Page 1

Warning:

®

MiniMax CH

POOL & SPA HEATERS

OPERATION & INSTALLATION MANUAL

WARNING

FOR YOUR SAFETY - READ BEFORE OPERATING

If you do not follow these instructions exactly, a fire or explosion may

result, causing property damage, personal injury or loss of life.

For additional free copies of this manual; call (800) 831-7133.

1

1

1

U.S. Patent Numbers

6,295,980

5,318,007 - 5,228,618

5,201,307 - 4,595,825

WARNING

Warning: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, personal injury or death. Installation and service must be

performed by a qualified installer, service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

For Your

Safety

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

To

Consumer

Retain For

Future

Reference

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or other appliances.

Pentair Pool Products, Inc.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 W. Los Angeles Ave., Moorpark, CA 93021

Rev. B 1-17-03 P/N 472128

• (805) 523-2400

Page 2

Table of Contents

Introduction ............................................................................................................... 3

Important Notices ...................................................................................................................................................................... 3

Warranty Information ................................................................................................................................................................. 4

Operation .................................................................................................................... 4

Safety Rules .............................................................................................................................................................................. 4

Millivolt Lighting/Operation - Natural & Propane ........................................................................................................................ 5

Operating (Controls) .................................................................................................................................................................. 6

Maintenance ............................................................................................................... 7

Maintenance Instructions ........................................................................................................................................................... 7

Relief Valve................................................................................................................................................................................ 7

Energy Saving Tips.................................................................................................................................................................... 7

Spring and Fall Operation .......................................................................................................................................................... 7

Winter Operation ....................................................................................................................................................................... 7

Chemical Balance ...................................................................................................................................................................... 8

Installation Instructions ............................................................................................ 9

2

Specifications .......................................................................................................................... 9

Plumbing Connections ........................................................................................................... 10

Plumbing/Valves ........................................................................................................................................................................ 10

Manual Bypass .......................................................................................................................................................................... 10

Below Pool Installation .............................................................................................................................................................. 10

Water Connections.................................................................................................................. 11

Reverse Water Connections ...................................................................................................................................................... 11

Insulating High Limits when Reversing Heads ........................................................................................................................... 11

Gas Connections ..................................................................................................................... 12

Gas Line Installation .................................................................................................................................................................. 12

Pipe Sizing Chart/Gas Pressure Requirements ......................................................................................................................... 12

Pipe Sizing Chart/Propane 2 Stage Regulation ......................................................................................................................... 13

Regulated Manifold Pressure Test ............................................................................................................................................. 13

Ventilation ................................................................................................................................ 14

Outdoor Installation Requirements ............................................................................................................................................ 14

Outdoor Cap Installation ............................................................................................................................................................ 14

Indoor Installation Requirements ............................................................................................................................................... 15

Installation on Floors Constructed of Combustible Materials ..................................................................................................... 16

Indoor Draft Hood Installation .................................................................................................................................................... 16

Electrical .................................................................................................................................. 17

Millivolt Wiring Diagram ............................................................................................................................................................. 17

Trouble Shooting (General)....................................................................................... 18

MiniMax CH Parts List & Exploded View ................................................................. 19-21

MiniMax CH (150 IID Model) Appendix ..................................................................... A1-A9

MiniMax CH (150 IID Model) Parts List & Exploded View ....................................... A10-A12

Warranty Information ................................................................................................. Back Cover

P/N 472128 Rev. B 1-17-03

Page 3

3

Introduction

MiniMax CH

Pool and Spa Heaters

Congratulations on your purchase of a MiniMax CH high performance heating system. Proper installation

and service of your new heating system and correct chemical maintenance of the water will ensure years of

enjoyment. The MiniMax CH is a compact, lightweight and efficient gas fired high performance pool and

spa heater that can be directly connected to schedule 40 PVC pipe and has a built-in top. The MiniMax CH

is a millivolt heater and has a self sustaining pilot and requires NO external power source.

IMPORTANT NOTICES

...For the installer and operator of the MiniMax CH pool and spa heater. The manufacturer’s warranty may

be void if, for any reason, the heater is improperly installed and/or operated. Be sure to follow the

instructions set forth in this manual. If you need any more information, or if you have any questions

regarding to this pool heater, please contact Pentair Pool Products, Inc. at (800) 831-7133.

These heaters are designed for the heating of swimming pools and spas, and should never be employed for

use as space heating boilers, general purpose water heaters, in non-stationary installations, or for the heating

of salt water.

CAUTION

OPERATING THIS HEATER CONTINUOUSLY AT WATER TEMPERATURE BELOW 68° F. WILL CAUSE

HARMFUL CONDENSATION AND WILL DAMAGE THE HEATER AND WILL VOID THE WARRANTY.

Do not use the heater to protect pools or spas from freezing if the final maintenance temperature desired is

below 68° F. as this will cause condensation related problems.

CODE REQUIREMENTS

The installation must conform with local codes or in the absence of local codes with the latest

National Fuel Gas Code, ANSI Z223.1, and the latest edition of the National Electrical Code, NFPA 70.

Installation in Canada to be made in accordance with the latest CAN/CGA-B149.1 or .2 and

CSA C22.1 Canadian Electric Code, part 1.

Rev. B 1-17-03 P/N 472128

Page 4

Operation (contd.)

4

This instruction manual provides operating

instructions, installation and service information for

the MiniMax CH high performance heater. The

information in this manual applies to the MiniMax

CH 150, 200, 250, 300, 350, and 400 natural gas

and propane (LP) models.

It is very important that the owner/installer read and

understand the section covering installation

instructions, and recognize the local and state codes

before installing the MiniMax CH. History and

experience has shown that most heater damage is

caused by improper installation practices.

Operation

WARRANTY INFORMATION

The MiniMax CH pool heater is sold with a limited

factory warranty. Specific details are described on

the back cover of this manual and a copy of the

warranty and warranty registration card are

included with the product. Return the warranty

registration card after filling in the serial number

from the rating plate inside the heater.

Pentair Pool Products’ high standards of excellence

include a policy of continuous product improvement

resulting in your state-of-the-art heater. We reserve

the right to make improvements which change the

specifications of the heater without incurring an

obligation to update the current heater equipment.

SAFETY RULES

1. Spa or hot tub water temperatures should never

exceed 104° F (40° C). A temperature of 100° F

(38° C) is considered safe for a healthy adult.

Special caution is suggested for young children.

2. Drinking of alcoholic beverages before or during

spa or hot tub use can cause drowsiness which

could lead to unconsciousness and subsequently

result in drowning.

3. Pregnant women beware! Soaking in water

above 102° F (39° C) can cause fetal damage

during the first three months of pregnancy

(resulting in the birth of a brain-damaged or

deformed child). Pregnant women should stick

to the 100° F (38° C) maximum rule.

WARNING

4. Before entering the spa or hot tub, the user

should check the water temperature with an

accurate thermometer. Spa or hot tub

thermostats may err in regulating water

temperatures by as much as 4° F (2.2° C).

5. Persons with a medical history of heart disease,

circulatory problems, diabetes or blood pressure

problems should obtain their physician's advice

before using spas or hot tubs.

6. Persons taking medication which induce

drowsiness, such as tranquilizers, antihistamines

or anticoagulants should not use spas or hot

tubs.

Should overheating occur or the gas supply fail to shut off, turn off the manual gas control valve to the

appliance. Do not use this heater if any part has been under water. Immediately call a qualified service

technician to inspect the heater and to replace any part of control system and gas control which has been

under water.

P/N 472128 Rev. B 1-17-03

Page 5

Operation (contd.)

MINIMAX CH MILLIVOLT LIGHTING/OPERATION-NATURAL GAS & PROPANE

FOR YOUR SAFETY: READ BEFORE LIGHTING

WARNING

If you do not follow these instructions exactly, a fire or explosion may result causing personal injury, loss of life

and property damage.

Since propane gas is heavier than air, escaping propane will accumulate and remain at ground level. Do not

attempt to light the heater. If you suspect a propane leak, lighting the heater can result in a fire or explosion

which can cause personal injury, death, and property damage.

A. This heater is equipped with a pilot which must be

lighted manually. When lighting the pilot, follow

these instructions exactly.

B. BEFORE LIGHTING smell all around the heater

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle

on the floor.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any heater.

- Do not touch any electrical switch; do not use any

phone in your building.

- Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

- If you cannot reach your gas supplier, call the Fire

Department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turn by hand, don't try to repair it. Call a qualified

service technician. Forced or attempted repair may

result in a fire or explosion.

D. Do not use this heater if any part has been under

water. Immediately call a qualified service

technician to inspect the heater and to replace any

part of the control system and any gas control which

has been under water.

5

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the thermostat to the lowest setting.

