Page 1

BATTERY BACKUP SYSTEM

MBSP-3

ENGLISH: 2-17 FRANCAIS: 18-34 ESPANOL: 35-51

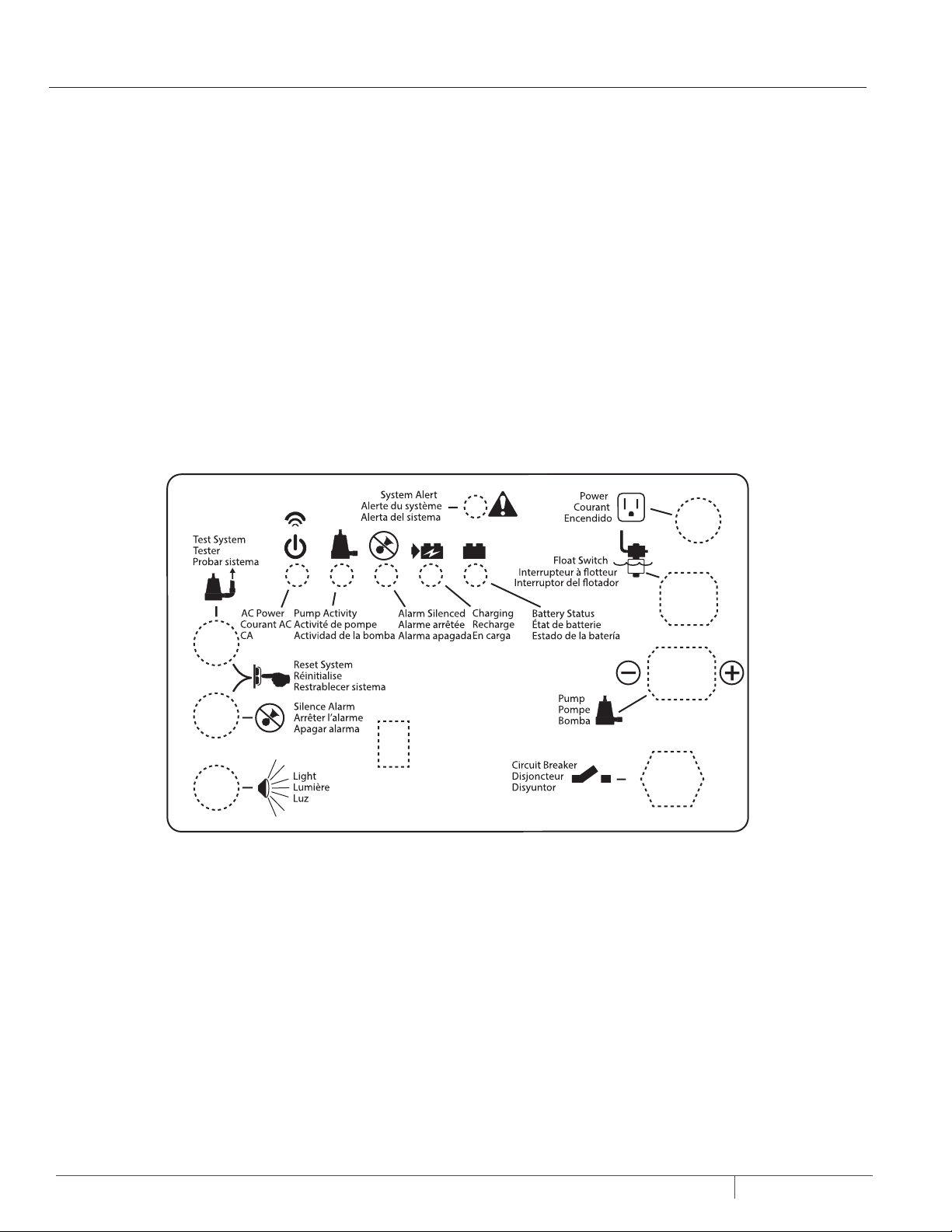

Test System

Tester

Probar sistema

System Alert

Alerte du système

Alerta del sistema

AC Power

Courant AC

CA

Pump Activity

Activité de pompe

Actividad de la bomba

Reset System

Réinitialise

Restrablecer sistema

Silence Alarm

Arrêter l’alarme

Apagar alarma

Light

Lumière

Luz

Power

Alarm Silenced

Courant

Encendido

Alarme arrêtée

Alarma apagada

Interrupteur à otteur

Float Switch

Interruptor del otador

Charging

Recharge

En carga

Battery Status

État de batterie

Estado de la batería

Pump

Pompe

Bomba

Circuit Breaker

Disjoncteur

Disyuntor

+

INSTALLATION AND

OPERATION MANUAL

pentair.com

MY979 (06-08-20) ©2020. All Rights Reserved.

Page 2

TABLE OF CONTENTS

SECTION .................................................................................................................................................................................................. PAGE

Safety Information ..................................................................................................................................................................................3

General Information ................................................................................................................................................................................4

Internet And Alerts Setup ........................................................................................................................................................................5

Installation ..............................................................................................................................................................................................6

Battery Requirements ........................................................................................................................................................................... 10

Wiring And Setup .................................................................................................................................................................................... 11

Charger/Controller Display .................................................................................................................................................................... 13

Troubleshooting .................................................................................................................................................................................... 15

Parts List ............................................................................................................................................................................................... 16

Warranty ................................................................................................................................................................................................ 17

2

MY979 (06-08-20)

Page 3

SAFETY INFORMATION

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS - This manual contains important

instructions that should be followed during installation,

operation, and maintenance of the product.

This is the safety alert symbol. When you see this symbol

on your pump or in this manual, look for one of the following

signal words and be alert to the potential for personal injury!

indicates a hazard which, if not avoided, will

result in death or serious injury.

indicates a hazard which, if not avoided, can

result in death or serious injury.

indicates a hazard which, if not avoided, can or

may result in minor or moderate injury.

NOTE: Addresses practices not related to personal injury.

Keep safety labels in good condition. Replace missing or

damaged safety labels.

To avoid risk of serious bodily injury due to electrical shock

or burns and property damage due to flooding, carefully

read the safety instructions in this manual and on the

pump before installing pump.

Battery acid is corrosive. Do not spill on

skin, clothing, or battery charger. Wear eye and head

protection when working with battery. Connect and

disconnect DC output terminals only after removing the

charger from the AC outlet. Never allow the DC terminals to

touch each other.

Hazardous Voltage. Can cause severe or

fatal electrical shock. Do not plug in or unplug battery

charger while standing on a wet floor or in water. Be sure

one hand is free when plugging in or unplugging charger. If

basement floor is wet, disconnect power to basement

before walking on floor.

Risk of flooding. Do not run pump dry.

To do so will damage seals and can cause leaking

and property damage.

Follow local and/or national plumbing and electrical

codes when installing the system. A ground fault circuit

interrupter (GFCI) is recommended for use on any

electrical appliance submerged in water.

Use this system only for backup sump pump duty in a

residential application. It is not designed as a primary

sump pump.

Do not lift pump by electrical cord.

Risk of electrical shock. Do not lift the

pump by the electrical cord; lift pump only by the

discharge pipe, lifting ring or handle on the pump. Lifting

by the cord can damage the cord.

Pump clear water only with this pump.

Pump is permanently lubricated at the factory. Do not try

to lubricate it!

Keep battery charger and battery box off of the floor and

in a dry, cool, well ventilated area.

NOTE: If a Carbon Monoxide (CO) sensor is installed, it

must be at least 15 feet away from battery charger in

order to avoid nuisance CO alarms. Please refer to your CO

detector’s installation guidelines for more information.

To avoid danger of fire or explosion, keep sparks and flame

(pilot light) away from battery.

Maximum vertical pumping distance is 15 feet (4.6M) .

Make sure sump is clear of debris. Debris can damage the

pump which can result in flooding.

California Proposition 65 Warning

This product and related accessories contain

chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm.

MY979 (06-08-20)

