Pentair MASTERTEMP MT200HD, MASTERTEMP MT300HD, MASTERTEMP MT400HD Installation And User Manual

1 1

MASTERTEMP™ POOL AND SPA EURO HEATER

INSTALLATION AND USER’S GUIDE

FOR YOUR SAFETY - READ BEFORE OPERATING

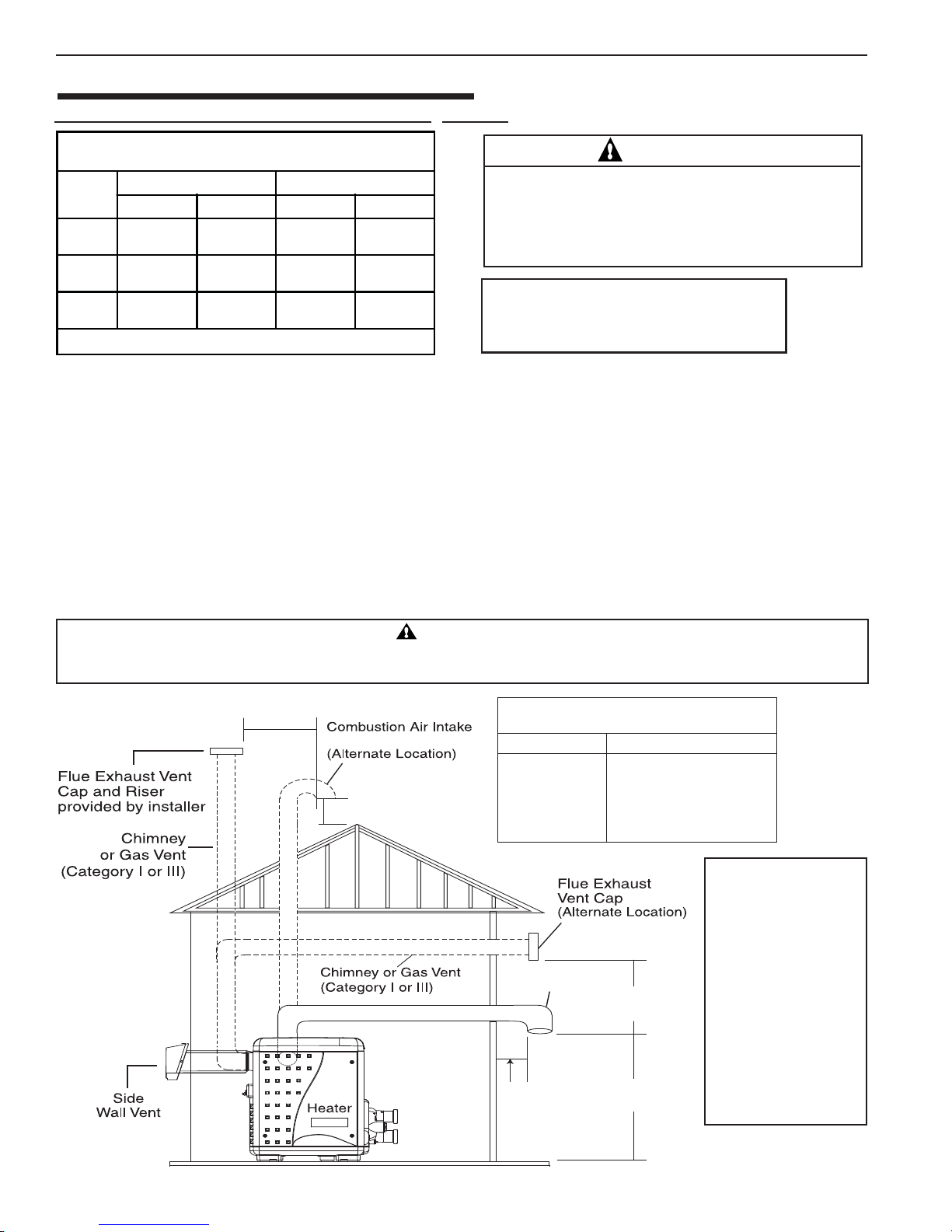

If you do not follow these instructions exactly , a fire or explosion may result, causing

property damage, personal injury or loss of life. For additional free copies of this

manual; call USA (800) 831-7133

FOR YOUR SAFETY - This product must be installed and serviced by authorized personnel, qualified in pool/spa

heater installation. Improper installation and/or operation can create carbon monoxide gas and flue gases which can

cause serious injury, property damage, or death. For indoor installations, as an additional measure of safety, Pentair

Aquatic Systems strongly recommends installation of suitable Carbon Monoxide Detectors in the vicinity of this

appliance and in any adjacent occupied spaces. Improper installation and/or operation will void the warranty.

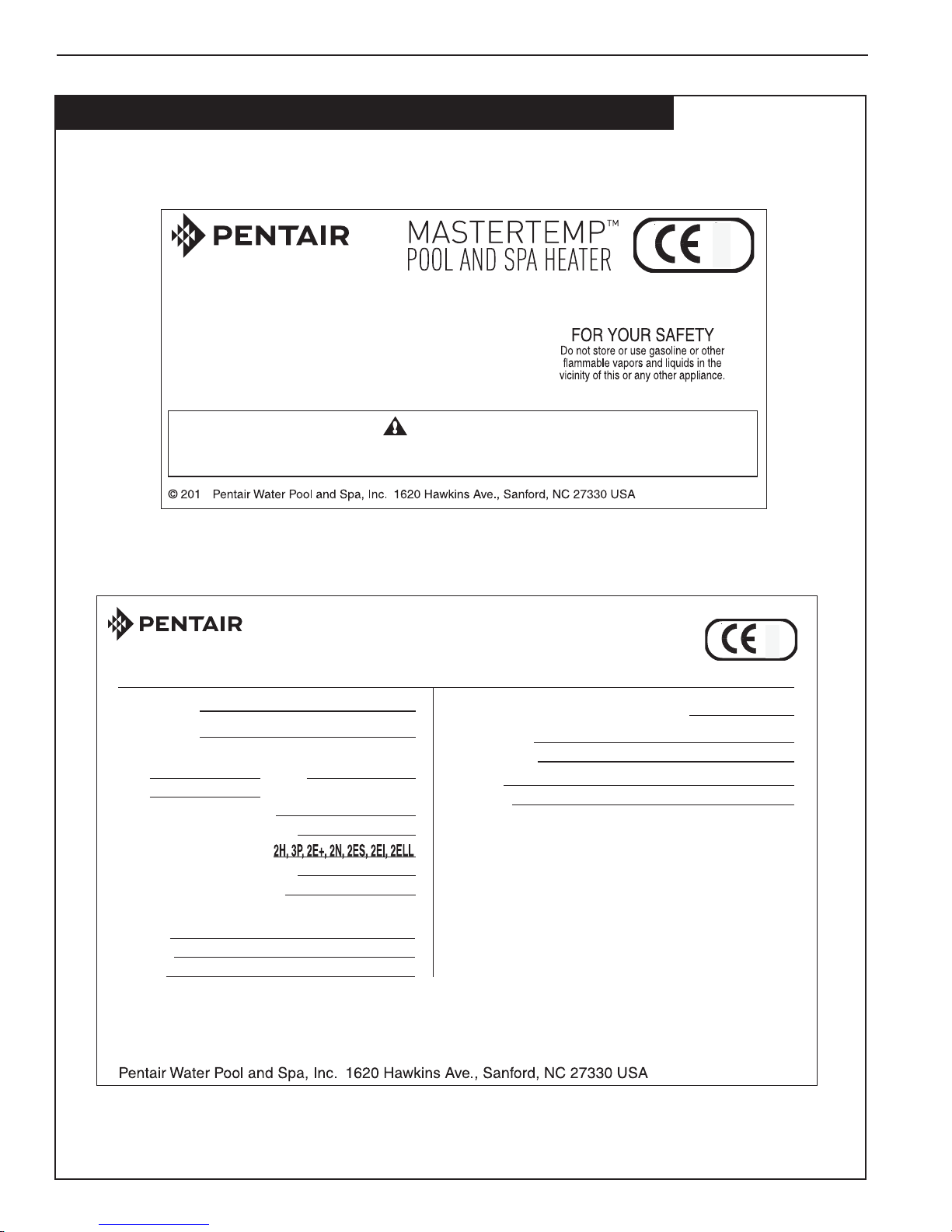

Models

(240 VAC)

MT200HD, EURO

MT300HD, EURO

MT400HD, EURO

alteration, service or maintenance can

cause property damage, personal injury or death.

Natural Gas

(G20, G25)

461082 461083

461086 461087

461090 461091

Propane Gas

(G31)

COUNTRY OF DESTINATION:

GB, BE, FR, DE

Improper installation, adjustment,

0087

1312

OWNER:

Retain For

Reference

Installation and service must be performed by a qualified

installer , service agency or the gas supplier.

NOx CLASS 5

FOR YOUR SAFETY

• If you do not follow these instructions exactly, a fire or explosion may result, causing property damage,

personal injury or loss of life.

• Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal

injury or death. Installation and service must be performed by a qualified installer , service agency or the gas

supplier.

• Do not place articles or against this appliance.

• Do not use or store flammable materials near this appliance.

• Do not spray aerosols in the vicinity of this appliance while it is in operation.

Future

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

FOR

YOUR

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire dep artment.

SAFETY

DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity

of this or other appliances.

Pentair Water Pool and Spa, Inc. EMEA – Head Office: Industriepark, Wolfstee, Toekomstlaan 30, 2200 Herentals - Belgium.

Pentair Water Pool and Spa, Inc. USA – 1620 Hawkins Ave., Sanf ord, NC 27330, USA • (919) 566-8000 • (800) 831-7133 –

www. pentaireurope.com - www.pentairwater.com.au - www.pentairpool.com - www.staritepool.com

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

10951 W. Los Angeles Ave., Moorpark, CA 93021, USA • (805) 553-5000 • (800) 831-7133

| Technical Data

i

Technical Data

General Specifications

GAS TYPE:

GAS GROUP:

GAS SUPPLY PRESSURE:

TYPE OF APPLIANCE:

COUNTRY OF DESTINATION:

READ THE TECHNICAL INSTRUCTIONS BEFORE INST ALLING THIS APPLIANCE.

READ THE INSTALLATION AND USER’S GUIDE BEFORE LIGHTING THIS APPLIANCE.

WARNING!

1312

0087

6

MASTERTEMP™ POOL HEATER

0087

1312

DESIGN AND MANFACTURED BY PENTAIR WATER POOL AND SPA, INC.

MODEL NO.

SERIAL NO.

GAS SUPPLY PRESSURE:

G20:

G31:

TEST POINT PRESSURE

MAX. WORKING PRESSURE

APPLIANCE CATEGORY

COUNTRY OF DESTINATION

YEAR OF MANUFACTURE

ELECTRICAL RATINGS:

VOLTS:

HERTZ:

AMPS:

APPROVED FOR INDOOR AND OUTDOOR INSTALLATIONS ELECTRICAL COMPLIANCE: IN ACCORDANCE

WITH LOCAL ELECTRICAL CODES.

THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE EUROPEAN STANDARD INSTALLATION

CODES, AND WITH THE REQUIREMENTS OF THE AUTHORITY HAVING JURISDICTION.

mbar,

mbar

G25:

mbar

3.45 mbar

GB, BE, DE, FR

mbar

Hz

12 A

THIS HEATER IS EQUIPPED TO BURN

INPUT RATE

ORIFICE SIZE

OUTPUT

ALTITUDE

MINIMUM CLEARANCE FROM COMBUSTIBLE

CONSTRUCTED 15 CM REAR, 15 CM TOP

DO NOT INSTALL THIS HEATER UNDER AN OVERHANG

LESS THAN 1 METER FROM THE TOP. THE AREA UNDER

THE OVERHANG MUST BE OPEN ON THREE (3) SIDES.

V

REFER TO THE OPERATING INSTRUCTIONS FOR

APPROVED WATER TREATMENT.

TYPE G23

GAS

kW

mm

kW

2000 m

Label P/N

P/N 475106 Rev . D 1/2016

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

Contents |

Contents

T echnical Data / Heater Identification Information (HIN) .................................................................................................................................... ii - iii

Code Requirements / References .................................................................................................................................................................... iv

Consumer Information and Safety / Warnings and Safety Instructions / General Specifications............................................................ v - vii

Section 1. Operations ........................................................................................................................... 1

Overview / Important Notices / Warranty Information .................................................................................................................. 1

Using the Heater’s Control Panel.................................................................................................................................................... 2

Operating Instructions / Basic System Operation ........................................................................................................................ 3

Basic System Operation / HSI (Hot-Surface Ignition) Lighting/Operation.................................................................................. 3

Start-up and Operation .................................................................................................................................................................... 3

Operating Instructions ..................................................................................................................................................................... 4

To Turn Off Gas to Appliance .......................................................................................................................................................... 4

Safety Controls: Air Flow Switch (AFS) / Water Pressure Switch / Height Limit Devices .......................................................... 5

Operation of Ignition Module ........................................................................................................................................................... 6

T emperature Setting / Maximum Temperature Set Point ............................................................................................................... 6

Section 2. Installation Instructions ...................................................................................................... 7

Heater Description................................................................................................................................................................................ 7

Sequence of Operation......................................................................................................................................................................... 7

Putting the Heater into Service ............................................................................................................................................................ 8

Specifications ...................................................................................................................................................................................... 8

Plumbing Connections.......................................................................................................................................................................... 9

Valves .................................................................................................................................................................................................. 9

Manual By-Pass .................................................................................................................................................................................. 9

Water Connections ............................................................................................................................................................................... 10

Below Pool Installation ......................................................................................................................................................................... 10

Gas Connections ................................................................................................................................................................................. 11

Gas Pipe Sizing ................................................................................................................................................................................... 11

Sediment Trap/Drip Leg ....................................................................................................................................................................... 11

T esting Gas Leaks and Gas Pressure.................................................................................................................................................. 12

Gas Pressure Requirements ................................................................................................................................................................ 12

Outdoor Installation / Heater Clearances .............................................................................................................................................. 13 - 14

Indoor Venting—General Requirements / Heater Clearances / Outside Vent Removal ) .................................................................... 15- 16

Combustion Air Supply .................................................................................................................................................................... 15

Vent Installation (Indoor Installation or Outdoor Shelter) - Vertical Venting...................................................................................... 16

Direct Air Intake Duct with 63 mm (2.5 in) PVC Pipe (Heater Indoor Installation)............................................................................. 16

Horizontal or Vertical Venting - Using Single-Wall Stainless Gas Vent ........................................................................................... 17

Connecting Single-Wall Stainless Steel Vent to the Heater ............................................................................................................. 18 - 19

Corrosive Vapors and Possible Causes.............................................................................................................................................. 20

Control Panel Indexing ....................................................................................................................................................................... 20

Final Installation Check....................................................................................................................................................................... 20

Electrical Connections ........................................................................................................................................................................ 21

Fireman’s Switch Connection/Remote Control Connections .............................................................................................................. 21 - 22

MasterTemp Wiring Diagram / Electrical Schematic Ladder Diagram................................................................................................. 23 - 24

Section 3. Troubleshooting ................................................................................................................. 25

Initial Troubleshooting and Troubleshooting Chart ............................................................................................................................. 25

Heater Will Not Fire Troubleshooting (A, B, C, D) ............................................................................................................................... 26 - 29

LED Diagnostics (AGS, AFS, HLS, PS Thermistor)............................................................................................................................. 30 - 31

Burner / Heat Exchanger Troubleshooting.......................................................................................................................................... 32

Section 4. Maintenance Instructions.................................................................................................. 33

Care and Maintenance ....................................................................................................................................................................... 33

Pressure Relief Valve .......................................................................................................................................................................... 33

After Start-Up....................................................................................................................................................................................... 34

Spring, Fall (Autumn) and Winter Operation ...................................................................................................................................... 34

Maintaining Pool Temperature / Energy Saving Tips .......................................................................................................................... 35

Chemical Balance ............................................................................................................................................................................... 35 - 36