3. Turn off electric power to the heater.

4. Push in gas control knob slightly and turn clockwise to “OFF”.

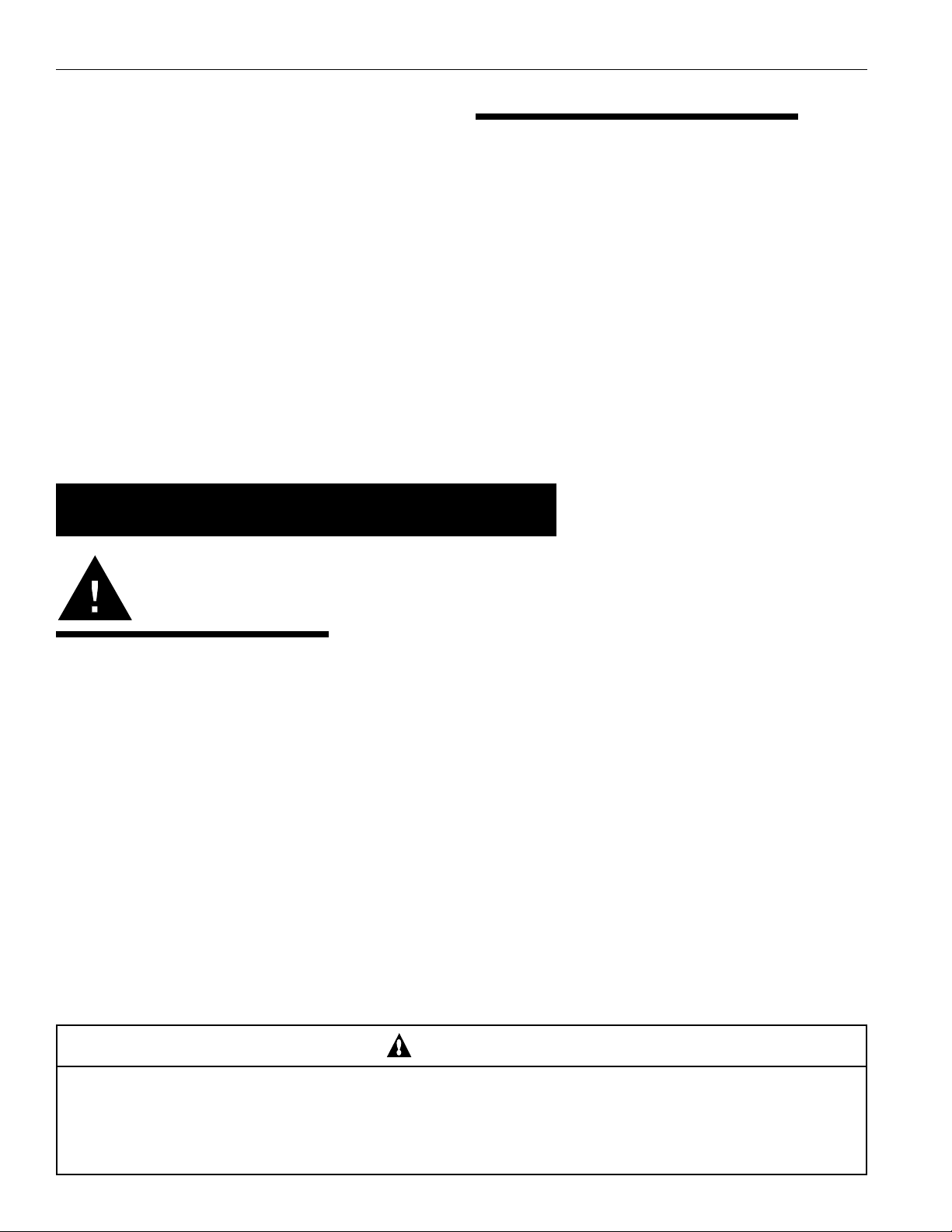

Robertshaw Millivolt Gas Valve Honeywell Millivolt Gas Valve

Figure 1. Figure 2.

Gas control knobs shown in “OFF” position.

NOTE

Knob cannot be turned from “Pilot to “OFF”” unless

knob is pushed in slightly. DO NOT FORCE.

5. Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Follow "B" in the safety information above. If you don't smell gas, go to the next step.

6. Push in gas control knob slightly and turn counterclockwise to “Pilot”.

7. Push the control knob all the way and hold in.

Immediately light the pilot with Presslite matchless

ignition system by pressing the red igniter button

(located at the panel next to the gas valve). Continue

to hold the control knob in for about one (1) minute

after the pilot is lit. Release knob and it will pop

back up. Pilot should remain lit. If it goes out, repeat

steps 4 through 7.

• If knob does not pop up when released, stop and

immediately call your service technician or gas

supplier.

• If the pilot will not stay lit

after several tries, turn the

gas control knob to “OFF”

and call your service

technician or gas supplier.

8. Turn knob on gas control

counterclockwise to

“ON”.

9. Replace the control access

door.

10. Set the thermostat to the

desired setting.

Figure 3.

Figure 4.

Pilot

TO TURN OFF GAS TO HEATER

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the heater if service is

to be performed.

3. Remove control access door.

Rev. B 1-17-03 P/N 472128

4. Push in gas control knob slightly and turn clockwise

to "OFF". Do not force.

5. Replace control access door.

Page 6

Operation (contd.)

SPAPOOL

COLD COLDHOT HOT

OFF

POOL TEMP SPA TEMP

6

OPERATING (CONTROLS)

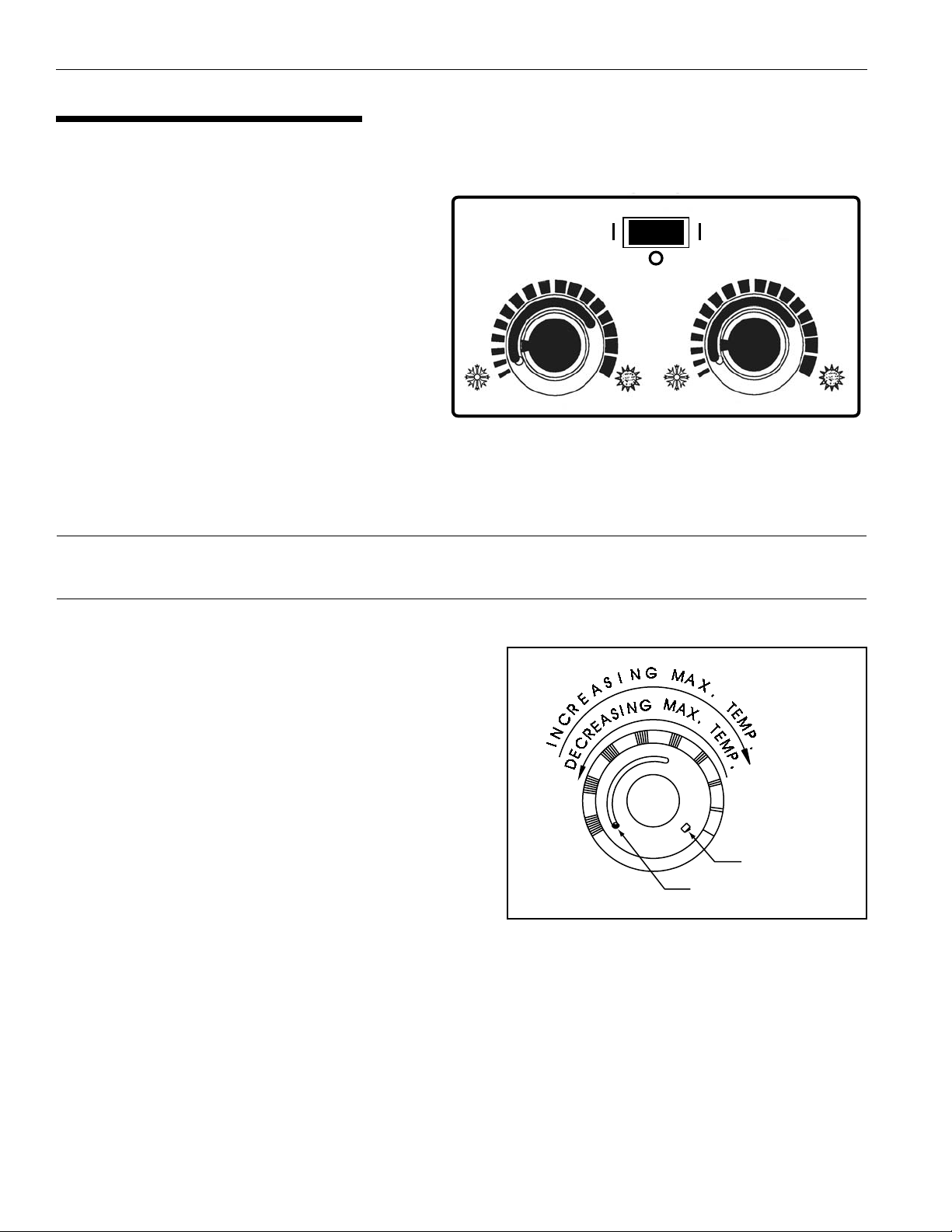

Dual Temperature Control System

For convenience and economy all MiniMax CH

heaters are equipped with two thermostats on the

front of the heater control panel; see Figure 5.

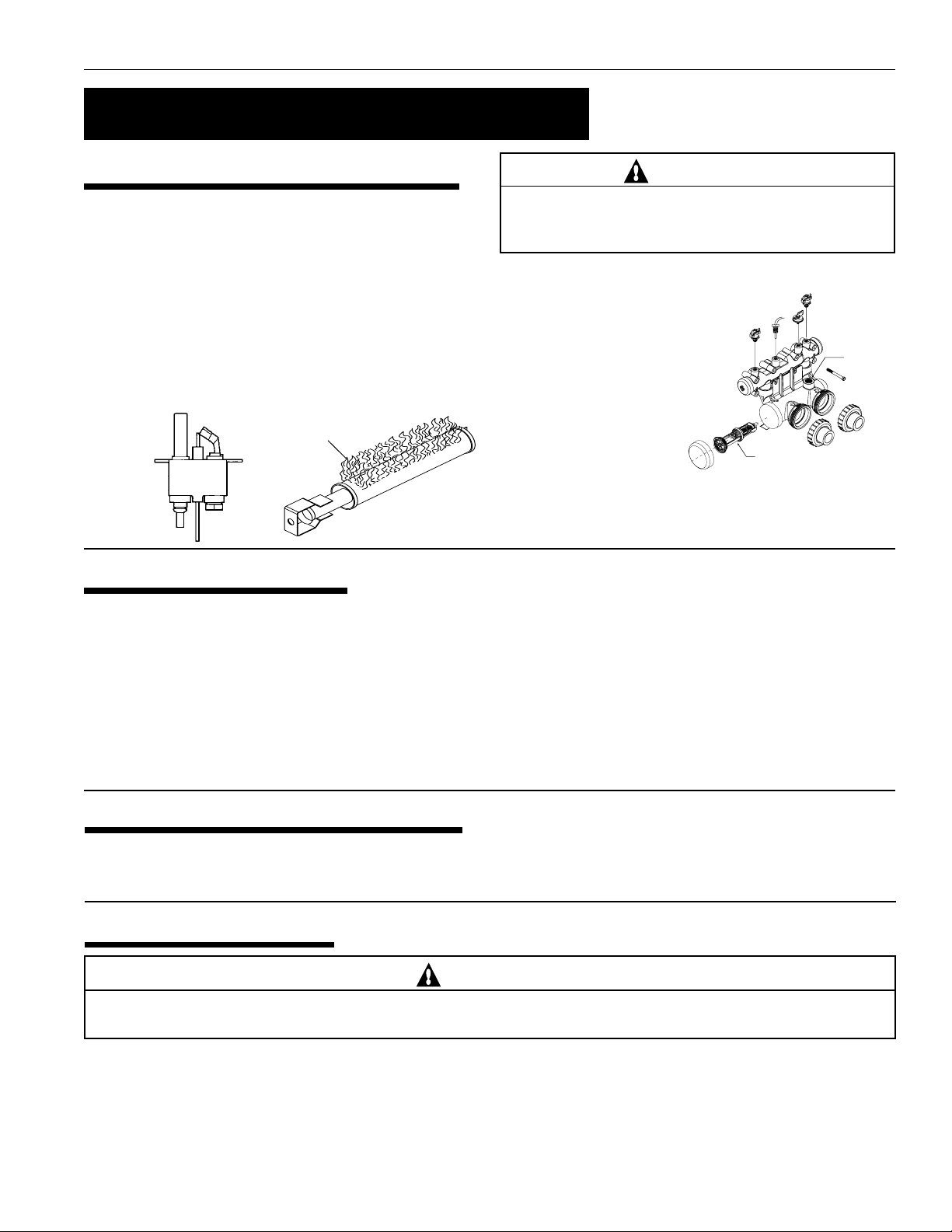

THERMOSTAT KNOB STOPPER

Each thermostat is equipped with a mechanical

stop that can be locked or unlocked with use of a

screwdriver to prevent temperatures in excess of

that desired by the user; see Figure 6.

