Pentair Hypro 4101 Series, Hypro 1502N, Hypro 1502C, Hypro 1502XL, Hypro 1700N Original Instruction Manual

...Page 1

O

U

T

I

N

®®

¤¤

®®

®®

OUT

IN

HYPRO

Hypro Series 1502, 1700, 4001, 4101,

6500, 7560 and 7700 Roller Pumps

®®

L-0100R

Rev. C

Original Instruction Manual

Keep for Future Reference

Series 1502

6-Roller Pump

Series 4001 & 4101

4-Roller Pump

Series 7560

8-Roller Pump

Series 1700

5-Roller Pump

Series 6500

6-Roller Pump

Series 7700

7-Roller Pump

Pentair

375 5th Ave., New Brighton, MN 55112 USA

Phone: (651)766-6300 -OR- 800-424-9776 Fax: 800-323-6496

www.hypropumps.com

Authorized Representative: QNET BV Hommerterweg 286

EC REP

6436 AM Amstenrade, The Netherlands

KvK Zuid-Limburg 14091511

Page 2

Contents

EU Language Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Intended Use(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Purpose of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Misuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pump Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pump Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1502 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1700 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

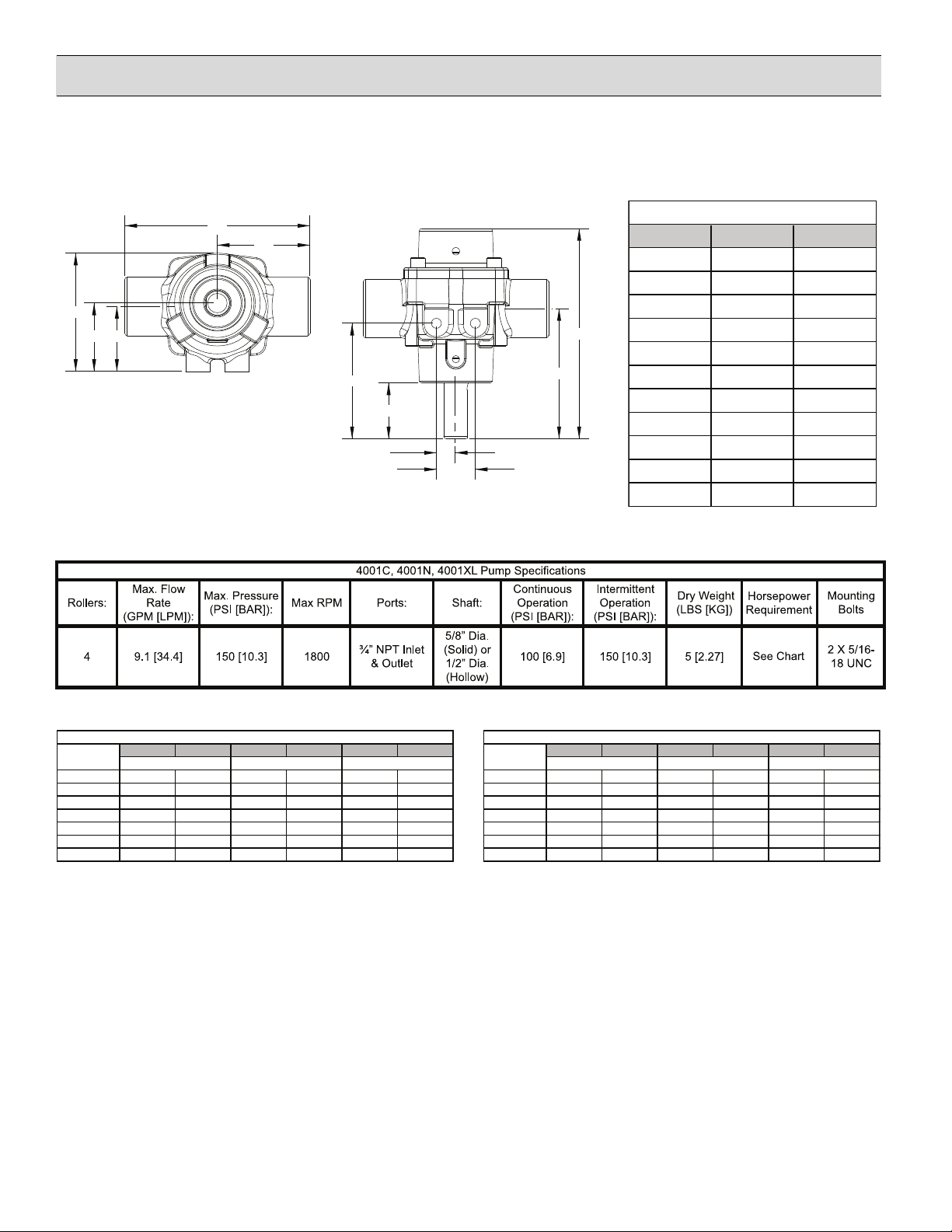

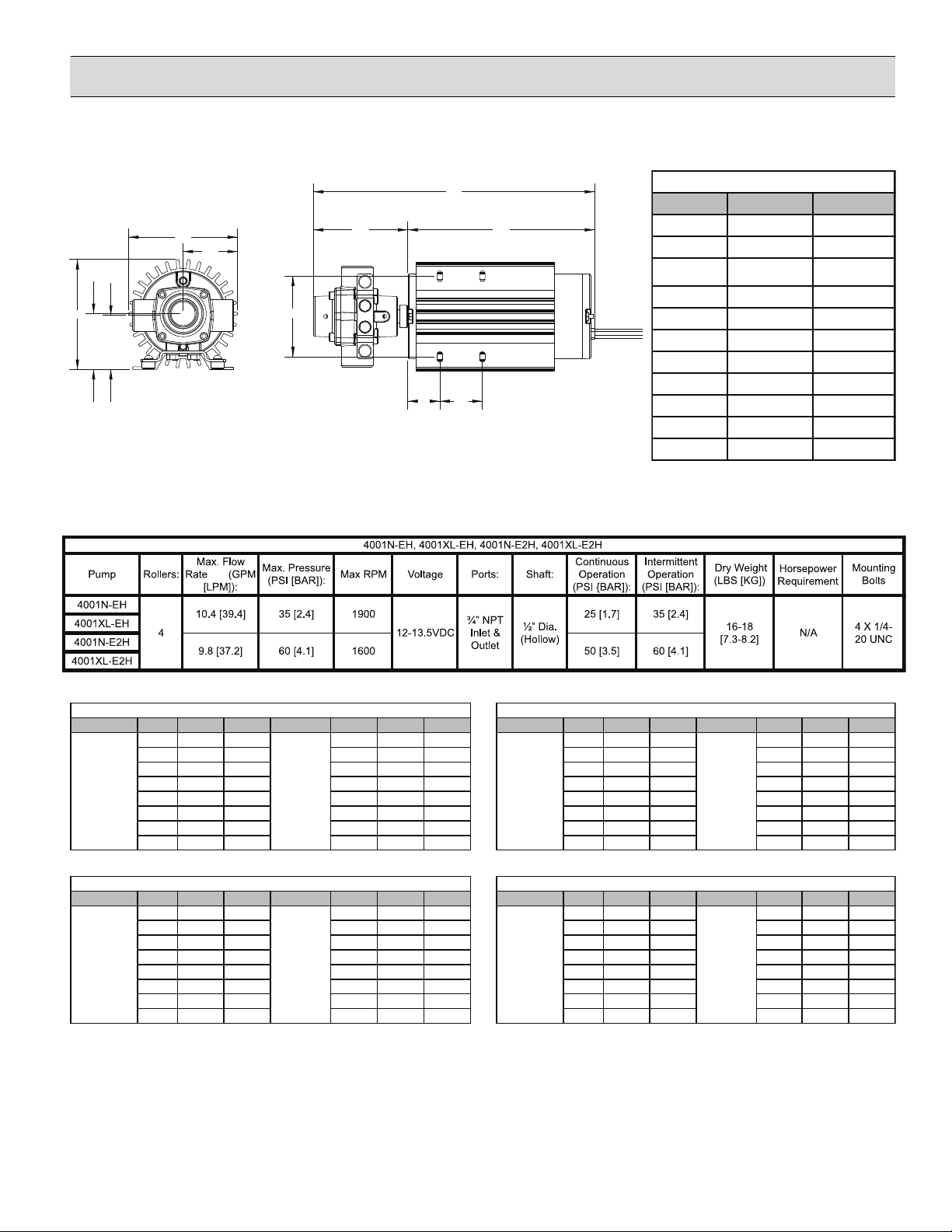

4001 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

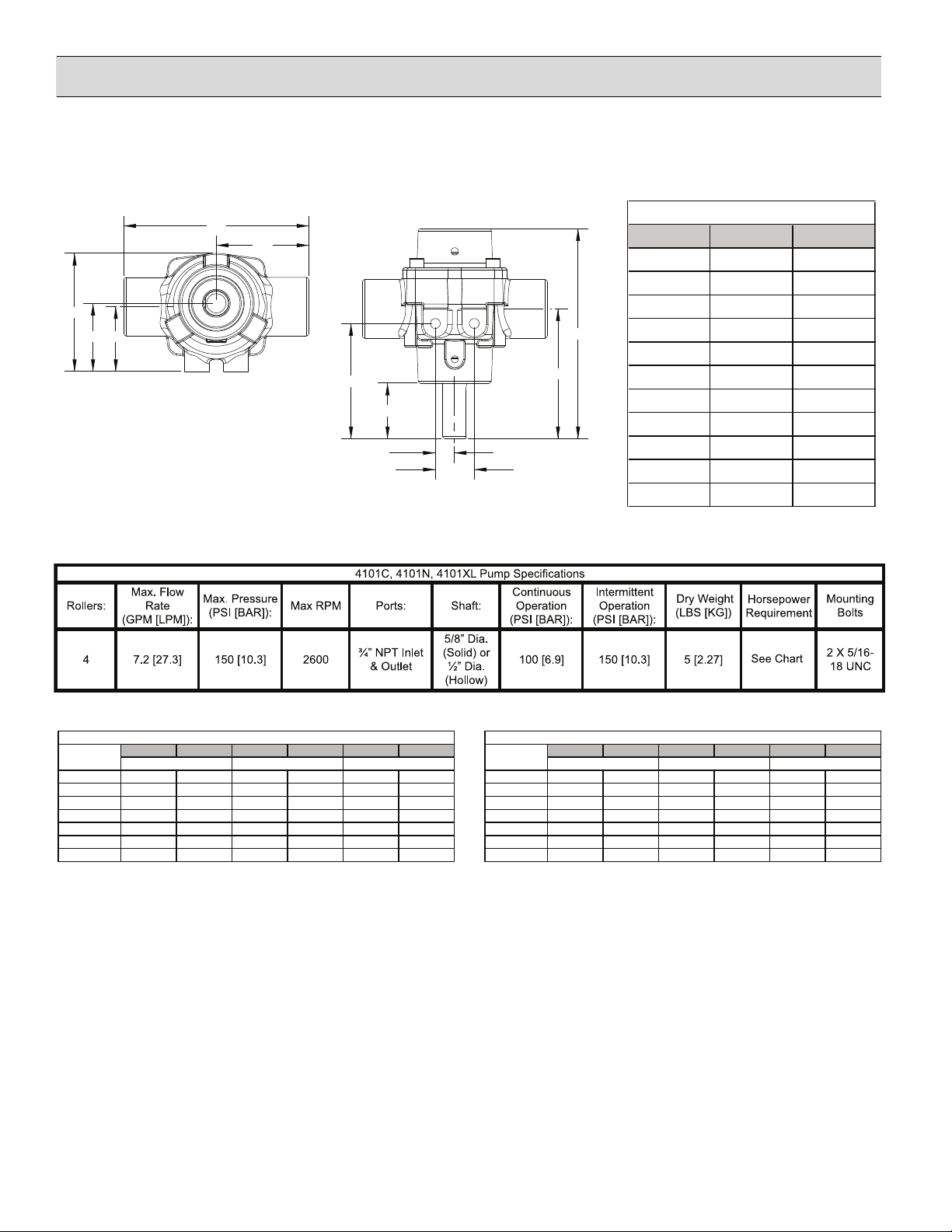

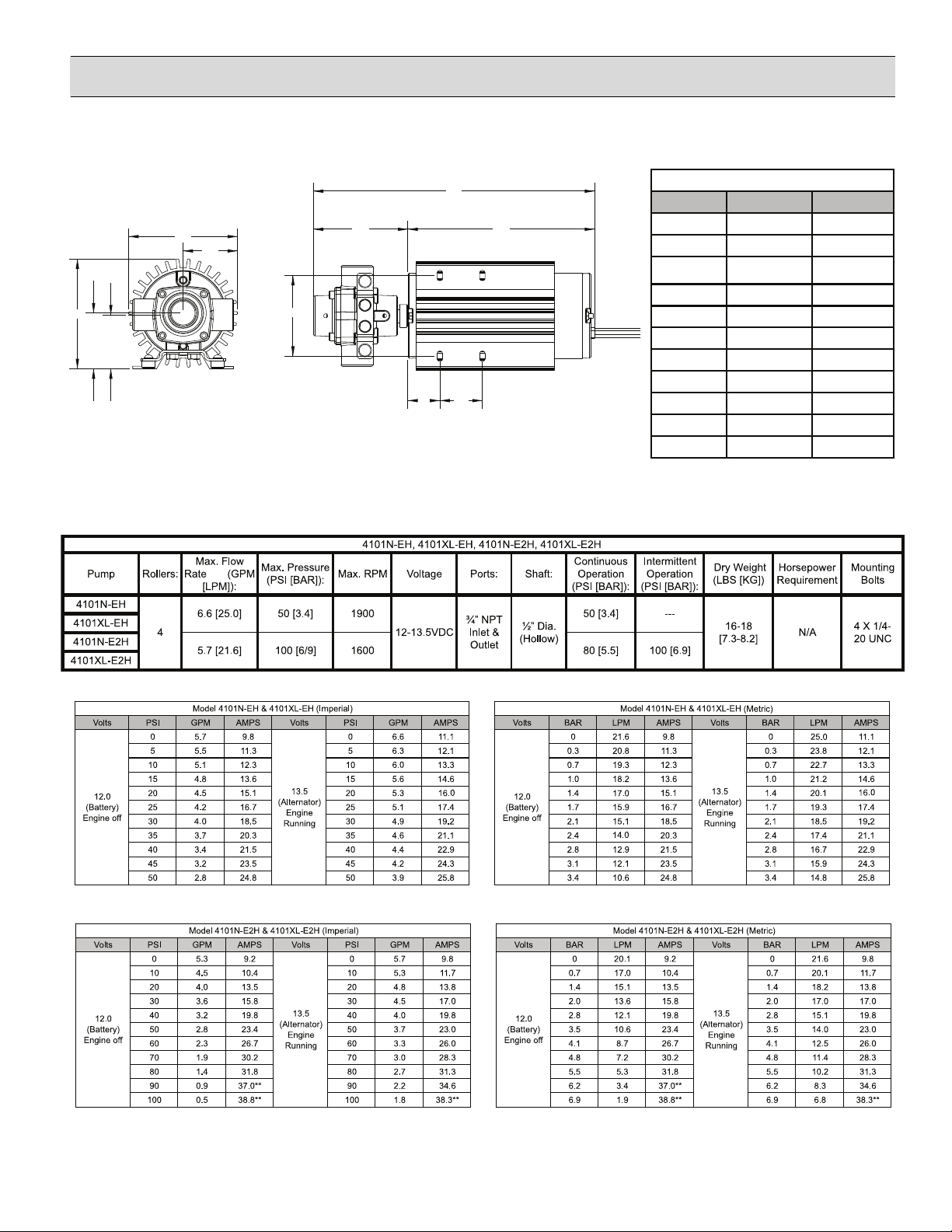

4101 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-12

6500 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

7560 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-16

7700 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Fluid Pumping Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Lifting, Transport, and Intermediate Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-19

Assembly and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-23

Control System(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Commissioning Start-Up, Operation, Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Start-Up, Operation, Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-25

Pumps Equipped with Only DC Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Pumps Equipped with Hydraulic Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

PTO/Belt Drive/Flexible Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Maintenance and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Maintenance, Routine Servicing, and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26-35

Series 4001 and 4101 Electric Motor-Driven Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Repair Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37-38

Declaration of Incorporation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .back cover

- 2-

Page 3

EU Language Manuals

DO NOT attempt to install or operate your pump before reading the manual. Original copies of the manual for Hypro

pumps are provided in English. To find a copy in your native language, go to www.hypropumps.com.

Vor dem Ablesen des Handbuches versuchen Sie NICHT, Ihre Pumpe zu installieren. Originale des Handbuches für

Hypro-Pumpen werden auf englisch zur Verfügung gestellt. Zu eine Kopie in Ihrer Muttersprache finden, zu

www.hypropumps.com zu gehen (German)

N'essayez pas d'installer votre pompe avant de lire le manuel. Des exemplaires originaux du manuel pour des pompes

de Hypro sont fournis en anglais. Pour trouver une copie dans votre langue maternelle pour aller à

www.hypropumps.com (French)

NON tentare di installare la vostra pompa prima di leggere il manuale. Esemplare originale del manuale per Hypro

pompe sono in inglese. Per trovare una copia nella vostra lingua andare a www.hypropumps.com (Italian)

Не пытайтесь установить ваш насос до чтения руководства. Оригинальные копии этого руководства для насосы

Hypro на английском языке. Найти копию на ваш родной язык перейти к www.hypropumps.com (Russian)

NO intente instalar su bomba antes de leer el manual. Copias originales del manual para Hypro se provee de bombas

en inglés. Para encontrar una copia en tu idioma nativo ir a www.hypropumps.com (Spanish)

NIE próbować instalować pompy przed jej odczytaniem instrukcji. Oryginalne kopie instrukcji obsługi pomp Hypro są

dostarczane w języku angielskim. Aby uzyskać kopię w twoim ojczystym języku przejdź do www.hypropumps.com

(Polish)

Takmaya çalışmayın okumadan önce pompanın manuel. Orijinal kopyalarını Hypro pompaları için Ingilizce olarak

sunulmuştur. Bir kopyasını bulmak için yerel dil git www.hypropumps.com (Turkish)

