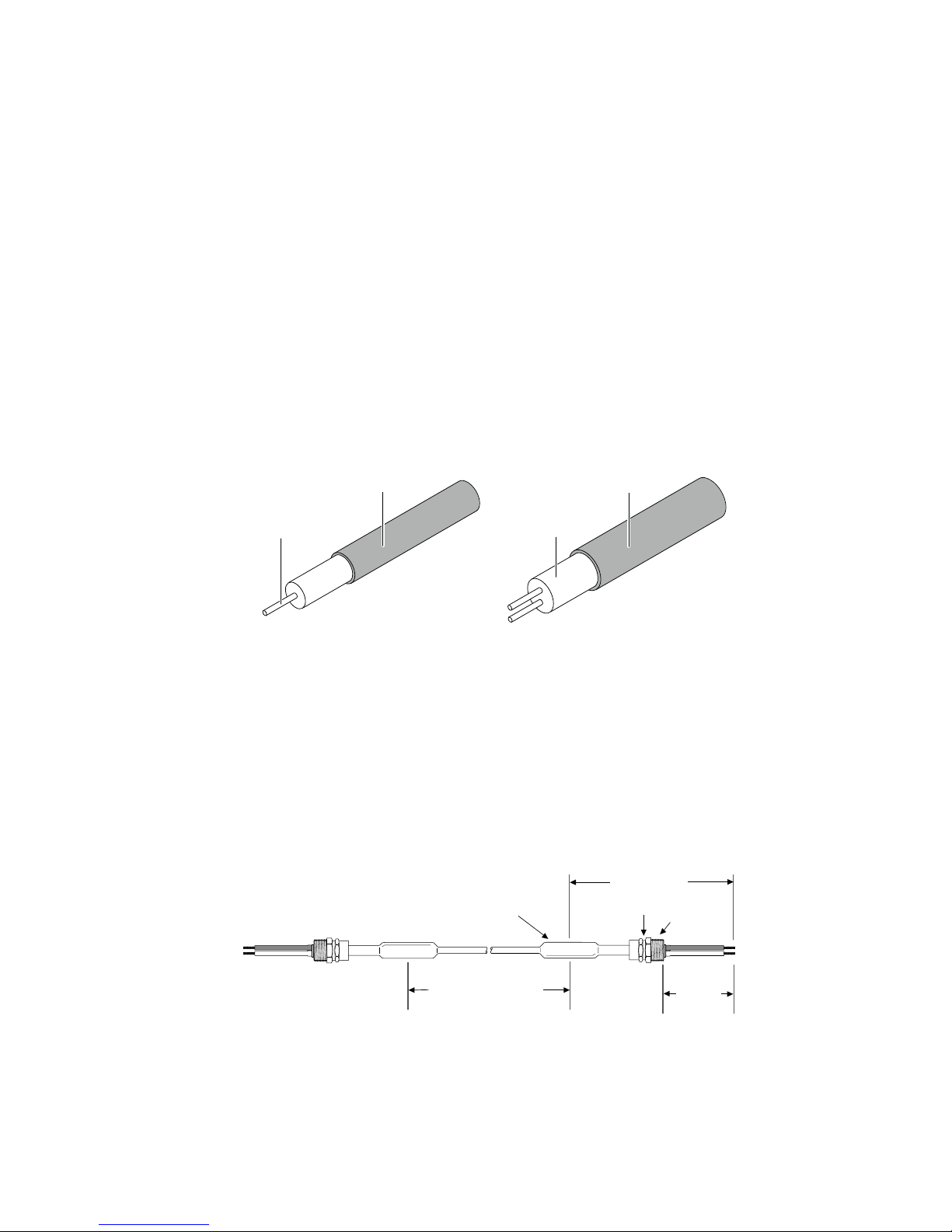

Figure 1: Typical cable construction

Various types of the MI bulk heating cables are available:

HCC/HCH: Copper sheathed MI heating cables

HDF/HDC: Cupro-nickel sheathed MI heating cables

HSQ: Stainless steel sheathed MI heating cables

HAx: Alloy 825 sheathed MI heating cables

HIQ: Inconel sheathed MI heating cables

Figure 2: Typical heating unit designs

Design type B

Single conductor

Heating

conductor(s)

Insulation

(magnesium oxide)

Single-conductor cable

Dual-conductor cable

Metal sheath

Metal sheath

Potted seal

Heating cable length

Hot/cold joint

Cold lead cable

(standard 2 m)

300 mm

Flexible

tail length

Gland

4

Design type D

Dual conductor

Design type E

Dual conductor

The joints can be either brazed or laser welded, refer to Pentair Thermal

Management product literature for more detailed information.