The maximum setting can be adjusted by

loosening the screw "A" and turning the stopper

dial to desired maximum setting. Lock the setting

by tightening the screw. The Mechanical stop is

under the knob. Ensure that the knob is stopping at the correct position when the knob is rotated clockwise

from a lower temperature position. (See Thermostat Adjustment.)

Figure 5.

NOTE

To eliminate error due to piping heat losses, measure pool temperature with an accurate

thermometer directly at the pool or spa.

THERMOSTAT ADJUSTMENT

The knob with locking feature eliminates the need for

constant thermostat adjustments. Set the knob pointer to

the desired pool or spa temperature.

If further adjustment is needed, rotate the knob until the

desired temperature is obtained. This knob position

corresponding to your desired maximum pool or spa

temperature may now be preset (locked) by the knob

stopper which prevents the knob from being turned

beyond the maximum temperature you set.

POWER (THERMOSTAT SELECT) SWITCH

Figure 6.

Screw A

The Pool/Off/Spa switch allows the heater to be turned

off when heating is not desired.

1. “Pool” position - Maintains selected pool temperature.

Knob Stopper

2. “Off” position - Heater will not come on regardless of drop in pool or spa temperature.

3. “Spa” position - This allows separate control of spa water temperature or an alternate lower pool

temperature.

P/N 472128 Rev. B 1-17-03

Page 7

Maintenance

7

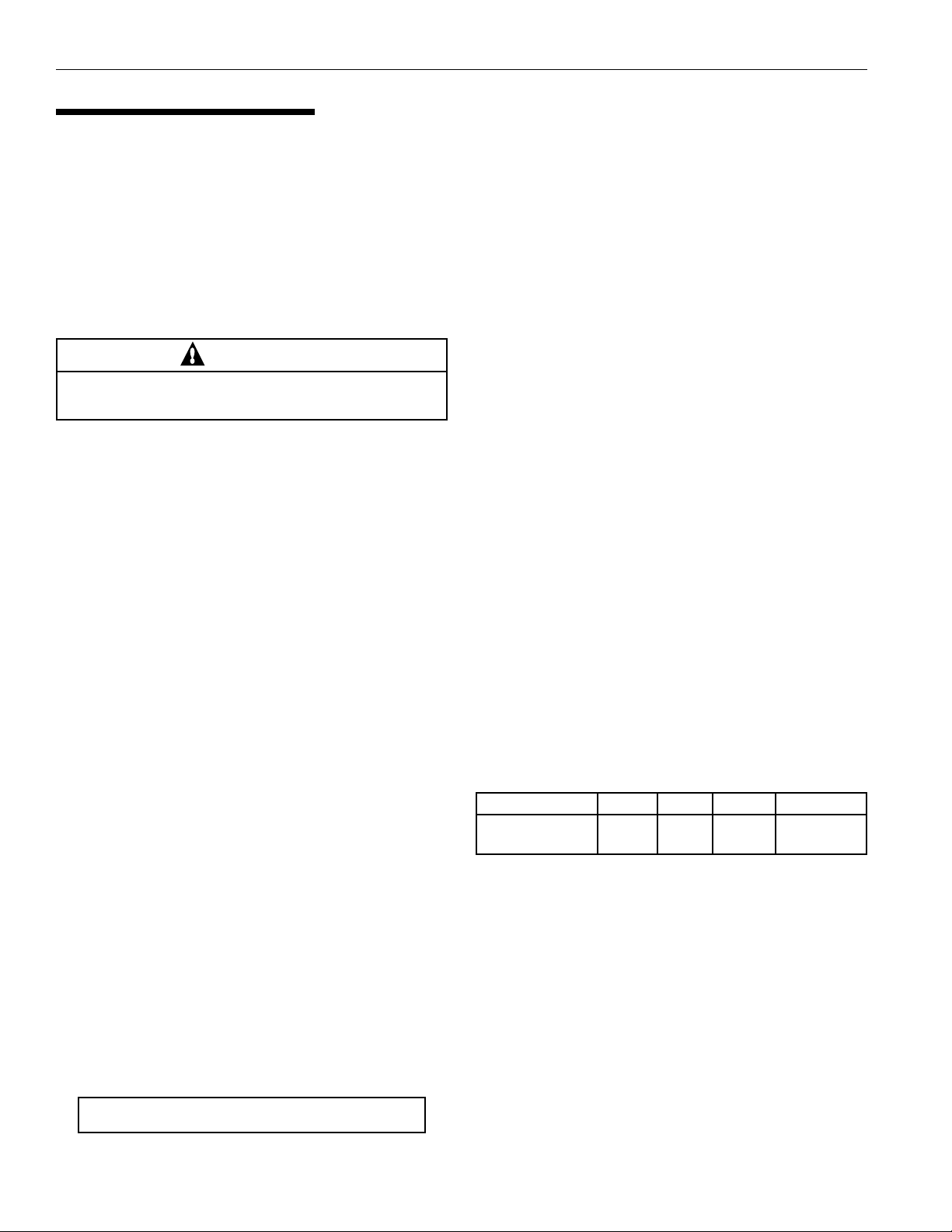

MAINTENANCE INSTRUCTIONS

It is recommended that you check the following items at least

every six months and at the beginning of every swimming

season.

1. Examine the venting system. Make sure there are no obstructions in the flow of combustion and ventilation air.

2. Visually inspect the main burner and the pilot burner

flame. The normal color of the flame is blue. When flame

appears yellow, burners should be inspected and cleaned;

see Figure 8.

3. Keep the heater area clear and free from combustibles

and flammable liquids.

Blue Flame

Figure 7.

Figure 8.

ENERGY SAVING TIPS

1. If possible, keep pool or spa covered when not in use.

This will not only cut heating costs, but also keep dirt and

debris from settling in the pool and conserve chemicals.

2. Reduce the pool thermostat setting to 78° F. or lower.

This is accepted as being the most healthy temperature

for swimming by the American Red Cross.

3. Use an accurate thermometer.

4. When the proper maximum thermostat settings have been

determined, tighten the thermostat knob stopper.

CAUTION

REMOVE THE FLOW VALVE ASSEMBLY WHEN DRILLING

THE HOLE TO INSTALL A PRV. OTHERWISE, YOU WILL

DRILL INTO THE VALVE ASSEMBLY.

Pressure Relief Valve

In some installations, a

pressure relief valve

(PRV) is required on the

MiniMax CH heater. To

install a PRV, carefully

drill a 3/8 in. hole in

center of 3/4 in. NPT

port (on main header)

being careful to drill

only thru wall at bottom

of 3/4 in. NPT port and

no deeper—now thread

in the 3/4 NPT PRV. (Sold separately.)

5. Set time clock to start circulation system no earlier than

daybreak. The swimming pool loses less heat at this time.

6. For pools that are only used on the weekends, it is not

necessary to leave the thermostat set at 78° F. Lower the

temperature to a range that can be achieved easily in one

day. Generally, this would be 10° F. to 15° F., if pool

heater is sized properly.

7. During the winter or while on vacation, turn the heater off.

8. Set up a regular program of preventative maintenance

for the heater each new swimming season. Check heat

exchanger, controls, burners, operation, etc.

Figure 9.

REMOVE FLOW VALVE

BEFORE DRILLING

THE NPT PORT

FOR PRV

INSTALLATION

DRILL THRU

THE NPT PORT

SPRING AND FALL OPERATION

If the pool is being used occasionally, do not turn the heater completely off. Set the thermostat down to 65° F. This will

keep the pool and the surrounding ground warm enough to bring the pool up to a comfortable swimming temperature in a

shorter period of time.

WINTER OPERATION

CAUTION

OPERATING THIS HEATER CONTINUOUSLY AT WATER TEMPERATURE BELOW 68° F. WILL CAUSE HARMFUL

CONDENSATION AND WILL DAMAGE THE HEATER AND WILL VOID THE WARRANTY.

If the pool won't be used for a month or more, turn the heater off at the main gas valve. For areas where there is no danger of

water freezing, water should circulate through the heater all year long, even though you are not heating your swimming pool.

The MiniMax CH should not be operated out doors at temperatures below 0° F. for propane and -20° F. for natural gas. Where

freezing is possible, it is necessary to drain the water from the heater. This may be done by opening the drain valve located at

the inlet/outlet header (see Figure 9.) allowing all water to drain out of the heater. It would be a good practice to use

compressed air to blow the water out of the heat exchanger. (See additional notes under Important Notices in Introduction

on page 3.)

Rev. B 1-17-03 P/N 472128

Page 8

Maintenance (contd.)

8

CHEMICAL BALANCE

POOL AND SPA WATER

Your Pentair Pool Products pool heater was designed

specifically for your spa or pool and will give you many

years of trouble free service provided you keep your

water chemistry in proper condition.

Three major items that can cause problems with your

pool heater are improper pH, disinfectant residual, and

total alkalinity. These items, if not kept properly

balanced, can shorten the life of the heater and cause

permanent damage.

CAUTION

Heat exchanger damage resulting from chemical

imbalance is not covered by the warranty.

WHAT A DISINFECTANT DOES

Two pool guests you do not want are algae and bacteria.

To get rid of them and make pool water sanitary for

swimming - as well as to improve the water's taste, odor

and clarity - some sort of disinfectant must be used.

Chlorine and bromine are universally approved by health

authorities and are accepted disinfecting agents for

bacteria control.

RULE: 7.4 to 7.6 is a desirable pH range. It is essential

to maintain correct pH, see Table 2.

If pH becomes too high (over alkaline), it

has these effects:

1. Greatly lowers the ability of chlorine to destroy

bacteria and algae.

2. Water becomes cloudy.

3. There is more danger of scale formation on the

plaster or in the heat exchanger.

4. Filter elements may become blocked.

If pH is too low (over acid) the following

conditions may occur:

1. Excessive eye burn or skin irritation.

2. Etching of the plaster.

3. Corrosion of metal fixtures in the filtration and

recirculation system, which may create brown, blue,

green, or sometimes almost black stains on the

plaster.

4. Corrosion of copper in the heater, which may cause

leaks.

5. If you have a sand and gravel filter, the alum used as

a filter aid may dissolve and pass through the filter.

WHAT IS A DISINFECTANT

RESIDUAL?

When you add chlorine or bromine to the pool water, a

portion of the disinfectant will be consumed in the

process of destroying bacteria, algae and other

oxidizable materials. The disinfectant remaining is

called chlorine residual or bromine residual. You can

determine the disinfectant residual of your pool water

with a reliable test kit, available from your local pool

supply store.

You must maintain a disinfectant residual level adequate

enough to assure a continuous kill of bacteria or virus

introduced into pool water by swimmers, through the air,

from dust, rain or other sources.