3

Page 4

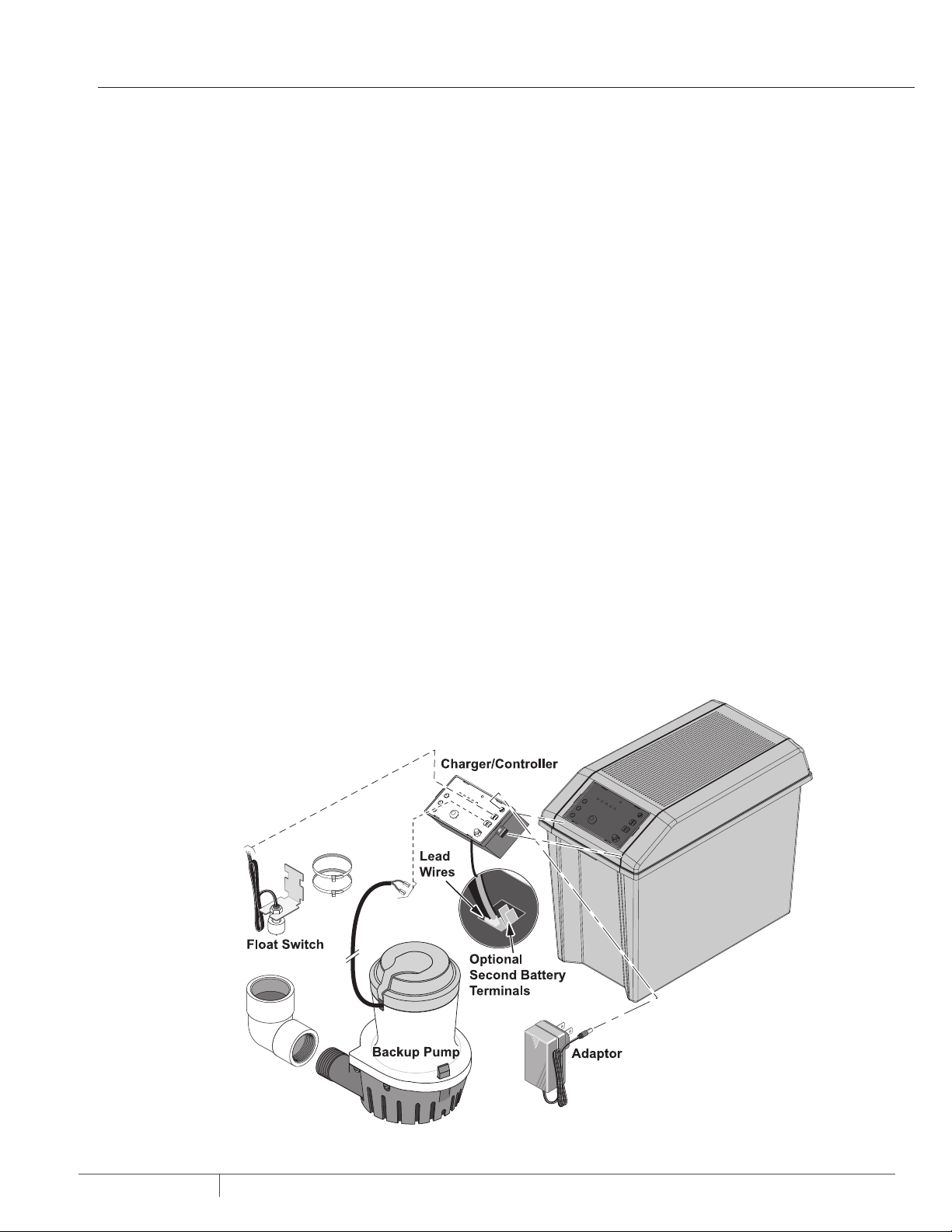

GENERAL INFORMATION

GENERAL INFORMATION

The battery backup sump system is not a substitute for your

primary sump pump. It is designed to temporarily backup your

primary sump pump during a power outage or other problem

which prevents normal operation of the primary pump. Do not

use this system to pump flammable liquids or chemicals. Pump

clear water only with this pump.

Keep the battery charger dry and protected from damage.

This system is designed to work with a deep cycle sealed

maintenance free lead-acid AGM battery. It will also work with

a flooded lead acid battery. Gel and Sealed flooded lead acid

batteries are not recommended.

In an emergency (such as an extended power outage) which

depletes the system deep cycle battery, your automobile

battery may be temporarily substituted. Be sure to replace the

system deep cycle battery as soon as possible.

Use of an automobile battery instead of a deep cycle battery

in this system will significantly reduce the system’s total

performance. Automobile batteries are not designed for this

type of application and will be quickly ruined by the repeated

charge/discharge cycling.

NOTE: This system is not designed for applications involving salt

water, brine, or where fish may be present! Use with these will

void warranty.

BASIC TOOLS AND PARTS NEEDED (PURCHASE SEPARATELY)

Tongue and groove, or large adjustable pliers

Tape measure

Socket wrench or 5/16” nut driver

Side cutters

Hacksaw (to cut PVC pipe)

Medium size pliers

Slotted screwdriver

Phillips head screwdriver

Pencil or marker

PTFE pipe thread sealant tape

PVC glue (solvent weld)

PVC pipe cleaner

Cloth towel

Plastic fittings

Check valve(s) - 1 or 2 depending on installation

38-120 Ampere-Hour Storage or Deep Cycle Battery

PERFORMANCE

HEAD IN FT 0 5 10 15

HEAD IN METERS 0 1.5 3 4.6

GPM 45 34 21 0

LPM 170 129 80 0

BATTERY BACKUP SYSTEM (BBU) INSTALLATION AND OPERATION

Install this system during a time when the primary pump will not

be needed.

Gather all supplies before starting.

Read all warnings and installation steps before you start.

Be prepared for water to leak from the coupling or piping when

disassembling or cutting the discharge pipe. Protect system

components, tools and supplies from getting wet. Dry any work

areas that get wet.

Study pages 5-8 to determine which installation method will be

best for you. The “Separate Discharge” (Figure 2), installation is

recommended.

NOTE: Check your local codes and ordinances regarding waste

water disposal (especially when running the pump discharge

outside the house) before you start. The installation must

conform to all legal requirements.

If possible, install the BBU so that the discharge goes directly

outdoors (separate discharge pipe from the primary sump pump

discharge pipe). If this is not a practical option, see the “Common

Discharge” (Figure 3) option.

For ALL installations, once the installation is complete, run

both the primary sump pump and the BBU through at least one

complete cycle to make sure that everything operates correctly.

REQUIRED BATTERY CAPACITY

For best results, use the following AGM Storage Batteries.

Gal/Charge

Part Amp-Hour

BAT4 0 40 4,800 5 Hours

Unit equipped with dual battery capability

Maximum amp-hour: 120

NOTE: The charger will not fully charge batteries with excessive

at 10’

Approx Run

Time

amp hour ratings without resetting system.

4

Figure 1: Mark Pipe at ‘Start ’ Water Level

MY979 (06-08-20)

Page 5

INTERNET AND ALERTS CONFIGURATION

INTERNET CONNECTION AND ALERTS CONFIGURATION

1. Complete the Battery Backup Registration, Internet

Connection and Alert Configuration BEFORE connecting

the battery and AC power supply to your BBU.

NOTE: If you have already connected the battery and

AC power supply to the BBU before connecting to to the

internet, complete the device registration process.

Then disconnect the battery and remove the AC power

supply from the BBU panel and gateway for 2 minutes in

order to reset the panel. Resume with Step 8.

2. Download the Pentair Home app to your mobile device

from the App Store® or Google Play™ Store.

3. Open the app.

EXISTING USERS: LOGIN to your account.

NEW USERS: Scroll down in the App and click SIGN

UP.

4. Enter a valid EMAIL and PASSWORD.

5. Select TERMS OF SERVICE.

6. Click CREATE AN ACCOUNT.

7. Complete instruction in the VERIFICATION EMAIL

8. LOGIN to your account.

9. Register your device using the Unique Device ID Key

included on the device and your manual cover.

10. The Alerts will use the e-mail(s) and phone number(s)

entered here.

11. Find an open network connection on your internet router

or other hardwired connection (like an internet switch).

12. Rotate the Gateway antenna up on the gateway. Using

the supplied 1 meter Ethernet cable (or a longer cable if

necessary)

13. Connect the Gateway to the open internet port

14. An uninterrupted power supply for your internet modem,

home router and the gateway power supply is recommended.

15. Connect the Gateway power supply to a 115 VAC outlet, plug

the cord into the back of the Gateway.

The Gateway will blink red for a few seconds.

When the LED becomes solid Green or solid Green with

an occasional blink – your Gateway is communicating with

the Link2O server. If not, refer to Gateway Trouble in the

manual.

16. Connect the red positive (+) charger/controller lead wire to the

positive (+) (red) battery terminal.

17. Connect the black negative (-)charger/controller lead wire to

the negative (-) (black) battery terminal.

18. Connect the Charger Power Supply cable (supplied) to the

Charger/Controller’s Power input jack. Plug the other end into

a 115 VAC outlet.

19. Check the AC power LED on the Controller. If it is solid green

the unit is communicating with the web site.

20. Verify the system is operational by pressing the TEST

SYSTEM button and observing the test sequence.

21. Test communication by clicking the Test icon on the web page

and verify the unit has run the test.

22. Using the drop down menu, configure the desired method of

Alerts you want to receive: text or email.

23. Alerts can be tested by activating the pump with thefloat

switch.

Gateway Status Definition Action Needed

Green Power on. Gateway connected to servers. OK - Connection complete and operational

Green, quick blink Power on. Data trac to servers. OK - Operating, data is moving between BBU and server

Green, slow blink

(1-2 blinks per second)

Red Power on. Gateway has no local connection to

Red, slow blink

(1-2 blinks per second)

Off Power off or product fault. Check power source, verify power adapter is

Power on. Gateway connected to local router, but not

connected to Internet or servers.

router. The gateway does not recognize/see that it is

connected to the router.

Power on. Gateway communicating with router, but

router cannot assign Dynamic Host Conguration

Protocol (DHCP) or Domain Name System (DNS) to

gateway.

System is online and scanning for destination/server

(add a net work switch inline to help dene unit).

Check Ethernet cable connections and/or quality or

cable. Try a different router port. Is the router turned on.

Router is not permitting the gateway to access the

internet (add a network switch inline to help dene unit).

functioning. Defective gateway.

Table I: Gateway Troubleshooting

MY979 (06-08-20)

5

Page 6

INSTALLATION

INSTALLATION (TYPICAL): SEPARATE DISCHARGE

Unplug the primary sump pump before beginning this

procedure.

Risk of electrical shock. Can shock, burn, or kill.

1. Allow for overlap when cutting piping and run a trial (dry)

fitting before you glue.

2. Use PTFE pipe thread sealant tape on male ends of

discharge pipe. Thread the 1-1/4” x 1-1/2” elbow (supplied)

onto the discharge. When tight, the elbow must point up.

3. If possible, install the Battery Backup Unit (BBU) on

the floor of the sump. Be sure that the two pumps do

not touch each other and do not interfere with switch

operation.

NOTE: If debris or gravel is present in the bottom of the

sump pit that could get sucked up into the pump, set

both the primary sump pump and the BBU up on bricks or

cinder blocks to prevent clogging.

4. If the sump is too small to allow both pumps to sit on

the bottom of the sump, install an angle bracket on the

primary sump pump’s discharge pipe with stainless steel

hose clamps.

Mount the backup pump on the angle bracket (Figure 2).

5. Cut a piece of 1-1/2” PVC pipe to reach from the backup

pump discharge elbow to about one (1) foot above the

basement floor. This is the lower discharge pipe.

6. To prevent airlocking the pump during operation, drill a

1/8” hole in the lower discharge pipe about 2” above the

bottom of the pipe (below floor level).

7. Install FP0026-10 check valve (purchase separately) on

the upper end of the pipe.

Tighten the hose clamps securely. BE SURE that the flow

arrows point UP (away from the BBU). If they point down,

the valve will not pass water and the pump will not work.

8. Cut a short length of 1-1/2” PVC pipe for a riser pipe and

clamp it into the top of the check valve.

9. Install a U74-68 Hose and Clamp Assembly (sold

separately) on the top of the riser pipe. For 1-1/2” pipe,

remove and discard the short piece of 1-1/4” hose in the

Hose and Clamp Assembly. Leave the hose clamps loose

and slide the Assembly down below the top of the riser

pipe.