Please note that this manual only covers the installation of prefabricated MI heating units. The complete termination process and

repair of heating cable units is not covered by this manual and must be

carried out by qualified and experienced personal only.

For more information contact your Pentair Thermal Management

representative.

Important

For the Pentair Thermal Management warranty to apply, the

instructions of this manual must be followed. Design, installation,

inspection, operation and maintenance must be in accordance with the

standards IEC 60519,

IEC 62086, EN 50019 and EN60079-7 (where applicable). Other local

requirements and national electric codes applicable to electrical heattracing systems must be followed as well. The thermal safety class is 2

(to IEC 60519-2).

Personal involved in the installation, testing and maintenance of electric

heat-tracing systems must be suitably trained in all special techniques

required, as well as in general electrical installation work. All work

should be monitored by supervisors experienced in heat-tracing

applications.

300 mm

Flexible

tail length

Potted seal

Heating cable length

Hot/cold joint

Gland

End cap

Cold lead cable

(standard 2 m)

300 mm

Flexible

tail length

Potted seal

Heating cable length

Hot/cold joint

Gland

Cold lead cable

(standard 2 m)

5

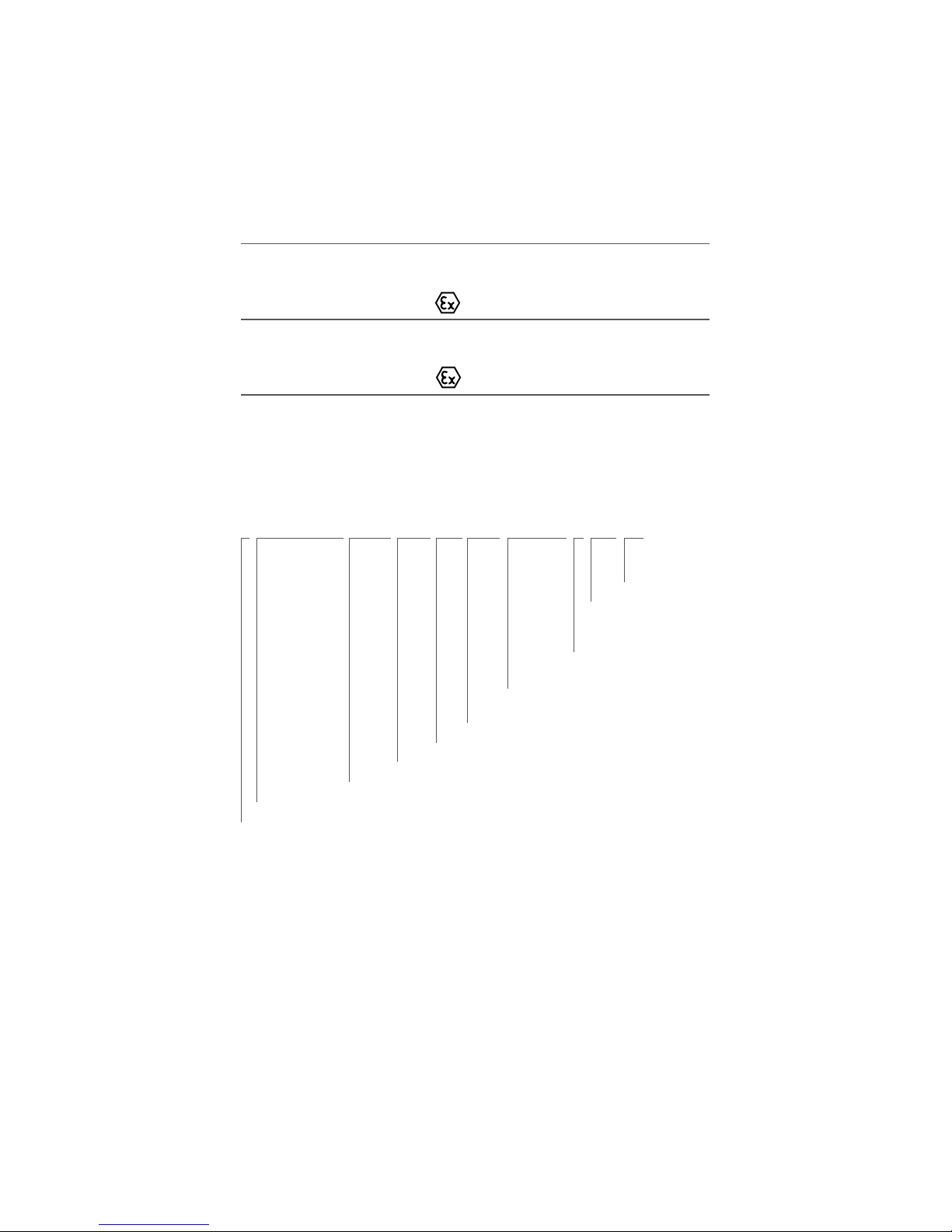

Area Classification – Ordinary

HCC/HCH/ HDC/HDF/HSQ/HAx/HIQ

Area Classification – Hazardous, Zone 1 or Zone 2

Special conditions for safe use in hazardous area:

