Pentair Hydromatic S4PP, Hydromatic H4HP, Hydromatic H3HP, Hydromatic S4MP, Hydromatic S4HVP Installation And Service Manual

...Page 1

INSTALLATION AND SERVICE MANUAL

HYDROMAT IC

SUBMERSIBLE

SOLIDS HANDLING

PUMP

Models

C4S(X)P, H3H(X)P,

H4H(X)P, S4M(X)P,

S4P(X)P, S4HV(X)P

and S4MV(X)P

(Class I, Division 1, Groups C & D): FM

ENGLISH: PAGES 2-12

Installation and Service Manual

For use with product built with Premium

Efficient motor.

Make sure this manual is provided to the owner

of the equip ment or to the responsible party who

maintains the system.

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-557 | Part # 056255571 | © 2018 Pentair plc | 09/25/18

(Hazardous Location

Motor End)

Page 2

General Information

Attention:

This manual contains important

information for the safe use of this

product. Read completely and do not

throw away.

Reasonable care and safe methods

should be practiced. Check local codes

and requirements before installation.

Unpacking Pump:

When unpacking unit, check for damage.

Claims for damage must be made at

the receiving end through the delivery

carrier. Damage cannot be processed

from the factory.

WARNING: Before handling these

pumps and controls, always

disconnect the power first. Do not

smoke or use sparkable electrical

devices or flames in a septic

(gaseous) or possible septic sump.

CALIFORNIA PROPOSITION 65 WARNING:

This product and

related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductiveharm.

Pumps in Storage or Not Operating:

Pumps with silicon/carbide seals

must have impellers manually rotated

(6 revolutions) after setting nonoperational for 3 months or longer and

prior to electrical start-up.

Pumps with tungsten carbide seals

must have impellers manually rotated

(6 revolutions) after setting nonoperational for 3 weeks or longer and

prior to electrical start-up.

Seal Failure Probes:

All hazardous location submersible

pumps have two factory installed

moisture detectors (seal failure

probes). They are in a normally open

series circuit in the seal chamber.

Under normal operating conditions,

the circuit remains open. If the lower

seal leaks and moisture enters this

chamber, the moisture would settle to

the bottom of the chamber and will

complete the circuit between the

moisture detectors.

This circuit must be connected to a

sensing unit and signaling device. This

is supplied in a Hydromatic® built control

panel.

NOTE: Failure to install such a device

negates all warranties by Hydromatic.

Heat Sensors:

All motors in this family have heat

sensors on or embedded in the motor

winding to detect excessive heat.

This prevents damage to the motor.

If sensor trips due to excessive

winding temperature, the starter in

the panel breaks power to the pump.

Once the sensor resets, the starter is

automatically reset for FM for continued

operation of the pump. This circuitry is

supplied in a Hydromatic control panel.

The sensors are set to trip at 130°C.

NOTE: Failure to install such circuitry

would negate FM approvals and all

warranties by Hydromatic.

Power Cords:

The power cord and heat sensor seal

failure cord are potted into the cord

cap. The cords must not be spliced.

NOTE: Each cable has a green lead.

This is the ground wire and must

be grounded properly per NEC and/

or local codes. Cords should be

inspected for abnormal wear and

replaced accordingly.

Overload Heaters:

If the Hydromatic electrical panel is not

used, starters with 3 leg overload relay

must be supplied on 3 phase pumps.

Each leg is to have an identical heater

sized in accordance with the nameplate

amps on the motor housing. The amp

draw on these submersible motors is

slightly higher than a corresponding

horsepower surface motor, so heaters

must be sized by the nameplate rating.

Capacitor start single phase pumps

have a run and start winding that draws

different currents. To adequately

protect these windings with the

appropriate heaters, consult the

factory.

NOTE: The red lead is always the

start winding of a pump using single

phase.

Pump Installation

Installing Sump Level Controls Float

Controls:

In either simplex, duplex or triplex

systems the lower or turn-off control

is to be set to maintain a minimum level

in the sump. This level shall be no more

than 3-1/4" from the top of the motor

housing down to the surface of the

sewage.

The second or turn-on control is set

above the lower turn-off control. The

exact distance between the two floats

must be a compromise between a

frequent pumping cycle (10 starts per

hour max.) to control septicity, solids

and a slower cycle for energy economy.

This distance should be determined by

the engineer or consulting engineer,

depending on the conditions of

the application.

Installing Pump in Sump:

Before installing the pump in the

sump, lay it on its side and rotate

impeller. Impeller may be slightly

stuck due to factory test water.

The impeller should turn freely.

Do not connect the power until

after this test.

Clean all debris from sump and connect

pump to piping. A check valve must

be installed on each pump. A gate or

plug valve in each pump discharge is

highly recommended. This valve should

be installed on the discharge side of the

check valve so if necessary to service

the check valve, the line pressure can

be cut off. Single pump systems are

sometimes installed without a check

valve where it is desirable to self-drain

the discharge line to prevent freezing.

This can be done only with short

discharge lines; otherwise water will

return to the sump and cause short

cycling of the pump.

Making Electrical Connections:

All electrical wiring must be in

accordance with local codes, and only

competent electricians should make

the installations. Complete wiring

diagrams are glued to the inside

cover of the panel. All wires should be

checked for grounds with an ohmmeter

or Megger® after the connections are

made.

