Page 1

MiniMax® NT Heater

Digital Display Temperature Controller (DDTC)

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Table of Contents

SECTION I. INSTALLATION .............................................................................................................................. 2

SECTION II. WIRING ............................................................................................................................................ 2

SECTION III. INTRODUCTION OF DDTC ...........................................................................................................7

SECTION IV. SET UP ............................................................................................................................................. 8

SECTION V. LED INDICATORS .......................................................................................................................... 8

SECTION VI. TEMPERATURE SETTING ............................................................................................................ 9

SECTION VII. HEATING MODE SELECTION ...................................................................................................... 9

SECTION VIII. REMOTE CONTROL ....................................................................................................................... 9

SECTION IX. TROUBLE SHOOTING ..................................................................................................................10

SECTION X. MINIMAX NT HEATER DDTC RETROFIT KIT PARTS .......................................................... 12

This instruction is to be used with the DDTC Retrofit Kit (P/N 472377) to replace the 6800 Temperature

Controller for all Pentair Pool Products NT Heaters.

DANGER

FOR YOUR SAFETY – READ BEFORE OPERATING

This product must be installed and serviced by a professional service technician qualified in pool/spa heater

installation and maintenance. If you do not follow these instructions exactly, a fire or explosion may result,

causing property damage, personal injury or loss of life.

WARNING

Before installing this product, read and follow all warning notices and instructions which are included. Failure

to follow safety warnings and instructions can result in severe injury, death, or property damage.

Call (800) 831-7133 for additional free copies of this manual.

Important Notice

Attention Installer.

This manual contains important information about the installation, operation and safe use of this

product. This information should be given to the owner/operator of this equipment.

