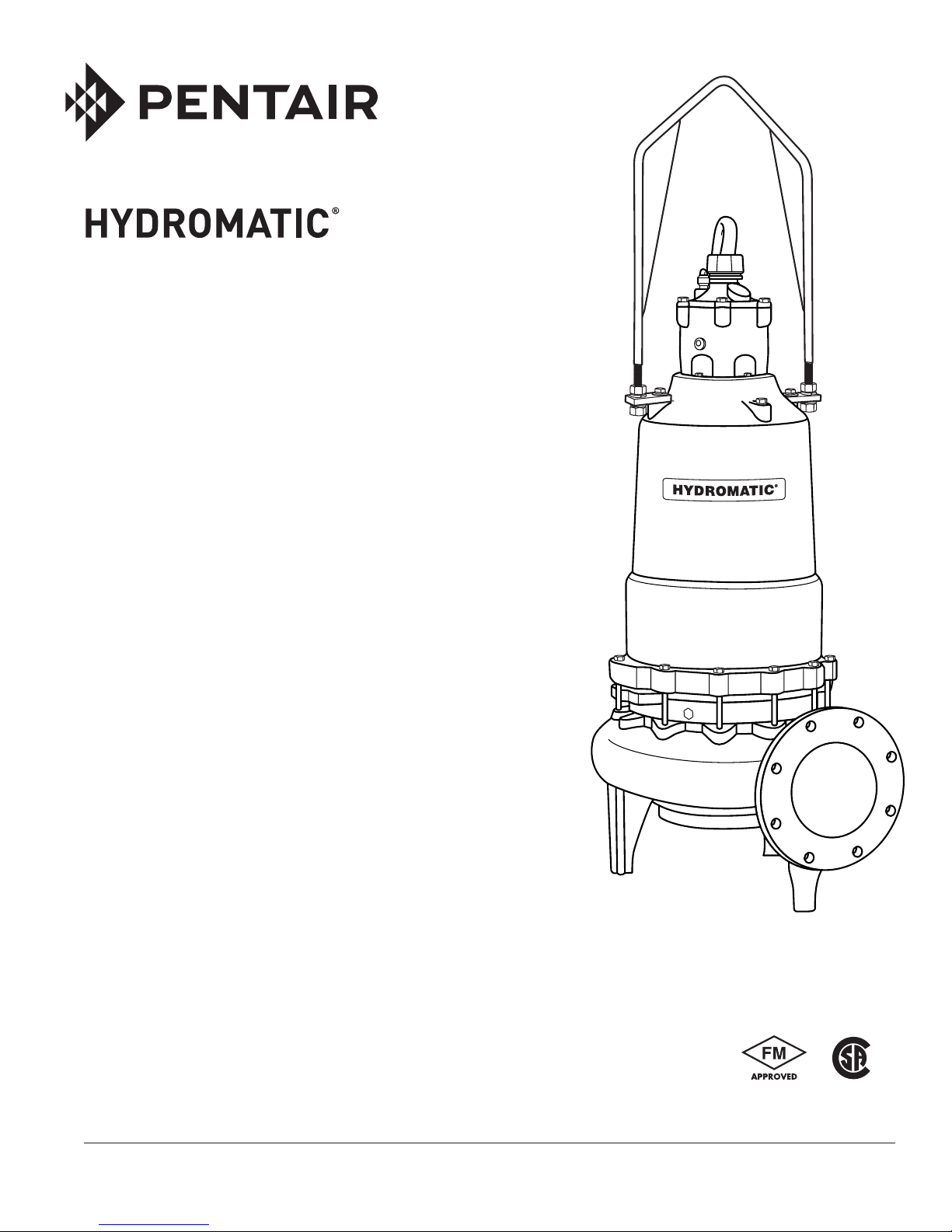

Pentair HYDROMATIC S4T, HYDROMATIC S8LA, HYDROMATIC S8L, HYDROMATIC S12L Installation And Service Manual

Page 1

MODELS

S4T(X*), S8L(X*),

S8LA(X*) and S12L(X*)

*

Used in Hazardous Locations Class I, Division 1

SUBMERSIBLE

SOLIDS HANDLING PUMP

INSTALLATION AND SERVICE MANUAL

For use with product built with USEM motor.

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-503 | 320 Frame | Part # 5625-503-1 | © 2014 Pentair Ltd. | 06/20/14

(*Hazardous Location

Motor End)

Page 2

General

Information

Attention:

This manual contains important

information for the safe use of

this product. Read this manual

completely before using this

product and refer to it often

for con tin ued safe product use.

DO NOT THROW AWAY OR

LOSE THIS MAN U AL. Keep

it in a safe place so that you may

refer to it often.

Reasonable care and safe

meth ods should be practiced.

Check local codes and

requirements before installation.

Unpacking Pump:

Remove pump from carton.

When un pack ing unit, check for

con cealed damage. Claims

for damage must be made at

the receiving end through the

delivery carrier. Dam age cannot

be processed from the factory.

WARNING: Before handling

these pumps and controls,

always disconnect the power

first. Do not smoke or use

sparkable electrical devices or

flames in a septic (gaseous) or

possible septic sump.

The Pump

IMPORTANT—Read all the

directions before replacing

any parts.

CALIFORNIA PROPOSITION

65 WARNING:

This product and

related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductive

harm.

Pumps Not Operating or

in Storage:

Pumps with carbon ceramic seals

must have impellers manually

rotated (6 revolutions) after

setting non-op er a tion al for 3

2

months or longer and prior to

electrical start-up.

Pumps with tungsten carbide seals

must have impellers manually

rotated (6 revolutions) after

setting non-op er a tion al for

3 weeks or longer and prior to

electrical start-up.

Pump:

The submersible pumps are

supplied for three phase only and

for 460 and 575 volts. Power

cable is supplied with ground. Be

sure ground wire is con nect ed to a

water pipe or ground stake.

Power Cords:

The power cord and heat sensor

seal failure cord are potted into

the con nec tion box cap. The cords

must not be spliced.

NOTE: Each cable has a green

lead. This is the ground wire

and must be grounded properly

per NEC and/or local codes.

Cords should be in spect ed for

abnormal wear and replaced

ac cord ing ly.

Overload Heaters:

If the Hydromatic electrical

panel is not used, start ers with

3 leg overload relay must be

supplied on 3 phase pumps.

Each leg is to have an iden ti cal

heater sized in accordance with

the nameplate amps on the motor

hous ing. The amp draw on these

sub mers ible motors is slightly

higher than a cor re sponding

horsepower sur face motor, so

heat ers must be sized by the

nameplate rating. To adequately

protect these windings with the

appropriate heaters, consult the

factory.

Seal Failure Probes:

All hazardous location

submersible pumps have two

factory installed mois ture

detectors (seal failure probes).

They are in a normally open series

cir cuit, in the seal chamber. Un der

normal operating conditions, the

circuit remains open. If the lower

seal leaks and moisture enters this

cham ber, the moisture would settle

to the bottom of the chamber and

will com plete the circuit between

the mois ture detectors.

This circuit must be connected

to a sensing unit and signaling

device. This is supplied in a

Hydromatic built control panel.

NOTE: Failure to install such a

device negates all war ran ties by

Hydromatic.

Seal Failure:

An electrode probe is installed in

the seal chamber so if any water

enters the chamber through the

first seal the electrode will be

energized and a sig nal will be

transmitted to the sens ing unit at

ground surface causing a red light

to turn on. The electrode probe

is installed in all units but the

sensing unit is supplied at extra

cost and must be ordered.

In operation the seal failure unit

in di cates only that there is some

water in the seal chamber. The

pump will con tin ue to operate

without damage but the seal

should be checked im me di ate ly

after failure is indicated.

The sensing unit is recommended

on all installations as good

insurance against motor failure.

Heat Sensors —

Standard Equipment:

All motors have heat sensor units

em bed ded in the motor winding

to detect excessive heat. The

sensors automatically reset when

mo tor cools to safe tem per a ture.

The sensors are connected in

series with the motor starter coil

so that the starter is tripped if

the heat sensor opens. The motor

starter is equipped with overload

heaters so all normal over loads

are protected by the starter.

Sump Level Control:

Sump level is controlled by

Hydromatic float switch con trols.

Page 3

The float is held in position in

the sump by a weight at tached to

the power cord above the float.

The cord supports the float and

is adjusted for height from the

sur face.

Duplex systems use three

controls: one set at turn-off, one

set at turn-on for one pump, and

one set for turn-on for two pumps.

Pumps alternate op er a tion on each

successive cycle.

Two pumps operate together only

if sump level rises to the third

or over ride control. The override

control also brings on the second

pump in case of failure of the first

pump. The extra float is for alarm.

Triplex systems use four controls:

one set at turn-off, one set at

turn-on for one pump, one set

at turn-on for two pumps, and

one set at turn-on for three

pumps. Pumps alternate each

successive cycle.

Three pumps operate together

only if sump level rises to the

fourth control (second override).

This control also brings on

the third pump in case of failure

of either or both of the first

two pumps.

Alarm Controls:

The alarm level is usually set

above the override level so the

alarm will signal only if the

override level is ex ceed ed.

However, some engineers prefer

to have the alarm level set be low

the override level as it is pos si ble

for one pump to fail and the other

pump to operate on the override

level with the sump level never

reach ing the alarm level. This is

par tic u lar ly true in cases of low

inflow ca pac i ty.

Electrical Control Panel:

Hydromatic electrical equip ment

is installed in a weatherproof

NEMA 3R enclosure. The

electrical equip ment includes

a main circuit breaker for each

pump, a magnetic starter with

overload protection for each

pump, an H-O-A switch and run

light for each pump, an electric

alternator and a transformer to

provide appropriate control for

control and circuit and alarms.

Installation

Instructions

Installing Pump in Sump:

Before installing pump in sump,

lay it on side and turn impeller

manually. Impeller may be

slightly stuck due to factory test

water, so it must be broken loose

with small bar or screwdriver

in edge of vanes. After breaking

loose, the impeller should

turn freely.

Clean all trash and sticks from

sump and connect pump to piping.

A check valve must be installed

on each pump. A gate or plug

valve in each pump discharge

line is also recommended. This

valve should be installed on the

discharge side of the check valve

so if it is necessary to service the

check valve, the line pressure can

be shut off.

NEMA IV Junction Box:

(Optional)

This must be used with 60 and

above horsepower pumps and

with all systems if the electrical

control panel is to be set remote

from the pumps. The Hydromatic

NEMA 4 junction box is provided

with com pres sion connectors

for sealing all wires. No sealing

compound is needed to make

connections wa ter proof.

Wiring diagrams are provided

with the panel for making

connections. The size wire to use

from panel to sump depends on

motor size and distance in feet.

