Pump Installation and Service Manual

S4S/SB4S

Submersible

Sewage Pump

S4S Shown

NOTE! To the installer: Please make sure you provide

this manual to the owner of the pumping equipment or to

the responsible party who maintains the system.

Part # 5625-321-1

Item # E-03-321 04/09

General

Information

Thank you for purchasing your

Hydromatic

ensure years of trouble-free

operation, please read the

following manual carefully.

Before Operation:

Read the following instructions

carefully. Reasonable care and

safe methods should be practiced.

Check local codes and

requirements before installation.

Attention:

This manual contains important

information for the safe use of

this product. Read this manual

completely before using this

product and refer to it often for

continued safe product use.

DO NOT THROW AWAY OR

LOSE THIS MANUAL. Keep it in

a safe place so that you may refer

to it often.

Unpacking Pump:

Remove pump from carton. When

unpacking unit, check for

concealed damage. Claims for

damage must be made at the

receiving end through the delivery

carrier. Damage cannot be

processed from the factory.

WARNING: Before handling

these pumps and controls,

always disconnect the power

first. Do not smoke or use

sparkable electrical devices or

flames in a septic (gaseous) or

possible septic sump.

®

pump. To help

Pumps Not Operating or

in Storage:

Pumps with carbon ceramic seals

must have impellers manually

rotated (6 revolutions) after

setting non-operational for 3

months or longer and prior to

electrical start-up.

Pump:

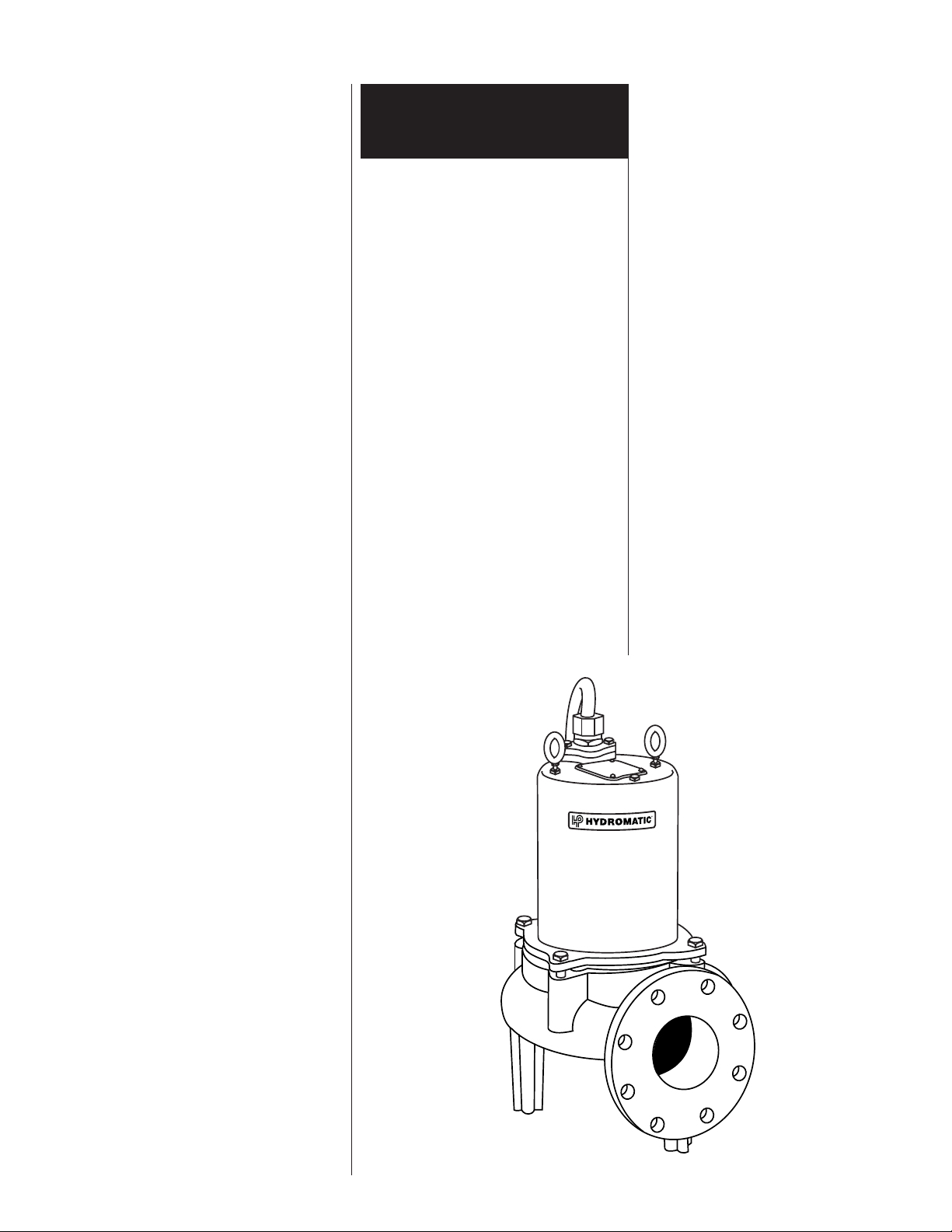

The S4S/SB4S submersible

pumps are supplied for 1 and 3

phase and for 200, 230, 460 or

575 volts. Pump is supplied with

15 feet of power cord. Longer

cable lengths can be furnished

but must be specified at time of

order. Power cable is 4 wire with

the green wire for ground. Be sure

green wire is connected to a

ground lug in the control panel

and the control panel must be

connected to a ground rod or

ground wire from supply service.

NOTE: All single phase pumps

require properly sized start

capacitor, start relay and run

capacitor in the panel.

Sump Level Control:

Sump level is controlled by

Hydromatic 3900 mercury switch

level controls. The 3900 level

controls is a metal case

mercury switch sealed in a solid

polyurethane float. The float is

held in position by a weight

attached to the power cord above

the float. The cord supports the

float and is adjusted for height

from the surface.

Typical duplex systems use three

floats: the lowest float turns the

pumps off, the next higher float

starts the lead pump, the next

higher float (override) starts the

lag pump. The pumps alternate

on successive cycles.

Two pumps operate together only

if sump level rises to the third or

override float. The override float

also brings on the second pump in

case of failure of the first pump.

Extra floats with appropriate

controls can be supplied for alarm

functions. Triplex systems use

four floats. The fourth highest

float brings on the second lag

pump. Three pumps operate

together only if sump level rises to

the fourth float (second override).

This float also brings on the third

pump in case of failure of either or

both of the first two pumps.

Alarm Controls:

The alarm float is usually set

above the override level so

the alarm will signal only if the

override level is exceeded.

However, some engineers prefer

to have the alarm float set below

the override level as it is possible

for one pump to fail and the other

pump to operate on the override

level with the sump level never

reaching the alarm level. This is

particularly true in cases of low

inflow capacity.

Electrical Control Panel:

It is recommended that the

Hydromatic control panel be used

with all pumps as proper start

components and pump protection

are furnished.

NOTE: All single phase pumps

require properly sized start

capacitor, start relay, and run

capacitor in the control panel.

IMPORTANT: If Hydromatic

control panel is not used and the

motor fails because of improper

components, the motor guarantee

is void.

2

Hydromatic electrical equipment

is installed in a weatherproof

enclosure. The electrical

equipment includes a main circuit

breaker for each pump, a

magnetic starter with overload

protection for each pump, an

H-O-A switch and run light for

each pump, an electric

alternator and a transformer to

provide appropriate control for

control circuit and alarms.

Overload Heaters:

If a Hydromatic control panel

is not used, on three phase pumps

all three phases must have

overload protection. The overload

should be ambient compensated

class 10. The heater's full load

amps on the pump must be sized

in accordance with the nameplate

amps on the motor housing. The

amp draw on these submersible

motors is slightly higher than

a corresponding horsepower

surface motor, so heaters must be

sized by the nameplate full load

amp rating.

Installing:

Before installing pump in sump,

lay it on side and turn impeller

with fingers. Impeller may be

slightly stuck due to factory test

water, so it must be broken loose

with small bar or screwdriver in

edge of vanes. The impeller

should turn freely.