Não tente instalar a bomba antes de ler o manual. As cópias originais dos manuais para Hypro bombas são

fornecidos em Inglês. Para encontrar uma cópia em sua língua nativa ir para www.hypropumps.com (Portuguese)

VERGEET NIET uw pomp vóór het lezen van het handboek. Exemplaren van de handleiding voor Hypro pompen zijn

beschikbaar in het Engels. Op zoek naar een exemplaar in uw eigen taal ga naar www.hypropumps.com (Dutch)

- 3-

Page 4

Introduction

Description

Hypro roller pumps are designed for creating and boosting pressure in fluid circuits. The economical rotary-action roller

principle requires no check valves, while providing positive displacement characteristics with less friction and lower

starting torque than other pumps. The pump operates by receiving a fluid through the inlet port where it is captured and

transported by the rollers, and then expelled through the outlet port. Construction features include housings and rollers,

which are made in a variety of materials in order to be resistant to a wide range of chemicals. Standard models of roller

pumps rotate counterclockwise, when looking at the shaft end of the pump. Reverse rotation pumps are available.

Intended Use(s)

Hypro roller pumps are intended for creating or booting dynamic pressure and, depending on the type of body, rotor

and rollers used, will work with a variety of fluids. Hypro roller pumps will work in a variety of environments but they

should never be used to pump liquids above 140°F (60°C) or below 34°F (1°C), or when the ambient air temperature

is above 140°F (60°C). Any uses outside of those specified in this manual are considered misuses and are prohibited.

Contact Hypro technical service about any questions regarding specific acceptable uses.

Purpose of Manual

Hypro has provided this manual to provide instructions and requirements that must be met when installing, using and

maintaining the product(s) identified on the cover.

If the product is sold, the seller must pass this manual on to the new owner.

The following special attention notices are used to notify and advise the user of this product of procedures that may be

dangerous to the user or result in damage to the product.

Attention is used to notify of installation, operation, or maintenance information that is important but not safety related.

This symbol is used to denote the presence of an electrical hazard that may result in personal injury, death, or property

damage.

This symbol is used to denote the presence of a hazard that may result in personal injury, death, or property damage.

California Proposition 65 Warning -- This product and related accessories contain chemicals known to the

State of California to cause cancer, birth defects or other reproductive harm.

- 4-

Page 5

Introduction - cont’d.

Misuses

Hypro roller pumps are designed to operate effectively within the specified speed, pressure and environmental ranges.

Going outside of these ranges will void the warranty and could cause damage to property, serious injury or death.

• DO NOT run the pump faster than the maximum recommended speed.

• DO NOT run the pump higher than the maximum recommended pressure.

• DO NOT run pumps when the liquid, or ambient air, has exceeded the maximum or minimum temperature limit.

(See Intended Uses)

• DO NOT pump non-approved liquids.

• DO NOT pump water or other liquids for human consumption.

• DO NOT operate any Hypro pump under the influence of drugs or alcohol.

• DO NOT run the pump dry.

• DO NOT pump abrasive fluids.

• DO NOT exceed the duty cycle for pumps with electric motors.

• DO NOT run the pump with a higher than recommended voltage.

Pump Identification

Hypro uses serialized labeling to enable users to precisely identify the pump’s manufacturing date.

Serial Number:

First and second digits: year (12 = 2012)

Third through fifth digits: consecutive day of the year the pump was manufactured.

- 5-

Page 6

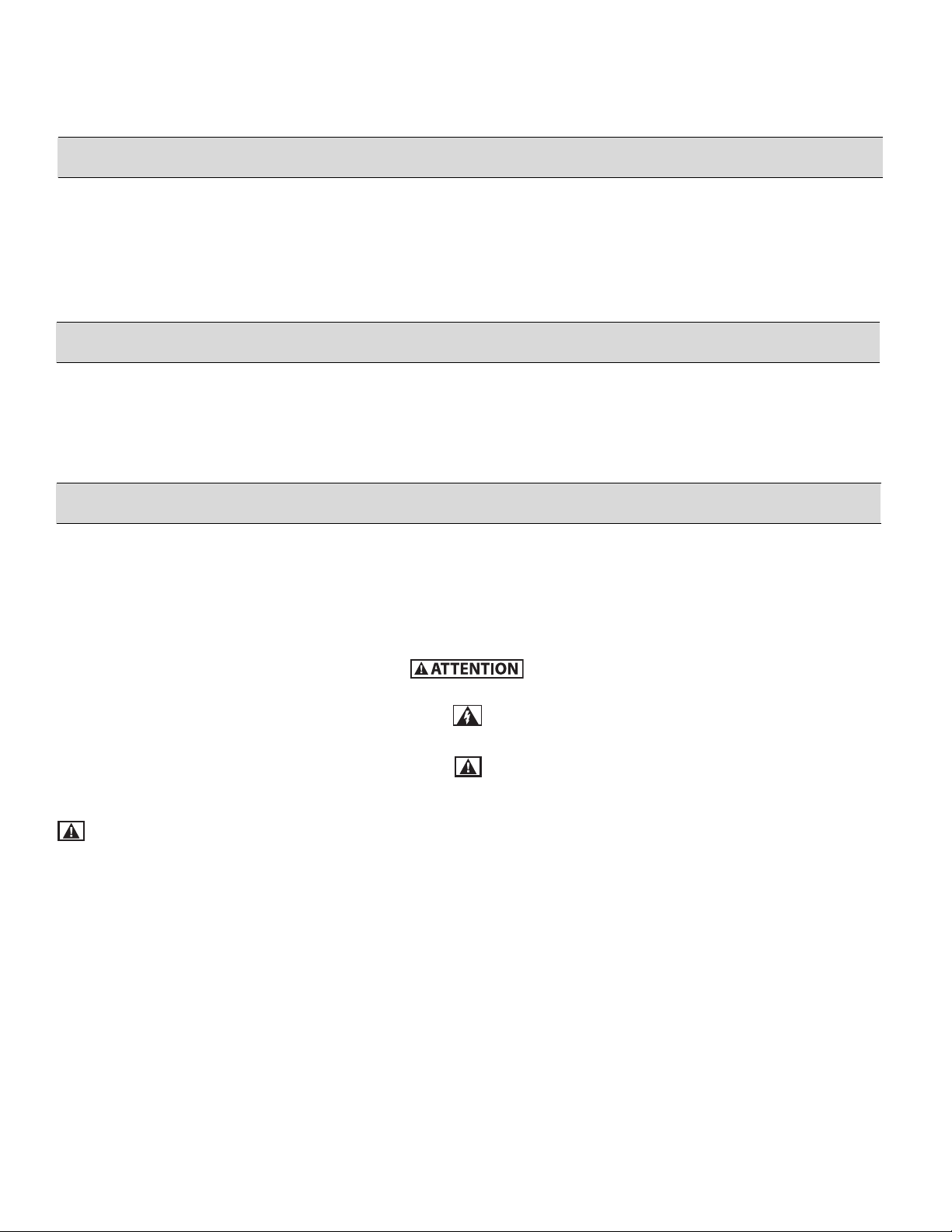

Pump Technical Data

GPM HP GPM HP GPM HP LPM HP LPM HP LPM HP

0 PSI 33.1 0.5 36.8 0.7 62.1 2.0 0 BAR 125.3 0.5 139.3 0.7 235.1 2.0

25 PSI 29.7 1.0 33.6 1.2 58.5 3.0 1.7 BAR 112.4 1.0 127.2 1.2 221.4 3.0

50 PSI 27.8 1.5 31.7 1.7 56.9 3.7 3.4 BAR 105.2 1.5 120.0 1.7 215.4 3.7

100 PSI 24.3 2.5 28.3 2.8 53.9 5.3 6.9 BAR 92.0 2.5 107.1 2.8 204.0 5.3

150 PSI 21.0 3.5 25.0 4.0 50.9 7.1 10.3 BAR 79.5 3.5 94.6 4.0 192.7 7.1

Performance Data 1502C, 1502N, 1502XL (Imperial)

Performance Data 1502C, 1502N, 1502XL (Metric)

Pressure

Pressure

@540 RPM

@600RPM

@1000RPM

@540 RPM

@600RPM

@1000RPM

(All specifications and performance data are based on water as a carrier fluid.)