Be sure each wire is checked

so that a wrong connection will

not be made. An ohmmeter or

Megger can be used to check

wire continuity.

Installing Float Switch Controls:

The controls are supported by a

mounting bracket that is attached

to sump wall, cover, or to the

NEMA 4 junction box. Cord

snubbers are used to hold the cord

in place. Control level can be

changed at any time by loosening

the snubber and readjusting

cord height.

In either duplex or triplex

systems, the bottom of the lower

or turn-off control is set just above

the top of volute, so that the volute

will always be submerged during

the pumping cycle. The second,

or turn-on control, is set about

24 inches above the lower turn-off

control.

More distance between turn-on

and turn-off controls can be used,

but sewage may become septic,

and excessive solids may collect

for the pump to handle. A frequent

pumping cycle is recommended

for best operation.

In a duplex system the third or

override control is usually set

about 6 inches above the one pump

turn-on control.

In a triplex system the third or

override control is usually set

24 inches above the one pump

turn-on control, and the fourth

or second override control is

24 inches higher.

If an alarm system is used, this

control is usually set about 6

inches above the override control.

Making Electrical Connections:

All electrical wiring must be in

ac cor dance with local codes, and

only competent electricians should

make the in stal la tions. Complete

wiring diagrams are glued to the

inside cover of the panel. All wires

should be checked for grounds

with an ohmmeter or Megger after

the con nections are made. This is

important, as one grounded wire

can cause considerable trouble.

3

Page 4

Heat Sensors and Seal Failure

Connections:

Be sure heat sensor wires are

con nect ed in series with the

starter coil. Con nec tions are

provided on the terminal strip.

will exist. One leg can be

somewhat higher (5 to 10%)

without causing trouble.

For excessive amp draw on

one leg, the power company

should be consulted.

is required.

Generally, these pumps give

very reliable service, and can

be expected to operate for many

years on normal sewage pumping

without failure.

Pump

Operations

Starting System:

1. Turn H-O-A switch to

Off position and then turn on

main circuit breakers.

2. Open all discharge valves and

allow water to rise in sump.

3. Turn H-O-A switch to Hand

posi tion on one pump and

notice oper ation. If pump is

noisy and vibrates, rotation

is wrong. To change rotation,

interchange any two line

leads to motor 3ø only. Do not

interchange main incoming

lines. If duplex system, check

second pump in same manner.

4. Now set both H-O-A switches

to Auto position and allow

water to rise in sump until

one pump starts. Allow pump

to operate until level drops to

turn-off point.

5. Allow sump level to rise to

start other pump. Notice run

lights on panel. Pumps should

alternate on each successive

cycle of op er a tion.

6. Turn both H-O-A switches

to Off position and allow

sump to fill to the override

control level.

7. Turn both switches to Auto

position and both pumps

should start and operate

together until level drops to

turn-off point.

8. Repeat this operation

cycle several times before

leaving job.

9. Check voltage when pumps

are operating and check the

amp draw of each pump.

Check amps on each wire,

as sometimes a high leg

4

Pump

Maintenance

Field Service on Hydromatic

Hazardous Location Pumps:

If a Hydromatic hazardous location

pump is used in a hazardous

location, or if the pump is still

in war ran ty, the pump must be

returned to the factory for service

or repaired at an authorized

Factory Mutual Hydromatic

service center. Charges will not

be allowed if in war ran ty pump is

not taken to an authorized Factory

Mutual Hydromatic service center.

This will ensure the integrity of

the hazardous location rating of

the pump and com ply with our

warranty re quire ments.

Disconnecting Pump Cords:

If a Hydromatic hazardous location

pump is to be removed from its

loca tion, the pump cords may be

disconnected at control panel (on

sump mounted con trol panels) and

cord as sem bly taken with pump.

CAUTION: If cord openings

from sump to con trol panel are

open, gas es from sump could

enter panel and an explosive

condition could ex ist.

Replacing Cords:

The power cord and heat sensor seal failure cord is potted into the

con nec tion box cap, forming the

cord and cap assembly.

If cords require replacement due to

damage or cords being too short,

cord and cap assembly must be

replaced as a complete assembly

avail able from factory.

Check pump for proper rotation

before re turn ing to normal service.

Motor:

As the motors are oil filled, no

lubrication or other maintenance

Field Service on Motor:

All submersible motors out

of warranty can be serviced in

the field by any reliable motor

service shop. Any pump in

warranty must be returned to the

factory for service or repaired

at an authorized Hydromatic

service center. Charges will not

be allowed if in warranty pump is

not taken to an authorized

Hydromatic

When field service is performed

on a pump, these instructions

should be carefully followed.

Replacing Stator:

1. If stator only is damaged,

it may not be necessary to

completely dismantle pump

as stator and housing can be

lifted from pump without

disturbing seals or bearings.

2. Drain all oil from upper

housing, remove drain plug in

bottom of stator housing and

remove plug in top of housing

to allow air to enter.

3. After chamber is drained,

remove hold-down bolts

and lift off. Use care in

lifting as the seal failure

connecting wire must be

dis con nect ed before housing

is com plete ly removed.

4. Set assembly on bench and

remove connection box.

When box is lifted off,

connection wires to motor will

be exposed. These wires will

probably be burned, but each

wire is tagged with a metal

marker giving wire number.

Cut the wires.

If the leads to the connection

box are burned, a complete

new con nec tion box with new

wire must be used. The wires

service center.

Page 5

are potted in with sealing

compound and a new unit

must be obtained from

the factory.

5. The stator is held in the

housing with a bolted-in

retaining ring and prevented

from rotating by a key.

6. Remove the retaining ring and

socket head cap screw.

7. After ring is removed, turn

housing upright and bump on

hard wood blocks. This should

jar the stator loose and allow

it to drop out.

8. Thoroughly clean housing

before replacing new stator.

Replace stator and make

all wire con nec tions to

the connection box before

replacing housing on pump.

This is important as leads

must be tucked behind the

windings by using hands up

through rotor core.

Do not tape leads as oil will

de te ri o rate the tape and cause

damage to stator and bearings.

9. Check top bearing. If clean

and does not turn rough,

bearings can be reused and it

is not necessary to completely

dismantle pump to change

bearings. If bearings are

damaged with dirt or heat,

they must be re placed.

10. Replace stator housing onto

seal chamber and bolt in place.

Be sure seal failure wire is

connected before housing is

assembled. Be sure back-off

screws have been loosened

so that parts can come metal

to metal. Be sure O-ring seal

has been replaced. If O-ring

is nicked or cut, replace with

new ones. This applies to all

O-rings used in assembly.

11. After all leads are reconnected

in the connection box, make

a high voltage ground test

on each wire. The only wire

that should show ground is

the green power lead and the

ground lead in the auxiliary

control cable.

12. For safety, complete pump

should be air checked under

water for leaks. Lay pump

on side for this oil filling

with oil fill hole upright.

Do not completely fill; leave

oil about 1 inch below plug

hole. Use only Hydromatic

submersible oil in this

chamber. Replace plug; use

Permatex on threads. Install

air valve in top plug opening

of motor housing and charge

housing with about 10 psi

of air. Be sure air is dry.

Do not use air line where

water may be trapped in

the line. Submerge complete

unit under water and check

for leaks.

13. Refill motor chamber with

oil. Use Hydromatic special

submers ible oil. Fill chamber

until oil covers top of the

windings. Leave air space in

the top for expansion. Use

Permatex on plug threads.

Replacing Seals and Bearings:

1. Drain all oil from motor

chamber and seal chamber

as described.

2. Remove motor housing as

described.

3. Remove bolts that hold seal

chamber to pump housing.

Use back-off screws to break

loose. With hardwood block,

tape end of impeller to loosen

from shaft. When free, remove

impeller from shaft.

4. Lift rotating assembly from

pump case and place on bench.

5. Impeller Removal: Hold rotor

and remove bolt and washer

from impeller end of shaft,

then thread bolt back into

shaft. The impeller is keyed

to the shaft, so by using a

screw driv er on opposite sides

behind the im pel ler, apply force

then tap on the end of the bolt

to break impeller loose from

taper shaft. Remove impeller.

6. Remove key and pry on each

side of shoulder of shaft sleeve

to remove. Seal should come

off with sleeve. If sleeve is not

free, leave in place and push off

when seal plate is removed.

7. To remove seal plate take

out socket head flat screws

and using screws in back-off

holes, pry plate loose. This

will also force seal off if not

already re moved.

8. Remove snap ring that holds

upper seal. Pull seal if it

is free. If not free, it can

be forced off when shaft

is removed.

9. Set seal housing assembly in

upright position and bump end

of shaft on hardwood block.

This will push the bearing

from the housing and will

force upper seal from shaft.

10. Use bearing puller to remove

bearings. Replace with new

bearings. Press only on

inner face of bearing when

replacing. Pressing on outer

face can damage the bearing.

IMPORTANT — Do not

use any of the old seal parts.

Replace with all new seals.

11. Thoroughly clean all castings

before replacing seals. One

grain of dirt between the seal

faces can cause failure.

12. Examine all O-Rings for nicks

before reusing.

13. Be sure key is in place in notch

of shaft sleeve to prevent

sleeve from turning.

®

14. Use Locktite

on socket head

locking screw in end of shaft.

15. Before refilling chamber with

oil, air test as described above

and refill both chambers

with oil.

16. Always check all leads with

high voltage or with Megger

for grounds before operating

the pump.

5

Page 6

Pump

Troubleshooting

The following is a list of common

problems and their probable

causes.

Pump will not start.

1. No power to the motor.

Check for blown fuse or open

circuit breaker.

2. Selector switch may be in the

Off position.

3. Control circuit transformer

fuse may be blown.

4. Overload heater on starter

may be tripped. Push to reset.

Pump will not start and

overload heaters trip.

1. Turn off power and check

motor leads with Megger

or ohmmeter for possible

ground.

2. Check resistance of motor

windings. All 3 phases should

show the same reading.

3. If no grounds exist and

the motor windings check

OK, remove pump from sump

and check for clogged or

blocked impeller.

Pump operates with selector

switch in Hand position but will

not operate in Auto position.

1. This indicates trouble in the

level control or the alternator

relay.

2. Check control panel for

trouble.

Pump runs but will not shut off.

Pump does not deliver proper

capacity.

1. Discharge gate valve may

be partially closed or

partially clogged.

2. Check valve may be partially

clogged. Raise the level up

and down to clear.

3. Pump may be running in

wrong direction. Low speed

pumps can operate in reverse

direction without much noise

or vibration.

4. Discharge head may be too

high. Check total head with

gauge when pump is operating.

