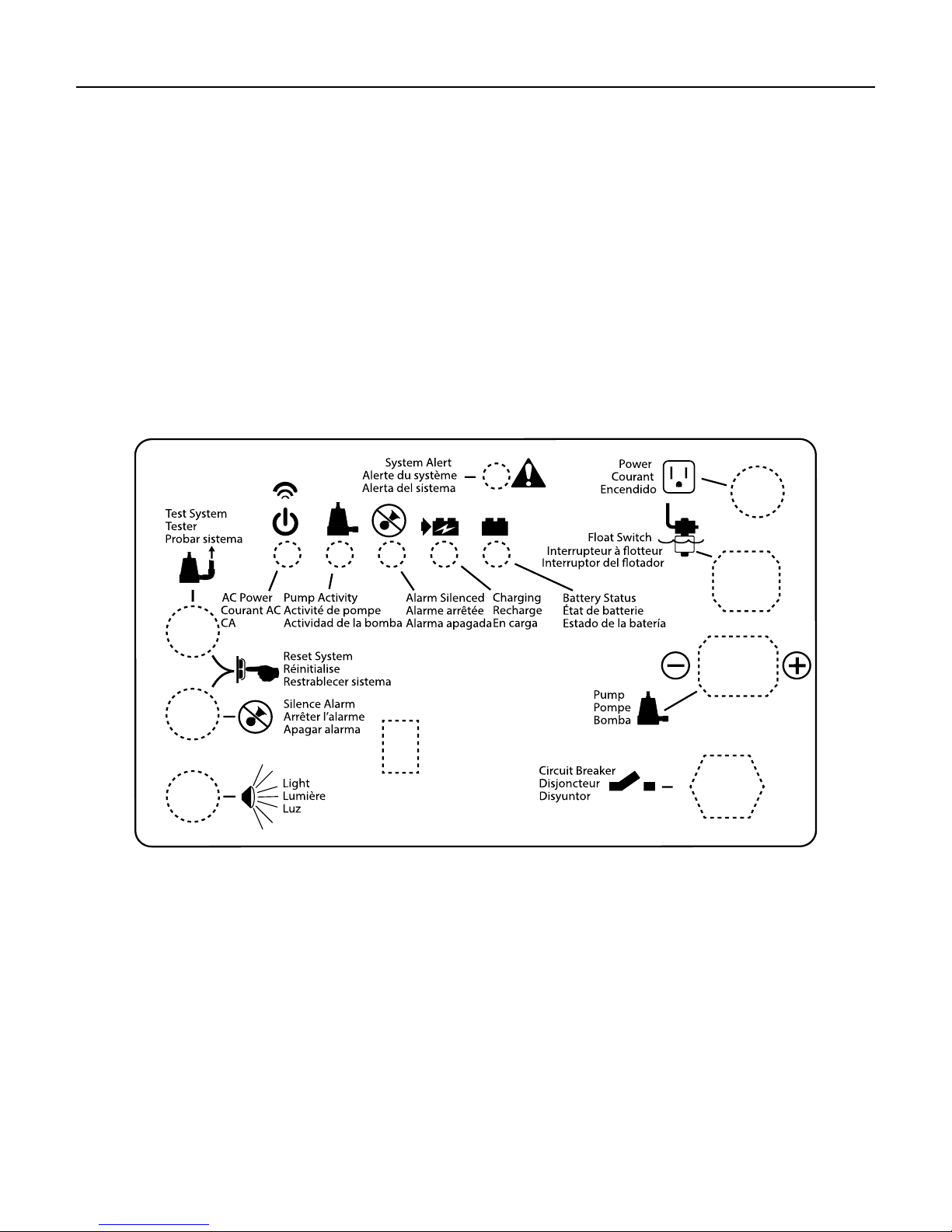

Pump Activity

Activité de pompe

Actividad de la bomba

System Alert

Alerte du système

Alerta del sistema

AC Power

Courant AC

CA

Charging

Recharge

En carga

Battery Status

État de batterie

Estado de la batería

Alarm Silenced

Alarme arrêtée

Alarma apagada

Test System

Tester

Probar sistema

Silence Alarm

Arrêter l’alarme

Apagar alarma

Light

Lumière

Luz

Circuit Breaker

Disjoncteur

Disyuntor

Pump

Pompe

Bomba

Float Switch

Interrupteur à flotteur

Interruptor del flotador

Power

Courant

Encendido

Reset System

Réinitialise

Restrablecer sistema

+

OWNER’S MANUAL

Battery Backup System

NOTICE D’UTILISATION

Système de secours à batterie

Device ID Key

MANUAL DEL USUARIO

Sistema de batería de respaldo

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

888-987-8677 US

800-387-4386 CA

English ........................... Pages 2-16

©2014 MY983 (06/23/14)

MBSP-3C

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

(888) 987-8677 US

(800) 387-4386 CA

Français .................... Pages 17-31

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

888-987-8677 US

800-387-4386 CA

Español ..................... Paginas 32-46

Safety 2

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury!

indicates a hazard which, if not avoided,

will result in death or serious injury.

indicates a hazard which, if not avoided,

can result in death or serious injury.

indicates a hazard which, if not avoided,

can or may result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

Carefully read and follow all safety instructions in this

manual and on pumps.

Keep safety labels in good condition. Replace missing or

damaged safety labels.

Battery acid is corrosive. Do not spill on

skin, clothing, or battery charger. Wear eye and head

protection when working with battery. Connect and

disconnect DC output terminals only after removing the

charger from the AC outlet. Never allow the DC

terminals to touch each other.

Hazardous Voltage. Can cause severe or

fatal electrical shock. Do not plug in or unplug battery

charger while standing on a wet floor or in water. Be sure

one hand is free when plugging in or unplugging charger.

If basement floor is wet, disconnect power to basement

before walking on floor. If shut-off box is in basement,

call electric company or hydro authority to shut-off

service to house, or call your local fire department for

instructions. Remove pump and repair or re place. Failure

to follow this warning can result in fatal electrical shock.

Risk of flooding. Do not run pump dry. To

do so will damage seals and can cause leaking and

property damage.

Risk of electrical shock. Do not lift the

pump by the electrical cord; lift pump only by the

discharge pipe, lifting ring or handle on the pump. Lifting

by the cord can damage the cord.

California Proposition 65 Warning

This product and related accessories contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

1. Know the pump application, limitations, and potential

hazards.

2. Do not use in water with fish present. If any oil leaks

out of the motor it can kill fish.

NOTICE This unit is not designed as a waterfall or

fountain pump, or for applications involving salt water

or brine! Use with waterfalls, fountains, salt water or

brine will void warranty.

3. Disconnect power before servicing.

4. Drain all water from system before servicing.

5. Secure discharge line before starting pump. An

unsecured discharge line will whip, possibly causing

personal injury and/or property damage.

6. Check hoses for weak or worn condition before each

use, making certain that all connections are secure.

7. Periodically inspect sump, pump and system

components. Keep free of debris and foreign objects.

Perform routine maintenance as required.

8. Provide means of pressure relief for pumps whose

discharge line can be shut-off or obstructed. Release all

pressure within system before servicing any component.

9. Personal Safety:

j. Wear safety glasses at all times when working with

pumps.

k. Keep work area clean, uncluttered and properly

lighted – replace all unused tools and equipment.

l. Keep visitors at a safe distance from work area.

m. Make workshop child-proof – with padlocks, master

switches, and by removing starter keys.

14. Follow local and/or national plumbing and electrical

codes when installing the system. A ground fault

circuit interrupter (GFCI) is recommended for use on

any electrical appliance submerged in water.

15. All wiring should be performed by a qualified

electrician.

16. This equipment is only for use on 115 volt

(single phase) and is equipped with an approved

3-conductor cord and 3-prong, grounding-type plug.

17. Where a 2-prong wall receptacle is encountered, it

must be replaced with properly grounded 3-prong

receptacle installed in accordance with codes and

ordinances that apply.

18. Make certain power source conforms to requirements of

your equipment.

19. Protect electrical cord from sharp objects, hot surfaces,

oil, and chemicals. Avoid kinking cord. Replace or

repair damaged or worn cords immediately.

20. Do not touch an operating motor. Modern motors can

operate at high temperatures.

21. Pump clear water only with this pump.

22. Pump is permanently lubricated at the factory. Do

not try to lubricate it!

23. This pump is designed for use in a residential sump

only.

Safety • Specifications 3

GENERAL INFORMATION

The Battery Backup Combo Kit is pre-plumbed up to

the hose and clamp assembly. The system includes the

primary sump pump (PSP), backup sump pump (BSP)

assembly, and vertical float switch. The unit is equipped

with two check valves - one for the primary pump and

one for the backup pump.