Please refer to relevant hazardous area certifications

Certificate No. Code Nos.

HCC/HCH/HDC/HDF/HSQ/HAx/HIQ

(heating elements)

Baseefa 02ATEX0046X II 2 G EEx e II T6 to T1

HCC/HCH/ HDC/HDF/HSQ/HAx/HIQ

(bulk cable)

Baseefa 02ATEX0045U II 2 G EEx e II T6 to T1

For other national approvals please contact Pentair Thermal

Management.

The order reference of MI heating units uses

the following nomenclature

When ordering, the complete order reference of the MI heating unit

needs to be provided. For hazardous areas, information must also

be provided about the T-rating and temperature data relevant to the

application (max. sheath temperature data) to enable the correct

representation of data on hazardous area tags attached to the completed

heating unit in the factory. Before installation, check the suitability of the

heating units supplied. Changes to any of the parameters may require a

re-design and must be confirmed before installation.

B/HSQ1M1000/43.0M/1217/230/2.0M/SC1H2.5/X/M20/EX

Area classification:

EX, ORD

Gland size M20, M25, etc...

Hot/cold joint material type:

X -stainless steel, Y - brass,

LW - laser welded

Cold lead size and sheath type

(see table on next page)

Cold lead length: M for unit in meters

(standard is 2 m)

Heating unit: Operating voltage

Heating unit: total wattage in W

Unit length: M for unit in meters

Heating cable reference

Heating cable unit type: Type B, D or E

6

2 HEATING CABLE SELECTION AND

STORAGE

The selection of the proper heating cable and components, best suited

for the application must be checked against the relevant product

literature, the most important product properties are summarized in

following table:

Table 1: Properties of MI heating units

Please check against individual datasheet or contact Pentair Thermal

Management for further details.

The maximum cable power output is directly dependant on the

application and control method used. The actual limits of MI heating

cables in a specific application are given in Pentair Thermal Management

Engineering Software (e.g. TraceCalc Pro design software). For more

details, please contact Pentair Thermal Management.

Ensure that the heating cable voltage and temperature rating is suitable

for the application.

MI Heating Cable Type HCC/ HCH HDC/ HDF HSQ

Number of conductors 1 1 1

Maximum voltage (U0/U) 300 / 500 V

Maximum withstand temp.(1)

Brazed heating unit 200°C 400°C 450°C

Laser welded heating unit – – 700°C

Temperatureclassification T6 – T3 T6 – T2 T6 – T1

Minimum cable spacing 25 mm

Minimum installation temp. –60°C

Minimum bending radius 6 x Cable Diameter

Chemical resistance Low Medium Medium

MI Heating Cable Type HAx1N HAx2N HAx2M HIQ

Number of conductors 1 2 2 1

Maximum voltage (U0/U) 346/600 V 300/300 V 300/500 V

Maximum withstand temp.(1)

Brazed heating unit 450°C 450°C 450°C 450°C

Laser welded heating unit 650°C 650°C 650°C 700°C

Temperature classification T6 – T1 T6 – T1 T6 – T1 T6 – T1

Minimum cable spacing 25 mm

Minimum installation temp. –60°C

Minimum bending radius 6 x Cable Diameter

Chemical resistance High High High High

(1)

The hot-cold junction used in a heating unit may lead to temperature

limits below the limit of the heating cable. Contact Pentair Thermal

Management if the exposure temperature exceed values given in

the tables above for more detailed instructions how the unit can be

installed under those circumstances.

7

Changing design parameters such as voltage or cable length will result

in a different power output and maxi-mum sheath temperature. This

may require a redesign of the entire system.

To prevent fire or explosion in hazardous areas, verify that the

maximum sheath temperature of the heating cable is below T-class

or auto-ignition temperature of the gases present in those areas. For

further information, see design documentation (e.g. TraceCalc Pro

reports).

For the evaluation of the chemical resistance of MI heating cables (for

corrosion aspects), refer to our product datasheets or contact Pentair

Thermal Management for assistance. Check the design specification to

make sure the correct heating cable is installed on each pipe or vessel.