Total head is discharge gauge

pressure converted to feet

plus vertical height from

water level in sump to center

line of pressure gauge in

discharge line. Gauge should

be installed on pump side of

all valves. Multiply gauge

pressure in pounds by 2.31 to

get head in feet.

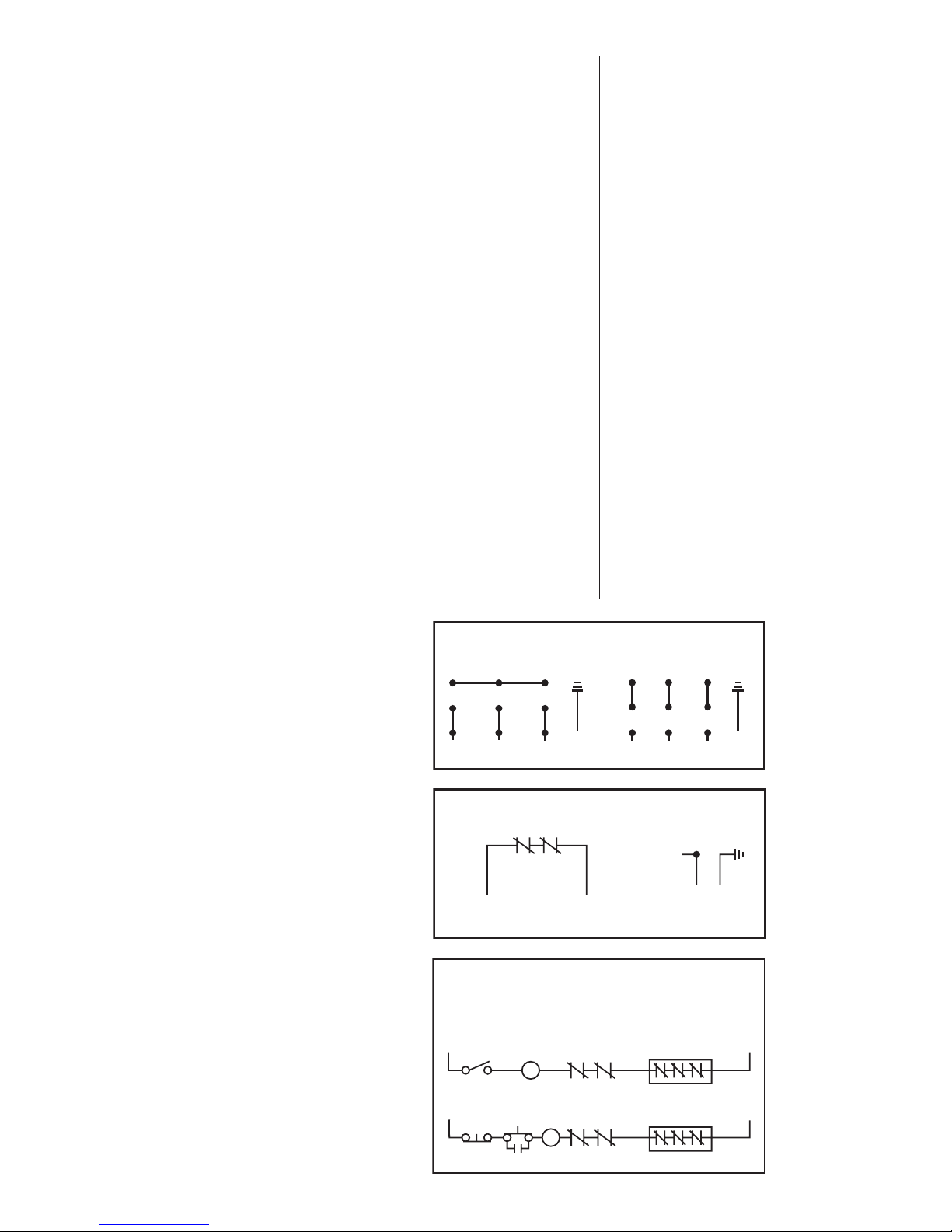

DUAL VOLTAGE

3 PHASE MOTOR WIRING

230V 3ø 460V 3ø

45 6

78 9

12 3

BL

(L1)

HEAT SENSORS AND SEAL FAILURE CONNECTIONS

W

(L2)

HEAT SENSORS

IN MOTOR

WINDINGS

HEAT SENSORS SEAL FAILURE

GREEN GREEN

R

(L3)

FOR ANY VOLTAGE MOTOR

WHITEBLACK

5. If pump has been in service for

some time and capacity falls

off, remove pump and check

for wear or clogged impeller.

Motor stops and then restarts

after short period but overload

heaters in starter do not trip.

1. This indicates heat sensors

in the motor are tripping due

to ex ces sive heat. Impeller

may be partially clogged,

giving a sus tained overload

but not high enough to trip

overload heater switch.

2. Motor may be operating out

of liquid due to a failed level

control.

3. Pump may be operating on

a short cycle due to sump

being too small or from water

returning to sump due to a

leaking check valve.

45 6

78 9

12 3

BL

(L1)

ELECTRODE

R

W

(L3)

(L2)

REDDARK

GREEN

1. Pump may be air locked.

Turn pump off and let set for

several minutes, then restart.

2. Lower float control may be

hung-up in the closed position.

Check in sump to be sure

control is free.

3. Selector switch may be in the

Hand position.

6

COIL

WARNING

COIL

THERMOSTATS

IN SERIES

BLACK

BLACK

THERMOSTATS

IN SERIES

OL OLSTART

WHITE

WHITE

WARRANTY IS VOID IF HEAT SENSORS ARE NOT

CONNECTED AS SHOWN (IN SERIES WITH CONTACTOR OIL)