It is wise to test pool water regularly. Never allow

chlorine residual to drop below 0.6 ppm (parts per

million). The minimum level for effective chlorine or

bromine residual is 1.4 ppm.

pH - The term pH refers to the acid/alkaline balance of

water expressed on a numerical scale from 0 to 14. A test

kit for measuring pH balance of your pool water is

available from your local pool supply store; see Table 1.

Table 1.

Strongly Acid Neutral Strongly Alkaline

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Muriatic Acid has a pH of about 0. Pure water is 7

(neutral). Weak Lye solution have a pH of 13-14.

pH Chart

CAUTION: Do not test for pH when the chlorine

residual is 3.0 ppm or higher, or bromine residual

is 6.0 ppm or higher. See your local pool supply

store for help in properly balancing your water

chemistry.

RULE: Chemicals that are acid lower pH. Chemicals

that are alkaline raise pH.

Table 2.

6.8 7.0

Add Soda, Ash or

Sodium Bicarbonate

pH Control Chart

7.4 7.6

7.2

7.8 8.0 8.2 8.4

Add AcidMarginalIdealMarginal

ALKALINITY High - Low:

"Total alkalinity" is a measurement of the total amount

of alkaline chemicals in the water, and control pH to a

great degree. (It is not the same as pH which refers

merely to the relative alkalinity/acidity balance.) Your

pool water's total alkalinity should be 100 - 140 ppm to

permit easier pH control.

A total alkalinity test is simple to perform with a

reliable test kit. You will need to test about once a

week and make proper adjustments until alkalinity is

in the proper range. Then, test only once every month

or so to be sure it is being maintained. See your local

pool dealer for help in properly balancing the water

chemistry.

P/N 472128 Rev. B 1-17-03

Page 9

Installation Instructions

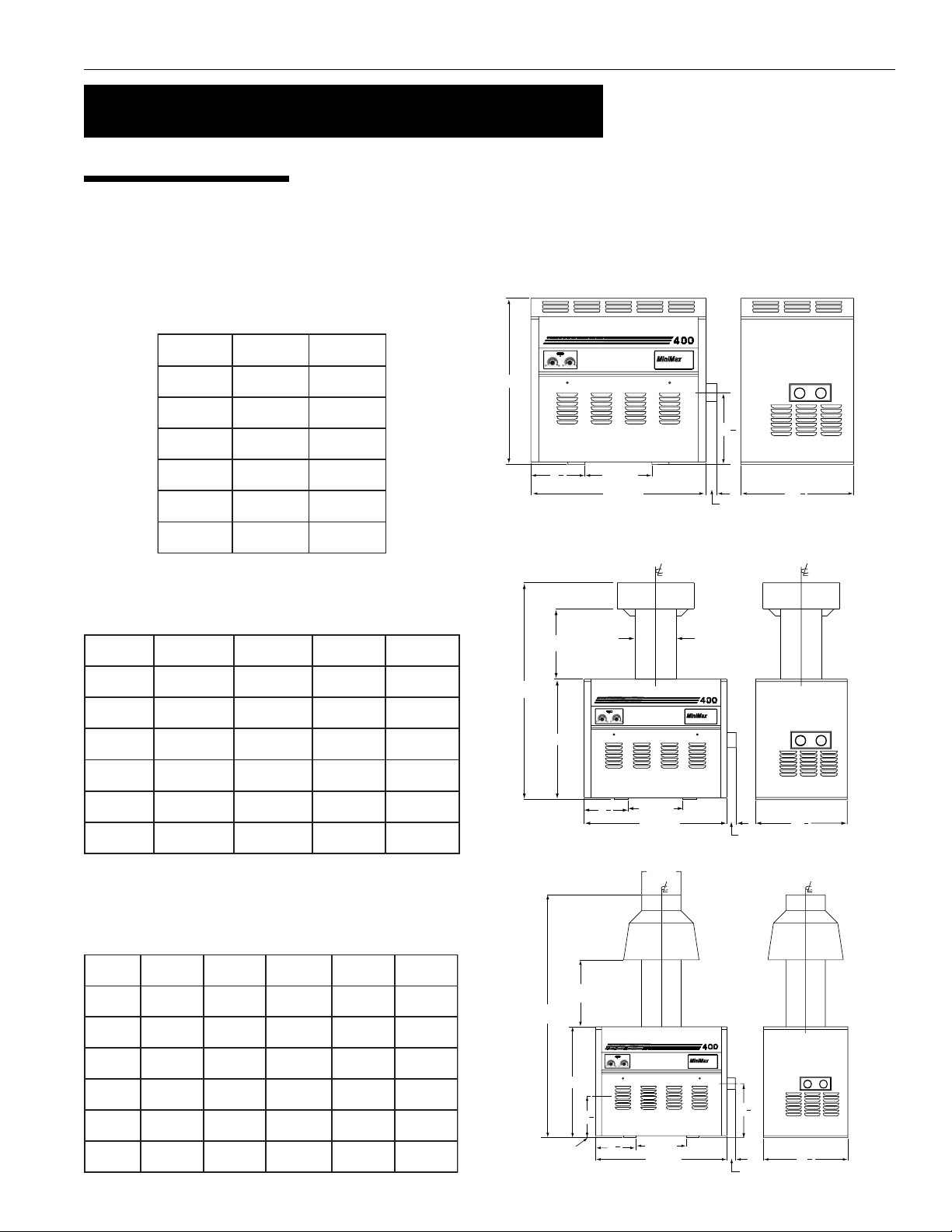

SPECIFICATIONS

IMPORTANT NOTICE: These installation instructions are designed for use by qualified personnel

only, trained especially for installation of this type of heating equipment and related components. Some

states require installation and repair by licensed personnel. If this applies in your state, be sure your

contractor bears the appropriate license.

Outdoor installation - stackless

9

ledoMmiD"A"miD"B"

051.ni8/771.ni½6

002.ni8/702.ni½9

052.ni8/732.ni½21

003.ni8/762.ni½51

053.ni8/792.ni½81

004.ni8/333.ni8/322

Table 3.

Outdoor installation - with vent kit

ledoMmiD"A"miD"B"miD"C"miD"D"

051.ni8/771.ni½6.ni¾7.ni¾93

002.ni8/702.ni½9.ni01.ni¾24

052.ni8/732.ni½21.ni01.ni¾24

003.ni8/762.ni½51.ni¼01.ni¾34

SPAPOOL

OFF

COLD COLDHOT HOT

POOL TEMP SPA TEMP

32

1

"B" DIM.

2

"A" DIM.

FRONT VIEW SIDE VIEW

SPAPOOL

OFF

COLD COLDHOT HOT

POOL TEMP SPA TEMP

"D"

DIM

5

"C"

DIM.

28"

HIGH PERFORMANCE HEATER

TM

CH

"E" DIM.

HIGH PERFORMANCE HEATER

7

13

8

1

21

4.875

TM

CH

2

1

053.ni8/792.ni½81.ni31.ni¾74

004.ni8/333.ni8/322.ni71.ni¾15

Table 4.

"B" DIM.

5

2

"A" DIM.

"E" DIM.

4.875

1

21

2

Indoor installation - stack (USA only)

Outdoor shelter installation (Canada)

ledoMmiD"A"miD"B"miD"C"miD"D"miD"E"

"C"

051.ni8/771.ni½6.ni31.ni¾25.ni6

002.ni8/702.ni½9.ni31.ni8/735.ni7

052.ni8/732.ni½21.ni31.ni8/735.ni7

003.ni8/762.ni½51.ni31.ni55.ni8

053.ni8/792.ni½81.ni31.ni65.ni9

004.ni8/333.ni8/322.ni71.ni¾06.ni01

Table 5.

Rev. B 1-17-03 P/N 472128

"D"

DIM

GAS LINE

OPENING

28

DIM.

SPAPOOL

OFF

COLD COLDHOT HOT

POOL TEMP SPA TEMP

7

10

8

1

"B" DIM.

5

2

"A" DIM.

HIGH PERFORMANCE HEATER

TM

CH

7

13

8

1

21

4.875

2

Page 10

Installation (contd.)

T

H

E

P

R

M

O

O

S

O

T

A

T

L

S

E

L

E

C

T

S

O

P

F

A

F

C

O

L

D

P

O

O

L

T

E

M

P

H

O

T

C

O

L

D

S

P

A

T

E

M

P

H

O

T

10

MANUAL BY-PASS

POOL

HEATER

1

Optional.

2

Required when installation is below water level.

Required when flow rates exceed 120 gpm.

3

3

MANUAL

BY-PASS

1

CHECK

VALVE

TO

POOL

ISOLATION

VALVE

ISOLATION

VALVE

FILTER

FROM

POOL

CHECK

VALVE

PUMP

2

Figure 10.

PLUMBING CONNECTIONS

The MiniMax CH heater has the unique capability of

direct schedule 40 PVC plumbing connections.

CAUTION

Before operating the heater on a new installation,

turn on the circulation pump and bleed all the air

from the filter using the air relief valve on top of the

filter. Water should flow freely through the heater.

Do not operate the heater unless water in the pool/

spa is at the proper level.

Where the flow rate exceeds the maximum 120

GPM, a manual bypass should be installed and

adjusted. After adjustments are made, the valve

handle should be removed to avoid tampering.

ledoM.niM*.xaM

05102021

00202021

05203021

00303021

05304021

00404021

dednemmocermumixamehtdeecxetonoD*

.gnipipgnitcennocehtrofetarwolf

Table 6.

BELOW POOL INSTALLATION

PLUMBING

VALVES

When any equipment is located below the surface

of the pool or spa, valves should be placed in the

circulation piping system to isolate the equipment

from the pool or spa.

Check valves are recommended to prevent back

siphon.

CAUTION

Exercise care when installing chemical feeders so

as to not allow back siphoning of chemical into the

heater, filters or pump. When chemical feeders are

installed in the circulation of the piping system,

make sure the feeder outlet line is down stream of

the heater, and is equipped with a positive seal

non-corrosive “Check Valve”, (P/N R172288),

between the feeder and heater.

If the heater is below water level, the pressure

switch should be adjusted. This adjustment must

be done by a qualified service technician.

See following CAUTION.

CAUTION

BELOW OR ABOVE POOL INSTALLATION

The water pressure switch is set in the factory at 1½

PSI. This setting is for a heater installed at pool level or

within 3’ above or 3’ below. If the heater is to be installed

more that 3’ above or 3’ below, the water pressure switch

must be adjusted by a qualified service technician.

FLOW SWITCH

If the heater is installed more the 6’ above the pool or

more than 10’ below the pool level, you will be beyond

the limits of the pressure switch and a flow switch must

be installed. Locate and install the flow switch externally

on the outlet piping from the heater, as close as possible

to the heater. Connect the flow switch wires in place of

the water pressure switch wires.

P/N 472128 Rev. B 1-17-03

Page 11

Installation (contd.)