1502 Series Pump Only

A

B

D

K

E

C

J

I

F

H

G

- 6-

Page 7

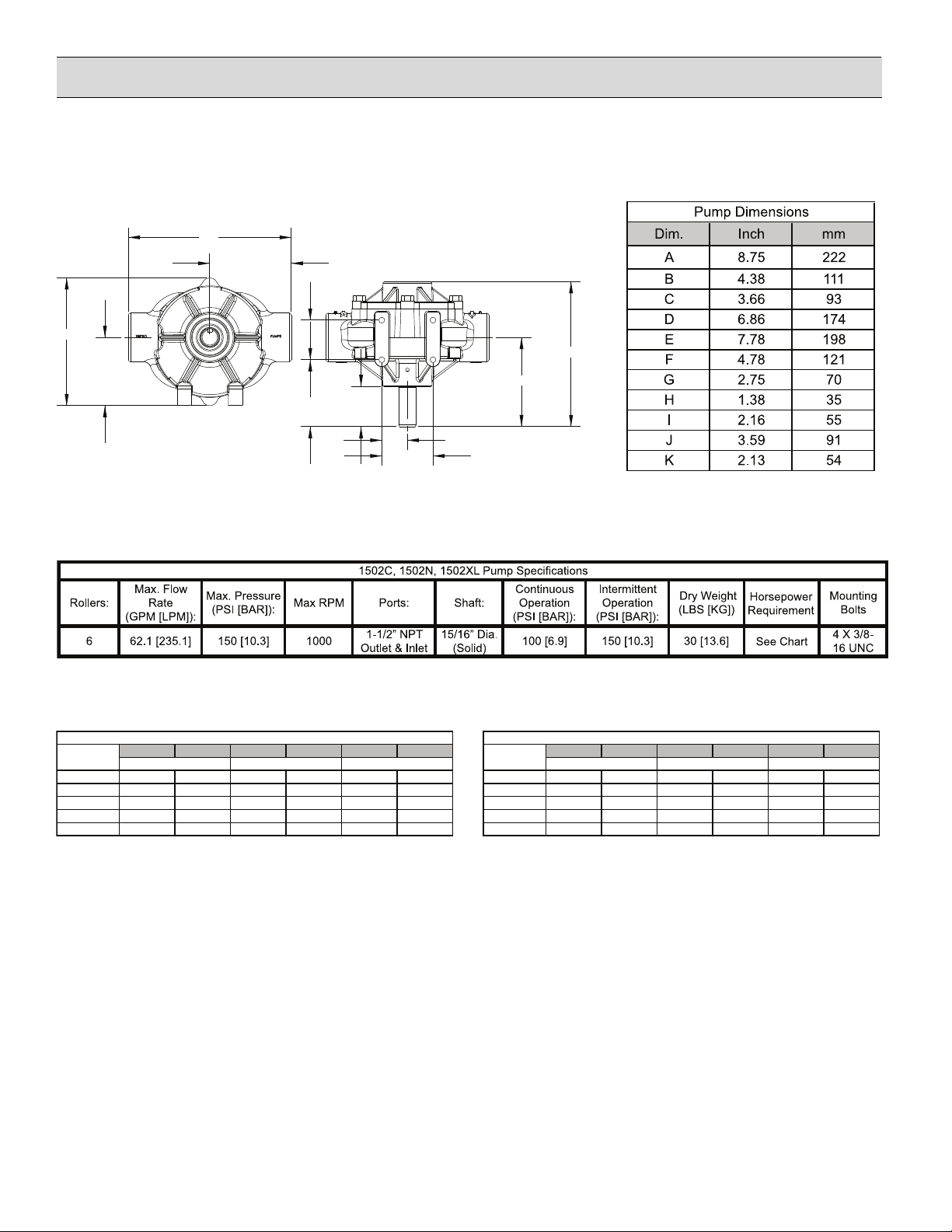

Pump Technical Data

1700 Series Pump Only

A

B

K

D

C

J

I

H

G

E

F

- 7-

Page 8

Pump Technical Data

GPM HP GPM HP GPM HP LPM HP LPM HP LPM HP

0 PSI 5.5 0.1 7.1 0.1 9.1 0.1 0 BAR 20.8 0.1 26.9 0.1 34.4 0.1

25 PSI 4.9 0.1 6.4 0.2 8.5 0.3 1.7 BAR 18.5 0.1 24.2 0.2 32.2 0.3

50 PSI 4.4 0.2 5.9 0.3 8.0 0.5 3.4 BAR 16.6 0.2 22.3 0.3 30.3 0.5

75 PSI 4.1 0.3 5.6 0.4 7.6 0.6 5.2 BAR 15.5 0.3 21.2 0.4 28.7 0.6

100 PSI 3.8 0.4 5.3 0.6 7.3 0.8 6.9 BAR 14.4 0.4 20.1 0.6 27.6 0.8

125 PSI 3.5 0.5 5.0 0.7 7.0 1.0 8.6 BAR 13.2 0.5 18.9 0.7 26.5 1.0

150 PSI 3.3 0.6 4.8 0.8 6.7 1.1 10.3 BAR 12.5 0.6 18.2 0.8 25.4 1.1

Performance Data 4001C, 4001N, 4001X (Imperial)

Performance Data 4001C, 4001N, 4001XL (Metric)

Pressure

Pressure

@1100 RPM

@1400RPM

@1800RPM

@1100 RPM

@1400RPM

@1800RPM

Dim. Inch mm

A 4.75 121

B 2.38 61

C 1.67 42

D 3.03 77

E 5.39 137

F 3.34 85

G 1.00 25

H 0.49 13

I 1.43 36

J 2.96 75

K 1.75 45

Pump Dimensions

4001 Series Pump Only

A

B

D

C

K

E

J

F

I

H

G

- 8-

Page 9

Pump Technical Data

Dim. Inch mm

A 5.12 130

B 2.56 65

C 2.54 64

D 5.17 (5.15) 131 (130)

E 3.8 97

F 13.24 (11.91) 336 (302)

G 4.45 113

H 8.79 (7.45) 223 (189)

I 1.5 38

J251

K 2.63 67

Pump Dimensions

Volts PSI GPM AMPS Volts PSI GPM AMPS Volts BAR LPM AMPS Volts BAR LPM AMPS

0 9.4 14.8 0 10.4 17.1 0 35.6 14.8 0 39.4 17.1

5 9.0 16.4 5 10.3 17.5 0.3 34.1 16.4 0.3 39.0 17.5

10 8.6 18.0 10 9.9 19.0 0.7 32.6 18.0 0.7 37.5 19.0

15 8.1 20.1 15 9.4 21.5 1.0 30.7 20.1 1.0 35.6 21.5

20 7.5 23.1 20 8.9 23.8 1.4 28.4 23.1 1.4 33.7 23.8

25 6.9 25.3 25 8.4 26.8 1.7 26.1 25.3 1.7 31.8 26.8

30 6.1 28.5* 30 7.8 29.6* 2.1 23.1 28.5* 2.1 29.5 29.6*

35 5.8 30.3* --- --- --- 2.4 22.0 30.3* --- --- ---

Volts PSI GPM AMPS Volts PSI GPM AMPS Volts BAR LPM AMPS Volts BAR LPM AMPS

0 8.6 10.9 0 9.8 11.6 0 32.6 10.9 0 37.2 11.6

10 8.0 13.3 10 9.1 14.5 0.7

30.2

13.3 0.7

34.3

14.5

20 7.2 17.5 20 8.2 19.5 1.4

27.1

17.5 1.4

30.9

19.5

30 6.0 22.0 30 7.3 23.2 2.1

22.6

22.0 2.1

27.6

23.2

35 5.6 24.4 35 6.8 25.6 2.4

21.0

24.4 2.4

25.6

25.6

40 5.3 36.1 40 6.3 27.8 2.8

19.9

36.1 2.8

24.0

27.8

50 4.7 30.7 50 5.6 31.8 3.5

17.6

30.7 3.5

21.3

31.8

60 3.9 35.5 60 4.9 36.2** 4.1

14.8

35.5 4.1

18.7

36.2**

12.0 (Battery)

Engine Off

13.5

(Alternator)

Engine

Running

Model 4001N-E2H & 4001XL-E2H (Imperial)

Model 4001N-E2H & 4001XL-E2H (Metric)

12.0 (Battery)

Engine Off

13.5

(Alternator)

Engine

Running

Model 4001N-EH & 4001XL-EH (Imperial)

Model 4001N-EH & 4001XL-EH (Metric)

12.0 (Battery)

Engine Off

13.5

(Alternator)

Engine

Running

12.0 (Battery)

Engine Off

13.5

(Alternator)

Engine

Running

Motorized

F

A

G

H

B

D

K

C

E

I

J

Dimensions in ( ) are for 4001-EH

series pumps.

*denotes a duty cycle of 66% (40 minutes on, 20 minutes off)

**denotes a duty cycle of 50% (30 minutes on, 30 minutes off)

- 9-

Page 10

Pump Technical Data

GPM HP GPM HP GPM HP LPM HP LPM HP LPM HP

0 PSI 5.0 0.1 6.2 0.1 7.2 0.2 0 BAR 18.9 0.1 23.5 0.1 27.3 0.2

25 PSI 4.8 0.2 5.8 0.3 6.9 0.3 1.7 BAR 18.2 0.2 22.0 0.3 26.1 0.3

50 PSI 4.5 0.3 5.6 0.4 6.6 0.5 3.4 BAR 17.0 0.3 21.2 0.4 25.0 0.5

75 PSI 4.2 0.5 5.4 0.6 6.4 0.6 5.2 BAR 15.9 0.5 20.4 0.6 24.2 0.6

100 PSI 3.9 0.6 5.0 0.7 6.0 0.8 6.9 BAR 14.8 0.6 18.9 0.7 22.7 0.8

125 PSI 3.7 0.7 4.7 0.8 5.7 0.9 8.6 BAR 14.0 0.7 17.8 0.8 21.6 0.9

150 PSI 3.4 0.8 4.4 1.0 5.4 1.1 10.3 BAR 12.9 0.8 16.7 1.0 20.4 1.1

Performance Data 4101C, 4101N, 4101XL (Imperial)

Performance Data 4101C, 4101N, 4101XL (Metric)

Pressure

Pressure

@1800 RPM

@2200RPM

@2600RPM

@1800 RPM

@2200RPM

@2600RPM

Dim. Inch mm

A 4.75 121

B 2.38 61

C 1.67 42

D 3.03 77

E 5.39 137

F 3.34 85

G 1.00 25

H 0.49 13

I 1.43 36

J 2.96 75

K 1.75 45

Pump Dimensions

4101 Series Pump Only

A

B

D

C

K

E

J

F

I

H

G

- 10 -

Page 11

Pump Technical Data

Dim. Inch mm

A 5.12 130

B 2.56 65

C 2.54 64

D 5.17 (5.15) 131 (130)

E 3.8 97

F 13.24 (11.91) 336 (302)

G 4.45 113

H 8.79 (7.45) 223 (189)

I 1.5 38

J251

K 2.63 67

Pump Dimensions

Motorized

F

A

B

D

K

C

E

G

I

H

J

Dimensions in ( ) are for 4101-EH

series pumps.