Replacement Parts.............................................................................................................................................................................. 37 - 41

ii

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

| Heater Identification Information

iii

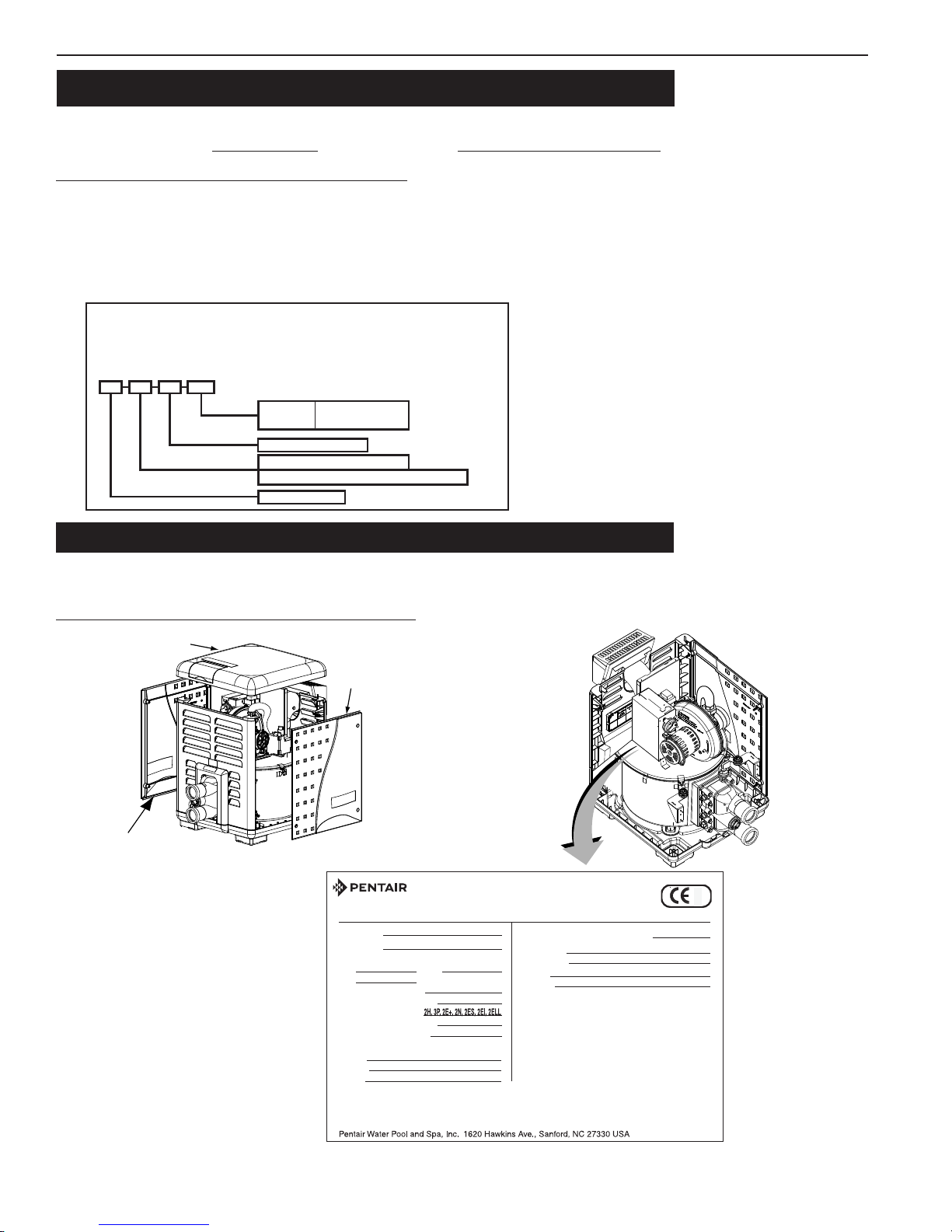

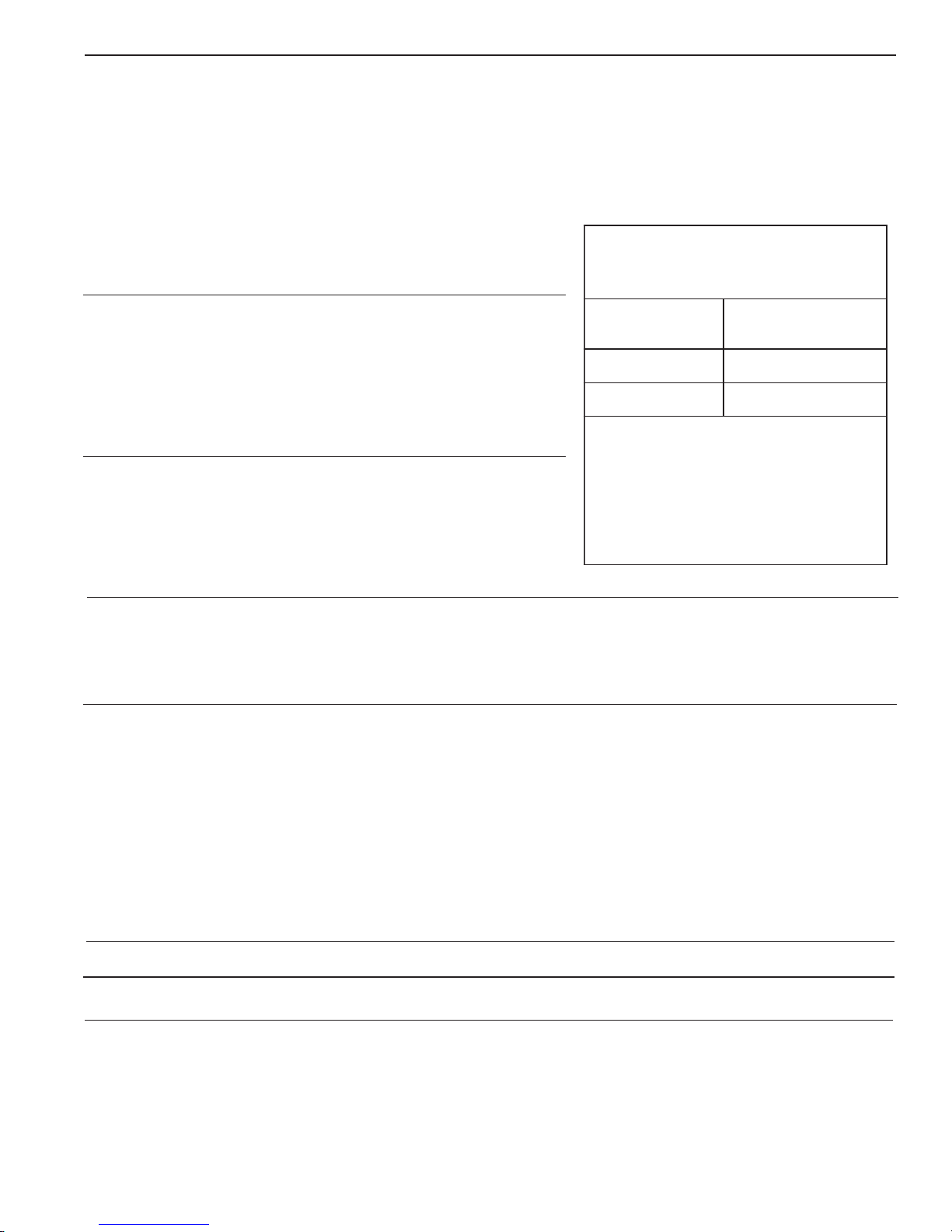

Heater Identification Information (HIN)

To identify the heater, see the data rating plate on the inner front panel of the heater. There are two designators for

each heater, one is the

Model Number and the other is the Heater Identification Number (HIN).

Heater Identification Number (HIN)

The following example simplifies the identification system:

1) MT : MasterTemp

2) Model Size : (200, 300 or 400) : Input rating (Gross BTU/hr)

3) Construction : (HD = Heavy Duty Model)

4) Fuel Type : (LP = Propane gas or NA = Natural gas)

ID DESIGNATOR FOR PENTAIR POOL AND SPA MASTERTEMP™ HEATERS

HEATER IDENTIFICATION NUMBER

Example:

123 4

MT 300 HD

N

H. I. N.

FUEL TYPE =

HD = HEAVY DUTY MODEL

MODEL SIZE = BTU/hr GROSS INPUT

200 (200 [

MT = MASTERTEMP

NA = NATURAL GAS

LP = PROPANE GAS

BTU/hr

), 300 (300 [

BTU/hr

) or 400 (400 [

BTU/hr

)

Heater Data Rating Plate

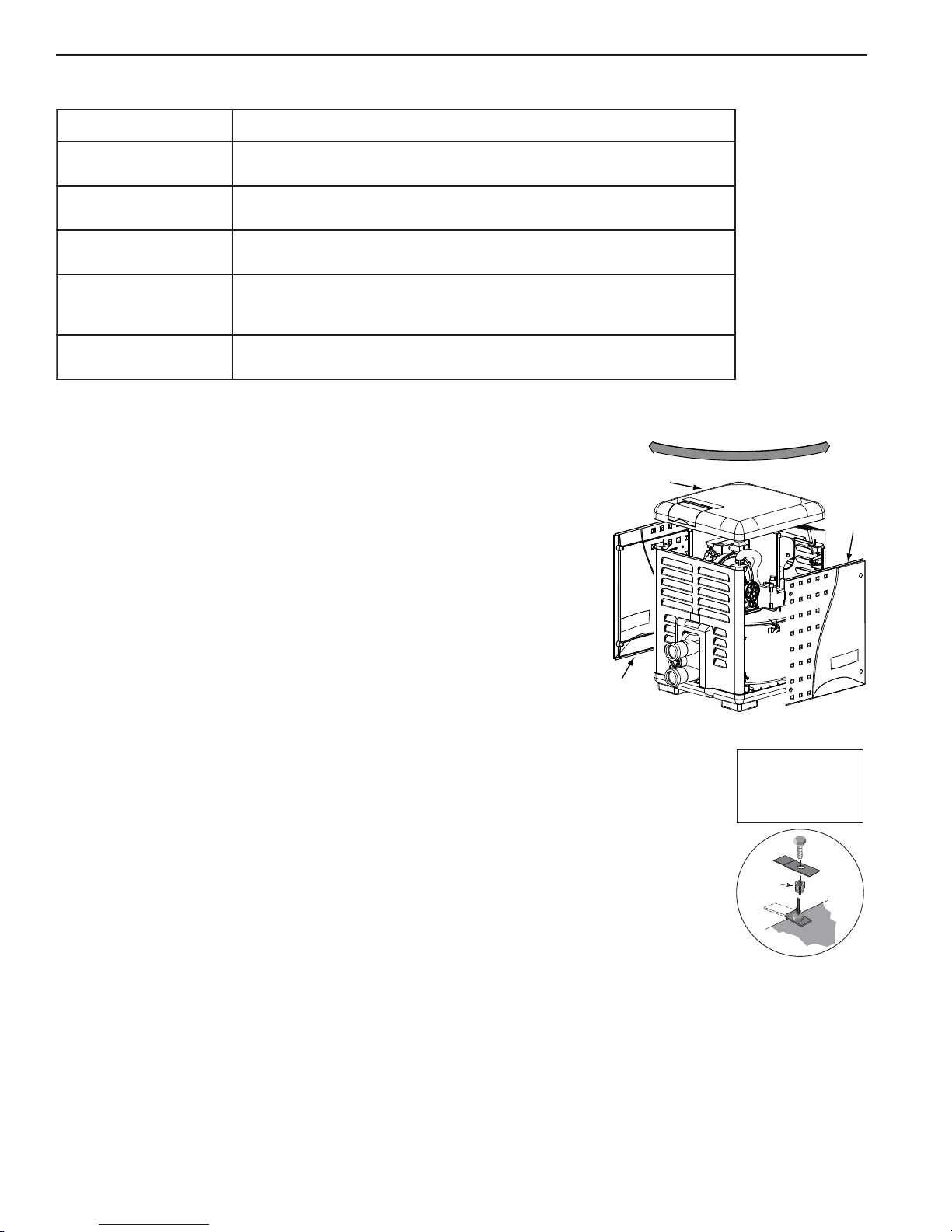

The heater data rating plate is located on the inner front panel of the heater. To access the data rating plate, unbolt and

remove the side door access panel as shown below.

Heater Data Rating Plate Location

Top Panel

Remove this Door

Access Panel to access

the DATA RATING PLATE

Door

Access

Panel

MASTERTEMP™ POOL HEATER

DESIGN AND MANFACTURED BY PENTAIR WATER POOL AND SPA, INC.

MODEL NO.

SERIAL NO.

GAS SUPPLY PRESSURE:

G20:

G31:

TEST POINT PRESSURE

MAX. WORKING PRESSURE

APPLIANCE CATEGORY

COUNTRY OF DESTINATION

YEAR OF MANUFACTURE

ELECTRICAL RATINGS:

VOLTS:

HERTZ:

AMPS:

APPROVED FOR INDOOR AND OUTDOOR INSTALLATIONS ELECTRICAL COMPLIANCE: IN ACCORDANCE

WITH LOCAL ELECTRICAL CODES.

THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE EUROPEAN STANDARD INSTALLATION

CODES, AND WITH THE REQUIREMENTS OF THE AUTHORITY HAVING JURISDICTION.

mbar,

mbar

G25:

3.45 mbar

GB, BE, DE, FR

mbar

THIS HEATER IS EQUIPPED TO BURN

INPUT RATE

ORIFICE SIZE

mbar

OUTPUT

ALTITUDE

MINIMUM CLEARANCE FROM COMBUSTIBLE

CONSTRUCTED 15 CM REAR, 15 CM TOP

DO NOT INSTALL THIS HEATER UNDER AN OVERHANG

LESS THAN 1 METER FROM THE TOP. THE AREA UNDER

THE OVERHANG MUST BE OPEN ON THREE (3) SIDES.

V

REFER TO THE OPERATING INSTRUCTIONS FOR

Hz

12 A

APPROVED WATER TREATMENT.

TYPE G23

kW

kW

2000 m

Label P/N

GAS

mm

0087

1312

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

Code Requirements / References |

CODE REQUIREMENTS / REFERENCES

Gas Safety (Installation and Use) Regulations, (as amended).

It is the law that all gas appliances are installed by a competent person (e.g. a CORGI registered operative) in accordance with Regulations.

Failure to install appliances correctly could lead to prosecution. The installation of the Heater MUST also be in accordance with the

current I.E.E.. Wiring Regulations, the European Building Standards, the Bye Laws of the Local Water Undertaking, any relevant

requirements of the Local Authority, and Health and Safety document No 635, “Electricity at Work Regulations”.

Detailed recommendations are contained in the following European Standard Codes of Practice.

iV

Installation must be in accordance with the code requirements:

• Manufacturer’s Installation Instructions

• Local Gas Fitting Regulations

• Municipal Building Codes

•

EN 437: 2003 + A1 (2009) Test Gases - Test

pressures appliances categorizes.

•

EN 60335-2-102/A1 - Household and similar

electric appliances - Safety - 2- 2012

• BS 6891 Specification for installation of

low pressure gas pipe work.

• BS5482:1 Code of practice for domestic

butane and propane gas burning

installations. Building Regulations|

Part L1.

IMPORTANT NOTICE:

DO NOT directly connect any external control device to this appliance, unless noted in this Installation and User’s Guide

or recommended by the manufacturer. Any installed control device not recommended by the manufacturer could violate

the Gas Safety Regulations (the installation and use), the above described regulations and the appliance warranty.

The manufacturer’s notices DO NOT supersede any legal requirements.

• Local Electrical Regulations

• Any other statutory regulations

•E

N 15502-1 : 2012 Gas fired heating

boilers general requirements test.

• BS 6644 : 2011 Specifications for

the installation and maintenance of

gas fired hot water boilers between

70Kw - 1.8 mW, (2nd. and 3rd. gas

family).

1312

0087

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

| Code Requirements / References

V

CONSUMER INFORMA TION AND SAFETY

THE MASTERTEMP HEATER IS CLASSIFIED AS A CLASS 5 LOW NOX BOILER.

WARNING

Should overheating occur or the gas supply fail to shut off, turn off the manual gas control valve to the heater. Do not

use this heater if any part has been under water. Immediately call a qualified service technician to inspect the heater

and to replace any part of control system and gas control which has been under water.

D ANGER

CARBON MONOXIDE GAS IS DEADLY – Exhaust from this pool heater contains toxic levels of carbon monoxide, a dangerous,

poisonous gas you cannot see or smell.

WARNING

The Consumer Product Safety Commission warns that carbon monoxide is an "invisible killer". Carbon monoxide is a

colorless and odorless gas.

1. Carbon monoxide is produced by burning fuel, including natural gas and propane.

2. Proper installation, operation and maintenance of fuel-burning appliances in the home is the most important factor in reducing

carbon monoxide poisoning.

3. Be sure that fuel burning appliances such as heaters are installed by professionals according to manufacturer's instructions and

codes.

4. Always follow the manufacturer's directions for safe operation.

5. Have the heating system (including vents) inspected and serviced annually by a trained service technician.

6. Examine vents regularly for improper connections, visible cracks, rust or stains.

7. Install battery-operated carbon monoxide alarms. The alarms should be certified to the requirements of the most recent UL, CE,

IAS, CSA and IAPMO standard for carbon monoxide alarms. T est carbon monoxide alarms regularly and replace dead batteries.

WARNING

The Consumer Product Safety Commission warns that elevated water temperature can be hazardous. See below

for water temperature guidelines before setting temperature.

1. Spa or hot tub water temperatures should never exceed 40° C. A temperature of 37° C. is considered safe for a healthy adult.

Special caution is suggested for young children. Prolonged immersion in hot water can induce hyperthermia.

2. Drinking of alcoholic beverages before or during spa or hot tub use can cause drowsiness which could lead to unconsciousness

and subsequently result in drowning.

3. Pregnant women beware! Soaking in water above 37° C. can cause fetal damage during the first three months of pregnancy

(resulting in the birth of a brain-damaged or deformed child). Pregnant women should stick to the 37° C. maximum rule.

4. Before entering the spa or hot tub, the user should check the water temperature with an accurate thermometer . Spa or hot tub

thermostats may error in regulating water temperatures by as much as -15° C.

5. Persons with a medical history of heart disease, circulatory problems, diabetes or blood pressure problems should

obtain their physician's advice before using spas or hot tubs.

6. Persons taking medication which induce drowsiness, such as tranquilizers, antihistamines or anticoagulants should

not use spas or hot tubs.