TWO WIRE CONTROL OFFERING AUTOMATIC RESET

L1

ON-OFF

SWITCH

THREE WIRE CONTROL OFFERING AUTOMATIC RESET

L1

IN CERTAIN APPLICATIONS THE NEC MAY REQUIRE THREE OVERLOAD RELAYS

L2

L2

Page 7

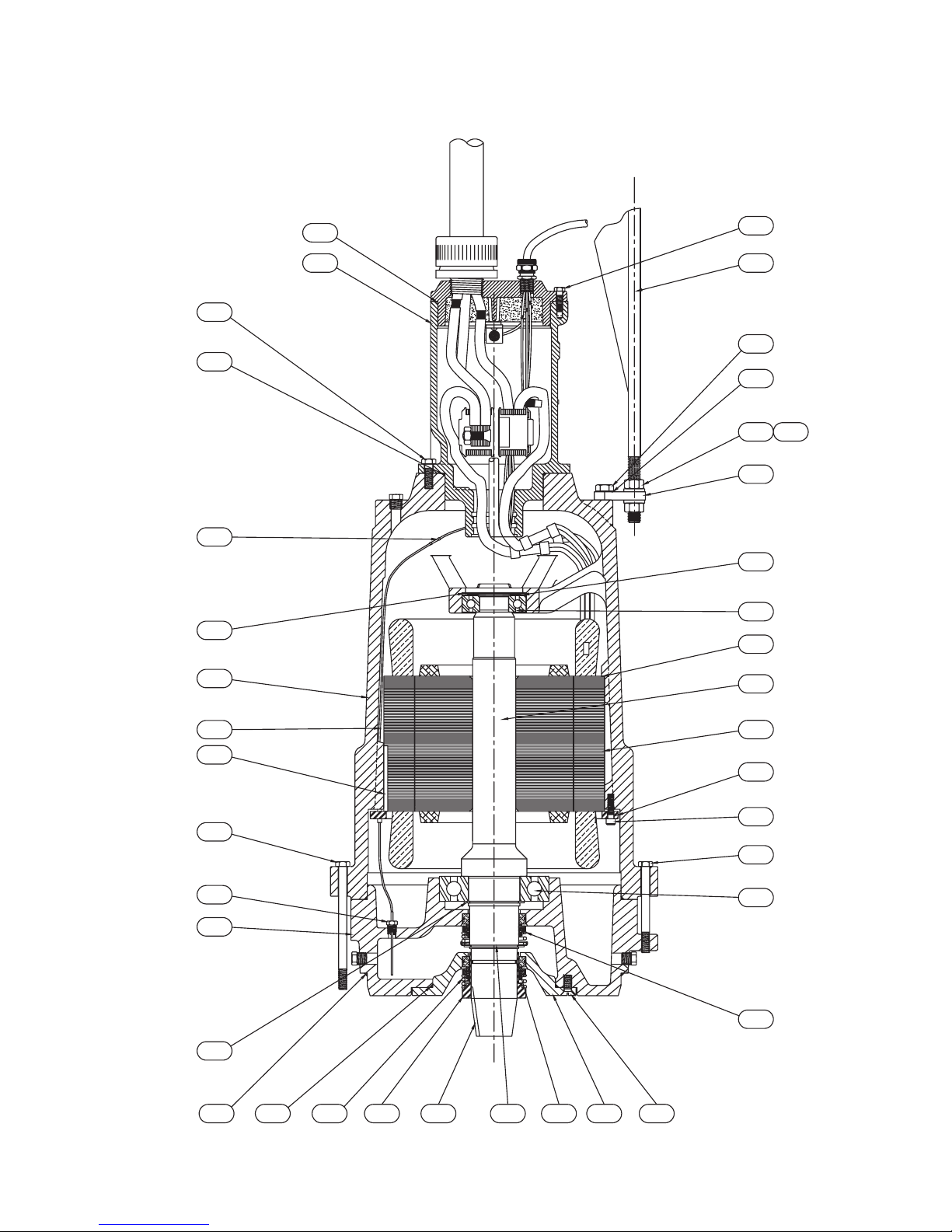

Standard Location

S4T, S8L, S8LA, S12L Motor End Components

18

27

26

3

B3

4

28

31

34

32

29

33

35

30

1

B2

22

19

20

25

23

12

B4

B1

24

9

7

17211116151465

10

8

2

13

7

Page 8

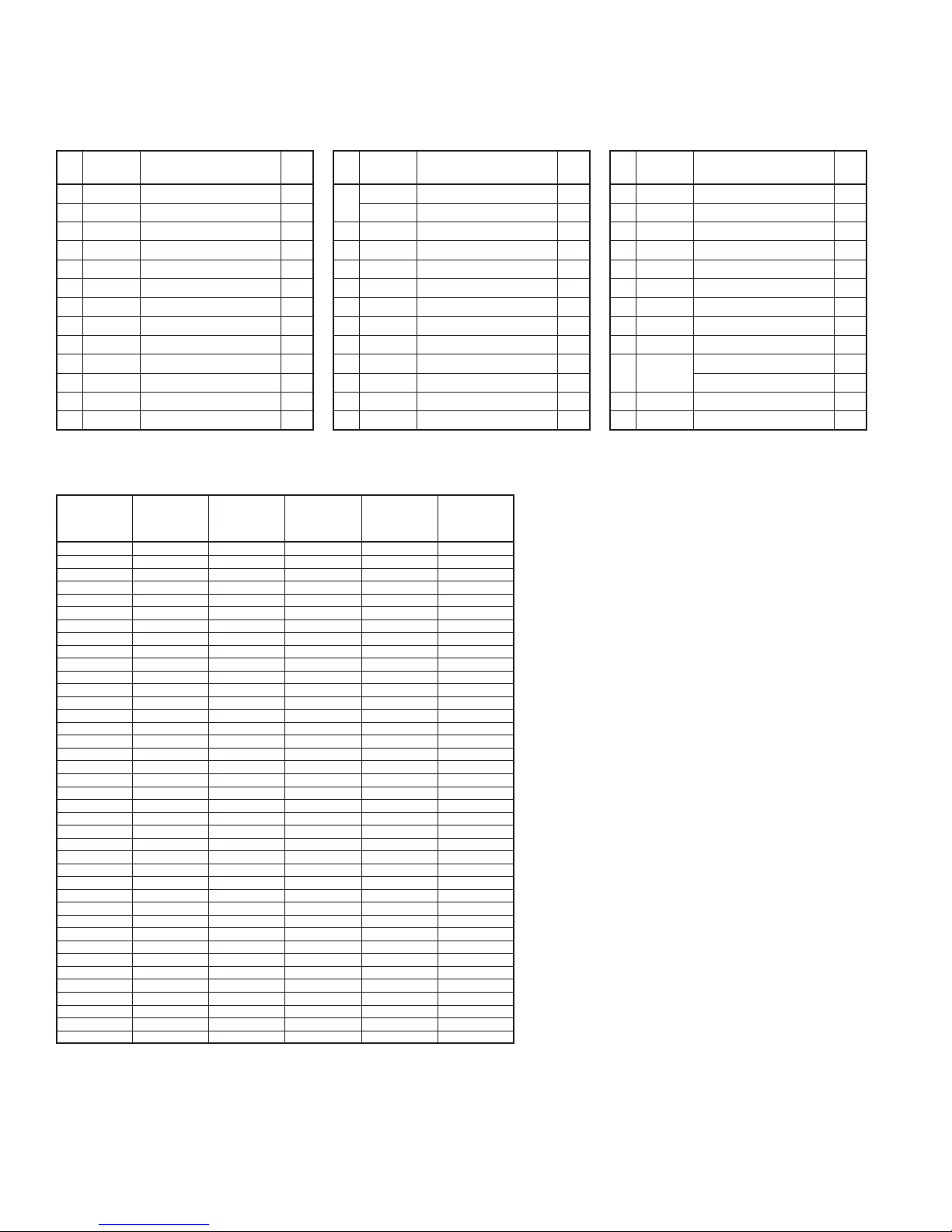

Standard Location

S4T, S8L, S8LA, S12L Motor End Parts List

For use with product built with USEM motor.

Ref.

Part

No.

No.

Description Qty.

1 08565A026 BEARING – BALL (UPPER) 1

2 000650231 BEARING – BALL (LOWER) 1

3 001500191 O-RING 1

4 001500321 O-RING SC 1

5 001500381 O-RING 2

6 001500571 O-RING 1

7 001501081 O-RING (VITON

8 002390351 SCREW – HHC 1/2-13 x 5-1/4 4

9 002390381 SCREW – HHC 1/2-13 x 7-1/4 12

10 005560071 SCREW – CAP (HEX SOC.) 6

11 009750141 RING – RETAINING 1

12 009750101 RING – RETAINING 1

13 037180051 SEAL Carbon Ceramic / Viton

®

) SC 1

®

S 1

Notes: S — Parts in Seal Kit C — Parts in Carbide Seal Kit

Amount of oil required will vary between 8 and 10.5 gal. depending on stator size, fill to above motor windings.

Part

Ref.

Part

No.

14 037180051 SEAL Carbon Ceramic / Viton

037180021 SEAL Tungsten Carbide / Viton

15 023100093 SLEEVE – SHAFT SC 1

16 028550011 KEY – SQUARE 3/8 1

17 029210011 SCREW – CAP (FL. HD SOC) 4

18 19103A052 SCREW – CAP HEX SST 1/2 6

19 060000111 WIRE W/TERMINAL 14 GA. RED 1

20 065790021 KEY – SQUARE 1/4 1

21 073980002 HOUSING – SEAL 1

22 074000042 HOUSING – MOTOR 1

23 074011002 HOUSING – BEARING 1

24 083540003 RING – RETAINING STATOR 1

25 084720025 SEAL FAILURE ASS’Y 1

Part

No.

Description Qty.

®

S 1

®

C Optional

Ref.

Part

No.

26 110650023 SCREEN 3.81 DIA. 1

27 12672A002 CONNECTOR – BUTT 3

28 19101A017 SCREW – CAP HEX SST 3/8 6

29 19109A080 NUT – HEX SST 3/4 4

30 05454A030 WASHER – LOCK 3/4 4

31 151753001 BAIL – LIFTING 1

32 05454A027 WASHER – LOCK 5/8 2

33 151740001 BRACKET – MOUNTING 2

34 19105A033 SCREW – CAP HEX SST 5/8 2

35 000640051

517000687 Seal Kit S

517003687 Carbide Seal Kit C

Part

No.

Description Qty.

SPRING–BEARING 100 hp AND BELOW

SPRING–BEARING 125 hp AND ABOVE

2

3

hp

15–20 200/3/870 141632031 086620121 137690035 141630125

15–20 230/3/870 141630031 086620121 137690065 141630125

15–20 460/3/870 141630031 086620121 137690075 141630125

15–20 575/3/870 141636031 086620121 137690045 141630125

25 200/3/870 141622031 086620091 137690025 141620125

25 230/3/870 141620031 086620091 137690055 141620125

25 460/3/870 141620031 086620091 137690075 141620125

25 575/3/870 141626031 086620091 137690045 141620125

30 200/3/870 141622031 086620091 137690015 141620125

30 230/3/870 141620031 086620091 137690055 141620125

30 460/3/870 141620031 086620091 137690075 141620125

30 575/3/870 141626031 086620091 137690045 141620125

30 200/3/1150 141612031 086620111 137690015 141610125

30 230/3/1150 141610031 086620111 137690055 141610125

30 460/3/1150 141610031 086620111 137690065 141610125

30 575/3/1150 141616031 086620111 137690035 141610125

40 200/3/1150 141612031 086620111 137690015 141610125

40 230/3/1150 141610031 086620111 137690015 141610125

40 460/3/1150 141610031 086620111 137690065 141610125

40 575/3/1150 141616031 086620111 137690035 141610125

50 230/3/1150 141600031 086620041 137690015 141600125

50 460/3/1150 141600031 086620041 137690055 141600125

50 575/3/1150 141606031 086620041 137690035 141600125

60 460/3/1150 141590031 086620031 137690025 141590125

60 575/3/1150 141596031 086620031 137690025 141590125

75 460/3/1150 141590031 086620031 137690015 141590125

75 575/3/1150 141596031 086620031 137690025 141590125

50 460/3/1750 141580031 086620031 137690025 141570125

50 575/3/1750 141586031 086620031 137690035 141570125

60 460/3/1750 141580031 086620031 137690025 141570125

60 575/3/1750 141586031 086620031 137690025 141570125

75 460/3/1750 141580031 086620031 137690015 141570125

75 575/3/1750 141586031 086620031 137690025 141570125

100 460/3/1750 141570031 086620031 137690015 141570125

100 575/3/1750 141576031 086620031 137690015 141570125

125 460/3/1750 141560031 — 137690015 141560125

125 575/3/1750 141566031 — 137690015 141560125

150 460/3/1750 141560031 — 137690085 141560125

150 575/3/1750 141566031 — 137690015 141560125

VOLTAGE/

ph/RPM

B1

STATOR

B2

RING –

SPACER

B3

BOX –

CONNECTION

B4

ROTOR/

SHAFT

8

Page 9

Impeller Parts List / Cord Cap For use with product built with USEM motor.

Description hp Volt/ph Trim Impeller Cord Cap

S4T(X)

1750 RPM

S4T7500M4-4 75 460/3 13 135321092 152760355 152790355

S4T7500M5-4 75 575/3 13 135321092 152760345 152790345

S4T10000M4-4 100 460/3 14 135321052 152760365 152790365

S4T10000M5-4 100 575/3 14 135321052 152760355 152790355

S4T12500M4-4 125 460/3 15 135321012 152760375 152790375

S4T12500M5-4 125 575/3 15 135321012 152760365 152790365

S4T15000M4-4 150 460/3 15.13 135321262 152760375 —

S8L(X)

1750 RPM

S8L7500M4-4 75 460/3 12.12x11.12 25252D559 152760355 152790355

S8L7500M5-4 75 575/3 12.12x11.12 25252D559 152760345 152790345

S8L10000M4-4 100 460/3 13x12 25252D558 152760365 152790365

S8L10000M5-4 100 575/3 13x12 25252D558 152760355 152790355

S8L12500M4-4 125 460/3 13.75x12.75 25252D556 152760375 152790375

S8L12500M5-4 125 275/3 13.75x12.75 25252D556 152760375 —

S8L15000M4-4 150 460/3 15x14 25252D551 152760375 —

S8L15000M5-4 150 575/3 15x14 25252D551 152760365 —

1150 RPM

S8L3000M6-6 30 200/3 13x12 25252D558 152760355 152790355

S8L3000M3-6 30 230/3 13x12 25252D558 152760355 152790355

S8L3000M4-6 30 460/3 13x12 25252D558 152760325 152790325

S8L3000M5-6 30 575/3 13x12 25252D558 152760325 152790325

S8L40000M6-6 40 200/3 14.25x13.25 25252D553 152760365 152790365

S8L40000M3-6 40 230/3 14.25x13.25 25252D553 152760355 152790355

S8L40000M4-6 40 460/3 14.25x13.25 25252D553 152760335 152790335

S8L40000M5-6 40 575/3 14.25x13.25 25252D553 152760325 152790325

S8L50000M3-6 50 230/3 15x15 25252D551 152760365 —

S8L50000M4-6 50 460/3 15x15 25252D551 152760345 152790345

S8L50000M5-6 50 575/3 15x15 25252D551 152760335 152790335

S8L60000M4-6 60 460/3 15x15 25252D550 152760345 152790345

S8L60000M5-6 60 575/3 15x15 25252D550 152760335 152790335

870 RPM

S8L1500M6-8 15 200/3 13.38x12.38 25252D557 152760335 152790335

S8L1500M3-8 15 230/3 13.38x12.38 25252D557 152760325 152790325

S8L1500M4-8 15 460/3 13.38x12.38 25252D557 152760315 152790315

S8L1500M5-8 15 575/3 13.38x12.38 25252D557 152760305 152790305

S8L2000M6-8 20 200/3 14.85x13.85 25252D552 152760335 152790335

S8L2000M3-8 20 230/3 14.85x13.85 25252D552 152760335 152790335

S8L2000M4-8 20 460/3 14.85x13.85 25252D552 152760325 152790325

S8L2000M5-8 20 575/3 14.85x13.85 25252D552 152760315 152790315

S8L2500M6-8 25 200/3 15x14 25252D550 152760345 152790345

S8L2500M3-8 25 230/3 15x14 25252D550 152760345 152790345

S8L2500M4-8 25 460/3 15x14 25252D550 152760325 152790325

S8L2500M5-8 25 575/3 15x14 25252D550 152760325 152790325

S8L3000M4-8 30 460/3 15x14 25252D550 152760325 —

Haz. Loc.