**denotes a duty cycle of 50% (30 minutes on, 30 minutes off).

- 11 -

Page 12

Pump Technical Data

Rollers:

Max. Flow

Rate

(GPM [LPM]):

Max. Pressure

(PSI [BAR]):

Max RPM Ports: Shaft:

Continuous

Operation

(PSI [BAR]):

Intermittent

Operation

(PSI [BAR]):

Dry Weight

(LBS [KG])

Engine

Mounting

Bolts

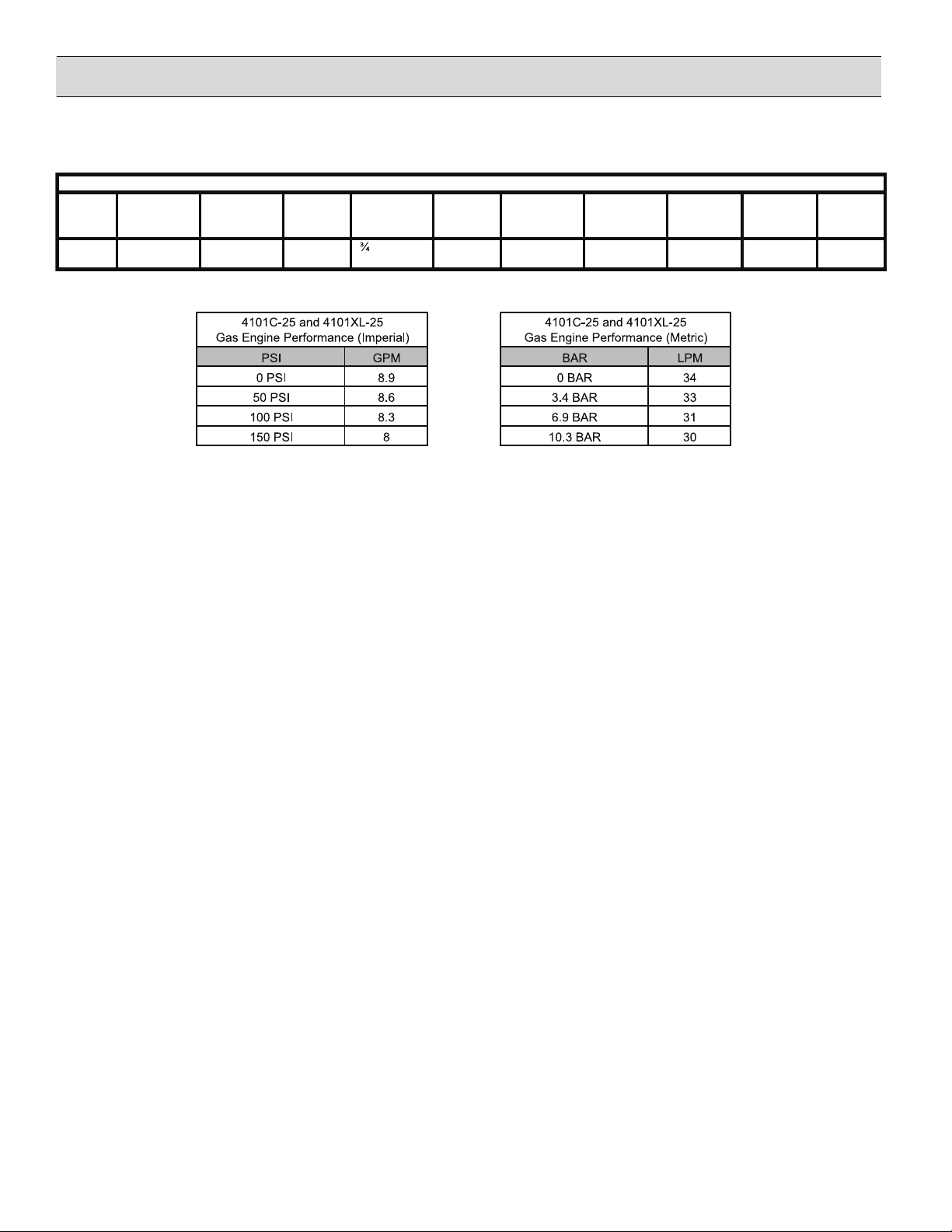

4 8.9 [33.7] 150 [10.3] 2600

” NPT Inlet

& Outlet

5/8” Dia.

(Solid)

100 [6.9] 150 [BAR] 29 [13.1] 2.5 HP

4 X 5/16-

18 UNC

4101C-25, 4101XL-25 Pump Specifications

Gas Engine

- 12 -

Page 13

Pump Technical Data

GPM HP GPM HP GPM HP LPM HP LPM HP LPM HP

0 PSI 9.7 0.1 18.2 0.2 21.8 0.3 0 BAR 36.7 0.1 68.9 0.2 82.5 0.3

50 PSI 8.0 0.4 16.5 0.7 20.1 0.9 3.4 BAR 30.3 0.4 62.5 0.7 76.1 0.9

100 PSI 7.2 0.7 15.4 1.3 19.1 1.5 6.9 BAR 27.3 0.7 58.3 1.3 72.3 1.5

150 PSI 6.6 1.0 14.7 1.8 18.2 2.1 10.3 BAR 25.0 1.0 55.6 1.8 68.9 2.1

200 PSI 5.6 1.3 14.0 2.3 17.3 2.8 13.8 BAR 21.2 1.3 53.0 2.3 65.5 2.8

250PSI 4.9 1.7 13.4 2.9 16.5 3.5 17.2 BAR 18.5 1.7 50.7 2.9 62.5 3.5

300PSI 4.3 1.9 12.7 3.5 15.7 4.2 20.7 BAR 16.3 1.9 48.1 3.5 59.4 4.2

Performance Data 6500C, 6500N, 6500XL (Imperial)

Performance Data 6500C, 6500N, 6500XL (Metric)

Pressure

Pressure

@540 RPM

@1000RPM

@1200RPM

@540 RPM

@1000RPM

@1200RPM

6500 Series Pump Only

A

B

D

E

C

J

F

I

H

G

- 13 -

Page 14

Pump Technical Data

7560 Series Pump Only

A

D

C

B

E

J

I

H

G

F

- 14 -

Page 15

Pump Technical Data

Rollers:

Max. Pump

Flow Rate

(GPM [LPM]):

Max. Pump

Pressure

(PSI [BAR]):

Max RPM Ports:

Hydraulic

Motor Ports

Continuous

Operation (PSI

[BAR]):

Intermittent

Operation (PSI

[BAR]):

Dry Weight

(LBS [KG])

Max .

Hydraulic Flow

(GPM [LPM])

Max. Hydraulic

Pressure

(PSI [BAR]

Mounting

Bolts

-

” NPT Inlet

& Outlet

-1” Hose Barb

included

13 [5.89]

12 [45.4]

2400 [165.5]

4 X 3/8 or

M10

7560C-GM30, 7560N-GM30, 7560XL-GM30 Pump Specifications

8

20.1 [76.1]

300 [20.7]

1000

-10 SAE (7/8"14 UNF)

100 [6.9]

300 [20.7]

Hyd. GPM

GPM @ 0

PSI

GPM @

25 PSI

GPM @

50 PSI

GPM @

75 PSI

GPM @

100 PSI

GPM @

125 PSI

GPM @

150 PSI

GPM @

200 PSI

GPM @

250 PSI

GPM @

300 PSI

5 9.0 8.5 7.8 7.3 6.7 6.1 5.5 4.4 3.3 2.2

6 10.5 10.0 9.5 8.9 8.4 7.8 7.3 6.2 5.2 4.1

711.9 11.5 11.0 10.4 9.9 9.4 8.9 7.8 6.8 5.7

8 13.7 13.1 12.5 12.0 11.5 10.9 10.4 9.4 8.4 7.3

9 15.2 14.6 14.1 13.6 13.1 12.6 12.1 11.1 10.0 9.1

10 16.9 16.5 15.9 15.4 14.9 14.3 13.9 12.9 11.9 11.0

11 18.6 18.2 17.6 17.1 16.6 16.1 15.6 14.7 13.8 12.9

12 20.1 19.6 19.1 18.6 18.1 17.6 17.1 16.3 15.3 14.5

Hyd. LPM

LPM @

0 BAR

LPM @

2 BAR

LPM @

4 BAR

LPM @

6 BAR

LPM @

8 BAR

LPM @

10 BAR

LPM @

12 BAR

LPM @

14 BAR

LPM @

16 BAR

LPM @

18 BAR

LPM @ 20

BAR

20 35.8 33.2 30.5 28.1 25.6 23.4 20.9 18.5 15.8 12.6 10.0

25 42.8 39.5 36.8 34.0 31.8 29.2 26.2 23.7 21.6 18.9 16.4

30 51.8 49.0 45.8 43.0 40.3 37.9 35.3 33.3 31.1 28.9 26.2

35 58.1 55.8 52.7 50.1 47.7 45.5 43.1 40.9 38.8 36.3 33.5

40 67.6 64.8 62.4 60.0 57.7 55.8 53.4 51.3 48.8 46.6 44.1

45 75.3 72.7 70.4 68.1 66.0 63.8 61.8 59.8 57.8 55.7 53.3

7560C-GM30, 7560N-GM30, 7560XL-GM30 Performance Data (Imperial)

7560C-GM30, 7560N-GM30, 7560XL-GM30 Performance Data (Metric)

Hydraulic

G

H

E

F

A

B

I

D

C

- 15 -

Page 16

Pump Technical Data

Rollers:

Max. Pump

Flow Rate

(GPM [LPM]):

Max. Pump

Pressure

(PSI [BAR]):

Max RPM Ports:

Hydraulic

Motor Ports

Continuous

Operation (PSI

[BAR]):

Intermittent

Operation (PSI

[BAR]):

Dry Weight

(LBS [KG])

Max.

Hydraulic Flow

(GPM [LPM])

Max. Hydraulic

Pressure

(PSI [BAR]

Mounting

Bolts

-

” NPT Inlet

& Outlet

-1” Hose Barb

included

7560C-GM15, 7560N-GM15, 7560XL-GM15 Pump Specifications

8

20.1 [76.1]

300 [20.7]

1000

-10 SAE (7/8"14 UNF)

100 [6.9]

300 [20.7]

13 [5.89]

6 [22.7]

2400 [165.5]

4 X 3/8 or

M10

Hydraulic - cont’d.

- 16 -

Page 17

Pump Technical Data

I

GPM HP GPM HP GPM HP LPM HP LPM HP LPM HP

0 PSI 14.2 0.2 15.3 0.3 22.1 0.4 0 BAR 53.8 0.2 57.9 0.3 83.7 0.4

50 PSI 12.9 0.6 14.0 0.6 20.7 0.9 3.4 BAR 48.8 0.6 53.0 0.6 78.4 0.9

100 PSI 11.9 1.1 13.0 1.2 19.5 1.7 6.9 BAR 45.0 1.1 49.2 1.2 73.8 1.7

150 PSI 11.2 1.6 12.3 1.8 18.6 2.4 10.3 BAR 42.4 1.6 46.6 1.8 70.4 2.4

200 PSI 10.3 2.2 11.6 2.4 17.8 3.3 13.8 BAR 39.0 2.2 43.9 2.4 67.4 3.3

Pressure

Pressure

@540 RPM

@600RPM

@800RPM

@540 RPM

@600RPM

@800RPM

Performance Data 7700C, 7700N, 7700XL (Imperial)

Performance Data 7700C, 7700N, 7700XL (Metric)

7700 Series Pump Only

A

B

D

K

E

C

J

F

I

H

G

- 17 -

Page 18

Fluid Pumping Applications

Pump Materials Compatibility

Application Cast Iron Ni-Resist Silver Series XL Comments

Weed Control Chemicals xxxUse with super rollers and viton seals.

When using with Roundup, use super

or polypropylene rollers and Viton

seals. Teflon rollers may be used with

Roundup up to 100 PSI. Only Ni-

Resist and Silver series pumps

should be used with Roundup.