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

Warnings and Safety Instructions |

vi

W ARNINGS AND SAFETY INSTRUCTIONS

The MasterTemp pool heaters are designed and manufactured to provide many years of safe and reliable service when

installed, operated and maintained according to the information in this manual. Throughout the manual, safety warnings and

cautions are identified by the “ “ symbol. Be sure to read and comply with all of the warnings and cautions.

DANGER — CARBON MONOXIDE GAS IS DEADLY

• • READ OWNERS MANUAL COMPLETELY BEFORE OPERATING. • •

THIS PRODUCT MUST BE INSTALLED AND SERVICED BY A PROFESSIONAL SERVICE

TECHNICIAN, QUALIFIED IN POOL HEATER INSTALLATION. Some jurisdictions require that

installers be licensed. Check with your local building authority about contractor licensing requirements.

Improper installation and/or operation could create carbon monoxide gas and flue gases which could

cause serious injury or death. Improper installation and/or operation will void the warranty.

Exhaust from this pool heater contains carbon monoxide, a dangerous, poisonous gas you cannot

see or smell. Symptoms of carbon monoxide exposure or poisoning include dizziness, headache,

nausea, weakness, sleepiness, muscular twitching, vomiting and inability to think clearly. IF YOU

EXPERIENCE ANY OF THE ABOVE SYMPTOMS, IMMEDIATELY TURN OFF THE POOL

HEATER, LEAVE THE VICINITY OF THE POOL OR SPA AND GET INTO FRESH AIR IMMEDIATELY.

THE POOL HEATER MUST BE THOROUGHLY TESTED BY A GAS PROFESSIONAL BEFORE

RESUMING OPERATION.

EXCESSIVE CARBON MONOXIDE EXPOSURE CAN CAUSE BRAIN DAMAGE OR DEATH.

Install this pool heater far from open windows, doors, vents and other openings, see page 16 for

minimum distances.

Pentair strongly recommends that all vents, pipes and exhaust systems be initially and periodically

tested for proper operation. This testing can be accomplished by using a hand-held carbon monoxide

meter and/or by consulting with a gas professional.

Pool heaters must be used in conjunction with carbon monoxide detectors installed near the pool

heater. The carbon monoxide detectors must be periodically inspected for proper operation so as to

insure continued safety. Broken or malfunctioning carbon monoxide detectors must be replaced

immediately.

WARNING —

WARNING —

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

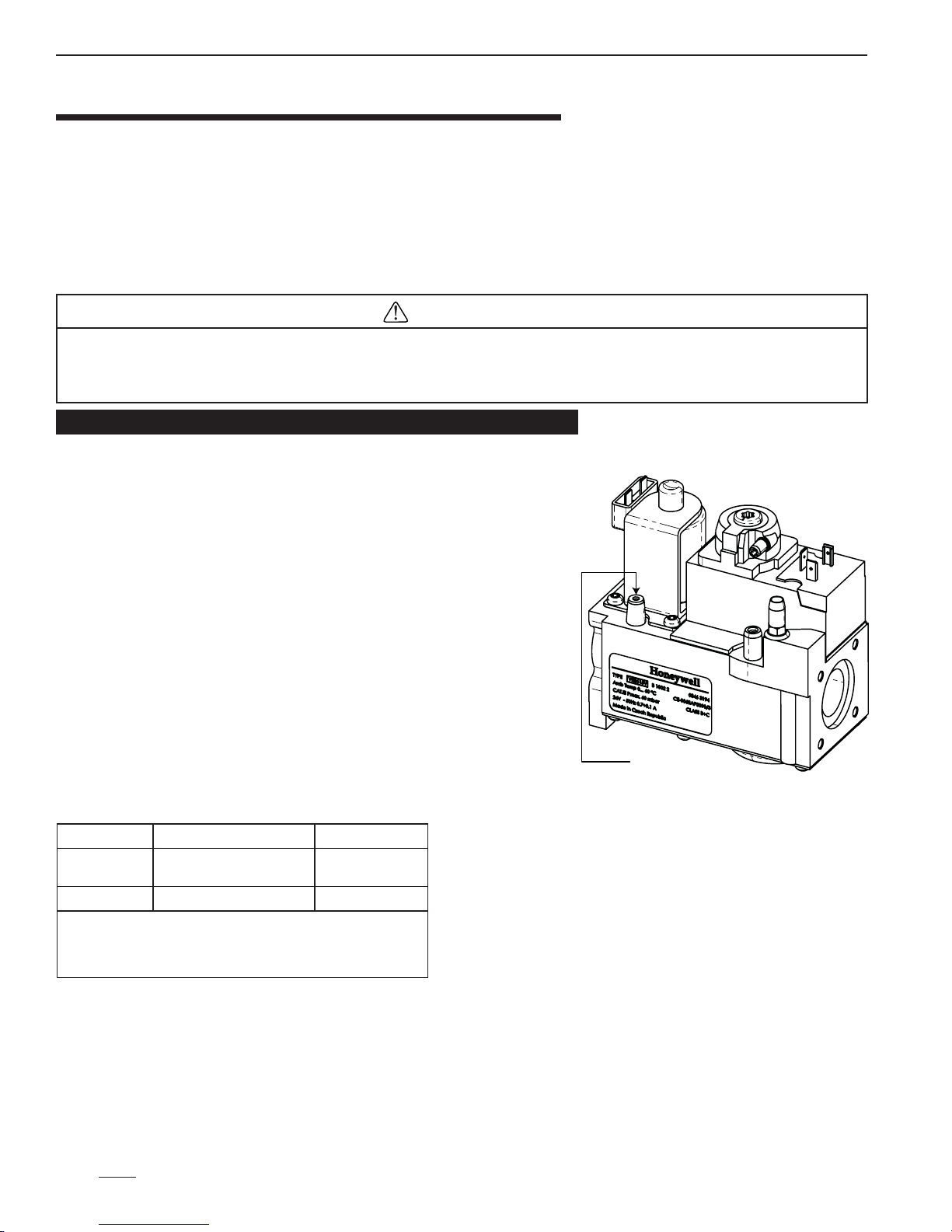

This heater is equipped with an unconventional gas control valve that is factory set with a

manifold pressure of 1.1 ± 0.5 mbar. Improper installation, adjustment, alteration, service or

maintenance can cause property damage, personal injury or loss of life. Installation or service must

be performed by a qualified installer, service agency or the gas supplier. If this control is replaced, it

must be replaced with an identical control.

Do not attempt to adjust the gas flow by adjusting the regulator setting.

Risk of fire or explosion from incorrect fuel use or faulty fuel conversion. Do not try to run a

heater set up for G20, G25 or G31 gas or vice versa. Only qualified service technicians should attempt to

convert heater from one fuel to the other. Do not attempt to alter the rated input or type of gas by

changing the orifice. If it is necessary to convert to a different type of gas, consult your Pentair dealer .

Serious malfunction of the burner can occur which may result in loss of life. Any additions, changes,

or conversions required in order for the appliance to satisfactorily meet the application needs must

be made by a Pentair dealer or other qualified agency using factory specified and approved parts.

The heater is available for use with G20, G25 or G31 gas only . It is not designed to operate with any other

fuels. Refer to the nameplate for the type of gas the heater is equipped to use.

• Use heater only with the fuel for which it is designed.

• If a fuel conversion is necessary , refer this work to a qualified service technician or gas supplier

before putting the heater into operation.

| Warnings and Safety Instructions

vii

W ARNINGS AND SAFETY INSTRUCTIONS (continued)

WARNING —

WARNING —

WARNING —

WARNING —

Vent

Cover

Risk of fire or explosion from flammable vapors. Do not store gasoline, cleaning fluids, varnishes,

paints, or other volatile flammable liquids near heater.

Risk of explosion if unit is installed near G31 gas storage. G31 gas is heavier than air. Consult

local codes and fire protection authorities about specific installation requirements and restrictions.

Locate the heater away from propane gas storage and filling equipment as specified by the Standard

for the Storage and Handling of G31 (latest edition).

Risk of fire. Do not place articles on, near or against the heater.

Risk of burn hazard. To reduce the risk of injury, do not touch the side heater vent cover when

the heater is operating. Side heater vent covers are HOT and can burn when touched causing

personal injury. Do not allow children to play on or around heater or associated equipment.

THE AVERAGE TEMPERATURE OF THE HEATERS FLUE EXHAUST IS 204 DEGREES

CELSIUS (°C).

WARNING —

CAUTION —

Risk of asphyxiation if exhaust is not correctly vented. Follow venting instructions exactly

when installing heater. Do not use a draft hood with this heater, as the exhaust is under

pressure from the burner blower and a draft hood will allow exhaust fumes to blow into the room

housing the heater. The heater is supplied with an integral venting system for outdoor installation.

Label all wires prior to disconnection when servicing controls. Wiring errors can cause

improper and dangerous operation. Wiring errors can also destroy the control board.

• Connect heater to 240 Volt, 50 Hz., Single Phase power only.

• Verify proper operation after servicing.

• Do not allow children to play on or around heater or associated equipment.

• Never allow children to use the pool or spa without adult supervision.

• Read and follow other safety information contained in this manual prior to operating this pool heater.

GENERAL SPECIFICA TIONS

NOTICE:

• Combustion air contaminated by corrosive chemical fumes can damage the heater and will void the warranty.

• The Combination Gas Control Valve on this heater differs from most appliance gas controls. If it must be replaced,

for safety reasons replace it only with an identical gas control.

• The access door panels must be in place to provide proper ventilation. Do not operate the heater for more than five (5)

minutes with the access door panels removed.

• This heater is design certified by CERTIGAZ as complying with the Standard for Gas Fired Pool Heaters, and is intended

for use in heating fresh water swimming pools or spas.

• The heater is designed for the heating of chlorine, bromine or salt system swimming pools and spas. It should NOT be

used as a space heating boiler, or general purpose water heater. The heater requires an external 240 VAC

single-phase electric power source.

• The heater should be located in an area where leakage of the heater or connections will not result in damage to the

area adjacent to the heater or to the structure. When such locations cannot be avoided, it is recommended that a

suitable drain pan, adequately drained, be installed under the heater. The pan must not restrict air flow.

• The heater may not be installed within 3.5 m (11.5 ft.) of the inside surface of a pool or spa unless it is separated by a

solid fence, wall or other permanent barrier.

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

Section 1. Overview

| 1

Introduction

MasterTemp™ P ool and Spa Heater

Congratulations on your purchase of a MasterT emp™ high performance heating system. Proper installation and service of

your new heating system and correct chemical maintenance of the water will ensure years of enjoyment. The MasterT emp

is a compact, lightweight, efficient, induced-draft, gas fired high performance pool and spa heater that can be directly

connected to 63 mm (2 in) PVC pipe. The MasterT emp also comes equipped with a multifunction temperature controller

which shows, at a glance, the proper functioning of the heater. All MasterT emp heaters are designed with a direct ignition

device, HSI (hot-surface ignition), which eliminates the need for a standing pilot. The MasterTemp requires an external

power source (240 VAC 50 Hz) to operate.

SPECIAL INSTRUCTIONS TO OWNER: Retain this manual for future reference. This instruction manual provides

operating instructions, installation and service information for the MasterT emp high performance heater. The information in

this manual applies to all MasterTemp models. READ AND REVIEW THIS MANUAL COMPLETELY, it is very

important that the owner/installer read and understand the section covering installation instructions, and recognize the European

Standard Codes of Practice before installing the MasterT emp. Its use will reduce service calls and chance of injury and will

lengthen product life. History and experience has shown that most heater damage is caused by improper installation practices.

IMPORT ANT NO TICES

THIS PRODUCT MUST BE INSTALLED AND SERVICED BY A PROFESSIONAL SERVICE TECHNICIAN, QUALIFIED

IN POOL HEATER INSTALLATION.

For the installer and operator of the MasterTemp pool and spa heater: The manufacturer’s warranty may be

void if, for any reason, the heater is improperly installed and/or operated. Be sure to follow the instructions set forth in

this manual. If you need more information or if you have any questions regarding to this pool heater, please contact

Pentair Water Pool and Spa, Inc. EMEA – Head Office: Industriepark, Wolfstee, Toekomstlaan 30, 2200 Herentals

- Belgium or Pentair Water Pool and Spa, USA – at (800) 831-7133 • (919) 566-8000 • (805) 553-5000.

W ARRANTY INFORMA TION

The MasterTemp pool heater is sold with a limited factory warranty. Specific details are described on the warranty

registration card which is included with the product. Return the warranty registration card after filling in the serial

number from the rating plate inside the heater.

High standards of excellence include a policy of continuous product improvement results in your state-of-the-art

heater. We reserve the right to make improvements which change the specifications of the heater without incurring

an obligation to update the current heater equipment.

These heaters are designed for the heating of chlorine, bromine or salt system swimming pools and spas or

in non-stationary installations, and should never be employed for use as space heating boilers or general

purpose water heaters. The manufacturer’s warranty may be void if, for any reason, the heater is improperly

installed and/or operated. Be sure to follow the instructions set forth in this manual.

OPERATING THIS HEATER CONTINUOUSLY AT WATER TEMPERATURE BELOW 20°C. WILL CAUSE HARMFUL

CONDENSATION AND WILL DAMAGE THE HEATER AND VOID THE WARRANTY. Do not use the heater to protect

pools or spas from freezing if the final maintenance temperature desired is below 20°C, as this will cause condensation

related problems.

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

CAUTION

2 | Section

1. Operations

USING THE HEATER’S CONTROL PANEL

Temperature

Up and Down

System Operation

Indicator Lights

Digital Temperature

Display

Dual Temperature

Controls

Heater "OFF"

Switch

The MasterT emp heater controls are as follows:

POOL ON Press this button to control the heater operation by the pool temperature setting.

SP A ON Press this button to control the heater operation by the spa temperature setting.

HEA TER OFF Press this button to switch off the heater .

TEMP Press this button to raise the temperature setting.

TEMP Press this button to lower the temperature setting.

T o toggle the display between degrees Centigrade (°C) and degrees Fahrenheit (°F):

1. Press the HEATER OFF button to switch the heater OFF.

2. Press TEMP or TEMP for five (5) seconds. The display will flash once and change modes (°C to °F or

vice versa).

3. Press the HEATER OFF button to switch the heater ON.

When either the TEMP or TEMP buttons are pressed, the digital display will indicate the temperature setting. After

five seconds, the display will return to the actual pool/spa temperature.

In addition to the digital temperature LED display, there are five indicator LEDs:

The POOL ON light indicates that the pool water temperature is governing operation of the heater.

The SPA ON light indicates that the spa water temperature is governing operation of the heater.

The HEATING light comes on and stays on when the heater’s burner chamber is firing. This light should be on whenever

the burner is on. This light blinks when the heater is calling for heat but not firing. If this light is on but the burner fails to

come on, one of the “service” lights should come on, indicating a fault in the system.

The SER VICE SYSTEM light indicates that there is insufficient water flow to the heater. If the pump is operating, this

usually indicates that the filter and/or skimmers should be cleaned (some filters may require back-washing). If the light

remains on after the filter/skimmers have been serviced, the system should be checked by a qualified service technician.

The SER VICE HEATER light indicates a fault in the heater or its controls. If this light comes on, shut down the heater

(See “TO TURN OFF GAS T O THE APPLIANCE” on page 4), and have a qualified service technician check the system.

Risk of explosion or fire causing burns or death if safety interlocks are disabled. DO NOT attempt to operate heater

when SERVICE HEATER light is on or if blower or burner will not start. Instead, follow instructions under “To Switch Off Gas to

the Appliance,” and call a qualified service technician to repair unit.

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

WARNING

Section 1. Operations

| 3

Operation Instructions

BASIC SYSTEM OPERATION

Start pump, make sure the pump is running and is primed, to close the water pressure switch and supply

power to heater. Be sure the pool and/or spa is properly filled with water. Follow the Lighting/Operating instructions

below .

MASTERTEMP HSI ELECTRONIC IGNITION LIGHTING/OPERATION

FOR YOUR SAFETY: READ BEFORE LIGHTING

WARNING

If you do not follow these instructions e xactly, a fire or explosion ma y result causing

property damage, personal injury or loss of life.

Do not attempt to light the heater if you suspect a gas leak. Lighting the heater can result

in a fire or explosion which can cause personal injury , death, and property damage.

WARNING! DO NOT INTERFERE WITH ANY SEALED COMPONENTS. THIS CAN ONLY BE

DONE BY A QUALIFIED SERVICE PROFESSIONAL.

THE MASTERTEMP HEATER IS INTENDED FOR INSTALLATION WITH A METERED GAS PRESSURE REGULATOR.

START-UP AND OPERATION

START-UP AND SHUTDOWN INSTRUCTIONS ARE ON THE LABEL ATTACHED TO THE COVER OF THE

APPLIANCE CONTROL BOX.

NOTICE: UPON INSTALLATION THE INSTALLER MUST INSTRUCT THE USER IN THE OPERATION AND SAFETY

DEVICES AND PROVIDE A COPY OF THE HEATER’S USER’S GUIDE.

BEFORE START-UP

A. This appliance does not have a pilot. It is equipped with

an ignition device which automatically lights the burners.

Do not try to light the burners by hand.

B. BEFORE OPERATING, smell all around the

appliance area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle on

the floor.

WHAT TO DO IF YOU SMELL GAS

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone

in your building.

– Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

– If you cannot reach your gas supplier, call the Fire

Department.

