Pentair MGPS7E, MGPS7E3, MGPS7D, MGPS7C3, MGPS7C3-575T Installation And Operating Instructions Manual

...

60 Hz. 1/2 through 3 HP

High Pressure Booster Pump

INSTALLATION AND OPERATING INSTRUCTIONS

REPAIR PARTS LIST

owner's Manual

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.BERKELEYPUMPS.COM

PH: 888-782-7483

269 TRILLIUM DRIVE, KITCHENER, ONTARIO, CANADA N2G 4W5

PH: 888-363-7867

© 2013 Pentair, Ltd. All Rights Reserved. BE327 (Rev. 02/25/13)

READ AND FOLLOW SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury:

DANGER warns about hazards that will cause serious

personal injury, death or major property damage if

ignored.

WARNING warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

CAUTION warns about hazards that will or can cause

minor personal injury or property damage if ignored.

ELECTRICAL SAFETY

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply.

3-wire, grounding type cord. Do not allow any part of

cord or receptacle ends to sit in water or damp

locations.

Unplug pump before servicing.

Burn Hazard. Do not touch an oper-

ating motor. Modern motors can operate at high

temperatures. To avoid burns when servicing pump,

allow it to cool for 20 minutes after shut-down before

handling.

Follow local and/or national plumbing and electrical

codes when installing.

pump with discharge shutoff, as hose may burst or

pump may be damaged due to high temperatures.

California Proposition 65 Warning

contain chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

Hazardous Pressure. DO NOT run the

This product and related accessories

Some models of

pump are supplied with

3-connector grounding

type cord. Connect only to

properly grounded,

GFCI protected outlet. Do

not lift pump by electrical

cord.

Pump is nonsubmersible. Keep motor

dry at all times. Do not

wash motor. Do not

immerse. Protect motor

from wet weather.

If using extension

cord, use only UL

approved indoor/outdoor,

The word NOTICE indicates special instructions which

are important but not related to hazards.

GENERAL SAFETY

To avoid risk of serious bodily injury and property

damage, read safety instructions carefully before

installing pump.

Do not allow pump or any system component to freeze.

To do so may damage system and void warranty.

Risk of electric shock. To avoid fatal

shocks, proceed as follows if pump needs servicing.

A. Disconnect power to pump outlet box before pul-

ling pump cord plug. After plug is pulled, let pump

cool for 20 minutes before attempting to work on it.

B. Take extreme care when changing fuses. To

re-duced chance of fatal electrical shocks, DO NOT

stand in water or put your finger in the fuse socket.

C. Ground electrical outlet box.

D. Use only Ground Fault Circuit Interrupter (GFCI)

protected grounded outlet for cord plug.

Never run pump dry. To do so can damage internal

parts, overheat pump (which can cause burns to people

handling or servicing pump), and will void warranty!

Do not pump chemicals or corrosive liquids with pump.

A. Use high pressure reinforced type discharge

hose ONLY. See parts list for available hose, nozzle

and fittings. A high pressure relief valve is recommended.

B. DO NOT use garden hose with H.P. Booster

pump! Garden hose will not stand the discharge

pressure produced and will fail!

C. High pressure discharge stream is dangerous! To

avoid injury, DO NOT aim the discharge stream at

any person or animal.

D. BE SURE pump suction pipe pressure plus pump

discharge pressure does not exceed pressure

rating of hose and fittings! See Table I for pump

discharge pressure ratings.

Hazardous Pressure.

2

INSPECT THE SHIPMENT

The high pressure booster pump has been carefully

inspected and packaged to assure safe delivery.

Inspect the pump and fittings and report to the carrier

any items which are damaged or missing.

INSTALLATION

The pump is designed to boost city water pressure or

water pressure from a private water system. Use this

high pressure stream to wash down milk parlors, barns,

garages and driveways, or for fire protection.

The pump is portable with a convenient carrying

handle. If an existing pressure water system is to

be used as a water supply, it can be connected with

available fittings and 1” or 1-1/4” high pressure hose

to the pump inlet. A special heavy duty 1” or 1-1/4”

suction hose with fittings is available as an accessory.

If the pump is permanently mounted on wall, use a 1”

or 1-1/4” pipe or heavy-duty hose for the suction line.

20 GPM models require a 1-1/4” discharge hose to

reduce friction losses.