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

Rev. B 1-20-04 1 P/N 472299

Page 2

SECTION I. INSTALLATION

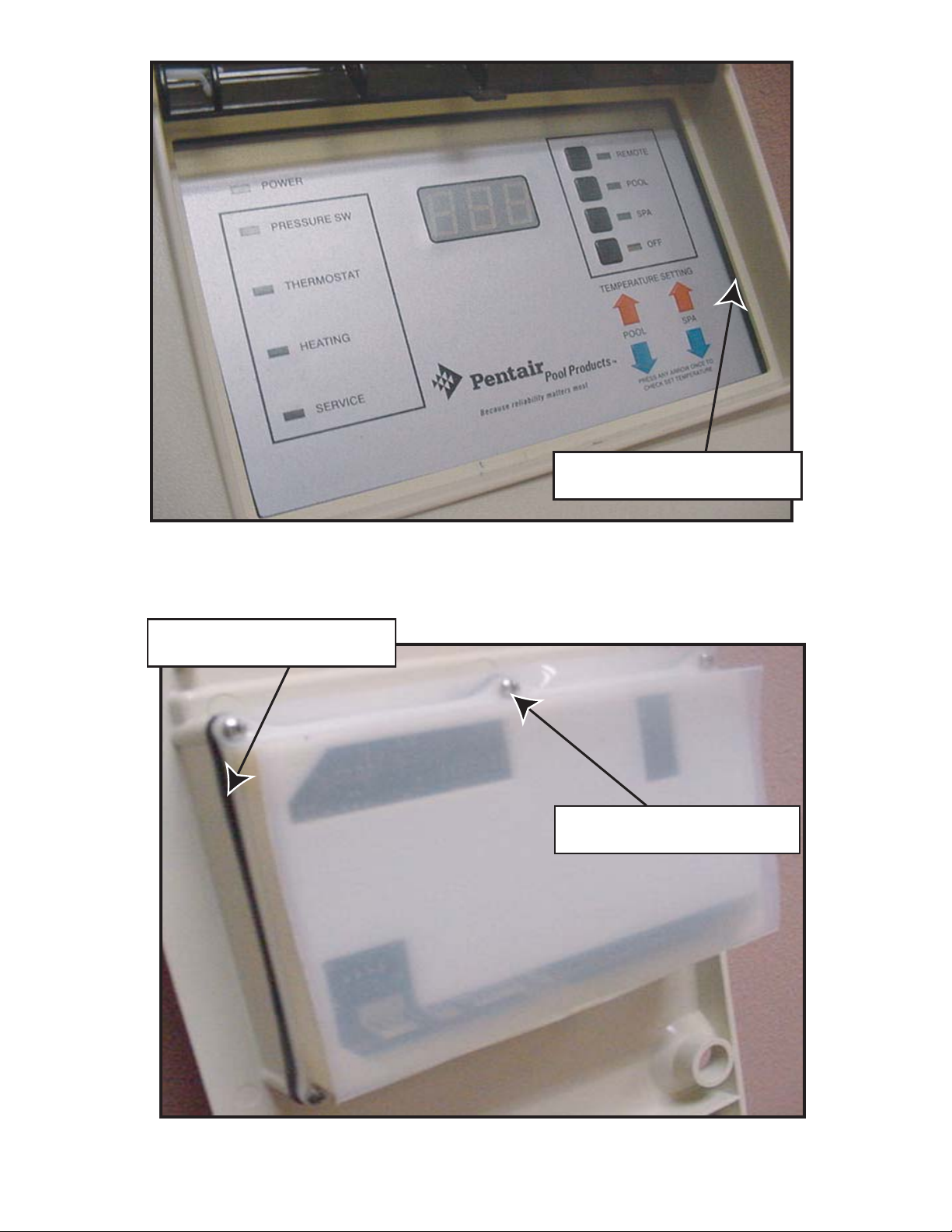

PANEL

DDTC COVER

BARRIER

(RAIN SHIELD)

DDTC PLATE

GASKET, DDTC PLATE

GASKET, DDTC COVER

1. Turn off the electrical power to the heater.

Figure 1.

2. Open the heater’s right door.

3. Disconnect all wires from the

6800 Temperature Controller.

4. Remove the left and right doors from the

heater if necessary.

5. Remove four screws on the cover of the

6800 Temperature Controller.

6. Remove the existing rain shield if any.

7. Install the mounting plate gasket before

putting DDTC board into the place,

see Figure 1 and Figure 2.

NOTE: Install mounting plate gasket before

installing face plate for DDTC board.

8. Install the cover gasket, DDTC cover, and

rain shield by using six screws, (six screws

are provided in the kit). See Figure 3.

9. NOTE: Apply some silicone between gasket and mounting frame to keep waterproof.

Do NOT over tighten screws on DDTC cover or gasket will be displaced.

10. Reconnect the wires per Section II. Wiring, below.

SECTION II. WIRING

1. Please see wiring diagram's, Figure 4 for MiniMax NT LN DV Heater, Figure 5 for

MiniMax NT DV Heater, and Figure 6 for MiniMax NT TSI LN Heater and follow the

instructions below exactly.

2. Reconnect the wire P4 to J4, P7 to J7, P9 to J9, P10 to J10, and P11 to J11 respectively

on the DDTC board.

3. Connect orange wire assembly from “FAN” of DDTC board to air pressure switch.

4. Disconnect the orange wire assembly from transformer to “24VAC” of Ignition Module.

5. Connect orange wire assembly (same wire as above #4) from “24VAC” of DDTC board to

“24VAC” of Ignition Module.

6. NOTE: Orange wire from transformer to module will no longer be used.

P/N 472299 2 Rev. B 1-20-04

Page 3

Figure 2.

Apply silicone between the gasket

and rear-mounting frame.

Apply silicone between the gasket

and front-mounting frame.

Secure DDTC cover and rain

shield by using six screws.

Figure 3.

Rev. B 1-20-04 3 P/N 472299

Page 4

FROM

TERM

BLOCK

120 VAC OR240 VAC

GRN

WHT

2

1

WHT

BLK

3

BLK

GREEN SCREW

ATTACH

GROUND

WIRE

HERE

GRN

(ON THE SIDE JACKET)

BLK

WHT

TRANSFORMER

BLOCK

TERM

ORG

PUR

RED

RED/WHT

BLK

BLK

WHT

WHT

1

2

WHT

BLK

WHT

CON-FEM(BLU)

FOR 120 VAC

BLU

YEL

BLK

CON-MAL(WHT)

BLK/WHT

WHT

BLK

3

WHT

BLK

4

5

BLK

WHT

GRN

GAS VALVE

MV

MV

RED

WHT

BLU

WHT

WHT

FOR 240 VAC

CON-FEM(BRN)

YEL

GRN

YEL

BLK

ORG

HOT SURFACE

PUR

IGNITOR

WHT

WHT

BLOWER

BURNER

WHT

P1

F1

WHT

IGN/120

BLU

IF ORIGINAL FACTORY WIRING MUST BE REPLACED,

INSTALLER MUST SUPPLY UL/CSA APPROVED WIRE

WITH 18 AWG, 600V, 105˚ C TEMP. RATING.

