Pentair ME40AC-21, ME40M-11, ME40P-1, ME40MC-21, ME40P-2 Owner's Manual

...

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.FEMYERS.COM

PH: 888-987-8677

OWNER’S MANUAL

Submersible Effluent Pumps

ME40 / ME40AG Series

Installation/Operation/Repair Parts

For further operating, installation or

maintenance assistance:

Call 1-888-987-8677

© 2016 Pentair plc. All Rights Reserved. 23833A245 (10/26/16)

2

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product.

Save this manual for future reference.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury!

indicates a hazard which, if not avoided, will

result in death or serious injury.

indicates a hazard which, if not avoided,

could result in death or serious injury.

indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE addresses practices not related to

personalinjury.

Keep safety labels in good condition. Replace missing or

damaged safety labels.

1. Read these rules and instructions carefully. Failure to

follow them could cause serious bodily injury and/or

property damage.

2. Check your local codes before installing. You must

comply with their rules.

3. Vent sewage or septic tank according to local codes.

4. Do not install pump in any location classified as

hazardous by National Electrical Code, ANSI/NFPA

80-1984 or the Canadian Electrical Code.

Risk of electric shock. Can shock, burn

or kill. During operation the pump is in water.

To avoid fatal shocks, proceed as follows if pump

needsservicing:

Do not smoke or use devices that can generate

sparks in a septic (gaseous) environment.

5A. Disconnect power to outlet box before

unpluggingpump.

5B. Take extreme care when changing fuses. Do not

stand in water or put your finger in the fuse socket.

5C. Do not modify the cord and plug. When using the

cord and plug, plug into a grounded outlet only.

When wiring to a system control, connect the pump

ground lead to the system ground.

6. Be sure that construction and access to septic sumps

conform with all OSHA requirements.

7. Risk of burns. Do not run the pump dry.

Dry running can overheat the pump, (causing burns

to anyone handling it) and will void the warranty.

8. Risk of burns. The pump normally runs

hot. To avoid burns when servicing pump, allow it to

cool for 20 minutes after shutdown before handling.

9. The pump is permanently lubricated. No oiling or

greasing is required in normal operation.

California Proposition 65 Warning

This product and related accessories contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm

When used in effluent dosing or S.T.E.P. applications,

the pump must be installed in a separate tank or

compartment at the discharge side of the septic tank.

NOTICE Never install the pump in the main tank where

sludge collects. Do not use the pump for raw sewage.

Description

Myers ME40 Series Pumps are single seal units,

automatic or manual, designed for use in effluent dosing,

Septic Tank Effluent Pumping (S.T.E.P.) or normal sump

and general dewatering applications where higher

pressure is required. Impellers are enclosed two-vane

type to handle 3/4” spherical solids and are made of

engineered thermoplastic. All pumps have a 1-1/2” NPT

discharge tapping. Each pump is packaged separately

in a carton marked with a catalog number and Myers

engineering number.

NOTICE Do not overtighten discharge pipe into pump

plastic discharge fitting.

NOTICE This unit is not designed for applications

involving salt water or brine! Use with salt water or brine

will void warranty.

NOTICE This pump is not approved for, and should not

be used in, swimming pools orfountains.

ME40

The ME40 Series pumps are available in 115 volt or

230volt, single phase, 4/10 HP motors. All units are

single seal only, available in automatic or manual with

either 10’ or 20’ power cords. All power cords have

either 115volt or 230volt grounded plugs.

ME40AG

The ME40AG Series pumps are single seal units designed

for use in continuous run agricultural evaporative cooling

applications. They will run continuously in elevated

temperatures with clean sump water.

The wetted pump components are the same as already

described for the ME40 series.