C. Use only your hand to turn the gas control on or off.

Never use tools. If you cannot change the ON/OFF

setting by hand, don't try to repair it, call a qualified

service technician. Forced or attempted repair may result

in a fire or explosion.

D. Do not use this heater if any part has been under water .

Immediately call a qualified service technician to inspect

the heater and to replace any part of the control system

and any gas control which has been under water.

E. Do not operate the pool heater unless the pool or spa is

properly filled with water.

F. Before operating the appliance for the first time or after

it has been off for an extended time, perform the

following checklist:

1. Remove debris or other articles from inside the heater

and the area around the heater and its exhaust vent.

Make sure the ventilation openings are clear of debris

or obstruction. For installations in an enclosed space,

make sure openings for combustion and ventilation

air are unobstructed.

2. Keep heater area clear and free from combustibles,

flammable liquids and chemicals.

3. Check that all water connections are tight.

4. Water must be flowing through the heater during

operation. Make sure that pool/spa is filled with water

and have pump operating. Check that water flow is

unobstructed from the appliance. When operating for

the first time or after an extended shut-down, run

filter pump for several minutes to clear all air from

the system.

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

4 | Section

1. Operations

OPERA TING INSTRUCTIONS

1. STOP! Read the safety information on (page v - vii).

2. Set both pool and spa thermostats to the lowest

settings.

3. Turn off all electric power to the appliance.

4. This appliance does not have a pilot. It is equipped

with an ignition device which automatically lights

the burner. Do not try to light the burner by hand.

5. Turn off the outside external manual shut-off gas

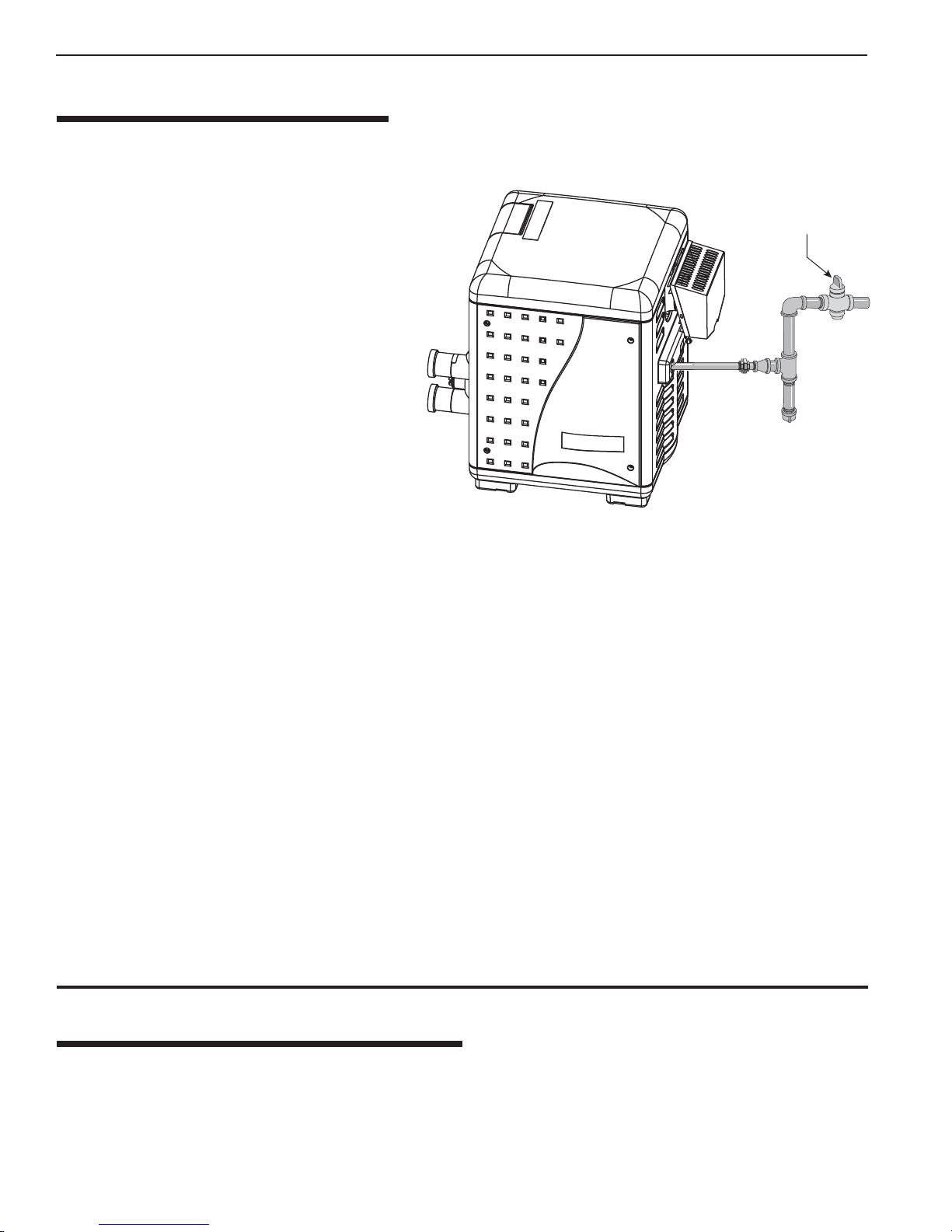

valve, see Figure 1.

W ait five (5) minutes to clear out any gas. If you

6.

then smell gas, STOP! Follow “B” in the “Before

Start-up” instructions (page 3). If you don’t smell

gas, go to the next step.

Turn on the outside external manual shut-off gas

7.

valve, see Figure 1.

External Manual

Shut-off Valv e

Figure 1.

Set 3-way valves on inlet and outlet to pool or

8.

spa, as appropriate.

9. Turn on all electric power to the appliance.

10. Press either the POOL ON or SPA ON button switch on the operating control.

1 1 . Set the thermostat to desired setting (NOTICE: Set point must be above actual water temperature or burner will not

fire). See page 2 “OPERATING THE CONTROL PANEL”.

12. The blower should come on immediately, and after about 20 seconds, the burner should fire. When operating for the

first time, the burner may not fire on the first try because of air in the gas line. If it does not fire at first, push the OFF

switch, wait five minutes, and again push the POOL or SPA ON switch. The burner should fire after about 20

seconds. You may have to repeat this until all of the air has cleared the gas line.

13. The burner should fire until the pool/spa temperature reaches the desired temperature set on the thermostat. The

blower will continue to run for about 45 seconds after the burner shuts off. If any of the safety interlocks should open

during burner operation, the burner shuts off immediately, but the blower continues to run for about 45 seconds.

Should overheating occur or the gas supply fail to shut off, turn off the manual gas control valve to the appliance.

14. If the appliance will not operate, follow the instructions below “TO TURN OFF GAS TO THE APPLIANCE”, and

call your service technician or gas supplier.

15. If the electrical power is lost while the heater is running, the heater will retain all program settings and the unit will

come back to it’s original mode and settings once the power is restored.

TO TURN OFF GAS TO APPLIANCE

1. Press the OFF button on operating control.

2. Switch off all electric power to the unit.

3. Turn off the outside external manual shut-off gas valve, see Figure 1.

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

SAFETY CONTROLS

AIR FLO W SWITCH (AFS)

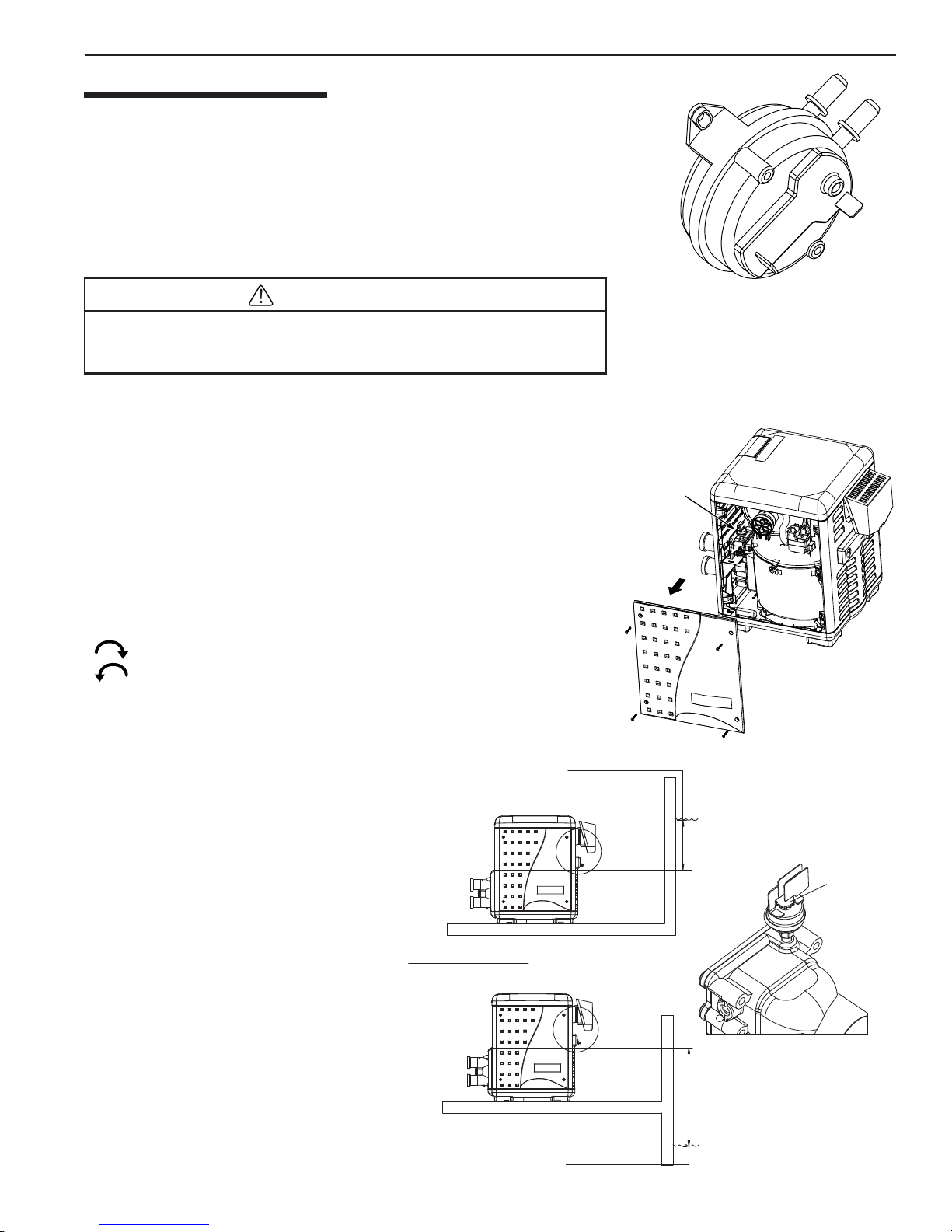

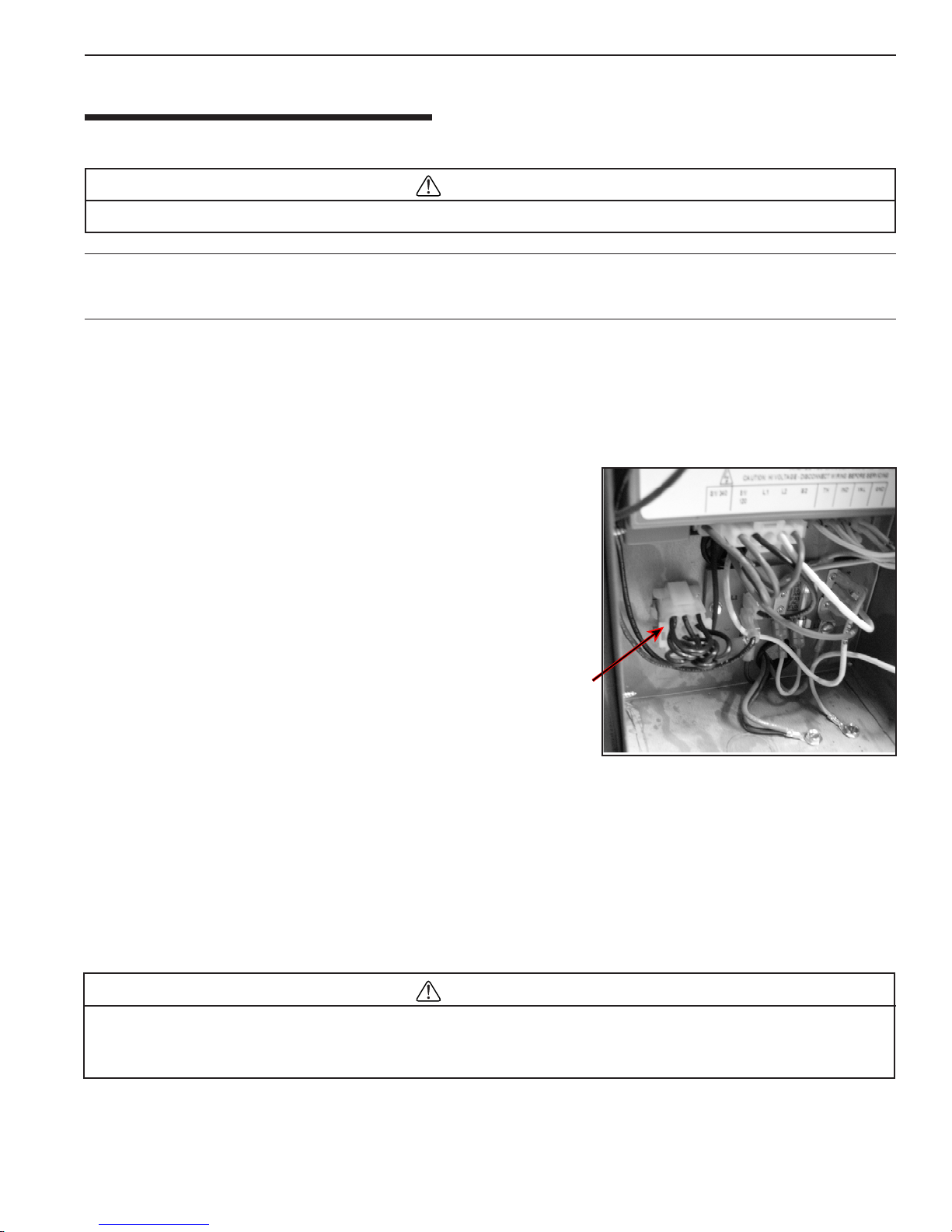

The air flow switch, (see Figure 2), is a safety device used to insure that the

combustion air blower (fan) is operating and has been designed to monitor the

vacuum (negative) pressure within the blower housing. The air flow switch is

factory set and is connected upstream of the ignition module. The ignition module

does not operate unless the air pressure switch and all safety switches are

closed.

Section 1. Operations

| 5

W A TER PRESSURE SWITCH

WARNING

Hazardous pressure. Do not bypass the Water Pressure Switch or render it inoper-

HAZARDOUS PRESSURE. DO NOT BYPASS THE WATER

able.

PRESSURE SWITCH OR RENDER IT INOPERABLE.

WA TER PRESSURE SWITCH

The water pressure switch, (see Figure 3). If the water flow is restricted, the

water pressure switch may prevent the burner from firing and cause the

“Service System” light to go on. If the light remains on after the filter has

been serviced, have a qualified service technician check the system.

For deck-level heater installations, the W ater Pressure Switch is factory set at

0.2 bar (3.00 psi). NOTE: See, Below Pool Level Installation instructions on

page 10. If the pressure switch is .3M (1 ft.) below or above the pool water

level, reset the switch so that it is open when the pump is off and closed

when the pump is running. Turn the star -wheel on the switch clockwise

( ) to raise setting (heater below the pool) and counterclockwise

( ) to lower the setting (heater above the pool – see Figure 4. Test the

switch after resetting.NOTICE: When the heater is mounted more than 1.5M

(5 ft.) above or 1.2M (4 ft.) below the deck level, a Pressure Switch is no

longer adequate. A Flow Switch must be installed instead.

Air Flow Switch

Water

Pressure

Switch

Figure 2.

Figure 4.

NOTICE: Heater operation with incorrect

Pressure Switch setting may cause operation

with no water flow. Operation of the heater

without sufficient water flow may severely

damage it and will void the warranty.

HIGH LIMIT SWITCH

A “High Limit”, is a safety device that opens

the electrical circuit and shuts off the heater

based on a water temperature set point within

the “High Limit Device”. The MasterTemp

series of heaters contains two (2) high limit

devices which are located on the main inlet /

outlet header (see page 41 item 6).

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

Turn star wheel clockwise to raise

pressure set point if pressure switch is more

than 1.2 M (4 ft) below water level

A reference scale is on

the back of pressure switch

Turn star wheel counterclockwise to lower

pressure set point if pressure switch is more

than 1.5 M (5 ft) above water level

1.2 M (4 ft)

Star Wheel

1.5 M (5 ft)

Figure 3.

6 | Section

s

1. Operations

SAFETY CONTROLS, (continued)

OPERATION OF IGNITION MODULE

Flame Current

Check Point

Diagnostic LED

1 Flash - Air Flow Fault

2 Flashes - Flame No Call For Heat

3 Flashes - Ignition Lockout

The Ignition Module, (see Figure 5), is microprocessor based and

operates on 24V AC supplied by the transformer . The control utilizes

a microprocessor to continually and safely monitor, analyze, and

control the proper operation of the gas flame holder. The module

with the presence of the flame sensor, using flame rectification,

allows the heater to operate.