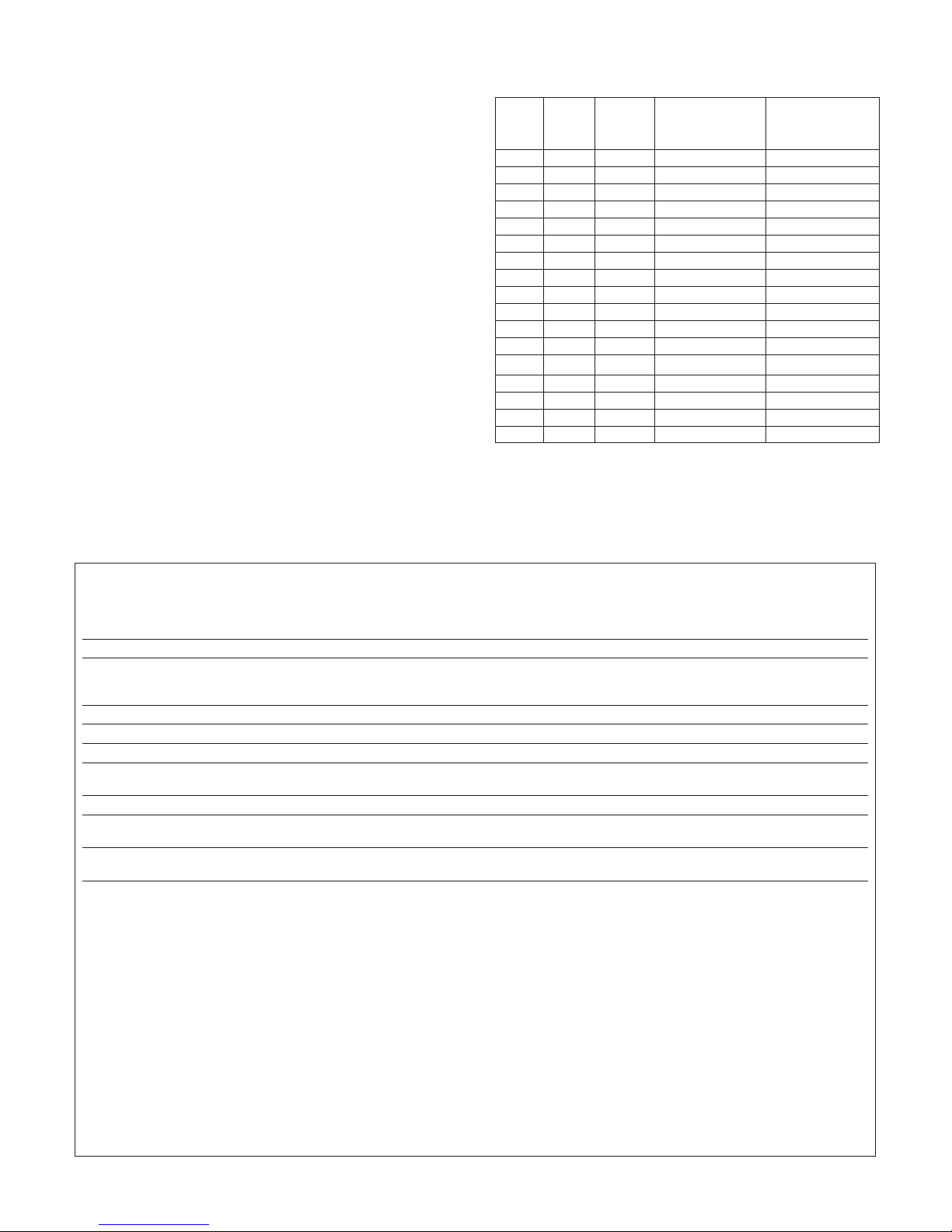

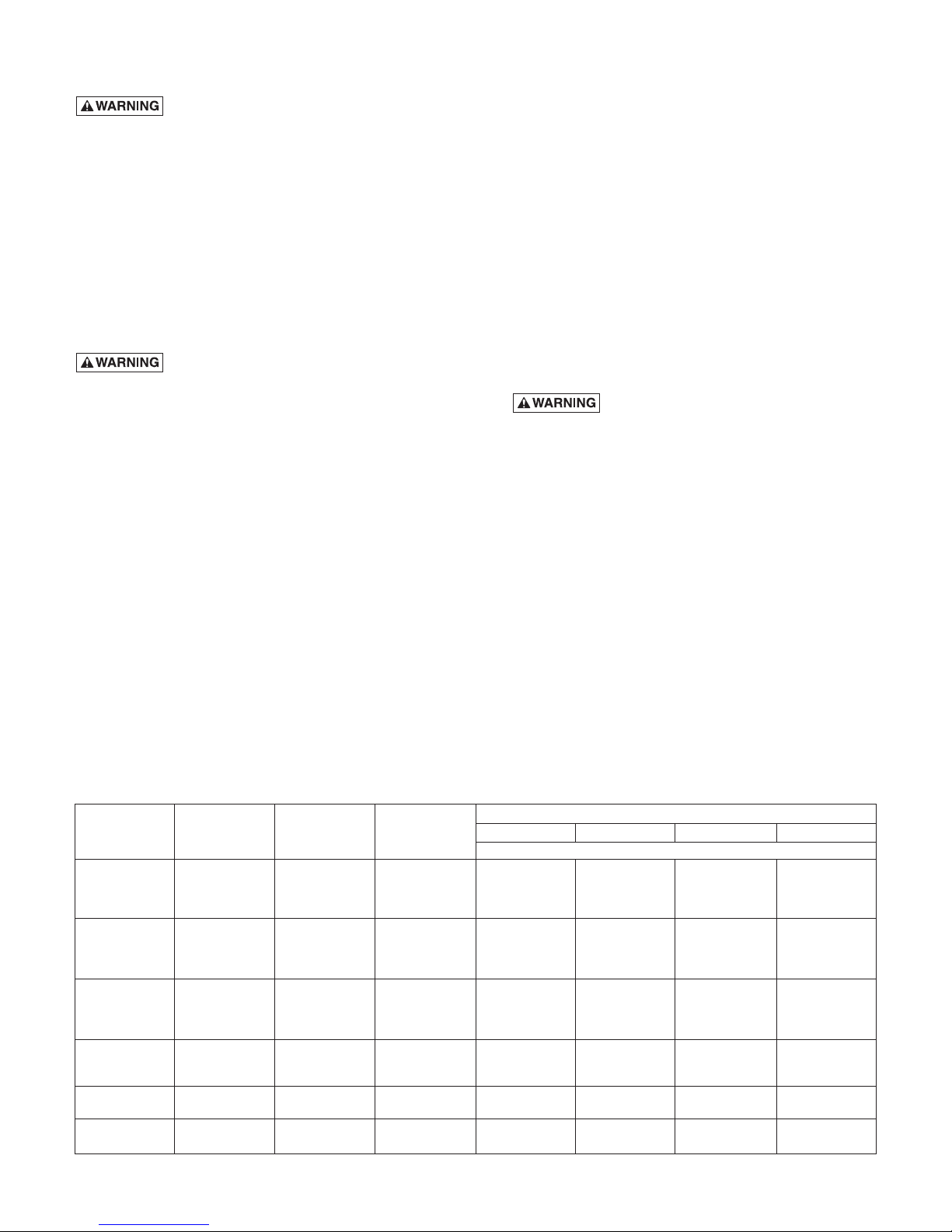

TABLE I - DISCHARGE PRESSURE

Discharge Discharge

No. of Pressure PSI Pressure PSI

GPM HP Stages at Rated Flow at No Flow

7 1/2 9 90 130

7 3/4 12 123 173

7 1 16 162 229

10 1/2 6 74 113

10 3/4 8 97 147

10 1 10 134 188

10 1 11 146 202

10 1-1/2 14 173 206

10 2 16 197 260

20 1 7 75 110

20 1-1/2 9 97 143

20 2 11 123 175

20 3 15 195 250

30 1 5 59 75

30 1-1/2 6 71 91

30 2 7 81 106

30 3 11 129 167

*For total discharge pressure, add this pressure to suction

pipe pressure. For example, an MGP7C pump taking suction from

a 100 psi water service line will produce 130 + 100 = 230 psi total

discharge pressure at 0 GPM flow. If suction pressure drops to 50

psi, discharge pressure will drop to 180 psi.