Cord Cap

Description hp Volt/ph Trim Impeller Cord Cap

S8LA(X)

1750 RPM

S8LA7500M4-4 75 460/3 13 135320052 152760355 152790355

S8LA7500M5-4 75 575/3 13 135320052 152760345 152790345

S8LA10000M4-4 100 460/3 14 135320012 152760365 152790365

S8LA10000M5-4 100 575/3 14 135320012 152760355 152790355

S8LA12500M4-4 125 460/3 15 135320092 152760375 152790375

S8LA12500M5-4 125 575/3 15 135320092 152760365 152790365

S12L(X)

1750 RPM

S12L7500M4-4 75 460/3 11x10 25456E562 152760355 152790355

S12L7500M5-4 75 575/3 11x10 25456E562 152760345 152790345

S12L10000M4-4 100 460/3 11.5x11 25456E563 152760365 152790365

S12L10000M5-4 100 575/3 11.5x11 25456E563 152760355 152790355

S12L12500M4-4 125 460/3 12.5x11 25456E564 152760375 152790375

S12L12500M5-4 125 275/3 12.5x11 25456E564 152760365 —

S12L15000M4-4 150 460/3 13x11 25456E565 152760375 —

S12L15000M5-4 150 575/3 13x11 25456E565 152760365 —

1150 RPM

S12L40000M3-6 40 230/3 12.31 25456E560 152760355 152790355

S12L40000M4-6 40 460/3 12.31 25456E560 152760335 152790335

S12L40000M5-6 40 575/3 12.31 25456E560 152760325 152790325

S12L50000M3-6 50 230/3 13.06 25456E560 152760365 —

S12L50000M4-6 50 460/3 13.06 25456E555 152760345 152790345

S12L50000M5-6 50 575/3 13.06 25456E555 152760335 152790335

S12L60000M4-6 60 460/3 13.63 25456E553 152760345 152790345

S12L60000M5-6 60 575/3 13.63 25456E553 152760335 152790335

S12L75000M4-6 75 460/3 14 25456E552 152760355 152790355

S12L75000M5-6 75 575/3 14 25456E552 152760345 152790345

870 RPM

S12L1500M6-8 15 200/3 12.25 25456E561 152760335 152790335

S12L1500M3-8 15 230/3 12.25 25456E561 152760325 152790325

S12L1500M4-8 15 460/3 12.25 25456E561 152760315 152790315

S12L1500M5-8 15 575/3 12.25 25456E561 152760305 152790305

S12L2000M6-8 20 200/3 13 25456E556 152760335 152790335

S12L2000M3-8 20 230/3 13 25456E556 152760335 152790335

S12L2000M4-8 20 460/3 13 25456E556 152760325 152790325

S12L2000M5-8 20 575/3 13 25456E556 152760315 152790315

S12L2500M6-8 25 200/3 13.5 25456E554 152760345 152790345

S12L2500M3-8 25 230/3 13.5 25456E554 152760345 152790345

S12L2500M4-8 25 460/3 13.5 25456E554 152760325 152790325

S12L2500M5-8 25 575/3 13.5 25456E554 152760325 152790325

S12L3000M6-8 30 200/3 14 25456E552 152760355 152790355

S12L3000M3-8 30 230/3 14 25456E552 152760345 152790345

S12L3000M4-8 30 460/3 14 25456E552 152760325 152790325

S12L3000M5-8 30 575/3 14 25456E552 152760325 152790325

Haz. Loc.

Cord Cap

Wet End Components

S4T(X)

Item

Number

D1 SCREW – CAP CHARTED 048200111 (4) 001780011 (4) — 07597A021 (4)

D2 WASHER – IMPELLER HOLD 019450013 1 1 1 1

D3 SCREW – CAP 038790021 1 1 1 1

D4 CASE – VOLUTE CHARTED 136880002 073942002 25457F200 073940002

D5 RING – WEAR CHARTED 136950003 083450002 25458D000 135350003

D6 RING – CLAMP CHARTED — — — 135360003

D7 BELL – SUCTION 105871002 — — 1 —

D8 STAND – PUMP S12L 106270005 — — 1 —

D9 SCREW – CAP 19106A017 — — 8 —

D10 SCREW – CAP SKT HD 1/4-20 06106A045 — — 4 —

D11 SCREW – CAP SST 19103A043 — — 8 —

Description Part Number S4T(X) S8L(X) S12L(X) S8LA(X)

S8L(X)

S8LA(X)

S12L(X)

9

Page 10

Hazardous Location

PROBE TEST RESISTOR

ON HAZARDOUS LOCATION ONLY

–

PROBE TEST RESISTOR

ON HAZARDOUS LOCATION ONLY

PROBE TEST RESISTOR

ON HAZARDOUS LOCATION ONLY

PROBE TEST RESISTOR

ON HAZARDOUS LOCATION ONLY

––

–

PROBE TEST RESISTOR

ON HAZARDOUS LOCATION ONLY

––

–

S4TX, S8LX, S8LAX, S12LX Motor End Components

B5

B3

17

23

B1

24

14

3

26

13

6

29

B4

1

18

B2

19

10

2

9

8

12

25

27

20

5

22 1542811 21 16

7

Wiring Diagrams

10

Page 11

Hazardous Location

S4TX, S8LX, S8LAX, S12LX Motor End Parts List

For use with product built with USEM motor.

Ref.

Part

No.

No.

Description Qty.

1 08565A026 BEARING–BALL (UPPER) 1

2 000650231 BEARING–BALL (LOWER) 1

3 001500191 O-RING 6.734 I.D. 1

4 001500211 O-RING 7.734 I.D. 1

5 001500381 O-RING 14.984 I.D. 2

6 001500421 O-RING 5.359 I.D. 1

7 001501081 O-RING 2.484 I.D. 1

8 002390241 SCREW–HHC 1/2-13 4

9 002390261 SCREW–HHC 1/2-13 12

10 005560071 SCREW–HEX SOC. 3/8 x 1-1/2 6

11 028550011 KEY–SQUARE 3/8 1

Note: Amount of oil required will vary between 8 and 10-1/2 gals. depending on stator size, fill to above motor windings.

4-Pole 1750 RPM

Part

4-Pole 1750RPM

Item

Description

B1 Stator 141580031 141586031 141570031 141576031 141560031 141566031

B2 Rotor/Shaft Assembly 141580145 141580145 141580145 141580145 141560145 141560145

B3 Box–Connection 114110105 114110045 114110105 114110105 114110105 114110105

B5 Cord Cap 152790355 152790345 152790365 152790355 152790375 152790365

75hp

460/3/1750

75hp

575/3/1750

100hp

460/3/1750

Ref.

Part

No.

12 009750141 RING–RETAINING 1

13 011240021 NUT–HEX 5/8 (JAM) 2

14 065790021 KEY–SQUARE .250 SQ. x 3.88 1

15 023100103 SLEEVE–SHAFT SEAL 1

16 029210011 SCREW–CAP 1/2-13 x 1-1/4 4

17 19103A043 SCREW–CAP 1/2-13 x 1-1/2 6

18 074000042 HOUSING–MOTOR 1

19 083540003 RING–RETAINING STATOR 1

20 107460002

107461002

21 107560002 PLATE-SEAL 1

100hp

575/3/1750

Part

No.

Description Qty.

HOUSING–BEARING 100 hp AND BELOW

HOUSING–BEARING 125 hp AND ABOVE

125hp

460/3/1750

125hp

575/3/1750

Ref.

Part

No.

22 107820013 RING–LABYRINTH 1

23 108980001 CONNECTOR–BUTT 4

24 109000045 SEAL SENSOR ASS’Y 1

25 109010001 PROBE–SEAL FAILURE 1

26 19101A017 SCREW–CAP 3/8-16 x 1-1/4 6

27 037180051 SEAL Carbon Ceramic / Viton

037180021 SEAL Tungsten Carbide / Viton

28 037180051 SEAL Carbon Ceramic / Viton

1

1

037180021 SEAL Tungsten Carbide / Viton

29 000640051

Part

No.

Description Qty.

SPRING–BEARING 100 hp AND BELOW

SPRING–BEARING 125 hp AND ABOVE

®

®

®

®

1

Optional

1

Optional

2

3

6-Pole 1150 RPM

6-Pole 1150RPM

Item

Description

B1 Stator 141612031 141610031 141610031 141616031 141612031 141610031 141610031 141616031 141600031 141606031 141590031 141596031 141590031 141596031

B2 Rotor/Shaft Assembly 141610145 141610145 141610145 141610145 141610145 141610145 141610145 141610145 141600145 141600145 141590145 141590145 141590145 141590145

B3 Box–Connection 114110105 114110055 114110035 114110025 114110105 114110105 114110035 114110025 114110055 114110025 114110045 114110045 114110105 114110045

B4 Ring–Spacer 086620101 086620101 086620101 086620101 086620101 086620101 086620101 086620101 086620071 086620071 — — — —

B5 Cord Cap 152790355 152790355 152790325 152790325 152790365 152790355 152790335 152790325 152790345 152790335 152790345 152790335 152790355 152790345

30hp

200/3/1150

30hp

230/3/1150

30hp

460/3/1150

30hp

575/3/1150

40hp

200/3/1150

40hp

230/3/1150

40hp

460/3/1150

40hp

575/3/1150

50hp

460/3/1150

50hp

575/3/1150

60hp

460/3/1150

60hp

575/3/1150

75hp

460/3/1150

575/3/1150

8-Pole 870 RPM

8-Pole 870RPM

Item

Description

B1 Stator 141632031 141630031 141630031 141636031 141632031 141630031 141630031 141636031 141622031 141620031 141620031 141626031

B2 Rotor/Shaft Assembly 141630145 141630145 141630145 141630145 141630145 141630145 141630145 141630145 141620145 141620145 141620145 141620145