Insect Control xxxAll pump, roller and seal combinations

Brush Control

Pest Control Chemical xxxUse super rollers and Viton seals

and Fumigants

Liquid Fertilizers x x Use polypropylene rollers and Buna-N seals

Powdered Fertilizers xxxUse super rollers or polypropylene

Fluid Transfer rollers with Buna-N or Viton seals

Acids x Use polypropylene or Teflon rollers

with Viton seals. Limit pressure to 100

PSI when using Teflon rollers. DO

NOT use super rollers with acids.

x - Pump approved for application

Table 1

The following chemicals should never be put through any Hypro pump:

• Gasoline (Petrol)

• Kerosene/Kerosine (paraffin)

• Diesel fuel

• Ceramic slurries

• Sewage

• Potable water

• Abrasive fluids

Tools

The Hypro roller pumps and mounting assemblies are designed with Imperial (inch) bolts, however, there are many

metric (mm) sizes which will work with these bolts. In most cases, an adjustable spanner (crescent) wrench can also

be used.

Lifting, Transport and Intermediate Storage

Packaging Descriptions and Unpacking Instructions

• Hypro roller pumps are shipped in cardboard boxes for safe transporting.

• When pumps are shipped in large quantities, they may be put on a pallet to allow for easy storage, lifting and

handling.

• Before lifting any pump or pallet, determine the weight of the item by looking at the attached packing slips to

establish what lifting equipment or method should be used.

• Once the pump is unpacked, dispose of all the packaging in a manner compliant with local and national

regulations.

Lifting Instructions

• Before attempting to lift a Hypro pump, ensure that the surrounding working area is free of hazards which could

cause injury or damage to property.

• During lifting operations, any personnel not involved in the lift should not enter the working area.

• If lifting hooks, rope or chains are being used for a lift, they must be free of damage and be rated to carry 150%

of the weight of the load to be lifted.

- 18 -

Page 19

Lifting, Transport and Intermediate Storage - cont’d.

• Always wear steel-toed shoes and cut-resistant gloves when attempting to lift.

• When lifting and carrying, always keep the pump close to your body. (See Figure 1.)

• When starting the lift, bend your knees and keep your back straight. (See Figure 1.) Tightening the stomach

muscles will help keep your back straight.

• During the lift, use your legs to do the work. Never use your back, and make sure your legs are at least shoulderwidth apart. (See Figure 1.)

Figure 1

Transport

• All Hypro pumps are capable of being transported by air, sea, rail or motor vehicle. When the pump is shipped,

ensure that the pump is moved in accordance with local and national laws and is properly secured to prevent

unwanted movement which could cause damage to person or property. Prior to shipping, all fluids should be

removed from the pump.

Storage

• New pumps in their boxes can be stored several years as long as the port plugs are not removed. Once the plugs

have been removed, if the pump is not to be used for an extended period of time (i.e. more than 30 days), the

pump must be winterized as described in the Cleaning section of this manual.

Assembly and Installation

Assembly

This pump comes completely assembled.

Installation

Before attempting to install your Hypro roller pump, it is imperative to read and understand the following:

• Installation of a Hypro pump should only be performed by a technician having the knowledge and skills

necessary to install the pump without the risk of property damage or personal injury.

• When handling Hypro pumps, one should wear steel-toed shoes and protective gloves in order to protect the

feet in the event the pump is dropped and protect the hands from any sharp surfaces on the pump or chemicals.

• Pumping systems must be installed in accordance with Hypro installation instructions. Failure to do so will

void your warranty and could cause damage to property, serious personal injury, or death.

• Electrical power cables and pump hoses must be routed where there is no risk of personnel tripping, walking

into, or falling because they have been routed in areas where personnel are expected to move. Electrical power

cables and pump hoses should be routed according to local and national standards.

• It is the installer’s responsibility that AC electric-drive motors, Hypro pumps, and metalwork of support

structures are bonded to earth (ground), per local and national standards, to prevent a buildup of static electricity.

• It is the installer’s responsibility to conduct earth continuity tests between AC electric-drive motors, Hypro

pumps, and metalwork of support structures and earth according to EN60204-1:2006/A1:2009, or its superseding

standard, to confirm that all components that need to be connected to earth are satisfactorily bonded.

• It is the installer’s responsibility to conduct electrical tests in accordance with EN60204-1:2006/A1:2009, or

its superseding standard, on finished pump assemblies.

- 19 -

Page 20

Assembly and Installation - cont’d.

• All connections to electrical components must be number, symbol, or color coded generally as recommended by

EN60204-1:2006/A1:2009, or its superseding standard.

• Installers must provide hydraulic components that are capable of withstanding maximum source pressure.

• The working pressure must be controlled by a pressure relief valve that is adjusted to operate at a maximum

pressure of the hydraulic motor.

• For pumps with gas engines, the exhaust must be directed away from operator and anyone standing nearby

to ensure that exhaust fumes do not enter their breathing zone.

• If a rigid plumbing system is to be used on a Hypro roller pump, the system must be properly aligned with the

inlet and outlet ports.

• The working pressure must be controlled by a pressure relief valve that is adjusted to operate at 10% of the

maximum system pressure.

• When installing, adjusting or removing a Hypro roller pump, ensure that there are no objects which can fall

on the installer and make certain that all machinery to which the pump is to be attached is turned off.

• Pumps must be installed in a location where they are accessible for any necessary maintenance.

• When a main electrical supply is needed to power electric-drive motors, installers are responsible for

ensuring that a supply disconnect device, capable of isolating the machine from its electricity supply, be provided.

• When hydraulic power is used, the system should contain a quick disconnect coupling that can be broken to

isolate the pump.

Standard Mounting

In order to prevent injury or damage to property, all Hypro pumps should be properly mounted to a solid base where

there is no danger of the pump falling or breaking loose. All Hypro pumps come with mounting holes, which allow bolts

to be put into the pump so it can be secured to a sturdy base. When mounting your Hypro roller pump, be sure to use

bolts and nuts which are compatible with any chemicals that may come into contact with them as well as choosing the

correct grade of bolt based on the pump weight and any expected loads.

Tractor PTO Installation

The preferred method for mounting the torque arm (3430-0540) and pump to a tractor is with the chains going up to

provide support for the pump (see Figure 2).

1. Attach the torque arm to the pump with the long side of the arm on the inlet side of the pump for mounting.

2. Mount the pump and torque arm to the PTO shaft using a Hypro series 1320, 1321 or 1323 coupler.

3. Attach the torque chain to the tractor frame with arm in horizontal position.

4. Attach the tensioning chain to the tractor frame while applying tension to the spring.

Do not attach torque arm to movable linkages.

Personnel should never be within 3 meters (9 ft.) of the pump while in operation.

Figure 2

- 20 -

Page 21

Assembly and Installation - cont’d.

Belt/Pulley Drive Installation

Belt and pulley drive systems are typically used to reduce pump speed. For determining proper pulley sizes, use the

formula below as a guideline and use “A” or “B” section belts.

MOTOR RPM FLOW (@ RATED SPEED) PUMP PULLEY DIA.

PUMP RPM FLOW (DESIRED) MOTOR PULLEY DIA.

=

=

Example:

Use a 1725 RPM electric motor to drive a pump at 950 RPM.

Typically, a pulley diameter on the motor is 3.4 inches. The pump pulley diameter can be determined from the formula

above:

1725 RPM Pump Pulley Diameter

950 RPM 3.4 inches

=

Solving this equation for the Pump Pulley diameter yields:

1725 RPM

950 RPM

x 3.4 inches = 6.2 inches

(1 inch = 2.54cm)

1. Install pulley or bushing/sheave combination onto pump and motor shaft. Mount pump next to the motor making

sure pulleys are lined up properly. (See Figure 3 for proper pump and motor orientation.) Use a straight edge as

shown (Figure 4). Rotate to check for run-out and bent shafts and replace if found.

Figure 3

Figure 4

2. Make sure belts have proper tension - belts too tight will cause bearing wear and belts too loose will cause

slipping (See Figure 5).

Push the belt midway between the pulleys,

check the deflection (d) and adjust:

d = 0.016 x L

Figure 5

Direct Drive-Flexible Coupling

When direct driving Hypro roller pumps with flexible couplings, make sure that the speed (rpm) of the gas engine or

electric motor is within the maximum rated rpm of your pump (see performance tables). Also make sure that shaft

rotation is correct between the pump and the motor or gas engine (see Figure 6).

1. Mount motor or engine into position on base.

2. Line up pump shaft with straight edge as shown in Figure 6 to assure they are aligned. Shim pump, if

necessary, to match shaft height of engine or motor. Shaft ends should not touch.

3. Mark exact position of pump on base - remove and install coupling halves on both shafts. Place coupling center

disc into one of the coupling halves.

4. Reposition pump, sliding coupling halves together.

ATTENTION: No end thrust should be applied to pump when coupling is connected.

5. Tighten pump mounting; then tighten the set screws on each coupling.

- 21 -

Page 22

Assembly and Installation - cont’d.

Figure 6

System Installation

ATTENTION: Use only pipe, fittings, accessories, hose, etc. rated for the maximum pressure rating of the pump.

1. Select adequate size drive unit to avoid overloading. Avoid unnecessary restrictions in the line such as elbows,

check valves, and all extraneous curves and bends.

2. Avoid using looped sections of tubing or pipe which might permit air to become trapped.

3. Use pipe joint sealant on pipe threads to assure watertight connections, and ensure that the sealant used is

compatible with any chemicals which will be pumped.

4. Selection of the right size and type of hose is vital for good performance. Be sure to hook up to the proper

ports on the pump (note markings “IN” and “OUT” on pump label).

a. Always use a suction hose compatible with the fluids being pumped and at least the same inside diameter

as pump ports. If the suction hose is over 5 feet long, use one size larger hose. Keep the suction hose as

short as possible and restrictions such as elbows, check valves, etc. at a minimum.

Attention: Suction lift not to exceed 3 feet.

b. High pressure pumps require the use of special high pressure discharge hose. Use a hose rated at least

50% greater than the highest operating pressure of pump. Example: If required pump pressure is 300 psi

[20.7 Bar], use hose rated at minimum of 450 psi [31.0 Bar] working pressure.

5. Use a suction line strainer with at least 3 to 5 times the suction port area in open screen area. Be sure the

screen is suitable for the liquid being pumped. The mesh should be appropriate for the nozzle tip to be used,

to avoid clogging.

Never attach an agitator or any restriction to a bypass line of a pressure relief device because system damage

may occur.

Bypass Line

Figure 7

Typical System Installation

Pump

Pressure

Relief

Valve

Pressure Regulator

Strainer

ELECTRICAL HOOK-UP FOR UNITS SUPPLIED WITH DC MOTOR

The motor must be fused to protect the electrical system. Use a 35-amp slow-blow fuse or circuit breaker for -EH

pumps and a 45-amp slow-blow fuse or circuit breaker for -E2H pumps.

The motor lead wires are identified by color with (+) being red and (-) being negative. For proper pump rotation, the

connections should be made as follows:

• Positive Motor Lead (+) to Positive Power Lead (Red, +).

• Negative Motor Lead (-) to Negative Power Lead (Black, -).

- 22 -

Page 23

Assembly and Installation - cont’d.

ON/OFF TOGGLE SWITCH INSTALLATION

See Figure 8.

1. The ON/OFF switch must be rated at or above 40 amps

for -EH pumps and at or above 50 amps for -E2H pumps.

2. If additional lead wire is required, use 10 gauge or larger

wire.

3. Performance may be improved by shortening the motor

lead wires. Minimize wire length where possible.

ON/OFF Toggle Switch

Figure 8

Slow-blow Fuse

or circuit breaker

12-volt

Battery

Hooking up the Hydraulic Motor to the Tractor Hydraulic System

Hypro Series 7560 hydraulic motor-driven pumps can be mounted on either the tractor or sprayer. When hooking up,

make sure that no dirt or liquid gets into the hydraulic motor. Keep all hydraulic connections clean. Series 7560

pumps utilize gear motor technology for high torque capacity and premium efficiency. Be sure to connect the hydraulic

motor into the system correctly by putting the pressure line to the (IN) port and return line to the (OUT) port. For

maximum performance, hose should be at least 1/2” (12.7mm). Be sure return line is appropriately sized and free of

restrictions.

Control System(s)

• All pump systems with electric or hydraulic power sources are required to have a control system which meets all

local and national standards.

• Overload and short-circuit protection devices should open at a current that is 10% higher than the normal

load current.

• For more detail on a typical system installation, see the preceding subsections of the “Assembly and Installation”

section of this manual.

Commissioning Start-Up, Operation, Shutdown

Before attempting to start your pump, the following must be understood and followed to ensure safe operation.

Information

• Only authorized operators having the knowledge and skill necessary to safely use a Hypro pump, or any

equipment the pump is connected to, may run the pump.