Refer to Pentair Thermal Management product literature to select an

appropriate heating cable for each thermal, chemical, electrical and

mechanical environment.

Storage

Store MI heating units in a clean, dry place.

Protect the heating cable from moisture and mechanical damage.

Storage below 10°C may result in surface condensation,

potentially causing low insulation resistance.

After extended storage, it is strongly recommended to measure

the insulation resistance of MI heating units prior to installation,

also refer to section 8.

8

3 HEATING CABLE INSTALLATION

Warning

As with any electrical equipment or wiring installation that operates at

line voltages, damage to heating cable and components, or incorrect

installation that allows the penetration of moisture or contamination

can lead to electrical tracking, arcing and potential fire hazard. In case

of damage and later repair on site any unconnected heating cable end,

exposed to the environment, must be sealed appropriately.

3.1 Pre-installation checks

Check design recommendations:

Verify that you have all required engineering documents

supporting the installation

Check for any special instructions in engineering documentation

(e.g. cover with aluminium foil, use of metal mesh, fixation etc...).

Verify that hazardous area information given in engineering

documentation is compatible with the area classification the

material will be installed in.

Check materials received:

Inspect heating cable and components for in-transit

damage.

Review the heating cable design and compare the list of designed

materials to the catalogue numbers of heating cables and

electrical components received to confirm that proper materials

have been received on site. The heating cable type and hazardous

area marking (if applicable) is printed on a tag label supplied with

each heating element.

Measure and note down the electrical resistance and the

insulation resistance of the cable. Compare these values to those

in the design documents (see section 8).

Check equipment to be traced:

Check identification, length and diameter of pipework/

vessel against the design documents. Also verify, that actual

temperatures and insulation properties are in alignment with the

design documentation.

Ensure all pressure testing of pipework/ vessel is complete and

final paint and pipe coatings are dry to touch.

Walk the system and plan the routing of the heating cable on

the pipe, including tracing of heat sinks. e.g. valves, flanges,

supports, drains etc.

9

Inspect piping for burrs, rough surfaces, sharp edges

etc. which could damage the heating cable. Smooth off

or cover with layers of aluminium foil. At elevated sheath

temperatures consider the use of stainless steel foil.

(e.g. HSQ; HIQ or HAx).

Surface areas where heat-tracing is to be installed must be

reasonably clean. Remove dirt, rust and scale with a wire brush

and oil and grease films with a suitable solvent.

3.2 Heating cable pulling and laying

Heating cable pulling tips:

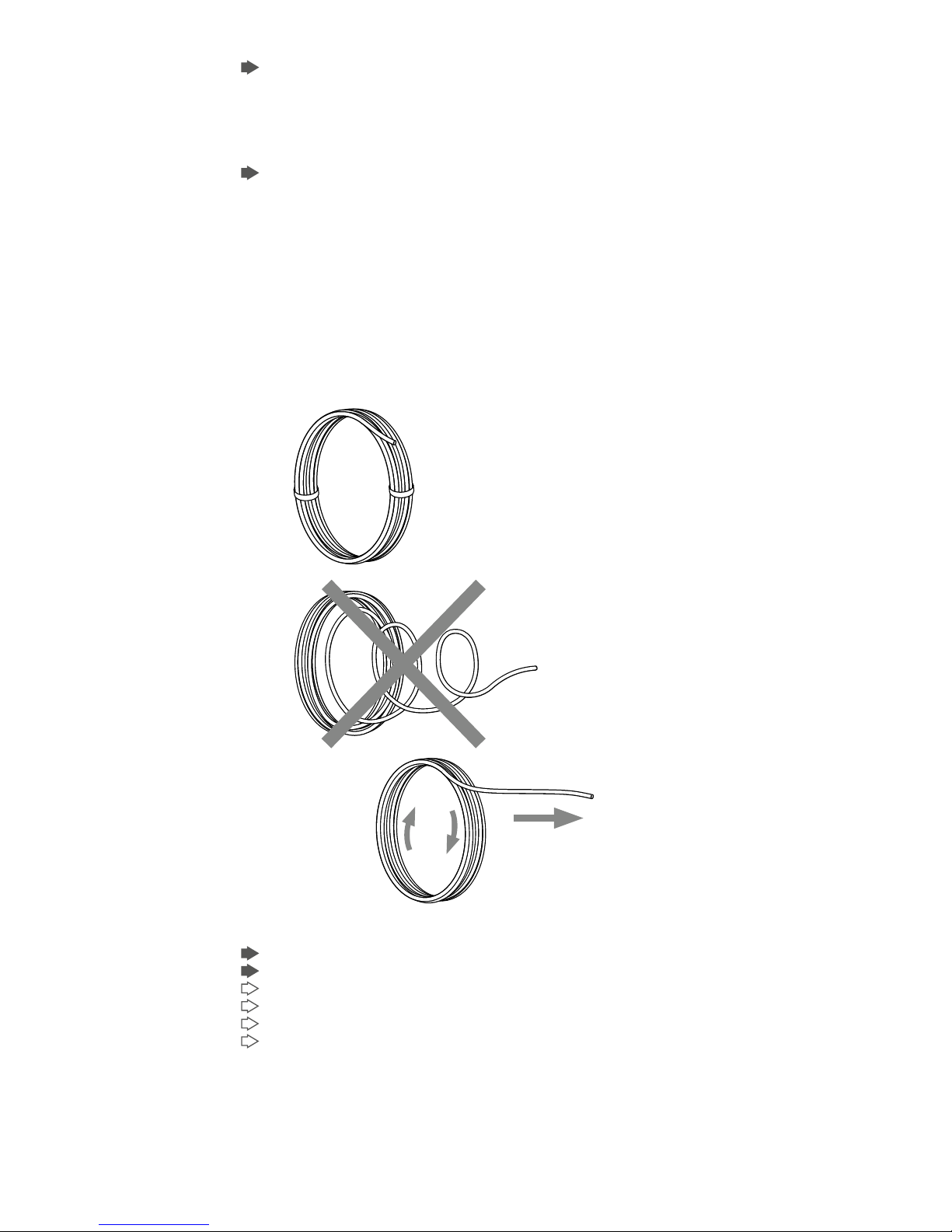

Figure 3: Importance of cable pulling direction

Avoid distortion of the cable and kinking.

When pulling the heating cable, avoid:

sharp edges

excessive pulling force

kinking and crushing

running over it with equipment.

The minimum bending radius of the heating cable must be respected.