THERMAL FUSE WIRING MUST BE REPLACED WITH

INTERCONNECTING WIRING TO APPLIANCE MUST

CONFORM TO THE NATIONAL ELECTRICAL CODE OR

SUPERSEDE LOCAL(WIRING) CODES.

18 AWG, 600V, 150˚ C TEMP. RATING.

ORG

ORG

P2

IND

F2

24 VAC

IGN MODULE

GND

VAL

TH

IGN

L2

L1

IGN/240

YEL

BLK

WHT

WHT

FS

WHT

WHT

BLU

RED

RED

WHT

BLU

ORG

ORG

ORG

IGN MODULE

J10 J11

VLV

SW/HL/TFUSE

J4 J7

P4 P7 P10 P11

24V

24 VAC FAN

COM NO

ORG

TPROBE

ORG

AIR PRESS. SW.

DDTC

J9

J5

POOL

J8

COM

J6

SPA

WHT

P9

GRN

THERMAL FUSE

WHT

WHT

WHT

RED

RED

ORG

150˚F

HIGH LIMIT

BLK/WHT

115˚F

HIGH LIMIT

MiniMax NT LN Dual Voltage W/DDTC Wiring Diagram

WHT

ORG

SWITCH

WATER PRESSURE

BLK

RED/WHT

RED

ORG

GRN

TEMP.

WHT

WHT

FOR

SYSTEMS

REMOTE CONTROL

SEE INSTRUCTIONS

LOW GAS

PRESSURE SW.

Figure 4.

P/N 472299 4 Rev. B 1-20-04

Page 5

FROM

TERM

BLOCK

120 VAC OR240 VAC

GRN

WHT

2

1

WHT

BLK

3

BLK

GREEN SCREW

ATTACH

GROUND

WIRE

HERE

GRN

(ON THE SIDE JACKET)

BLK

WHT

TRANSFORMER

BLOCK

TERM

ORG

PUR

RED

RED/WHT

BLK

WHT

WHT

1

2

WHT

BLK

WHT

CON-FEM(BLU)

FOR 120 VAC

BLU

YEL

BLK

CON-MAL(WHT)

BLK/WHT

BLK

WHT

BLK

3

WHT

BLK

4

5

BLK

WHT

GRN

GAS VALVE

MV

MV

RED

WHT

BLU

WHT

WHT

FOR 240 VAC

CON-FEM(BRN)

YEL

YEL

BLK

IGNITOR

HOT SURFACE

ORG

WHT

PUR

WHT

WHT

BLOWER

FLAME

SENSOR

BURNER

WHT

P1

F1

IF ORIGINAL FACTORY WIRING MUST BE REPLACED,

INSTALLER MUST SUPPLY UL/CSA APPROVED WIRE

WITH 18 AWG, 600V, 105˚ C TEMP. RATING.

THERMAL FUSE WIRING MUST BE REPLACED WITH

INTERCONNECTING WIRING TO APPLIANCE MUST

CONFORM TO THE NATIONAL ELECTRICAL CODE OR

SUPERSEDE LOCAL(WIRING) CODES.

18 AWG, 600V, 150˚ C TEMP. RATING.

WHT

ORG

ORG

P2

IND

F2

24 VAC

IGN MODULE

IGN/120

YEL

BLU

IGN/240

BLK

FS

GND

VAL

TH

IGN

L2

L1

WHT

BLU

WHT

WHT

WHT

RED

WHT

RED

WHT

BLU

ORG

ORG

IGN MODULE

J10 J11

VLV

SW/HL/TFUSE

J4 J7

P4 P7 P10 P11

24V

24 VAC FAN

WHT

COM NO

AIR PRESS. SW.