2

Page 3

THIS IS IMPOR TANT, AS ONE GROUNDED

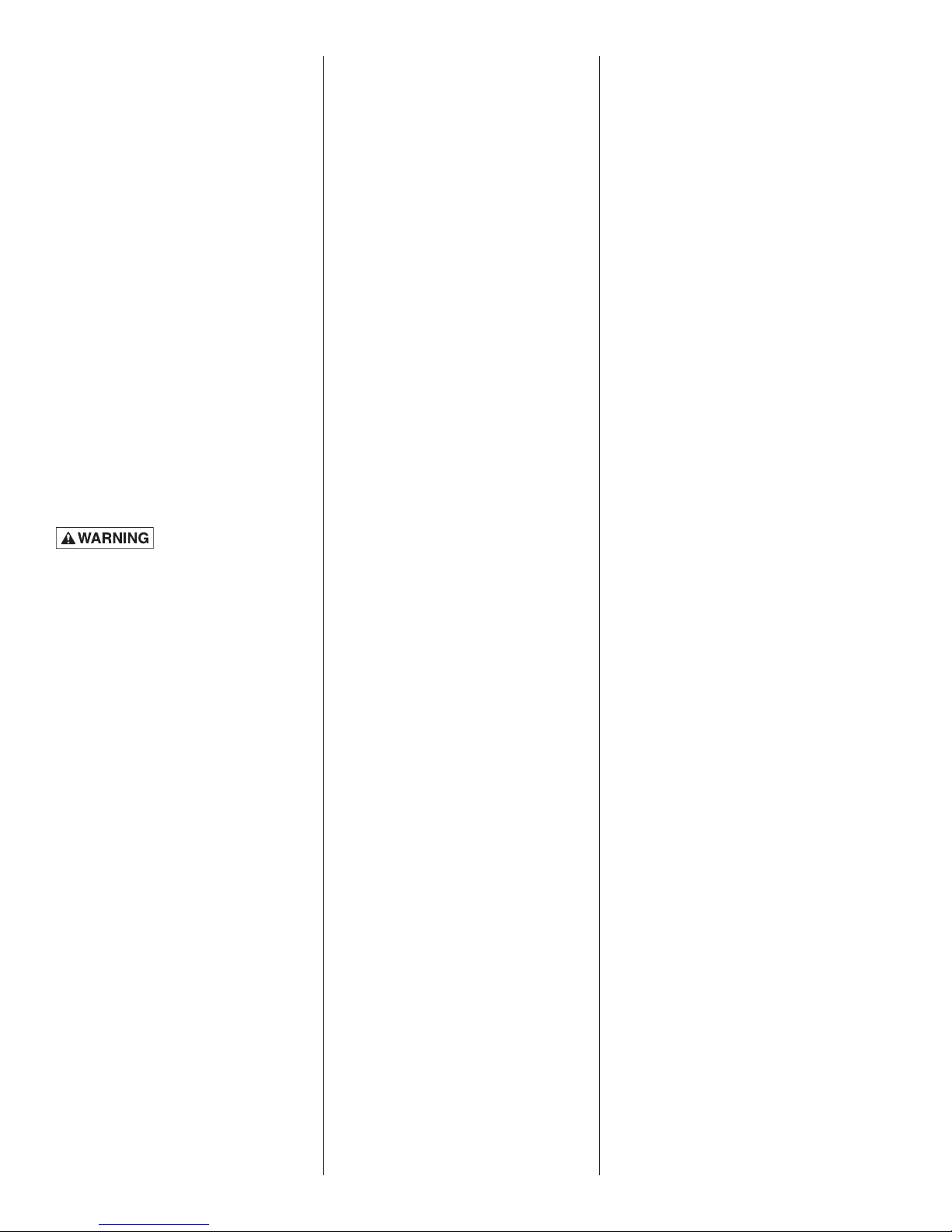

WIRE SIZE TABLE

FOR REMOTE LOCAT ION OF CONTROL PA NEL

LENGTHS ARE BASED ON A VOLTAGE DROP OF TWO PERCENT

Maximum length in feet from NEMA 4 Junction Box to control panel. All contro l wire s can be = 14–16 or 18 gauge wire. If power lines are greater than

300 volts, and the control wires are used in the same conduit, then the insulation of the control wires must be for 600 volts.

1 Phase 3 Phase

HP HP

Wire Size Volts 1

1

⁄2 2 3 5 Volts 11⁄2 2 3 5 71⁄2 10 15

200V - - - - 200 217 190 101 - - - -

230 105 95 - - 230 291 250 134 - - - -

12 460 1165 1019 540 412 333 233 -

575 1820 1450 820 624 515 364 -

200 121 111 103 - 200 340 297 158 119 - - -

230 163 148 139 - 230 456 390 210 161 - - -

10

460 1822 1594 846 645 522 364 -

575 2847 2270 1360 976 806 569 -

200 190 175 162 - 200 533 466 249 187 155 - -

230 257 232 219 - 230 715 613 330 252 204 - -

8 460 2860 2500 1328 1013 819 572 390

575 4468 3570 2145 1532 1266 894 -

200 296 272 252 - 200 830 726 387 291 242 170 -

230 400 362 340 181 230 1114 955 514 393

318 223 -

6 460 4455 3898 2068 1577 1275 891 607

575 - - 3341 2386 1972 1392 -

200 452 416 384 - 200 1268 1110 592 444 370 260 -

230 610 553 520 276 230 1701 1458 785 601 486 340 232

4 460 - - 3160 2410 1449 1361 928

575 - - - 3646 2513 2127 -

200 689 633 586 - 200 1932 1690 902 676 563 395 -

230 930 842 792 421 230 2592 2222 1196 915 741 578 353

*2* 460 - - - 3672 2969 2074 1414

575 - - - - 4590 3240 -

*Special junction box required for wire sizes larger than #4.

WIRE CAN CAUSE CONSIDERABLE

TROUBLE.

IMPORTANT: If equipment is not

properly wired and protected as

recommended, the warranty is void.

Caution: The 230 volt 3 phase pump

has a dual marked nameplate. Voltage

may be rewired by the manufacturer

or a Class I Div 1 equipment qualified

electrician. Once the voltage is changed,

the factory cord tag indicating 230 volt

3 phase must be removed.

For record keeping purposes, we

suggest the pump be marked externally

with the new voltage and qualified

personnel that performed the change.

Pumps shipped from the factory as 460

volt 3 phase cannot be rewired to any

other voltage.

To Re-wire the pump from 230V to

460V 3 phase:

Only a 230V pump from the factory

is considered dual voltage, a cord

label clearly states the factory wound

voltage.

Remove all six cap screws then raise

the cord cap assembly enough to slip

a prying instrument on opposite sides

between the cord cap casting and

the motor housing. Take care to not

damage the o-ring or the machined

surfaces of the castings. Doing so

could void FM agency certifications.

While prying evenly on both sides;

NUMBER OF CONDUCTORS REQUIRED BETWEEN CONTROL PANEL AND NEMA 4 JUNCTION BOX

POWER LINES AND CONTROL WIRES CAN BE CARRIED IN CONDUIT OR CAN BE UNDERGROUND BURIED CABLE

System Number of Number of Number of

Type Control Wires Power Lines Ground Wires #8 Number of Number of

Sensor Wires Ground Wires

Simplex 4 3 1 3 1

Simplex with Alarm 6 3 1 3 1

Duplex 6 6 2 6 2

Duplex with Alarm 8 6 2 6 2

230V 3ø 460V 3ø

3 PHASE MOTOR WIRING

DUAL VOLTAGE

separate the cord cap casting from the

motor housing, the assembly is airtight

and will have a vacuum effect when

disassembling. Once separated, the

cord cap can be inverted and rotated

to the outside of the pump assembly,

and a bolt can be re-used to secure

the upside down cord cap to the motor

housing for ease of rewiring.