Limited Warranty

BERKELEY warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free from defects in material

and workmanship for the Warranty Period shown below.

Product Warranty Period

Water Systems:

Water Systems Products — jet pumps, small centrifugal pumps, submersible pumps and related

accessories

Pro-Source™ Composite Tanks 5 years from date of original installation

Pro-Source™ Steel Pressure Tanks 5 years from date of original installation

Pro-Source™ Epoxy-Lined Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products

Agricultural/Commercial:

Centrifugals – close-coupled motor drive, frame mount, SAE mount, engine drive, VMS, SSCX,

SSHM, solids handling, submersible solids handling

Submersible Turbines, 6” diameter and larger

Our limited warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication, improper installation, or

improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase power through a phase converter will void the

warranty. Note also that three phase motors must be protected by three-leg, ambient compensated, extra-quick trip overload relays of the recommended

size or the warranty is void.

Your only remedy, and BERKELEY’s only duty, is that BERKELEY repair or replace defective products (at BERKELEY’s choice). You must pay all labor

and shipping charges associated with this warranty and must request warranty service through the installing dealer as soon as a problem is discovered.

No request for service will be accepted if received after the Warranty Period has expired. This warranty is not transferable.

BERKELEY SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES, INCLUDING

BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE FOREGOING LIMITED

WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an implied warranty, so the

above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You may also have other rights which vary from

state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

whichever occurs first:

12 months from date of original installation, or

18 months from date of manufacture

12 months from date of original installation, or

18 months from date of manufacture

12 months from date of original installation, or

24 months from date of manufacture

12 months from date of original installation, or

24 months from date of manufacture

In the U.S.: BERKELEY, 293 Wright St., Delavan, WI 53115

In Canada: 269 Trillium Dr., Kitchener, Ontario N2G 4W5

3

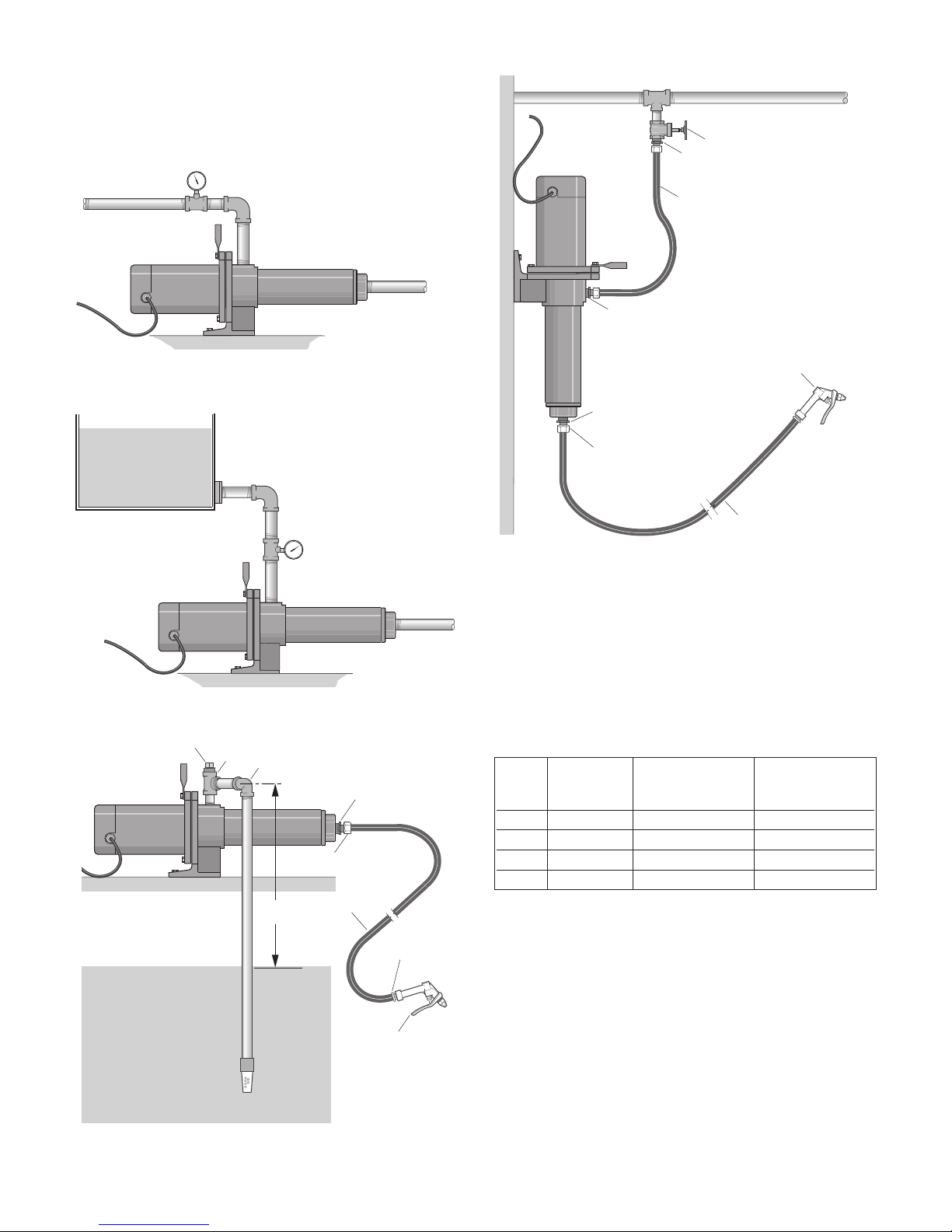

HIGH PRESSURE BOOSTER PUMP

Priming Plug

From pressurized

INSTALLATION INSTRUCTIONS

These instructions cover high pressure booster pump

installations as shown below:

To Power

Service Line

Gate Valve or Hose Bibb

Male Pipe to Male Hose Adapter

house service

Suction

Figure 1 – Connection to house service.

Water tank

or reservoir

Suction

Discharge

Discharge

High Pressure Hose with two

Female Connections

Male Pipe to Male Hose Adapter

Male Pipe to Male Hose Adapter

Female Hose Connection

(Suction)

(Discharge)

Gun Nozzle

Weeping Type ONLY

High Pressure Hose

Figure 4 – Wall mounted to pressurized

service line.