10

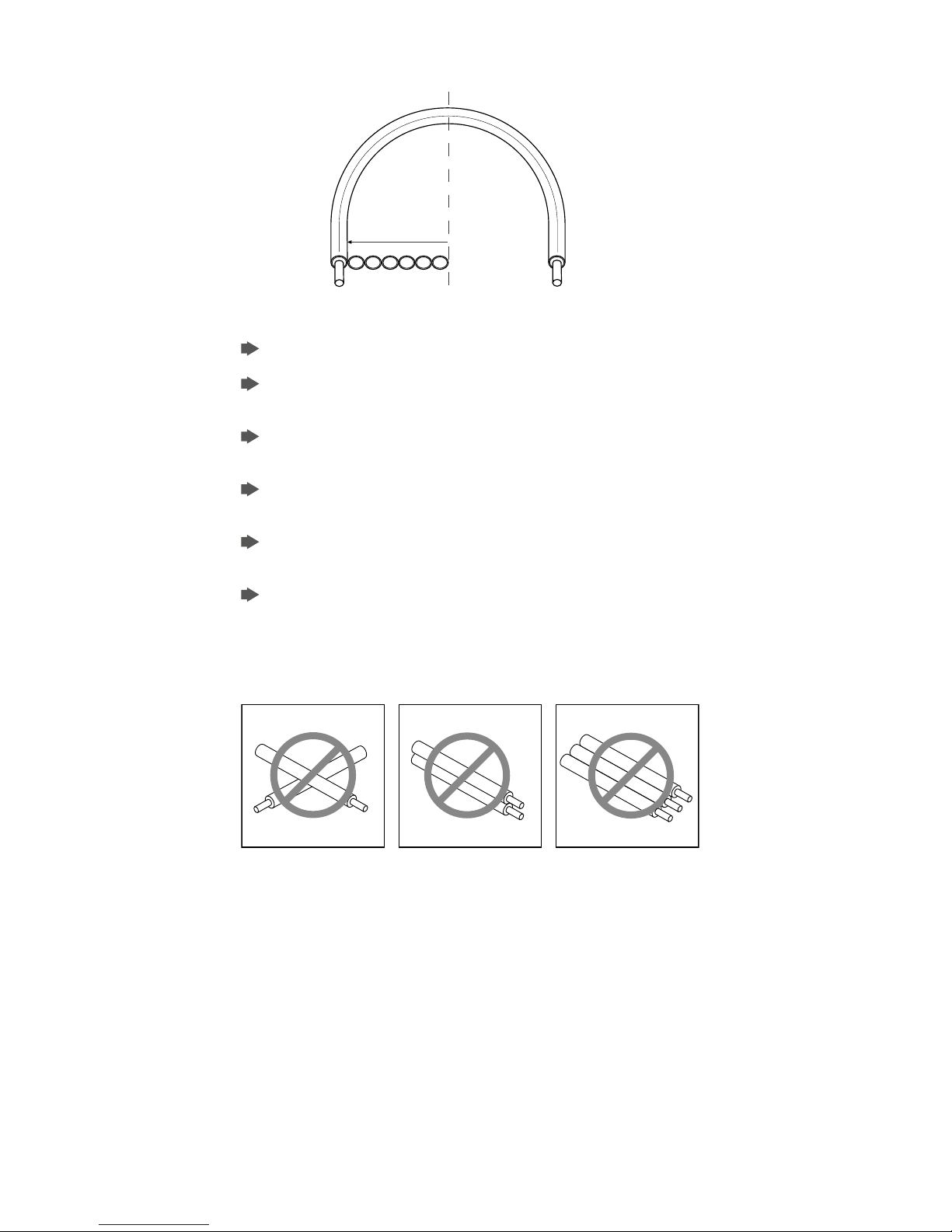

Figure 4 : Minimum bending radius of MI heating cables

Do not repeatedly bend and straighten the cable.

Keep heating cable strung loosely but close to the pipe being

traced, to avoid interference with supports and other equipment.

Add additional heating cable to trace the fittings and supports as

required by the design specification or engineering documents.

Leave the appropriate amount of heating cable at all power

connection, splice and tee locations.

Do not bend the cable within 150 mm of the hot to cold junction

or remote terminations.

When installing MI and other constant wattage heating cables,

ensure that they do not overlap or cross. Doing so may lead to

local over-heating and hazard of fire.

Figure 5 : Minimal spacing must be respected

Minimum cable spacing: 25 mm (lower spacings may be possible but

require special attention and must be properly documented in the

engineering documentation).

For installation in hazardous areas, the standard minimum spacing is

50 mm. This must be respected, unless lower spacings are specifically

allowed in the engineering documentation.