Refer to the wiring diagram within

this manual for wiring details. Once

all electrical connections are finished

and secure (a crimped electrical

connector is best to prevent issues

due to vibration if required), the cord

cap should be re-attached reversing

the steps above. Ensure the o-ring is

in place and perform a hi-pot test for

safety once everything is complete.

Heat Sensors and Seal Failure Connections:

Be sure heat sensor wires are

connected in series with the starter

coil. Connections are provided on the

terminal strip.

Pump Operations

Starting System:

1. Double check all wire connections.

2. Turn pumps to Off position on

H-O-A switches.

3. Turn on breakers.

4. When using single phase pumps,

make sure red pump lead is

connected to capacitor circuit.

Connect amprobe to pump power

cord and turn pump on. The pump will

show high amp draw momentarily,

then as pump comes off start wirings,

amps will drop to normal nameplate

amps.

When using three phase pumps

(230/460/575), turn the H-O-A

switch to Hand position on one

pump and notice operation. If

pump is noisy and vibrates, rotation

is wrong. To change rotation,

interchange any two line leads to

pump. Do not interchange main

incoming lines. Check rotation of

all pumps in this same manner.

5. Now set both H-O-A switches to

Auto position and allow water to

rise in sump until one pump starts.

Allow pump to operate until the

level drops to turn-off point.

6. Allow sump level to rise to start

other pump(s). Notice run lights

in panel. Pumps should alternate

on each successive cycle of

operation.

7. Turn both H-O-A switches to Off

position and allow sump to ll to

the override control level(s).

8. Turn switches to Auto position, and

pumps should start and operate

together until level drops to turnoff point.

9. Repeat this operation and cycle

several times before leaving the

job.

HEAT SENSOR & SEAL FAILURE

45 6

78 9

12 3

BL

(L1)

W

(L2)

GREEN GREEN

R

(L3)

45 6

78 9

12 3

BL

(L1)

W

(L2)

R

(L3)

ELECTRODE RESISTANCE 330 kΩ

3

Page 4

10. Check voltage when pumps are

operating and check the amp draw

of each pump. Check amps on each

wire as sometimes a high leg will

exist. For excessive voltage on one

leg, the electric utility company

should be consulted.

Pump Maintenance

As the motors are oil filled, no lubrication

or other maintenance is required.

If the heat sensor and seal failure are

hooked up properly, no attention is

necessary as long as the seal failure

indicator light does not come on. To

ensure continuity of the seal sensor

leads, a test light is provided on

intrinsically safe Hydromatic panels as

standard equipment.

Pump should be checked every quarter

for corrosion and wear.

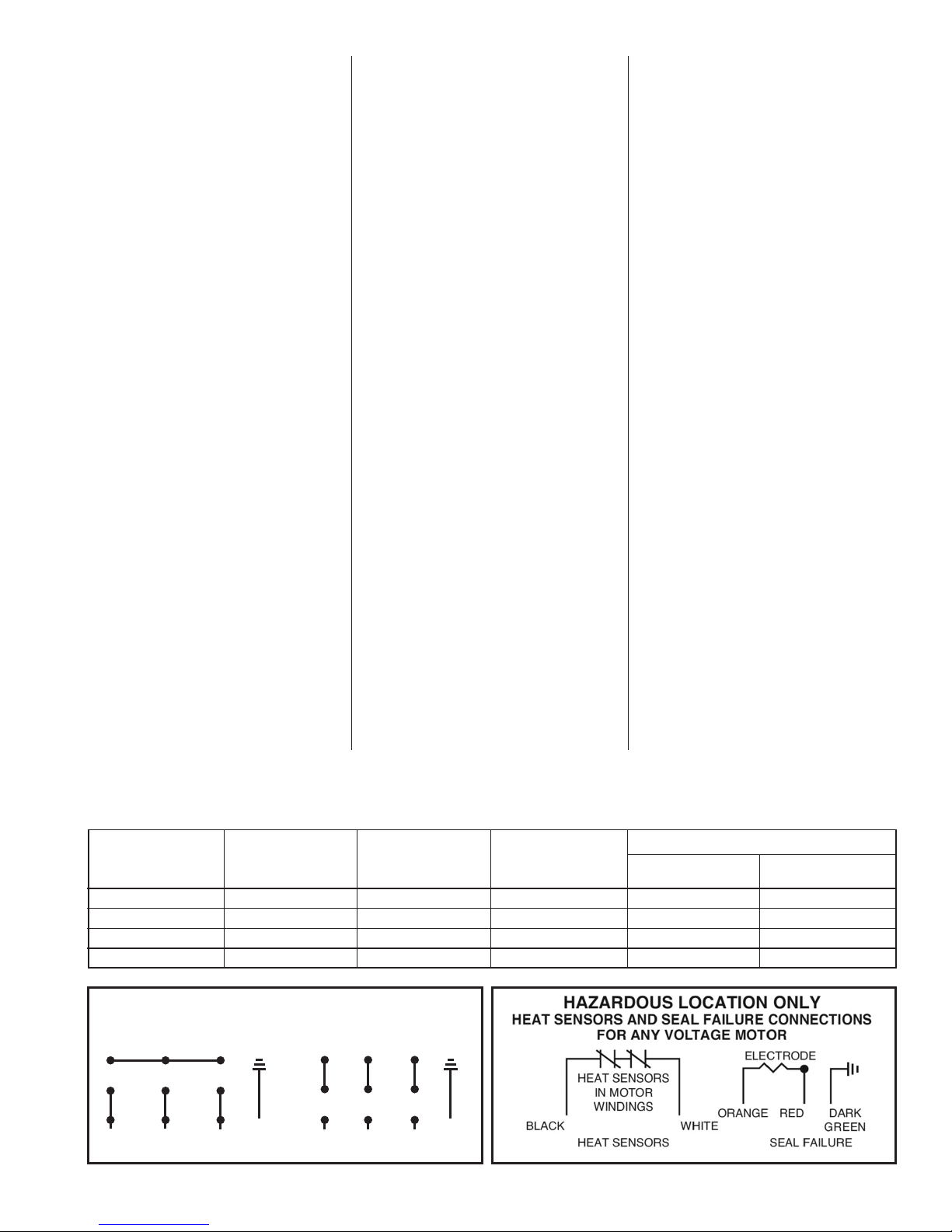

Field Service on Hydromatic Hazardous Location Pumps:

If a Hydromatic hazardous location

pump is used in a hazardous location,

the pump must be returned to the

factory for electrical and motor

service. This will ensure the integrity

of the hazardous location rating of the

pump and comply with our warranty

requirements.