• When running Hypro roller pumps, it is essential that operators use hearing protection as the sound levels

can reach levels of 80 decibels.

• When handling Hypro pumps, wear steel-toed shoes and protective gloves in order to protect the feet in the

event the pump is dropped and protect the hands from chemcials or any sharp surfaces on the pump.

• When spraying manually, chemical-resistant facemasks and clothing should be worn to prevent any

chemicals from coming into contact with the skin or being inhaled.

• When spraying manually, always spray downwind of yourself as long as the sprayed chemical will not drift

into the vicinity of other people.

•• When installing, adjusting or removing a Hypro roller pump, ensure that there are no objects which can fall

onthe installer, and make certain that all machinery to which the pump is to be attached is turned off.

• Hypro roller pumps should only be used on tractors or tow-behind spray platforms which have electrically-

conductive tires, in order to reduce the risk of electrocution.

• Never operate a Hypro roller pump outside while there is a chance of getting struck by lightning.

•• Never leave electrical wires or plumbing components where they can be a tripping hazard or become

entangled in a moving component. Ideally, electrical cables, hoses, pipes and fittings should be routed overhead.

In the event electrical wiring must be routed over, the ground operators are required to use rubber ramps if they

cross a gangway.

- 23 -

Page 24

Commissioning Start-Up, Operation, Shutdown - cont’d.

• If users of a Hypro roller pump are using a PTO shaft, flexible coupling or belt drive, they are required to use CEapproved PTO shafts and guards.

• Hypro roller pumps should not be used if the ambient light is below 200lux.

• For roller pumps which use gas engines, the user should always ensure the exhaust is properly attached to

the engine and is not leaking.

Only use approved chemicals in your pump. For a complete list of approved chemicals, see the “Fluid

Pumping Applications” section. Failure to follow this warning will void your warranty and could lead to

property damage, serious injury or death.

Start-Up, Operation, Shutdown

Before Starting the Pump

• Ensure all unnecessary personnel are clear of the area.

• For initial setup and test of your system, it is recommended to start with clean water instead of chemicals, and

confirm the system and plumbing connections are leak free.

• Ensure that there is fluid in the source tank or supply line. Do not run dry.

• Check line strainer for debris or clogs. Remove any found.

• Check all plumbing connections to make sure they are tight.

• Check power source and connections.

• Check that all valves and regulators are set to the desired setting and are functioning properly.

• Ensure all hoses are properly positioned and are not damaged in any way.

• Ensure PTO shaft shields are in place and are not loose.

Priming the Pump

To help prime the pump, keep the inlet or suction line as short as possible with a minimum of bends, elbows and kinks.

Make sure all connections are tight and do not leak air. Make sure line strainer is free of debris. If pump does not selfprime, disconnect suction hose, fill with water and reconnect to liquid source. Often a squirt of oil into the ports of the

pump will seal clearances and help with priming.

Pumps Equipped with Only DC Motor

Startup and Operation

Prior to operation, make sure all discharge lines and hoses are secure, and not frayed, and there are no personnel

close to the pump. Make sure the tank valve / inlet line to the pump is open.

To start the pump, turn on main power switch to start the motor. Make sure pump is primed before proceeding. Adjust

pressure to reach desired spray output.

Duty Cycle

Duty cycle is the ratio of motor-on time to total cycle time in one hour. It is used to determine the acceptable level of

running time so that the thermal limits of the motor are not exceeded. Use the following equation and example to

determine Duty Cycle:

Duty Cycle = ON TIME / [Cycle ON TIME + (60 Minutes - Cycle ON TIME)] * 100.

(ON TIME cannot exceed 60 minutes.)

An example of a 75% Duty Cycle Motor is = 45/ [45+ (60-45)]*100 = 75% or 45 minutes on time per hour of operation

at maximum rated pressure and flow. ON TIME can be extended by reducing the maximum pressure the pump

operates at.

Duty cycle is affected by ambient temperature. If operating in extremely hot environments, duty cycles will decrease.

Do not run DC electric motors to an external operating temperature over 175º F (80º C), or the motor life will be

compromised.

Shutdown

To shut down the unit, first turn the switch or power supply off, then close all valves. If the pump will not be used for

several hours, it must be cleaned in accordance with the “Cleaning” section of this manual.

- 24 -

Page 25

Start-Up, Operation, Shutdown - cont’d.

Pumps Equipped with Hydraulic Motor

Startup and Operation

Open Center Systems

The 7560 series pump hydraulic motors are not equipped, from the factory, with a bypass for excess hydraulic flow in a

given system. In situations where the hydraulic system has more flow than the motor is rated for, an external bypass

must be mounted to the hydraulic lines. Failure to restrict the pump to these levels may result in leaks and premature

pump failure. To plumb the hydraulic motor into an open center hydraulic system that is not sized to the 7560 pump

requirements, follow these installation instructions:

1. Ensure there is a bypass valve in the high pressure hydraulic line. Route bypass flow either to the return line or

directly back to tank.

2. Prime the pump as above with all valves open.

3. Open hydraulic bypass all the way. Start hydraulic system and allow oil to circulate for approximately 10 to 15

minutes or until adequately warmed to 135°F (57°C).

When operating a Hypro pump with a hydraulic motor, the maximum allowable temperature of the hydraulic fluid

passing through the motor is 135°F (57°C).

4. Gradually close the hydraulic bypass valve until the pump reaches the desired pressure or flow.

5. Lock down the system hydraulic bypass valve in this position. DO NOT let the pump exceed its maximum

pressure or flow. Failure to restrict the pump to these levels may result in leaks and premature failure.

Closed Center (Load Sensing) Systems

1. Set the system hydraulic flow control valve for minimum hydraulic oil flow to the remote outlet (Tortoise position).

2. Prime the pump as above with all valves open.

3. Start the hydraulic system and allow the hydraulic oil to circulate for approximately 10 to 15 minutes or until

adequately warmed to 135°F (57°C).

When operating a Hypro pump with a hydraulic motor, the maximum allowable temperature of the hydraulic fluid

passing through the motor is 135°F (57°C).

4. Increase system hydraulic flow until pump reaches desired pressure or flow.

5. Lock down the system hydraulic bypass valve in this position. DO NOT let the pump exceed its maximum

pressure or flow. Failure to restrict the pump to these levels may result in leaks and premature failure.

Shutdown

Standard spool valves, which are found on all tractor hydraulic systems, may cause potentially damaging high peak

pressures in the hydraulic system when closed because of abrupt shut-off of oil flow in both the supply and return lines.

When shutting off the pump, move the selector to the FLOAT position to allow the pump to come to a stop gradually. If

pump will not be used for several hours, it must be cleaned in accordance with the “Cleaning” section of this manual.

PTO/Belt Drive/Flexible Coupling

Startup and Operation

1. Prime the pump as described above with all valves open.

2. Start PTO/ Gas Engine/or Flexible coupling. If possible, slowly increase the RPM until the desired flow or

pressure is reached. DO NOT let the pump exceed its maximum pressure or flow. Failure to restrict the pump to

these levels may result in leaks and premature failure.

Shutdown

Slowly decrease RPM until the pump comes to a stop, and then close all valves in the system. If pump will not be used

for several hours, it must be cleaned in accordance with the “Cleaning” section of this manual.

- 25 -

Page 26

Maintenance and Servicing

Information

• All maintenance should be done when machinery is stationary and has been isolated from its energy

sources. It is dangerous to perform maintenance while machinery is still connected to its power source. Machinery

should be isolated from its electrical, hydraulic, shaft driven, or gas engine power source.

• Be sure to release all pressure from the system before performing any sort of maintenance on a Hypro pump.

• DO NOT perform service or maintenance to the pump, or attached components, until the pump unit is

below 109°F (43°C).

• The lubrication of this pump unit has been done at the factory prior to shipping.

• When handling Hypro pumps, wear steel-toed shoes and protective gloves in order to protect your feet in the

event the pump is dropped and protect yours hands from chemicals or any sharp surfaces on the pump. If the

pump is being repaired while the pump is in service, eye protection should also be worn.

• Any hazardous liquids should be disposed of in a manner which complies with local and national regulations.

Never dump fluids onto the ground.

Disposal

When disposing of a Hypro pump, be sure to remove all fluids from the pump before scrapping. These fluids should be

disposed of in a manner which complies with local and national regulations. Never dump fluids onto the ground. Once

the pump is free of all fluids, it must be scrapped in accordance with local and national laws.

Cleaning

Your pump will last longer and give best performance when properly taken care of. Proper pump care depends on the

liquid being pumped and when the pump will be used again. After each use, flush pump with a neutralizing solution for

the liquid just pumped. Follow with a clean water rinse. This is especially important for corrosive chemicals. It is good

practice to clean the pump after each use to prevent deposits from forming and damaging the pump. For infrequent

use and before long periods of storage, drain pump thoroughly. Open any drain plugs, remove suction hose from

liquid, and blow pump dry with air. An antifreeze/rust inhibitor should be injected into the pump before both ports are

plugged and the pump is stored. Plug all ports to keep out air until pump is used again.

Maintenance, Routine Servicing, and Inspection

Preventative Maintenance Checklist

Check Daily Weekly

Belt Tension X

Clean Filters X

Water Leaks X

Plumbing X

• Each system’s maintenance cycle will be exclusive. If system performance decreases, check immediately.

• Duty cycle, temperature, quality and type of fluid being pumped, and inlet feed conditions all affect the life of

pump, motor components, and service cycle.

Replacement Parts

The following drawings show the pumps and their replacement parts.

Only genuine replacement parts should be used. Failure to follow this warning can result in damage to

property, serious injury or death. If the pump malfunctions or is defective, it should be sent back to Hypro for

service.

- 26 -

Page 27

Parts Illustration

11

Series 1502

9

2

8

7

6

5

4

3

2

1

6A

10

7

IMPORTANT:

When ordering parts, give PART

NUMBER and PART DESCRIPTION.

Reference Numbers are used ONLY

to point out parts in the drawing and

are NOT to be used as ordering

numbers.

12

1

Ref. Qty. Part

No. Req'd. Number Description

122008-0001 Sealed Ball Bearing

222112-0001 Buna-N Seal (Standard)

222112-0003 Viton Seal (Optional) (Std. for SilverCast)

362210-0026 Bolt

410200-1500C Endplate (Cast Iron) with Seal

410200-1500N Endplate (Ni-Resist) with Seal

410200-1500X Endplate (SilverCast) with Seal

511720-0003 O-ring Gasket for Endplate

610300-1502C Rotor (Cast Iron) with shaft (Std. Rotation)

610300-1502N Rotor (Ni-Resist) with shaft (Std. Rotation)

610300-1502X Rotor (SilverCast) with shaft (Std. Rotation)

6A 1 0301-1502C Rotor (Cast Iron) w/shaft (Reverse Rot.)

6A 1 0301-1502N Rotor (Ni-Resist) w/shaft (Reverse Rot.)

6A 1 0301-1502X Rotor (SilverCast) w/shaft (Reverse Rot.)

Repair Parts Kit No. 3430-0383 (Universal) Consists of: (6) Ref. 8

Super Rollers, (1) Ref. 5 O-Ring Gasket, (1) O-ring Gasket (not shown),

and (2) Ref. 2 Viton Seals.

Repair Parts Kit No. 3430-0386 Consists of: (6) Ref. 8 Super Rollers,

(1) Ref. 5 O-Ring Gasket, and (2) Ref. 2 Viton Seals.

Repair Parts Kit No. 3430-0387 Consists of: (6) Ref. 8 Super Rollers,

(1) Ref. 5 O-Ring Gasket, and (2) Ref. 2 Buna-N Seals.

Repair Parts Kit No. 3430-0162 Consists of: (6) Ref. 8 Polypropylene

Rollers and (1) Ref. 5 O-Ring Gasket.

Ref. Qty. Part

No. Req'd. Number Description

711610-0005 Key

861005-0005 Super Roller (Standard)

861002-0005 Polypropylene Roller (Optional)

861055-0005 Teflon Roller (Optional)

910100-1500C Body (Cast Iron) with Seal

910100-1500N Body (Ni-Resist) with Seal

910100-1500X Body (SilverCast) with Seal

10 1 kit 3420-0004 Base Kit — Sold Separately

Includes: (1) Base, (4) Bolts and

(4) Lockwashers

11 1 2300-0020 Bearing Cover

12 1 2300-0022 Shaft Bearing Cover

Repair Parts Kit No. 3430-0164 Consists of: (6) Ref. 8 Polypropylene

Rollers, (1) Ref. 5 O-Ring Gasket, and (2) Ref. 2 Viton Seals.