The battery backup pump is not a substitute for your

primary sump pump. It is designed to temporarily backup

your primary sump pump during a power outage or other

problem which prevents normal operation of the primary

pump. Do not use this system to pump flammable liquids

or chemicals. Pump clear sump water only with this

pump. For residential use only.

Keep the battery charger dry and protected from damage.

This system is designed to work with either a sealed

lead-acid AGM battery or a flooded lead-acid battery.

Use of a true Gel Cell (often confused for AGM) or a

standard automotive battery with this charger is not

recommended. An automotive battery may require

charging after only 1-2 hours of continuous use, and the

repeated charging cycles may cause early plate failure in

the battery.

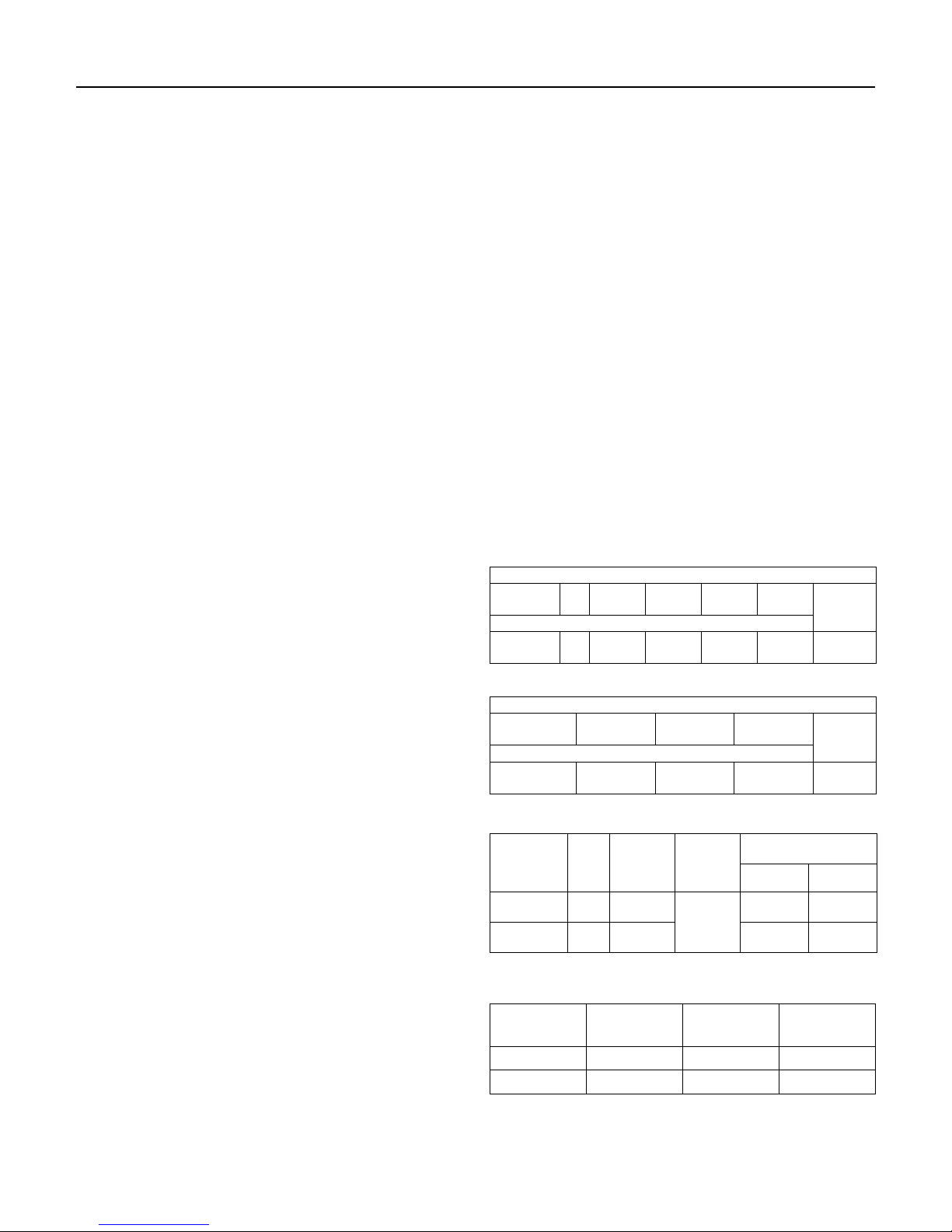

Specifications

Maximum vertical pumping distance is 15 feet (4.6M) for

Model MBSP-3C.

Power supply required

Primary Sump Pump..........................115V, 60 HZ.

Backup Sump Pump........................12V DC Battery

Liquid Temp. Range..........................32°F to 70°F(0°-21°C)

Individual Branch Circuit Required (min.).............15 Amps

Discharge:

Hose & Clamp Assembly...................1-1/4”Slip / 1-1/2”Slip

Minimum pit diameter ....................................................14”

Minimum depth...............................................................10”

NOTICE Do not reduce size of discharge pipe or hose

below 1-1/4” diameter. If discharge is too small, pump will

overheat and fail prematurely.

NOTICE: If a Carbon Monoxide (CO) sensor is installed,

it must be at least 15 feet away from battery charger

in order to avoid nuisance CO alarms. Please refer

to your CO detector’s installation guidelines for more

information.

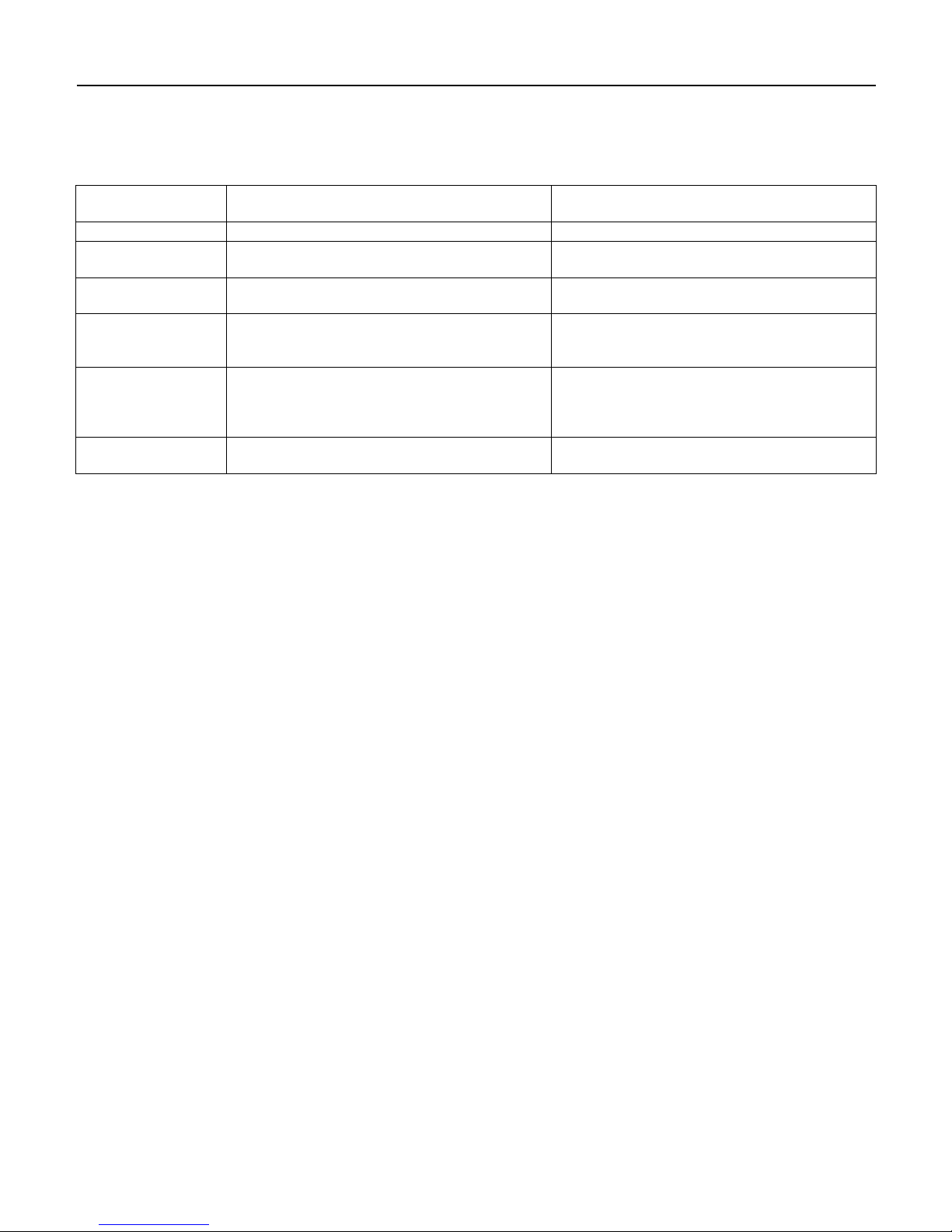

Performance - PSP

GPM (LPM) at total feet (m) of lift

Series HP

Primary

(MS50V1)

5

(1.5m)

Capacity Gallons(L)/Hour

66

1/2

(250)

10

(3m)

56

(212)

15

(4.6m)

44

(167)

20

(6.1m)

28

(106)

MAX.

