Page 1

TROUBLE GUIDE

35-7000

Re

v

.

B 5/2005

ag

er or more con

A

v

e

This warranty does not cover failure in service due to fire, wreckage, freezing, willful abuse, improper repackaging

., Sanf

ord, NC 27330 or 10951 West Los Angeles Ave., Moorpark, CA 93021, whichever is clos-

v

enient.

or damage incurred in shipping nor does it extend to consequential damages.

PR

All adjustments are to be based on list prices in effect at the time of adjustment. PENTAIR POOL

PRODUCTS, INC.

rees to prepa

y all shipping charges to and from

will not be liable for the cost of labor or removing or replacing parts. Purchase

PENT

w

chase

or

ODUCTS,

kmanship. Should any of the operating parts become defective within one year from date of pur-

AIR POOL PR

, the

y will be replaced or repaired if def

INC.

ODUCTS,

D. MOTOR WILL 1. Check that all power switches are on, fuse not blown, and circuit breaker

NOT TURN is not tripped.

2. Timer improperly set.

3. Impeller is against volute face.

c. Low voltage.

d. Wiring is incorrect size for load.

b. Poor ventilation.

C. MOTOR 1. Motors will run hot to the touch, however, they are designed this way. Thermal

RUNS HOT overload protector will function to turn the motor off if there is an overload problem.

2. Factors which will increase operating temperature:

a. Installed in direct sun.

e. Debris on impeller vanes.

a. Pump or skimmer strainer basket is clogged.

b. Skimmer or main drain valve is closed.

c. Air leak in suction line.

d. Impeller setting is incorrect.

B. LOW FLOW 1. If filter gauge reads high.

11. Check voltage at pump to be sure it is same as motor specs.

2. If filter pressure gauge reads low.

a. Filter is dirty.

b. Clogged return lines.

10. Remove and replace pump seal if needed.

9. Open all valves in return and suction lines.

5. Make sure strainer pot is full of water.

6. TIghten all fittings and seal all joints on suction side.

7. Clean skimmer and pump strainer baskets.

8. Remove pump lid and check for clogging.

A. PUMP WILL 1. Make sure pool water is midway of skimmer opening.

NOT PRIME: 2. Make sure strainer basket is not clogged.

PROBLEMS POSSIBLE CAUSES & SOLUTIONS

4. Tighten lid down snugly.

3. Make sure strainer basket is positioned properly!

THE FOLLOWING ARE SOME COMMON CAUSES OF PROBLEMS THAT MAY ARISE:

P

INC.

pumps are w

ect is pro

PENT

AIR

POOL PRODUCTS, INC.

ved to be the responsibility of

WARRANTY

PUMPS

arr

anted to be free from def

SAVE THESE INSTRUCTIONS.

LIMITED

P

ects in material and

1620 Ha

Pr

inted in the U

.S.A.

wkins

PENT

AIR POOL

& SERVICE MANUAL

INSTALLATION, OPERATION

HYDROPUMP

TWO SPEED POOL AND SPA PUMP

ENERGY MASTER

HYDROPUMP

AND

®

™

®

Page 2

R.T.V. or other sealing materials approved for pipe

diagram supplied with the motor. All wiring should be

and not supported by the pump.

voltage, and rotation, in accordance with the wiring

done by a licensed electrician in accordance with

grounded. Use lug on top of motor frame to bond

together motor and all metallic parts of pool, spa or

guide only.

.

W

ARNING:

NEVER

The f

ollo

wing tab

a

w and other motor inf

The wir

ing to motor should be k

Motor name plate has voltage, phase, ampere

inside walls of a swimming pool, spa or hot tub, when

of the swimming pool, spa or hot tub structure with a

metal conduit, and metal piping within 5 feet of the

the motor is installed within 5 feet of the inside walls

solid copper conductor not less than No. 8 A.W.G.

plate or name plate has wiring connection informa-

dr

tion.

possible and large enough to carry the necessary

current for required length without excessive voltage

drop

sure that the proper wire size is selected. Use as a

local codes, be certain that the motor frame is

hot tub structure and to all electrical equipment,

The piping should be supported independently

The pump motor must be wired for the proper

threads.