1209 0894

Figure 2 – Connection to water reservoir.

Figure 3 – Cistern or shallow well installation.

Water Supply

Tee

Foot Valve

90 Elbow

Male Pipe to Male Hose Adapter

Female Hose Connection

15 Feet

Maximum

High Pressure

Hose

Gun Nozzle

Weeping Type ONLY

Male Hose

Connection

To reduce friction losses to a minimum, inlet (suction)

line should be short and have as few elbows as

possible.

Size inlet according to the chart below:

Recommended Recommended

Ave. Threaded Inlet Discharge

GPM Inlet Size Line Size Line Size

7 3/4” NPT 1” 1”

10 3/4” NPT 1” 1”

20 1” NPT 1-1/4” 1-1/4”

30 1-1/4” NPT 1-1/2” 1-1/2”

An inlet strainer will prevent suspended debris from

clogging pump.

The internal running surfaces of the pump and seals

require water lubrication for good, consistent operation.

Allowing pump to run dry will severely damage

pump and seals.

Install a pressure gauge in pump inlet line. Keep at

least two pounds per square inch pressure (2 PSI)

in inlet line whenever pump is operating. If this is not

possible, consult customer service representative.

4

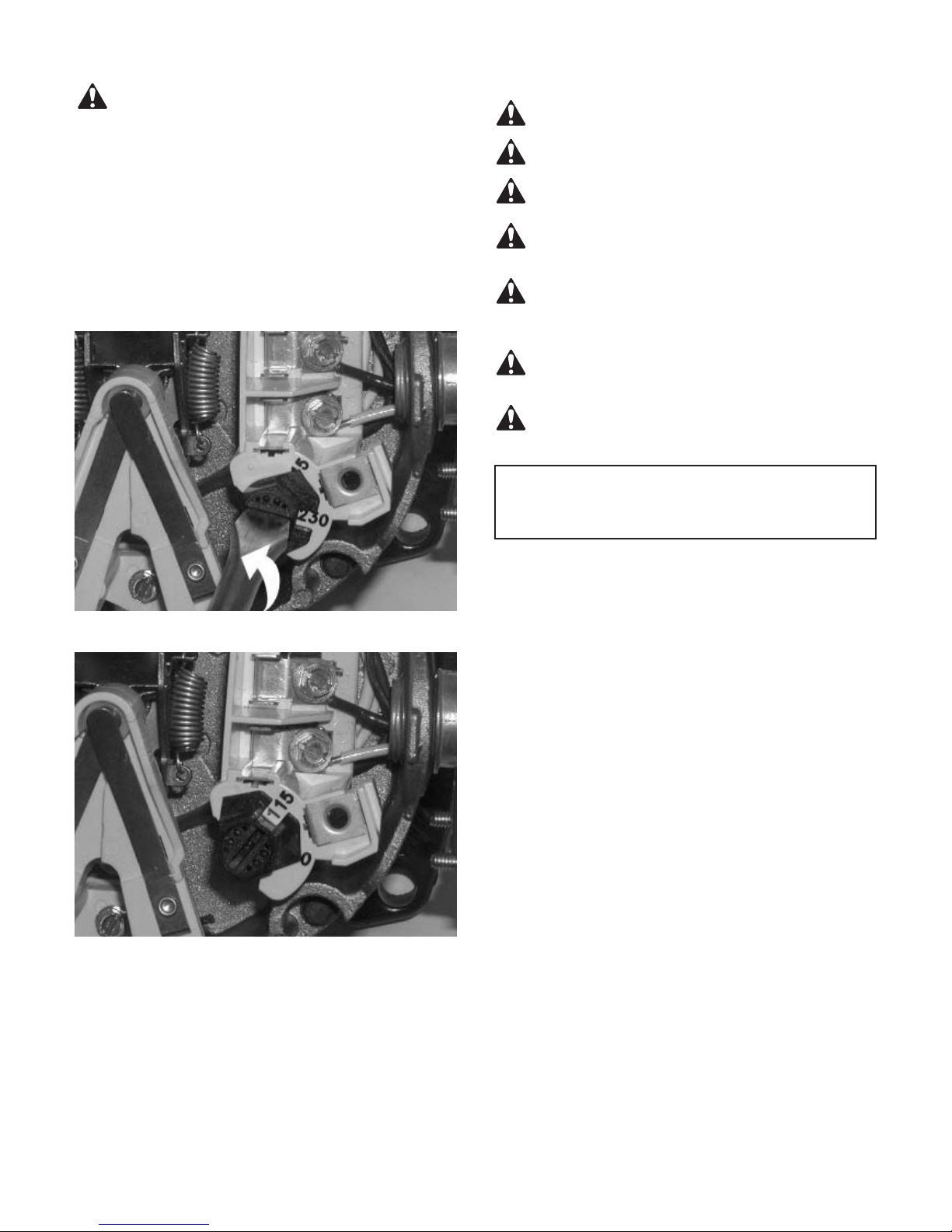

Disconnect power before working on

pump, motor, pressure switch, or wiring.

THE MOTOR IS SET FOR 230 VOLTS

WHEN SHIPPED.*

To change the motor to use 115 volts:

1. Turn off power

2. Remove the back motor cover.

3. Use a screwdriver or 1/2” wrench and turn the

voltage selector dial counterclockwise until 115

shows in the dial opening.

4. Reinstall the motor cover.

ELECTRICAL

Ground motor before connecting to electrical

power supply.

Failure to ground motor can cause severe or

fatal electrical shock hazard.

Explosion hazard. Do not ground to a gas

supply line.

To avoid dangerous or fatal electrical shock,

turn OFF power to motor before working on

electrical connections.

Supply voltage must be within ±10% of

nameplate voltage. Incorrect voltage can

cause fire or serious damage to motor and voids

warranty. If in doubt consult a licensed electrician.

Use wire size specified in Wiring Chart (Table II,

Page 6). If possible, connect pump to a

separate branch circuit with no other appliances on it.

Wire motor according to diagram on motor

nameplate. If nameplate diagram differs from

diagrams above, follow nameplate diagram.

For All 3-phase Motors: Follow the wiring

diagram on the motor junction box or on the

motor nameplate.

Figure 5: Changing the Voltage Setting.

Figure 6: Motor Set for 115 Volt Operation.

* Models with power cords are pre-wired for 115 volts.