Clean all trash and sticks from

sump and connect pump to piping.

A check valve must be installed

on each pump. A gate or plug

valve in each pump discharge line

is also recommended. This valve

should be installed on the

discharge side of the check valve

so if necessary to service the

check valve, the line pressure can

be cut off. Single pump systems

are sometimes installed without a

check valve where it is desirable

Pump

Installation

to self-drain the discharge line to

prevent freezing. This can be done

only with short discharge lines.

Otherwise water will return to the

sump and cause short cycling of

the pump.

NEMA 4 Junction Box

(Optional):

If electrical control panel is to be

set remote from the pump sump, a

NEMA 4 junction box should be

used to make power and control

connections. The Hydromatic

NEMA 4 junction box is provided

with compression connectors for

sealing all wires. No sealing

compound is needed to make

connections waterproof.

Wiring diagrams are provided

with the panel for making

connections. An extra set of

diagrams is included so that one

set can be used during installation

when making connections. The

size of any additional wiring from

the pump cord to the panel is

Single phase pumps with

capacitor start circuit must have

the overload protection on the

black pump lead.

NOTE: On single phase pumps

the white, black, and red pump

leads must be connected

properly for the pump to run.

3

Pump

Installation

based on the distance and pump

current. Double check that all

wiring is properly connected and

tight. NOTE: On single phase

pumps the white, black and red

pump wires must be connected

properly to the panel. Only the

proper sequence will work.

Installing 3900 Mercury

Switch Float:

The float cords are supported by a

mounting bracket that is attached

to sump wall or cover or to the

NEMA 4 junction box.

Cord snubbers are used to hold the

cord in place. Float level can be

changed at any time by loosening

the snubber and readjusting

cord length.

In either simplex or duplex

system the lower or turn-off float

is set just above the top of volute

so that the volute will always be

submerged during the pumping

cycle. The second or lead/on float

higher is set at about 24 inches

above the lower turn-off control.

More distance between turn-on

and turn-off controls can be used,

but sewage may become septic

and excessive solids may collect

for the pump to handle. A frequent

pumping cycle is recommended

for best operation.

If an alarm system is used, this

control is usually set about 6

inches above the override control.

Some engineers as described

previously prefer to have the

alarm control set below the

override control.

Making Electrical Connections:

All electrical wiring must be in

accordance with local code, and

only competent electricians

should make the installations. A

set of prints is included for use in

making the installation. All wires

should be checked for grounds

with an ohmmeter or Megger

after the connections are made.

This is important, as one

grounded wire can cause

considerable trouble.

IMPORTANT: If equipment

is not properly wired and

protected as recommended, the

motor guarantee is void.