LIFTr

25 ft

(7.6m)

Performance - BSP

GPM (LPM) at total feet (m) of lift

Series

Backup

(PS17-2005)

5

(1.5m)

Capacity Gallons(L)/Min

34

(129)

10

(3m)

21

(79)

14

(4.3m)

6

(23)

MAX.

LIFT

15

(4.6m)

Electrical & Switch Specifications

Motor

Series HP

MS50V1 1/2 4.1

PS17-2005 - -

Full Load

Amps

Branch

Circuit

Req.

(Amps)

15

Required Battery Capacity:

For best results, use the following AGM Storage Batteries:

Gal/Charge

Part Amp-Hour

at 10’

BAT40 40 4,800 5 Hours

BAT75 75 11,500 11.5 Hours

• Unit equipped with dual battery capability

• Maximum amp-hour: 120

• 38-120 Ampere-Hour Storage or Deep Cycle Battery

Switch Setting in

inches (cm)

On Off

7.5

(19.1)

10.5

(26.7)

3

(7.6)

25 sec.

Approx Run

Time

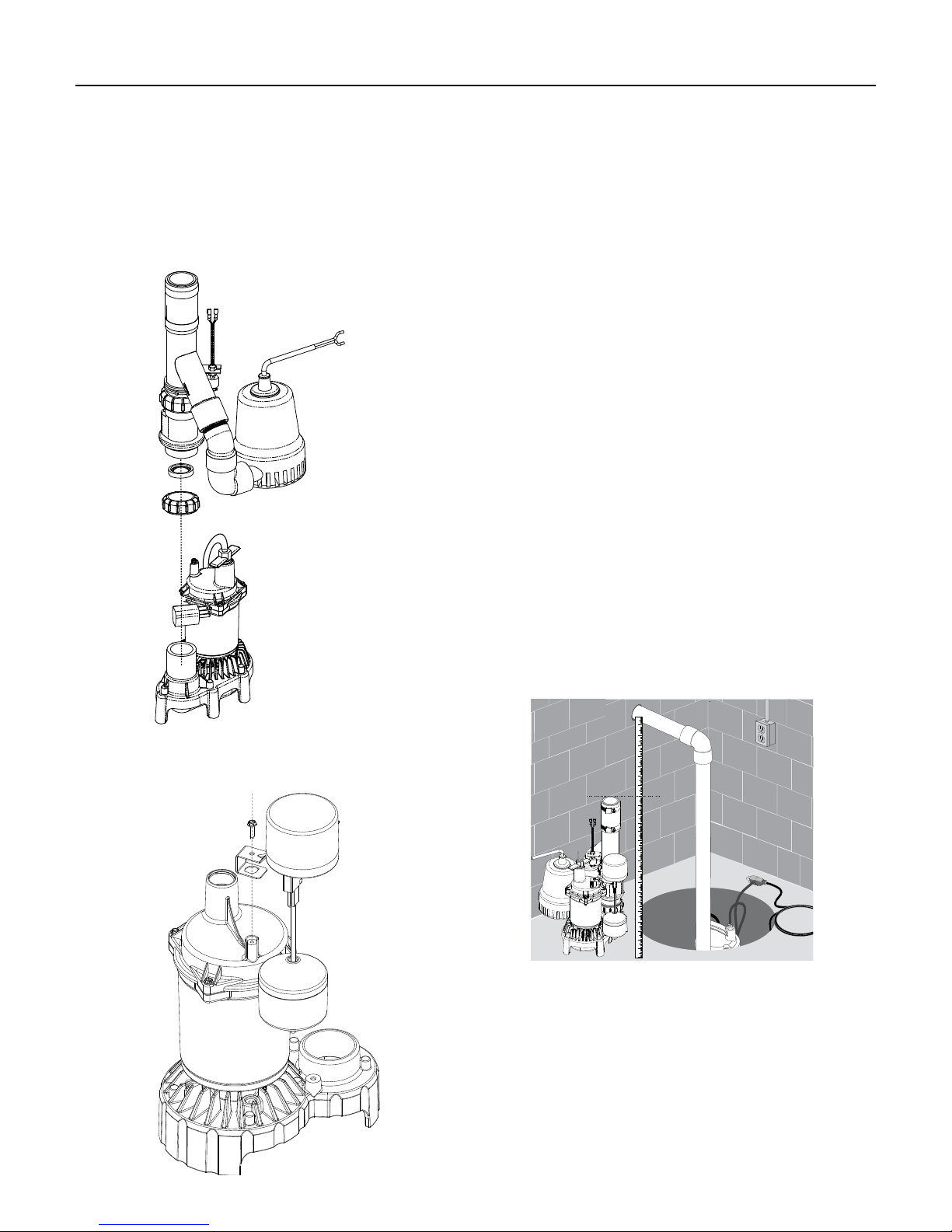

Pump Installation 4

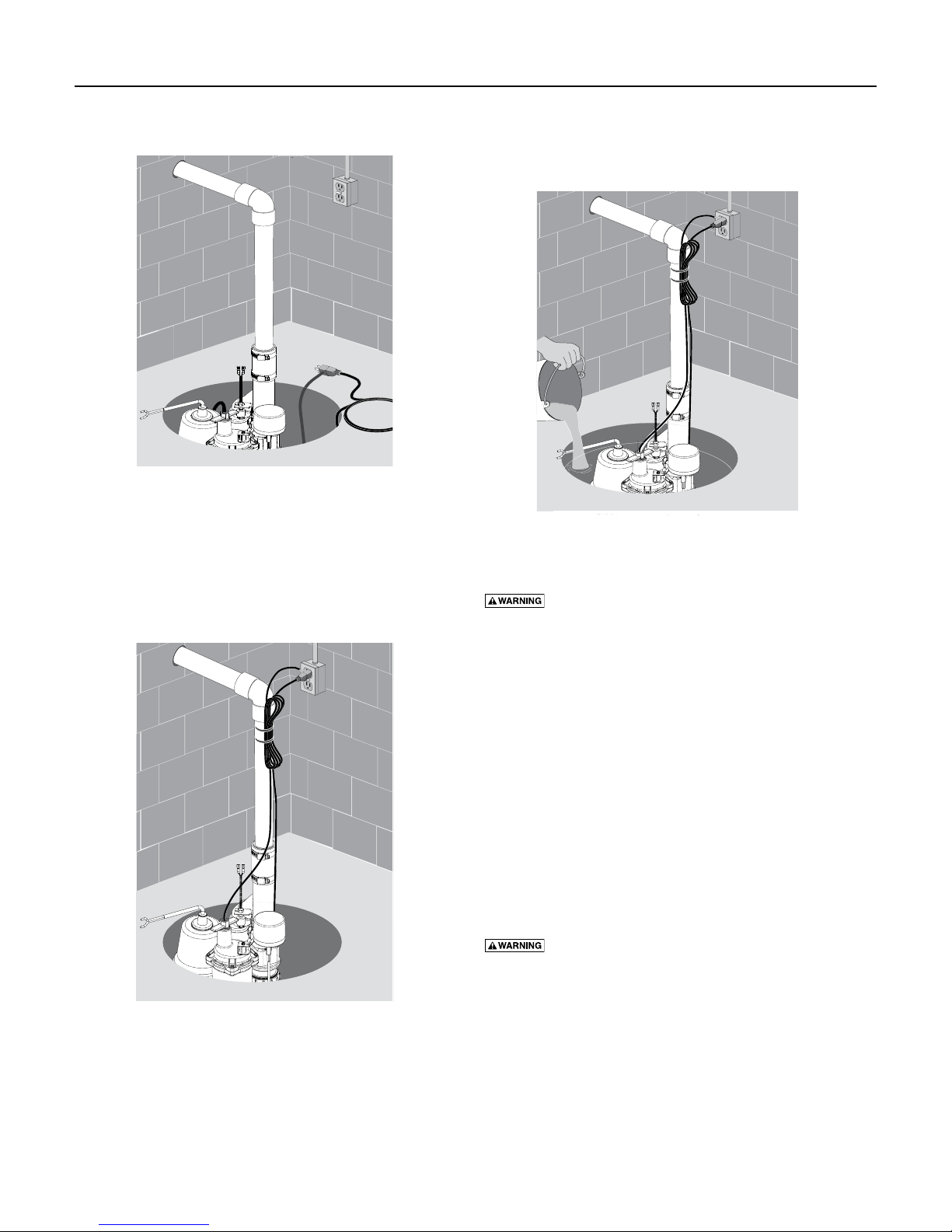

Backup Assembly Installation

Attach backup pump assembly to primary pump. To do

so, un-screw bottom nut on check valve and remove

rubber seal. Place nut from check valve around discharge

PVC pipe on primary pump, then place rubber seal.