Specifications

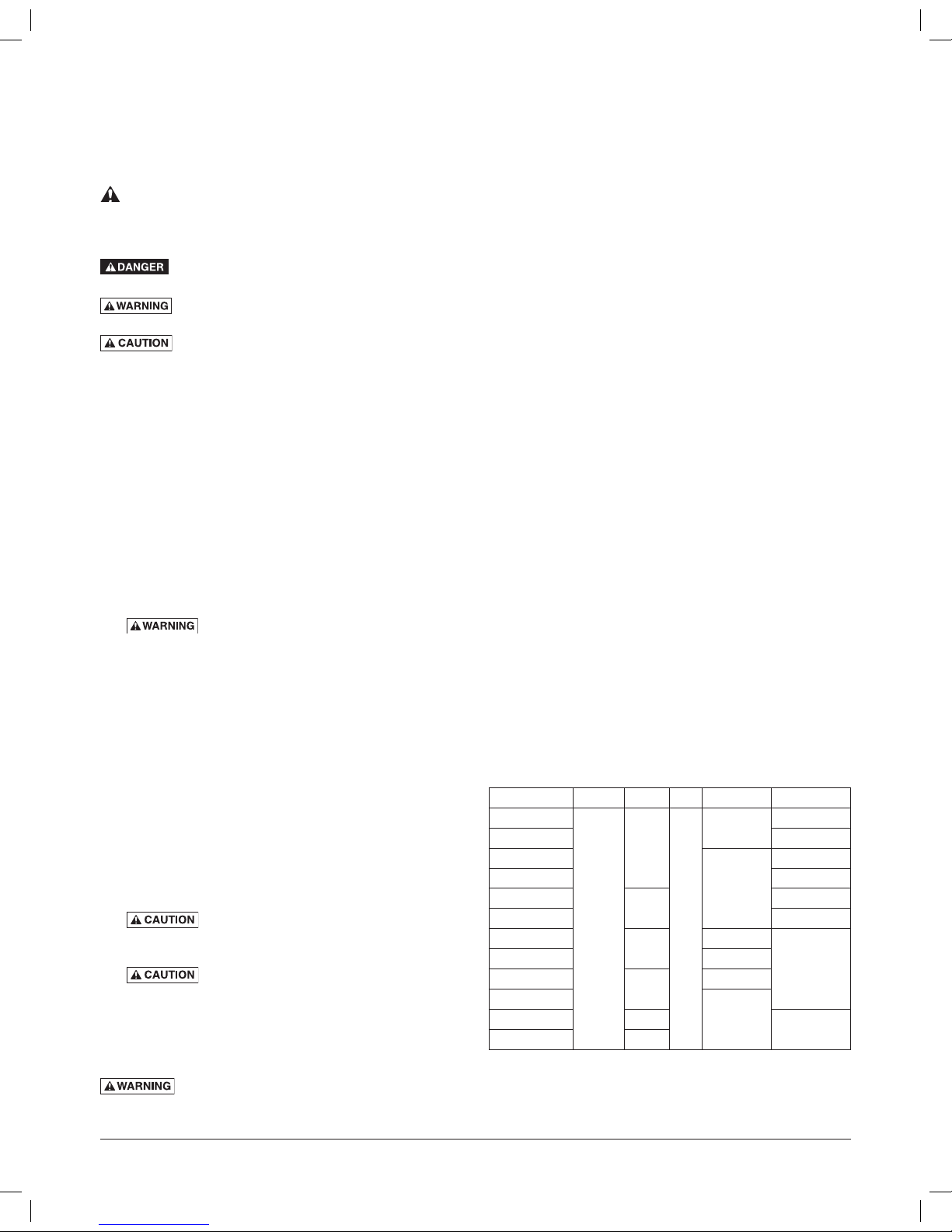

Model HP Volts Ph Cord Lgth. Type

ME40A-11

4/10

115

1

10’

Auto

ME40M-11 Manual

ME40AC-11

20’

Auto

ME40MC-11 Manual

ME40AC-21

230

Auto

ME40MC-21 Manual

ME40P-1

115

10’

Auto

ME40PC-1 20’

ME40P-2

230

10’

ME40PC-2

20’ME40AG-11 115

Manual

ME40AG-21 230

3

Motor Type

The motors used in the ME40/ME40AG pumps are

pressed into the cast iron housing and surrounded by

dielectric oil for the greatest heat dissipation. The ME40

uses a shaded pole, 4/10HP, 1550RPM motor. The

ME40AG uses a permanent split capacitor, 4/10HP,

1625RPM motor. Both units have Class A motor

insulation, are available in single phase 115 or 230volt

with overload protection, and use a lower ball bearing

- upper sleeve bearing. These pumps have no starting

switches and do not require a control panel for simplex

installation. All pumps have UL and CSA approval. Myers

is a SSPMA-certified pump member.

Air Locking

A sump pump is said to be air locked if air is trapped

in the pump and it cannot get out, thus preventing the

pump from operating.

The ME40/ME40AG pumps have a built-in air vent

hole in the impeller chamber to let out trapped air.

It is normal for liquid to spray out of this hole during

operation. If this hole becomes plugged, the pump may

air lock. As a secondary precaution a 1/8” hole should

be drilled in the discharge pipe below the check valve.