Figure 5.

TEMPERA TURE SETTING

The heater comes factory set at 25.6° C (78° F). for the pool mode and 37.8° C (100° F). for the spa mode. Using the up

and down arrows, you can set the pool/spa thermostats to a minimum temperature of 18.3° C (65° F.), or a maximum of

40° C (104° F). If you desire to heat only one body of water, the thermostat is capable of an off mode. As an example, if

you only wish to heat the spa and not the pool, simply depress and hold the pool down arrow, and the thermostat will

lower its setting to 18.3° C (65° F.) then go to an off mode. See below to change the heater ’s factory set temperature

settings.

MAXIMUM TEMPERA TURE SET POINT

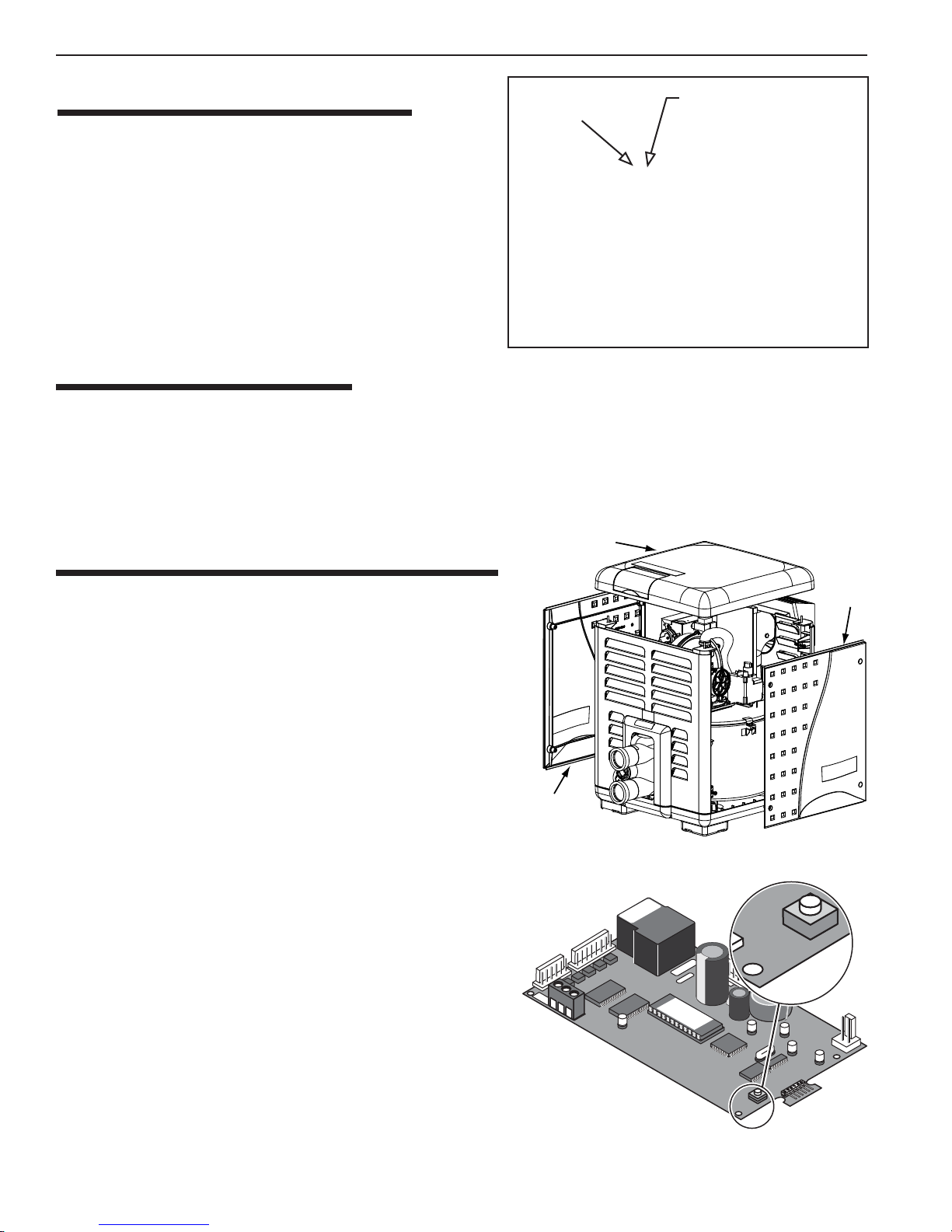

1. Unbolt and remove the door panels (see Figure 6).

Top Panel

Door

Acces

Panel

2. Access the control panel board on the underside of the top cover.

Locate the yellow button on the corner of the control board.

3. Push the Max. Temp. Set Point button on the back of the

control board (see Figure 7).

The following sequence should happen:

1. The unit turns on and the POOL ON light will

turn on.

2. Press the

TEMP or TEMP button (on TOP of the

control panel) to set maximum pool temperature.

3. W ait up to 30 seconds; the POOL ON light will turn of f

and the SPA ON

light will turn on. T o override the time

delay, push the Max. Temp. Set P oint button again.

4. Press the

TEMP or TEMP button on the control

panel and set maximum spa temperature to 40°C

(104° F) or less.

5. W ait up to 30 seconds; the SPA ON light will turn off

and the unit will shut down. T o override the time delay,

push the Max. Temp. Set P oint

button again.

6. Reinstall the access door panels.

Door

Access Panel

Figure 6.

SET

MA

X

S1

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

SET

MAX

S1

Figure 7.

Section 2. Installation

| 7

Installation Instructions

THIS PRODUCT MUST BE INSTALLED AND SERVICED BY A PROFESSIONAL SERVICE TECHNICIAN, QUALIFIED IN POOL

HEATER INSTALLATION. THE MASTERTEMP HEATER IS INTENDED FOR INSTALLATION WITH A METERED GAS PRESSURE

REGULATOR.

Pentair strongly recommends that all vents, pipes and exhaust systems be initially and periodically tested for proper operation. This testing

can be accomplished by using a hand-held carbon monoxide meter and/or by consulting with a gas professional.

Pool heaters must be used in conjunction with carbon monoxide detectors installed near the pool heater. The carbon monoxide detectors must

be periodically inspected for proper operation so as to insure continued safety.

Broken or malfunctioning carbon monoxide detectors must be replaced

immediately. If not fitted on the heater, the installer must installed any safety

devices according to

the European Standard Codes of Practice.

Air

NOTICE: UPON INSTALLATION THE INSTALLER MUST INSTRUCT THE

USER IN THE OPERATION AND SAFETY DEVICES AND PROVIDE A

COPY OF THE HEATER’S USER’S GUIDE (THIS MANUAL).

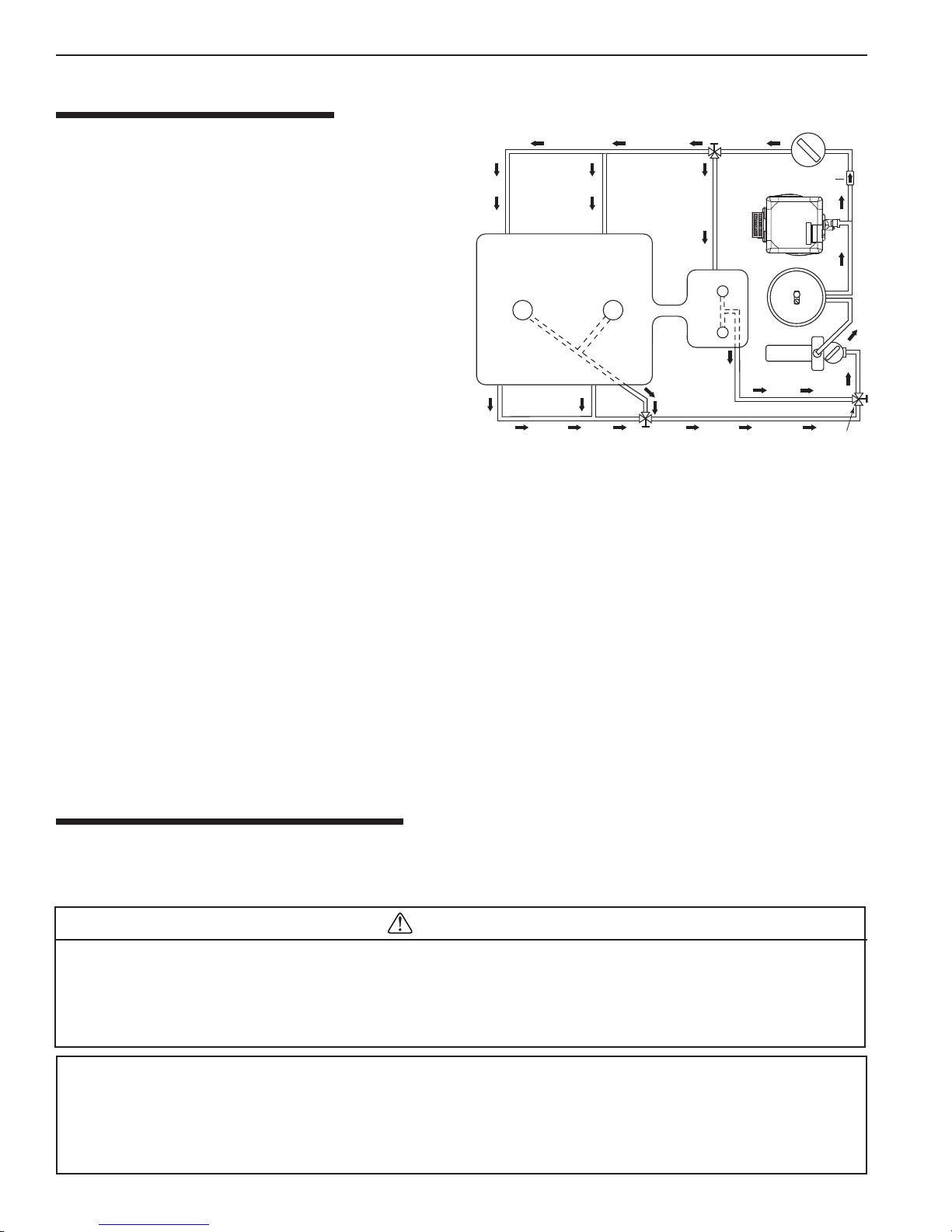

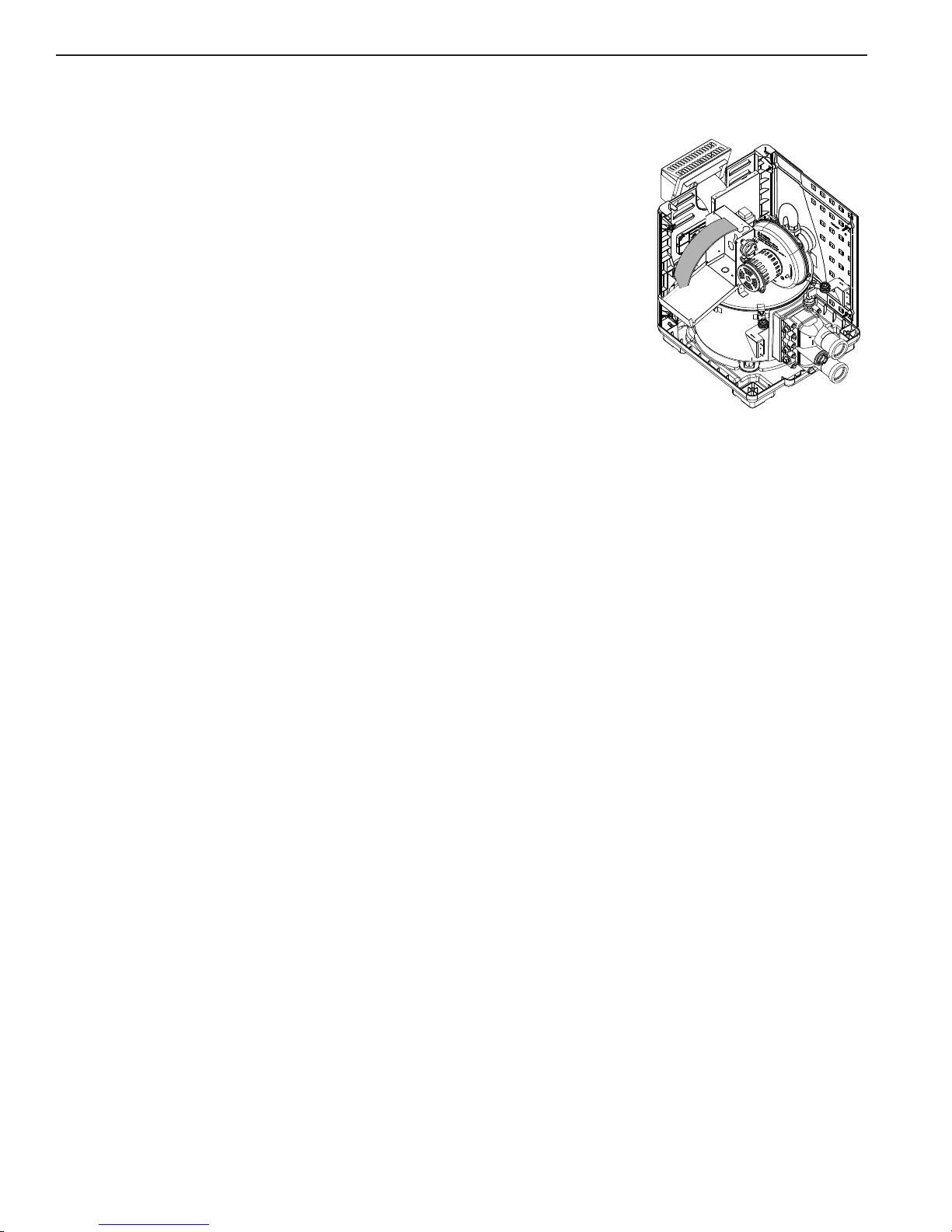

HEATER DESCRIPTION

Inlet

(Cold

Water)

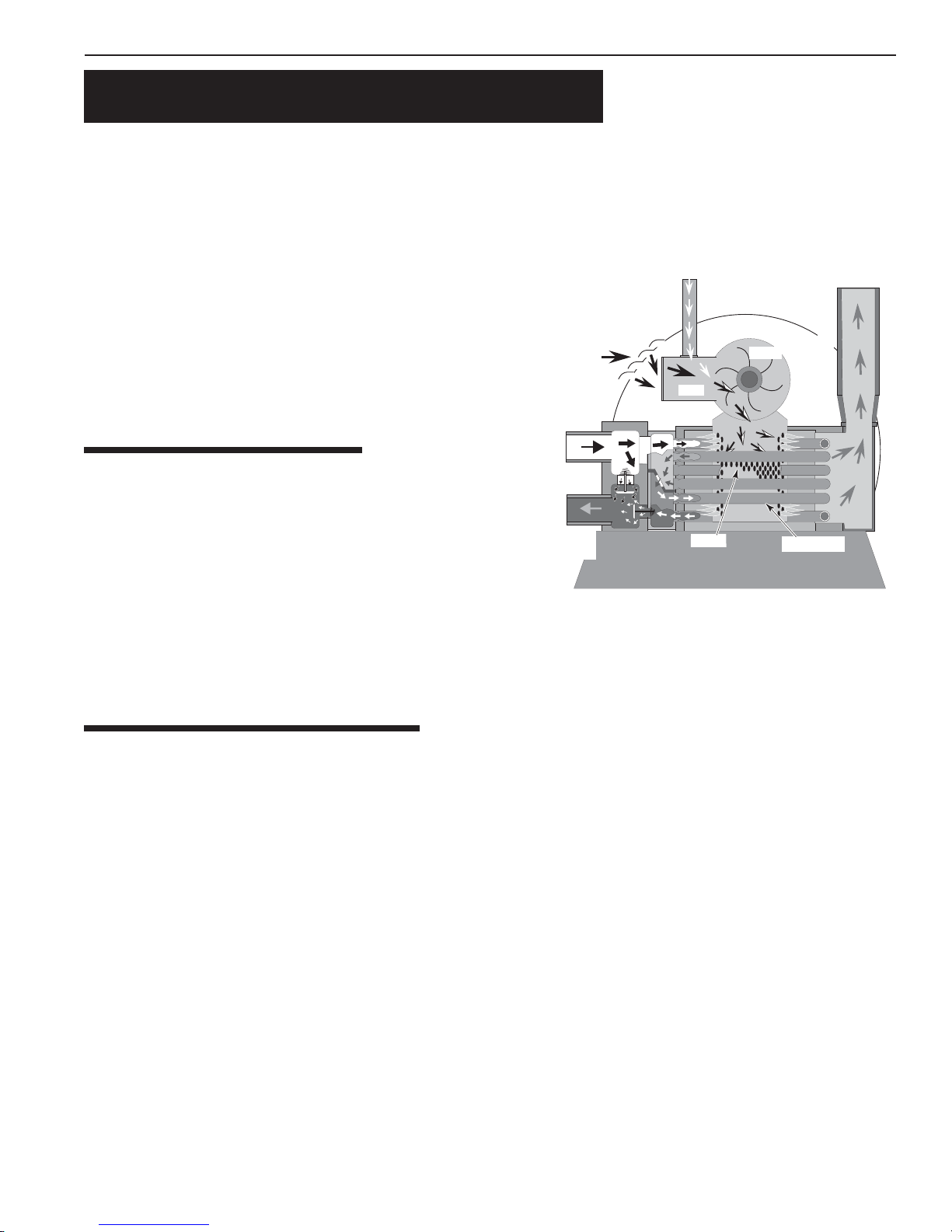

Figure 8 is a diagram of the heater showing how it operates. Precisely

matched orifice plates meter the air and gas into the mixer. The blower

draws the air and gas through the mixer and forces it into the burner’s

flame holder. A sealed heat exchanger surrounds the flame holder,

discharging exhaust gases out the flue.