Attach backup pump assembly to the primary pump by

tightening nut to the rest of the check valve unit.

Adjust backup pump to sit at an angle (approx. 10°).

(10° angle)

Combo Unit Installation

Suggested Materials Needed:

Screwdriver, tape measure, hacksaw, cable ties

1. Drain the sump pit as far as possible without running

the pump dry. Do this by:

A. Piggyback switch: Unplug the pump and switch

from the outlet, then unplug the pump from the

piggyback switch. Reset the circuit breaker or

reinstall the fuse and plug the pump directly into

the outlet. The pump will start. Drain the pit and

unplug the pump. OR

b. No piggyback switch: Reset the circuit breaker

or reinstall the fuse and use a non-conducting

broom handle or stick to raise the float switch;

the pump should start. Drain the pit and then

release the switch.

c. When the pit has drained, turn off (open) the

circuit breaker or remove the fuse again to avoid

electrical shock while working on the installation.

Unplug existing sump pump and place power cord

and piggyback switch out of the way of work and

water.

2. Measure height of MBSP-3C Combo Kit from base to

top of hose clamp assembly. Subtract 1”.

Drop the tape measure into the bottom of sump pit

and mark the cut line on the discharge pipe (1” less

than total height of the Combo Kit).

3. Use hacksaw to cut horizontally along cut line completely through pipe.

NOTICE Depending on where your current check

Float Switch Installation

Assemble float switch as shown.

valve is located, there may be excess water. Let the

water drain/drip into the sump pit.

4. Remove old sump from sump pit.

NOTICE Remove all sand, clay, and gravel before

installing.

5. Place Combo Kit into sump pit. Make sure vertical

float switches can operate freely inside sump pit.

Installation • Operation 5

6. Once the Combo Kit is firmly seated in the base of the

pit, connect the hose and clamp switch to the existing

discharge pipe and clamp it securely.

7. Secure power cord (PSP & BSP), piggyback switch,

and reed switch cord high up and around pipe with

a cable tie. Plug the primary pump into a standard

household 15 amp outlet.

NOTICE The circuit should be dedicated to the sump

pump exclusively.

Remember: Do not handle the pump while it is

plugged in; whether it is running or not.

9. Once all wiring is complete, fill your pit with water

and verify that the PSP removes the water and the

BBU doesn’t run. Then, unplug your PSP and refill

your pit with water. Verify that the BBU removes the

water.

10. Make sure that the power is on to both pumps, and

your system is ready to use.

Operation

Risk of electric shock. Can shock, burn or kill. Do

not handle a pump or pump motor with wet hands or when

standing on wet or damp surface, or in water.

1. Shaft seal depends on water for lubrication. Do not

operate pump unless it is submerged in water as seal may

be damaged if allowed to run dry.

2. Motor is equipped with automatic reset thermal protector.

If temperature in motor should rise, switch will cut off

all power before damage can be done to motor. When

motor has cooled, switch will reset automatically and

restart motor. If protector trips repeatedly, pump should be

removed and checked. Low voltage, long extension cords,

clogged impeller, very low head or lift, or a plugged or

frozen discharge pipe, etc., could cause cycling.

3. Pump will not remove all water. If operating a pump

manually and suddenly no water comes out of the

discharge hose, shut off the unit immediately. The unit has

broken prime due to a very low water level.

Risk of electric shock. Can shock, burn or kill.

Before attempting to check why unit has stopped operating,

disconnect power from unit.

8. Connect BBU. See “BBU Wiring and Setup”.

BBU Wiring and Setup 6

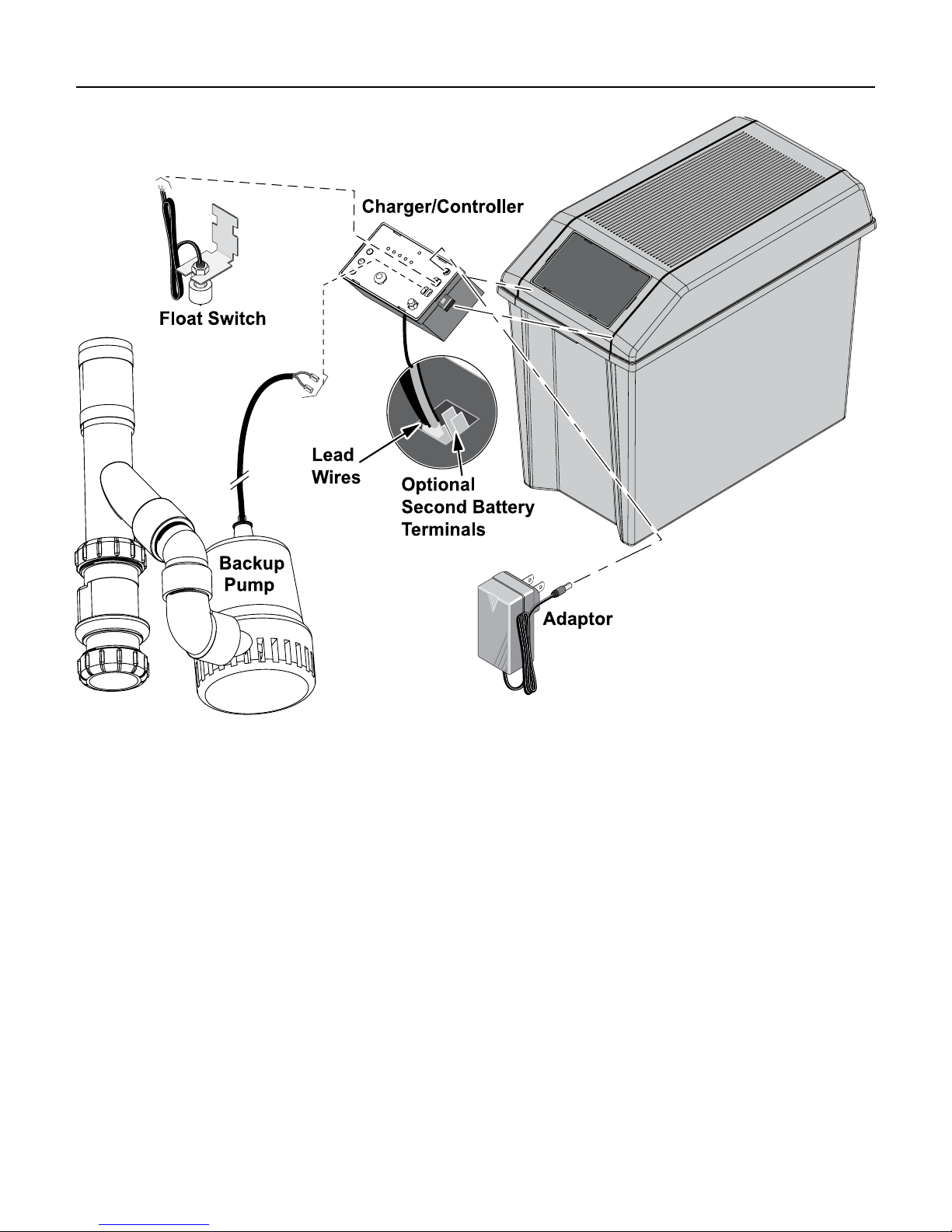

1. Connect the positive (+) charger/controller lead

wire (red) to the positive (+) battery terminal (red).

Connect the negative (–) charger/controller lead

wire (black) to the negative (–) terminal (black) on

the battery. If you are using two batteries, use the

set of optional terminals and connect the second

battery. Use lead wires (not included) to connect

the positive (+) charger/controller terminal to the

positive (+) battery terminal and the negative (–)

charger/controller terminal to the negative (–) battery

terminal.

2. The backup pump leads are polarity sensitive;

connect the positive pump lead to the terminal

labeled Pump ‘+’ and the negative pump lead to the

terminal labeled Pump ‘–’.

NOTICE: If the leads are reversed, the pump will run

backward and not pump water.