TIGHTEN.

required to insure a tight connection. DO NOT OVER

must be sealed with: pipe sealant, Teflon

long years of trouble-free operation.

Tighten the pump fitting only as much as is

The threads of pipe fittings screwed into pump

the pipe size on the inlet of the pump.

materials available today. A few simple precautions

taken during the initial installation, will insure many

The pump suction line should not be smaller than

Your pump is made of the finest engineering

near motor.

INSTALLATION:

floor to allow easy access to mounting screw. Locate

allow several inches of clearance below the motor to

away from pool chemicals to prevent spilling on or

future inspection and servicing of the unit. If possible,

LOCATION:

Provide the necessary space around the pump for

Locate the pump as close as possible to the pool.

indications of damage should be carefully noted on

designed to prevent transit damage. However, any

the delivery ticket and a claim filed promptly with the

carrier.

Our shipping container has been specifically

READ AND FOLLOW ALL INSTRUCTIONS

GENERAL:

W

ORK ON PUMP

WHILE IT IS R

2 7

UNNING OR POWER IS STILL CONNECTED.

Lid, tightening knobs by hand only. The pump seal

requires no lubrication. Refer to motor service center

f

or motors

.

le should be f

or

mation.

ept as shor

ollo

wed to be

and cleaned twice each w

Lid

clear lid. Remove the basket and clean. Inspect the

easy to clean. Loosen the knobs and remove the

“O”-Ring;

if damaged, replace

.

Install the Clear

The strainer basket in pump should be inspected

eek.

The str

ainer bask

et is

Terminal cover

®

t as

motor started, allow a few moments for the pump to

start pumping water. If flow does not start within four

GUIDE). Be sure all suction and discharge valves are

open when the pump is running. Operating the pump

damage.

WINTERIZING:

protect pump by removing both drain plugs, one from

the pump volute and one from the pot. Do Not

Replace Plugs, store them in strainer basket for the

winter.

from plumbing and store them indoors in a w

MAINTENANCE:

location.

An alternate is to remove the pump and motor

ar

m, dr

y

In areas subject to freezing winter temperatures,

minutes, stop motor and refer to (THE TROUBLE

with a closed valve in the system can cause pump

After the pump has been filled with water, and the

Tape,

Suction Lifts, require additional time for priming.

OPERATION:

pot accidentally or by draining purposely, it will be

necessary to refill it with liquid before starting. High

pump. This may be done by removing clear lid.

Pumps are self priming providing the pump pot is

filled with water. Should you lose this liquid from the

PRIMING:

closely supervised at all times.

permit children to use this product unless they are

Fill the pump pot with water before starting the

WARNING - To reduce the risk of injury, do not

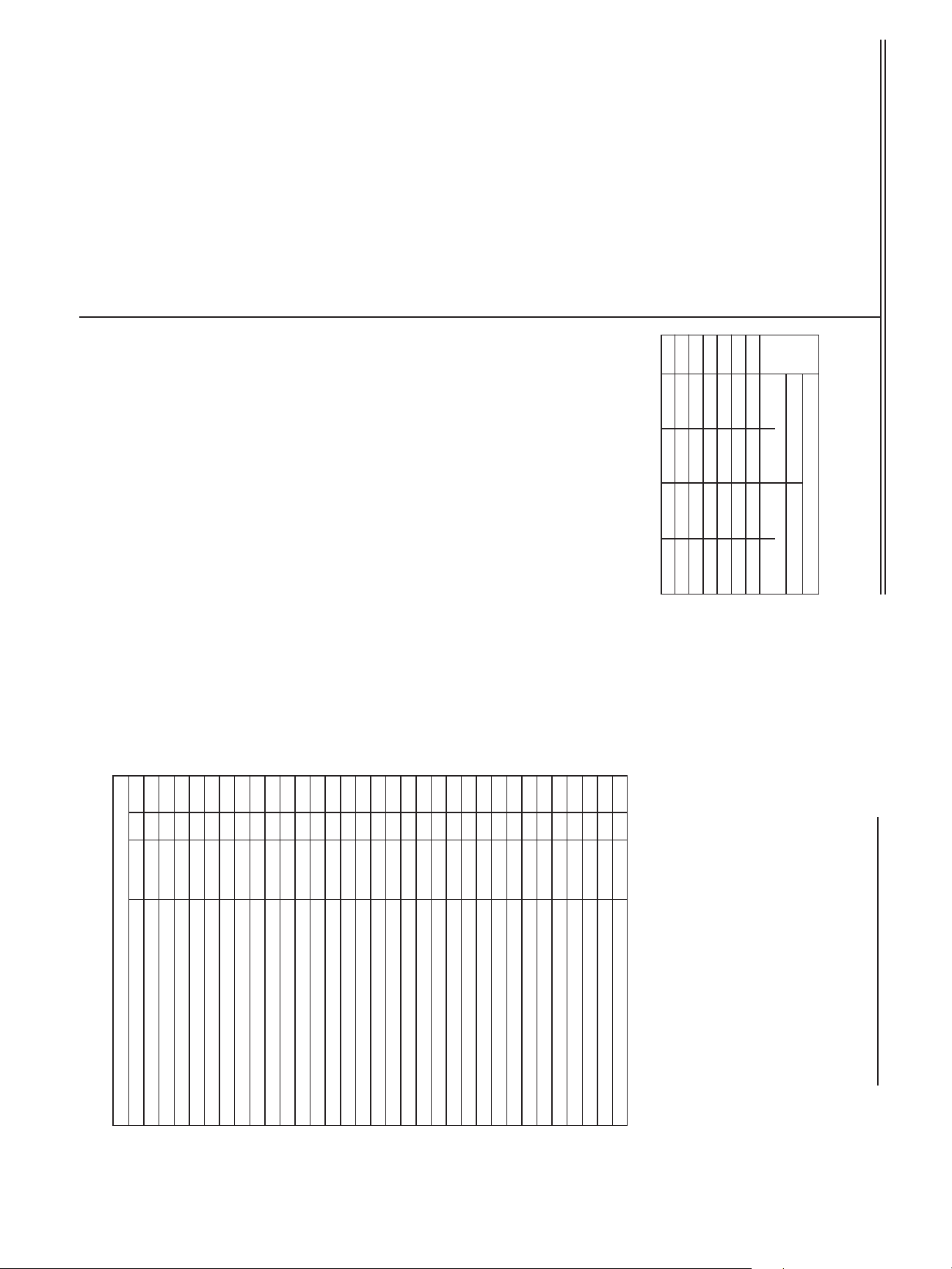

1 1/2 10 14 10 14

1/2 14 14 12 14

3/4 12 14 12 14

1 12 14 10 14

2 10 12 8 12

3 - 12 - 12

H.P.

1/3 14 14 14 14

SINGLE-PHASE POOL PUMP MOTORS

115 230 115 230

50 FEET 100 FEET

VOLTS VOLTS

WIRE LENGTH

FOR

INSTRUCTIONS

TABLE OF A.W.G. WIRE SIZE

H.P., PUMP SERIAL NO., MODEL NO. & ITEM NO.

Item Qty. Part No. NAME OR DESCRIPTION

1 Motor

LIST OF MATERIAL OR PARTS LIST

4

2 1 35-3750 Shaft Extension - Bronze

3 2 35-4294 Screw, Cap 3/8 - 16 x 1 1/4” Cad. Pltd.

1 35-3775 Seal Bracket - Plastic

7 1 35-3041 Impeller, RPA 1/2 HP

6 2 15-4445 Hex Nut 3/8 - 16 Cad. Pltd.

5 1 35-4894 Pump Tri Pod Base Plastic

7 1 35-3013 Impeller RPF 1HP, 1 1/2HP

7 1 35-3044 Impeller RFP 3/4HP, RPA 1HP

7 1 35-3043 Impeller RFP 1/2HP, RPA 3/4HP

7 1 35-3220 Impeller RPF 3HP

8 1 35-2626 O-Ring Volute to Bracket

7 1 35-3050 Impeller RPF 2HP, 21/2HP

7 1 35-3049 Impeller RPF 1 1/2HP, RPA 2HP

11 2 154699 Plug-Wing .25” Drain Lgr

10 1 19-2323 O-Ring (Pot to Volute)

9 1 35-3912 Volute - Plastic

12 1 35-4125 Strainer Pot 590 (Plastic)

14 1 35-3625 Clear Lid - 590 Plastic

13 2 35-4280 Knob - Pot Plastic

12 1 35-4127 Strainer Pot 700 (Plastic)

15 1 35-2600 Lid O-Ring 700

15 1 35-2602 Lid O-Ring 590

14 1 35-3525 Clear Lid - 700 Plastic

17 1 35-4001 3/4 Mechanical Seal

18 8 35-4265 Hex Washer Head Screw 5/16” - 18

16 1 35-2670 Basket w/Handle - Plastic 700

16 1 35-2656 Basket w/Handle - Plastic 590

19 4 35-4290 Cap Screw 3/8 - 16 x 1” S.S.

21 1 15-4909 Motor Outrigger

22 1 35-3450 Motor Support (for 5 1/2 Dia. Motor)

20 2 35-4256 Set Screw 1/4” x 20 x 3/8” S.S.

ARE LOCATED ON PUMP

H.P., PUMP SERIAL NO. & MODEL NO.

HOW TO ORDER PARTS

WHEN ORDERING PARTS, GIVE

TO YOUR LOCAL DEALER

--------------------

Page 3

tem friction. These lower friction losses result in

energy savings are 60%.

will drop GREATLY which is due to much lower sys-

operated mostly at low speed for cost savings, minor

rine dispenser, the skimmers and the heater due to

electrical cost savings. Since the pump should be

connected to the motor as follows:

removed and the BLACK wire discarded. See

speeds, the wiring connected to the switch should be

Diagram 2. The timer should then be installed and

If an automatic timer is installed to change

nameplate for the motor being installed. ALL electri-

cal connections should be made in the SIDE BOX

which also includes a prewired HI-LO switch. See

Diagram 1.

All electrical work MUST be done by a licensed

adjustments may be required in the automatic chlo-

the lower flow. (See the equipment manufacturers

operation manuals).

electrician. Before working on motors be certain that

the electrical power is OFF at the main junction

box. TWO SPEED pumps have SINGLE VOLTAGE

motors which cannot be changed. See the motor

or back washing of filter is required, for fast clean-up

of pool water, and for priming the system to rid it of all

air. Turn motor to lo

GREAT energy savings. On low speed the electrical

reading the pressure gauge to determine if cleaning

Turn motor to high speed for vacuuming the pool,

high speed as the same model single speed pump,

both hydraulically and prime wise. At low speed the

pump will produce one half the flow and the pressure

SPECIAL INSTRUCTION FOR TWO

SPEED ENERGY MASTER HYDROPUMP:

The performance of this pump will be the same at

w speed for quiet operation and

4 5

disconnected when HYDROPUMP

trolled by the timer or the motor will be damaged.

NOTE: When time switch is ON

When time switch is OFF

CAUTION: Manual switch on motor side box must be

be made in the side box.

screws if not needed.

2) Connect the timer to the motor following Diagram

*These models have skip-a-day wheel. Remove skip

3. All electrical connections to the motor should

Hydropump H.P. Voltage Timer Model

1, 1 1/2, 2 230 T176*

intermatic timers should be used.

modes at present intervals.

switch may be used to automatically switch the

HYDROPUMP

1) Check to see that timer voltage is the same as

that of the HYDROPUMP

TIMER INSTALLATION FOR HI-LO SWITCHING

OF 2 SPEED HYDROPUMP

An intermatic timer with single pole, double throw

3/4 115 T175*

®

between the high and low speed

- pump is on LO.

®

®

- pump is on HI.

motor. The following

®

is being con-

oper

motor side box. The 2 speed motor is designed to

only. Wiring with a different line voltage will damage

the motor.

the HYDRO-PUMP

A.W

.G.

ate on the v

NOTE: When time switch 1 is ON - pump is on HI.

When time s

All wiring connections should be made with 12

or larger wire siz

witch 1 is OFF - pump is on LO

oltage stamped on the nameplate

®

should be made inside the

e

.

All wiring connections to

Diagram 4.)

for the proper operation of the switching circuits.

Therefore it is necessary to make a connection

between line 1 and the clock input of timer No.1. (See

the HYDRO-PUMP

The clocks of both timers must run continuously

2) Timer No. 1 will be used to control the hi speed-

3) Timer No. 2 will be used to automatically switch

in-1 raintight case is ideal for this installation.

lo speed switching of the motor.

screws if not needed.

1) Mount the timers side by side, between the power

•These models have skip-a-day wheel. Remove skip

supply and the HYDRO-PUMP

1, 1 1/2, 2 230 T176* T102

H.P. Voltage S.P.D.T. S.P.S.T.

3/4 115 T175* T101

timers are recommended for this installation:

Hydropump Timer Model No.

PUMP

other types may be used if desired. The following

single throw switch. Both timers and the HYDRO-

same voltage.

Only Intermatic timers are discussed below, but

®

the ENERGYMASTER 2 speed pump can be

obtained by properly installing two appropriate

timers. One timer must have a single-pole, double

throw switch and the other must have a single-pole,

HYDROPUMP

ON-OFF, HI-LO SWITCHING OF 2 SPEED

TIMER INSTALLATION FOR PROGRAMMED

Automatic on-off and hi speed-lo speed control of

motor must be designed to operate on the

®

®

on and off.

®

an Intermatic 2-

Intermatic

.

marked.

imum wall height of 42 inches.

beneath the skirt of a hot tub or spa unless so

and has a maximum dimension of 18 feet and a max-

for storage and reassembled to its original integrity

is constructed so that it may be readily disassembled

pools. A permanently installed pool is constructed in

be readily disassembled for storage. A storable pool

and spas if so marked. Do not use with storable

or on the ground or in a building such that it cannot

Do not install within an outer enclosure or

at the same time.

CAUTION: This pump is for use with permanently

installed pools and may also be used with hot tubs

the HI and LO speed motor windings to be energized

CAUTION: Always turn power off at main panel

before servicing switches or pumps.

CAUTION: Be certain the wiring CANNO

4) The pump may be manually switched between hi

allows priming of the pump and evacuation of air

mum at hi speed when it is switched on. This

PUMP

from the piping system.

and lo speed by flipping the manual lever of timer

No. 1, and may be switched on and off by flipping

the manual lever of timer No. 2.

®

3) Locate the trippers on the clock dial of timer No.

1 to switch the HYDRO-PUMP

always be programmed so that the HYDRO-

lo speed at the desired time. The timers should

2) Locate the trippers on the clock dial of timer No.

desired times.

2 to switch the HYDRO-PUMP

OPERATING INSTRUCTIONS

1) Set both clock dials to the exact time of day.

will always operate for 10 minutes mini-

®

between hi and

®

on and off at the

T allow both

Page 4

6 3

a screwdriver between the motor bracket and

force the impeller face to touch the volute. Place

the shaft extension as depicted below. Move the

ment may be required.

this will allow the mechanical seal spring to

Loose the shaft extension set screws and

normal operating conditions it is not necessary

to make further adjustment, however, if the

which was precisely set at the factory. Under

pump draws excessive current a slight adjust-

The Hydropump has an open face impeller

IMPELLER CLEARANCE ADJUSTMENT

screwdriver handle away from the motor, this

ment needs to be redone.

rating or if the pump performs poorly the adjust-

draw. If the amperage exceeds the nameplate

will pull the impeller away from the volute. You

should move the shaft extension about 1/32”

and holding the screwdriver at this position firm-

ly tighten the shaft extension set screws.

Start the pump and check the amperage

Loading...

Loading...