G

R

O

ORG

DDTC

J9

TPROBE

J5

POOL

J8

COM

J6

SPA

P9

SEE INSTRUCTIONS

THERMAL FUSE

WHT

WHT

WHT

RED

RED

ORG

150˚F

HIGH LIMIT

BLK/WHT

115˚F

HIGH LIMIT

MiniMax NT STD Dual Voltage W/DDTC Wiring Diagram

WHT

ORG

SWITCH

WATER PRESSURE

BLK

RED/WHT

RED

ORG

GRN

TEMP.

PROBE

WHT

WHT

FOR

SYSTEMS

REMOTE CONTROL

Figure 5.

Rev. B 1-20-04 5 P/N 472299

Page 6

FOR 120 VAC

CON-FEM(BL)

A

TERM

B

TERM

BLOCK

BLOCK

G

G

1

BK

BL

OR

120 VAC

W

N

W

W

2

W

W

240 VAC

BK

L

BK

BK

3

BK

G

ATTACH

BOND LOG

(ON THE SIDE JACKET)

W

5

4

W

BK

FOR 240 VAC

CON-FEM(BR)

GROUND

W

Y

WIRE HERE

WIRE COLOR CODE

BK : BLACK

BK

Y

BK

O

BL : BLUE

PR

BR : BROWN

R : RED

Y

BK

PR O

O : ORANGE

Y : YELLOW

BLOWER

G : GREEN

GY : GRAY

W

PR : PURPLE

W : WHITE

R/W : RED W/WHITE TRACE

O

W

W

BK/W : BLACK W/WHITE TRACE

IF ORIGINAL FACTORY WIRING MUST BE REPLACED,

INSTALLER MUST SUPPLY UL/CSA APPROVED WIRE

WITH 18 AWG, 600V, 105˚ C TEMP. RATING.

THERMAL FUSE WIRING MUST BE REPLACED WITH

18 AWG, 600V, 150˚ C TEMP. RATING.

Y

CON-MAL(W)

R

R/W

BK

BK

BK/W

O

PR

W

W

THERMAL FUSE

W

R

G

GAS VALVE

R

W

R

MV

BL

MV

W

W

W

W

O

GY

SWITCH

WATER PRESSURE

O

W

HOT SURFACE

W

R

SEE OPERATION

FLAME SENSOR

IGNITER

BR

O

BL

MANUAL FOR

& INSTALLATION

REMOTE CONTROL

P11

PI0P4 P7

{

F1 F2

IGN/

240

Y

J11

IGN MOD

JI0

VLV

J7

TFUSE/HLMT/PRESS

J4

24V

FAN

J2

24VAC

J1

SPA

COM

POOL

J5 J6J8

+

24

FC

VAC

-

IGN/

L1

120

BL

BL

BK

J9

P9

GY

THERMISTER

VAL GNDPS THFS

R

O

W

BL

DDTC

115˚F

HIGH LIMITS

MiniMax NT TSI w/DDTC WIRING DIAGRAM

150˚F

G

O

R

BK

R/W

BK/W

NO

COM

GY

BLOWER

AIR PRESSURE SW.

O

O

Figure 6.