This includes models MGP7C and MGP7D.

WIRING CONNECTIONS

1. Install, ground, wire and maintain this pump in

compliance with the National Electrical Code (NEC)

or the Canadian Electrical Code (CEC) and with all

local codes and ordinances that apply. Consult your

local building inspector for local information.

2. Make sure that the voltage, frequency and phase

(single phase or three phase) of the power supply

agree with that stamped on the motor nameplate. If

in doubt, check with the power company.

3. Some models are equipped with three phase

motors. Three phase motors require magnetic

starters and can run in either direction, depending

on how they are connected to the power supply.

NOTICE: Dual voltage motors without cords are factory

wired for 230 volts. If necessary, reconnect the motor

for 115 volts, as shown. All cord connected motors are

wired for 115 volts (see Page 6). Do not alter the wiring

in single voltage motors.

Install, ground, wire, and maintain your pump in

comliance with the National Electrical Code (NEC) or

the Canadian Electrical Code (CEC), as applicable, and

with all local codes and ordinances that apply. Consult

your local building inspector for code information.

NOTICE: Clamp the power cable to prevent strain on

the terminal screws.

NOTICE: Your Motor Terminal Board (under the

motor end cover) looks like the board shown at

left. Do not change motor wiring if line voltage is

230 volts. Connect power supply as shown for your

supply voltage.

5

To Check For Proper Rotation – 3 Phase Motors

Risk of electrical shock.

1. Be sure power is disconnected to motor when

working on electrical connections.

2. Remove the motor end cover, exposing motor shaft.

Momentarily start pump. If hookup is correct, the

shaft will rotate clockwise.

3. If rotation is not clockwise, reverse any two leads to

the starter. The rotation will now be correct.

GROUNDING THE MOTOR

Ground the pump permanently using a wire of size and

type specified by local or National Electrical Code.

Models with a factory installed cord and plug:

Risk of electric shock. This equipment

is only for use on 115V and is equipped with an

approved 3-conductor cord and 3-prong, groundingtype plug. To reduce the risk of electric shock, be

certain that it is connected to a properly grounded,

grounding-type receptacle. Do not modify or remove

the plug. Make sure the pump circuit meets the

National Electrical Code. To avoid a dangerous

electrical shock hazard, keep the cord dry at all times.

Models without a cord or plug:

1. Connect ground wire first. Connect the ground wire to

the green grounding terminal provided under motor

canopy (see Figure 5) identified as GRD. Make the

ground connection to this terminal. Do not connect

the motor to an electrical power supply until the unit

is permanently grounded; otherwise a serious or fatal

electrical shock hazard may be caused.

2. For the best ground connection, connect to a

grounded lead in the service panel or to a metal

underground water pipe or well casing at least 10 ft.

long. If a plastic pipe or insulated fittings are used,

run the ground wire directly to the metal well casing

or use a ground electrode furnished by the power

company.

LUBRICATION

It is not necessary to lubricate the pump or the motor.

The motor is equipped with sealed ball bearings,

lubricated for the life of the bearing. The mechanical

shaft seal in the pump is self-lubricating and requires

no adjustment. Disassemble the pump to replace the

seal (See “Maintenance”, Pages 7 and 8).

OPERATION

NOTICE: Observe the following precautions when

operating the pump:

1. Keep the motor dry! Do not direct the stream from

pump discharge onto the motor!

2.

pump with the discharge shutoff, as the hose may

burst or the pump may be damaged due to high

temperatures.

3. Do not use a standard trigger gun with this pump.

Use only trigger guns with an automatic weeping

feature. These are available as accessories and are

provided with three nozzles. The smallest nozzle

restricts the flow, allowing use of a smaller water

source. The two larger nozzles are used if the water

source will supply the pump’s full capacity.

4. Do not run the pump dry; to do so may damage the

seal.

5. To avoid internal damage to the pump, Do not

operate with water at temperatures above 175

degrees F.

Hazardous pressure. Do not run the

TABLE II - RECOMMENDED FUSING AND WIRING

For 115/230 volt, 1-phase and 230/460 volt, 3-phase. For 575 volt installations, consult a licensed electrician.

Max. Branch

Motor Volts/ Load Fuse Rating 0’-50’ 51-100’ 101-200’ 201-300’

H.P. Phase Amps Amps Wire Size

1/2 115/1 12.4 20 12 12 10 8

1/2 230/1 6.2 15 14 14 14 14

1/2 230/3 3.1 15 14 14 14 14

1/2 460/3 1.55 15 14 14 14 14

3/4 115/1 14.8 20 12 12 8 6

3/4 230/1 7.4 15 14 14 14 14

3/4 230/3 3.6 15 14 14 14 14

3/4 460/3 1.8 15 14 14 14 14

1 115/1 19.2 25 10 10 8 6

1 230/1 9.6 15 14 14 14 12

1 230/3 4.7 15 14 14 14 14

1 460/3 2.35 15 14 14 14 14

1-1/2 230/1 12.0 15 14 14 14 12

1-1/2 230/3 6.8 15 14 14 14 14

1-1/2 460/3 3.4 15 14 14 14 14

2 115/230/1 24.0/10.4 30/15 12/14 10/14 6/14 6/12

2 230/460/3 6.0/3.0 15 14 14 14 14

3 208-230/1 15.0 20 12 12 12 10

3 230/460/3 11.5/5.8 15/15 14/14 14/14 14/14 12/14

Wire Length

6

MAINTENANCE

Pump Disassembly

Hazardous voltage. Can shock, burn

or cause death. Disconnect power to pump before

servicing.

Tools required:

1. 7/16" open end wrench (2 required).