The check valve should be 12to18 inches above pump

discharge. Do not put check valve directly into pump

dischargeopening.

Level Controls

All pumps must use sealed level control switches for

automatic operation. All automatic pumps have built-in

level control float switches. The power cord has a ground

pin that plugs into a grounded receptacle. The grounded

receptacle cannot be used in the wet sump or basin due

to danger of current leakage.

Manual pumps can be made automatic with MLC

or MFLC controls with a series plug. Plug the MLC

or MFLC series plug into a proper voltage grounded

receptacle. Then plug the pump cord plug into the back

of the switch cord series plug. The float control must

be tethered a minimum 4” to pump or discharge pipe.

Control must float free from pump and basin wall.

On all duplex units or simplex installations with

additional options like high water alarm, the power cord

plug must be cut off and wired into a control panel or

into a sealed junction box if used in wet sump or basin.

The AWS-1 control also acts as a sealed junction box for

connecting power cord to pump cord.

NOTICE The ME40 sump/effluent pump can be easily

changed from one style, automatic or manual, to the

other by merely interchanging the plug ends of the float

control with the manual plug. The ball float must be

tethered with a cable clamp, as shown. Do not remove

the motor cap.

ME40P pumps have a

mechanical (mercury free)

float switch with a 10’ or

20’ cord with a 115volt or

230volt piggyback plug with

the switch mounted to the

pump. Plug the switch cord

plug into a proper voltage,

properly grounded outlet

and plug the power cord into

the back of the switch cord

and tape the cords to the

discharge pipe every 12”.