B3 Box–Connection 114110025 114110035 114110015 114110005 114110025 114110035 114110015 114110005 114110045 114110055 114110015 114110005

B4 Ring–Spacer 086620091 086620091 086620091 086620091 086620091 086620091 086620091 086620091 086620021 086620021 086620021 086620021

B5 Cord Cap 152790335 152790325 152790315 152790305 152790335 152790335 152790325 152790315 152790345 152790345 152790325 152790325

8-Pole 870RPM

Item

Description

B1 Stator 141622031 141620031 141620031 141626031

B2 Rotor/Shaft Assembly 141620145 141620145 141620145 141620145

B3 Box–Connection 114110105 114110055 114110015 114110005

B4 Ring–Spacer 086620021 086620021 086620021 086620021

B5 Cord Cap 152790355 152790345 152790325 152790325

15hp

200/3/870

30hp

200/3/870

15hp

230/3/870

30hp

230/3/870

15hp

460/3/870

30hp

460/3/870

15hp

575/3/870

30hp

575/3/870

20hp

200/3/870

20hp

230/3/870

20hp

460/3/870

20hp

575/3/870

25hp

200/3/870

25hp

230/3/870

25hp

460/3/870

25hp

575/3/870

75hp

11

Page 12

STANDARD LIMITED WARRANTY

Pentair Hydromatic® warrants its products against defects in material and workmanship for a period of 12 months

from the date of shipment from Pentair Hydromatic or 18 months from the manufacturing date, whichever

occurs first – provided that such products are used in compliance with the requirements of the Pentair Hydromatic

catalog and technical manuals for use in pumping raw sewage, municipal wastewater or similar, abrasive-free,

noncorrosive liquids.

During the warranty period and subject to the conditions set forth, Pentair Hydromatic, at its discretion, will repair

or replace to the original user, the parts that prove defective in materials and workmanship. Pentair Hydromatic

reserves the right to change or improve its products or any portions thereof without being obligated to provide such

a change or improvement for prior sold and/or shipped units.

Start-up reports and electrical schematics may be required to support warranty claims. Submit at the time of start up

through the Pentair Hydromatic website: http://forms.pentairliterature.com/startupform/startupform.asp?type=h.

Warranty is effective only if Pentair Hydromatic authorized control panels are used. All seal fail and heat sensing

devices must be hooked up, functional and monitored or this warranty will be void. Pentair Hydromatic will cover

only the lower seal and labor thereof for all dual seal pumps. Under no circumstance will Pentair Hydromatic be

responsible for the cost of field labor, travel expenses, rented equipment, removal/reinstallation costs or freight

expenses to and from the factory or an authorized Pentair Hydromatic service facility.

This limited warranty will not apply: (a) to defects or malfunctions resulting from failure to properly install, operate or

maintain the unit in accordance with the printed instructions provided; (b) to failures resulting from abuse, accident

or negligence; (c) to normal maintenance services and parts used in connection with such service; (d) to units that

are not installed in accordance with applicable local codes, ordinances and good trade practices; (e) if the unit is

moved from its original installation location; (f) if unit is used for purposes other than for what it is designed and

manufactured; (g) to any unit that has been repaired or altered by anyone other than Pentair Hydromatic or an

authorized Pentair Hydromatic service provider; (h) to any unit that has been repaired using non factory specified/

OEM parts.

Warranty Exclusions: PENTAIR HYDROMATIC MAKES NO EXPRESS OR IMPLIED WARRANTIES THAT EXTEND

BEYOND THE DESCRIPTION ON THE FACE HEREOF. PENTAIR HYDROMATIC SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE.

Liability Limitation: IN NO EVENT SHALL PENTAIR HYDROMATIC BE LIABLE OR RESPONSIBLE FOR

CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES RESULTING FROM OR RELATED IN ANY MANNER TO

ANY PENTAIR HYDROMATIC PRODUCT OR PARTS THEREOF. PERSONAL INJURY AND/OR PROPERTY DAMAGE

MAY RESULT FROM IMPROPER INSTALLATION. PENTAIR HYDROMATIC DISCLAIMS ALL LIABILITY, INCLUDING

LIABILITY UNDER THIS WARRANTY, FOR IMPROPER INSTALLATION. PENTAIR HYDROMATIC RECOMMENDS

INSTALLATION BY PROFESSIONALS.

Some states do not permit some or all of the above warranty limitations or the exclusion or limitation of incidental or

consequential damages and therefore such limitations may not apply to you. No warranties or representations at any

time made by any representatives of Pentair Hydromatic shall vary or expand the provision hereof.

740 EAST 9TH STREET 490 PINEBUSH ROAD, UNIT #4

ASHLAND, OHIO, USA 44805 CAMBRIDGE, ONTARIO, CANADA N1T 0A5

419-289-1144 800-363-PUMP

WWW.HYDROMATIC.COM

Warranty Rev. 12/13

Page 13

S8L

S4T

MODELS S4T, S8L,

S8LA and S12L

SUBMERSIBLE

SOLIDS HANDLING PUMPS

INSTALLATION AND SERVICE MANUAL

For use with product built with GE® motor.

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-342 | Part # 5625-342-1 | © 2012 Pentair Pump Group, Inc. | 10/25/12

Page 14

General

Information

Thank you for purchasing your

Hydromatic

ensure years of trouble-free

op er a tion, please read the

fol low ing manual carefully.

Before Operation:

Read the following in structions care ful ly. Reasonable care

and safe meth ods should be

practiced. Check local codes and

requirements before installation.

Attention:

This manual contains important

information for the safe use of

this product. Read this manual

completely before using this

product and refer to it often

for con tin ued safe product use.

DO NOT THROW AWAY OR

LOSE THIS MAN U AL. Keep

it in a safe place so that you may

refer to it often.

Unpacking Pump:

Remove pump from carton.

When un pack ing unit, check for

con cealed damage. Claims

for damage must be made at

the receiving end through the

delivery carrier. Dam age cannot

be processed from the factory.

WARNING: Before handling

these pumps and controls,

always disconnect the power

first. Do not smoke or use

sparkable electrical devices or

flames in a septic (gaseous) or

possible septic sump.

2

®

pump. To help

CALIFORNIA PROPOSITION

65 WARNING:

This product and

related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductive

harm.

Pumps Not Operating or

in Storage:

Pumps with carbon ceramic seals

must have impellers manually

rotated (6 revolutions) after

setting non-op er a tion al for 3

months or longer and prior to

electrical start-up.

Pumps with tungsten carbide seals

must have impellers manually

rotated (6 revolutions) after

setting non-op er a tion al for

3 weeks or longer and prior to

electrical start-up.

Pump:

The submersible pumps are

supplied for three phase only and

for 230, 460 or 575 volts. Power

cable is supplied with ground. Be

sure ground wire is con nect ed to a

water pipe or ground stake.

Seal Failure:

An electrode probe is installed in

the seal chamber so if any water

enters the chamber through the

first seal the electrode will be

energized and a sig nal will be

transmitted to the sens ing unit at

ground surface causing a red light

to turn on. The electrode probe

is installed in all units but the

sensing unit is supplied at extra

cost and must be ordered.

In operation the seal failure unit

in di cates only that there is some

water in the seal chamber. The

pump will con tin ue to operate

without damage but the seal

should be checked im me di ate ly

after failure is indicated.

The sensing unit is recommended

on all installations as good

insurance against motor failure.

Heat Sensors—

Standard Equipment:

All motors have heat sensor units

em bed ded in the motor winding

to detect excessive heat. The heat

sen sors are set to trip at 105°C,

so will not op er ate unless

dangerous heat occurs. The

sensors automatically reset when

mo tor cools to safe tem per a ture.

The sensors are connected in

series with the motor starter coil

so that the starter is tripped if heat

sensor opens. The motor starter is

equipped with overload heaters so

all normal over loads are protected

by the starter.

Sump Level Control:

Sump level is controlled by

Hydromatic float switch con trols.

The float is held in position in

the sump by a weight at tached to

the power cord above the float.

The cord supports the float

and is adjusted for height from

the sur face.

Duplex systems use three

controls: one set at turn-off, one

set at turn-on for one pump, and

one set for turn-on for two pumps.

Pumps alternate op er a tion on each

successive cycle.

Two pumps operate together only

if sump level rises to the third

or over ride control. The override

control also brings on the second

pump in case of failure of the first

pump. The extra float is for alarm.

Triplex systems use four controls:

one set at turn-off, one set at

turn-on for one pump, one set

at turn-on for two pumps, and

one set at turn-on for three

pumps. Pumps alternate each

successive cycle.

Page 15

Three pumps operate together

only if sump level rises to the

fourth control (second override).

This control also brings on

the third pump in case of failure

of either or both of the first

two pumps.

Alarm Controls:

The alarm level is usually set

above the override level so the

alarm will signal only if the

override level is ex ceed ed.

However, some engineers prefer

to have the alarm level set be low

the override level as it is pos si ble

for one pump to fail and the other

pump to operate on the override

level with the sump level never

reach ing the alarm level. This is

par tic u lar ly true in cases of low

inflow ca pac i ty.

Electrical Control Panel:

Hydromatic electrical equip ment

is installed in a weatherproof

NEMA 3R enclosure. The

electrical equip ment includes

a main circuit breaker for each

pump, a magnetic starter with

overload protection for each

pump, an H-O-A switch and run

light for each pump, an electric

alternator and a transformer to

provide appropriate control for

control and circuit and alarms.

Installation

Instructions

Installing Pump in Sump:

Before installing pump in sump,

lay it on side and turn impeller

manually. Impeller may be

slightly stuck due to factory test

water, so it must be broken loose

with small bar or screwdriver

in edge of vanes. After breaking loose, the impeller should

turn freely.

Clean all trash and sticks from

sump and connect pump to piping.

A check valve must be installed

on each pump. A gate or plug

valve in each pump discharge

line is also recommended. This

valve should be installed on the

discharge side of the check valve

so if it is necessary to service the

check valve, the line pressure can

be shut off.

NEMA IV Junction Box:

(optional)

This must be used with 60 and

above horsepower pumps and

with all systems if the electrical

control panel is to be set remote

from the pumps. The Hydromatic

NEMA 4 junction box is provided

with com pres sion connectors

for sealing all wires. No sealing

compound is needed to make

connections wa ter proof.

Wiring diagrams are provided

with the panel for making

connections. The size wire to use

from panel to sump depends on

motor size and distance in feet.

Be sure each wire is checked so

that a wrong connection will not

be made. An ohmmeter or

Megger can be used to check

wire continuity.

Installing Float Switch

Controls:

The controls are supported by a

mounting bracket that is attached

to sump wall, cover, or to the

NEMA 4 junction box. Cord

snubbers are used to hold the cord

in place. Control level can be

changed at any time by loosening

the snubber and readjusting

cord height.