Outlet

(Mixed

Water)

63 mm (2 in - UK) PVC water piping connects directly to the manifold/

header on the heat exchanger using 63 mm (2 in - UK) PVC slip

unions provided with the heater. The outer manifold remains cool; no

heat sinks are required. A thermal regulator and an internal bypass

regulate the water flow through the heat exchanger to maintain the correct outlet temperature. The heater operator control

panel board assembly is located on top of the heater.

Mixer

Gas

Burner

Blower

Exhaust

Heating Coils

Figure 8.

SEQUENCE OF OPERATION

An electronic temperature sensing thermistor in the manifold adapter inlet controls the heater operation. When the inlet

water temperature drops below the temperature set on the operating control, the burner controller supplies power to the

combustion air blower through a series of safety interlocks. The interlocks consist of:

• the pressure switch (PS), which senses that the pump is running,

• the high limit switch (HLS), which opens if the heat exchanger outlet temperature goes above 55° C (131° F), and

• the air flow switch (AFS), which senses the pressure drop across the air metering orifice,

• the automatic gas shut-off (AGS) switch, which opens if the heat exchanger outlet temperature goes above 60° C (140° F).

• the inlet temperature control switch, which opens if the inlet temperature goes above 45° C (110° F).

• the stack flue sensor (SFS), which shuts down the heater if the flue gas temperature reaches 249° C (480° F).

The air flow switch (AFS) senses the pressure drop across the air metering orifice. As soon as there is suf ficient air flow,

the AFS closes, closing the circuit to the hot surface igniter (HSI), which ignites the fuel mixture. On a call for heat, the

blower and HSI are energized. In about 20 seconds, the gas valve opens and ignition occurs. The HSI then switches to a

sensing mode and monitors the flame.

The heater is equipped with a digital operating control that enables the user to pre-set the desired pool and spa water

temperatures. The control enables the user to select between pool and spa heating, and features a digital display that

indicates the water temperature.

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

8 | Section

1. Installation

PUTTING THE HEATER INTO SERVICE

If the heater is installed below the level of the pool, or more than 0.6 meters (2 feet) above pool level, the pressure switch

setting should be adjusted. See “WATER PRESSURE SWITCH” in the “SAFETY CONTROLS Section” (page 5) and

the “CAUTION” under “BELOW POOL INSTALLATION Section” (see page 10).

Before putting the heater into service for the first time, follow the instructions under “BEFORE ST AR T-UP” (page 3) in

the front of this manual. Check for proper operation of the heater by following the steps under, see page 4 “OPERATION

INSTRUCTIONS.”

Notice: Damage to equipment caused by improper installation or repair will void the warranty.

SPECIFICATIONS

These installation instructions are designed for use by qualified personnel only, trained especially for installation of this

type of heating equipment and related components. Some states require installation and repair by licensed personnel. If

this applies in your state, be sure your contractor bears the appropriate license. See Figure 9 for Outdoor Installations.

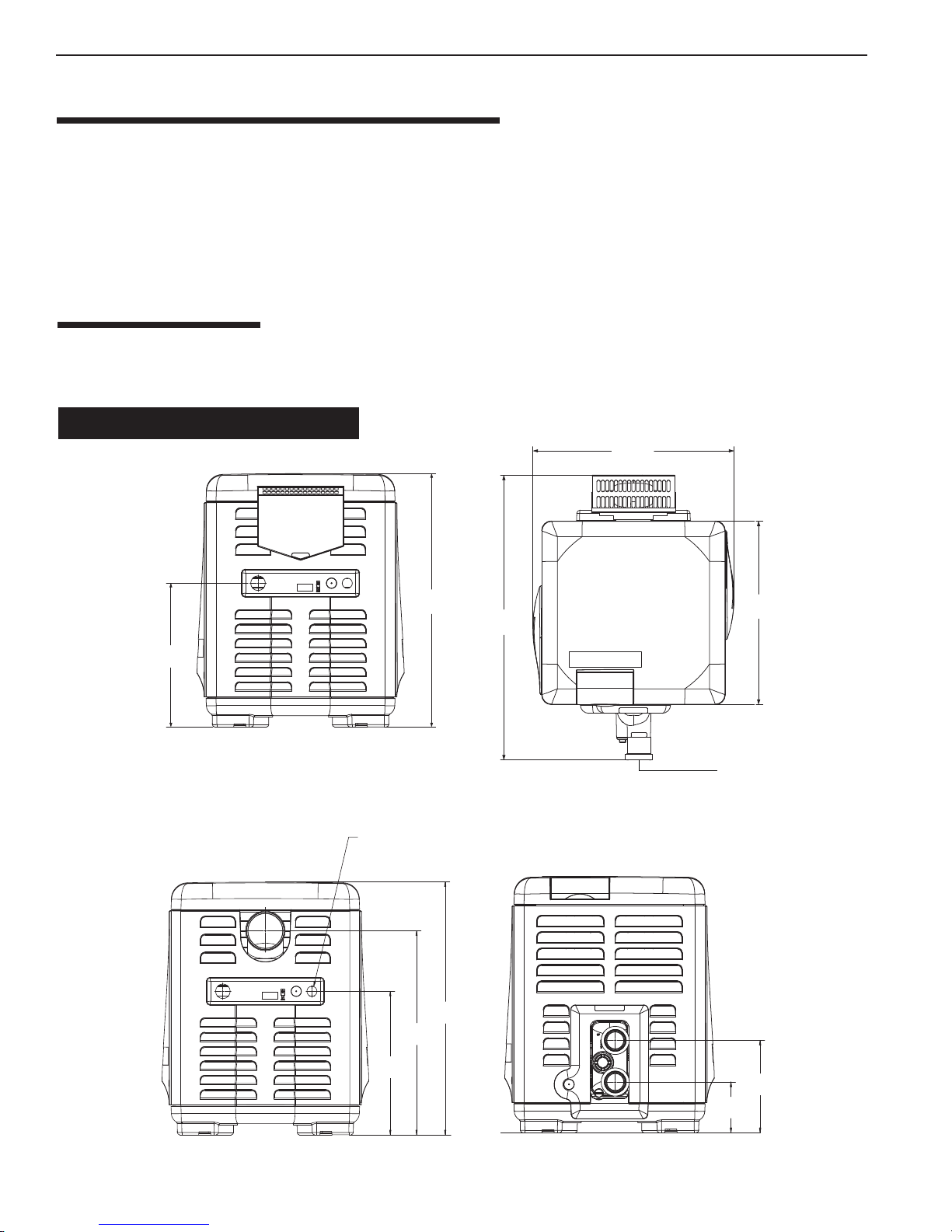

DIMENSIONS IN CENTIMETERS & INCHES

585 mm

(23")

406 mm

(16")

715 mm

(28")

ELECTRICAL

CONDUIT PORT

715 mm

(28")

578 mm

(23")

406 mm

(16")

828 mm

(31”)

533 mm

(21")

63 mm

(2" - UK)

TOPFRONT

257 mm

(10")

142 cm

(6")

Figure 9.

EXHAUST SIDE PLUMBING SIDE

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

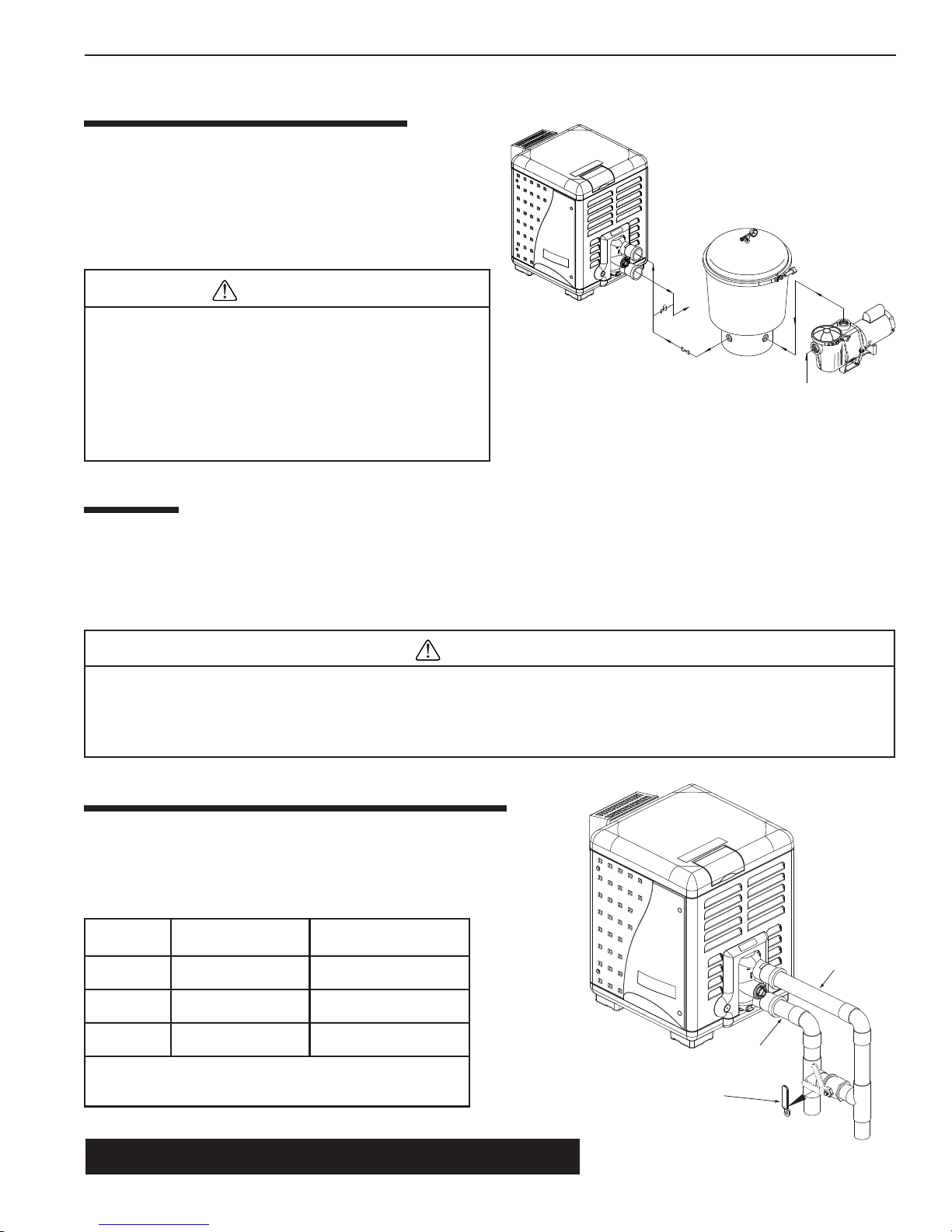

PLUMBING CONNECTIONS

The MasterTemp™ heater has the capability of direct PVC

water piping plumbing connections. A set of bulkhead fittings

is included with the MasterTemp to insure conformity with

Pentair’s recommended PVC plumbing procedure. Other

plumbing connections can be used. See Figure 11 for plumbing

connections.

Section 2. Installation

| 9

CAUTION

POOL

HEATER

Before operating the heater on a new installation, turn on

the circulation pump and bleed all the air from the filter using

Figure 10.

MANUAL

BY-PASS

TO

POOL

GATE

VALVE

FILTER

PUMP

the air relief valve on top of the filter. Water should flow

freely through the heater . Do not operate the heater unless

FROM

POOL

water in the pool/spa is at the proper level. If a manual bypass is installed, temporarily close it to insure that all air is

purged from the heater .

VALVES

When any equipment is located below the surface of the pool or spa, valves should be placed in the circulation piping

system to isolate the equipment from the pool or spa. Check valves are recommended to prevent back-siphoning. Backsiphoning is most likely to occur when the pump stops, creating a pressure-suction differential. Do NOT sanitize the pool

by putting chlorine tablets or sticks into the skimmer(s). When the pump is off, this will cause a high concentration of

chlorine to enter the heater, which could cause corrosion damage to the heat exchanger.

CAUTION

Exercise care when installing chemical feeders so as to not allow back siphoning of chemical into the heater, filters

or pump. When chemical feeders are installed in the circulation of the piping system, make sure the feeder outlet line

is down stream of the heater, and is equipped with a positive seal noncorrosive “Check Valve”, (P/N R172288),

between the feeder and heater.

MANU AL BY-PASS ( W A TER FLOW RATE)

Where the water flow rate exceeds the maximum 454 L/m, a manual

bypass should be installed and adjusted. After installing the valve, adjust

the valve to bring the flow rate within the acceptable range. Then remove

the valve handle or lock it in place to avoid tampering. See Figure 11.

ledoM)MPG(m/L.niM*)MPG(m/L.xaM

002)02(67)021(454

003)03(411)021(454

004)04(251)021(454

See page 33 for Pressure Relief Valve Installations.

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

Cool water in

Warm water out

dednemmocermumixamehtdeecxetonoD*

.gnipipgnitcennocehtrofetarwolf

Table 1.

1. Set Manual By-Pass Valve.

2. Remove Handle.

Figure 11.

Outlet to pool

Inlet to heater

10 | Section

2. Installation

WATER CONNECTIONS

3-Way

The heater requires proper water flow and pressure for its

Valve

operation. See Figure 12 for the recommended installation.

The filter pump discharges to the filter, the filter dischar ges to

the heater, and the heater discharges directly to the pool or

spa.

A manual bypass valve should be installed across the heater

when the pump flow exceeds 454 L/m (120 GPM). See

“WATER FLOW RATE” on page 9 - Table 1 for setting of

the manual by-pass valve.

Main

Drain

Pool

Heater

Spa

Make sure that the outlet plumbing from the heater contains

no shut-off valves or other flow restrictions that could prevent

flow through the heater (except for below pool as noted below ,

or winterizing valves where needed). T o switch flow between

the pool and spa, use a diverter valve. Do not use any valve

that can shut off the flow. Do not use a shut-off valve to

isolate the heater unless it is below the level of the pool or spa.

From Pool

3-Way

Valve

Figure 12.

Install the chemical feeder downstream of the heater. Install

a chemical resistant one-way check valve between the heater and the chemical feeder to prevent back-siphoning through

the heater when the pump is off.

NOTICE: If the heater is plumbed in backwards, it will cycle continuously. Make sure piping from filter is not reversed

when installing heater.

Connect the heater directly to 63 mm (2 in - UK) PVC pipe, using the integral unions provided. Heat sinks are not

required. The low thermal mass of the heater will prevent overheating of the piping connected to the pump even if the

heater shuts down unexpectedly . Occasionally a two-speed pump will not develop enough pressure on the low speed to

operate the heater. In this case, run the pump at high speed only to operate the heater . If this does not solve the problem, do

not try to run the heater. Instead, correct the installation.

Do not operate the heater while an automatic pool cleaner is also operating. If the circulation pump suction is plugged (for

example by leaves), there may not be adequate flow to the heater. Do not rely on the pressure switch in this case.

If European Standard Codes of Practice require the installation of a pressure relief valve (PRV), see page 33 for

“PRESSURE RELIEF VALVE INSTRUCTIONS”.

Chlorinator

Check Valve

Filter

Pump

3-Way

Valve

BELO W POOL INST ALLA TION

If the heater is below water level, the pressure switch must be adjusted. This adjustment must be done by a qualified

service technician.

See following CAUTION before installation.

BELOW OR ABOVE POOL INSTALLATION

The Water Pressure Relief V alve Switch is set in the factory at 0.20 bar (3.00 psi). This setting is for a heater installed at pool

level. If the heater is to be installed more than 0.3 m above or below, the water pressure switch must be adjusted by a

qualified service technician. See page 33, Figure 32.

If the heater is installed more than 1.5 m above the pool or more than 1.2 m below the pool level, you will be beyond the

limits of the pressure switch and a flow switch must be installed. Locate and install the flow switch externally on the outlet

piping from the heater , as close as possible to the heater. Connect the flow switch wires in place of the water pressure

switch wires.

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

CAUTION

FLOW SWITCH INSTALLATION

Section 2. Installation

| 11

GAS CONNECTIONS

GAS LINE INST ALLA TIONS

The gas supply must be installed in accordance with the Eur opean S tandard Codes of Practice for gas installation as applicable and

all applicable local codes.

THE MASTERTEMP HEATER IS INTENDED FOR INSTALLATION WITH A METERED GAS PRESSURE REGULATOR.

Before installing the gas line, be sure to check which gas the heater has been designed to burn. This is important because different

types of gas require different gas pipe sizes. The rating plate on the heater will indicate which gas the heater is designed to burn.

T able 2 below shows the recommended gas inlet pipe sizes required for the distance from the gas meter to the heater . The table is

for G20 and G25 at a specific gravity of .65 and G31 at a specific gravity of 1.55.