Repair Parts Kit No. 3430-0163 Consists of: (6) Ref. 8 Polypropylene

Rollers, (1) Ref. 5 O-Ring Gasket, and (2) Ref. 2 Buna-N Seals.

Repair Parts Kit No. 3430-0406 Consists of: (6) Ref. 8 Super Rollers,

(1) Ref. 5 O-Ring Gasket, (2) Ref. 2 Viton Seals and (2) Ref. 1 Sealed

Ball Bearing.

- 27 -

Page 28

11

Parts Illustration

Series 1700

12

1

2

9

8

7

6

5

4

3

2

1

6A

10

7

Ref. Qty. Part

No. Req'd. Number Description

122008-0001 Sealed Ball Bearing

222112-0003 Viton Seal (Standard)

222112-0001 Buna-N Seal (Optional)

362210-0005 Bolt

410200-1700C Endplate (Cast Iron) with Seal

410200-1700N Endplate (Ni-Resist) with Seal

410200-1700X Endplate (SilverCast) with Seal

511720-0099 O-ring Gasket for Endplate

610300-1700C Rotor (Cast Iron) with shaft (Std. Rotation)

610300-1700N Rotor (Ni-Resist) with shaft (Std. Rotation)

610300-1700X Rotor (SilverCast) with shaft (Std. Rotation)

6A 1 0301-1700C Rotor (Cast Iron) w/shaft (Reverse Rot.)

6A 1 0301-1700N Rotor (Ni-Resist) w/shaft (Reverse Rot.)

6A 1 0301-1700X Rotor (SilverCast) w/shaft (Reverse Rot.)

IMPORTANT:

When ordering parts, give PART

NUMBER and PART DESCRIPTION.

Reference Numbers are used ONLY

to point out parts in the drawing and

are NOT to be used as ordering

numbers.

Ref. Qty. Part

No. Req'd. Number Description

711610-0005 Key

851005-0005 Super Roller (Standard)

851002-0005 Polypropylene Roller (Optional)

851055-0005 Teflon Roller (Optional)

910100-1700C Body (Cast Iron) with Seal

910100-1700N Body (Ni-Resist) with Seal

910100-1700X Body (SilverCast) with Seal

10 1 kit 3420-0010 Base Kit — Sold Separately

Includes: (1) Base and (4) Bolts

11 1 2300-0020 Bearing Cover

12 1 2300-0022 Shaft Bearing Cover

Repair Parts Kit No. 3430-0437 Consists of: (5) Ref. 8 Super Rollers,

(1) Ref. 5 O-Ring Gasket, and (2) Ref. 2 Viton Seals.

Repair Parts Kit No. 3430-0383 (Universal) Consists of: (6) Ref. 8

Super Rollers, (1) Ref. 5 O-Ring Gasket, (1) O-ring Gasket (not shown),

and (2) Ref. 2 Viton Seals.

Repair Parts Kit No. 3430-0160 Consists of: (5) Ref. 8 Polypropylene

Rollers and (1) Ref. 5 O-Ring Gasket, and (2) Ref. 2 Buna-N Seals.

Repair Parts Kit No. 3430-0161 Consists of: (5) Ref. 8 Polypropylene

Rollers and (1) Ref. 5 O-Ring Gasket, and (2) Ref. 2 Viton Seals.

Repair Parts Kit No. 3430-0407 Consists of: (5) Ref. 8 Super Rollers,

(1) Ref. 5 O-Ring Gasket, (2) Ref. 2 Viton Seals and (2) Ref. 1 Sealed

Ball Bearing.

- 28 -

Page 29

Parts Illustration

Series 4001 and 4101

16

15

5

3A

18

19

8

9

14

Ref. Qty. Part

No. Req'd. Number Description

17

20

6

2

7

13

9

8

1

5

12

3

IMPORTANT:

10

When ordering parts, give PART

NUMBER and PART DESCRIPTION.

Reference Numbers are used ONLY

to point out parts in the drawing and

are NOT to be used as ordering

11

Ref. Qty. Part

No. Req'd. Number Description

numbers.

110100-4001C Body (Cast Iron) with Std. Seal (4001)

110100-4101C Body (Cast Iron) with Std. Seal (4101)

110100-4001N Body (Ni-Resist) with Std. Seal (4001)

110100-4101N Body (Ni-Resist) with Std. Seal (4101)

110100-4001X Body(SilverCast) with Std. Seal (4001)

110100-4101X Body(SilverCast) with Std. Seal (4101)

210200-4001C Endplate (Cast Iron) with Std. Seal (4001)

210200-4101C Endplate (Cast Iron) with Std. Seal (4101)

210200-4001N Endplate (Ni-Resist) with Std. Seal (4001)

210200-4101N Endplate (Ni-Resist) with Std. Seal (4101)

210200-4001X Endplate (SilverCast) with Std. Seal (4001)

210200-4101X Endplate (SilverCast) with Std. Seal (4101)

310300-4001C Rotor (Cast Iron) & Shaft Assembly (4001)

310300-4101C Rotor (Cast Iron) & Shaft Assembly (4101)

313430-0765 Rotor Assembly (Std. 4001 Ni-Resist & XL)

313430-0766 Rotor Assembly (Std. 4101 Ni-Resist & XL)

3A 1 3430-0780 Rotor Assembly (Hollow Shaft 4001

Ni-Resist & XL)

3A 1 3430-0781 Rotor Assembly (Hollow Shaft 4101

Ni-Resist & XL)

541005-0002 Super Rollers (Std.)

541002-0002 Polypropylene Rollers (Optional)

541055-0002 Teflon Rollers (Optional)

611720-0104 O-Ring Gasket for Endplate

742220-0018 Endplate Screw

Repair Parts Kit No. 3430-0390 Consists of: (4) Ref. 5 Super Rollers,

(1) Ref. 6 O-Ring Gasket, (2) Ref. 8 Viton Seals.

822107-0002 Viton Seal (Std.)

822102-0001 Buna-N Seal (Optional)

822102-0001T Teflon Coated Buna-N Seal (Optional)

922000-0010 Ball Bearing (High temp. grease)

10 1 3420-0024 Base Kit — Sold Separately

Includes: 1 Base, 2 Bolts, and 2 Lock

washers for mounting pump to electric

motors with 3-1/2" shaft centerline

11 1 3420-0025 Base Kit — Sold Separately

Includes: 1 Base, 2 Bolts, and 2 Lock

washers for mounting pump to electric

motors/gas engines with 4-3/16" shaft

centerlines

12 1 kit 1320-0016 Adapter with 4 set screws for gas engine

mount (5/8" x 5/8") — Sold Separately

12 1 kit 1320-0015 Adapter (5/8" x 3/4") — Sold Separately

13 1 2300-0023 Shaft Bearing Cover

14 1 2300-0021 Bearing Cover

15 1 1420-0001 Locking Collar

16 1 2230-0001 Set Screw

17 1 1510-0054 Base — Sold Separately

18 2 1450-0003 Bumper — Sold Separately

19 2 2210-0003 Bolt — Sold Separately

20 2 2260-0002 Lock Washer — Sold Separately

Repair Parts Kit No. 3430-0158 Consists of: (4) Ref. 5 Polypropylene

Rollers, (1) Ref. 6 O-Ring Gasket, (2) Ref. 8 Viton Seals.

- 29 -

Page 30

Parts Illustration

Models 4101C-25 and 4101XL-25

5

2

4

3

6

1

10

15

Ref. Qty. Part

No. Req'd. Number Description

111320-0016 Adapter and Kit

2119209 Key 3/16 x 1-1/2”

322210-0166 Hed Head Capscrew

422270-0041 Washer

512549-0043 Engine: 2.5 HP PowerPro

612840-0084 Shield

710100-4101C Body (Cast Iron) with Seal

710100-4101X Body (SilverCast) with Seal

810200-4101C Endplate (Cast Iron) with Seal

810200-4101X Endplate (SilverCast) with Seal

910300-4101C Rotor & Shaft Assembly (Cast Iron)

913430-0766 Rotor Assembly (SilverCast)

10 4 1005-0002 Super Rollers

11 1 1720-0104 O-ring Gasket for Endplate

12 2 2000-0010 Ball Bearing

13 2 2107-0002 Viton Seal

14 4 2220-0018 Socket Head Screw

15 1 2300-0021 Bearing Cover

16 1 2300-0023 Bearing Cover w/Hole

7

9

11

8

14

13

12

IMPORTANT:

When ordering parts, give PART

NUMBER and PART DESCRIPTION.

Reference Numbers are used ONLY to

point out parts in the drawing and are

NOT to be used as ordering numbers.

Repair Parts Kit No. 3430-0390 Consists of: (4) Ref. 10 Super Rollers,

(1) Ref. 11 O-Ring Gasket, (2) Ref. 13 Viton Seals.

- 30 -

Page 31

Parts Illustration

Series 4001 and 4101 Electric Motor-Driven Pumps

When order ing pa rts, g ive QU ANTIT Y, PAR T

NU M B ER, D ESCR I PTIO N and C OMPL E TE

MODE L NUMB ER. Re feren ce num bers a re use d

ONLY to ide ntify parts in the drawi ng and are

NOT to b e u se d as orde r n umber s.

9

3

6

5

4

8

7

10

16

15

14

1

11

5

2

13

12

Ref. Qty. Part

No. Req'd Number Description

110100-4001N Body (Ni-Resist) with Std. Seal (4001)

110100-4101N Body (Ni-Resist) with Std. Seal (4101)

110100-4001X Body (Silvercast) with Std. Seal (4001)

110100-4101X Body (Silvercast) with Std. Seal (4101)

212570-0013 Electric Motor (12 vdc, .33 hp) (gold)

212570-0015 Electric Motor (12 vdc, .39 hp) (black)

310200-4001N Endplate (Ni-Resist) Std. Seal (4001)

310200-4101N Endplate (Ni-Resist) Std. Seal (4101)

310200-4001X Endplate (Silvercast) Std. Seal (4001)

310200-4101X Endplate (Silvercast) Std. Seal (4101)

412300-0021 Bearing Cover

522107-0002 Viton Seal (Standard)

522102-0001 Buna-N Seal (Optional)

522102-0001T Teflon-Coated Buna-N Seal (Optional)

642220-0018 Endplate Screw

711720-0104 O-ring Gasket for Endplate

813430-0780 Rotor Assembly (Std. 4001 Ni-Resist & XL)

Contains: rotor, shaft and pin

1 3430-0781 Rotor Assembly (Std. 4101 Ni-Resist & XL)

Contains: rotor, shaft and pin

Ref. Qty. Part

No. Req'd Number Description

941005-0002 Super Rollers (Standard)

941002-0002 Polypropylene Rollers (Optional)

941055-0002 Teflon Rollers (Optional)

10 1 1510-0054 Base

11 2 2260-0002 Lock Washer

12 2 2210-0003 Bolt

13 2 1450-0003 Bumper

14 2 2000-0010 Ball Bearing

15 1 1420-0001 Locking Collar

16 1 2230-0001 Set Screw

1 4001N-H Complete Roller Pump Assy (Not Shown)

1 4001XL-H Complete Roller Pump Assy (Not Shown)

1 4101N-H Complete Roller Pump Assy (Not Shown)

1 4101XL-H Complete Roller Pump Assy (Not Shown)

Repair Parts Kit No. 3430-0390 Consists of: (4) Ref. 9 Super Rollers,

(1) Ref. 7 O-Ring Gasket, (2) Ref. 5 Viton Seals.

Repair Parts Kit No. 3430-0158 Consists of: (4) Ref. 9 Polypropylene

Rollers, (1) Ref. 7 O-Ring Gasket, (2) Ref. 5 Viton Seals.

- 31 -

Page 32

Parts Illustration

Series 6500

10

2

3

9

7

3

2

1

IMPORTANT:

When ordering parts, give PART

NUMBER and PART DESCRIPTION.

Reference Numbers are used ONLY to

point out parts in the drawing and are

NOT to be used as ordering numbers.

4

6

5

Ref. Qty. Part

No. Req'd. Number Description

112300-0021 Bearing Cover

222000-0010 Sealed Ball Bearing

322107-0002 Viton Seal (Standard)

322102-0001 Buna-N Seal (Optional)

322102-0001T Teflon-coated Buna-N Seal (Optional)

442210-0004 Bolts

510200-6600C Endplate (Cast Iron) with Seal

510200-6600N Endplate (Ni-Resist) with Seal

510200-6600X Endplate (SilverCast) with Seal

611720-0008 O-ring Gasket for Endplate

761005-0004 Super Roller (Standard)

761002-0004 Polypropylene Roller (Optional)

761055-0004 Teflon Roller (Optional)

11

8

Repair Parts Kits:

No. 3430-0380 Consists of (6) Ref. 7

Super Rollers, (1) Ref. 6 O-ring, and

(2) Ref. 3 Viton seals.