A

The quick disconnect cords, upper

and lower seal, volute and impeller

components may be repaired or

replaced by an authorized Hydromatic

service facility without compromising

the hazardous location rating to the

pump.

Any time the seal is disturbed, it must

be replaced.

Check the pump for proper rotation

before returning to service.

RECOMMENDED

MAX CUTTER GAP

.015

.010

B

C

CHOPPER PLATE

3/8-16 BOLTS

PLATE RETAINING RING

1/2-20 BOLTS

D

CUTTER INSERT

IMPELLER

4

Page 5

Adjust Cutter Clearance on

Chopper Pump

WARNING: Disconnect power before

adjusting chopper clearance; always

keep fingers and hands away from

chopper parts.

1. First install the chopper plate (Item

D) into the volute. It may be helpful

to install ½-20 studs into the

chopper plate to line up the holes

with the corresponding volute

holes. You may have to tap the

plate all the way down with a rubber

hammer.

2. Remove the studs and replace with

four ½-20 x 1 (Item A) in long socket

head screws from beneath the

volute, do not tighten.

3. Install motor with impeller

mounted, tighten motor housing

bolts to the volute

4. Install the chopper retainer

ring (Item B) and tighten the four

3/8 -16 x 1" long (Item C) socket head

cap screws to force the chopper

plate up against the impeller and

chopper blade

5. Next back off these 3/8-16 (Item

C) bolts one quarter of a turn. This

should give you .015 clearances.

6. Tighten the outer four ½ -20 screws

(Item A) to 75-85 Ft-lbs.

7. Measure the clearance with a feeler

gage it should be between .010 and

.015.

8. Spin impeller with a hex wrench

on the Impeller hub screw or use a

wooden pry bar to spin impeller to

make sure there is no rub.

9. If you hear or feel a rub readjust the

clearance by loosening the inner

3/8-16 screws evenly and tightening

the ½- 20 screws.

Pump Troubleshooting

Below is a list of common problems and

the probable causes:

Pump will not start.

1. No power to the motor. Check for

blown fuse or open circuit breaker.

2. Selector switch may be in the Off

position.

3. Control circuit transformer fuse

may be blown.

4. Overload heater on starter may be

tripped. Push to reset.

Pump will not start and overload

heaters trip.

1. Turn off power and check motor

leads with Megger or ohmmeter for

possible ground.

2. Check resistance of motor

windings. All 3 phases should show

the same reading.

3. If no grounds exist and the motor

windings check OK, remove pump

from sump and check for clogged

or blocked impeller.

Pump operates with selector switch

in Hand position but will not operate

in Auto position.

1. This indicates trouble in the oat

level control or the alternator relay.

2. Check control panel for trouble.

Pump runs but will not shut off.

1. Pump may be air locked. Turn pump

off and let set for several minutes,

then restart.

2. Lower oat control may be hung-

up in the closed position. Check in

sump to be sure control is free.

3. Selector switch may be in the Hand

position.

Pump does not deliver proper

capacity.

1. Discharge gate valve may be

partially closed or partially clogged.

2. Check valve may be partially

clogged. Raise level up and down to

clear.

3. Pump may be running in wrong

direction. Low speed pumps

can operate in reverse direction

without much noise or vibration.

4. Discharge head may be too high.

Check total head with gauge

when pump is operating. Total

head is discharge gauge pressure

converted to feet plus vertical

height from water level in sump

to center line of pressure gauge

in discharge line. Gauge should be

installed on pump side of all valves.

Multiply gauge pressure in pounds

by 2.31 to get head in feet.

5. If pump has been in service for

some time and capacity falls off,

remove pump and check for wear

or clogged impeller.

Motor stops and then restarts after

short period but overload heaters in

starter do not trip.

1. This indicates heat sensors in the

motor are tripping due to excessive

heat. Impeller may be partially

clogged giving a sustained overload

but not high enough to trip overload

heater switch.

2. Motor may be operating out of

liquid due to a failed level control.

3. Pump may be operating on a short

cycle due to sump being too small

or from water returning to sump

due to a leaking check valve.