10. Determine where you want the discharge to exit the

basement. At that point, drill the necessary holes (large

enough to have clearance for a 1-1/2” pipe) to allow you

to run the discharge pipe from above the sump to the

outdoors.

11. Install the horizontal discharge pipe. Install a 90° elbow on

the inside end but do not glue.

12. Cut another short piece of 1-1/2” PVC for the Upper

Discharge Pipe to run from the top of the riser pipe up to

the 90° elbow. Be sure to allow enough overlap for the glue

joint in the elbow.

13. Do a trial fit with NO GLUE, installing the 1-1/2” upper

discharge pipe in the 90° elbow and the upper discharge

pipe in the vertical end of the 90° elbow.

The upper discharge pipe should just fit between the riser

pipe and the elbow.

14. Whenever using PVC primer and PVC cement, follow the

glue manufacturer’s instructions. Risk of

fire and chemical inhalation.

15. Make sure that the BBU clears the primary sump pump

and its switch. If there isn’t room for both pumps to sit

on the floor of the sump, the BBU will have to be raised

(depending on your particular situation).

16. Clean, prime and glue the upper discharge pipe into the

90º elbow. When the glue has set, slide the Hose and

Clamp Assembly up to cover the joint and tighten all the

hose clamps.

17. Install the Battery Backup Switch as shown, 1” above start

water level of primary pump. Fasten it to the pipe with

cable ties.

18. Tape the pump cord to the riser pipe so that the plug

cannot fall into the sump.

19. Go to BBU WIRING AND SETUP section of this manual for

wiring instructions.

20. Once all wiring is complete, fill your pit with water and

verify that the primary sump pump removes the water and

the BBU doesn’t run.

21. Then, unplug your primary sump pump and refill your pit

with water. Verify that the BBU pump removes the water.

22. Make sure that the power is on to both pumps, and your

system is ready to use.

6

MY979 (06-08-20)

Page 7

INSTALLATION

“Separate Discharge”

NOTICE:

Check Valve Flapper(s) must swing AWAY and flow arrow(s) must point

AWAY from pump being protected.

The water level when the switch shuts off must be above the BBU

pump intake.

* Supplied with the Battery Backup System.

Items in italics must be purchased separately.

Slope DOWN

to outlet

1-1/2” PVC Upper

Discharge Pipe

(cut to fit)

U74-68 Hose and

Clamp Assembly

(Purchase Separately)

1-1/2” PVC Riser Pipe

(cut to fit)

Flow Arrow; Must point

AWAY from Pump

being Protected

FP0026-10

Check Valve

(Purchase

Separately)

Not to scale.

Wiring omitted for clarity.

Sill

Floor

Joist

If the sump is small,

hang the BBU from

the Primary discharge

pipe on an angle bracket.

Lower Discharge Pipe

1-1/2” PVC Pipe

(cut to fit)

Battery Backup

Switch*

Drill 1/8” Anti-Airlock

Hole

1-1/4” FNPTx1-1/2” Slip

Elbow*

PTFE pipe thread

sealant tape on all

threaded joints

Battery Back Up

Sump Pump*

Primary Sump Pump

Check Valve

FLOW

6782 0313a

Figure 2: Separate Discharge - Typical Installation

NOTE: Check valve flapper(s) must swing AWAY and flow arrow(s) must point AWAY from pump being protected.

* The water level when the switch shuts off must be above the BBU pump intake.

MY979 (06-08-20)

7

Page 8

INSTALLATION

INSTALLATION (TYPICAL): COMMON DISCHARGE

Unplug the primary sump pump before beginning this

procedure. Risk of electrical shock. Can shock,

burn, or kill.

1. Allow for over lap when cutting piping and run a trial (dry)

fitting before you glue.

2. If there is no check valve in the primary sump pump’s

discharge, you will need to install one. You must also

install one in the BBU’s discharge pipe (Figure 3). Make

sure that the check valve flow arrow points AWAY from the

pump it is protecting.

3. Use PTFE pipe thread sealant tape on male ends of

discharge pipe. Thread the 1-1/4” x 1-1/2” elbow (supplied)

onto the discharge. When tight, the elbow must point up.

4. If possible, position the BBU on the floor of the sump; be

sure that the two pumps do not touch each other and do

not interfere with switch operation.

NOTE: If debris or gravel is present in the bottom of the

sump pit that could get sucked up into the pump, set

both the primary sump pump and the BBU up on bricks or

cinder blocks to prevent clogging.

5. If the sump is too small to allow both pumps to sit on the

bottom of the sump, find a raised position that doesn’t

interfere with the primary sump pump switch.

6. Cut a piece of 1-1/2” PVC pipe to reach from the backup

pump discharge elbow to about one (1) foot above the

basement floor. This is the lower discharge pipe.

7. To prevent airlocking the pump during operation, drill a

1/8” hole in the lower discharge pipe about 2” above the

bottom of the pipe (below floor level).

8. Install FP0026-10 check valve (purchase separately)

on the upper end of the pipe. Tighten the hose clamps

securely. BE SURE that the flow arrows point UP (away

from the backup pump). If they point down, the valve will

not pass water and the pump will not work.

9. Cut the discharge pipe for the primary sump pump above

the union and check valve (if any). Make this cut about

18” above the top of the BBU’s riser pipe with the backup

pump sitting as installed.

10. If the primary sump pump does not have a check valve

installed in the discharge pipe, install one now.

11. Cut a length of discharge pipe for the primary sump pump

to fit between the check valve and a 45° slip wye. Be sure

to allow for the overlap needed for gluing joints.

12. Install the 45° wye on the primary sump pump’s discharge

pipe.

13. Install a 45° elbow on the 1-1/2” BATTERY BACKUP

discharge pipe.

14. Fit the upper discharge pipe to the upper end of the wye.

NOTICE: It is good practice to cut a short length of pipe to

go into the wye and install a union on the pipe. Continue

the discharge pipe from the outlet side of the union.

This will allow easier removal of the system for cleaning

or service. A U74-68 Hose and Clamp Assembly (sold

separately) can be used for this.

15. Make sure that the BBU will clear the primary sump pump

and its switch. If there isn’t room for both pumps to sit

on the floor of the sump, the BBU will have to be raised

(depending on your particular situation).

16. Do a trial assembly to make sure that everything is

going to fit. This may require a helper to assist in holding

everything together while you check the fit without glue.

Mark all joints before gluing.

Follow the glue manufacturer’s instructions regarding fire

hazards and ventilation when using PVC solvents, primer,

and cement. Risk of fire and chemical

inhalation.

17. Take all the pipe apart, clean all joints, and then

reassemble the system, gluing it with PVC primer and

glue.

18. Install the Battery Backup Switch as shown, 1” above start

water level of primary pump. Fasten it to the pipe with the

cable ties provided.

19. Tape the pump cord to the riser pipe so that the plug

cannot fall into the sump.

20. Go to BBU WIRING AND SETUP section of this manual for

wiring instructions.

21. Once all wiring is complete, fill your pit with water and

verify that the primary sump pump removes the water and

the BBU doesn’t run.

22. Then, unplug your primary sump pump and refill your pit

with water. Verify that the BBU pump removes the water.

23. Make sure that the power is on to both pumps, and your

system is ready to use.

8

MY979 (06-08-20)

Page 9

INSTALLATION

“Common Discharge”

NOTICE: In this installation, if the Primary Sump Pump (PSP) does not have a

check valve installed below the wye, you MUST install a check valve for the PSP

as shown. This prevents backflow of water into the sump from the Battery Backup

System. Check Valve Flapper(s) must swing AWAY and flow arrow(s) must point

AWAY from the pump being protected.

The water level when the switch shuts off must be above the BBU pump intake.

Typical installation,

assembled.

Both check valves

must be installed

on the pump side

of the wye.

Optional 1-1/2”

PVC Pipe (cut to fit)

45º Slip Elbow

Battery Backup

Switch*

1-1/2” PVC Pipe

(cut to fit)

Flow Arrow; Must point

AWAY from Pump

being Protected

FP0026-10

Check Valve

(Purchase

Separately)

Lower Drischarge Pipe

1-1/2” PVC Pipe

(cut to fit)

Drill 1/8”

Anti-Airlock Hole

1-1/4” FNPTx1-1/2”

Slip Elbow*

PTFE pipe thread

sealant tape on all

threaded joints

Battery Back Up

Sump Pump*

Not to scale.

Wiring omitted for clarity.

Supplied with the Battery Backup System.

*

Items in italics must be purchased separately

1-1/2” PVC Upper

Discharge Pipe

(cut to fit)

U74-68 Hose and

Clamp Assembly

(Purchase Separately)

FLOW

1-1/2” PVC Riser Pipe

(cut to fit)

45 degree Slip Wye

AlternateWye/Elbow

Setup

Primary Pump

Discharge Pipe

(cut to fit)

Thread to Slip

Adapter

Primary Pump

Check Valve

Flow Arrow; Must point

FLOW

AWAY from Pump

being Protected

Primary Sump Pump

Discharge Port

45º Slip Street

Elbow

Figure 3: Common Discharge Pipe - Typical Installation

In this installation, if the primar y sump pump does not have a check valve installed below the wye, you MUST

install a check valve for the primary sump pump as shown. This prevents backflow of water into the sump from

the battery backup system.

Check Valve Flapper(s) must swing away and flow arrow(s) must point away from the pump being protected.

The water level when the switch shuts off must be above the BBU pump intake.

MY979 (06-08-20)

9

Page 10

BATTERY REQUIREMENTS

BATTERY REQUIREMENTS

Install the battery in the battery case. To prevent accidental

shorting across battery terminals, close and latch the battery

case securely. Do not leave the battery uncovered.

Hazardous electric current. Can cause severe

burns and start a fire if the battery terminals are short

circuited.

Do not allow children to play around the battery backup

system installation.

The performance of your backup sump pump depends on

the battery used with it for power. We recommend using

our BAT40. You can also use a group 24M or 27M Deep Cycle

battery. They will provide acceptable performance and will

stand up well to long periods of little or no use.

This system is designed to work with either a sealed lead-acid

AGM battery or a flooded lead-acid batter y. Use of a true Gell

Cell (often confused for AGM) or a standard automotive battery

with this charger is not recommended. An automotive battery

may require charging after only 1-2 hours of continuous use,

and the repeated charging cycles may cause early plate failure

in the battery.