2. Flat blade screwdriver with insulated handle.

3. Work bench with vise recommended.

4. Pliers or similar tool.

5. Pipe wrench.

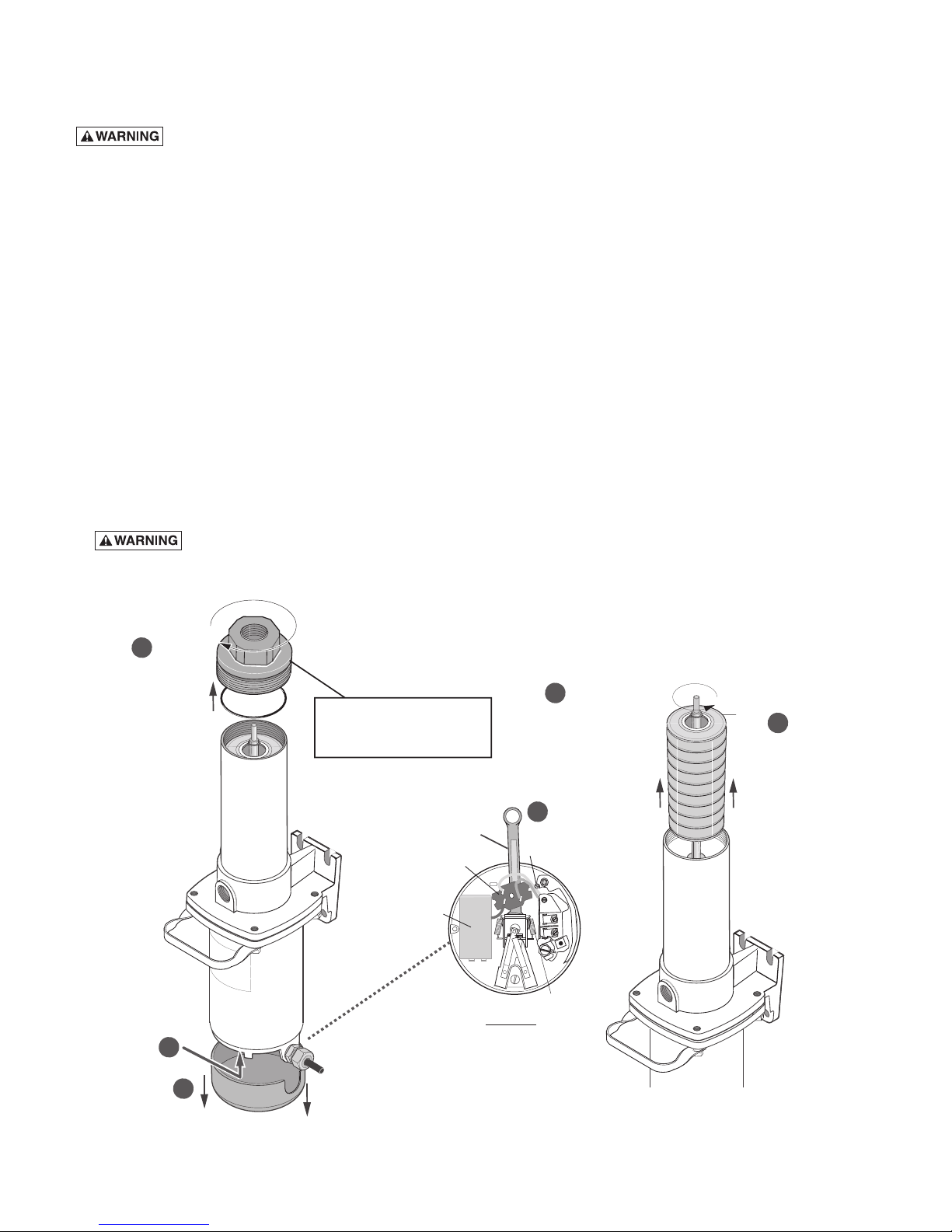

Impeller Stack Changeout (See Figure 7)

Remove pump from service and mount vertically in

vise (if available) motor side down. Hold at center of

motor. It may be desirable to wrap motor with a shop

rag to protect outside surface.

Proceed as follows:

1. Attach pipe wrench to flats on discharge connection

and turn clockwise to remove (left hand threads).

2. Remove screws holding motor canopy and remove

canopy. Pull straight off as shown. Leave switch

wires attached (if present).

ous. To discharge capacitor, hold insulated handle

screwdriver by the handle and short capacitor term-

Capacitor voltage may be hazard-

inals together. Do not touch metal screwdriver blade

or capacitor terminals.

3. Unscrew overload and move it aside. Do not

disconnect wires. Slide 7/16" open end wrench in

behind spring loaded centrifugal switch as shown.

Place on motor shaft flats to hold shaft stationary.

4. With one 7/16" wrench in place on motor shaft,

place second wrench on shaft hex at pump end and

unscrew impeller stack by turning counter-clockwise.

5. Once loose from motor shaft, hold shaft by snap

ring using a pliers or similar tool, and pull stack

from shell. You may have to apply a back and forth

motion to break stack loose from shell.

To assemble with replacement impeller stack, keep

pump in the vertical position, motor down, and reverse

instructions 1 through 5.

Assembly hints:

A. Apply a soapy water solution to suction and

discharge O-Rings to ease seating of shell.

B. Make sure mechanical shaft seal spring is in

proper position on motor shaft.

C. On three-phase models, apply Loctite No. 271 to

motor shaft threads before reinstalling stack.

Discharge

1

Connection

See View A-A

3

2

Remove with

clockwise

rotation.

Remove with

Counter-clockwise

4

3

rotation.

Centrifugal

Switch

Snap

Ring

Impeller

Stack

5

Torque discharge

connection to 80 - 100 ft-lbs

at reassembly

7/16" Open

End Wrench

Overload Protector

(Moved for access)

Capacitor

Motor end view with

Disconnect from

power source.

A

Motor Canopy

canopy removed

7 / 16

View A-A

Overload screw

(remove)

Figure 7 – Impeller stack changeout.