3. The float switch leads are not polarity sensitive;

connect the float switch leads to the ‘Float Switch’

tabs on the charger/controller.

4. Test the float and the pump by lifting and holding

the float. The system alert LED will blink while

the float is up. The ‘PUMP STATUS’ LED will light

continuously and the buzzer will beep steadily. The

pump should start after 3 seconds. If the pump does

not run, check all the connections and remake them

as necessary.

5. To stop the pump, lower the float; after 25 seconds

the pump should stop, the ‘PUMP STATUS’ LED

should flash, and the buzzer should beep.

6. With the pump operating, test the ‘SILENCE ALARM’

button; hold for one second; release. The ‘ALARM

SILENCED’ LED should illuminate and the buzzer

should stop sounding. To reset the buzzer (allow it to

sound) and extinguish the ‘ALARM SILENCED’ LED,

press the ‘SILENCE ALARM’ button again for one

second.

Depress the ‘TEST SYSTEM’ button; hold it for one

second; release. The ‘PUMP STATUS’ LED should stop

flashing.

BBU Wiring and Setup 7

NOTICE: During normal operation, the flashing

‘PUMP STATUS’ LED indicates that the pump has

run in your absence.

1. Press and hold ‘TEST SYSTEM’ button. All LEDs will

light up, pump will run and buzzer will sound.

Release the button and LEDs should go off, pump

should stop, buzzer should stop.

2. The ‘BATTERY STATUS’ LED indicates the battery

capacity when the A.C. power is off.

A. Continuously ON - the battery voltage is above

10.9 Volts Direct Current (10.9VDC) and

capacity is above 20%.

B. Slow Beep/Slow LED Flash - the battery’s

capacity is between 0 and 20%.

LED Display and Control Buttons

C. Fast Beep/Fast LED Flash - the battery is severely

discharged. The battery will continue to charge

(as long as the 115V AC power to the charger is

on) at the rate of .5 AH until the battery’s charge

is above 20%.

When the first warning occurs (slow beep/slow

flash), you will have approximately 2 hours (or less)

of pump operation left. The actual time of operation

will depend on the condition of the battery and may

be as little as 15 minutes.

3. Connect the Power Supply cable (supplied) to the

Charger/Controller’s Power Input jack.

NOTICE: When the unit is first plugged in, or when it first receives power from the battery, the ‘BATTERY STATUS’

LED will flash for 3 seconds.

NOTICE: To activate any Control Button, press and hold it for 1 second.

Battery Requirements 8

BATTERY REQUIREMENTS

Hazardous electric current. Can cause

severe burns and start a fire if the battery terminals are

short circuited. Install the battery in the battery case. To

prevent accidental shorting across battery terminals,

close and latch the battery case securely. Do not leave

the battery uncovered.

Do not allow children to play around the battery

backup system installation.

The performance of your backup sump pump depends on

the battery used with it for power. We recommend using

our BAT40 or BAT75. You can also use a group 24M or

27M Deep Cycle battery. They will provide acceptable

performance and will stand up well to long periods of

little or no use.

This system is designed to work with either a sealed

lead-acid AGM battery or a flooded lead-acid battery.

Use of a true Gell Cell (often confused for AGM) or a

standard automotive battery with this charger is not

recommended. An automotive battery may require

charging after only 1-2 hours of continuous use, and the

repeated charging cycles may cause early plate failure in

the battery.

Use only lead-acid batteries. This unit is not designed to

use with Li-Ion, NiMh, NiCAD, Liquid Polymer, etc.

Use only the recommended battery or one of the same

type and size so it will fit in the battery box (maximum

size: 13” long x 7” wide x 10” tall (330.2mm x 177.8mm

x 254mm) including terminals) and supply enough

voltage for full performance.

BATTERY MAINTENANCE

Severe burn hazard. An acid-filled standard

lead-acid battery contains sulfuric acid. Avoid contact with

skin, eyes or clothing.

NOTICE: To protect the battery case from chipping and

gouging, do not let the battery sit on a concrete floor.

Install the battery on a shelf or protective pad (plywood,

2x4s, etc.). Always install the battery in a dry location

that is protected from flooding.

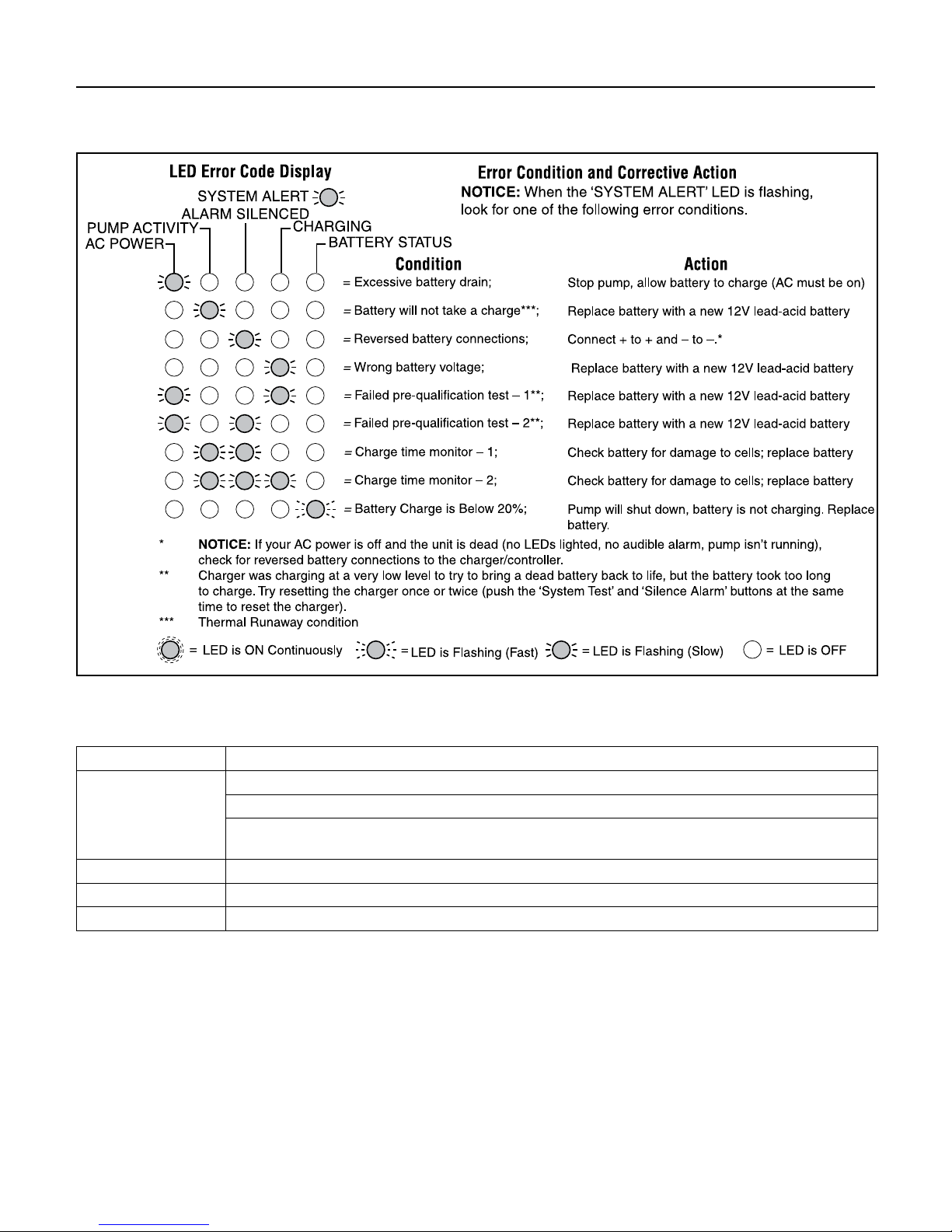

Pre-Qualification Test – 1 and 2

Charger is charging at a very low level to try to bring a

dead battery back to life. If the battery is taking too long,

try resetting the charger once or twice (push the ‘SYSTEM

TEST’ and ‘SILENCE ALARM’ buttons together to reset the

charger).

Special Features:

The charger is equipped with reverse battery, short

circuit, and “runaway charge” protection.

Possible Problems and Remedies

1. Wrong Battery Voltage

Reconnect charger to a 12 volt battery.

2. Reversed Battery Connections

Check all connections. The negative (black) on the

battery must connect to the negative (black) on

the charger, and the positive (red) on the battery

must connect to the positive (red) on the charger.

Reversing the battery connections will cause the

‘SYSTEM ALERT’ and ‘SILENCED AUDIBLE ALARM’

LEDs to flash.