Use only lead-acid batteries. This unit is not designed to

use with Li-Ion, NiMh, NiCAD, Liquid Polymer, etc.

Use only the recommended battery or one of the same

type and size so it will fit in the battery box (maximum size:

13” long x 7” wide x 10” tall (330.2mm x 177.8mm x 254mm)

including terminals) and supply enough voltage for full

performance.

BATTERY MAINTENANCE

To protect the battery case from chipping and gouging, do

not let the battery sit on a concrete floor.

Install the battery on a shelf or protective pad (plywood,

2x4s, etc.).

Always install the battery in a dry location that is

protected from flooding.

Severe burn hazard. An acid-filled standard

lead-acid battery contains sulfuric acid. Avoid contact with

skin, eyes or clothing.

PRE-QUALIFICATION TEST – 1 AND 2

Charger is charging at a very low level to try to bring a dead

battery back to life.

SPECIAL FEATURES

The charger is equipped with reverse battery, short circuit,

and “runaway charge” protection.

POSSIBLE PROBLEMS AND REMEDIES

1. Wrong Battery Voltage: Reconnect charger to a 12 volt

batter y.

2. Reversed Battery Connections: Check all connections.

The negative (black) on the battery must connect to the

negative (black) on the charger, and the positive (red)

on the battery must connect to the positive (red) on the

charger. Reversing the batter y connections will cause the

System Alert and Silenced Audible Alarm LEDs to flash.

3. Thermal Runaway Condition: “Thermal Runaway” is the

technical term for the condition of the battery when some

(or all) of the cells have deteriorated to the point that they

won’t take a charge. In this case, replace the battery.

4. Charge Time Monitor – 1 and 2: Battery took too long to

complete its charge. The Charge Time Monitor will shut

down the charger after 84 hours of continuous charging.

Possible causes are:

Pump ran for a long period of time during charging, or

Battery is too large for the charger (including several

batteries connected in a parallel circuit).

EXCESSIVE BATTERY DRAIN

Pump may have run for a very long time, discharging the

batter y.

1. If 115VAC power is OFF, the charger shuts down until the

power comes back on, but the pump will run as long as the

battery charge lasts. You may need to replace the battery

afterwards.

2. If 115VAC power is ON, the charger/controller continues to

try to charge the battery at a charging rate of .5 AH until

the battery charge is more than 20%, at which point the

charger will resume charging at a rate of 2 AH.

3. If the pump is running and the AC power is on, you may

need to stop the pump to allow the battery to charge.

Follow the battery manufacturer’s recommendations for

maintenance and safe use of the battery.

If the battery is taking too long, try resetting the charger once

or twice (push the System Test and Silence Alarm buttons

together to reset the charger).

10

MY979 (06-08-20)

Page 11

WIRING AND SETUP

WIRING AND SETUP

1. Connect the positive (+) charger/controller lead wire (red)

to the positive (+) battery terminal (red).

2. Connect the negative (–) charger/controller lead wire

(black) to the negative (–) terminal (black) on the battery.

3. If you are using two batteries, use the set of optional

terminals and connect the second battery. Use lead

wires (not included) to connect the positive (+) charger/

controller terminal to the positive (+) battery terminal and

the negative (–) charger/controller terminal to the negative

(–) battery terminal.

4. The backup pump leads are polarity sensitive. Connect

the positive pump lead to the terminal labeled Pump ‘+’ and

the negative pump lead to the terminal labeled Pump ‘–’.

NOTE: If the leads are reversed, the pump will run

backward and not pump water.

5. The float switch leads are not polarity sensitive. Connect

the float switch leads to the Float Switch tabs on the

charger/controller.

6. Test the float and the pump by lifting and holding the float.

The system alert LED will blink while the float is up.

The Pump Status LED will light continuously and the

buzzer will beep steadily.

The pump should start after 3 seconds.

If the pump does not run, check all the connections

and remake them as necessary.

7. To stop the pump, lower the float. After 25 seconds the

pump should stop, the Pump Status LED should flash, and

the buzzer should beep.

8. With the pump operating, test the ‘SILENCE ALARM’

button:

Hold for one second; release.

The Alarm Silenced LED should illuminate and the

buzzer should stop sounding.

To reset the buzzer (allow it to sound) and extinguish

the Alarm Silenced LED, press the ‘Silence Alarm’

button again for one second.

Depress the Test System button. Hold it for one

second and then release. The Pump Status LED

should stop flashing.

MY979 (06-08-20)

Figure 4: Wiring and Setup

11

Page 12

WIRING AND SETUP

During normal operation, the flashing Pump Status LED

indicates that the pump has run in your absence.

Press and hold Test System button. All LEDs will light up,

pump will run and buzzer will sound.

Release the button and LEDs should go off, pump should

stop, buzzer should stop.

The Battery Status LED indicates the battery capacity

when the A.C. power is off.

1. Continuously ON - the battery voltage is above 10.9 Volts

Direct Current (10.9VDC) and capacity is above 20%.

2. Slow Beep/Slow LED Flash - the battery ’s capacity is

between 0 and 20%.

3. Fast Beep/Fast LED Flash - the battery is severely

discharged. The battery will continue to charge (as long

as the 115V AC power to the charger is on) at the rate of

.5 AH until the battery’s charge is above 20%.

When the first warning occurs (slow beep/slow flash),

you will have approximately 2 hours (or less) of pump

operation left. The actual time of operation will depend

on the condition of the battery and may be as little as 15

minutes.

Connect the Power Supply cable (supplied) to the Charger/

Controller’s Power Input jack.

12

Figure 5: LED Display and Control Buttons

When the unit is first plugged in, or when it first receives power from the battery, the Battery Status LED will flash for 3

seconds.

To activate any Control Button, press and hold it for 1 second.

MY979 (06-08-20)

Page 13

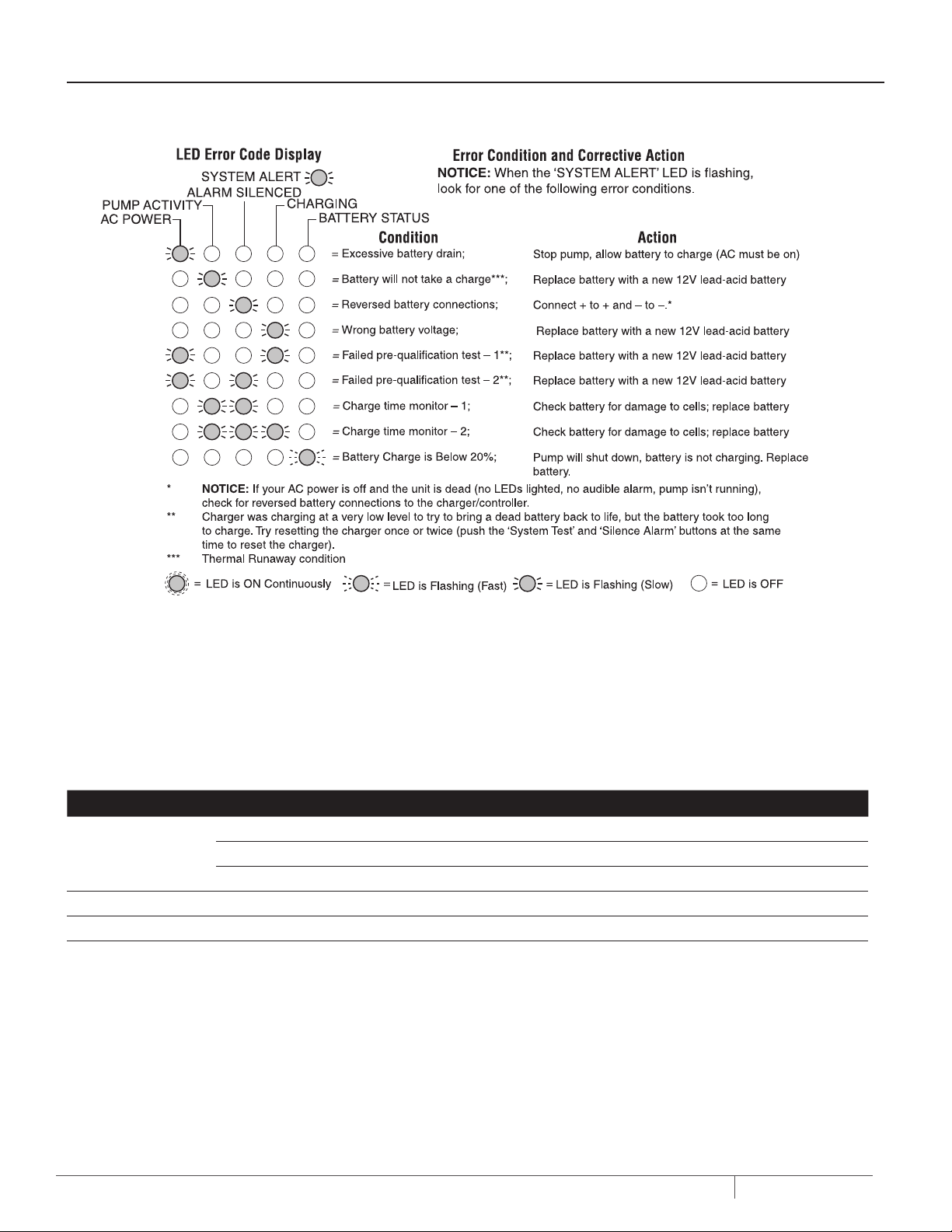

CHARGER/CONTROLLER LED DISPLAY

LED Operating Code Display

System Operating Condition

AC POWER

SYSTEM ALERT

PUMP ACTIVITY

ALARM SILENCED

CHARGING

BATTERY STATUS

Indicates 115V AC Power is connected / Unit online

Indicates 115V AC Power is connected / Unit offline

Indicates Pump is running (continuous LED)

Indicates Fast flashing LED: Pump has run

Indicates Audible alarm is switched off

Indicates Fast flashing LED: Battery pre-qualification test is running

Indicates Battery is charging normally

Indicates Continuous LED: battery charge is above 20%,

system is maintaining charge

Indicates Slow flashing LED: battery charge is below 20%

= =

LED is ON Continuously

=

LED is Flashing (Fast)

=

LED is Flashing (Slow)

LED is OFF

Figure 6: Operating Code Displays

(LEDs Lighted Continuously or Flashing)

When the System Alert light IS NOT flashing, refer to Figure 6.