1211 0605

7

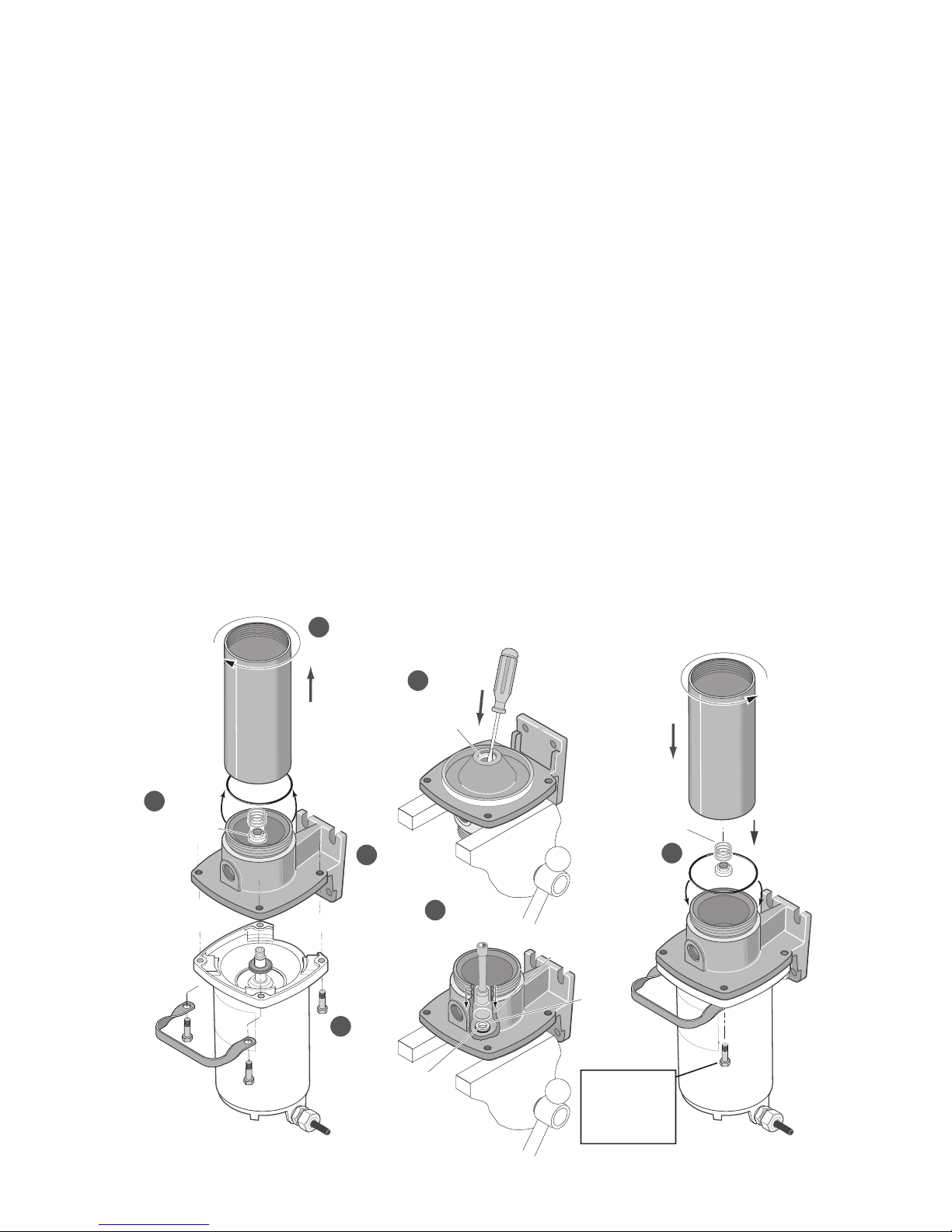

Mechanical Seal Changeout

7

(refer to Figures 7 and 8)

This procedure is best completed with the pump held in

a vertical position, motor down.

First complete “Disassembly” instructions 1 through

5 under “Impeller Stack Changeout.” (see Figure 7).

6. Remove 4 capscrews holding pump body to motor.

Pump handle will come off with top capscrews.

7. Unscrew pump shell from pump body, turning

clockwise (left hand threads).

8. Remove mechanical shaft seal spring and rotating

half from motor shaft. Use care not to scratch motor

shaft when removing rotating half.

9. Remove pump body from motor and place on flat

surface, face down. Again, use care not to scratch

motor shaft.

10. Use a screwdriver to push ceramic seat out from

seal cavity as shown.

11. Installation of ceramic seat:

A. Turn pump body over so seal cavity is up; clean

cavity thoroughly.

B. Clean polished surface of ceramic seat with a

clean cloth.

C. Lubricate outside rubber surface of seat with

soapy water. Place cardboard washer over

polished face of seat and press into seal cavity

using a 3/4" socket or a piece of 3/4" standard

pipe.

D. Be sure polished surface of seat is free of

dirt and has not been damaged by insertion.

Re-move excess soapy water. Dispose of cardboard washer.

12. Installation of rotating half and spring:

A. Reinstall pump body on motor using extreme

caution not to hit ceramic portion of seal on

motor shaft. Reattach pump body to motor using

capscrews. Be sure to reinstall pump handle at

this time.

B. Inspect shaft to make sure that it is clean.

C. Clean face of rotating half of seal with a clean

cloth.

D. Lubricate inside diameter of rotating half with

soapy water and slide onto motor shaft (sealing

face first).

E. Place spring over motor shaft so it rests on

rotating half.

13. To complete reassembly from this point, reverse

instructions 1 through 5 under “Impeller Stack

Changeout.”

NOTICE: Lubricate suction and discharge O-Rings

with soapy water for easier installation of shell.

8

Rotating Half

of Mechanical

Seal

Remove shell;

turn clockwise.

10

9

Remove

Pump Body

Push ceramic

seat out of

pump body

Rotating

Half

12

11

3/4" pipe or

3/4" socket

with extender

Cardboard

washer (supplied

w/seal)

Polished

Face

6

Ceramic Seat

Torque bolts to

15-27 ft-lbs

during

reassembly.

Figure 8 – Mechanical seal changeout.