5

Page 6

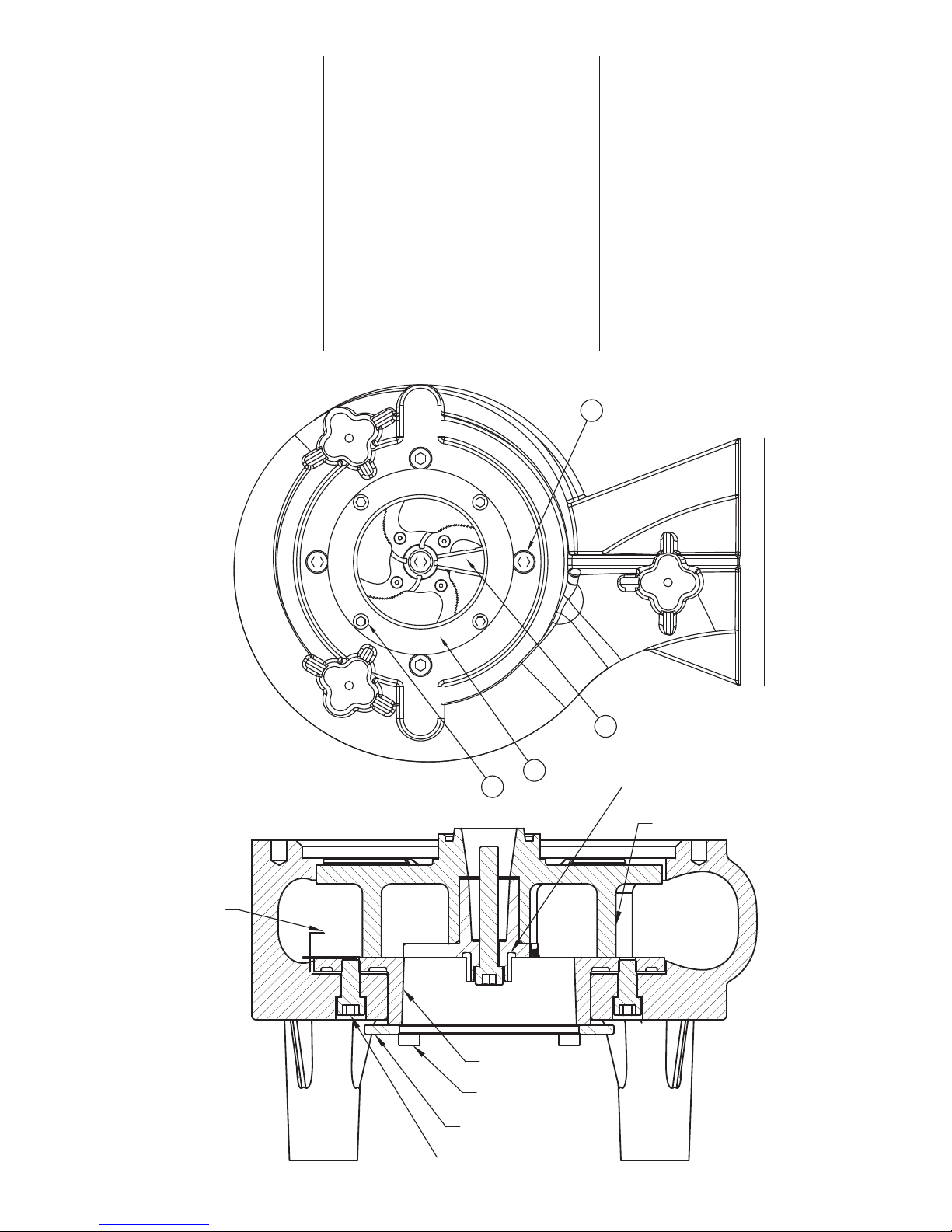

C4S(X)P, H3H(X)P, H4H(X)P, S4M(X)P, S4P(X)P,

S4HV(X)P and S4MV(X)P Parts List

For use with product built with Premium Efficient motor.

7

24

10

3, 4

16

A1

A2

5

6

14

A4

1

9

A3

8

2

11

21

15

19

16

17

20

22

13

12

B5

18

B6

23

Ref.

Part

No.

No.

1 28010D000 MOTOR HOUSING 1

2 27818D010 BEARING HOUSING 1

3 27882A009 TERMINAL BLOCK 1

4 06106A069 SCREW (TERMINAL BLOCK) 2

5 110650033 SCREEN 1

6 19331A007 WASHER SPRING (THRUST) 1

7 19101A017 CAP SCREW (CORD CAP) 6

8 026032103 STATOR RING 1

9 05818A090 KEY SQ. 5/32 1

10 001500191 O-RING (CORD CAP) 1

11 05876A135 O-RING (MOTOR HOUSING) 1

12 05876A121 O-RING (SEAL PLATE) 1

13 19103A048 SCREW CAP 1/2–13 x 2.5 LG 4

14 000650111 BALL BEARING UPPER 1

15 071670181 DOUBLE ROW BALL BEARING LOWER 1

16 009240101 PIPE PLUG 1/2 SOCKET HEAD BRASS 3

Part

Description Qty.

66

Ref.

Part

No.

No.

17 19103A048 CAPSCREW – S4M(X)P, S4MV(X)P, S4HV(X)P 4

19103A060 CAPSCREW – S4P(X)P, H3H(X)P, H4H(X)P, C4S(X)P 4

18 109010011 SEAL FAILURE PROBE 2

19 109000025 SENSOR WIRES 1

20 12558A017 RETAINING RING EXTERNAL 1

21 009740031 RETAINING RING INTERNAL 1

22 110491001 UPPER SEAL 1

23 009201001 LOWER SEAL 1

24 152880315 CORD CAP ASSEMBLY – 10-4 SOOW 1

152880325 CORD CAP ASSEMBLY – 8-4 W 1

152880335 CORD CAP ASSEMBLY – 6-4 W 1

B5 278190003 SEAL PLATE - S4M(X)P, S4MV(X)P, S4HV(X)P 1

278190103 SEAL PLATE- S4P(X)P, H3H(X)P, H4H(X)P, C4S(X)P 1

B6 07597A017 BOLT(SEAL PLATE) S4M(X)P, S4MV(X)P, S4HV(X)P 4

047560061 BOLT(SEAL PLATE) S4P(X)P, H3H(X)P, H4H(X)P, C4S(X)P 4

Part

Description Qty.