When the System Alert light IS flashing, refer to Figure 7 .

All of the situations listed above indicate normal system operation; no action is required. However, if the BBU pump is running or

has run, check the primary pump and actively monitor the charger status for batter y life. Always reset the charger after the pump

runs.

During normal system operation, the SYSTEM ALERT LED blinks while the float switch is on,indicating the pump should start

within 3 seconds. The “AC POWER” LED is lighted (solid or blinking) as long as the system is plugged in to an operating AC power

circuit.

CONTROL LED CONTINUOUS ILLUMINATION INDICATES NORMAL OPERATION

AC Power AC power is present. Unit is online.

Pump Status The oat switch has been activated. The LED remains on (ashing) after the pump has stopped.

Depress the ‘System Test’ button to reset it.

Silenced Audible Alarm Audible Alarm has been silenced. Press and release the ‘Silence Alarm’ button to reset (activate) the

audible alarm and turn OFF the LED.

Charging Indicates that the battery is charging – see Table II, above.

Battery Status Continuous ON - the battery voltage is above 10.9 Volts DC and capacity is above 20%.

Slow Beep/Slow LED Flash - the battery’s capacit y is below 20%, and voltage is between 8.2VDC and

10.9VDC.

Fast Beep/Fast LED Flash - the battery has been discharged to less than 8.2VDC.

System Alert Flashing (in unison with the buzzer) indicates that the charger has entered ‘Failure Mode’. Press the

System Test and Silence Alarm buttons to reset it. If the source of the failure is not corrected, the

charger will reenter Failure Mode. See Table IV for error code information.

MY979 (06-08-20)

Table II: LED Function Displays (LEDs Lighteded Continuously)

13

Page 14

CHARGER/CONTROLLER LED DISPLAY

Figure 7: Error Code Displays (LEDs Flashing)

When the System Alert light IS NOT flashing, refer to Figure 6.

When the System Alert light IS flashing, refer to Figure 7 .

CONTROL BUTTON: RESULT OF PUSHING BUTTON:

System Test Pump starts and all LEDs light up.

Will reset the pump Activity LED.

When pushed with the Silence Alarm button, the Charger/Controller microprocessor resets and error code resets.

Silence Alarm Toggle; Prevents the audible alarm sounding. Press and release to reset.

Light Toggles the light on the Charger/Controller on and off.

System Reset Press and release Test System and Silence Alarm to reset system.

Table II: Control Button Functions

14

MY979 (06-08-20)

Page 15

TROUBLESHOOTING

TROUBLESHOOTING - PUMP

Pump won’t run. Check all the wiring connections.

Check for a low or defective battery.

Check that the automatic switch is free to move up and down.

Press the circuit breaker reset button on the control panel.

Motor hums but pump won’t run. Check for low or defective battery.

Make sure a check valve is installed and functioning between the primary pump discharge and the

Battery Backup wye.

Pump runs but pumps very little or no

water.

Pump cycles too frequently. The check valve located between the discharge of the primar y pump and the Battery Backup wye is

Check for an obstruction in the discharge pipe.

The discharge pipe length and/or height exceeds the capacity of the pump.

Check for a low or defective battery.

The Positive (+) and negative (–) pump wires are reversed. Disconnect them and reconnect

correctly.

not installed or is not working properly. Install an auxiliary check valve or replace the existing check

valve as required.

MY979 (06-08-20)

15

Page 16

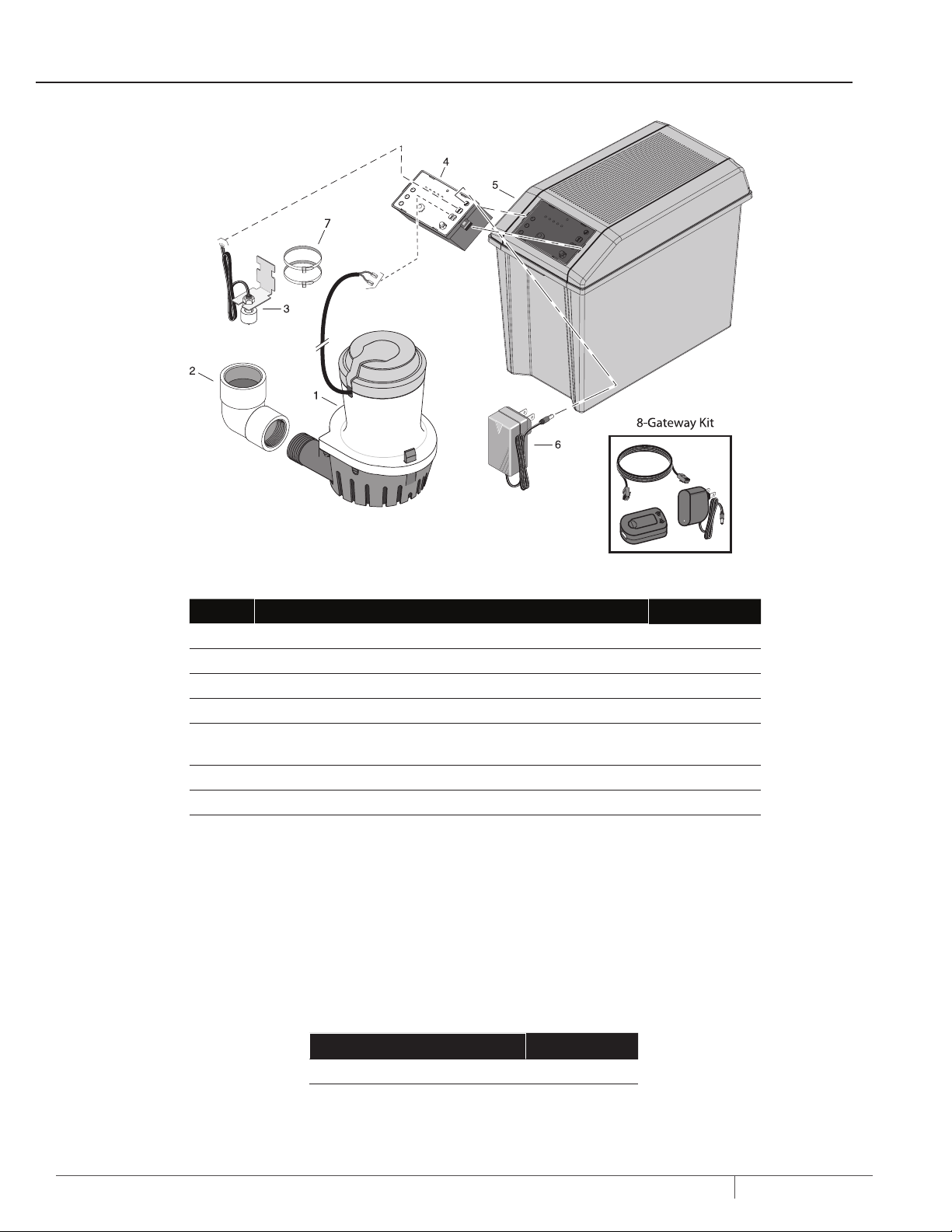

PARTS LIST

Key No. Part Description Part Number

1 DC Backup Pump PS17-2005*

2 1-1/4 FNP T x 1-1/2 Slip Elbow U78-1012

3 Float Switch PS17-2003

4 Charger/Controller PS217-1522

5 Battery Case Base

Battery Case Cover

6 AC Adaptor PS17-2008

7 Cable Ties - 11” **

8 Gateway Kit (Gateway, Power Supply, 1m RJ45 Cable) U117-1568

PS17-204 4

PS17-204 5

* If pump fails, replace entire system.

** Sold separately.

NOTICE: All check valves must be installed as described in the installation instructions or the warranty is

void. This includes the check valve for the primary sump pump in a Common Discharge installation.

Optional Batterry Supplies Sold Separately

Part Description Part Number

AGM 40A-Hour BAT4 0

Second Batter y Case & Cable U117-1577

16

MY979 (06-08-20)

Page 17

WARRANTY

Limited Warranty

Myers® warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free from

defects in material and workmanship for the Warranty Period shown below.

Product

Jet pumps, small centrifugal pumps, submersible pumps and

relatedaccessories

Fibrewound Tanks 5 years from date of original installation

Steel Pressure Tanks 5 years from date of original installation

Sump/Sewage/Effluent Products

Battery Backup Units

MBSP-2, MBSP-2C

MBSP-3, MBSP-3C

Wastewater Solids Handling Pumps

Our warranty applies only where such products are used in compliance with the requirements of the applicable product catalog

and/or manuals. For additional information, please refer to the applicable standard limited warranty featured in the product manual.

Our warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication, improper

installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase power

through a phase converter will void the warranty. Note also that three phase motors must be protected by three-leg, ambient

compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and MYERS’s only duty, is that MYERS repair or replace defective products (at MYERS’s choice). You must pay all

labor and shipping charges associated with this warranty and must request warranty service through the installing dealer as soon

as a problem is discovered. No request for service will be accepted if received after the Warranty Period has expired. This warranty

is not transferable.

MYERS SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE

FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an

implied warranty, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You

may also have other rights which vary from state to state.

Warranty Period

whichever occurs first:

12 months from date of original installation,

or 18 months from date of manufacture

12 months from date of original installation,

or 36 months from date of manufacture

12 months from date of original installation,

or 18 months from date of manufacture

24 months from date of original installation,

or 30 months from date of manufacture

12 months from date of shipment from factory

or 18 months from date of manufacture

This Limited Warranty is effective April 1, 2014 and replaces all undated warranties and warranties dated before April 1, 2014.