In either duplex or triplex

systems, the bottom of the lower

or turn-off control is set just above

the top of volute, so that the

volute will always be submerged

during the pumping cycle. The

second, or turn-on control, is set

about 24 inches above the lower

turn-off control.

More distance between turn-on

and turn-off controls can be used,

but sewage may become septic,

and excessive solids may collect

for the pump to handle. A frequent

pumping cycle is recommended

for best operation.

In a duplex system the third or

override control is usually set

about 6 inches above the one

pump turn-on control.

In a triplex system the third or

override control is usually set

24 inches above the one pump

turn-on control, and the fourth

or second override control is 24

inches higher.

If an alarm system is used, this

control is usually set about 6

inches above the override control.

Making Electrical Connections:

All electrical wiring must be in

ac cor dance with local codes, and

only competent electricians should

make the in stal la tions. Complete

wiring diagrams are glued to the

inside cover of the panel. All wires

should be checked for grounds

with an ohmmeter or Megger after

the con nec tions are made. This is

important, as one grounded wire

can cause considerable trouble.

IMPORTANT: If equipment is

not properly wired and protected

as rec om mend ed, the warranty

is void.

3

Page 16

Installation

Instructions

Heat Sensors and Seal Failure

Connections:

Be sure heat sensor wires are

con nect ed in series with the

starter coil. Con nec tions are

provided on the terminal strip.

Pump

Operations

Starting System:

1. Turn H-O-A switch to

Off position and then turn on

main circuit breakers.

2. Open all discharge valves and

allow water to rise in sump.

3. Turn H-O-A switch to Hand

posi tion on one pump and

notice oper ation. If pump is

noisy and vibrates, rotation

is wrong. To change rotation,

interchange any two line leads

to motor 3ø only. Do not

interchange main incoming

lines. If duplex system, check

second pump in same manner.

4. Now set both H-O-A switches

to Auto position and allow

water to rise in sump until

one pump starts. Allow pump

to operate until level drops to

turn-off point.

5. Allow sump level to rise to

start other pump. Notice run

lights on panel. Pumps should

alternate on each successive

cycle of op er a tion.

6. Turn both H-O-A switches

to Off position and allow

sump to fill to the override

control level.

7. Turn both switches to Auto

position and both pumps should

start and operate together until

level drops to turn-off point.

8. Repeat this operation cycle

several times before leaving

the job.

9. Check voltage when pumps

are operating and check the

amp draw of each pump.

Check amps on each wire,

as sometimes a high leg

will exist. One leg can be

somewhat higher (5 to 10%)

without causing trouble. For

excessive amp draw on one

leg, the power company should

be consulted.

As the motors are oil filled, no

lubrication or other maintenance

is required.

Generally, these pumps give

very reliable service, and can

be expected to operate for many

years on normal sewage pumping

without failure.

Field Service on Motor:

Submersible motors out of

warranty can be serviced in

the field by any reliable motor

service shop. Any pump in

warranty must be returned to the

factory for service or repaired

at an authorized Hydromatic

service center. Charges will not be

allowed if in warranty pump is not

WARRANTY IS VOID IF HEAT SENSORS ARE NOT

CONNECTED AS SHOWN (IN SERIES WITH CONTACTOR OIL)

TWO WIRE CONTROL OFFERING AUTOMATIC RESET

L1

ON-OFF

SWITCH

WARNING

COIL

taken to an authorized

Hydromatic

service center.

When field service is performed

on a pump, these instructions

should be carefully followed.

Replacing Stator:

1. If stator only is damaged,

it may not be necessary to

completely dismantle pump

as stator and housing can be

lifted from pump without

disturbing seals or bearings.

2. Drain all oil from upper

housing, remove drain plug in

bottom of stator housing and

remove plug in top of housing

to allow air to enter.

3. After chamber is drained,

remove hold-down bolts

and lift off. Use care in

lifting as the seal failure

connecting wire must be

dis con nect ed before housing

is com plete ly removed.

4. Set assembly on bench and

remove connection box. When

box is lifted off, connection

wires to motor will be exposed.

These wires will probably be

burned, but each wire is tagged

with a metal marker giving

wire number. Cut the wires.

If the leads to the connection

box are burned, a complete

new con nec tion box with new

wire must be used. The wires

are potted in with sealing

BLACK

THERMOSTATS

IN SERIES

L2

WHITE

4

THREE WIRE CONTROL OFFERING AUTOMATIC RESET

L1

IN CERTAIN APPLICATIONS THE NEC MAY REQUIRE THREE OVERLOAD RELAYS

COIL

OL OLSTART

BLACK

THERMOSTATS

IN SERIES

WHITE

L2

Page 17

compound and a new unit

must be obtained from

the factory.

5. The stator is held in the

housing with a bolted-in

retaining ring and prevented

from rotating by a key.

6. Remove the retaining ring and

socket head cap screw.

7. After ring is removed, turn

housing upright and bump on

hard wood blocks. This should

jar the stator loose and allow it

to drop out.

8. Thoroughly clean housing

before replacing new stator.

Replace stator and make all

wire con nec tions to connection

box before replacing housing

on pump. This is important as

leads must be tucked behind

the windings by using hands

up through rotor core.

Do not tape leads as oil will

de te ri o rate the tape and cause

damage to stator and bearings.

9. Check top bearing. If clean and

does not turn rough, bearings

can be reused and it is not

necessary to completely

dismantle pump to change

bearings. If bearings are

damaged with dirt or heat,

they must be re placed.

10.Replace stator housing onto

seal chamber and bolt in place.

Be sure seal failure wire is

connected before housing is

assembled. Be sure back-off

screws have been loosened

so that parts can come metal

to metal. Be sure O-ring seal

has been replaced. If O-ring

is nicked or cut, replace with

new ones. This applies to all

O-rings used in assembly.

11.After all leads are reconnected

in the connection box, make

a high voltage ground test

on each wire. The only wire

that should show ground is

the green power lead and the

ground lead in the auxiliary

control cable.

12.For safety, complete pump

should be air checked under

water for leaks. Lay pump on

side for this oil filling with

oil fill hole upright. Do not

completely fill; leave oil about

1 inch below plug hole. Use

only Hydromatic submersible

oil in this chamber. Replace

plug; use Permatex on threads.

Install air valve in top plug

opening of motor housing and

charge housing with about

10 psi of air. Be sure air is dry.

Do not use air line where water

may be trapped in the line.

Submerge complete unit under

water and check for leaks.

13.Refill motor chamber with

oil. Use Hydromatic special

sub mers ible oil. Fill chamber

until oil covers top of the

windings. Leave air space in

the top for expansion. Use

Permatex on plug threads.

Replacing Seals and Bearings:

1. Drain all oil from motor

chamber and seal chamber

as described.

2. Remove motor housing

as described.

3. Remove bolts that hold seal

chamber to pump housing.

Use back-off screws to break

loose. With hardwood block,

tape end of impeller to loosen

from shaft. When free, remove

impeller from shaft.

4. Lift rotating assembly from

pump case and place on bench.

5. Impeller Removal: Hold rotor

and remove bolt and washer

from impeller end of shaft,

then thread bolt back into shaft.

The impeller is keyed to the

shaft, so by using a screwdriver on opposite sides behind the

im pel ler, apply force then tap

on the end of the bolt to break

impeller loose from taper shaft.

Remove impeller.

6. Remove key and pry on each

side of shoulder of shaft sleeve

to remove. Seal should come

off with sleeve. If sleeve is not

free, leave in place and push

off when seal plate is removed.

7. To remove seal plate take

out socket head flat screws

and using screws in back-off

holes pry plate loose. This

will also force seal off if not

already re moved.

8. Remove snap ring that holds

upper seal. Pull seal if it is free.

If not free, it can be forced off

when shaft is removed.

9. Set seal housing assembly in

upright position and bump end

of shaft on hardwood block.

This will push the bearing

from the housing and will force

upper seal from shaft.

10.Use bearing puller to remove

bearings. Replace with new

bearings. Press only on the

inner face of bearing when

replacing. Pressing on outer

face can damage the bearing.

IMPORTANT—Do not use any

of the old seal parts. Replace

with all new seals.

11.Thoroughly clean all castings

before replacing seals. One

grain of dirt between the seal

faces can cause failure.

12.Examine all O-Rings for nicks

before reusing.

13.Be sure key is in place in

notch of shaft sleeve to prevent

sleeve from turning.

14.Use Locktite

®

on socket head

locking screw in end of shaft.

5

Page 18

15.Before refilling chamber

with oil, air test as described

above and refill both chambers

with oil.

16.Always check all leads with

high voltage or with Megger

for grounds before operating

the pump.

Pump

Troubleshooting

Below is a list of common

problems and the probable causes:

Pump will not start.

Pump operates with selector

switch in Hand position but will

not operate in Auto position.

1. This indicates trouble in

the level control or the

alternator relay.

2. Check control panel for trouble.

Pump runs but will not shut off.

1. Pump may be air locked.

Turn pump off and let set for

several minutes, then restart.

2. Lower float control may be

hung-up in the closed position.

Check in sump to be sure

control is free.

3. Selector switch may be in the

Hand position.

Motor stops and then restarts

after short period but overload

heaters in starter do not trip.

1. This indicates heat sensors

in the motor are tripping due

to ex ces sive heat. Impeller

may be partially clogged

giving a sus tained overload

but not high enough to trip

overload heater switch.

2. Motor may be operating

out of liquid due to a failed

level control.

3. Pump may be operating on

a short cycle due to sump

being too small or from water

returning to sump due to a

leaking check valve.

1. No power to the motor.

Check for blown fuse or open

circuit breaker.

2. Selector switch may be in the

Off position.

3. Control circuit transformer

fuse may be blown.

4. Overload heater on starter may

be tripped. Push to reset.

Pump will not start and

overload heaters trip.

1. Turn off power and check

motor leads with Megger or

ohmmeter for possible ground.

2. Check resistance of motor

windings. All 3 phases should

show the same reading.

3. If no grounds exist and

the motor windings check

OK, remove pump from sump

and check for clogged or

blocked impeller.

Pump does not deliver proper

capacity.

1. Discharge gate valve may

be partially closed or

partially clogged.

2. Check valve may be partially

clogged. Raise level up and

down to clear.

3. Pump may be running in

wrong direction. Low speed

pumps can operate in reverse

direction without much noise

or vibration.

4. Discharge head may be

too high. Check total head

with gauge when pump is

operating. Total head is

discharge gauge pressure

converted to feet plus vertical

height from water level in

sump to center line of pressure

gauge in discharge line. Gauge

should be installed on pump

side of all valves. Multiply

gauge pressure in pounds by

2.31 to get head in feet.