6 x ∆

Cable ∆ > 6 mm

11

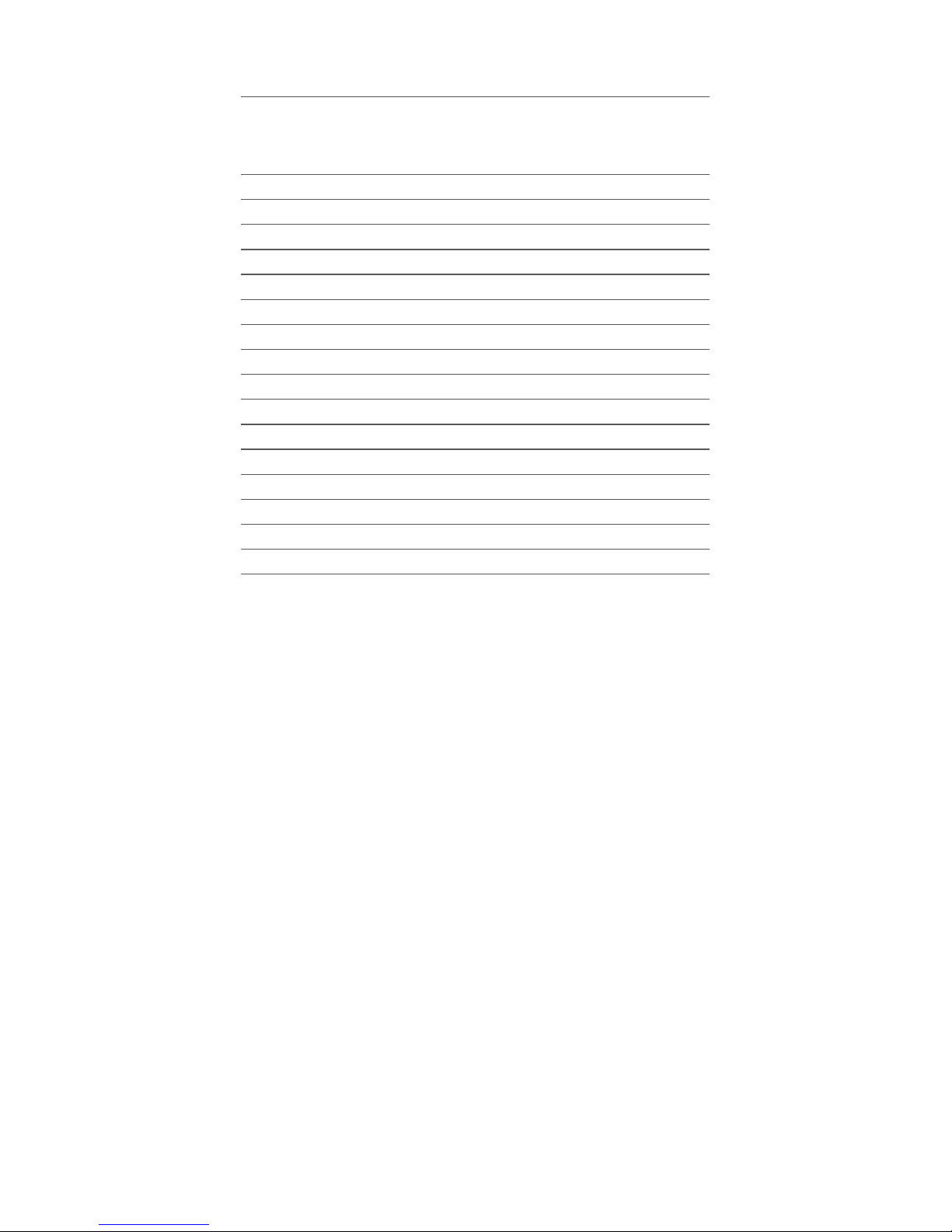

Table 2: Typical allowances (in mm) per run of cable

NPS

inchDNmm

Light

valve

(flanged)

Light

valve

(threaded

or welded)

Heavy

valve

(flanged)

Heavy

valve

(threaded

or welded)

Typical

pipe

shoe

Flange

pair

Field

variance

0.5 15 300 300 300 300 910 300 2%

0.75 20 460 300 460 300 910 300 2%

1 25 610 300 610 300 910 460 2%

1.5 40 760 460 910 460 910 460 2%

2 50 760 610 1060 610 910 460 2%

3 80 910 760 1220 760 910 610 3%

4 100 1220 910 1520 910 910 610 3%

6 150 1520 1060 1830 1060 910 610 3%

8 200 2140 1220 2440 1220 910 610 3%

10 250 2440 1520 3050 1520 910 910 3%

12 300 2750 1830 3660 1830 910 1060 3%

14 350 3050 2140 4270 2140 1370 1220 3%

16 400 3350 2440 4880 2440 1370 1370 3%

18 450 3660 2750 5500 2750 1370 1680 3%

20 500 3970 3050 6100 3050 1370 1830 3%

24 600 4580 3660 7320 3660 1370 2140 3%

1. Allowances above are based on typically available fittings and

supports, with an insulation thickness equivalent to the pipe

insulation. Please refer to the engineering documentation for project

specific allowances.

2. For pipes requiring more than one run of heating cable, apply the

full allowance for each run of cable on each fitting or support as

long as space allows. However, MI heating cables must not touch or

overlap and the minimum spacing between the heating cables must

be respected.

3. For some applications, it may be physically impossible to install all

of the recommended heating cable directly on the fitting or support.

In this case, install the excess heating cable on the pipe, on either

side of the fitting or support, or distribute the additional heater

length along the entire circuit length if a lower local temperature

is acceptable. This constraint may be difficult for small pipes

and/or multiple cable runs. If required, contact Pentair Thermal

Management for assistance.

4. The field variance is important to accomodate expansion and

contraction of the heated equipment. Also refer to figures 12-14 for

more detailed information.

1212

3.3 Heating cable attachment

Fix in place with metal bandings, tie wire or wire cloth band at a

typical interval of 300 mm and additionally where necessary.

The use of tie wire with softer sheath MI heating cables (like

copper HC and cupro-nickel HD) should be avoided, as the tie wire

can damage the heating cable surface over time. Do not tighten

tie wire, use wire cloth band wherever possible.

The hot to cold junction should be secured with metal bands at a

typical distance of 150 mm on either side of the joints.

Cable must be installed and fixed such that movement of cable

during its heating up cycles is permitted, but not to allow cable

to move freely under its own weight. Other attachments (like

aluminium tape or glass tape) may be used, if specified in the

design documentation.

The heating cables may be installed in straight, multiple runs as

required by the design specification.