P/N 472299 6 Rev. B 1-20-04

Page 7

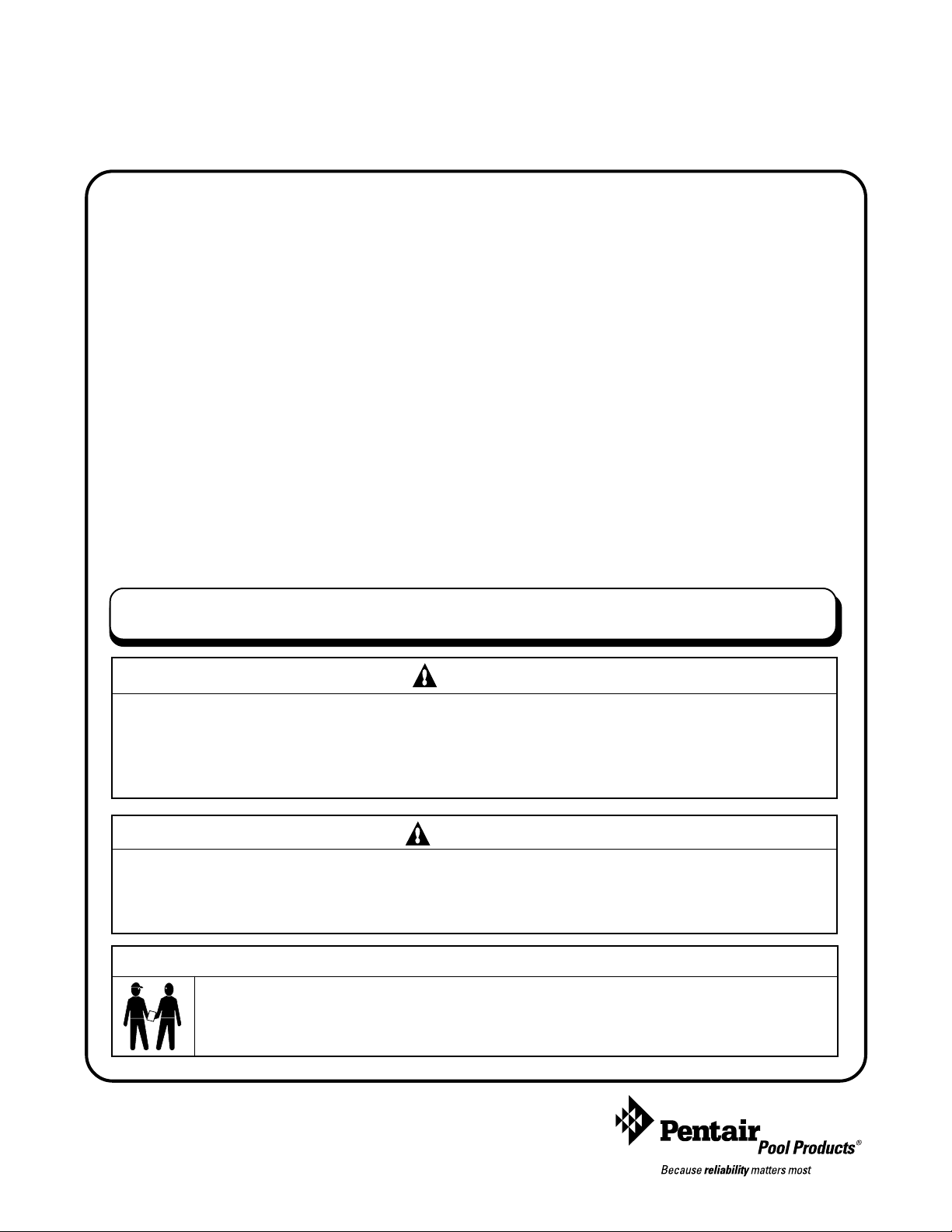

POWER

PRESSURE SW

REMOTE

POOL

REMOTE BUTTON

POOL BUTTON

SYSTEM

INDICATOR

LIGHTS

THERMOSTAT

HEATING

SERVICE

TEMPERATURE SETTING

POOL SPA

SPA

OFF

SPA BUTTON

OFF BUTTON

TEMP. UP

PRESS ANY ARROW ONCE TO

CHECK SET TEMPERATURE

SPA AND POOL

TEMPERATURE

SET BUTTONS

Figure 7.

TEMP. DOWN

SECTION III. INTRODUCTION OF DDTC

The DDTC board, shown in Figure 7, is a digital temperature controller capable of controlling the pool,

spa or both to a minimum temperature of 65° F. (below 65° F. display reads "Off") and a maximum of

104° F. The DDTC board also functions as a system status indicator, using LED lights and programmed

error codes.

During normal operation, the DDTC will display the current temperature of the water returning to the

heater, depending on which mode has been selected, “Pool” or “Spa”. This is accomplished by a

thermister (sensor) on the inlet port of the water header of the heater and working in conjunction with

the internal microprocessor controlling the operation of the heater.

Changing the desired pool or spa temperature is easily done by simply depressing the appropriate up or

down arrow until the display reads the desired set-point temperature. For example, set pool to 78° F.

and the spa to 104° F., when releasing the up or down arrow the display will flash once then return to

the current temperature.

At any time, you wish to know the temperature setting of the pool or spa, simply press the appropriate

up or down arrow, the display will flash once and display the set-point temperature for three (3) seconds,

then flash once again and return to the current temperature.