Page 7

Hydraulic End Parts List

D7

D6 D5

D1

D7 D6 D5 D1

D8

S4MXP

D7

D15

D5

D6

D8

S4PXP

D7 D1

D15

D5

D6

D8

S4HVXP

D7

D5 D6 D1

D15

D8D15

S4MVXP

D1

D7 D5

D6

D15

D1

D8

H3HXP

D1 D15

D10 D8 D9 D12 D11 D13

C4SXP

D15

D8

H4HXP

Item No. Description S4M(X)P S4MV(X)P S4HV(X)P S4P(X)P H3H(X)P H4H(X)P C4S(X)P

D1 O-RING 001500581 001500581 001500581 05876A136 05876A136 05876A136 05876A136

D5 IMPELLER KEY 083460033 083460011 083460011 083460033 083460033 083460033 083460033

D6 WASHER – IMPELLER 080230001 080230001 080230011 080230001 080230001 080230001 N/A

D7 VOLUTE 070680015 070800002 082120002 137210015 151540015 151470015 153300002

D8 IMP BOLT 005680021 005680021 029210041 005680021 005680021 005680021 005680191

D9 CHOPPER PLATE N/A N/A N/A N/A N/A N/A 153340002

D10 CHOPPER BLADE N/A N/A N/A N/A N/A N/A 153320002

D11 RETAINER PLATE N/A N/A N/A N/A N/A N/A 153330001

D12 SCREW-CAP (RETAINER) N/A N/A N/A N/A N/A N/A 06106A028

D13 SCREW-CAP (CHOPPER PLATE) N/A N/A N/A N/A N/A N/A 005680021

D14 SCREW - FLAT HEAD SOCKET N/A N/A N/A N/A N/A N/A 07597A037

D15 IMPELLER 070710012 070810002 082130052 137220012 151465002 151465002 153310002

77

Page 8

Motor Parts Group

10 – 15 hp

Item 2-Pole 3450 RPM

A1 STATOR 27889D003 27889D003 27889D603 27887D003 27887D003 27887D603

A2 ROTOR/SHAFT ASSEMBLY 27887D011 27887D011 27887D011 27887D011 27887D011 27887D011

A3 BOLT – STATOR (4) 001780051 001780051 001780051 001780051 001780051 001780051

A4 SPACER 007362141 007362141 007362141 007362141 007362141 007362141

CONNECTOR – 12672A001 – – 12672A001 –

Item 4-Pole 1750 RPM

A1 STATOR 27886D003 27886D003 27886D603 27885D001 27884D003 27884D003 27884D603

A2 ROTOR/SHAFT ASSEMBLY 27886D011 27886D011 27886D011 27885D011 27884D011 27884D011 27884D011

A3 BOLT – STATOR (4) 06106A070 06106A070 06106A070 001780051 001780041 001780041 001780041

A4 SPACER – – – 007362141 007362141 007362141 007362141

CONNECTOR – 12672A001 – – – 12672A001 –

Item 6-Pole 1150 RPM

A1 STATOR 27883D003 27883D003 27883D603

A2 ROTOR/SHAFT ASSEMBLY 27883D011 27883D011 27883D011

A3 BOLT – STATOR (4) 001780051 001780051 001780051

A4 SPACER 007362141 007362141 007362141

CONNECTOR – 12672A001 –

208-230/3/60

10 – 15 hp

208-230/3/60

3 – 5 hp

208-230/3/60

10 – 15 hp

460/3/60

10 – 15 hp

460/3/60

3 – 5 hp

460/3/60

10 – 15 hp

575/3/60

10 – 15 hp

575/3/60

3 – 5 hp

575/3/60

7.5 hp

208-230/3/60

5 – 7.5 hp

208-230/1/60

7.5 hp

460/3/60

5 – 7.5 hp

208-230/3/60

7.5 hp

575/3/60

5 – 7.5 hp

460/3/60

5 – 7.5 hp

575/3/60

Impeller Parts List

H3H(X)P

Description Part No. hp Voltage/ph Cord Trim Impeller

1750 RPM

H3H(X)P500BC 528040007 5 208/1 8-4 7.50 151465102

H3H(X)P500CC 528040017 5 230/1 8-4 7.50 151465102

H3H(X)P500DC 528040027 5 208/3 10-4 7.50 151465102

H3H(X)P500EC 528040037 5 230/3 10-4 7.50 151465102

H3H(X)P500FC 528040047 5 460/3 10-4 7.50 151465102

H3H(X)P500GC 528040057 5 575/3 10-4 7.50 151465102

H3H(X)P750CC 528040067 7. 5 230/1 8-4 8.00 151465082

H3H(X)P750DC 528040077 7.5 208/3 8-4 8.00 151465082

H3H(X)P750EC 528040087 7. 5 230/3 8-4 8.00 151465082

H3H(X)P750FC 528040097 7.5 460/3 10-4 8.00 151465082

H3H(X)P750GC 528040107 7.5 575/3 10-4 8.00 151465082

H3H(X)P1000DC 528040117 10 208/3 8-4 8.50 151465062

H3H(X)P1000EC 528040127 10 230/3 8-4 8.50 151465062

H3H(X)P1000FC 528040137 10 460/3 10-4 8.50 151465062

H3H(X)P1000GC 528040147 10 575/3 10-4 8.50 151465062

H3H(X)P1500DC 528040157 15 208/3 8-4 10.00 151465002

H3H(X)P1500EC 528040167 15 230/3 8-4 10.00 151465002

H3H(X)P1500FC 528040177 15 460/3 8-4 10.00 151465002

H3H(X)P1500GC 528040187 15 575/3 10-4 10.00 151465002

H4H(X)P

Description Part No. hp Voltage/ph Cord Trim Impeller

1750 RPM

H4H(X)P500BC 528050007 5 208/1 8-4 7.50 151465102

H4H(X)P500CC 528050017 5 230/1 8-4 7.50 151465102

H4H(X)P500DC 528050027 5 208/3 10-4 7.50 151465102

H4H(X)P500EC 528050037 5 230/3 10-4 7.50 151465102

H4H(X)P500FC 528050047 5 460/3 10-4 7.50 151465102

H4H(X)P500GC 528050057 5 575/3 10-4 7.50 151465102

H4H(X)P750CC 528050067 7.5 230/1 8-4 8.00 151465082

H4H(X)P750DC 528050077 7.5 208/3 8-4 8.00 151465082

H4H(X)P750EC 528050087 7.5 230/3 8-4 8.00 151465082

H4H(X)P750FC 528050097 7.5 460/3 10-4 8.00 151465082

H4H(X)P750GC 528050107 7.5 575/3 10-4 8.00 151465082

H4H(X)P1000DC 528050117 10 208/3 8-4 8.63 151465142

H4H(X)P1000EC 528050127 10 230/3 8-4 8.63 151465142

H4H(X)P1000FC 528050137 10 460/3 10-4 8.63 151465142

H4H(X)P1000GC 528050147 10 575/3 10-4 8.63 151465142

H4H(X)P1500DC 528050157 15 208/3 8-4 9.50 151465022

H4H(X)P1500EC 528050167 15 230/3 8-4 9.50 151465022

H4H(X)P1500FC 528050177 15 460/3 8-4 9.50 151465022

H4H(X)P1500GC 528050187 15 575/3 10-4 9.50 151465022

8

Page 9

Impeller Parts List

S4M(X)P

Description Part No. hp Voltage/ph Cord Trim Impeller

1750 RPM

S4M(X)P500BC 528010177 5 208/1 8-4 6.75 070710312