6

5. If pump has been in service for

some time and capacity falls

off, remove pump and check

for wear or clogged impeller.

Page 19

S4T Parts List

For use with product built with GE® motor.

Ref. Part Part

No. No. Description Qty.

1 00238-006-1 Capscrew 6

2 00087-004-1 1/8” Pipe Plug 1

3 00282-001-1 Wire Connector 3

4 01664-002-1 1/8” Pipe Plug Brz 1

5 RTF Cord Assy. 1

6 02498-008-1 Split Bolt Connector 3

7 06000-011-1 Seal Failure Conn Wire 1

8 03718-005-1 Up per Seal S 1

9 03718-005-1 Lower Seal, ceramic (std) S 1

03718-002-1 Lower Seal, carbide (opt) C 1

10 08472-002-5 Seal Failure Probe 1

11 00150-038-1 O-Ring SC 2

12 00924-003-1 1/2 Pipe Plug, brz 2

13 11065-002-3 Bearing Plate Screen 1

14 00239-035-1 1/2 Hex Hd Capscrew 12

15 07398-000-2 Seal Housing 1

16 02310-004-3 Seal Sleeve SC 1

17 00150-108-1 O-Ring SC 1

18 03879-002-1 Soc Hd Capscrew 1

19 00829-009-1 Machine Screw 4

20 13695-000-3 Wear Ring 1

21 13532-101-2 Impeller 15” Dia 1

13532-105-2 Impeller 14” Dia 1

13532-109-2 Impeller 13” Dia 1

22 01945-001-3 Impeller Washer 1

23 13688-000-2 Volute 1

24 02855-001-1 Impeller Key 1

25 02921-001-1 Flt Hd Soc Capscrew 4

26 07401-000-2 Bearing Housing 1

27 00150-057-1 O-Ring SC 1

28 00239-024-1 Hex Hd. Capscrew 4

29 00975-014-1 Snap Ring 1

30 00065-023-1 Lower Bearing 1

31 08354-000-3 Stator Retaining Ring 1

32 00975-010-1 Snap Ring 1

33 00556-007-1 Soc. Hd Capscrew 6

34 07400-000-2 Motor Housing 1

35 RTF Stator 1

36 RTF Rotor w/shaft 1

37 00065-006-1 Upper Bearing 1

38 00064-005-1 Load Spring 2

39 11667-000-1 Connector 3

40 01124-002-1 5/8” Jam Nut 2

41 00589-004-1 5/8” Eyebolt 2

42 00239-005-1 Hex Hd Capscrew 6

43 00150-032-1 O-Ring SC 2

44 08372-000-5 Conn Box 1

45 00557-000-1 Connector 3

46 08675-000-1 Insulator (split bolt) 3

51700-068-7 Seal Kit S 1

51700-368-7 Carbide Seal Kit C 1

Notes: S — Parts in Seal Kit C — Parts in Carbide Seal Kit RTF — Refer To Factory

— Fill Oil to above the Motor Windings

5

2

6

46

42

4

3

38

37

35

36

7

14

10

8

11

9

16

21

32 24 22 17 18 20 19 27 25 23

29

43

45

44

43

41

40

39

13

34

30

33

31

26

28

11

12

1

15

7

Page 20

S8L Parts List

For use with product built with GE® motor.

Ref. Part Part

No. No. Description Qty.

1 00238-006-1 Hex Head Mach. Screw 6

2 14981-001-1 1/4” Pipe Plug 1

3 00282-001-1 Wire Connector 3

4 01664-008-1 3/8” Pipe Plug Br. 3

5 11065-002-3 Bearing Plate Screen 1

6 03718-005-1 (Carbon/Ceramic) Viton

7 06000-011-1 Seal Fail ure Conn. Wire 1

8 08662-006-1 75 HP Spac er Ring 1

08662-010-1 40 HP Spac er Ring 1

08662-009-1 20 & 25 HP Spacer Ring 1

9 06579-002-1 Stator Lock ing Key 1

10 3718-005-1 Upper Seal 1

11 00975-010-1 Snap Ring 1

12 08472-002-5 Seal Fail ure Probe 1

13 00150-038-1 O-Ring SC 2

14 00073-001-1 Wire Connector 3

15 00239-026-1 1/2” Hex Hd. Cap Screw 10

16 07398-000-2 Seal Hous ing 1

17 02310-002-3 Seal Sleeve SC 1

18 00150-108-1 O-Ring SC 1

19 03879-002-1 Soc. Hd. Capscrew 1

20 07597A021 Flt. Hd. Capscrew 4

21 08345-000-2 Wear Ring 1

22 07395-000-2 Impeller 15” x 15” Dia. 1

07395-001-2 Impeller 15” x 14” Dia. 1

07395-008-2 Impeller 14.85” x 13.85” Dia. 1

07395-014-2 Impeller 14.25” x 13.25” Dia. 1

07395-010-2 Impeller 13.75” x 12.75” Dia. 1

07395-018-2 Impeller 13.37” x 12.37” Dia. 1

07395-005-2 Impeller 13” x 12” Dia. 1

07395-012-2 Impeller 12.13” x 11.13” Dia. 1

23 01945-001-3 Imp. Washer 1

24 07394-000-2 Volute Case 1

25 02855-001-1 Imp. Key 1

26 02921-001-1 Flt. Hd. Soc. Capscrew 4

27 RTF Cord Assy. 1

28 07401-000-2 Bearing Housing 1

29 00150-057-1 O-Ring SC 1

30 00239-024-1 Hex Hd. Capscrew 4

31 00975-014-1 Snap Ring 1

32 00065-023-1 Lower Bearing 1

33 08354-000-3 Stator Retaining Ring 1

34 00556-007-1 Soc. Hd. Capscrew 6

35 07400-000-2 Motor Housing 1

36 RTF Stator 1

37 RTF Rotor w/Shaft 1

38 00065-006-1 Upper Bearing 1

39 09176-000-1 Wire Sleeve 3 Ft.

40 00064-005-1 Load Spring 2

41 11667-000-1 Elec. Conn. 30–125 HP 3

01006-001-1 Elec. Conn. 15–25 HP 575V 3

42 01124-002-1 5/8” Jam Nut 2

43 00589-004-1 5/8” Eye Bolt 2

44 00239-005-1 Hex Hd. Capscrew 6

45 00150-032-1 O-Ring SC 2

®

1

Ref. Part Part

No. No. Description Qty.

46 08372-000-5 Conn. Box Assy. 60–125 HP & 1

30 HP 230V

08372-001-5 Conn. Box Assy. 30–40 HP & 1

50 HP 575V

08372-002-5 Conn. Box Assy. 15–25 HP 575V 1

08372-003-5 Conn. Box Assy. 15–25 HP 230/460V 1

08372-004-5 Conn. Box Assy. 50 HP 230/460V 1

47 02494-000-1 Cord Nut 20–25 HP 460/575V 3

00853-000-1 Cord Nut 15 HP 460V 6

00853-000-1 Cord Nut 15 HP 575V 20–25 HP 460V 3

1

2

3

4

5

7

8

9

10

11

12

13

14

15

27

47, 48

14

46

45

44

43

42

41

40

38

39

37

36

35

31

34

33

32

30

29

28

26

25

24

23

216 202219181716

Ref. Part Part

No. No. Description Qty.

02494-000-1 Cord Nut 15–25 HP 230V 4

02498-008-1 Split Bolt Conn. 100–125 HP 3

30 HP 200V

02498-007-1 Split Bolt Conn. 60–75 HP 30 HP 230V 3

02498-005-1 Split Bolt Conn. 30–50 HP 460/575V 3

48 08675-000-1 Insulator (Split Bolt) 3

03718-002-1 Lower Seal (Carbide) Optional C 1

51700-020-7 Seal Kit

51700-320-7 Carbide Seal Kit

Notes: S — Parts in Seal Kit C — Parts in Carbide Seal Kit RTF — Refer To Factory

— Fill Oil to above the Top of Motor Windings

8

Page 21

S8LA Parts List

For use with product built with GE® motor.

Ref. Part Part

No. No. Description Qty.

1 00238-006-1 Capscrew 6

2 14891-001-1 1⁄4”PipePlug 1

3 00282-001-1 Wire Connector 3

4 01664-008-1 3/8” Pipe Plug Brz 3

5 11065-002-3 Bearing Plate Screen 2

6 13536-000-3 Clamp Ring 1

7 06000-011-5 Seal Failure Conn Wire 1

8 03718-000-1 Upper Seal S 1

9 03718-000-1 Lower Seal, ceramic (std) S 1

03718-001-1 Lower Seal, carbide (opt) C 1

10 08472-002-5 Seal Failure Probe 1

11 00150-038-1 O-Ring SC 2

12 RTF Cord Assy. 1

13 00239-035-1 1/2 Hex Hd Capscrew 12

14 07398-000-2 Seal Housing 1

15 02310-004-3 Seal Sleeve SC 1

16 00150-108-1 O-Ring SC 1

17 03879-002-1 Soc Hd Capscrew 1

18 04756-005-1 Machine Screw 4

19 13535-000-3 Wear Ring 1

20 13532-009-2 Impeller 15” Dia 1

13532-001-2 Impeller 14” Dia 1

13532-005-2 Impeller 13” Dia 1

21 01945-001-3 Impeller Washer 1

22 07394-000-2 Volute 1

23 02855-001-1 Impeller Key 1

24 02921-001-1 Flt Hd Soc Capscrew 4

25 02498-008-1 Split Bolt Connector 3

26 07401-000-2 Bearing Housing 1

27 00150-057-1 O-Ring SC 1

28 00239-024-1 Hex Hd. Capscrew 4

29 00975-014-1 Snap Ring 1

30 00065-023-1 Lower Bearing 1

31 08354-000-3 Stator Retaining Ring 1

32 00975-010-1 Snap Ring 1

33 00556-007-1 Soc. Hd Capscrew 6

34 07400-000-2 Motor Housing 1

35 RTF Stator 1

36 RTF Rotor w/shaft 1

37 00065-006-1 Upper Bearing 1

38 00064-005-1 Load Spring 2

39 11667-000-1 Connector 3

40 01124-002-1 5/8” Jam Nut 2

41 00589-004-1 5/8” Eyebolt 2

42 00239-005-1 Hex Hd Capscrew 6

43 00150-032-1 O-Ring 2

44 08372-000-5 Conn Box 1

45 00557-000-1 Connector 3

46 08675-000-1 Insulator (split bolt) 3

51700-068-7 Seal Kit S 1

51700-368-7 Carbide Seal Kit C 1

Notes: S — Parts in Seal Kit C — Parts in Carbide Seal Kit RTF — Refer To Factory