Rev. B 1-20-04 7 P/N 472299

Page 8

SECTION IV. SET UP

The MiniMax NT Heater comes from the factory preset with a pool temperature setting of 78° F. and

a preset spa temperature of 100° F., and in the off mode setting. Once the power is turned on, the

DDTC board will do a self diagnostic internal check, during this time the display will first read “888”,

then the display will switch to three dashes “- - -“, this process takes approximately ten (10) seconds.

The DDTC will then illuminate the “Power” LED and “Off” LED, see Figure 8.

1. Turn on the power to the heater; the switch is on the bottom of the electrical junction box located

internally on the right side of the cabinet. The DDTC will now go through the self-diagnostic’s test

as stated above.

2. Turn on the circulating system pump and make sure that adequate water is being delivered

to the heater, The “PRESSURE SW” LED will now illuminate.

3. If you are using the heater with a remote control system, open the right door of the heater

to access the rear portion of the DDTC. Locate the three terminals marked “Pool” (J5),

“Spa” (J6) and “Com” (J8). If the remote system is a three-wire remote unit, connect the

pool lead to the “pool” terminal J5, connect the spa lead to the “spa” J6 terminal and connect

the common wire to the “com” terminal J8. If the remote system is a two-wire remote, the remote

system will be used to turn the heater on for a selected body of water, Pool or Spa, select which

application you are working with and connect one wire to the common terminal J8 and the other

wire to either “Pool J5” or “Spa J6”. Close and latch the door.

SECTION V. LED INDICATORS

There are nine lights that can be seen from the front of the control panel, (five are system indicators and

four are mode indicators), which helps you understand the operation of the heater, see Figure 7.

If something should go wrong, the lights will aid in troubleshooting the problem. An additional four lights

can be seen after opening the control panel. These four lights are diagnostic indicators for the service

technician to troubleshoot the system.

On the right front of the DDTC board there are four Buttons and corresponding LED lights,

see Figure 7. Using the buttons allows you to select one of the four modes and the lights indicate which

operational mode that the heater is in, Off, Spa mode, Pool mode or Remote mode. If the heater is

not connected to a remote system then the remote mode will not be used.

The following are descriptions of the five system indicators:

• POWER

The light is on at all times, in any switch position, indicating 24VAC power is being supplied to the

control circuit. If it fails to light, no other light will be on. Possible causes are:

1. External power to the heater is disconnected; check service panel circuit breaker or fuses;

2. Transformer has failed.

• PRESSURE SW (WATER PRESSURE SWITCH)

This light is on when Spa/Pool Selector switch is on, indicates the circulating pump is running properly.

If pressure light fails to light, the pump may have lost its prime or water flow may be restricted by an

inadvertently closed valve or clogged filter or pump basket. If you have determined that there is no

water flow restriction to the heater, you should call a qualified technician.

P/N 472299 8 Rev. B 1-20-04

Page 9

• THERMOSTAT

This light is on when the thermostat contacts close, signaled by the water temperature falling below the

set-point, calling for the heater to fire to maintain the desired water temperature.

• HEATING

The heating light is on any time the thermostat has signaled a call for heat which initializes the ignition

safety circuit — the light comes on indicating successful firing of the main burners and stays on until the

pool/spa reach the water temperature setting.

• SERVICE

The service light is off during normal operation of heater. The light only comes on if a problem with a

control has occurred or when the heater is first firing. The problem must be investigated by the technician

prior to attempts to fire the heater again.

SECTION VI. TEMPERATURE SETTING

The heater comes factory set at 78° F. for the pool mode and 100° F. for the spa mode, using the

up and down arrows, you can set the thermostats to a minimum temperature of 65° F., or a maximum

of 104° F. If you desire to heat only one body of water, the thermostat is capable of an off mode. As

an example, if you only wish to heat the spa and not the pool, simple depress and hold the pool down

arrow, and the thermostat will lower its setting to 65° F. then go to an off mode. If there is a remote

system connected to the heater, please see the special thermostat setting features under Heating Mode

Selection & Remote mode.

SECTION VII. HEATING MODE SELECTION

1. Off Mode: The heater will not come on. NOTE: The "Off" display on the Digital Display

Temperature Controller does not mean that the heater is off. It only states that the pool or spa

thermostat has been turned off.