11

WATER CONNECTIONS

Reversible Inlet/Outlet Connection

The MiniMax CH heater is factory assembled with

right side inlet/outlet water connections. The inlet/

outlet header can be reversed for left side water

connections without removing the heat exchanger.

Reversing Water Connections

Disassembly

Tools needed:

1/4 in Nut Driver

9/16 in. Socket and Wrench

1/2 in. & 9/16 in. Open Wrench

Screw Driver(s) - (Flathead & Phillips)

1. Remove the inspection plates.

2. Disconnect all wires from the high-limit

switches except the short jumper wire. The

exact order of the disconnection is not

important.

INSULATING THE HIGH LIMITS

When Reversing Heads on the

MiniMax CH Heater

On the MiniMax CH heater there is insulation installed

by the factory on the return head side of the heaters.

This insulation is there so that if the heads are reversed

in the field, during initial installation of the heater, the

reflected heat from the flue collector will be insulated

from the high limits.

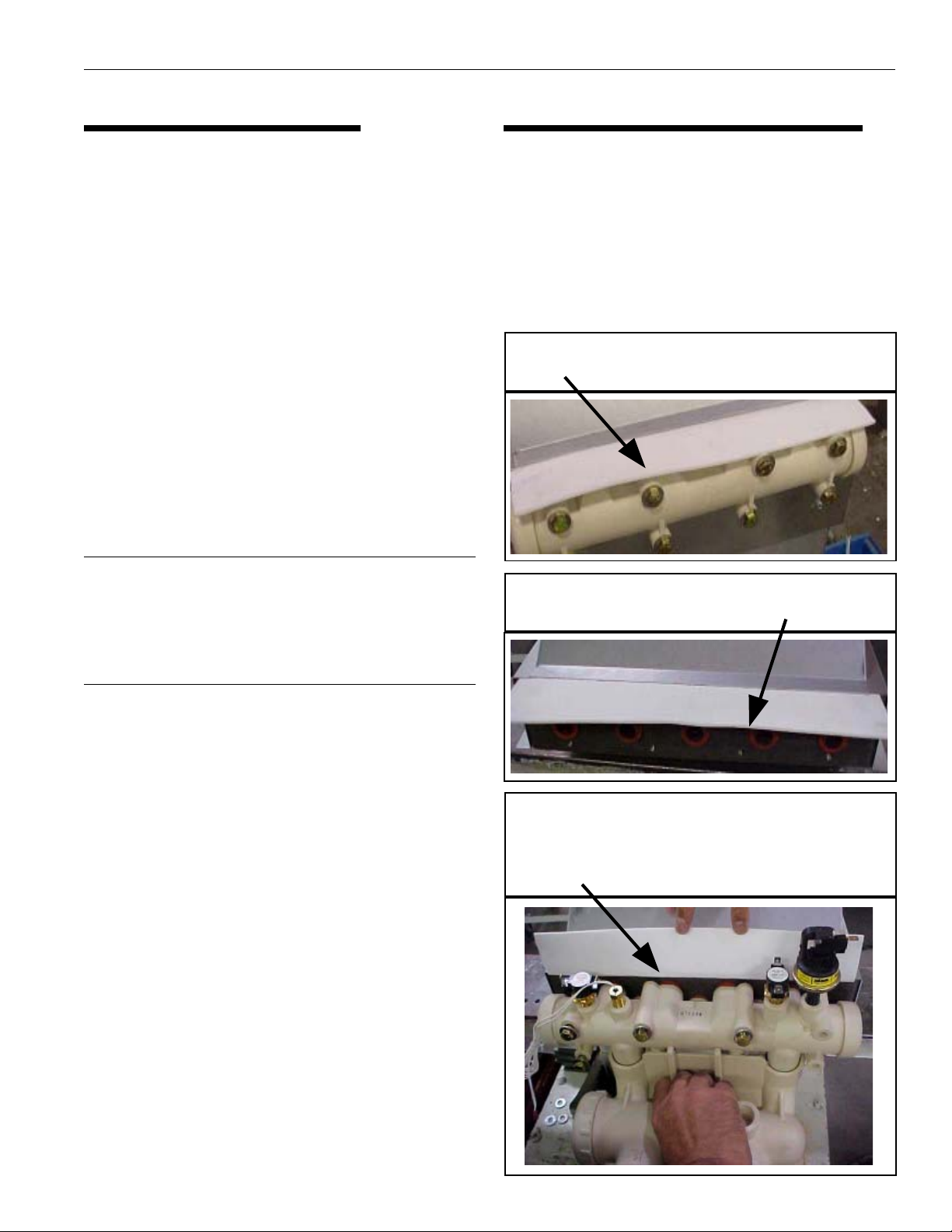

Return head in position before removal.

This view shows the insulation installed by the factory.

NOTE

There is no reason to remove the high-limit

and pressure switches or the thermister from the

front header during the reversing procedure, as

they will be in the proper location when

installed on the left side.

3. Disconnect the pressure switch wiring.

4. Disconnect the thermostat thermister leads from

the control board.

5. Exchange the in/out header with the return

header. Replace the heat exchanger tube seals

with new seals provided in the Quick-Flange

Accessory Bag.

6. Install the temperature sensing bulb by passing

the wires through the hole provided on the left

side of the brace panel. Route wires through the

support bracket.

7. Reconnect all the high limit wires. Reconnect

the pressure switch wiring. Route the wires

through the same hole as the thermostat sensor

wires and reconnect thermister to the board.

Return head removed and new tube seals installed. Now

ready to accept the installation of the main head.

Lift the installation to allow the main head to be installed.

When head is placed into position, release the insulation;

it will now shield the high limits from the heat produced

by the flue collector.

8. Reinstall the inspection plates.

Rev. B 1-17-03 P/N 472128

Page 12

Installation (contd.)

12

GAS CONNECTIONS

GAS LINE INSTALLATIONS

Before installing the gas line, be sure to check which gas the heater has been designed to burn. This is

important because different types of gas require different gas pipe sizes. The rating plate on the heater will

indicate which gas the heater is designed to burn. Tables 7-9, on pages 12 and 13, shows which size pipe is

required for the distance from the gas meter to the heater. The table is for natural gas at a specific gravity

of .65 and propane at specific gravity of 1.5.

When sizing gas lines, calculate three (3) additional feet of straight pipe for every elbow used.

When installing the gas line, avoid getting dirt, grease or other foreign material in the pipe as this may cause

damage to the gas valve, which may result in heater failure.

The gas meter should be checked to make sure that it will supply enough gas to the heater and any other

appliances that may be used on the same meter.

The gas line from the meter will usually be of a larger size than the gas valve supplied with the heater.

Therefore a reduction of the connecting gas pipe will be necessary. Make this reduction as close to the

heater as possible.

The heater and any other gas appliances must be disconnected from the gas supply piping system during any

pressure testing on that system, (greater that ½ PSIG).

The heater and its gas connection must be leak tested before placing the heater in operation. Do not use

flame to test the gas line. Use soapy water or another nonflammable method.

A manual main shut-off valve must be installed externally to the heater.

WARNING

Do not install the gas line union inside the heater cabinet. This will void your warranty.

Pipe Sized For Length Of Run In Equivalent Feet

”2/1”4/3”1”4/1-1”2/1-1”2”2/1-2

TANORPTANORPTANORPTANORPTANORPTANORPTANORP

LEDOM

001&57’02’05’05’051’051’006 --------

051’01’04’05’051’051’006 --------

002-’02’03’08’521’052’054’006 ------

052-’01’02’05’07’051’052’005’006 -----

003--’01’03’05’001’002’053’004’006 ----

053--’01’02’03’07’521’052’052’005’005 ---

004 --- ’01’02’06’001’051’002’054’004 ---

525 --- ’5’51’53’56’051’031’063’093’007--

057 ----- ’02’53’08’57’081’062’006--

009 ----- ’51’02’05’54’08’051’063’004-

SNOITCENNOCENILSAGROFGNIZISEPIP

HTGNELEPIPTNELAVIUQEMUMIXAM

tooFcibuCrep.U.T.B0001tasaglarutaN

tooFcibuCrep.U.T.B0052tasaGenaporP

Table 7.

P/N 472128 Rev. B 1-17-03

Page 13

Installation (contd.)

13

Pipe Sized For Length Of Run In Equivalent Feet, (cont’d.)

PROPANE 2 STAGE REGULATION

In many “RESIDENTIAL” Propane gas line installations, the gas supplier and or installer will utilize a two stage regulation

process where by at the supply tank they will install the first stage gas regulator, which would be at a higher pressure, usually

10 psi and can be for longer distance and in a smaller pipe size. Then within a short distance from the heater they will install

a second regulator, which is the second stage, and this would be set at the reguired inlet pressure of 11 inches of W.C. for all the

Pentair Pool Heaters.

gniziSepiPsaG"erusserPhgiH"enOegatS

HTGNELEPIPTNELAVIUQEMUMIXAM

ledoMteeF05ot0teeF001ot05teeF051ot001

001&57.ni2/1.ni2/1.ni2/1

051.ni2/1.ni2/1.ni2/1

002.ni2/1.ni2/1.ni2/1

052.ni2/1.ni2/1.ni2/1

003.ni2/1.ni2/1.ni2/1

053.ni2/1.ni2/1.ni2/1

004.ni2/1.ni2/1.ni2/1

Table 8.

REGULATED MANIFOLD PRESSURE TEST

1. Attach the manometer to the heater jacket.

2. Shut off the main gas valve.

3. Remove 1/8 in. NPT plug on the outlet side of

the valve and screw in the fitting from the

manometer kit.

4. Connect the manometer hose to the fitting.

5. Fire the heater.

6. The manometer must read 4 in. WC for natural

gas, 11 in. WC for propane gas, while the heater

is operating.

7. For adjustment, remove the Regulator

Adjustment Cap and using a screwdriver turn the

screw clockwise to increase - counterclockwise

to decrease gas pressure.

CAUTION

The use of Flexible Connectors (FLEX) is NOT

recommended as they cause high gas pressure drops.

gniziSepiPsaG"erusserPwoL"owTegatS

HTGNELEPIPTNELAVIUQEMUMIXAM

ledoMteeF01ot0teeF02ot01

001&57.ni2/1.ni2/1

051.ni2/1.ni2/1

002.ni2/1.ni4/3

052.ni2/1.ni4/3

003.ni4/3.ni4/3

053.ni4/3.ni4/3

004.ni4/3.ni4/3

Table 9.

REGULATOR

ADJUSTMENT CAP

PILOT

HONEYWELL

Figure 11.

1/2 P.S.I.

PILOT

ADJ.

PRESS

TAP

MINIMAX CH GAS PRESSURE REQUIREMENTS*

Natural

Maximum inlet gas pressure 10 in. WC 14 in. WC

Minimum inlet gas pressure **5 in. WC 12 in. WC

Normal manifold pressure 4 in. WC 11 in. WC

** 6 WC for 400 model

*All Readings are taken with the heater fired. Any adjustments

made with heater off will give incorrect readings.