Installation

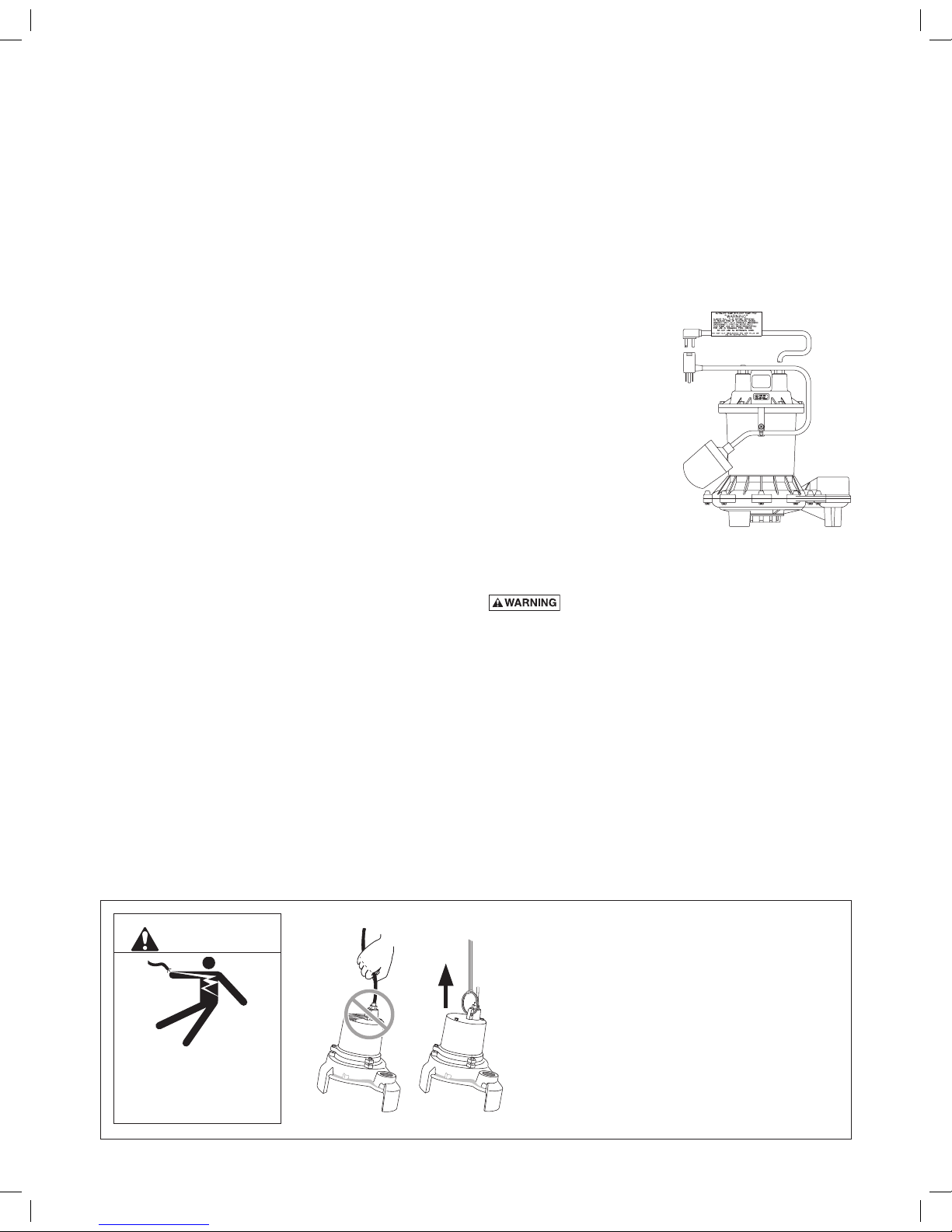

Risk of electric shock. Can shock, burn or

kill. Do not lift pump by the power cord. See Cord Lift

Warning below.

NOTICE Install the pump on a hard, level surface

(cement, asphalt, etc.). Never place the pump directly on

earth, clay or gravel surfaces. Install the pump in a sump

basin with a minimum diameter of 18” (46cm).

1. Attempting to lift or support pump by power

cord can damage cord and cord connections.

2. Cord may pull apart, exposing bare wires with

possibility of fire or electrical shock.

3. Lifting or supporting pump by power cord will

void warranty.

4. Use lifting ring or handle on top of pump for

all lifting/lowering of pump. Disconnect power

to pump before doing any work on pump or

attempting to remove pump from sump.

Risk of electrical shock.

Can burn or kill.

Do not lift pump by power

cord.

WARNING

Cord Lift Warning

Typical pump shown

Piping

Piping must not be smaller than pump discharge.

The pump is designed to operate partially or completely

submerged in effluent liquids and pump semi-solid fluids

up to 3/4” (51mm) in diameter.

When installed in an effluent system, the pipe must be

capable of handling semi-solids of at least 3/4” (19mm)

in diameter.

The rate of flow in the discharge pipe must keep any

solids present in suspension in the fluid. To meet

minimum flow requirements (2 feet per second in the

discharge line), size the pipe as follows:

A Pipe Size Of: Will Handle a Flow Rate Of:

1-1/2” (38mm) 12 GPM

2” (51mm) 21 GPM

2-1/2” (64mm) 30 GPM

3” (76mm) 48 GPM

In an effluent system use a 1-1/2” (38mm) check valve in

pump discharge to prevent backflow of liquid into sump

basin. The check valve should be a free flow valve that

will easily pass solids. Be sure check valve installation

complies with local codes.

Be sure that the float switch hangs freely. It should not be

able to come in contact with the sides or bottom of the

sump pit.

Make sure the sump pit is free of any debris that could

obstruct the intake volute or switch.

Use plumbing materials that are approved by local

building codes when connecting pipes between pump

and sewer outlet.