F.E. MYERS

293 Wright Street, Delavan, WI 53115

MY979 (06-08-20)

17

Page 18

SYSTÈME DE SECOURS À BATTERIE

MBSP-3

Test System

Tester

Probar sistema

System Alert

Alerte du système

Alerta del sistema

AC Power

Courant AC

CA

Pump Activity

Activité de pompe

Actividad de la bomba

Reset System

Réinitialise

Restrablecer sistema

Silence Alarm

Arrêter l’alarme

Apagar alarma

Light

Lumière

Luz

Power

Alarm Silenced

Courant

Encendido

Alarme arrêtée

Alarma apagada

Interrupteur à otteur

Float Switch

Interruptor del otador

Charging

Recharge

En carga

Battery Status

État de batterie

Estado de la batería

Pump

Pompe

Bomba

Circuit Breaker

Disjoncteur

Disyuntor

+

MANUEL D’INSTALLATION

ET D’UTILISATION

pentair.com

MY979 (08-06-20) ©2020. Tous droits réservés.

Page 19

TABLE DES MATIÈRES

SECTION .......................................................................................................................................................................................................................PAGE

Renseignements relatifs à la sécurité ...................................................................................................................................................................... 20

Renseignements généraux ....................................................................................................................................................................................... 21

Conguration de la connexion Internet et des alertes ............................................................................................................................................. 22

Installation ................................................................................................................................................................................................................ 23

Exigences relatives à la batterie ............................................................................................................................................................................... 27

Câblage et installation .............................................................................................................................................................................................. 28

Achage du chargeur/contrôleur ............................................................................................................................................................................ 30

Dépannage ................................................................................................................................................................................................................ 32

Liste des pièces ........................................................................................................................................................................................................ 33

Garantie ..................................................................................................................................................................................................................... 34

MY979 (06-08-20)

19

Page 20

CONSIGNES DE SÉCURITÉ

IMPORTANTES CONSIGNES DE SÉCURITÉ

CONSERVEZ CES INSTRUCTIONS – Ce manuel comporte des

consignes impor tantes qui doivent être suivies lors de l ’installation,

de l’utilisation et de l’entretien du produit.

Ceci est le symbole d’aler te de sécurité. Si vous voyez ce

symbole sur votre pompe ou dans ce manuel, recherchez l ’un des

mots d’avertissement ci-dessous et faites attention aux risques de

blessures!

indique un danger qui, s’il n’est pas évité, entraînera la

mort ou des blessures graves.

indique un danger qui, s’il n’est pas évité, peut

entraîner la mort ou des blessures graves.

indique un danger qui, s’il n’est pas évité, peut ou

pourrait entraîner des blessures légères ou moyennement graves.

REMARQUE: concerne des pratiques non liées aux lésions

corporelles.

Conservez les étiquettes de sécurité en bon état. Remplacez-les

si elles sont manquantes ou endommagées.

Pour éviter tout risque de blessures graves causées par un

choc électrique ou par des brûlures, ainsi que des dommages

matériels en raison d’une inondation, lisez attentivement et

suivez toutes les instructions de sécurité figurant dans ce

manuel et sur la pompe avant d’installer la pompe.

les éclaboussures sur la peau, les vêtements ou le chargeur

de batterie. Portez un équipement de protection pour les yeux

et la tête lorsque vous manipulez la batterie. Branchez et

débranchez les bornes de sortieCC uniquement après avoir

débranché le chargeur de la prise de courantCA. Ne laissez

jamais les bornes de courant continu(CC) se toucher.

un choc électrique grave ou mortel. Ne branchez ou ne

débranchez pas le chargeur de batterie lorsque vous vous

trouvez sur un plancher mouillé ou dans l’eau. Assurez-vous

de garder une main libre lorsque vous branchez ou débranchez

le chargeur. Si le plancher du sous-sol est mouillé, coupez

l’alimentation électrique du sous-sol avant de marcher sur

le plancher.

L’acide de batterie est corrosif. Évitez

Tension dangereuse. Peut provoquer

Risque d’inondation. Ne faites pas

fonctionner la pompe à sec. Cela endommage les

joints et pourrait provoquer des fuites et des

dommages matériels.

Conformez-vous aux codes de plomberie et d’électricité

lorsque vous installez le système. Il est recommandé d’utiliser

un disjoncteur différentiel de fuite à la terre (DDFT) lors de

l’utilisation d’un appareil électrique immergé sous l’eau.

N’utilisez ce système que comme pompe de puisard de secours

à utilisation résidentielle. Ce système n’est pas conçu pour être

utilisé comme pompe de puisard principale.

Ne soulevez pas la pompe par le cordon électrique.

pas la pompe par le cordon électrique, soulevez-la uniquement

par le tuyau d’évacuation, l ’anneau de levage ou la poignée de

la pompe. Soulever la pompe par le cordon peut endommager

ce dernier.

Utilisez cette pompe uniquement pour pomper de l’eau claire.

La pompe est dotée d’une lubrification permanente installée

en usine. N’essayez pas de la lubrifier!

Gardez le chargeur de batterie et le compartiment de batterie

à l’écart du plancher, dans un endroit sec, frais et bien aéré.

REMARQUE: Si un détecteur de monoxyde de carbone(CO)

est installé, il doit se situer à au moins 15pieds du chargeur de

batterie pour éviter les fausses alarmes. Pour obtenir de plus

amples renseignements, veuillez consulter les instructions

d’installation de votre détecteur de monoxyde de carbone.

Pour éviter les risques d’incendie ou d ’explosion, gardez la

batterie loin de sources étincelles et de flammes (par exemple,

un brûleur de veilleuse).

La distance verticale maximale de pompage est de 15pi (4,6m).

Assurez-vous que la pompe de puisard ne contient pas de

débris. Les débris peuvent endommager la pompe et causer

des inondations.

Avertissement concernant la proposition 65 de la Californie

contiennent des produits chimiques considérés par l’État de la

Californie comme pouvant causer le cancer, des anomalies

congénitales ou d’autres troubles du système reproducteur.

Risque de choc électrique. Ne soulevez

Ce produit et les accessoires connexes

20

MY979 (06-08-20)

Page 21

RENSEIGNEMENTS GÉNÉRAUX

Marquer le tuyau

RENSEIGNEMENTS GÉNÉRAUX

Cette pompe de secours à batterie ne remplace pas votre pompe de

puisard principale. Elle est conçue pour remplacer temporairement

votre pompe de puisard principale pendant une panne de courant

ou tout autre problème qui empêche son fonctionnement normal.

N’utilisez pas cette pompe pour pomper des liquides ou des produits

chimiques inflammables. Utilisez cette pompe uniquement pour

pomper de l’eau claire.

Gardez le chargeur de batterie au sec et protégez-le contre

les dommages.

Ce système est conçu pour fonctionner avec une batterie au plombacide à séparateur s en fibre de verre microporeuse (absorbent glass

mat, ou «AGM»), scellée, sans entretien, et à décharge poussée.

Le système peut également fonctionner avec une batterie au plombacide à électroly te liquide. Les batteries au plomb-acide à électrolyte

gélifié ou scellées à électrolyte liquide ne sont pas recommandées.

En cas d ’urgence (par exemple, lors d’une panne de courant

prolongée) qui épuise la batterie à décharge poussée, celle-ci peut

être remplacée temporairement par la batterie de votre automobile.

Assurez-vous de remettre en place la batterie à décharge poussée

dès que possible.

L’utilisation de ce système avec une batterie d’automobile au lieu

d’une batterie à décharge poussée diminue considérablement la

performance d’ensemble du système. Les batteries d’automobile

ne sont pas conçues pour ce type d’utilisation et se détériorent

rapidement par des cycles répétés de recharge et de décharge.

REMARQUE: Ce système n’est pas conçu pour être utilisé avec de

l’eau salée, de la saumure, ou en présence de poissons! Une telle

utilisation aura pour effet d’annuler la garantie.

OUTILS DE BASE ET PIÈCES NÉCESSAIRES (VENDUS SÉPARÉMENT)

CAPACITÉ DE BATTERIE NÉCESSAIRE

Pour obtenir de meilleurs résultats, utilisez les batteries

AGM suivantes:

REMARQUE: Le chargeur ne pourra pas recharger complètement

les batteries d’une capacité de charge excessive sans une

réinitialisation du système.

Pince multiprise ou prince réglable de grande taille

Ruban à mesurer

Clé ou tournevis à douille de 5/16po

Pince coupante de côté

Scie à métaux (pour couper les tuyaux en PVC)

Pince de taille moyenne

Tournevis à tête plate

Tournevis cruciforme

Crayon ou marqueur

Ruban d’étanchéité pour filetage de tuyau en PTFE

Colle pour PVC (collage au solvant)

Produit nettoyant pour tuyau en PVC

Linge en tissu

Raccords en plastique

Clapet(s) de non-retour – un ou deux, selon l’installation

Batterie rechargeable ou à décharge poussée de 38

à 120ampères-heures

Pièce Ah Gal par recharge à 10pi Autonomie approximative

BAT4 0 40 4 800 5heures

L’appareil peut être équipé de deux batteries

Charge maximale (Ah): 120

PERFORMANCE

HAUTEUR EN PI 0 5 10 15

HAUTEUR EN MÈTRES 0 1,5 3 4,6

gal/min 45 34 21 0

l/min 170 129 80 0

SYSTÈME DE SECOURS À BATTERIE: INSTALLATION

ET FONCTIONNEMENT

Installez ce système lorsqu’il n’est pas nécessaire de faire

fonctionner la pompe principale.

Rassemblez toutes les pièces et tous les outils nécessaires avant

de commencer.

Lisez tous les avertissements et toutes les étapes d’installation

avant de commencer.

Attention! De l’eau pourrait s’écouler des raccords ou de la

tuyauterie lorsque vous démontez ou coupez le tuyau d ’évacuation.

Faites attention à ne pas mouiller les composants du système,

les outils et les pièces. Séchez toutes les zones de travail qui sont

mouillées.

Consultez les pages5 à 8 pour déterminer la méthode d’installation

qui vous convient le mieux. Une installation à «évacuation

séparée» (voir la figure2) est recommandée.

REMARQUE: Consultez les codes et les règlements locaux

concernant l’élimination des eaux usées (surtout si vous déversez

le rejet d’eau de la pompe à l’extérieur de la maison) avant de

commencer. L’installation doit être conforme à toutes les

exigences prévues par la loi.

Si cela est possible, installez le système de secours à batterie de

façon à ce que le rejet d ’eau soit dirigé directement à l’extérieur

(utilisez un tuyau d ’évacuation distinct du tuyau d ’évacuation de la

pompe de puisard principale). Si cette option n’est pas pratique,

consultez l’option à «évacuation commune» à la figure3.