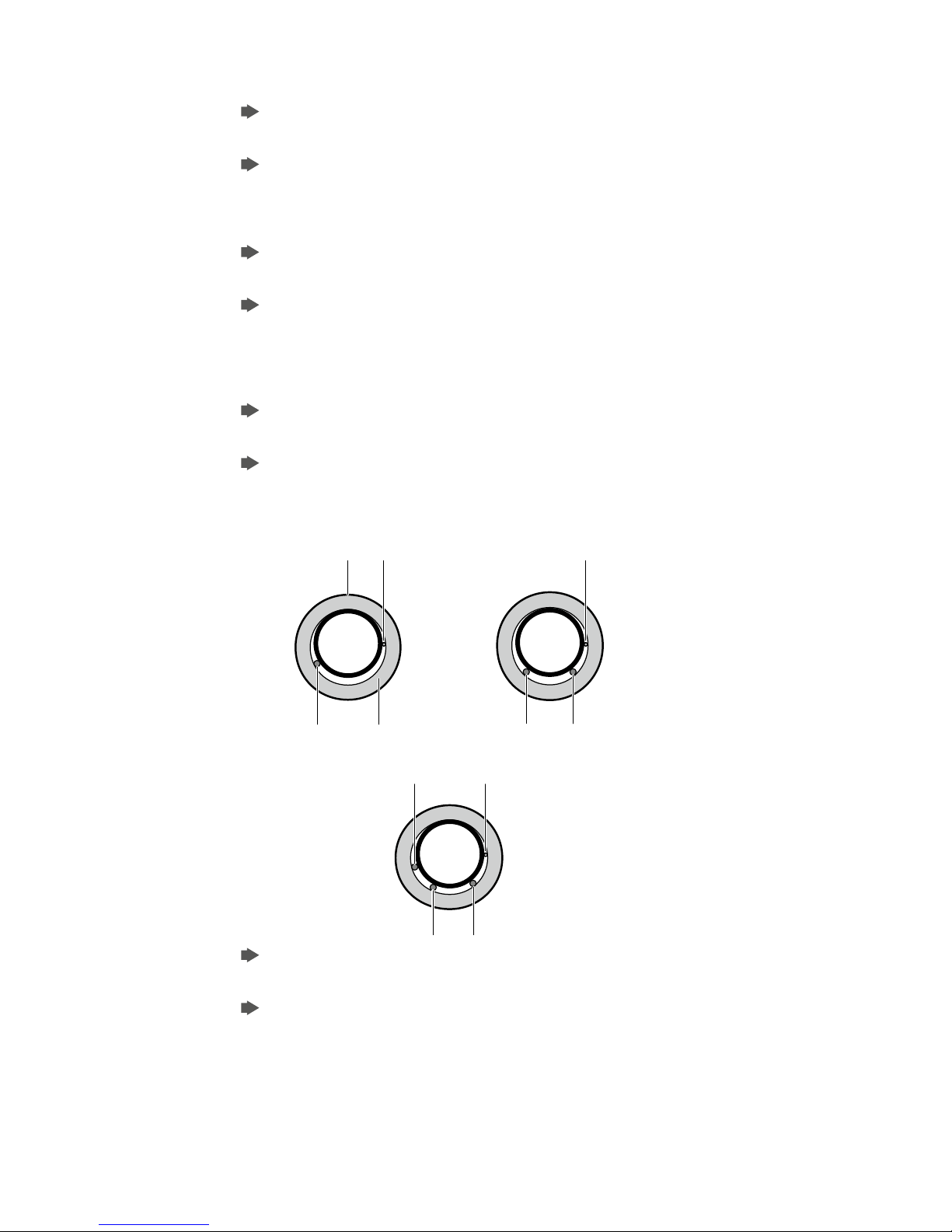

On horizontal pipes fix on lower quadrant as shown below and not

on bottom of pipe.

Figure 6 : Cable orientation on pipe

On vertical pipe sections fix the heating cables equally distributed

around the pipe circumference.

Read the design documents, in particular concerning the need

for cable allowances and regard the location of junction boxes/

controllers before permanently attaching the cable to the pipe.

Weatherproof

jacket (typ)

Insulation

(typ)

Cable

Pipe

One heating cable

Cable

Cable Cable

Cable

Two heating cables

Cable

Temperature

sensor

Temperature

sensor

Temperature

Sensor

1313

Verify if the design documentation requires that the heating

cables have to be covered by aluminium or stainless steel foil

before the insulation is applied.

Installation on tanks typically requires additional fixing devices as

pre-punched steel strips as shown below:

Figure 7: Typical cable layout on large surfaces like tank walls

Figure 8: Fixing device: pre-punched metal strap

Avoid sharp edges and properly seal penetration of MI cold lead

cables through the insulation cladding.

14

Cold

leads

Junction

box

Temperature

controller

Heating cable

Temperature

sensor

Banding

Prepunched

strapping

Loading...

Loading...