Table 10.

Propane

Rev. B 1-17-03 P/N 472128

Page 14

Installation (contd.)

14

VENTILATION

OUTDOOR INSTALLATION ONLY

For outdoor installation with built in vent top, the heater

must be placed in a suitable area on a level,

noncombustible surface. Do not install the heater under

an overhang with clearances less than 3 feet from the top

of the heater. The area under an overhang must be open

on three sides.

IMPORTANT!

In an outdoor installation it is important to protect

your heater from water damage. Ensure water is

diverted from overhanging eves with a proper gutter/

drainage system. The heater must be set on a level

foundation for proper rain drainage.

Maintain minimum clearances as indicated below. Install

a minimum of 4 feet below, and 4 feet horizontally from

any opening to a building.

The heater should not be installed closer than 6 inches to

any fences, walls or shrubs at any side or back, or any

combustible material, nor closer than 18 inches at the

plumbing side. A minimum clearance of 24 inches must

be maintained at the front of the heater.

STACK TYPE OUTDOOR VENT KIT

ledoMpaCtneV.oNtcudorP.aiDtneV

05151VO732064.ni6

00202VO222064.ni7

05252VO322064.ni7

00303VO422064.ni8

05353VO522064.ni9

00404VO622064.ni01

Outdoor Stack

Top Cover

Flue Adaptor

Inner Panel

Flue Collector

Table 11.

DOOR

24"

Figure 12.

6"

6"

18"

IMPORTANT!

When locating the heater, consider that high

winds can roll over or deflect off adjacent

buildings and walls. Normally, placing the

heater at least three feet from any wall will

minimize downdraft.

Unusually high prevailing wind conditions and

downdrafts may require the use of a stack type

outdoor vent kit (available at additional cost).

NOTE

This unit shall not be operated outdoors at

temperatures below 0o F. for propane and -20o F. for

natural gas.

Figure 14.Figure 13.

OUTDOOR VENT CAP INSTALLATION

The MiniMax CH heater is shipped standard as an

outdoor stackless unit. To install the outdoor vent kit:

1. Take out the louvered outer top after first

removing all 1/4 in. sheet metal screws attaching

it along its perimeter to the cabinet. Set it aside.

2. Place the flue adaptor over the flue collector

opening. Temporarily, put the top cover, from the

kit, on with the label to the front of the heater.

Center the flue adaptor evenly inside the top cover

flue stack opening. Remove the top cover and

secure the centered flue adaptor to the inner panel

with the provided #8 x 1/2 in. drill qwik screws.

3. Place the top cover, with the hole for the stack, on

the heater cabinet.

4. Install the vent stack through the hole in the top

cover, over the flue adaptor top ring.

5. Using a 3/32 in. drill bit, position the “L” bracket

to hold the top cover and outdoor stack. Drill the

pilot holes through the “L” bracket holes to accept

the screws.

6. Secure the vent stack and the inner top with the

#8 x 1/4 in. sheet metal screws through the “L”

brackets.

P/N 472128 Rev. B 1-17-03

Page 15

Installation (contd.)

Height above

any roof surface

within 10 ft.

horizontally

Vent Cap

Ridge

Chimney

3 ft. min.

2 ft. min.

10 ft.

Roof

Jack

More Than10 ft.

INDOOR INSTALLATION (USA ONLY)

OUTDOOR SHELTER INSTALLATION

(CANADA)

15

All products of combustion and vent gases must be

completely removed to the outside atmosphere

through a vent pipe which is connected to the draft

hood. A vent pipe extension of the same size must

be connected to the draft hood and extended at least

2 feet higher than highest point of the roof within a

10 foot horizontal radius, and at least 3 ft. higher

than the point at which it passes through the roof, or

as permitted by local code; see Figures 15 and 16.

The vent should terminate with an approved vent

cap (weather cap) for protection against rain or

blockage by snow. Double-wall vent pipe and an

approved roof jack shall be employed through the

roof penetration. The use of double-walled type B

vent pipe is recommended.

The draft hood must be installed so as to be in the

same atmospheric pressure zone as the

combustion air inlet to the pool heater. The

certified (factory) draft hood must not be

modified in any way and must be employed in

every indoor installation.

Installations in basements, garages, or

underground structures where flammable liquids

may be stored must have the heater elevated 18

inches from the floor using a non-combustible

base. The following minimum clearances from

combustible materials must be provided.

Side Front Back Top

Water Connection 18 in. 24 in.

Remaining 6 in. 6 in.

Ceiling Clearance 36 in.*

*To ceiling or roof.

The heater must be located as close as practical to

a chimney or gas vent. The heater should be

installed at least 5 feet away from the pool or spa.

Figure 15.

The heater must be placed in a suitable room on a

non-combustible floor or on a non-combustible

base and in an area where leakage from heat

exchanger or water connections will not result in

damage to the area adjacent to the heater or the

structure. When such locations cannot be

avoided, it is recommended that a suitable drain

pan with adequate drainage, be installed under the

* Rise

heater. The pan must not restrict air flow.

Rev. B 1-17-03 P/N 472128

* 1” Rise Per Foot

Recommended

Figure 16.

Vent Cap and

Riser Furnished

by Installer

Air Supply

Ventilation

Air Supply

Gas Combustion

Page 16

Installation (contd.)

Screw

(2 PLC's)

HEATER

Top Cover

Adaptor

Draft Hood

16

NOTE

The heater requires two uninterrupted air supply

openings; one for ventilation and one to supply oxygen

for proper gas combustion. The air supply openings

should be sized according to Tables 12. and 13.

Air supply requirements below apply to all

MiniMax heaters

All opening sizes are minimum and unobstructed.

edisnImorFriAllA

ledoM

noitsubmoCrofriA

.nI.qS

noitalitneVriA

.nI.qS

051051051

002002002

052052052

003003003

053053053

004004004

Table 12.

edistuOmorFriAllA

ledoM

noitsubmoCrofriA

.nI.qS

noitalitneVriA

.nI.qS

0517373

0020505

0523636

0037777

0530909

004001001

Table 13.

I

NSTALLATION ON FLOORS CONSTRUCTED

OF COMBUSTIBLE MATERIALS

b) Construct a non-combustible base from masonry

blocks as illustrated, see Figure 17.

BASE FOR USE ON

COMBUSTIBLE FLOORS

T

O

H

TM

R

E

T

A

E

H

E

C

N

A

M

R

O

F

R

E

P

H

G

I

H

T

H

E

R

A

M

O

S

T

A

SP

T

S

E

L

E

C

T

L

O

F

F

O

P

O

T

O

H

P

M

E

T

A

P

S

D

L

O

C

T

O

SHEET

METAL

BLOCKS

Figure 17.

H

P

M

E

T

L

O

O

P

D

L

O

C

HOLLOW MASONARY BLOCKS, NOT LESS THAN

4" THICK (LAID WITH ENDS UNSEALED AND JOINTS

MATCHED FOR AIR CIRCULATION). COVER BLOCKS

WITH 24 GA. (MIN.) GALVANIZED SHEET METAL.

6" Min.

.

in

" M

6

CAUTION

Chemicals should not be stored near the heater

installation. Combustion air can be contaminated by

corrosive chemical fumes which can void the warranty.

STACK TYPE INDOOR DRAFT HOOD KIT

The proper draft hood and adapter must be installed on

the heater as shown below:

ledoMdooHtfarD.oNtcudorP.aiDtneV

05151HD722064.ni6

00202HD822064.ni7

05252HD032064.ni7

00303HD132064.ni8

05353HD332064.ni9

00404HD432064.ni01

The heater may be placed on a “combustible floor”

Table 15.

using either of the two methods listed below:

INDOOR DRAFT HOOD INSTALLATION

a) Use Listed Factory Non-combustible Base Kit

for use on combustible floors.

ledoMtiKesaBelbitsubmoC-noN

051983174

002093174

052193174

003293174

053393174

004493174

Table 14.

P/N 472128 Rev. B 1-17-03

1. Take out the louvered outer top piece after first

removing the sheet metal screws, attaching it to

the cabinet.

2. Install the adaptor

(vent kit).

3. Install the top cover

(vent kit).

4. Install the draft hood

(vent kit).

Use the provided screws

to secure the vent

assembly.

Figure 18.

Page 17

Installation (contd.)

17

ELECTRICAL

MiniMax CH Millivolt Wiring Diagram

MINIMAX WIRING DIAGRAM (MILLIVOLT) DUAL THERM

(HONEYWELL ELECTRONIC)

IF ORIGINAL FACTORY WIRING MUST BE REPLACED, INSTALLER MUST SUPPLY UL OR CSA (IF CANADA)

APPROVED WIRE, 18 GAUGE, 600V, 105 C˚ TEMPERATURE RATING. THERMAL FUSE WIRING MUST BE

REPLACED WITH UL OR CSA (IF CANADA) APPROVED WIRE, 18 GAUGE, 600V, 125 C˚ TEMPERATURE RATING.

INTERCONNECTING WIRING TO APPLIANCE MUST CONFORM TO THE NATIONAL ELECTRICAL CODE OR

SUPERCEDING LOCAL (WIRING) CODES.

PILOT

TH/PP

TH

GAS VALVE

WHT

RED

PP

GENERATOR

HI-LIMIT

SAFETY

SHUT-OFF

PRESS

SWITCH

ORN

WHT

WHT

PP

TH/PP

TH

THERMOSTAT BOARD

SEN

POT

WHT

POT 1

SENSOR

POT 2

WHT

WHT

THERMAL

CUT-OFF

WHT

POOL

OFF

SPA

Figure 19.

NOTE: When connecting a remote control to the MiniMax CH, you must install the low voltage

thermostat wires in separate conduit from ANY line voltage wires. Failure to follow these

instructions will cause the thermostat relay to react erratically..

Rev. B 1-17-03 P/N 472128

Page 18

Troubleshooting - General

Possible Cause Remedy

Heater will not come on

Pump not running Place pump in operation

Pump air locked Check for leaks

Filter dirty Clean filter

Pump strainer clogged Clean strainer

Defective wiring or connection Repair or replace wires

Defective pressure switch Replace switch

Defective gas controls Call serviceperson

On-Off switch in "OFF" position Turn switch to "ON"

18

Heater Short Cycling (Rapid On and Off Operation)

Insufficient water flow Clean filter and pump strainer

Defective wiring Repair or replace wiring

Defective flow valve or out of adjustment Call serviceperson

Defective hi-limit and/or thermostat Call serviceperson

Heater Makes Knocking Noises,

Make sure all valves on system are open

Heater operating after pump has shut off Shut off gas supply and call serviceperson

Heater exchanger scaled Shut off gas supply and call serviceperson

CAUTION

Please consult the latest edition of the “MiniMax Service Manual” for complete service and repair

instructions. Repairs should only be attempted by properly trained service personnel.