3. Thermal Runaway Condition

“Thermal Runaway” is the technical term for the

condition of the battery when some (or all) of the

cells have deteriorated to the point that they won’t

take a charge. In this case, replace the battery.

4. Charge Time Monitor – 1 and 2

Battery took too long to complete its charge. The

“Charge Time Monitor” will shut down the charger

after 84 hours of continuous charging.

Possible causes are:

A) Pump ran for a long period of time during

charging, or

B) Battery is too large for the charger (including

several batteries connected in a parallel circuit).

Excessive Battery Drain

Pump may have run for a very long time, discharging the

battery. In this case:

a. If 115VAC power is OFF, the charger shuts down

until the power comes back on, but the pump will

run as long as the battery charge lasts. You may need

to replace the battery afterwards.

b. If 115VAC power is ON, the charger/controller

continues to try to charge the battery at a charging

rate of .5 AH until the battery charge is more

than 20%, at which point the charger will resume

charging at a rate of 2 AH.

c. If the pump is running and the AC power is on, you

may need to stop the pump to allow the battery to

charge.

Follow the battery manufacturer’s recommendations for

maintenance and safe use of the battery.

Charger/Controller LED Display 9

(solid or blinking) as long as the system is plugged in to an operating AC power circuit.

TABLE II – Operating Code Displays (LEDs Lighted Continuously or Flashing)

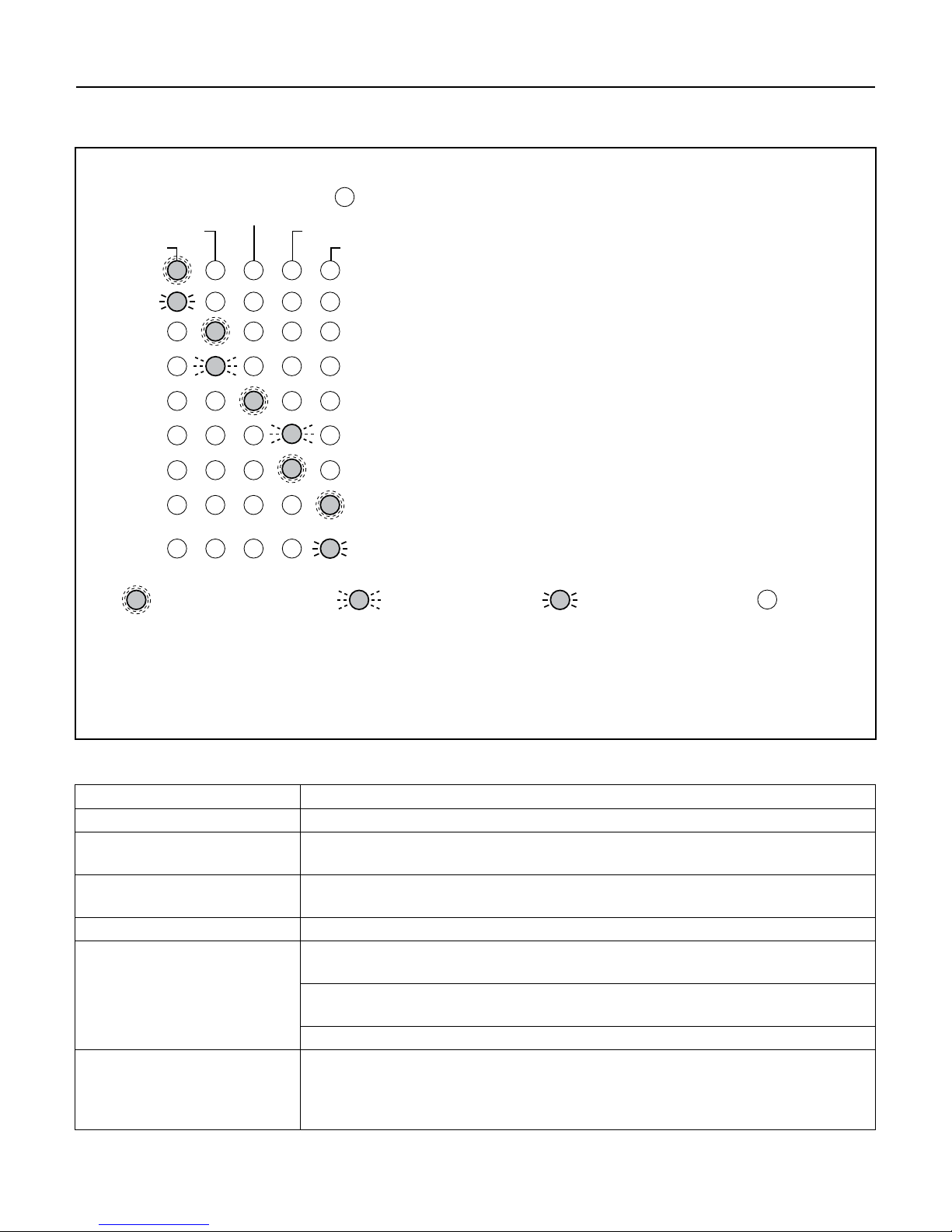

LED Operating Code Display

PUMP ACTIVITY

AC POWER

= =

LED is ON Continuously

SYSTEM ALERT

ALARM SILENCED

CHARGING

System Operating Condition

BATTERY STATUS

Indicates 115V AC Power is connected / Unit online

Indicates 115V AC Power is connected / Unit offline

Indicates Pump is running (continuous LED)

Indicates Fast flashing LED: Pump has run

Indicates Audible alarm is switched off

Indicates Fast flashing LED: Battery pre-qualification test is running

Indicates Battery is charging normally

Indicates Continuous LED: battery charge is above 20%,

system is maintaining charge

Indicates Slow flashing LED: battery charge is below 20%

=

LED is Flashing (Fast)

=

LED is Flashing (Slow)

LED is OFF

NOTICE: All of the situations listed above indicate normal system operation; no action is required.

However, if the BBU pump is running or has run, check the primary pump and actively monitor the

charger status for battery life. Always reset the charger after the pump runs.

During normal system operation, the ‘SYSTEM ALERT’ LED blinks while the float switch is on,

indicating the pump should start within 3 seconds. The “AC POWER” LED is lighted

TABLE III – LED Function Displays (LEDs Lighted Continuously)

Control LED: Continuous Illumination Indicates Normal Operation:

AC Power AC power is present. Unit is online.

Pump Status

Silenced Audible Alarm Audible Alarm has been silenced. Press and release the ‘SILENCE ALARM’ button

Charging

Battery Status A. Continuous ON - the battery voltage is above 10.9 Volts DC and capacity is

System Alert Flashing (in unison with the buzzer) indicates that the charger has entered ‘Failure

The float switch has been activated. The LED remains on (flashing) after the pump

has stopped. Depress the ‘SYSTEM TEST’ button to reset it.

to reset (activate) the audible alarm and turn OFF the LED.

Indicates that the battery is charging – see Table II, above.

above 20%.

B. Slow Beep/Slow LED Flash - the battery’s capacity is below 20%, and voltage is

between 8.2VDC and 10.9VDC.

C. Fast Beep/Fast LED Flash - the battery has been discharged to less than 8.2VDC.

Mode’. Press the ‘SYSTEM TEST’ and ‘SILENCE ALARM’ buttons to reset it.

NOTICE: If the source of the failure is not corrected, the charger will reenter

“Failure Mode”. See Table IV for error code information.

Charger/Controller LED Display 10

TABLE IV – Error Code Displays (LEDs Flashing)

TABLE V – Control Button Functions

Control Button: Result of Pushing Button:

System Test Pump starts and all LEDs light up.

Will reset the ‘PUMP ACTIVITY’ LED.

When pushed with the ‘SILENCE ALARM’ button, the Charger/Controller microprocessor resets

and error code resets.

Silence Alarm Toggle; Prevents the audible alarm sounding. Press and release to reset.

Light Toggles the light on the Charger/Controller on and off.

System Reset Press and release ‘TEST SYSTEM’ and ‘SILENCE ALARM’ to reset system.

