HYPRO

Hypro Series 1502, 1700, 4001, 4101,

6500, 7560 and 7700 Roller Pumps

®

Form L-1572R

Rev. A

Repair Manual

Keep for Future Reference

OUT

Series 1502

6-Roller Pump

N

I

®

T

U

O

Series 4001 & 4101

4-Roller Pump

®

®

Series 1700

5-Roller Pump

®

Series 6500

6-Roller Pump

IN

Series 7560

8-Roller Pump

Pentair

Pentair

375 5th Ave., New Brighton, MN 55112 USA

375 5th Ave., New Brighton, MN 55112

Phone: (651)766-6300 -OR- 800-424-9776 Fax: 800-323-6496

Phone: (651)766-6300 -OR- 800-424-9776 Fax: 800-323-6496

www.hypropumps.com

www.hypropumps.com

Authorized Representative: QNET BV Hommerterweg 286

EU Authorized Representative: QNET BV Hommerterweg 286

EC REP

6436 AM Amstenrade, The Netherlands

KvK Zuid-Limburg 14091511

EC REP

6436 AM Amstenrade, The Netherlands

KvK Zuid-Limburg 14091511

Series 7700

7-Roller Pump

REPAIR

Repair Instructions

To Take the Pump Apart

1. Remove the adapter from the pump shaft, if equipped.

2. File off any burrs on the pump shaft.

3. Using a screwdriver, pry off the bearing cover on the endplate and pump body.

4. Remove the endplate bolts.

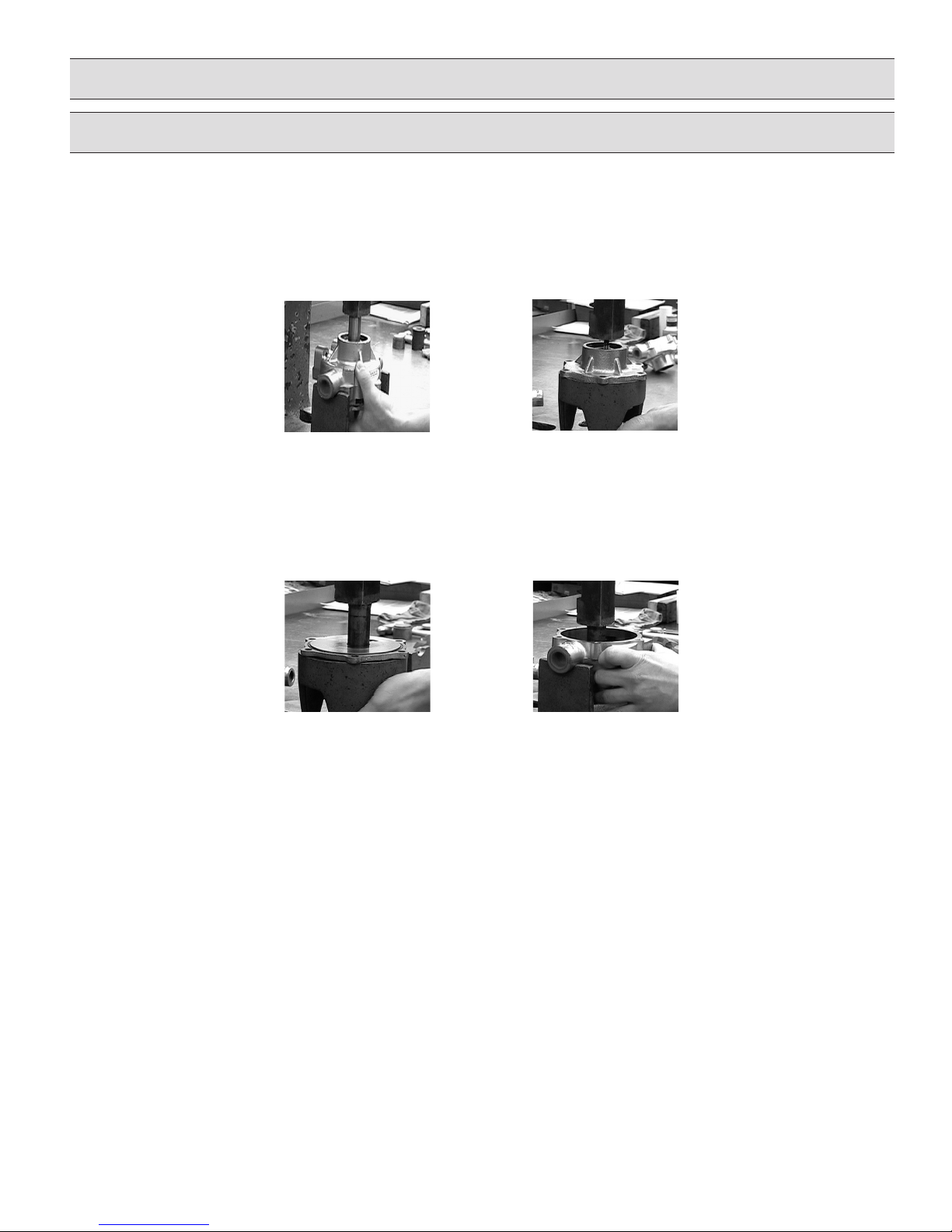

5. Support the pump at its ports in a support fixture with the endplate down. Wood blocks may be used. Place on

press bed. Center press on pump shaft and apply pressure to press the pump apart (See Figure 9).

Figure 9

6. With the rollers exposed, remove them. When replacing damaged rollers, always replace the full set.

7. To remove the rotor with shaft from the endplate, support the endplate in a support fixture with the rotor down. Center a

3/8" bolt on pump shaft. Apply pressure to press shaft out of ball bearing (See Figure 9).

8. To remove the ball bearing, place the endplate in a support fixture with the front of the endplate down (See Figure 10).

Center bearing support tool, and slowly press bearing out of casting. Repeat procedure to remove bearing from pump body

(See Figure 10).

9. After removing the ball bearing, check the seals in both endplate and pump body. If wear is evident or leakage has been

noticed, punch the seals out with a screwdriver and hammer. Seals cannot be removed without damaging them.

Figure 10

10. To press the shaft out of the rotor, first carefully wash the rotor and shaft - removing all traces of rust and other foreign

matter. Use steel wool or emery cloth, rinsing parts afterward to wash off all emery dust. Remove the Allen set screw.

Support the rotor in the press through the slot in the base and press shaft through.

While the Pump is Apart

Carefully inspect all parts for wear, such as:

• Undersize or swollen rollers in both length and diameter.

•Worn seals.

•Worn shaft at drive end, and pitted or grooved at the seal area.

• Rough bearings and loss of grease from the bearings.

• Undersize rotor and/or worn roller slots.

• Excessive wear in body - both on inside diameter and at back face.

• Body cracks at the bolt holes and at the o-ring sealing area.

• End wear (body, endplate and rotor).

•

Damaged o-ring in the endplate.

After the above parts have been checked and the various points have been considered, decide if the pump is repairable. If repairing

the pump, be sure to inspect inside of endplate. If a groove is noticeable, the endplate should be replaced.

ATTENTION: If an attempt has been made to pry the pump apart with a screwdriver, be sure to file off all nicks, burrs and

other damage marks around the bolt holes.

- 2 -

- 2-

Loading...

Loading...