No. 3430-0175 Consists of (6) Ref. 7

Polypropylene Rollers, (1) Ref. 6 O-ring,

and (2) Ref. 3 Viton seals.

Ref. Qty. Part

No. Req'd. Number Description

8 1 kit 3420-0023 Base Kit - Sold Separately

Includes: (1) Base, (2) Bolts and

(2) Washers

910100-6600C Body (Cast Iron) with Seal

910100-6600N Body (Ni-Resist) with Seal

910100-6600X Body (SilverCast) with Seal

10 1 2300-0023 Shaft Bearing Cover

11 1 0300-6600C Rotor Assembly (Cast Iron)

11 1 3430-0767 Rotor Assembly (Std. Ni-Resist & XL)

- 32 -

Page 33

Parts Illustration

Series 7560

13

8

7

12

2

3

11

10

5

2

1

IMPORTANT:

When ordering parts, give PART

NUMBER and PART DESCRIPTION.

Reference Numbers are used ONLY to

point out parts in the drawing and are

NOT to be used as ordering numbers.

3

4

Ref. Qty. Part

No. Req'd. Number Description

112300-0020 Bearing Cover

222008-0001 Sealed Ball Bearing

322112-0003 Viton Seal (Standard)

322112-0001 Buna-N Seal (Optional)

462210-0004 Bolts

510204-7500C Endplate (Cast Iron) with Seal

510204-7500N Endplate (Ni-Resist) with Seal

510204-7500X Endplate (SilverCast) with Seal

611720-0014 O-ring Gasket for Endplate

781005-0004 Super Roller (Standard)

781002-0004 Polypropylene Roller (Optional)

781055-0004 Teflon Roller (Optional)

6

Repair Parts Kits:

No. 3430-0381 Consists of (8) Ref. 7

Super Rollers, (1) Ref. 6 O-ring, and

(2) Ref. 3 Viton seals

No. 3430-0167 Consists of (8) Ref. 7

Polypropylene Rollers, (1) Ref. 6 O-ring,

and (2) Ref. 3 Viton seals

Ref. Qty. Part

No. Req'd. Number Description

813430-0745 Rotor Assembly (Std. Ni-Resist & XL)

810308-7560C Rotor Assembly (Cast Iron only)

10 1 kit 3420-0003 Base Kit - Sold Separately

Includes: (1) Base, (3) Bolts and

(3) Washers

11 1 0104-7500C Body (Cast Iron) with Seal

11 1 0104-7500N Body (Ni-Resist) with Seal

11 1 0104-7500X Body (SilverCast) with Seal

12 1 2300-0022 Shaft Bearing Cover

13 1 1610-0005 Key

1 1610-0059 Key (Stainless Steel)

- 33 -

Page 34

7A

Parts Illustration

Models 7560C-GM30, 7560N-GM30, and 7560XL-GM30

Models 7560C-GM15, 7560N-GM15, and 7560XL-GM15

11

10

2

3

9

6

5

4

3

2

1

Ref. Qty. Part

No. Req'd. Number Description

8

7

18

17

13

12

Ref. Qty. Part

No. Req'd. Number Description

19

16

15

14

112300-0020 Bearing Cover

222008-0001 Seated Ball Bearing

322112-0003 Viton Seal (Standard)

322112-0001 Buna-N Seal (Optional)

410104-7500C Body (Cast Iron) with Seal

410104-7500N Body (Ni-Resist) with Seal

410104-7500X Body (SilverCast) with Seal

511720-0014 O-ring

681005-0004 Super Roller (Standard)

681002-0004 Polypropylene Roller (Optional)

681052-0004 Buna-N Roller (Optional)

681055-0004 Teflon Roller (Optional)

713430-0745 Rotor Assembly (Ni-Resist and SilverCast)

7A 1 0308-7560C Rotor Assembly (Cast Iron)

811610-0005 Key

Repair Parts Kit No. 3430-0381 Consists of: (8) Ref. 6 Super Rollers, (1) Ref. 5 O-Ring and (2) Ref. 3 Viton Seals.

Repair Parts Kit No. 3430-0167 Consists of: (8) Ref. 6 Polypropylene Rollers, (1) Ref. 5 O-Ring and (2) Ref. 3 Viton Seals.

Flange Kit No. 3430-0636 Consists of: (1) Ref. 13 Mounting Flange, (1) Ref. 12 Coupler, (1) Ref. 11 Spacer, (2) Ref. 14 Bolts,

(2) Ref. 16 Nuts, (3) Ref. 18 Bolts and (1) Ref. 8 Key.

910204-7500C Endplate (Cast Iron) with Seal

910204-7500N Endplate (Ni-Resist) with Seal

910204-7500X Endplate (SilverCast) with Seal

10 1 2300-0022 Shaft Bearing Cover

11 1 1410-0111 Spacer

12 1 0524-2500 Coupler

13 1 0750-7500C Mounting Flange

14 2 18044 Bolt

15 1 2500-0028 Hydraulic Motor (GM30)

15 1 2500-0042 Hydraulic Motor (GM15)

16 2 2250-0082 Nut

17 3 1410-0120 Spacer

18 3 11621 Bolt

19 3 2210-0004 Bolt

- 34 -

Page 35

Parts Illustration

Series 7700

11

12

10

2

3

9

8

6

5

3

2

1

IMPORTANT:

When ordering parts, give PART

NUMBER and PART DESCRIPTION.

Reference Numbers are used ONLY to

point out parts in the drawing and are

NOT to be used as ordering numbers.

4

Ref. Qty. Part

No. Req'd. Number Description

112300-0020 Bearing Cover

222008-0001 Sealed Ball Bearing

322112-0003 Viton Seal (Standard)

322112-0001 Buna-N Seal (Optional)

462210-0004 Bolts

510200-7700C Endplate (Cast Iron) with Seal

510200-7700N Endplate (Ni-Resist) with Seal

510200-7700X Endplate (SilverCast) with Seal

611720-0014 O-ring Gasket for Endplate

771005-0004 Super Roller (Standard)

771002-0004 Polypropylene Roller (Optional)

771055-0004 Teflon Roller (Optional)

8 1 kit 3420-0010 Base Kit - Sold Separately

Includes: (1) Base and (4) Bolts

7

Repair Parts Kits:

No. 3430-0384 Consists of (7) Ref. 7

Super Rollers, (1) Ref. 6 O-ring, and

(2) Ref. 3 Viton seals

No. 3430-0167 Consists of (7) Ref. 7

Polypropylene Rollers, (1) Ref. 6 O-ring,

and (2) Ref. 3 Viton seals

Ref. Qty. Part

No. Req'd. Number Description

910100-7700C Body (Cast Iron) with Seal

910100-7700N Body (Ni-Resist) with Seal

910100-7700X Body (SilverCast) with Seal

10 1 2300-0022 Shaft Bearing Cover

11 1 1610-0005 Key

12 1 0300-7700C Rotor Assembly (Cast Iron)

12 1 0300-7700N Rotor Assembly (Ni-Resist)

12 1 0300-7700X Rotor Assembly (SilverCast)

12 1 0301-7700C Rotor Assembly (Cast Iron)

12 1 0301-7700N Rotor Assembly (Ni-Resist) Rev. Rot.

12 1 0301-7700X Rotor Assembly (SilverCast) Rev.Rot.

Rev. Rot.

- 35 -

Page 36

Troubleshooting

Troubleshooting Guide

Before attempting to service your pump, be sure that it is disconnected from all energy sources.

Symptom Probable Cause(s) Corrective Action

Pump does Leak in suction line Check hose and fittings for leaks and correct

not prime Obstruction in suction line Inspect hose for obstructions such as debris or loose

inner liner and remove from the line

Suction hose sucked to bottom Cut a notch or “V” in end of suction hose

or side of tank

Rollers stuck in pump Disassemble pump and inspect rollers

Pump seals leaking air Replace seals

Pump turning in wrong direction Correct rotation of pump

Loss of pressure Clogged suction strainer Check strainer and clean regularly

Kinked or blocked suction hose Inspect suction hose and repair as necessary

Air leak in inlet side plumbing Check hose and connections for leaks. Use pipe

joint sealant and retighten connections

Relief valve setting too low Check relief valve and correct setting or replace

or weakened spring spring

Faulty gauge Replace gauge

Pump seals leak air Replace seals

Nozzle orifices worn Replace Nozzles

Pump worn Repair pump (See Repair Instructions)

Pump will not turn Corrosion (rust), scale or residue Replace pump

Solid object lodged in pump Disassemble pump and remove objects

Hydraulic system Improper hydraulic motor size Refer to Pump Selection Guide to determine proper

overheating size for your hydraulic system.

Insufficient hydraulic hose size Check hydraulic hose size. Hose should be at least

1/2” (12.7mm). For large open-center systems, hose

should be 3/4” (19.05mm).

Table 2

- 36 -

Page 37

Repair Instructions

To Take the Pump Apart

1. Remove the adapter from the pump shaft, if equipped.

2. File off any burrs on the pump shaft.

3. Using a screwdriver, pry off the bearing cover on the endplate and pump body.

4. Remove the endplate bolts.

5. Support the pump at its ports in a support fixture with the endplate down. Wood blocks may be used. Place on

press bed. Center press on pump shaft and apply pressure to press the pump apart (See Figure 9).

Figure 9

6. With the rollers exposed, remove them. When replacing damaged rollers, always replace the full set.

7. To remove the rotor with shaft from the endplate, support the endplate in a support fixture with the rotor down. Center a

3/8" bolt on pump shaft. Apply pressure to press shaft out of ball bearing (See Figure 9).

8. To remove the ball bearing, place the endplate in a support fixture with the front of the endplate down (See Figure 10).

Center bearing support tool, and slowly press bearing out of casting. Repeat procedure to remove bearing from pump body

(See Figure 10).

9. After removing the ball bearing, check the seals in both endplate and pump body. If wear is evident or leakage has been

noticed, punch the seals out with a screwdriver and hammer. Seals cannot be removed without damaging them.

Figure 10

10. To press the shaft out of the rotor, first carefully wash the rotor and shaft - removing all traces of rust and other foreign

matter. Use steel wool or emery cloth, rinsing parts afterward to wash off all emery dust. Remove the Allen set screw.

Support the rotor in the press through the slot in the base and press shaft through.

While the Pump is Apart

Carefully inspect all parts for wear, such as:

• Undersize or swollen rollers in both length and diameter.

• Worn seals.

• Worn shaft at drive end, and pitted or grooved at the seal area.

• Rough bearings and loss of grease from the bearings.

• Undersize rotor and/or worn roller slots.

• Excessive wear in body - both on inside diameter and at back face.

• Body cracks at the bolt holes and at the o-ring sealing area.

• End wear (body, endplate and rotor).

• Damaged o-ring in the endplate.

After the above parts have been checked and the various points have been considered, decide if the pump is repairable. If repairing

the pump, be sure to inspect inside of endplate. If a groove is noticeable, the endplate should be replaced.

ATTENTION: If an attempt has been made to pry the pump apart with a screwdriver, be sure to file off all nicks, burrs and

other damage marks around the bolt holes.

Re-Assembly

Replace Seals and Bearings

Carefully place the seal in the pump body with crimped side down. Press the seal to the bottom of the

cavity. Then put the bearing in position in the pump body and press into place (Figure 11). Repeat the above

procedure with the endplate. Seat the o-ring in the groove. If necessary, make sure the o-ring stays in

place by stretching it.

- 37 -

Figure 11

Page 38

Repair Instructions - cont’d.

Assemble Rotor and Shaft to Endplate

1. Install the shaft rotor assembly by carefully pushing the short end of the shaft rotor assembly through the shaft seal into the

endplate. Place in the arbor press with the drive end of the shaft pointed down and press the assembly together (Figure

12). Leave just enough clearance between the rotor and endplate so that rotor can be turned by hand. If it turns too freely,

sand a little more off the body end that faces the endplate. You should notice a slight drag, but be able to turn shaft with an

adapter on it, by hand. The “slight drag” will wear off after the pump has been used a short time. Installing new rollers,

seals, bearings and shafts will not prove entirely satisfactory for volume and pressure unless end clearance is taken up.

Figure 12