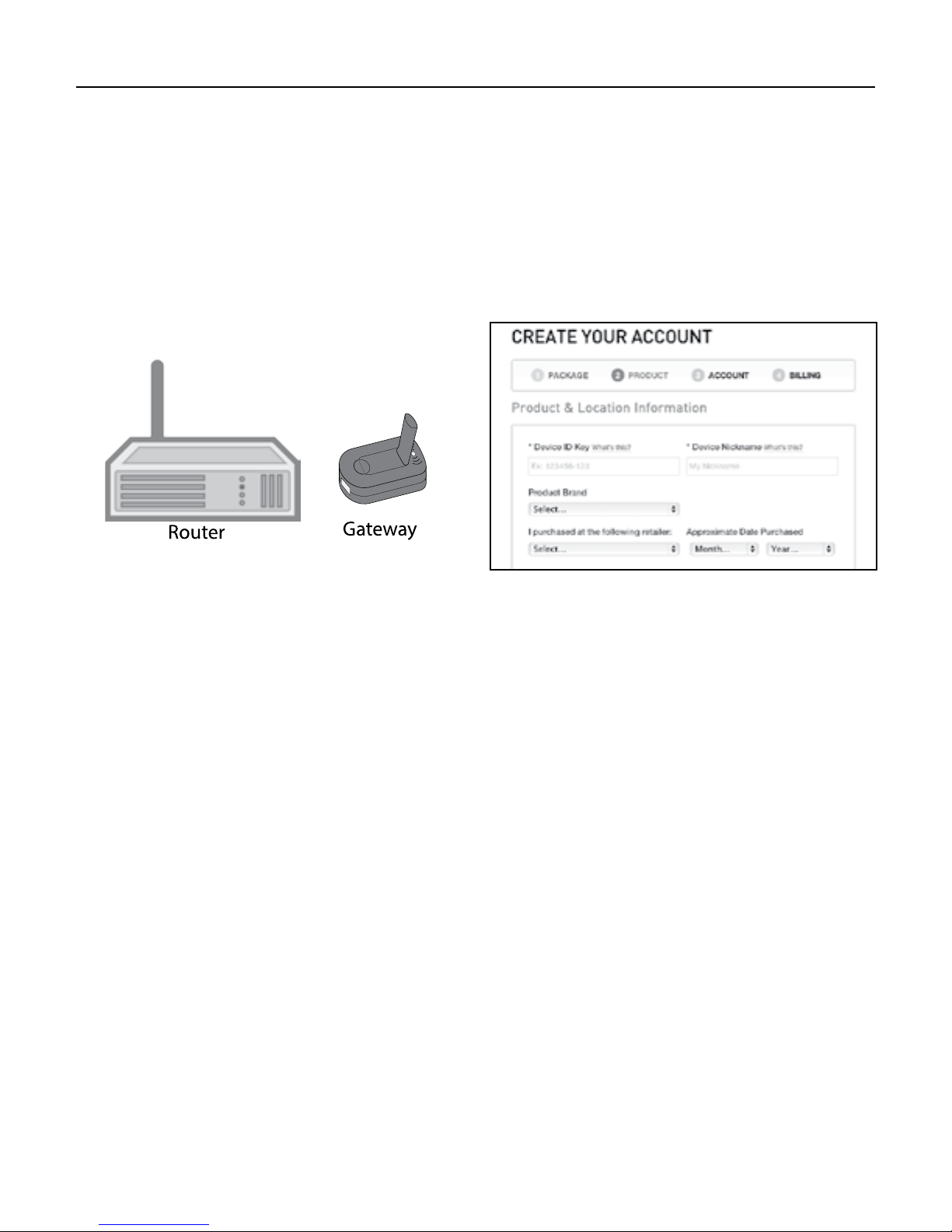

Virtual Water Assistant Setup 11

Battery Backup Internet Connection and

Alerts Configuration

Before setting up the Virtual Water Assistant (VWA), make

sure your Battery Backup Unit is installed correctly, refer

to Owner’s Manual for instruction. Make sure the primary

pump and battery backup unit has power. Verify the system is operational by pressing the ‘TEST SYSTEM’ button

and observing the test sequence.

1. Find an open network connection on your internet

router or other hard-wired connection. Rotate the

antennae up on the gateway.

NOTICE: We recommend the use of an uninterrupted

power supply for your internet modem, home router

and the gateway power supply.

2. Using the supplied 1 meter Ethernet cable (or longer

cable if necessary), connect the gateway to an open

network port.

3. Connect the gateway power supply to a 115 VAC

outlet, plug into the back of the gateway.

• The LED will blink red for a few seconds.

• When the LED becomes solid green or solid

green with an occasional blink your gateway is

connected to the VWA servers.

If not, refer to Gateway Troubleshooting.

4. Once the gateway LED is green, go to the BBU and

verify that the AC power LED is solid green. If not, the

gateway will have to be moved closer to the BBU.

5. Log onto the website www.VirtualWaterAssistant.com

• Select “Sign Up”

• Follow the online instructions and enter the

required personal information to create a user

account. The Alerts will use the e-mail addresses

and phone numbers entered here.

• Enter the Unique Device ID Key included - lo-

cated on BBU case and manual cover.

6. Test installation by clicking the “Test” icon on the

web page and verify the unit has run the test.

7. Refer to the Virtual Water Assistant website for setting

alerts.

8. Alerts can be tested by activating the pump with the

float switch.

Troubleshooting 12

TROUBLESHOOTING - PRIMARY PUMP

Symptom Possible Cause(s) Corrective Action

Pump is not plugged in. Check and see if pump is plugged into a proper outlet.

Blown fuse. If blown, replace with fuse of proper size.

If voltage under recommended minimum, check size of wiring from main

switch on property. If OK, contact power company or hydro authority.

If impeller won’t turn, remove lower pump body and locate source of

binding.

Remove pump and clean pump and piping.

If voltage under recommended minimum, check size of wiring from main

switch on property. If OK, contact power company or hydro authority.

Clean impeller if plugged; otherwise replace pump.

Drill a 1/16” - 1/8” (1.6mm-3.2mm) dia. hole between pump discharge &

check valve (1-2” above where the discharge pipe screws into the pump

discharge and below the waterline).

Be sure check valve is installed correctly.

Pump won’t

start or run.

Pump starts

and stops too

often.

Pump won’t

shut off

Pump

operates but

delivers little

or no water

Low line voltage

Defective motor. Replace pump.

Defective float switch. Replace float switch.

Impeller

Float obstructed Remove obstruction.

Backflow of water from piping Install or replace check-valve.

Faulty float switch Replace float switch.

Defective float switch Replace float switch.

Restricted discharge (obstacle or ice in

piping)

Float obstructed Remove obstruction.

Restricted intake screen Remove the pump and clean the intake screen and the impeller.

Low line voltage

Something caught in impeller Remove the pump and clean out the impeller.

Worn or defective parts or plugged

impeller

Check valve installed without vent

hole.

Restricted intake screen Remove the pump and clean out the intake screen.

Check valve is installed either

backward or upside down

TROUBLESHOOTING - BACKUP PUMP

Pump won’t run: Check all the wiring connections.

Check for a low or defective battery.

Check that the automatic switch is free to move up and down.

Press the circuit breaker reset button on the control panel.

Motor hums but pump won’t run: Check for low or defective battery.

Pump runs but pumps very little or no water: Make sure a check valve is installed and functioning between the

primary pump discharge and the Battery Backup wye.

Check for an obstruction in the discharge pipe.

The discharge pipe length and/or height exceeds the capacity of the

pump.

Check for a low or defective battery.

The Positive (+) and negative (–) pump wires are reversed.

Disconnect them and reconnect correctly.

Pump cycles too frequently: The check valve located between the discharge of the primary

pump and the Battery Backup wye is not installed or is not

working properly. Install an auxiliary check valve or replace the

existing check valve as required.

Troubleshooting 13

TROUBLESHOOTING - VWA GATEWAY

IF GATEWAY LED LIGHT IS NOT GREEN (GREEN, SLOW BLINK) FIRST TRY TO “POWER CYCLE” THE GATEWAY

(UNPLUG THE POWER CORD, WAIT 15+ SECONDS, THEN RE-APPLY POWER).

Gateway Status

Indicator (LED Color)

Green Power on: gateway connected to servers. OK - Connection complete and operational

Green, quick blink Power on: data traffic to servers. OK - Operating, data is moving between BBU and

Green, slow blink

(1-2 blinks per second)

Red Power on: gateway has no local connection to

Red, slow blink

(1-2 blinks per second)

Off Power off or product fault. Check power source, verify power adapter is

Definition Action Needed

Server

Power on: gateway connected to local router, but

not connected to Internet or servers.

router. The gateway does not "recognize/see" that it

is connected to the router.

Power on: gateway communicating with router, but

router cannot assign Dynamic Host Configuration

Protocol (DHCP) or Domain Name System (DNS) to

gateway.

System is online and scanning for destination/server

(add a network switch inline to help define unit).

Check Ethernet cable connections and/or quality or

cable. Try a different router port. Is the router turned

on.

Router is not permitting the gateway to access the

internet (add a network switch inline to help define

unit).

functioning. Defective gateway.