When sizing gas lines, calculate 0.9 additional meters of straight pipe for every elbow used. When installing the gas line, avoid getting

dirt, grease or other foreign material in the pipe as this may cause damage to the gas valve, which may result in heater failure.

The gas meter should be checked to make sur

be used on the same meter. Insufficient gas supply will cause the heater to operate below its designed performance or not at

all. The gas line from the meter will usually be of a larger size than the gas valve supplied with the heater. Therefore a

reduction of the connecting gas pipe will be necessary. Make this reduction as close to the heater as possible. If the gas

pressure is not adjusted to the correct working pressure, the heater will be over gassed and cause serious damage within

minutes. This damage is not covered under the heater warranty.

Install a manual shut-off valve that conforms with

located outside the heater panels, see Figure 13. Do not use a restrictive gas cock.

The heater and any other gas appliances must be disconnected from the gas supply piping system during any pressure testing on that

system, (greater than 6.0 kPa). The heater and its gas connection must be leak tested before placing the heater in operation. Do not

use flame to test the gas line. Use soapy water or another nonflammable method.

e that it will supply enough gas to the heater and any other appliances that may

European Standard Codes of Practice, and a sediment trap/drip leg and union

NOTE

A manual main shut-off valv e must be installed externally to the heater .

WARNING

DO NOT INSTALL THE GAS LINE UNION INSIDE THE HEA TER CABINET. THIS WILL VOID YOUR WARRANTY.

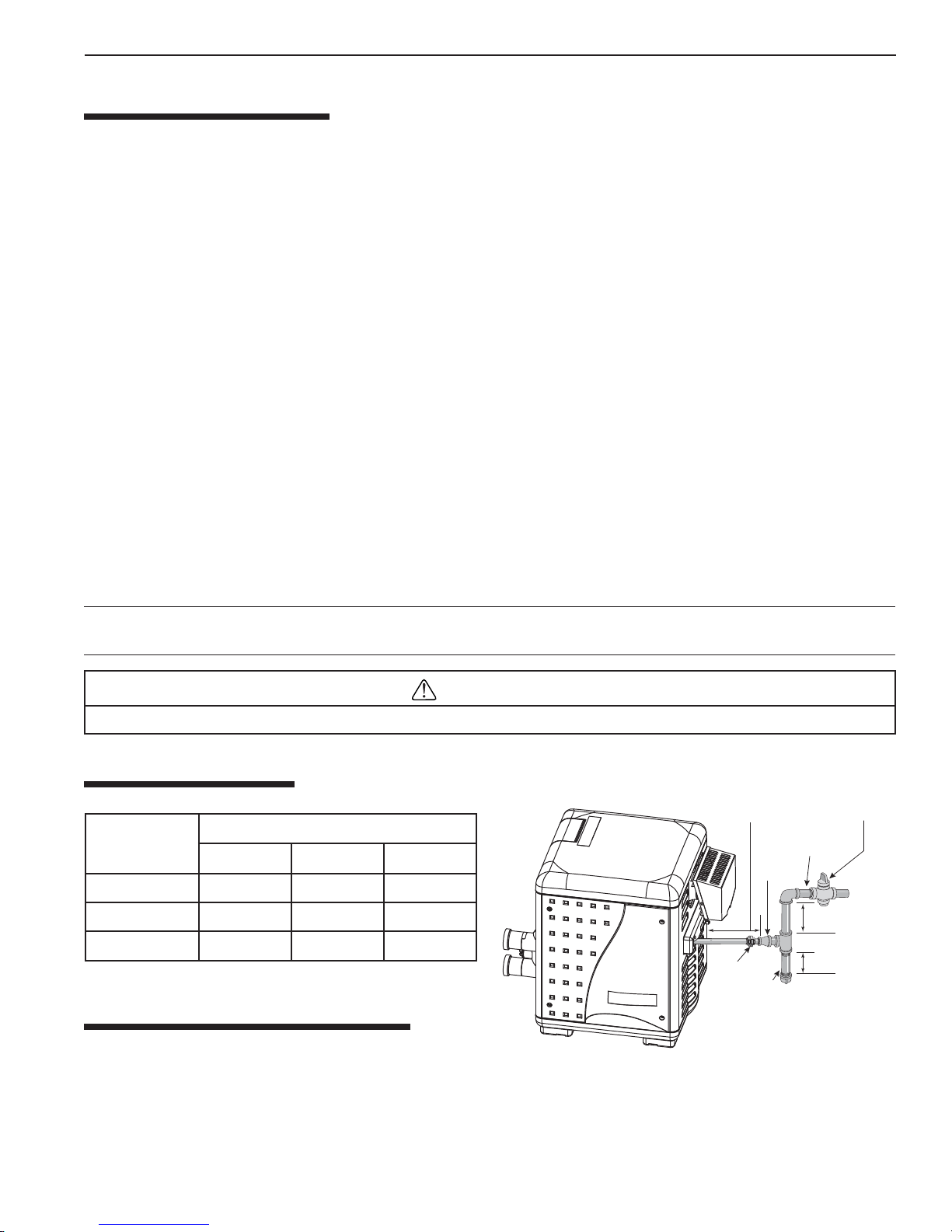

GAS PIPE SIZING

Table 2.

reteMehtmorfecnatsiD

eziSretaeH

m51ot0m03ot61m06ot13

002mm52mm23mm23

003mm23mm23mm04

004mm23mm04mm05

SEDIMENT TRAP/DRIP LEG

Install a sediment trap/drip leg and union located outside the

heater panels in accordance with European S tandard Codes of Practice requirements. Do not use a restrictive gas cock.

The sediment trap/drip leg shall be either a tee fitting with a capped nipple in the bottom outlet which can be removed for

cleaning, as illustrated in Figure 14, or an other device recognized as an effective sediment trap/drip leg. All gas piping

should be tested after installation in accordance with local codes.

45-60 cm x 3/4 in

(18–24" of 3/4")

Gas line from

Valve

2.54 cm (1") Dia. or larger

(See "Recommended

Bell

Reducer

Union

Sediment

Trap/Drip Leg

Pipe Sizes" Chart

At least 23 cm (9")

At least 8 cm (3")

Figure 13.

Manual

Shut-off

Valve

)

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

12 | Section

2. Installation

TESTING GAS LEAKS AND GAS PRESSURE

THE MASTERTEMP HEA TER IS INTENDED FOR INST ALLA TION WITH A METERED GAS PRESSURE REGULA T OR.

Before operating the heater, the heater and its gas connections must be leak tested. Do NOT use an open flame to test

for leaks. Test all gas connections for leaks with soapy water.

The gas valve must be completely disconnected from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 6.0 kPa (60 mbar).

TESTING THE GAS PRESSURE THROUGH THE COMBINATION GAS CONTROL VALVE

WARNING

Risk of fire and explosion. Alteration, service, or maintenance of the Combination Gas Control Valve can lead to fire or

explosion, causing loss of life, personal injury, and/or property damage.

VALVE.

These instructions are for the use of qualified service technicians only!

1. Shut off the gas supply to the heater.

2. Loosen the small screw inside the pressure tap as shown in Figure 14.

Connect the manometer hose.

3.

4. Open the gas supply to the heater.

5. Turn on the heater.

6. Take the gas pressure reading.

7. Turn off the heater.

8. Shut off the gas supply to the heater.

9. Disconnect the manometer hose.

10. Tighten the small screw inside the pressure tap.

11. Open the gas supply to the heater.

12 Verify that the seal connection in the pressure tap is closed by testing

for leaks with soapy water.

Note: If the pressure reading is out of range, (see Table 3), regulate the

incoming gas pressure.

INLET GAS PRESSURE REQUIREMENTS

noitpircseDepyTerusserPylppuSsaG

:ETON ehtdeecxetonoD.tnemtsujdatupnirofdevorppaeulavmuminimehT

Table 3.

saGlarutaN

saGenaporP

.erusserpylppusmumixam

LLE2;iE2,sE2;N2;+E2;H2

)52G/02G(

)13G(P3rabm73

.gnitareposiretaehelihwnekatebtsumsgnidaerllA sgnidaerrostnemtsujdaynA

.smelborpecnamrofrepnitluserlliwffosiretaehelihwedam

rabm52-02

DO NOT ATTEMPT TO ADJUST THE GAS CONTROL

Lightly loosen the

small screw inside the pressure tap,

and attach/connect the manometer hose.

Figure 14.

This appliance is equipped with an unconventional gas control valve that is factory set with a manifold pressure of

1.1 ± 0.5 mbar. Installation or service must be performed by a qualified installer, service agency, or the gas supplier . If

this control valve is replaced, it must be replaced with an identical control. The combination gas valve incorporates dual

shut-off valves and a negative-pressure regulator. For proper operation, the regulated pressure at the outlet manifold of

the valve must be 1.1 ± 0.5 mbar below the reference pressure at the blower mixer inlet, and the gas valve ‘VENT’

tap must be connected to the end cap air orifice as shown in Figure 14. DO NOT attempt to adjust the gas input by

adjusting the regulator setting. The correct gas regulator setting is required to maintain proper combustion and

must NOT be altered.

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

Lead

Anchor

For Heater mounting

bolts and clamps,

purchase separately

Bolt Down Bracket Kit,

Part No.

460738.

Section 2. Installation

| 13

OUTDOOR INSTALLATION

For heaters located outdoors, using the built-in stackless venting system.

DANGER

CARBON MONOXIDE GAS IS DEADL Y – Exhaust from this pool heater contains carbon monoxide, a dangerous, poisonous gas you

cannot see or smell. Symptoms of carbon monoxide exposure or poisoning include dizziness, headache, nausea, weakness, sleepiness,

muscular twitching, vomiting and inability to think clearly . IF YOU EXPERIENCE ANY OF THE ABOVE SYMPTOMS, IMMEDIATELY

TURN OFF THE POOL HEATER, LEAVE THE VICINITY OF THE POOL OR SPA AND GET INTO FRESH AIR IMMEDIATELY.

THE POOL HEATER MUST BE THOROUGHLY TESTED BY A GAS PROFESSIONAL BEFORE RESUMING OPERA TION.

EXCESSIVE CARBON MONOXIDE EXPOSURE CAN CAUSE BRAIN DAMAGE OR DEATH.

WARNING

Risk of explosion if a unit burning G31 is installed in a pit or other low spot. G31 is heavier than air . Do not install the heater

using propane in pits or other locations where gas might collect. Consult the European Standard Codes of Practice building code

officials to determine installation requirements and specific installation restrictions of the heater relative to propane storage tanks and

filling equipment. Installation must meet the requirements for the Standard for the Storage and Handling of Liquid Petroleum Gases.

Consult local codes and fire protection authorities about specific installation restrictions.

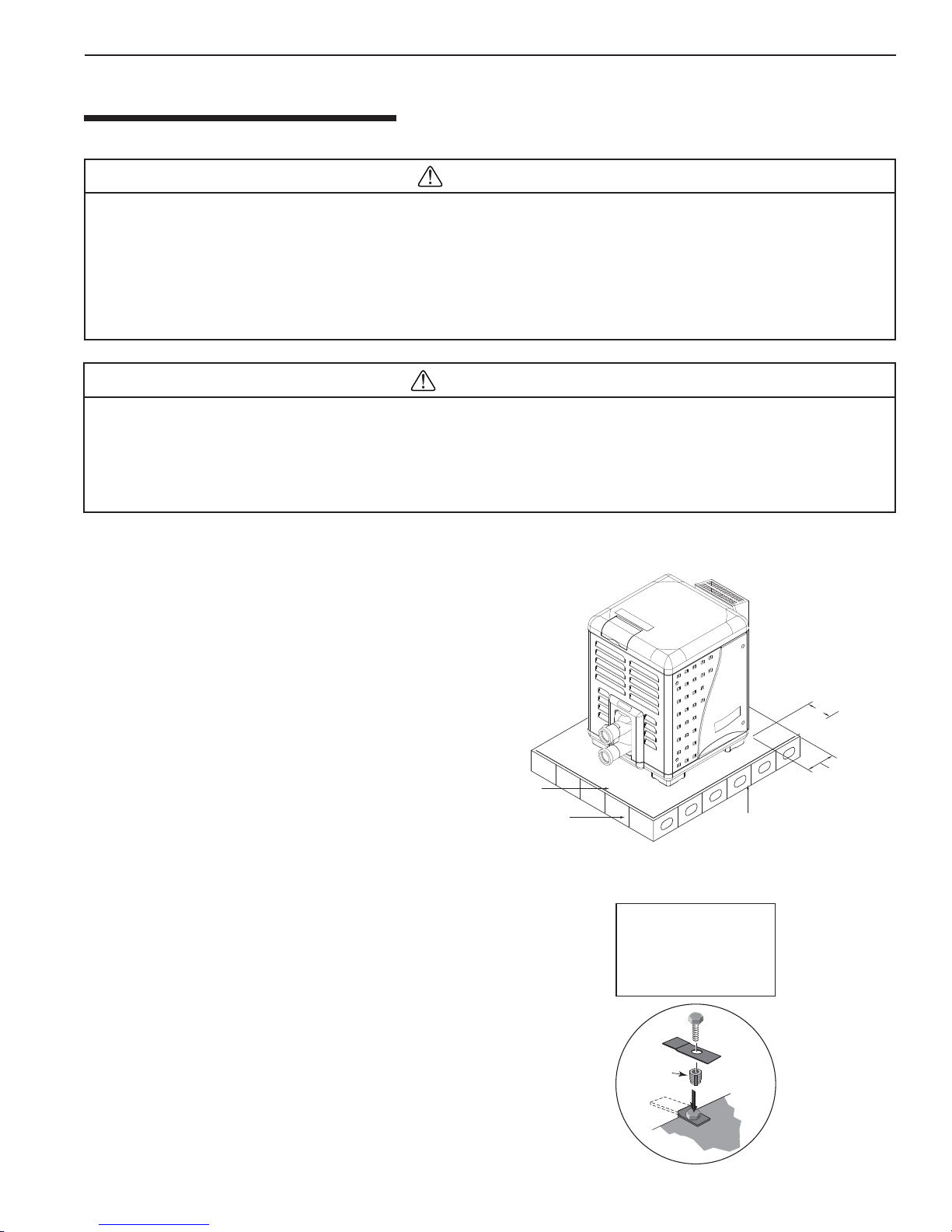

Locate the heater in an open, unroofed area and on a level surface that is protected from drainage or run-off. Install the

heater in an area where leaves or other debris will not collect

on or around the heater.

It is recommended that a non-combustible base be a platform

under the heater constructed of hollow masonry blocks, not

less than 100 mm (4 in) thick (laid with ends unsealed and

joints matched for air circulation). Cover blocks with 0.75

mm (0.03 in) minimum galvanized sheet metal, see Figure 15.

T

o avoid damage to the electronic components in the heater,

take care to prevent prolonged exposure to driving sources of

water (such as lawn sprinklers, heavy roof runoff, hoses, etc.).

Avoid operation in persistent, extreme, moist or salty

environments.

In extreme weather, shut down the heater and disconnect the

power to it until the weather has moderated. In areas subject

to hurricanes or very high winds, purchase the Bolt Down

Bracket Kit, P/N 460738, see Figure 16.

BASE FOR USE ON

COMBUSTIBLE FLOORS

150 mm

(6 in) Min.

150 mm

SHEET

METAL

BLOCKS

Hollow masonry blocks, not less than 100 mm (4 in) thick, (laid with ends unsealed and joints

matched for air circulation). Cover blocks with 0.75 mm (0.03 in) minimum galvanized sheet metal.

Figure 15.

.

Masonary blocks

100 mm (4 in) thick minimum

(6 in) Min.

P/N 475106 Rev. D 1/2016 MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide

Figure 16.