P/N 472128 Rev. B 1-17-03

Page 19

MINIMAX CH HEATER - ALL MODELS

32

H

O

T

31

30

19

SPOTRENNI

.oNledoM.oNtraP

051420074

002520074

052620074

003720074

053820074

004920074

1a

18

36

25

28

29

37

20

15

27

23

24

22

21

5

19

2

3

4

1

16

26

7

6

9

34

35

8

17

33

14

10

11

12

13

Rev. B 1-17-03 P/N 472128

Page 20

MiniMax CH Parts List

METI NOITPIRCSED YTQ 051 002 052 003 053 004

1)roodni(.yssatiktneV1722064 822064 032064 132064 332064 432064

a1)roodtuo(.yssatiktneV1732064 222064 322064 422064 522064 622064

2redaehnruteR1499070 499070 499070 499070 499070 499070

3regnahcxetaeh,tloB61199174199174199174199174199174199174

4DO"1DI"8/3rehsaW61481270 481270481270481270481270481270

5teksaglaesebuT81159070 159070 159070 159070 159070 159070

6bonktatsomrehT2481074 481074 481074481074481074 481074

7)worhtelbuod&elopelgnis(rekcorhctiwS1681074681074681074681074681074681074

8tlovilliM-)etelpmoc(.yssalenaplortnoC1571274 471274371274271274171274071274

9tlovilliM-rooD1864570 406570 884570 506570 606570 094570

01renrubdlofinaM1652070 525570 752070 625570 725570 852070

20

11

21tlovilliM-ebuttoliP480670 480670 580670 580670 680670 680670

31

41renruB032070 032070 032070 032070 032070 032070

a41tekcarbtoliphtiwrenruB)nwohston(1055074055074055074055074055074055074

51hctiwserusserP1276174 276174 276174 276174 276174 276174

61)etelpmoc(.yssarebmahcnoitsubmoC1858370 685570 758370 785570 885570 658370

71.yssaretingietilsserP1954570 954570 954570 954570 954570 954570

81retemoitnetoP2876174 876174 876174 876174 876174876174

91.yssaevlavwolF1057174 057174 057174057174 057174057174

02°511tatsomrehttimiL-iH1785174785174785174 785174785174 785174

12.ni2,daehklub-rotpadA2144174144174144174144174144174144174

22gnirdaehklub-rotpadA2044472044472 044472044472044472 044472

32.yssadlofinamniaM1399174399174399174399174399174399174

tlovilliM-larutanevlavsaG1754570 754570 754570 754570 754570 754570

tlovilliM-enaporpevlavsaG1854570 854570 854570 854570 854570 854570

tlovilliM-)etelpmoc(larutan.yssayartrenruB1394570 694570 494570 794570 894570 594570

tlovilliM-)etelpmoc(enaporp.yssayartrenruB1205570 505570 305570 605570 705570 405570

.AE2.AE3.AE4.AE5.AE6.AE7

42.yssaredaehniaM1299174 299174 299174299174299174299174

52mottobdlofinamniaM1914174914174914174914174914174914174

62mottobdlofinamniam,paC1024174024174024174024174024174024174

72°051tatsomrehttimiL-iH1496174 496174 496174 496174 496174 496174

82

92

elffaB

03004noselffab)2(nwoddlohelffaB1018370 018370 018370 018370 018370 018370

P/N 472128 Rev. B 1-17-03

)sdaehtuohtiw(regnahcxetaeH1131274 231274331274431274531274 631274

)sdaehhtiw(regnahcxetaeH1961274 861274761274 661274561274 461274

.ae8.ae8.ae8.ae8.ae61.ae61

772070 955570 672070 065570 772070 872070

Page 21

MiniMax CH Parts List, contd.

METI NOITPIRCSED YTQ 051 002 052 003 053 004

13rotcelloceulF1468370 226570 368370 326570 426570 268370

23.yssapotroodtuO1174074 274074 374074 474074 574074 674074

33)ylnostinusaGenaporP(dleihskcabthgiL1387570 487570 587570 687570 787570 887570

43)sledomtlovilliM(tatsomrehtcinortcelE1776174776174776174 776174776174 776174

53)nruter(lenaP1987370987370987370987370987370987370

63)tuo/ni(lenaP1721274721274721274721274721274721274

73)sledomtlovilliM(etelpmoc)eborp(rotsimrehT1101274101274101274101274101274101274

nwohStoN*

21

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

"4/1x6wercS617170 617170 617170 617170 617170 617170

"2/1gnihsuB155070 155070 155070 155070 155070 155070

rotareneg-toliP1515170 515170 515170 515170 515170 515170

tekcarbgnitnuomcitsalP517070 517070 517070 517070 517070 517070

ssenraheriwrofspilC772174772174772174772174772174772174

tlovilliM-tiKeriW115570 115570 115570 115570 115570 115570

HH"4/1x8wercS307170 307170 307170 307170 307170 307170

HH"2/1x8wercS896170 896170 896170 896170 896170 896170

"4/1x23-01wercS956170 956170 956170 956170 956170 956170

61/3x23-01wercS296570 296570 296570 296570 296570 296570

reppotsbonkmrehT2414074414074414074 414074414074 414074

'4/3x81-"61/5tloB2527370 527370 527370 527370 527370 527370

.ae3

ProN

larutanrenrubniamecifirO727370 727370 727370 727370 727370 727370

enaporprenrubniamecifirO827370 827370 827370 827370 827370 827370

tlovilliM-larutan-toliP1292174292174292174292174292174292174

tlovilliM-enaporp-toliP1192174192174192174192174192174192174

.ae4

ProN

.ae5

ProN

.ae6

ProN

.ae7

ProN

.ae8

ProN

*

*

*

*

*

*

*

*

Rev. B 1-17-03 P/N 472128

dleihsniartoliP1392174392174392174392174392174392174

stekcarb"L"3045470045470045470045470045470045470

repmuJ352270352270352270352270352270352270

hctalrooD042170042170042170042170042170042170

knilelbisuf-ffotuclamrehT1371570 371570 371570 371570 371570 371570

)evlav-wolf(tnemelerewoP1871074871074871074871074871074871074

)ylno(edortceletoliP1823174823174823174823174823174823174

VM,tolip973QretpadatekcarB172174172174172174172174172174172174

Page 22

NOTES

22

P/N 472128 Rev. B 1-17-03

Page 23

Warning:

MiniMax® CH (150 IID Model)

POOL & SPA HEATERS

OPERATION & INSTALLATION MANUAL

(APPENDIX)

WARNING

FOR YOUR SAFETY - READ BEFORE OPERATING

If you do not follow these instructions exactly, a fire or explosion may

result, causing property damage, personal injury or loss of life.

For additional free copies of this manual; call (800) 831-7133.

1

23

1

U.S. Patent Numbers

6,295,980

5,318,007 - 5,228,618

5,201,307 - 4,595,825

WARNING

Warning: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, personal injury or death. Installation and service must be

performed by a qualified installer, service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

For Your

Safety

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or other appliances.

Pentair Pool Products, Inc.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 W. Los Angeles Ave., Moorpark, CA 93021

• (805) 523-2400

Rev. B 1-17-03 P/N 472128

A-1

Page 24

Operation

24

MINIMAX CH (150 IID) ELECTRONIC IGNITION LIGHTING/OPERATION - NATURAL GAS

FOR YOUR SAFETY: READ BEFORE LIGHTING

WARNING

If you do not follow these instructions exactly, a fire or explosion may result causing personal injury, loss of life

and property damage.

Do not attempt to light the heater if you suspect a natural gas leak. Lighting the heater can result in a fire or

explosion which can cause personal injury, death, and property damage.

A. This heater is equipped with an ignition device

which automatically lights the pilot. Do not try

to light the pilot by hand.

B. BEFORE OPERATING smell all around the

heater area for gas. Be sure to smell next to

the floor because some gas is heavier than air

and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any heater.

- Do not touch any electrical switch; do not use

any phone in your building.

- Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

- If you cannot reach your gas supplier, call the

Fire Department.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the thermostat to the lowest setting.

3. Turn off electric power to the heater.

4. This heater is equipped with an ignition device

which automatically lights the pilot. Do not try

to light the pilot by hand.

5. Remove the control access door.

6. Push in gas control knob slightly and turn clockwise to “OFF”.

7. Wait five (5) minutes to clear out any gas. If you

then smell gas, STOP! Follow "B" in the safety

information above. If you don't smell gas, go to the

next step.

8. Turn knob on gas control counterclockwise

to “ON”; see Figure 1.

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will

not push in or turn by hand, don't try to repair it.

Call a qualified service technician. Forced or

attempted repair may result in a fire or explosion.

D. Do not use this heater if any part has been under

water. Immediately call a qualified service

technician to inspect the heater and to replace

any part of the control system and any gas

control which has been under water.

E. The MiniMax CH incorporates (9) nine

indicator lights to aid you in the operation of the

heater, and to assist in diagnosing a failure in the

heater’s function.

9. Replace the control access door.

10. Turn on the electrical power to the heater.

11. Set the thermostat to the desired setting.

12. If the heater will not operate, follow the instructions "To Turn Off Gas To Heater" and call your

service technician or gas supplier.

Gas

Inlet

ON

OFF

Gas control knob shown in “ON” position.Figure 1.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the heater if

service is to be performed.

3. Remove control access door.

P/N 472128 Rev. B 1-17-03

4. Push in gas control knob slightly and turn

clockwise to "OFF". Do not force.

5. Replace control access door.

A-2

Page 25

Operation (contd.)

25

MINIMAX CH (150 IID) ELECTRONIC IGNITION LIGHTING/OPERATION - PROPANE

FOR YOUR SAFETY: READ BEFORE LIGHTING

NOTE

The MiniMax CH propane models have special features for additional safety and protection.

Read the safety instructions for natural gas (page A-2) before proceeding.

WARNING

If you do not follow these instructions exactly, a fire or explosion may result causing personal injury, loss of life

and property damage.

Since propane gas is heavier than air, escaping propane will accumulate and remain at ground level. Do not

attempt to light the heater. If you suspect a propane leak, lighting the heater can result in a fire or explosion

which can cause personal injury, death, and property damage.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light matches or lighter.

- Do not try to light any heater.

- Do not touch any electrical switch; do not

use any phone in your building.

- Shut off gas line at propane tank.

Safety Lockout:

- Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

- If you cannot reach your gas supplier, call the

Fire Department.

- Do not tamper with the heater because it is

dangerous and voids all warranties.

This MiniMax CH Propane Heater is equipped with a 100% safety lockout feature. If the pilot does not light

within a maximum of 90 seconds, lockout will occur.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the thermostat to the lowest setting.

3. Turn off electric power to the heater.

4. This heater is equipped with an ignition device

which automatically lights the pilot. Do not try to

light the pilot by hand.