S4M(X)P500CC 528010187 5 230/1 8-4 6.75 070710312

S4M(X)P500DC 528010127 5 208/3 10-4 6.75 070710312

S4M(X)P500EC 528010137 5 230/3 10-4 6.75 070710312

S4M(X)P500FC 528010147 5 460/3 10-4 6.75 070710312

S4M(X)P500GC 528010157 5 575/3 10-4 6.75 070710312

S4M(X)P750CC 528010167 7.5 230/1 8-4 7.63 070710442

S4M(X)P750DC 528010087 7.5 208/3 8-4 7.63 070710442

S4M(X)P750EC 528010097 7.5 230/3 8-4 7.63 070710442

S4M(X)P750FC 528010107 7.5 460/3 10-4 7.63 070710442

S4M(X)P750GC 528010117 7.5 575/3 10-4 7.63 070710442

S4M(X)P1000DC 528010047 10 208/3 8-4 8.13 070710202

S4M(X)P1000EC 528010057 10 230/3 8-4 8.13 070710202

S4M(X)P1000FC 528010067 10 460/3 10-4 8.13 070710202

S4M(X)P1000GC 528010077 10 575/3 10-4 8.13 070710202

S4M(X)P1500DC 528010007 15 208/3 8-4 8.63 070710172

S4M(X)P1500EC 528010017 15 230/3 8-4 8.63 070710172

S4M(X)P1500FC 528010027 15 460/3 8-4 8.63 070710172

S4M(X)P1500GC 528010037 15 575/3 10-4 8.63 070710172

1150 RPM

S4M(X)P300DB 528010237 3 208/3 10-4 7.75 070710062

S4M(X)P300EB 528010247 3 230/3 10-4 7.75 070710062

S4M(X)P300FB 528010257 3 460/3 10-4 7.75 070710062

S4M(X)P300GB 528010267 3 575/3 10-4 7.75 070710062

S4M(X)P500DB 528010197 5 208/3 10-4 8.75 070710022

S4M(X)P500EB 528010207 5 230/3 10-4 8.75 070710022

S4M(X)P500FB 528010217 5 460/3 10-4 8.75 070710022

S4M(X)P500GB 528010227 5 575/3 10-4 8.75 070710022

S4MV(X)P

Description Part No. hp Voltage/ph Cord Trim Impeller

1750 RPM

S4MV(X)P500BC 528020007 5 208/1 8-4 6.50 070810332

S4MV(X)P500CC 528020017 5 230/1 8-4 6.50 070810332

S4MV(X)P500DC 528020027 5 208/3 10-4 6.50 070810332

S4MV(X)P500EC 528020037 5 230/3 10-4 6.50 070810332

S4MV(X)P500FC 528020047 5 460/3 10-4 6.50 070810332

S4MV(X)P500GC 528020057 5 575/3 10-4 6.50 070810332

S4MV(X)P750CC 528020067 7.5 230/1 8-4 7.38 070810072

S4MV(X)P750DC 528020077 7.5 208/3 8-4 7.38 070810072

S4MV(X)P750EC 528020087 7.5 230/3 8-4 7.38 070810072

S4MV(X)P750FC 528020097 7.5 460/3 10-4 7.38 070810072

S4MV(X)P750GC 528020107 7.5 575/3 10-4 7.38 070810072

S4MV(X)P1000DC 528020117 10 208/3 8-4 8.00 070810022

S4MV(X)P1000EC 528020127 10 230/3 8-4 8.00 070810022

S4MV(X)P1000FC 528020137 10 460/3 10-4 8.00 070810022

S4MV(X)P1000GC 528020147 10 575/3 10-4 8.00 070810022

S4MV(X)P1500DC 528020157 15 208/3 8-4 8.75 070810092

S4MV(X)P1500EC 528020167 15 230/3 8-4 8.75 070810092

S4MV(X)P1500FC 528020177 15 460/3 8-4 8.75 070810092

S4MV(X)P1500GC 528020187 15 575/3 10-4 8.75 070810092

1150 RPM

S4MV(X)P300DB 528020197 3 208/3 10-4 7.75 070810102

S4MV(X)P300EB 528020207 3 230/3 10-4 7.75 070810102

S4MV(X)P300FB 528020217 3 460/3 10-4 7.75 070810102

S4MV(X)P300GB 528020227 3 575/3 10-4 7.75 070810102

S4MV(X)P500DB 528020237 5 208/3 10-4 8.75 070810092

S4MV(X)P500EB 528020247 5 230/3 10-4 8.75 070810092

S4MV(X)P500FB 528020257 5 460/3 10-4 8.75 070810092

S4MV(X)P500GB 528020267 5 575/3 10-4 8.75 070810092

S4HV(X)P

Description Part No. hp Voltage/ph Cord Trim Impeller

3450 RPM

S4HV(X)P750DD 528000087 7.5 208/3 8-4 4.63 082130172

S4HV(X)P750ED 528000097 7.5 230/3 8-4 4.63 082130172

S4HV(X)P750FD 528000107 7. 5 460/3 10-4 4.63 082130172

S4HV(X)P750GD 528000117 7.5 575/3 10-4 4.63 082130172

S4HV(X)P1000DD 528000047 10 208/3 8-4 5 082130042

S4HV(X)P1000ED 528000057 10 230/3 8-4 5 082130042

S4HV(X)P1000FD 528000067 10 460/3 10-4 5 082130042

S4HV(X)P1000GD 528000077 10 575/3 10-4 5 082130042

S4HV(X)P1500DD 528000007 15 208/3 8-4 5.38 082130192

S4HV(X)P1500ED 528000017 15 230/3 8-4 5.38 082130192

S4HV(X)P1500FD 528000027 15 460/3 10-4 5.38 082130192

S4HV(X)P1500GD 528000037 15 575/3 10-4 5.38 082130192

S4P(X)P

Description Part No. hp Voltage/ph Cord Trim Impeller

1750 RPM

S4P(X)P500BC 528030007 5 208/1 8-4 6.50 137226152

S4P(X)P500CC 528030017 5 230/1 8-4 6.50 137226152

S4P(X)P500DC 528030027 5 208/3 10-4 6.50 137226152

S4P(X)P500EC 528030037 5 230/3 10-4 6.50 137226152

S4P(X)P500FC 528030047 5 460/3 10-4 6.50 137226152

S4P(X)P500GC 528030057 5 575/3 10-4 6.50 137226152

S4P(X)P750CC 528030067 7.5 230/1 8-4 7.75 137226102

S4P(X)P750DC 528030077 7.5 208/3 8-4 7.75 137226102

S4P(X)P750EC 528030087 7.5 230/3 8-4 7.75 137226102

S4P(X)P750FC 528030097 7. 5 460/3 10-4 7.75 137226102

S4P(X)P750GC 528030107 7.5 575/3 10-4 7.75 137226102

S4P(X)P1000DC 528030117 10 208/3 8-4 8.63 137226162

S4P(X)P1000EC 528030127 10 230/3 8-4 8.63 137226162

S4P(X)P1000FC 528030137 10 460/3 10-4 8.63 137226162

S4P(X)P1000GC 528030147 10 575/3 10-4 8.63 137226162

S4P(X)P1500DC 528030157 15 208/3 8-4 9.63 137226182

S4P(X)P1500EC 528030167 15 230/3 8-4 9.63 137226182

S4P(X)P1500FC 528030177 15 460/3 8-4 9.63 137226182

S4P(X)P1500GC 528030187 15 575/3 10-4 9.63 137226182

C4S(X)P

Description Part No. hp Voltage/ph Cord Trim Impeller

1750 RPM

C4S(X)P750CC 528280067 7.5 230/1 8-4 7.0 0 153310192

C4S(X)P750DC 528280077 7.5 208/3 8-4 7.00 153310192