2. Spa Mode: The heater will operate and heat the spa to the desired temperature.

3. Pool Mode: The heater will operate and heat the pool to the desired temperature.

4. Remote Mode: The DDTC is compatible with two and three wire remote control systems.

In order to operate by a remote control system, the REMOTE mode must be selected on the

front panel. When the REMOTE mode is selected, the REMOTE LED will light up.

SECTION VIII. REMOTE CONTROL

THE TWO-WIRE REMOTE CONTROL SYSTEM is typically installed and connected to the heater

for spa heating. The two-wire remote system is usually provided with a water temperature sensor that

monitors the system temperature and turns the heater on or off in response to the temperature of the spa.

To heat a spa, it should be connected to terminals J6 and J8. Pool heating remote control would

require connecting to terminals J5 and J8. If the REMOTE mode is set at the front panel LED light,

the DDTC will respond to a contact closure by remote system and heater will operate until the remote

system temperature setting is satisfied.

Rev. B 1-20-04 9 P/N 472299

Page 10

NOTE: With this type of two-wire remote, with its own temperature sensors and system control,

using the up arrows on the front of the DDTC, hold down the up arrow until you reach the maximum

setting of 104° F., this allows the remote system thermostat to operate the heater at any set-point

below 104° F., the heater thermostats then act as a secondary controller if water temperature

reaches 104° F.

THE THREE-WIRE REMOTE CONTROL SYSTEM will be connected to terminals J5, J6 & J8.

J8 is the common terminal. If the heater is in the REMOTE mode, the DDTC will monitor the terminals

and respond to a contact closure between J5 & J8 or J6 & J8. A contact closure between J5 & J8 will

cause the DDTC to switch to the POOL setting and control the heater to the DDTC pool set-point

temperature. A contact closure between J6 & J8 will cause the DDTC to switch to the SPA setting and

control the heater to the DDTC spa set-point temperature. If only heating the spa, then depress the pool

down arrow until the display goes to “Off”.

SECTION IX. TROUBLE SHOOTING

The DDTC temperature display contains three LED’s with a decimal point between the first and second,

this display is also used to display an error code if for some reason there is a failure within the heater

control system or a DDTC internal fault. The DDTC will display the actual temperature or set-point

temperature or OFF, as selected by the user. When DDTC detects an error, the display will show Exx,

see Figure 8, where Exx is the error code of DDTC fault, see Table 1. Codes 1 through 9 indicate a

“soft lockout” error that means after these errors are fixed, the heater will resume normal operation and

restart immediately. Code ERR indicates a “hard lockout” error that means after these errors are fixed,

you need to reset the power of the heater through the switch on the bottom of the electrical junction box

on the right side of the cabinet.

NOTE: If Code ERR is shown on the LED display at any time, turn the heater off, (from power switch),

then turn on the heater again. If the error code is still displayed, call a certified Pentair Service Technician

for repair.

edoCrorrEnoitpircseDrorrE

10EegatloVwoLmetsyS

20EtimiLerutarepmeThgiH

30EnepOesuFlamrehT

40EeruliaFnaF

50EeruliaFemalF/noitingI

60EeruliaFeludoM/evlaVniaMsaG

90E,80E,70EdesUtoN

RRE

Table 1.

P/N 472299 10 Rev. B 1-20-04

3317-138)008(:tatnemtrapeDecivreSlacinhceTs'riatnePllaC

Page 11

Figure 8.

Rev. B 1-20-04 11 P/N 472299

Page 12

SECTION X. MINIMAX NT HEATER DDTC RETROFIT KIT PARTS

P/N Description Qty.

072204 Wire Tie 2

471870 Wire Assembly, Orange 2

472060 Silicone Tube 1

472100 DDTC Board 1

472256 Gasket, DDTC Cover 1

472257 Gasket, DDTC Mounting Plate 1

472299 Instruction Sheet, DDTC Retrofit Kit 1

472379 DDTC Cover w/Label 1

472380 Barrier (Rain Shield) 1

472381 ¼ in. Female to Double Male, Piggyback 1

472383 DDTC Mounting Plate w/Label 1

98212800 Screw, #6 X 5/8 in. 6

SAVE THESE INSTRUCTIONS.

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

P/N 472299 12 Rev. B 1-20-04

Loading...

Loading...