Pour TOUTES les installations, une fois l’ installation terminée,

faites fonctionner la pompe de puisard principale et le système

de secours à batterie pendant au moins un cycle complet pour

vous assurer que tout fonctionne correctement.

ici avec un crayon

Puisard

Niveau d’eau de mise

en marche de la

pompe principale

Clapet de

non-retour

Figure1: Marquer le niveau d’eau de «mise en marche» sur le tuyau

MY979 (06-08-20)

21

Page 22

CONFIGURATION DE LA CONNEXION INTERNET ET DES ALERTES

CONFIGURATION DE LA CONNEXION INTERNET ET DES ALERTES

1. Terminez l’enregistrement, la connexion à Internet et la

configuration des alertes du système de secours à batterie

AVANT de brancher la batterie et l’alimentation électrique

sur secteurCA à votre système de secours à batterie.

REMARQUE: Si vous avez déjà connecté la batterie et

l’alimentation sur secteurCA au système de secours à batterie

avant de vous connecter à Internet, terminez le processus

d’enregistrement de l’appareil.

Ensuite, déconnectez la batterie et coupez l ’alimentation

sur secteurCA du panneau et de la passerelle du système de

secours à batterie pendant deuxminutes afin de réinitialiser

le panneau. Répétez l’étape8.

2. Téléchargez l’application Pentair Home sur votre appareil

mobile à partir de l ’App Store® d’Apple ou de Google Play™.

3. Lancez l’application.

UTILISATEURS DÉJÀ INSCRITS: SE CONNECTER

à son compte.

NOUVEAUX UTILISATEURS: Dans l’application, faire

défiler vers le bas et cliquer sur SIGN UP (S’INSCRIRE).

4. Saisir une adresse COURRIEL et un MOT DE PASSE valides.

5. Sélectionner les MODALITÉS DE SERVICE.

6. Cliquer sur CREATE AN ACCOUNT (CRÉER UN COMPTE).

7. Suivre les instructions contenues dans le COURRIEL

DE VÉRIFICATION.

8. SE CONNECTER à son compte.

9. Enregistrez votre appareil à l’aide de l’identifiant d’appareil

unique qui se trouve sur l’appareil et dans la page couverture

de votre manuel.

10. Les alertes seront envoyées au(x) courriel(s) et au(x) numéro(s)

de téléphone saisis ici.

11. Trouvez une connexion réseau ouverte sur votre routeur

Internet ou encore une connexion câblée (par exemple,

un commutateur Internet).

12. Tournez l ’antenne de la passerelle vers le haut en utilisant le câble

Ethernet de 1mètre fourni (ou un câble plus long au besoin).

13. Connectez la passerelle au port Internet ouver t.

14. Il est recommandé d’’utiliser une unité d’alimentation sans

interr uption pour votre modem Internet, votre routeur domestique

et le bloc d’alimentation de la passerelle.

15. Branchez le bloc d’alimentation de la passerelle sur une prise de

courant de 115VCA; branchez le cordon au dos de la passerelle.

Le voyant de la passerelle clignotera en rouge pendant

quelques secondes.

Lorsque le voyant passe au vert fixe ou au vert fixe avec un

clignotement occasionnel, cela indique que votre passerelle

communique avec le serveur Link2O. Sinon, reportez-vous au

tableau «Dépannage de la passerelle» de ce manuel.

16. Branchez le fil conducteur rouge positif(+) du chargeur/contrôleur

à la borne positive(+) (rouge) de la batterie.

17. Branchez le fil conducteur noir négatif(–) du chargeur/contrôleur

à la borne négative(–) (noire) de la batterie.

18. Branchez le câble d’alimentation du chargeur (inclus) à la prise

d’alimentation du chargeur/contrôleur. Branchez l’autre extrémité

à une prise de courant de 115VCA.

19. Vérifiez le voyant d’alimentation CA sur le contrôleur. Un vert fixe

indique que l’appareil communique avec le site Web.

20. Vérifiez que le système est opérationnel en appuyant sur le bouton

TEST SYSTEM (tester) et en observant la séquence de test.

21. Testez la communication en cliquant sur l’icône Test de la page

Web et assurez-vous que l’appareil a exécuté le test.

22. À l’aide du menu déroulant, choisissez la façon dont vous souhaitez

recevoir les alertes: par message texte ou par courriel.

23. On peut tester les aler tes en activant la pompe à l’aide

de l’interrupteur à flotteur.

État de la passerelle Définition Action nécessaire

Vert L’appareil est sous tension. La passerelle est connectée

Vert, clignotement

rapide

Vert, clignotement lent

(1 ou 2 clignotements

par seconde)

Rouge L’appareil est sous tension. La passerelle n’est pas

Rouge, clignotement lent

(1 ou 2 clignotements

par seconde)

Arrêt L’appareil est hors tension ou le produit est défectueux. Vériez la source d ’alimentation; vériez si l’adaptateur

aux serveurs.

L’appareil est sous tension. Le trac de données est

acheminé aux serveurs.

L’appareil est sous tension. La passerelle est connectée

au routeur local, mais pas à Internet ni au x serveur s.

connectée localement au routeur. La passerelle ne voit

pas ou ne reconnaît pas qu’elle est connectée au routeur.

L’appareil est sous tension. L a passerelle communique

avec le routeur, mais le routeur ne peut pas allouer de

protocole DHCP (Dynamic Host Conguration Protocol)

ou de système de noms de domaine (Domain Name

System, ou «DNS») à la passerelle.

OK – La connexion est établie et opérationnelle

OK – Fonctionne; les données circulent entre le système

de secours à batterie et le ser veur

Le système est en ligne et recherche la destination ou le serveur

(ajoutez un commutateur réseau en ligne pour aider à dénir

l’appareil).

Vériez les connexions ou la qualité du câble Ethernet ou

de communication RS-485. Essayez un autre port du routeur.

Le routeur est-il allumé?

Le routeur ne permet pas à la pas serelle d ’accéder à

Internet (ajoutez un commutateur réseau en ligne pour

aider à dénir l’appareil).

d’alimentation fonctionne. Passerelle défectueuse.

TableauI: Dépannage de la passerelle

22

MY979 (06-08-20)

Page 23

INSTALLATION

INSTALLATION TYPE: ÉVACUATION SÉPARÉE

Débranchez la pompe de puisard principale avant de commencer

cette procédure.

Risque de choc électrique. Peut causer

un choc électrique, des brûlures ou la mort.

1. Prévoyez un chevauchement lorsque vous coupez un tuyau

et effectuez un essai à sec avant de le coller.

2. Utilisez du ruban d’étanchéité pour filetage de tuyau en PTFE sur

les extrémités mâles du tuyau d’évacuation. Vissez le coude de

11/4po x 11/2po (inclus) sur le tuyau d’évacuation. Une fois serré,

le coude doit pointer vers le haut.

3. Si cela est possible, installez le système de secour s à batterie

sur le fond du puisard. Assurez-vous que les deux pompes

ne se touchent pas et ne nuisent pas au fonctionnement de

l’interrupteur.

REMARQUE: Si des débris ou du gravier qui pourraient être

aspirés par la pompe se trouvent au fond du puisard, placez la

pompe de puisard principale et le système de secours à batterie

sur des briques ou des blocs de béton de mâchefer pour prévenir

le bouchage.

4. Si le puisard est trop petit pour permettre aux deux pompes

de tenir côte à côte sur le fond du puisard, installez un support

en équerre sur le tuyau d’évacuation de la pompe de puisard

principale avec des colliers de serrage en acier inox ydable.

Installez la pompe de secours sur le suppor t en équerre

(figure2).

5. Coupez un morceau de tuyau en PVC de 11/2po allant du

coude d’évacuation de la pompe de secours jusqu’à environ

un (1)pied au-dessus du plancher du sous-sol. Il s’agit du tuyau

d’évacuation inférieur.

6. Pour éviter la formation de poches d’air dans la pompe

lorsqu’elle est en marche, percez un trou de 1/8po dans le tuyau

d’évacuation inférieur à environ 2po au-dessus du bas du tuyau

(sous le niveau du sol).

7. Installez le clapet de non-retourFP0026-10 (vendu séparément)

sur l’extrémité supérieure du tuyau.

Serrez fermement les colliers de serrage. ASSUREZ-VOUS que

les flèches indiquant le sens de l ’écoulement pointent VERS LE

HAUT (dans le sens opposé du système de secours à batterie).

Si les flèches pointent vers le bas, le clapet ne laissera pas

passer l’eau et la pompe ne fonctionnera pas.

8. Coupez une courte longueur de tuyau en PVC de 11/2po pour en

faire un tuyau ascendant et fixez-le sur la partie supérieure du

clapet de non-retour.

9. Installez un ensemble tuyau et collier de serrageU74-68 (vendu

séparément) sur la partie supérieure du tuyau ascendant. Pour

un tuyau de 11/2po, retirez et jetez le petit morceau de tuyau de

11/4po de l’assemblage tuyau et collier. Laissez les colliers de

serrage desserrés et faites glisser l ’assemblage vers le bas sous

la par tie supérieure du tuyau ascendant.

10. Déterminez à quel endroit vous voulez que la décharge soit

évacuée du sous-sol. À cet endroit, percez les trous nécessaires

(assez grands pour laisser passer un tuyau de 11/2po) pour vous

permettre de faire passer le tuyau d’évacuation depuis la partie

supérieure du puisard jusqu’à l’extérieur.

11. Installez le tuyau d’évacuation horizontal. Installez un coude

à 90° sur l’extrémité intérieure, mais ne le collez pas.

12. Coupez une autre courte longueur de tuyau en PVC de 11/2po

pour en faire le tuyau d’évacuation supérieur allant de la partie

supérieure du tuyau ascendant jusqu’au coude à 90°. Assurezvous de prévoir un chevauchement suffisant pour le joint de

colle du coude.

13. Faites un essai d ’ajustement SANS COLLE en insérant le tuyau

d’évacuation supérieur de 11/2po dans le coude à 90° et le tuyau

d’évacuation supérieur dans l’extrémité verticale du coude à 90°.

Il doit y avoir juste assez d’espace entre le tuyau ascendant

et le coude pour laisser passer le tuyau d’évacuation supérieur.