C4S(X)P750EC 528280087 7.5 230/3 8-4 7.00 153310192

C4S(X)P750FC 528280097 7.5 460/3 10-4 7.00 153310192

C4S(X)P750GC 528280107 7.5 575/3 10-4 7.0 0 153310192

C4S(X)P1000DC 528280117 10 208/3 8-4 7.00 153310192

C4S(X)P1000EC 528280127 10 230/3 8-4 7.00 153310192

C4S(X)P1000FC 528280137 10 460/3 10-4 7.00 153310192

C4S(X)P1000GC 528280147 10 575/3 10-4 7.00 153310192

C4S(X)P1500DC 528280157 15 208/3 8-4 8.50 153310072

C4S(X)P1500EC 528280167 15 230/3 8-4 8.50 153310072

C4S(X)P1500FC 528280177 15 460/3 8-4 8.50 153310072

C4S(X)P1500GC 528280187 15 575/3 10-4 8.50 153310072

1150 RPM

C4S(X)P300DB 528280197 3 208/3 10-4 7.25 153310172

C4S(X)P300EB 528280207 3 230/3 10-4 7.25 153310172

C4S(X)P300FB 528280217 3 460/3 10-4 7.25 153310172

C4S(X)P300GB 528280227 3 575/3 10-4 7.25 153310172

C4S(X)P500DB 528280237 5 208/3 10-4 8.88 153310122

C4S(X)P500EB 528280247 5 230/3 10-4 8.88 153310122

C4S(X)P500FB 528280257 5 460/3 10-4 8.88 153310122

C4S(X)P500GB 528280267 5 575/3 10-4 8.88 153310122

9

Page 10

Wiring Diagrams

10

Page 11

THIS PAGE INTENTIONALLY LEFT BLANK

11

Page 12

STANDARD LIMITED WARRANTY

HYDROMAT IC

Pentair Hydromatic® warrants its products against defects in material and workmanship for a period of 12 months

from the date of shipment from Pentair Hydromatic or 18 months from the manufacturing date, whichever

occurs first – provided that such products are used in compliance with the requirements of the Pentair Hydromatic

catalog and technical manuals for use in pumping raw sewage, municipal wastewater or similar, abrasive-free,

noncorrosive liquids.

During the warranty period and subject to the conditions set forth, Pentair Hydromatic, at its discretion, will repair

or replace to the original user, the parts that prove defective in materials and workmanship. Pentair Hydromatic

reserves the right to change or improve its products or any portions thereof without being obligated to provide such

a change or improvement for prior sold and/or shipped units.

Start-up reports and electrical schematics may be required to support warranty claims. Submit at the time of start up

through the Pentair Hydromatic website: http://forms.pentairliterature.com/startupform/startupform.asp?type=h.

Warranty is effective only if Pentair Hydromatic authorized control panels are used. All seal fail and heat sensing

devices must be hooked up, functional and monitored or this warranty will be void. Pentair Hydromatic will cover

only the lower seal and labor thereof for all dual seal pumps. Under no circumstance will Pentair Hydromatic be

responsible for the cost of field labor, travel expenses, rented equipment, removal/reinstallation costs or freight

expenses to and from the factory or an authorized Pentair Hydromatic service facility.

This limited warranty will not apply: (a) to defects or malfunctions resulting from failure to properly install, operate or

maintain the unit in accordance with the printed instructions provided; (b) to failures resulting from abuse, accident

or negligence; (c) to normal maintenance services and parts used in connection with such service; (d) to units that

are not installed in accordance with applicable local codes, ordinances and good trade practices; (e) if the unit is

moved from its original installation location; (f) if unit is used for purposes other than for what it is designed and

manufactured; (g) to any unit that has been repaired or altered by anyone other than Pentair Hydromatic or an

authorized Pentair Hydromatic service provider; (h) to any unit that has been repaired using non factory specified/

OEM parts.

Warranty Exclusions: PENTAIR HYDROMATIC MAKES NO EXPRESS OR IMPLIED WARRANTIES THAT EXTEND

BEYOND THE DESCRIPTION ON THE FACE HEREOF. PENTAIR HYDROMATIC SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE.

Liability Limitation: IN NO EVENT SHALL PENTAIR HYDROMATIC BE LIABLE OR RESPONSIBLE FOR

CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES RESULTING FROM OR RELATED IN ANY MANNER TO

ANY PENTAIR HYDROMATIC PRODUCT OR PARTS THEREOF. PERSONAL INJURY AND/OR PROPERTY DAMAGE

MAY RESULT FROM IMPROPER INSTALLATION. PENTAIR HYDROMATIC DISCLAIMS ALL LIABILITY, INCLUDING

LIABILITY UNDER THIS WARRANTY, FOR IMPROPER INSTALLATION. PENTAIR HYDROMATIC RECOMMENDS

INSTALLATION BY PROFESSIONALS.

Some states do not permit some or all of the above warranty limitations or the exclusion or limitation of incidental or

consequential damages and therefore such limitations may not apply to you. No warranties or representations at any

time made by any representatives of Pentair Hydromatic shall vary or expand the provision hereof.

1101 Myers Parkway

Ashland, Ohio 44805

USA

Ph: 855.274.8947

490 Pinebush Road

Unit 4

Cambridge, Ontario N1T 0A5

Canada

Ph: 800.363.PUMP

www.Hydromatic.com

Warranty Rev. 09/18

Loading...

Loading...