Pentair Hydromatic SW33A, Hydromatic SD33A, Hydromatic VS33A, Hydromatic SD50A, Hydromatic SW50A Installation And Service Manual

...Page 1

PumP InstallatIon and

servIce manual

SW/SD/VS33 & 50

Submersible Sump/

Effluent Pumps

SW33

SW50

NOTE! TO THE INSTALLER: Please make sure

you provide this manual to the owner of the

pumping equipment or to the responsible party

who maintains the system.

SD33

VS33

VS50

SD50

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.HYDROMATIC.COM

PH: 888-957-8677

269 TRILLIUM DRIVE, KITCHENER, ONTARIO, CANADA N2G 4W5

PH: 519-896-2163

© 2013 Pentair, Ltd. All Rights Reserved. W-03-445 (Rev. 03/04/13)

Page 2

General

Information

2. Risk of Electrical Shock:

Connect only to a properly

ground ed receptacle.

Approx. Turn-On Level

SW33A 9

SD33A 7

VS33A 8

1

/2”

3

/8”

3

/8”

Thank you for purchasing your

Hydromatic

®

pump. To help

ensure years of trouble-free

op er a tion, please read the

fol low ing manual carefully.

Before Operation:

Read the following in structions care ful ly. Reasonable care

and safe meth ods should be

practiced. Check local codes and

requirements before installation.

Attention:

This manual contains important

information for the safe use of

this product. Read this manual

completely before using this

product and refer to it often

for con tin ued safe product use.

DO NOT THROW AWAY OR

LOSE THIS MAN U AL. Keep

it in a safe place so that you may

refer to it often.

WARNING: Before handling

these pumps and controls,

always disconnect the power

first. Do not smoke or use

sparkable electrical devices or

flames in a septic (gaseous) or

possible septic sump.

California Proposition 65

Warning

This product and

related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductive harm.

Pump

Warning

To reduce risk of electrical shock:

1. Risk of Electrical Shock:

This pump has not been

in ves ti gat ed for use in

swimming pool areas.

Septic tank is to be vented

in ac cor dance with local

plumbing codes.

Do not smoke or use sparkable

electrical devices or flame in

a septic (gaseous) or possible

septic sump.

If a septic sump condition

exists and if entry into sump is

necessary, then (1) provide

proper safety precautions per

OSHA re quire ments and (2)

do not enter sump until

these precautions are strictly

adhered to.

Do not install pump in location

clas si fied as hazardous per

N.E.C., ANSI/NFPA 70 - 1999.

Failure to heed above cautions

could result in injury or death.

Pump

Installation

These important in struc tions

must be followed for sat is facto ry per for mance of your

pump. Before in stal la tion, check

your local electrical and

plumb ing codes.

1. Provide proper sump.

Minimum Sump Diameter

SW/SD/VS50 18”

SW33 18”

SD/VS33 12”

Approx. Turn-Off Level

SW33A 3

SD33A 3

VS33A 3

7

7

7

/8”

/8”

/8”

Approx. Turn-On Level

SW50A 9

SD50A 7

VS50A 7

1

/2”

7

/8”

1

/2”

Approx. Turn-Off Level

SW50A 3

SD50A 3

1

3

/2”

/8”

VS50A 4”

2. Make sure float (Models

SW33/50 and VS33/50) hangs

free. It should not come into

contact with side or bottom of

sump.

3. Make sure sump is free of

string, cloth, nails, gravel, etc.

before in stall ing pump.

4. Do not set pump directly on

the bottom of sump if it is

not solid. Raise the pump by

using bricks or concrete blocks

un der neath it.

5. Use steel or plastic pipe for

all connecting lines be tween

pump and sewer outlet.

NOTE: Some city regulations

do not allow in stall ing

a pump with plastic pipe.

Check local regulations.

6. Hydromatic check valve

should be installed in

dis charge pipe, at least twelve

inches above the discharge

outlet of the pump.

2

Page 3

7. Connect to power source using

3-prong grounded 115 volt

AC receptacle. Do not

remove ground pin from

elec tri cal plug. Do not use an

ex ten sion cord.

8. For proper automatic

operation make sure the pump

power cord is plugged into

the back of the piggyback

re cep tacle on the switch cord.

9. Use pump submerged for

pumping waterlike liquids

(temperature to 120°F).

WARNING: Risk of

Electrical Shock – This

pump has not been

in ves ti gat ed for use in

swimming pool areas.

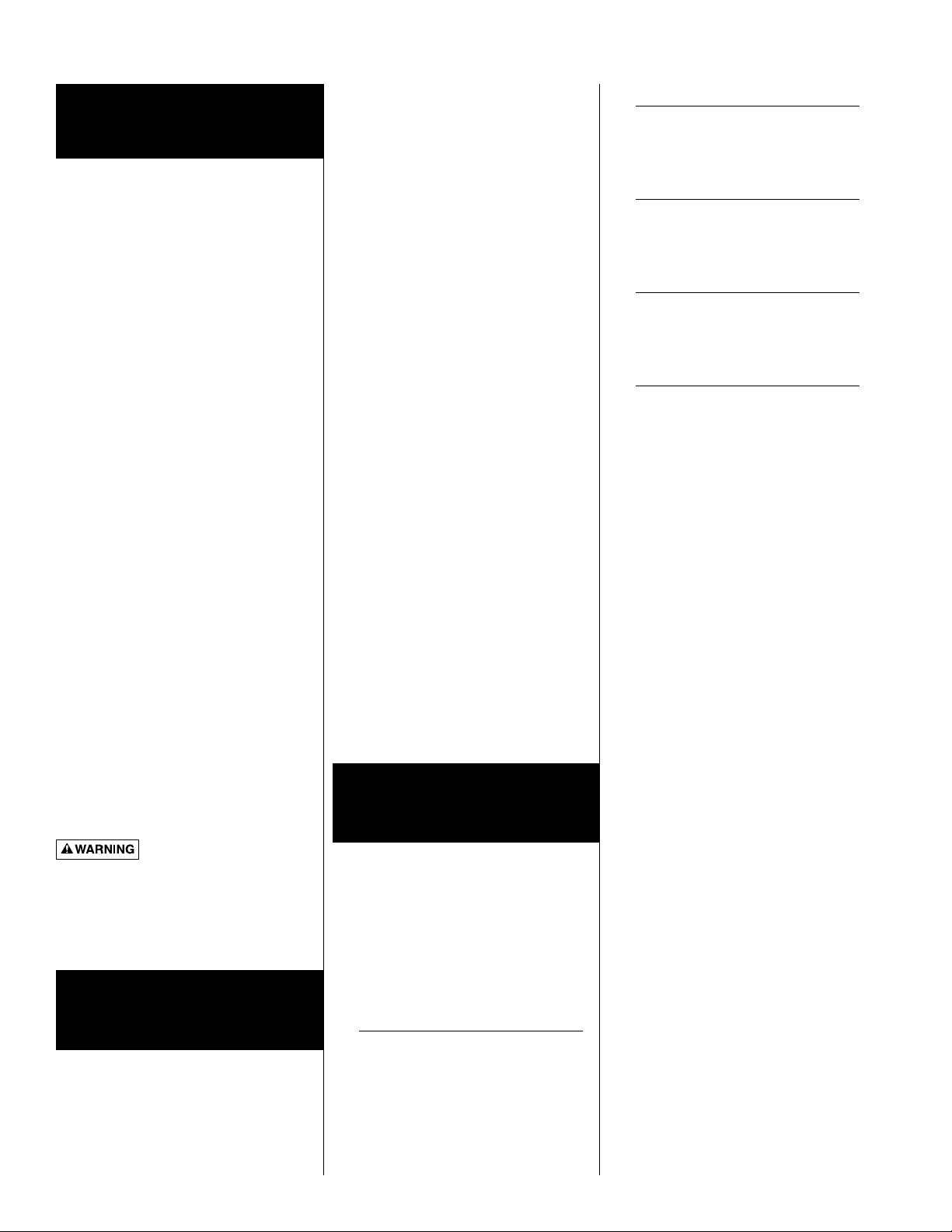

PERFORMANCE CURVE

10. CAUTION: Do not pump

flam ma ble liquids, strong

chemi cals or salt water.

11.In applications where the

pump may sit idle for months

at a time, it is recommended

that the pump(s) be cycled

every month to ensure

pumping system is working

properly when needed.

12. An audible alarm system such

as the Q Alert for high water

conditions should be installed

for additional protection

against high water conditions.

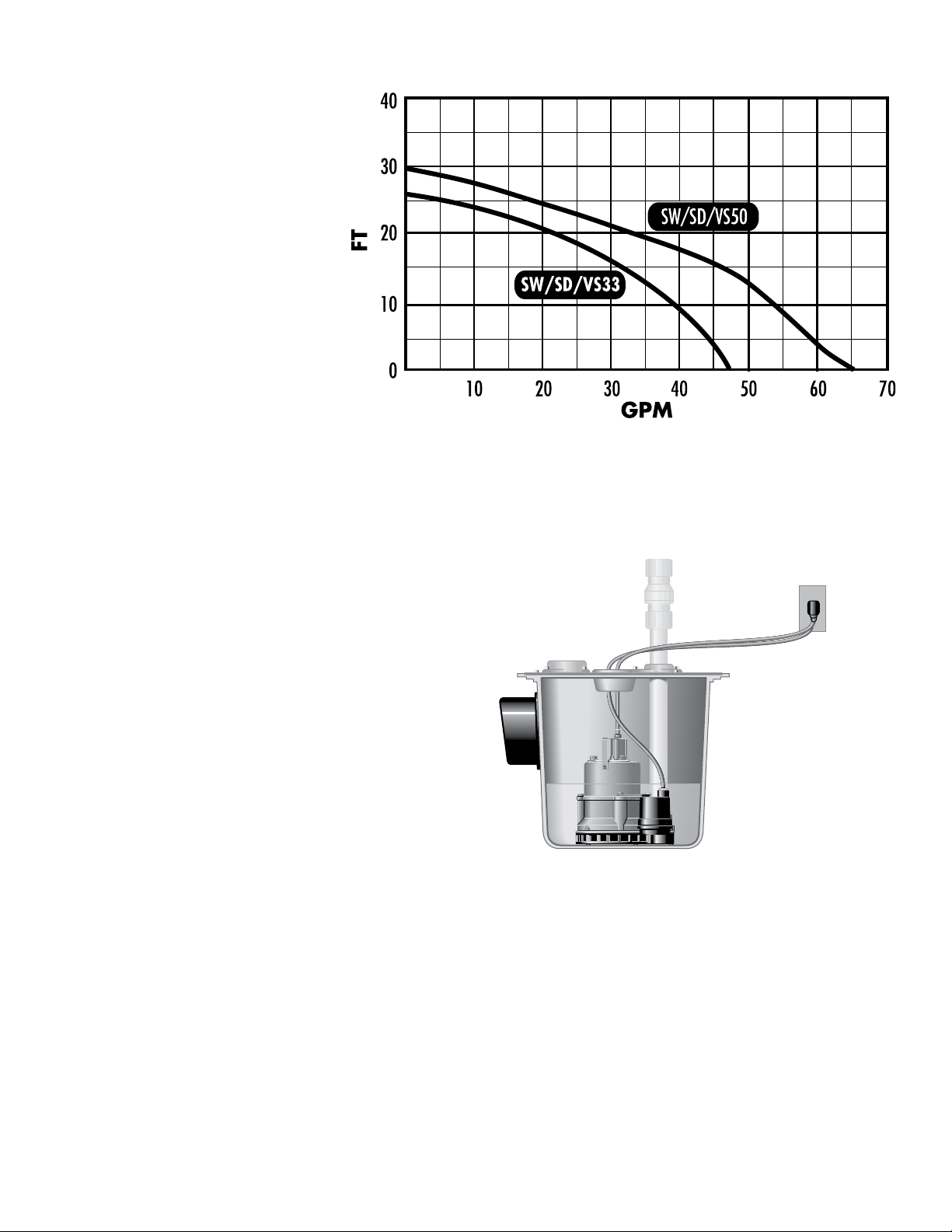

Example one

SD50

Example one illustrates a typical system installation.

3

Page 4

Pump

Servicing

Read the following instructions

carefully before replacing

any parts. Reasonable care

and safe methods should be

practiced. Check local codes and

requirements before installation.

Only com pe tent electrician

should make the installations.

Servicing should be performed

only by knowledgeable pump

service contractors or au tho rized

service stations.

1. WARNING: Always disconnect

the pump from power source

before handling or making

any adjustments. Always wear

rubber boots when there is

water on the floor and you

must unplug the pump.

2. Before re mov ing pump from

sump for repair, check if

the trouble could simply be

a blown fuse, tripped circuit

breaker, or a power cord

not com plete ly in serted into

the re cep tacle.

3. NOTE: Automatic thermal

over load protects the sealedin-oil motor. Running dry

will overheat the motor and

activate the over load pro tec tor

until the unit cools.

4. If the unit is being operated

by the optional float control

or di a phragm switch, unplug

the pump from the piggyback

receptacle and plug the pump

di rectly into the power source.

If the pump starts each time

it is plugged directly into

the re cep ta cle and does not

start each time when plugged

into the pig gy back switch with

the float raised up (or the

dia phragm switch pressed in)

to a start position, replace the

com plete piggyback switch

as sem bly and retest with

new assembly.

5. If pump fails the above

two steps, un plug and pull

the pump from the sump

by the handle. Sandblast, if

possible, any dirt or trash from

the outside of the pump

before proceeding.

6. Check for an obstruction in the

impeller cavity by laying the

pump on its side and removing

the screws (10) to remove the

plastic base and bottom plate

(12 & 13). If the impeller

does not rotate freely, clear

the impeller and cavity walls

before reassembling the base.

Repeat Step 4.

7. Air Locking: A sump pump

is said to be air locked if air

traps in the pump and it cannot

get out, thus preventing pump

from operation. Hydromatic

sump pumps have a small air

vent hole in the impeller cavity

to let out trapped air. If the

hole becomes plugged, pump

may air lock. To break the air

lock, use a small screwdriver

to clear the hole in the impeller

cavity. As a sec ond ary

precaution in in stal la tions of

this type –

be drilled in the discharge

pipe below the check valve.

The check valve should be

12 to 18 inches above pump

discharge. Do not put check

valve directly into pump

discharge opening.

NOTE: In sumps where the

pump is operating daily, air

locking rarely occurs.

8. If the above tests have not

resolved the problem,

the problem may be in the

1

⁄8” hole should

electrical components of the

pump. Starting with the power

cord, inspect for cuts or nicks

in the insulation. If the cord is

damaged, it must be replaced!

9. Using an ohmmeter, check

the resistance of the motor

windings by connecting one

lead clip to each electric flat

prong on the power cord plug.

The ohmmeter should be on

R x 1 setting.

To check for ground, place

the ohmmeter on R x 100k,

connect one lead clip to

the round ground prong on

the power cord and touch

the other lead clip to each

flat prong individually. If the

reading is other than infinity

(on the ohmmeter scale),

a leakage through stator

insulation or moisture in the

windings is occurring and the

pump must be replaced.

Pump

Troubleshooting

WARNING: Before handling

these pumps and controls,

always disconnect the

power first.

Do not smoke or use sparkable

electrical devices or flames in

a septic (gaseous) or possible

septic sump.

Pump does not run or hum.

1. Line circuit breaker may be

off, blown or loose.

2. Water level in sump may be

too low. Run in more water.

Turn-on level is 12 to 13

inches above sump bottom.

3. Pump and/or switch cord plug

may not be making contact

in receptacle.

4

Page 5

4. If pump is using the series cord

plug, the two plugs may not be

plugged tight together.

5. Float may be stuck. Be sure

float operates freely in basin.

6. If all symptoms check OK,

motor winding may be

open; take to service center

for check.

Pump runs but does not

deliver water.

1. Check valve may be installed

backward. Arrow in valve

points in direction of flow.

2. Discharge gate valve, if used,

may be closed.

3. Pump may be air locked. Start

and stop several times by

plugging and unplugging cord.

Check vent hole in pump case

for plugging.

4. Pump head may be too high.

Pump cannot deliver water

over 30’ (

1

⁄

HP), 26’ (1⁄

2

3

HP)

vertical. Horizontal distance

does not affect pumping,

except loss due to friction.

5. Inlet in pump base may be

clogged. Remove pump and

clean out openings.

6. Impeller or volute openings

may be plugged or

partially plugged. Re move

pump and clean per

main te nance instructions.

Pump runs and pumps out sump

but does not stop.

1. Float is stuck in Up position.

Be sure float operates freely

in basin.

Pump runs but delivers only

small amount of water.

1. Pump may be air locked. Start

and stop several times by

plugging and unplugging cord.

Check vent hole in pump case

for plugging.

2. Pump head may be too high.

Pump cannot deliver water

over 30’ (

1

⁄

HP), 26’ (1⁄

2

3

HP)

vertical. Horizontal distance

does not affect pumping,

except loss due to friction.

3. Inlet in pump base may be

clogged. Remove pump and

clean out open ings.

4. Impeller or volute openings

may be plugged or partially

plugged. Re move pump

and clean per main te nance

instructions.

5. Pump impeller may be

partially clogged causing

motor to run slow, resulting in

motor overload. Clear impeller.

Fuse blows or circuit break er

trips when pump starts.

1. Inlet in pump base may be

clogged. Remove pump and

clean out open ings.

2. Impeller or volute openings

may be plugged or

partially plugged. Re move

pump and clean per

main te nance instructions.

3. Pump impeller may be

partially clogged causing

motor to run slow, resulting

in motor overload. Clear

impeller.

4. Fuse size or circuit breaker is

too small.

5. Defective motor stator: return

to Hydromatic service center

for verification.

Motor runs for short time

then stops. Then after short

period starts again. Indicates

tripping over load caused by

symp tom shown.

1. Inlet in pump base may be

clogged. Remove pump and

clean out open ings.

2. Impeller or volute openings

may be plugged or

partially plugged. Re move

pump and clean per

main te nance instructions.

3. Pump impeller may be

partially clogged causing

motor to run slow, resulting in

motor overload. Clear impeller.

4. Defective motor stator: return

to Hydromatic service center

for verification.

Your pump warranty is void…

If… power cord has been cut or

spliced.

If… pump has been used to pump

mud, cement, tar, abrasives or

chemicals.

If… pump has been used for

pumping of hot water (above

120°F).

If… pump has been dismantled

by other than authorized

Hydromatic service center or

distributor.

5

Page 6

SW/SD/VS33 & 50

Parts List

6

Page 7

SW/SD/VS33 & 50

Parts List

Ref. No. Description Part No. Qty.

1 PLUG – PIPE 14981-001-1 1

2 HANDLE – PUMP 8522-006-1 1

3 SCREW – QUADREX #10-24 x 3/8” 14770-006-1 2

4 SCREW – QUADREX #8-32 x 5/16” 14770-001-1 1

5 WIRE W/ TERMINAL 6000-053-1 1

6 HOUSING – MOTOR 8507-013-5 1

7 SCREW – HHC 1/4-20 x 3/4” 176-005-1 3

8 SHAFT 5482-001-1 1

9 BRG. 65-024-1 1

10 SCREW – MACH 10-24 x 1-1/4” (1/3 HP) 27592C001 5

- SCREW – HHC 1/4-20 x 1-1/4” (1/2 HP) 176-007-1 7

11 IMPELLER (1/3 HP) 8498-003-1 1

- IMPELLER (1/2 HP) 14577-000-1 1

12 BASE – STRAINER (1/3 HP) 8520-002-1 1

- BASE – STRAINER (1/2 HP) 8520-003-1 1

13 PLATE – SUCTION (1/3 HP) 8521-002-1 1

- PLATE – SUCTION (1/2 HP) 8521-003-1 1

14 GASKET – FIBER ((1/2 HP ONLY) 14828-000-1 1

15 CASE – VOLUTE (1/3 HP) 8504-002-2 1

- CASE – VOLUTE (1/2 HP) 8504-005-2 1

16 SEAL – SHAFT ROT. 21607A001 1

18 SEAL – RING 149-001-1 1

19 STATOR (1/3 HP) 14590-001-1 1

Ref. No. Description Part No. Qty.

STATOR (1/2 HP) 14591-001-1 1

20 SCREW – HEX #8-32 x 3” 145-009-1 2

21 ROTOR (1/3 HP) 14590-010-1 1

- ROTOR (1/2 HP) 14591-010-1 1

22 SEAL – RING 139-014-1 1

24 CORD – POWER – 10’ 14623-010-1 1

- CORD – POWER – 20’ 14623-020-1 1

25 NUT – CORD 75-005-1 1

27 TIE – PUSH MOUNT 1055-001-1 1

28 SWITCH – FLOAT (10’ CORD) 13967-010-1 1

- SWITCH – FLOAT (20’ CORD) 13967-020-1 1

29 BRACKET (1/3 HP) 5502-011-1 1

- BRACKET (1/2 HP) 5502-005-1 1

30 SCREW – 1/4-20 x 3/8” 11455-003-1 1

31 SWITCH – DIAPHRAGM (10’ CORD) DPS41 10 1

- SWITCH – DIAPHRAGM (20’ CORD) DPS41 20 1

32 BRACKET 13871-000-1 1

33 SWITCH – VERT. (10’ CORD) VMSP1 10 1

- SWITCH - VERT. (20’ CORD) for 1/3 HP models VMSP1 20 1

7

Page 8

Limited Warranty

HYDROMATIC warrants to the original consumer purchaser (“Purchaser” or “You”) of HYDROMATIC Sump Pumps, Effluent

Pumps, Sewage Pumps (other than 2-1/2”), and Package Systems, that they will be free from defects in material and

workmanship for the Warranty Period of 36 months from date of manufacture.

Our warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication, improper

installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase power

through a phase converter will void the warranty. Note also that three phase motors must be protected by three-leg, ambient

compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and HYDROMATIC’s only duty, is that HYDROMATIC repair or replace defective products (at

HYDROMATIC’s choice). You must pay all labor and shipping charges associated with this warranty and must request warranty

service through the installing dealer as soon as a problem is discovered. No request for service will be accepted if received

after the Warranty Period has expired. This warranty is not transferable.

EXCEPTIONS: Hydromatic Special Application Pumps, Battery Back-Up Sump Pumps, Filtered Effluent Pumps, Grinder

Pumps, and 2-1/2” Sewage Pumps are warranted for a period of 12 months from date of purchase or 18 months from date of

manufacture, whichever comes first.

HYDROMATIC SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT

DAMAGES WHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE. THE FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION

PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an

implied warranty, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and

You may also have other rights which vary from state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

HYDROMATIC

293 Wright Street, Delavan, WI 53115

Phone: 888-957-8677 • Fax: 800-426-9446 • Web Site: hydromatic.com

Loading...

Loading...