14. En tout temps lorsque vous utilisez un apprêt pour PVC ou un

adhésif pour PVC, suivez les instructions du fabricant de la colle.

Risque d’incendie et d’ inhalation de

produits chimiques.

15. Assurez-vous qu’il y a un espace entre le système de secours

à batterie et la pompe de puisard principale et l’interrupteur de

cette dernière. S ’il n’y a pas assez d ’espace pour que les deux

pompes reposent côte à côte sur le fond du puisard, le système

de secours à batterie devra être surélevé (selon votre situation

particulière).

16. Nettoyez le tuyau d ’évacuation supérieur, appliquez-y un apprêt,

puis collez-le dans le coude à 90°. Une fois la colle séchée, faites

glisser l’ensemble tuyau et collier vers le haut pour recouvrir le

joint, puis serrez tous les colliers de serrage.

17. Installez l’interrupteur du système de secours à batterie comme

illustré, soit 1po au-dessus du niveau d’eau de mise en marche

de la pompe principale. Attachez l’interrupteur au tuyau avec

des attaches de câble.

18. Fixez le cordon d’alimentation de la pompe sur le tuyau

ascendant avec du ruban adhésif de manière à empêcher la fiche

de tomber dans le puisard.

19. Consultez la section CÂBLAGE ET INSTALLATION DU SYSTÈME

DE SECOURS À BATTERIE de ce manuel pour obtenir les

instructions de câblage.

20. Une fois tout le câblage terminé, remplissez le puisard d’eau

et assurez-vous que la pompe de puisard principale évacue l’eau

et que le système de secours à batterie n’est pas en marche.

21. Ensuite, débranchez la pompe de puisard principale et

remplissez de nouveau le puisard d’eau. Vérifiez si la pompe

du système de secours à batterie évacue l ’eau.

22. Assurez-vous que les deux pompes sont sous tension.

Votre système est maintenant prêt à être utilisé.

MY979 (06-08-20)

23

Page 24

INSTALLATION

* Fourni avec le système de secours à batterie.

Les articles en italique sont vendus séparément

Pas à l’échelle.

Câblage omis pour plus de clarté.

Pente vers le BAS

vers le rejet d’eau

Tuyau d’évacuation supérieur

de 1 1/2 po en PVC

(coupé à la bonne dimension)

Ensemble tuyau etcollier

de serrage U74-68

(vendu séparément)

Tuyau ascendant de 1 1/2 po en PVC

(coupé à la bonne dimension)

Flèche indiquant le sensde l’écoulement,

doit pointer DANS LE SENS OPPOSÉ

de la pompe à protéger

Clapet de

non-retour

FP0026-10

(vendu séparément)

Tuyau d’évacuation

inférieur de 1 1/2 po

en PVC (coupé à la

bonne dimension)

Seuil

Clapet de non-retour

de la pompe principale

Solive

de plancher

Si le puisard est petit, accrochez

le système de secours à batterie

au tuyau d’évacuation principal

avec un support en équerre.

Interrupteur du système

de secours à batterie*

Trou de 1/8 po contre

les poches d’air

Coude coulissant femelle,1 1/4 po

FNPT x 1 1/2 po

Ruban d’étanchéité pour

filetage de tuyau en PTFE

sur tous les joints filetés

Système de secours

à batterie

Niveau

de mise

en marche

de la pompe

principale

FLOW

Figure2: Évacuation séparée – Installation type

REMARQUE: Les battants du clapet de non-retour doivent pivoter DANS LE SENS OPPOSÉ et les flèches indiquant le sens

de l’écoulement doivent pointer DANS LE SENS OPPOSÉ de la pompe à protéger.

*Le niveau d’eau correspondant à la mise hors tension de l’interrupteur doit être situé au-dessus de l’entrée d’eau du système

de secours à batterie.

24

MY979 (06-08-20)

Page 25

INSTALLATION

INSTALLATION TYPE: ÉVACUATION COMMUNE

Débranchez la pompe de puisard principale avant de commencer

cette procédure. Risque de choc électrique.

Peut causer un choc électrique, des brûlures ou la mor t.

1. Prévoyez un chevauchement lorsque vous coupez un tuyau

et effectuez un essai à sec avant de le coller.

2. Si la décharge de la pompe de puisard principale ne comporte

pas de clapet de non-retour, vous devrez en installer un. Vous

devez également en installer un dans le tuyau d’évacuation du

système de secours à batterie (figure3). Assurez-vous que la

flèche du clapet de non-retour indiquant le sens de l’écoulement

pointe DANS LE SENS OPPOSÉ de la pompe qu’il est destiné

à protéger.

3. Utilisez du ruban d’étanchéité pour filetage de tuyau en PTFE sur

les extrémités mâles du tuyau d’évacuation. Vissez le coude de

11/4po x 11/2po (inclus) sur le tuyau d’évacuation. Une fois serré,

le coude doit pointer vers le haut.

4. Si cela est possible, placez le système de secour s à batterie

sur le fond du puisard. Assurez-vous que les deux pompes

ne se touchent pas et ne nuisent pas au fonctionnement de

l’interrupteur.

REMARQUE: Si des débris ou du gravier qui pourraient être

aspirés par la pompe se trouvent au fond du puisard, placez la

pompe de puisard principale et le système de secours à batterie

sur des briques ou des blocs de béton de mâchefer pour prévenir

le bouchage.

5. Si le puisard est trop petit pour permettre aux deux pompes

de se tenir côte à côte sur le fond du puisard, trouvez un

emplacement surélevé qui ne nuira pas au fonctionnement

de l’ interrupteur de la pompe de puisard principale.

6. Coupez un morceau de tuyau en PVC de 11/2po allant du

coude d’évacuation de la pompe de secours jusqu’à environ

un (1)pied au-dessus du plancher du sous-sol. Il s’agit du tuyau

d’évacuation inférieur.

7. Pour éviter la formation de poches d’air dans la pompe

lorsqu’elle est en marche, percez un trou de 1/8po dans le tuyau

d’évacuation inférieur à environ 2po au-dessus du bas du tuyau

(sous le niveau du sol).

8. Installez le clapet de non-retourFP0026-10 (vendu séparément)

sur l’extrémité supérieure du tuyau. Serrez fermement les

colliers de serrage. ASSUREZ-VOUS que les flèches indiquant

le sens de l’écoulement pointent VERS LE HAUT (dans le sens

opposé de la pompe de secours). Si les flèches pointent vers

le bas, le clapet ne laissera pas passer l ’eau et la pompe ne

fonctionnera pas.

9. Coupez le tuyau d ’évacuation de la pompe de puisard principale

au-dessus du raccord-union et du clapet de non-retour (le cas

échéant). Faites la coupe environ 18po au-dessus du sommet

du tuyau ascendant du système de secour s à batterie. La

pompe de secours doit reposer à son emplacement habituel.

10. Si le tuyau d’évacuation de la pompe de puisard principale

n’est pas pourvu d’un clapet de non-retour, installez-en

un maintenant.

11. Coupez une longueur de tuyau d’évacuation destinée à être

installée entre le clapet de non-retour de la pompe de puisard

principale et un raccord coulissant à 45°. Assurez-vous de

prévoir le chevauchement nécessaire afin de coller les joints.

12. Installez le raccord à 45° sur le tuyau d’évacuation de la pompe

de puisard principale.

13. Installez un coude à 45° sur le tuyau d’évacuation de 11/2po

de la POMPE DE SECOURS À BATTERIE.

14. Montez le tuyau d’évacuation supérieur sur l’extrémité

supérieure du raccord en Y. REMARQUE: Il est recommandé

de couper une courte longueur de tuyau à joindre au raccord

en Y et d’installer un raccord-union sur le tuyau. Prolongez le

tuyau d’évacuation à partir du côté décharge du raccord-union.

Cela permettra de retirer le système plus facilement pour le

nettoyage ou l’entretien. Un ensemble tuyau et collier de serrage

U74-68 (vendu séparément) peut être utilisé pour cette tâche.

15. Assurez-vous qu’il y aura un espace entre le système de secours

à batterie et la pompe de puisard principale et l’interrupteur de

cette dernière. S ’il n’y a pas assez d ’espace pour que les deux

pompes reposent côte à côte sur le fond du puisard, le système

de secours à batterie devra être surélevé (selon votre situation

particulière).

16. Faites un montage d’essai pour vous assurer que tout tiendra

correctement. Vous pourriez avoir besoin de l’aide d’une autre

personne pour tenir toutes les pièces ensemble pendant que

vous vérifiez l’ajustement sans colle. Marquez tous les joints

avant de les coller.

Suivez les instructions du fabricant de la colle relativement aux

risques d’incendie et à la ventilation lorsque vous utilisez des

solvants, des apprêts et des adhésifs pour P VC.

Risque d’incendie et d’ inhalation de

produits chimiques.

17. Démontez tous les tuyaux, nettoyez tous les joints, puis

réassemblez le système en le collant avec un apprêt PVC

et de la colle.

18. Installez l’interrupteur du système de secours à batterie comme

illustré, soit 1po au-dessus du niveau d’eau de mise en marche

de la pompe principale. Attachez l’interrupteur au tuyau avec

les attaches de câble incluses.

19. Fixez le cordon d’alimentation de la pompe sur le tuyau

ascendant avec du ruban adhésif de manière à empêcher

la fiche de tomber dans le puisard.

20. Consultez la section CÂBLAGE ET INSTALL ATION DU SYSTÈME

DE SECOURS À BATTERIE de ce manuel pour obtenir les

instructions de câblage.

21. Une fois tout le câblage terminé, remplissez le puisard d’eau et

assurez-vous que la pompe de puisard principale évacue l’eau

et que le système de secours à batterie n’est pas en marche.

22. Ensuite, débranchez la pompe de puisard principale et

remplissez de nouveau le puisard d’eau. Vérifiez si la pompe

du système de secours à batterie évacue l ’eau.

23. Assurez-vous que les deux pompes sont sous tension.

Votre système est maintenant prêt à être utilisé.

MY979 (06-08-20)

25

Page 26

INSTALLATION

Installation type,

assemblée.

Les deux clapets de

non-retour doivent être

installés du côté pompe

du raccord en Y.

Tuyau optionnel de 1 1/2 po en PVC