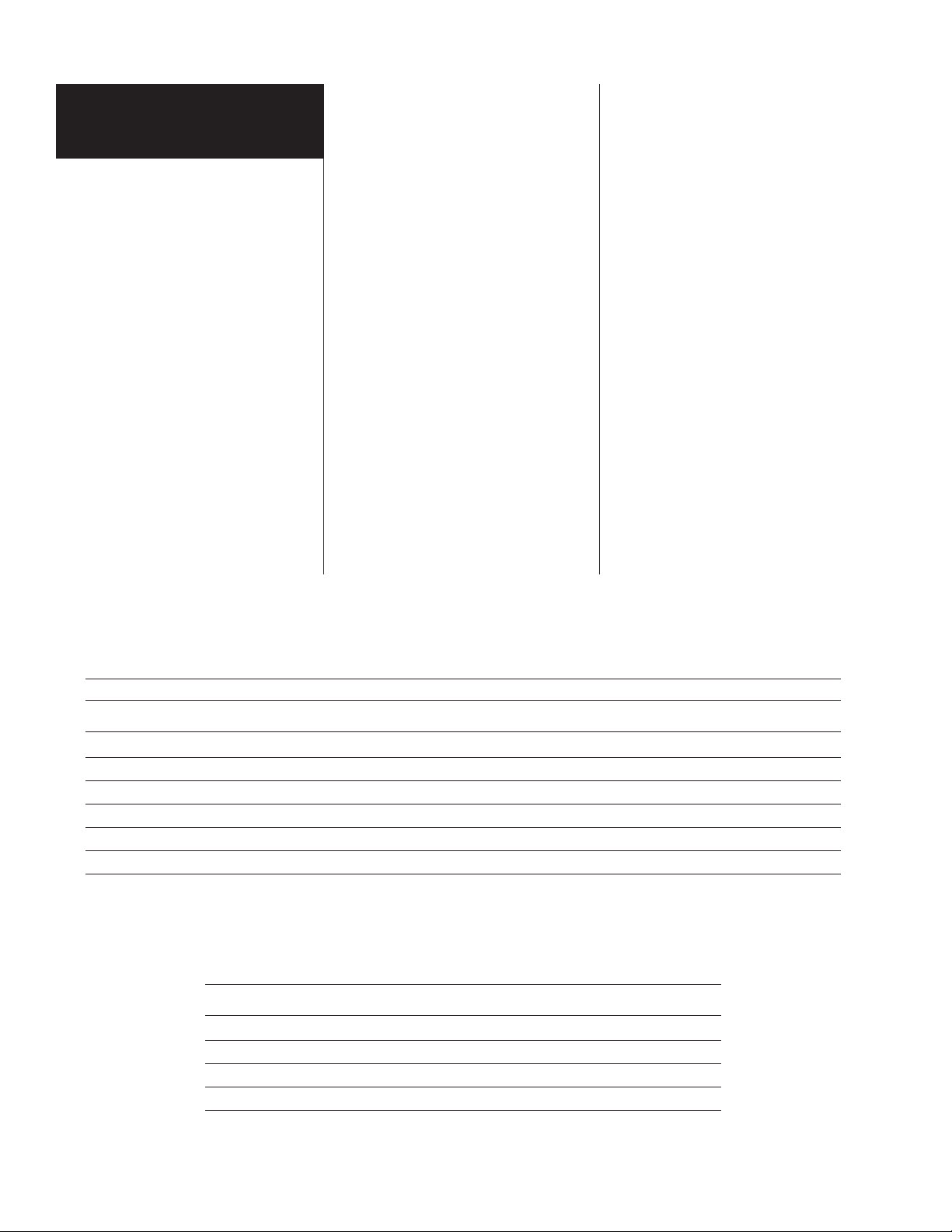

WIRE SIZE TABLE

FOR REMOTE LOCATION OF CONTROL PANEL; LENGTHS ARE BASED ON A VOLTAGE DROP OF TWO PERCENT

Maximum length in feet from NEMA 4 junction box to control panel. For 3 phase only and for power lines only. All control wires can be = 14–16 or 18 gauge

wire. If power lines are for 460 or 575 volts insulation of control wires must be for this voltage if used in conduit with power lines.

Volts 230 460 575 230 460 575 230 460 575 230 460 575 230 460 575 230 460 575 230 460 575 230 460 575 230 460 575

Wire Motor

Size HP 33355571⁄271⁄271⁄210 10 10 15 15 15 20 20 20 25 25 25 30 30 30 35 35 35

12 110 450 700 90 370 580

10 180 720 1120 140 550 370 90 360 560 50 220 340

8 270 1100 1650 220 900 1400 175 700 1100 105 420 650 320 500 230 360 180 280

6 400 1600 2500 350 1400 2200 220 900 1400 150 600 930 105 420 650 90 370 570 360 560 320 500 230 360

4 370 1500 2300 230 950 1450 175 700 1100 140 550 850 125 500 800 100 400 620 90 360 560

2 370 1500 230 270 1100 1700 220 900 1400 210 820 1250 200 800 1250 150 600 930

*Special Junction Box required for wire sizes larger than #4.

NUMBER OF CONDUCTORS REQUIRED BETWEEN CONTROL PANEL

AND NEMA 4 JUNCTION BOX

System Number of Number of Number of

Type Control Wires Power Lines Ground Wires #8

Simplex 3 3 1

Simplex with Alarm 5 3 1

Duplex 5 6 1

Duplex with Alarm 7 6 1

4

Loading...

Loading...