14 | Section

2. Installation

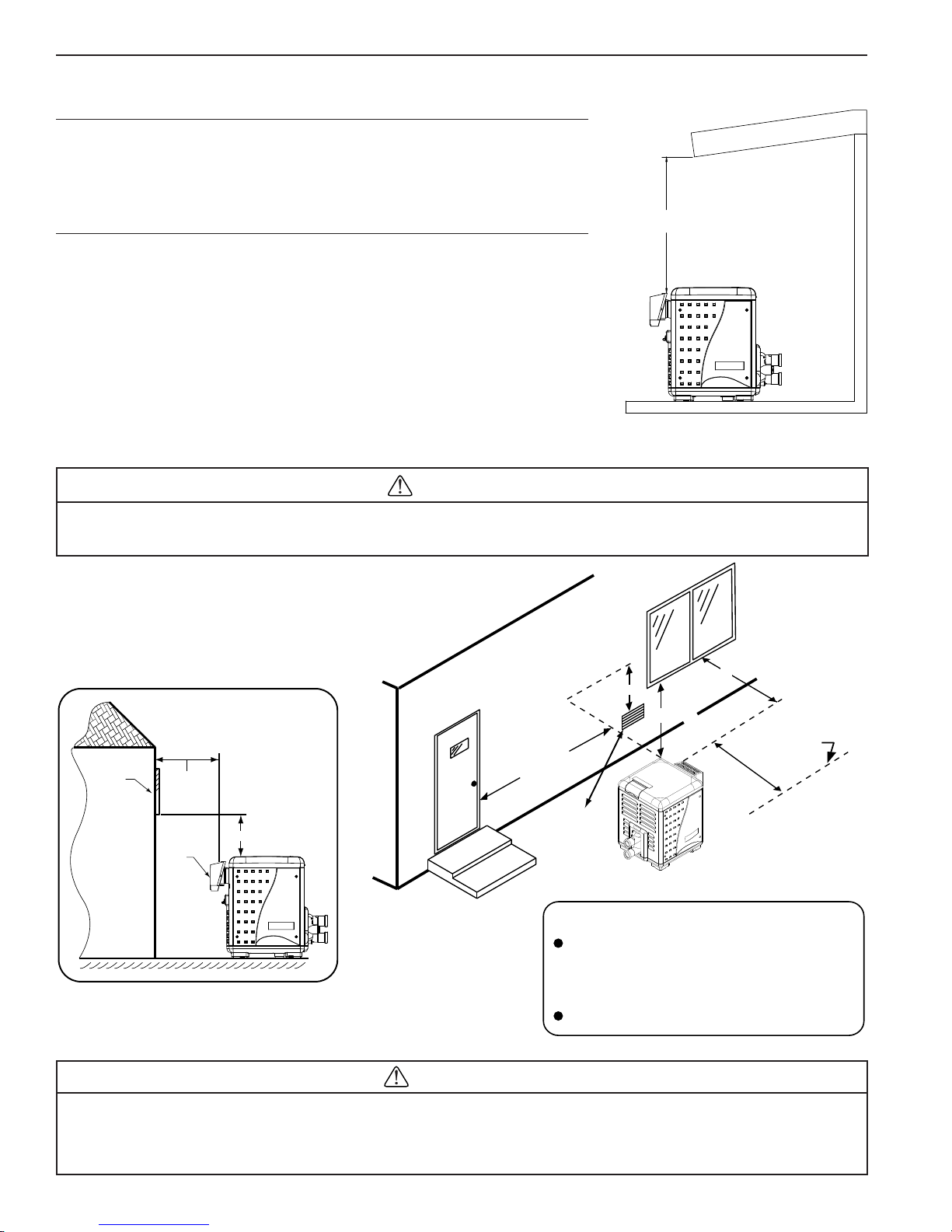

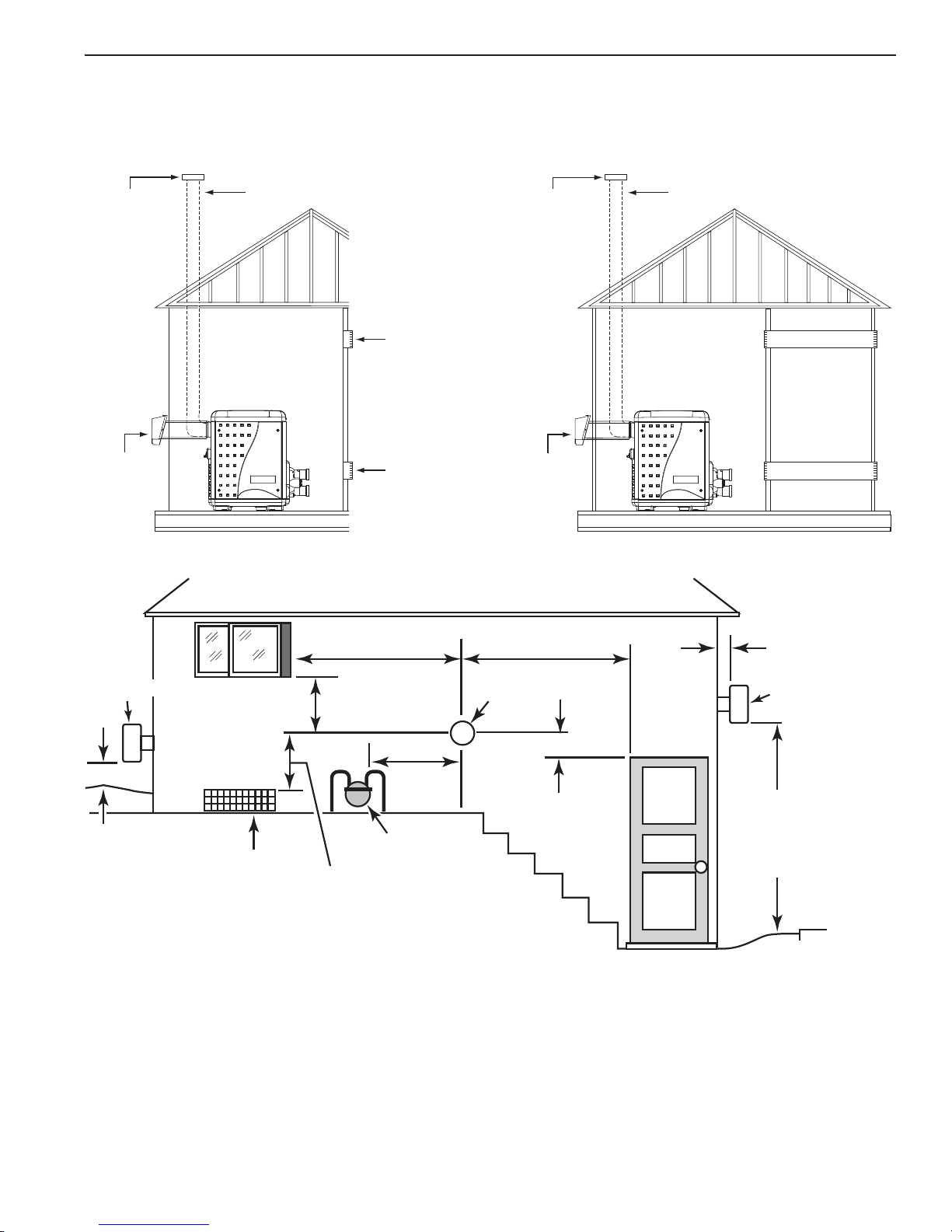

HEA TER CLEARANCES – OUTDOOR

IMPORTANT!

• In an outdoor installation it is important to ensure water is diverted

from overhanging eves with a pr oper gutter/drainage system. The heater

must be set on a level foundation for proper drainage.

• This unit shall not be operated outdoors at temperatures below -7o C.

If the heater is located under a roof or deck overhang, there must be at least

1 meter (3 ft.) of clearance between the bottom of the overhang and the top of

the heater exhaust vent, see Figure 17. If the heater is under a roof or deck

overhang, the space around the heater must be open on three sides.

For minimum exhaust vent clearances for building openings, see below Figure 18.

Orient the heater for convenient access to the water connections and the gas

and electrical connections.

Check the European Standard Codes of Practice for setback (property line)

requirements.

CAUTION

1 meter (3 ft.) or more

Figure 17.

If installing the heater next to or near an air conditioning unit or a heat pump, allow a minimum of 92 cm

(36 in.) between the air conditioning unit and the heater.

OUTDOOR INSTALLATION

VENTING GUIDELINES

1500 mm

1500 mm

Window

Building

1500 mm

Exhaust Grill

(Vent)

SIDE VIEW

1500 mm

1500 mm

Force

Air Inlet

Vent T ermination:

Must be installed at least 1500 mm away from

the building wall openings, and at the following

distances away from any door, window, or

gravity air inlet.

1500 mm

Property Line

Check local building codes

for setback requirements.

Figure 18.

Risk of fire and explosion. Do not spray aerosols in the vicinity of the heater while it is in operation. Chemicals

should not be stored near the heater installation. Combustion air can be contaminated by corrosive chemical fumes

which can damage the heater and will void the warranty.

MASTERTEMP™ Pool and Spa Heater Installation and User’s Guide P/N 475106 Rev. D 1/2016

The heater must also have no obstructions above it.

WARNING

Section 2. Installation

| 15

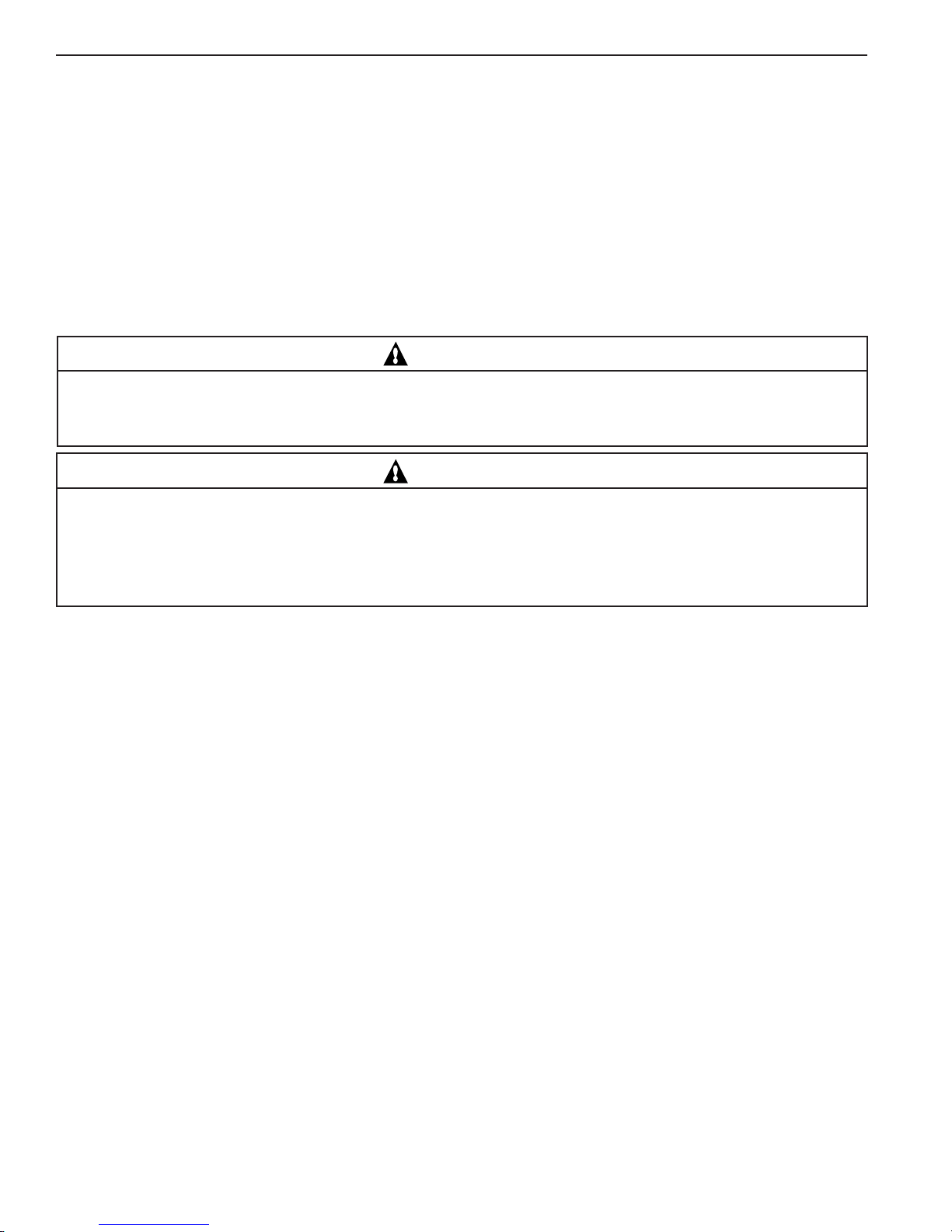

INDOOR VENTING — General Requirements

If you are considering connecting this heater to a pre-existing vent system, make sure that the vent system meets the

appropriate venting requirements as given in this manual on pages 15-20. If not, replace the vent system. DO NOT use a

draft hood with this heater. The MasterTemp heaters are capable of a 270-degree discharge rotation and with a vent gas

temperature less than 204° C (400° F). The total length of the horizontal run must not exceed the length that is listed in

T able 5 on page 17.

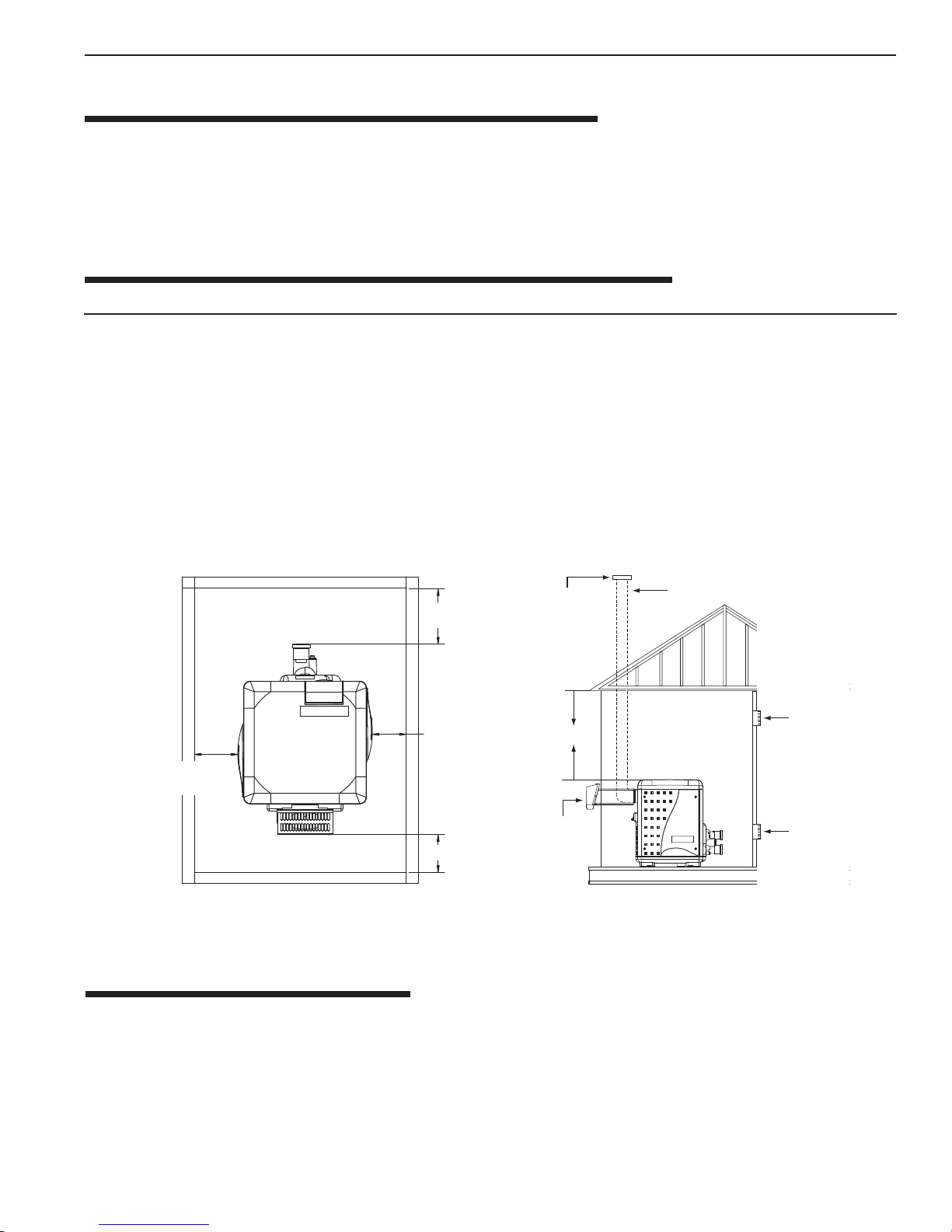

HEATER CLEARANCES — General Requirements

INDOOR INST ALLATION AND OUTDOOR SHEL TER

The following clearances must be maintained from the nearest walls: (See Figure 19, 20 & 21)

TOP ................................... 15 cm (6 in) HEADER SIDE ........................... 15 cm (6 in.)

EXHAUST SIDE ............... 15 cm (6 in.) DOOR PANELS* .......................... 15 cm (6 in.)

Note (*) For service access it is advisable to allow for sufficient clearance on at least one door panel. The heater is

designed for installation on combustible flooring. For installation on carpeting, the heater must be mounted on a metal or

wood panel that extends at least 10 cm (4 in) beyond the base of the heater. Note: Wall sensitive to heat

(for example wood), must be protected by a suitable insulation. If the heater is installed in a closet or alcove, the entire

floor shall be covered by the panel. On an outdoor shelter installation, the exhaust discharges into a vent pipe. Orient the

heater so that the vent pipe does not interfere with adjustment of the operating controls. The control panel located on the

top panel can be rotated to any of the three sides of the heater for easy access. However, the control panel must not be

located on the side where the vent is located.

Chimney or Gas Vent

Heater

Outlet Air

Opening

Inlet Air

Opening

Figure 19.

(*) For service access, it is advisable to allow for

sufficient clearance on at least one door panel.

15 cm*

(6 in)

15 cm

(6 in)

15 cm

(6 in)

15 cm

(6 in)

*

*

*

Vent Cap and

Riser Furnished

by Installer

Figure 20.

15 cm

(6 in)

Side

Wall V ent

OUTSIDE VENT COVER REMOVAL

THE HEA TER IS SUPPLIED FR OM THE F A CTORY WITH A B UILT-IN STA CKLESS OUTSIDE VENT FOR OUTDOOR INSTALLATION. REMO VE THE OUTSIDE VENT COVER FOR OUTDOOR SHEL TER INSTALLATION.

COMBUSTION AIR SUPPLY

For indoor installation, the heater location must provide sufficient air supply for proper combustion and ventilation of the