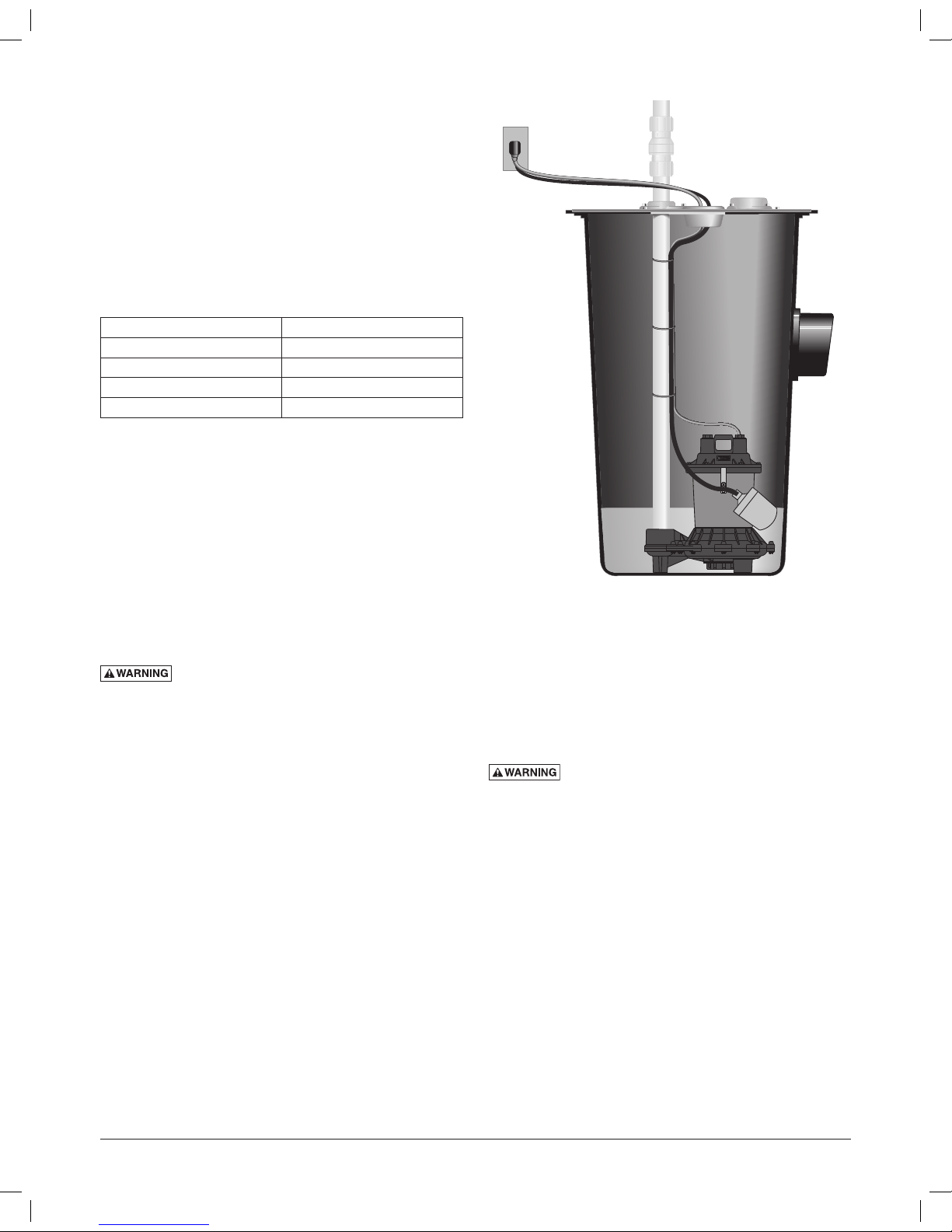

Risk of explosion and hazardous gas. Never

enter pump chamber after sewage or effluent has been

in basin. Sewage water can give off methane, hydrogen

sulfide, and other gasses which are highly poisonous. For

this reason, Myers recommends installing effluent pumps

with a quick removal system. The quick removal system

may be a union or quick-release coupling if the pipe or

discharge hose is within reach from the surface, or a rail

system type quick disconnect on deeper installations. See

Figure 2 for a typical installation.

The dosing tank or pumping chamber must be

constructed of corrosion resistant materials and must

be capable of withstanding all anticipated internal

and external loads. It also must not allow infiltration

or exfiltration. The tank must have provisions for antibuoyancy. Access holes or covers must be adequate

size and be accessible from the surface to allow for

installation and maintenance of the system. Access

covers must be lockable or heavy enough to prevent

easy access by unauthorized personnel. The pumping

chamber holding capacity should be selected to allow

for emergency conditions.

Test the pump installation by filling the sump basin with

enough water to activate the pump and repeat this cycle

until satisfied with pump operation.

NOTICE For critical indoor installations where additional

high water protection is desired, install an audible alarm

system in the sump pit. For outdoor installations, confer

with your distributor.

Connect the power cord to a 3-prong grounded

ACreceptacle.

Electrical

Risk of electric shock. Can shock, burn or

kill. When installing, operating, or servicing this pump,

follow the safety instructions listed below.

1. DO NOT splice the electrical power cord.

2. DO NOT allow the plug on the end of the electrical

cord to be submerged.

3. DO NOT use extension cords. They are a fire hazard

and can reduce voltage sufficiently to prevent

pumping and/or damage motor.

4. DO NOT handle or service the pump while it is

connected to the power supply.

5. DO NOT remove the grounding prong from the

plug or modify the plug. To protect against electrical

shock, the power cord is a three-wire conductor and

includes a 3-prong grounded plug. Plug the pump

into a 3-wire, grounded, grounding-type receptacle.

Connect the pump according to the NEC or CEC and

local codes.

6. DO NOT connect to GFCI outlet as premature

failure of motor could occur.

4

Figure 2: ME40 Typical Installation

Loading...

Loading...