OWNER’S MANUAL

Utility Sink Pump

NOTICE D’UTILISATION

Pompe à usage général

pour évier

MANUAL DEL USUARIO

Bomba de uso general

para fregadero

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-888-957-8677

English .......................... Pages 2-6

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.HYDROMATIC.COM

PH: 8889578677

© 2013 Pentair, Ltd. All Rights Reserved. HYD847 (Rev. 03/04/13)

HPUSP125

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

Français ..................... Pages 7-11

1 (888) 957-8677

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-888-957-8677

Español .................. Paginas 12-16

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential for

personal injury:

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

personal injury, death or major property damage if ignored.

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which are

important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

1. Read this manual carefully. Failure to follow these

instructions could cause serious bodily injury and/or

property damage.

2. Check your local codes before installing. You must

comply with their rules.

3. Connect the pump to a separate circuit with no other

appliances on the circuit. Consult a licensed electrician

for all wiring.

NOTICE: This pump does not require a connection to a

main stack vent, per the National Standard Plumbing Code

(NSPC) 2003 Section 11.7.9.

cause death. Unplug pump before working on it.

warns about hazards that can cause serious

warns about hazards that will or can cause

Hazardous voltage. Can shock, burn or

INSTALLATION

(SEE FIGURES 1 AND 2)

Electric Shock Hazard. Plug pump into a

properly grounded, GFCI protected outlet. Do NOT plug

in the pump until after it is completely installed. Do not

remove or modify the grounding pins on the plugs.

A

1

2

3

1-1/2” Pump

Inlet Port

1-1/4” Pump

Discharge

Sink Bottom with Drain Port;

Tail Piece integral with Sink

For easier maintenance,

use 2 short sections of

pipe connected by a

1-1/2” Solvent Union.

4

9

B

C

6

5

6

7

7

8

DESCRIPTION

This pump is designed to be used with a sink where a

gravity drain line is not available. Attach the pump to the

drain tail piece; the pump will start when water begins to

drain. Uses include basement laundry sinks, wet bars and

utility sinks.

SPECIFICATIONS

Power supply required ...................................115V, 60 HZ.

Liquid Temp. Range ..................... 32° – 120°F (0° – 50°C)

Individual Branch Circuit Required (min.) .............15 Amps

Pump Inlet ......................................................... 1-1/2" NPT

Pump Discharge ................................................ 1-1/4" NPT

Fire or explosion hazard. Do not use in

explosive atmospheres. Pump fresh water only with this

pump. Use with salt water or brine will void the warranty.

California Proposition 65 Warning

contain chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

This product and related accessories

Fittings Supplied: Qty.

A Sink Drain Screen 1

B 1-1/4” NPT x 1-1/4” Slip Check Valve 1

C 1-1/4” NPT Ball Valve 1

Purchase Separately: Qty.

1 1-1/2” NPT x 1-1/2” