Pentair Hydromatic TL-Pro Installation And Service Manual

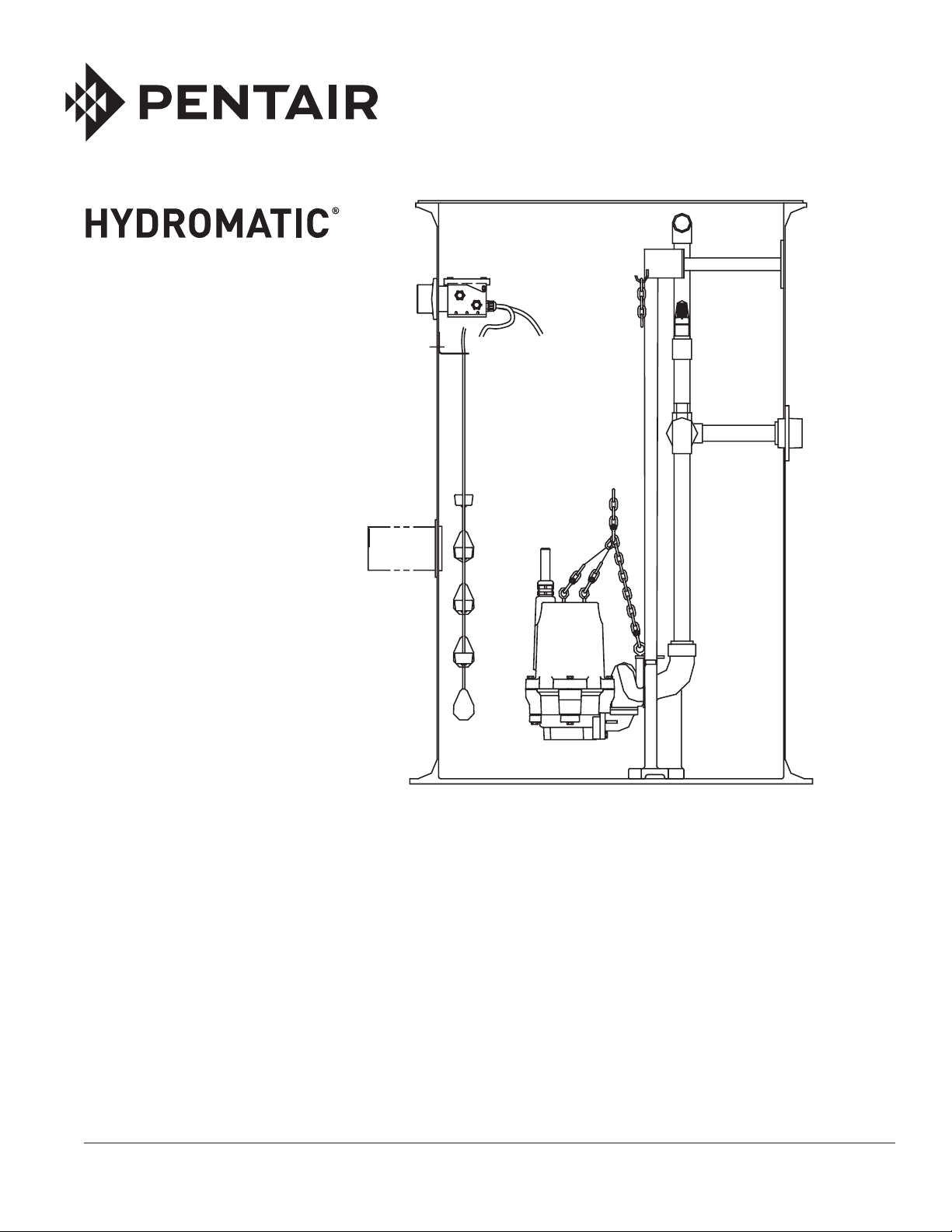

MODEL TL-PRO SYSTEM

COMPLETE GRINDER

PACKAGE OFFERING

INSTALLATION AND SERVICE MANUAL

For use with HPG(X)200 and HPGR200 Hydromatic Grinder Pumps.

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-457 | Part # 5625-457-1 | © 2012 Pentair Pump Group, Inc. | 10/31/12

General

Information

Thank you for purchasing your

Low Pressure Sewer Basin System.

Before Installation:

This manual contains important

information for the safe use of

this product. Read this manual

completely and follow the

instructions carefully. Reasonable

care and safe methods relating

to the installation and operation

of this product should be

practiced. Check local codes and

requirements before installation.

Risk of electrical shock or

electrocution. May result

in serious injury or death or

fire hazard. Installer must

disconnect all electrical sources

prior to installation. Only

qualified personnel may install

this system. NFPA 70/National

Electric Code (NEC) or local

codes must be followed. System

must be properly grounded

according to NEC.

Biohazard risk. Once wastewater

source has been connected to

system, biohazard risk exists.

Installer(s) and/or service

personnel must use proper

personal protective equipment

and follow handling procedures

per OSHA 29 CFR 1910.1030

when handling equipment after

wastewater source has been

connected to system.

Risk of fire or explosion. Do

not smoke or use open flames

in or around this system. This

system is not intended for use in

hazardous locations per NFPA

70 National Electric Code.

Consult factory for optional

equipment rated for this use.

Cutting risk. Risk of serious

cutting or amputation exists.

Disconnect all power sources

prior to servicing pump or

grinding mechanism. Pump may

start without warning. Grinding

mechanism is extremely sharp.

Use caution when handling

grinder mechanism.

CALIFORNIA PROPOSITION

65 WARNING:

This product and

related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductive

harm.

DO NOT THROW AWAY OR

LOSE THIS MANUAL. Keep

it in a safe place so that you may

refer to it often for the continued

safe operation of the product.

Installation Skill

Requirements

The installation of a basin system

is a specialized skill, which

requires individuals with the

basic understanding of pipe fitting,

excavating, and electrical wiring.

These instructions are meant

only to be an installation guide;

therefore, unusual installation

conditions not covered in these

instructions require experienced

personnel capable of using

reasonable engineering principles

for the installation and operation

of the system.

Excavation

Instructions

Excavation location shall be

made according to local codes

and regulations. Check with

local utility companies for

the location of underground

utilities prior to excavation.

Care should be taken to avoid

buried utility lines, piping, and

other buried structures and

foundations. Failure to follow

these instructions may result

in serious personal injury or

death.

Excavation for Basin Systems:

Effect appropriate excavation

based on size of the basin, desired

entrance point of the influent line,

and entrance of power connection.

Basin Installation

Instructions

If the basin is not tied down

during installation, rain or

flood conditions may cause the

basin to float upward, causing

damage to the basin or basin

con nec tions. Claims for this type

of damage cannot be processed

by Hydromatic.

Basin System Handling:

Factory built basin systems must

not be dropped, dragged, rolled,

or handled with sharp objects.

Improper handling of basins may

result in damage to the basin,

damage to basin components, or

leaks in the piping assemblies.

2

Step 1:

The pad under the basin requires

4 to 6 inches of appropriate fill.

The ideal basin pad is concrete

in conjunction with antiflotation

tie-down studs. Basin antiflotation

tie-down kits are available. If

concrete pad is not used, the

aggregate must be compacted to

a minimum 85% standard proctor

density per ASTM D698, or as

required by the Authority Having

Jurisdiction.

Concrete pad or aggregate surface

must be leveled flat and free of

voids to conform to the basin

bottom. Basin bedding depth

should be calculated such that the

basin top will protrude 3" above

the normal grade upon final

installation.

hub is used, refer to the directions

included with the hub.

Determine point at which influent

line will enter basin and, using a

properly maintained piloted hole

saw sized per chart below, drill a

hole through the basin wall. Clean

cut hole and apply a sealant

coating to the cut section to

prevent deterioration. Insert the

inlet grommet into the drilled

hole.

PIPE HOLE SAW

SIZE DI AM E TER*

3" 4"

4" 5"

6" 7"

* Contact the factory for availability

of proper size hole saw if necessary.

Backfill

Instructions

The Authority Having

Jurisdiction has the right to

require alternative materials or

procedures for backfilling the

installation.

Failure to properly backfill

may result in damage to the

basin which could cause

leaks or structural failure.

Failure to follow these backfill

instructions during the

installation of the basin voids

the basin warranty.

Step 2:

Lifting of the basin may be

done with a nylon or other nondamaging type material sling.

Do not wrap a chain or steel

cable around the basin as damage

may result. Do not attach lifting

mechanism around discharge hub

or electrical hub.

Step 3:

Lower the basin into excavation,

position and level properly. Mount

basin to base anchor bolts if an

antiflotation tie-down kit is used.

Seal off any cuts or scratches to

prevent deterioration.

Influent and

Discharge

Connections

Step 1:

An inlet grommet is the standard

supplied influent connection

device. If another type of inlet

Failure to use a properly piloted

hole saw may result in damage

to basin which may result in

structural failure or serious

leaks.

Step 2:

Lubricate inside lip of inlet

grommet with pipe soap. Clean

outer end of influent pipe and

push pipe through grommet.

Ensure pipe does not protrude

inside basin so as to interfere with

pump removal or float operation.

Step 3:

Close shut-off valve and make

discharge line connection. It is

strongly recommended that

an additional shutoff valve and

redundant check valve be located

outside the basin at any force main

entrances – check local codes for

specific requirements.

In freezing conditions the

backfill must be dry and free

of ice. Do not use other backfill

materials. Failure to use the

recommended bed and backfill

materials during installation

of the basin voids the basin

warranty.

Risk of electrical shock or

electrocution. May result in

serious injury or death or fire

hazard. Failure to properly

support electrical conduit, lines

and connections may result in

structural failure. Electrical

connections may be damaged,

exposing live electrical

connections.

Step 1:

Obtain proper backfill material.

The backfill material provides

as much as 90% of the basin’s

support under certain stress

conditions. The installer must

3

be positive that correct bed and

backfill materials are used per

instructions as follows:

a. Gravel – clean and free

flowing with particle size not

less than 1/8" nor more than

3/4" in diameter. Use this

description when ordering or

specifying as material varies

upon geographical location.

This material is commonly

known as “pea gravel”.

b. Stone or gravel crushings with

angular particle size of not

less than 1/8" nor more than

1/2" diameter, washed and

free flowing, is acceptable as

an alternative material.

Step 2:

At least a 4–6 inch wide band

of compacted aggregate must be

placed in successive layers (6"

lifts) around the entire periphery

of the basin. Carefully compact

aggregate under all piping and

electrical lines. Cover grade

should slope down 3" to the

normal surrounding grade. Care

must be taken to prevent damage

to any influent, discharge, or

electrical connections made to

the basin.

Internal Basin

Installation

Instructions

Systems Description:

Factory built basin systems are

available in 24" and 30" diameter

basins with 60" through 156"

depths in one foot increments.

In a TL-Pro system, the pump is

raised and lowered in the basin

using rope or chain attached to

the pump. This system includes

an integrated ball check valve

assembly that slides up and

4

down the dual rails, allowing

the pump to be removed without

disconnecting the piping.

Application:

These pump systems are designed

for pumping effluent or sewage

water with a pH ranging from 5

to 9, specific gravities from 0.9 to

1.1, viscosities ranging from 28

to 35 S.S.U. and temperatures up

to 140°F.

Inspection:

Check to be sure that all items

for your particular system are

included, and that the phase and

voltage on the pump nameplate

are correct as ordered. Codes: All

local codes must be observed.

Consult the local inspector(s)

before installation to avoid costly

delays or rework.

Grinder Pump Attachments:

Step 1:

Attach the ball check valve and

rail guide assembly to the grinder

pump discharge with bolts and

washers provided.

Risk of electrical shock or

electrocution. May result

in serious injury or death or

fire hazard. To reduce risk of

electrical shock, do not connect

conduit to pump .

Step 2:

Attach rope or chain as provided

to the guide plate lifting eye. A

hook is located on the top rail

support to hold the upper end of

the chain or rope when not in use.

Step 3:

Position pump so the guide rails

are located in the slots of the

guide plate. Slowly lower the

pump down the guide rails to

the base. The locating pins

(horizontal pin on seal plate)

should come to seat in the inclined

surface on the arms.

Internal Basin

Connections

Step 1:

If the system is supplied with a

float bracket, attach float switches

to the float bracket by clamping

strain relief bushings around the

float cords, then inserting and

twisting the bushings into the

float bracket slots.

Step 2:

After grinder pump attachments

have been made, lower the pump

unit down the rails and ensure ball

check valve aligns and connects

properly with base elbow in basin

bottom.

Junction Box Systems:

Step 1:

Ensure power source is off or

dis con nect ed.

Step 2:

Push pump power, seal failure/heat

sensor, and float cords through

cord grips in the junction box and

tighten. To prevent corrosion or

electrical short, plug any unused

holes.

Loading...

Loading...