5. Remove the control access door.

6. Push in gas control knob slightly and turn clockwise to “OFF”.

7. Wait five (5) minutes to clear out any gas. If you

then smell gas, STOP! Follow "B" in the safety

information on page 5. If you don't smell gas, go to

the next step.

8. Turn knob on gas control counterclockwise

to “ON”; see Figure 2.

9. Replace the control access door.

10. Turn on the electrical power to the heater.

11. Set the thermostat to the desired setting.

12. If the heater will not operate, follow the instructions "To Turn Off Gas To Heater" and call your

service technician or gas supplier.

Gas

Inlet

ON

OFF

Gas control knob shown in “ON” position.Figure 2.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the heater if

service is to be performed.

3. Remove control access door.

Rev. B 1-17-03 P/N 472128

4. Push in gas control knob slightly and turn

clockwise to "OFF". Do not force.

5. Replace control access door.

A-3

Page 26

Operation (contd.)

OPERATING (CONTROLS)

Dual Temperature Control System - (Electronic and Millivolt Models)

For convenience and economy all MiniMax CH heaters

are equipped with two thermostats on the front of the heater

control panel; see Figure 3.

Figure 3.

THERMOSTAT KNOB STOPPER

Each thermostat is equipped with a mechanical stop that

can be locked or unlocked with use of a screwdriver to

prevent temperatures in excess of that desired by the user;

see Figure 4.

The maximum setting can be adjusted by loosening the screw

"A" and turning the stopper dial to desired maximum setting.

Lock the setting by tightening the screw. The Mechanical

stop is under the knob. Ensure that the knob is stopping at the

correct position when the knob is rotated clockwise from a

lower temperature position. (See Thermostat Adjustment.)

NOTE

To eliminate error due to piping heat losses,

measure pool temperature with an accurate

thermometer directly at the pool or spa.

THERMOSTAT ADJUSTMENT

The knob with locking feature eliminates the need for

constant thermostat adjustments. Set the knob pointer to

the desired pool or spa temperature.

If further adjustment is needed, rotate the knob until the

desired temperature is obtained. This knob position

corresponding to your desired maximum pool or spa

temperature may now be preset (locked) by the knob

stopper which prevents the knob from being turned beyond

the maximum temperature you set.

Knob Stopper

Figure 4.

Screw A

POWER (THERMOSTAT SELECT) SWITCH

The Pool/Off/Spa switch allows the heater to be turned off

when heating is not desired.

1. “Pool” position - Maintains selected pool

temperature.

2. “Off” position - Heater will not come on regardless

of drop in pool or spa temperature.

3. “Spa” position - This allows separate control of spa

water temperature.

26

INDICATOR LIGHT DESCRIPTION

The MiniMax Pool Heater provides nine status indicator lights, six can be seen from the front of the control panel which

help you understand the operation of the heater. If something should go wrong, the lights will aid in troubleshooting the

problem. Three additional lights can be seen after opening the control panel. These three lights give the service technician

advanced troubleshooting capability. All the LED lights are green with the exception of the red service LED.

POWER LIGHT (POWER)

The light is on at all times, in any switch position, indicating

24 VAC power is being supplied to the control circuit. If it

fails to light, no other light will be on. Possible causes are:

a) external power to the heater is disconnected, check

service panel circuit breaker or fuses; b) local circuit

breaker inside the transformer has tripped -- investigate

cause before resetting; c) transformer has failed.

THERMOSTAT (TSTAT)

This light is on when the thermostat contacts close, signaled

by the water temperature falling below the setpoint, calling

for the heater to fire to maintain the desired water

temperature.

P/N 472128 Rev. B 1-17-03

AUXILIARY (AUX)

This light is on when it indicates the remote switch contacts

are closed. This allows you to observe if your remote switch

is properly closing the heater control circuit. When shipped

from the factory a jumper is installed to maintain closed

circuit in the absence of a remote switch.

PRESSURE (PRESS)

This light is on when Spa/Pool Selector switch is on,

indicates the circulation pump is running properly. If

pressure light fails to light, the pump may have lost its

prime or water flow may be restricted by an inadvertently

closed valve or clogged filter or pump basket. If you have

determined that there is no water flow restriction to the

heater, you should call a qualified serviceman.

A-4

Page 27

Operation (contd.)

27

HEAT (HEAT)

The heat light is on any time the thermostat has

signaled a call for heat which initializes the ignition

safety firing circuit -- the light comes on to indicate

successful firing of the main burners.

TROUBLESHOOTING (CONTROLS)

Example of troubleshooting with the assistance of the indicator lights.

SYMBOL TABLE

SWITCH OR DEVICE

LED LIT

LED OFF

OPEN CIRCUIT

(BLOCK CURRENT)

SERVICE (SERVICE)

The service light is off during normal operation of

heater. The light only comes on if a problem with a

control has occurred or when the heater is first

firing. The problem must be investigated by the

serviceman prior to attempts to fire the heater again.

The diagrams that follow give examples of

troubleshooting a malfunctioning heater using the

assistance of the indicator lights.

SWITCH OR DEVICE

CLOSED CIRCUIT

(PASS CURRENT)

IGNITION MODULE

THERM

AUX

PRESS

HEAT

THERM

AUX

INCOMING

LINE VOLTAGE

INCOMING

LINE VOLTAGE

TRANSFORMER

FRONT PANEL LEDS

TRANSFORMER

POWER

SERVICE

POWER

SERVICE

CIRCUIT

THERMOSTAT

PWR TSTAT RMT PRESS

REMOTE PRESS TFUSE

RELAY

SRVE

LIMIT SWITCHESBREAKER

HI TEMP

HI TEMP TFUSE

CLOSE IF

NO MV

IND GND VAL

MV HEAT

THERMOSTAT CIRCUIT BOARD

WATER AT SELECTED TEMPERATURE.... NORMAL OPERATION

OR POOL/OFF/SPA THERMOSTAT SELECT SWITCH OFF.... NORMAL OPERATION

IGNITION MODULE

GND VAL

CIRCUIT

BREAKER

PWR

THERMOSTAT

RELAY

TSTAT RMT

REMOTE

PRESS

PRESS

LIMIT SWITCHES

SRVE

HI TEMP

HI TEMP

CLOSE IF

NO MV

TFUSE

IND

HEAT

MVTFUSE

GAS VALVE

MV

MV

GAS VALVE

MV

MV

PRESS

HEAT

FRONT PANEL LEDS

THERMOSTAT CALLING FOR HEAT - PUMP OFF(NO PRESSURE) BLOCKS FIRING

NORMAL OPERATION

Rev. B 1-17-03 P/N 472128

THERMOSTAT CIRCUIT BOARD

A-5

Page 28

Operation (contd.)

TROUBLESHOOTING (CONTROLS) - Continued

SYMBOL TABLE

THERM

AUX

PRESS

HEAT

INCOMING

LINE VOLTAGE

TRANSFORMER

FRONT PANEL LEDS

POWER

SERVICE

SWITCH OR DEVICE

RMT

OPEN CIRCUIT

(BLOCK CURRENT)

PRESS

PRESS

CIRCUIT

BREAKER

PWR

LED LIT

THERMOSTAT

RELAY

TSTAT

LED OFF

REMOTE

THERMOSTAT CIRCUIT BOARD

HEATER FIRING - NORMAL OPERATION

LIMIT SWITCHES

SRVE

HI TEMP

HI TEMP

CLOSE IF

NO MV

SWITCH OR DEVICE

CLOSED CIRCUIT

(PASS CURRENT)

IND

TFUSE

TFUSE MV

IGNITION MODULE

GND

HEAT

28

VAL

GAS VALVE

MV

MV

THERM

AUX

PRESS

HEAT

INCOMING

LINE VOLTAGE

TRANSFORMER

POWER

SERVICE

FRONT PANEL LEDS

IGNITION MODULE

GND

CIRCUIT

BREAKER

PWR

THERMOSTAT

RELAY

TSTAT

REMOTE

RMT

PRESS

PRESS

THERMOSTAT CIRCUIT BOARD

LIMIT SWITCHES

SRVE

HI TEMP

HI TEMP

CLOSE IF

NO MV

IND

TFUSE

TFUSE MV

VAL

HEAT

THERMOSTAT CALLING FOR HEAT - BLOWN THERMAL FUSE BLOCKS FIRING

NOTE: SERVICE LED LIT FLAGS PROBLEM, TFUSE LED OFF SHOWS PROBLEM

IS IN THERMAL FUSE CIRCUIT

GAS VALVE

MV

MV

P/N 472128 Rev. B 1-17-03

A-6

Page 29

HONEYWELL

PILOT

1/2 P.S.I.

PILOT

ADJ.

REGULATOR

ADJUSTMENT CAP

PRESS

TAP

Installation

REGULATED MANIFOLD PRESSURE TEST

1. Attach the manometer to the heater jacket.

2. Shut off the main gas valve.

3. Remove 1/8 in. NPT plug on the outlet side of the valve and

screw in the fitting from the manometer kit.

4. Connect the manometer hose to the fitting.

5. Fire the heater.

6. The manometer must read 4 in. WC for natural gas,

11 in. WC for propane gas, while the heater is operating.

7. For adjustment, remove the Regulator Adjustment Cap and

using a screwdriver turn the screw clockwise to increase counterclockwise to decrease gas pressure.

1/8" NPT Plug

(Inlet Press)

Regulator Adjustment Cap

1/8" NPT Plug

(Manifold Press)

29

ON

OFF

ELECTRICAL, IID ELECTRONIC UNITS

Electrical Rating

60 Hz 115 V.A.C. or 230 V.A.C.

50/60 Hz 208 V.A.C. or 240 V.A.C.

NOTE

If any of the original wiring supplied with this

heater must be replaced, installer must supply

(No. 18 AWG 105° C. U.L. approved AWM low

energy stranded) copper wire or it's equivalent.

In Canada: wires must be CSA approved.

WARNING

The heater must be electrically grounded and

bonded in accordance with local codes or, in the

absence of local codes, with the latest national

electrical codes ANSI/NFPA No. 70.

In Canada: CSA standard C22.1 Canada Electrical

Code Part 1 and/or local codes.

Transformer Wiring Instruction

Always use crimp type connectors when connecting

two wires.

This heater is equipped with a reversible junction box

to allow line voltage to be wired from either side.

Rev. B 1-17-03 P/N 472128

Figure 5.

A-7

Figure 6.

Page 30

Installation (contd.)

MiniMax CH (150 IID Model) Electronic Ignition Wiring Diagram

MV/PV

PV/MV

MV

GAS VALVE

PLUG

PV

MV

IGNITION MODULE

PLUG

PV

GND

(BURNER)

GND

24 V

TH-W

( OPT )

SPARK

30

SPARK IGNITER

MV

PV

GRN

PV/MV

MV/PV

MV

PV

F2

BLU

RED

WHT

IGNITION RETURN

GRN

THERMAL FUSE

F1

ORG

RED

BLU