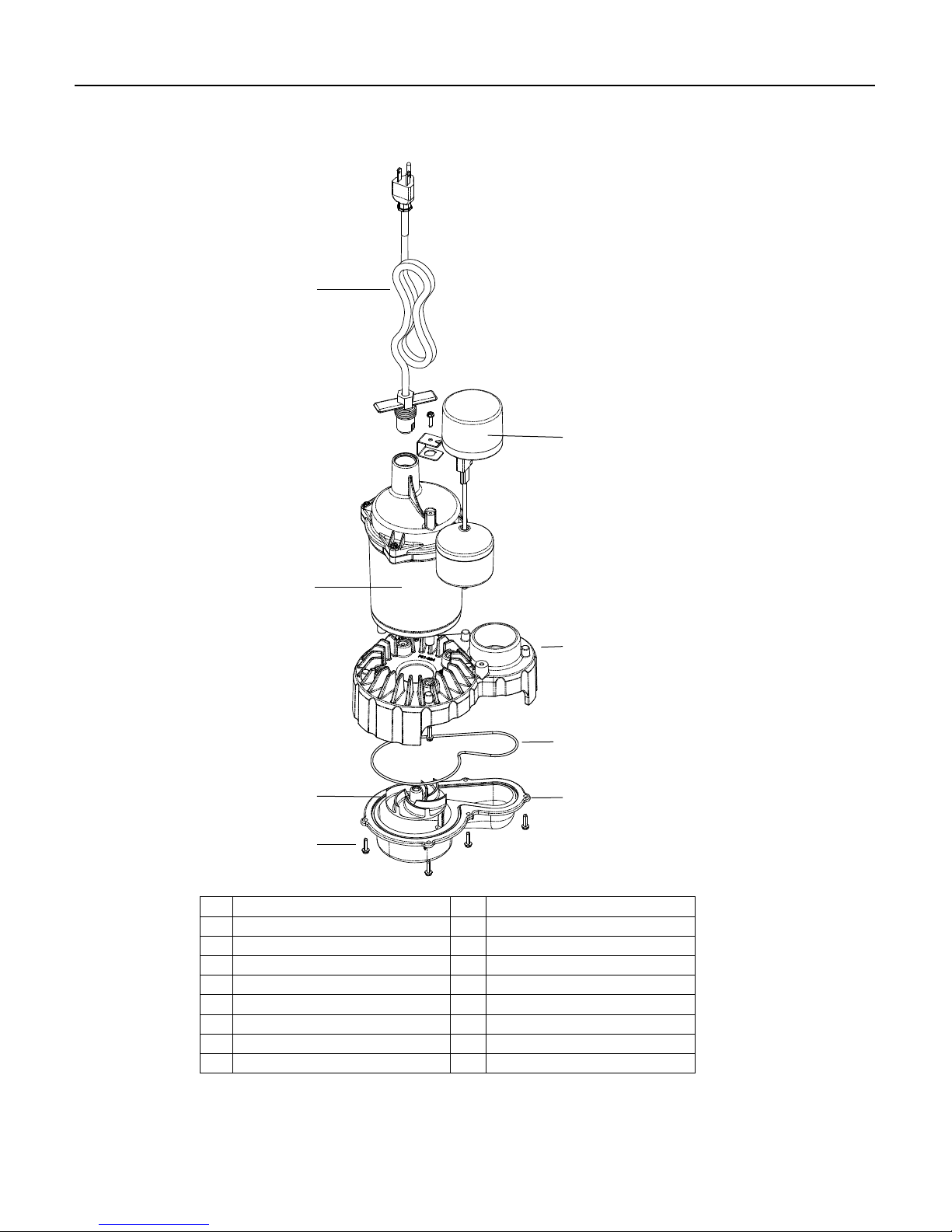

Repair Parts - Primary Pump 14

1

2

3

4

8

5

6

7

Ref Description Qty

1 Power Cord Assembly 1 PS117-54-TSU

2 Vertical Float Switch Assembly 1 FPS17-66

3 Motor 1 *

4 Upper Volute 1 PS1-324

5 Impeller 1 PS5-286

6 Lower Volute 1 PS1-326

7 Screw #8-32 x 1/2” 10 •

8 O-ring -162 Buna-N 5.75” x 3/32” 1 U9-470

*If motor fails, replace entire pump.

•Purchaselocally|

MS50V1

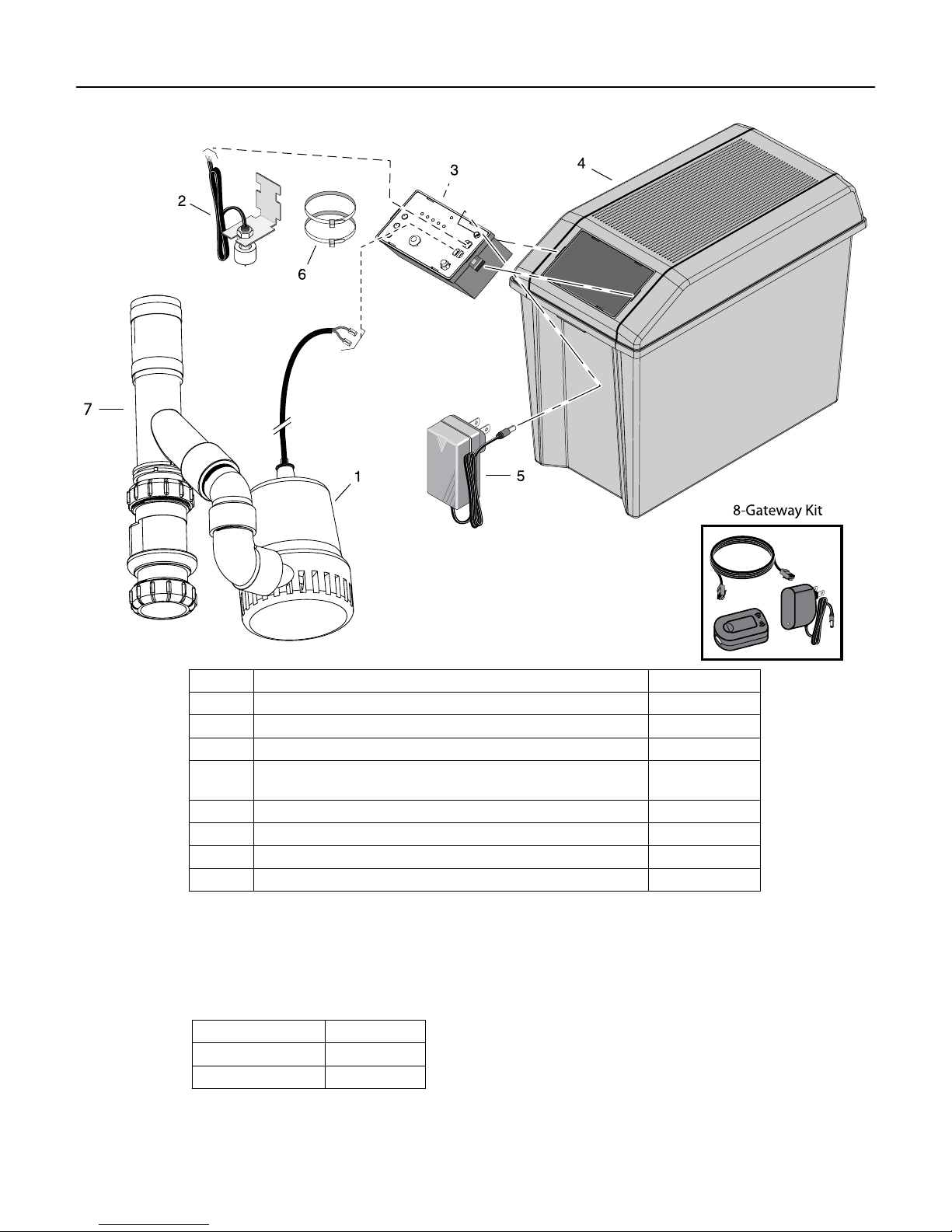

Repair Parts - Battery Backup Unit 15

Key No. Part Description Part Number

1 DC Backup Pump PS17-2005*

2 Float Switch PS17-2003

3 Charger/Controller PS217-1522

4 Battery Case Base

Battery Case Cover

5 AC Adaptor PS17-2008

6 Cable Ties - 11” **

7 Backup Combo Plumbing Kit (with check valves) U137-692

8 Gateway Kit: Gateway, Power Supply, 1m RJ45 Cable U117-1568

* If pump fails, replace entire system.

** Sold separately.

PS17-2044

PS17-2045

Optional Battery Supplies

Sold Separately

Part Description Part Number

AGM 75A-Hour BAT75

AGM 40A-Hour BAT40

Loading...

Loading...