8

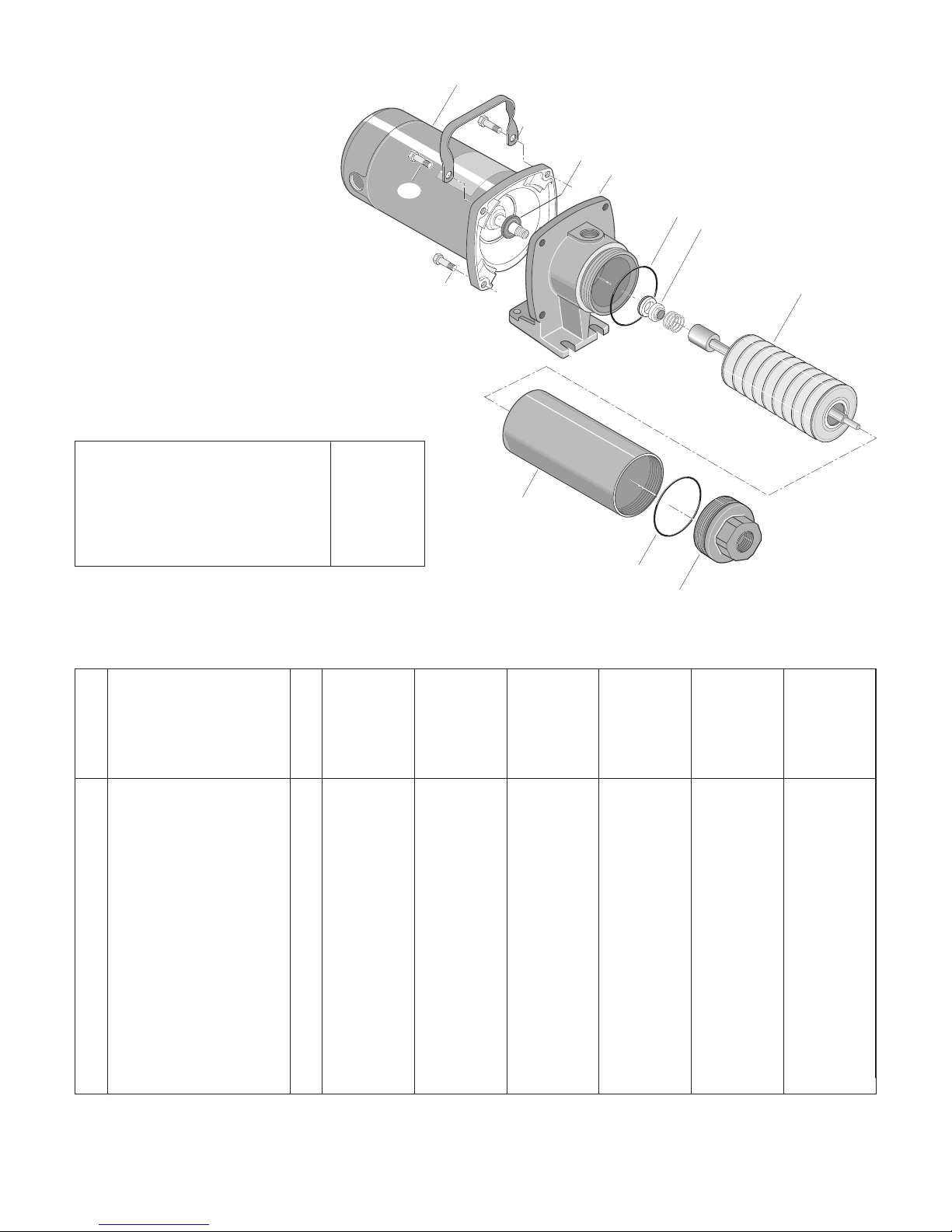

1

11

1206 0894 BE

2

3

4

5

6

10

7

THE FOLLOWING ACCESSORIES MAY BE

ORDERED FOR THE HIGH PRESSURE

BOOSTER PUMPS

Hose 6’-3/4" w/Female Ends

(150 PSI Rating) PKG 83

Hose 25’-3/4" w/Male & Female Ends

(150 PSI Rating) PKG 84

8

Adapter 3/4" NPT x 3/4" Hose PKG 85

Nozzle - High Pressure PKG 86

Suction Vacuum Relief Valve PKG 96

5

NOTE: Model numbers ending in “3” (MGP7C3,

MGPS10C3, etc.) have 3-phase motors.

9

REPAIR PARTS LIST

MGP7E-02

MGP7E3-02

MGP7C-02 MGP7D-02 MGP10E-02 MGP10F-02 MGP10G-02

MGP7C3-02 MGP7D3-02 MGP10E3-02 MGP10F3-02 MGP10G3-02

MGP10C-02 MGP10D-02 MGP20E-02 MGP20F-02 MGP20G-02 MGP20H

Key MGP10C3-02 MGP10D3-02 MGP20E3-02 MGP20F3-02 MGP20G3-02 MGP20H3

No. Description Qty. 1/2 HP 3/4 HP 1 HP 1-1/2 HP 2 HP 3 HP

1 Motor - 115/230 Volt, Single Phase 1 J218-590PKG J218-596PKG J218-601PKG J218-883APKG J218-628APKG –

1 Motor - 230 Volt, Single Phase 1 – – – – – AE100HLL

1 Motor - 230/460 Volt, Three Phase 1 AP100CH AP100DH AP100EH AP100EH AP100FH AP100HL

2 Handle (*) 1 C54-21 C54-21 C54-21 C54-21 C54-21 C54-21

3 Water Slinger 1 17351-0009 17351-0009 17351-0009 17351-0009 17351-0009 17351-0009

4 Pump Body 1 C2-85 C2-85 C2-85 C2-85 C2-85 –

4 Pump Body (20 GPM Models only) 1 – – C2-85A C2-85A C2-85A C2-85A

5 O-Ring 2 U9-430 U9-430 U9-430 U9-430 U9-430 U9-430

6 Shaft Seal 1 U109-118 U109-118 U109-118 U109-118 U109-118 U109-118

7 Pump Stack (7 GPM) 1 P325-422R P325-423R P325-424R – –

7 Pump Stack(10 GPM) 1 P325-425R P325-426R P325-439R P325-428R P325-429R –

7 Pump Stack(20 GPM) 1 – – P325-602R P325-431R P325-432R P325-718R

8 Pump Shell(7 GPM) 1 P56-430SSL P56-431SSL P56-432SSL – – –

8 Pump Shell(10 GPM) 1 P56-460SSL P56-461SSL P56-469SSL P56-452SSL P56-432SSL –

8 Pump Shell(20 GPM) 1 – – P56-433SSL P56-434SSL P56-452SSL P56-452SSL

9 Discharge Assembly 1 C152-3 C152-3 C152-3 C152-3 C152-3 –

9 Discharge Assembly

(20 GPM Models) 1 – – C152-3A C152-3A C152-3A C152-3A

10 Capscrew - 3/8 x 16 x 1-1/2" 4 U30-982ZP U30-982ZP U30-982ZP U30-982ZP U30-982ZP U30-982ZP

• CordandPlugAssembly† 1 U17-402 U17-1238 – – – –

• CordConnector† 1 U71-7 U71-7 – – – –

(*) The Handle (Key No. 2) comes with the 7 and 20 GPM pumps only.

• NotIlustrated

† MGP7C-02 and MGP7D-02 Only.

9

Loading...

Loading...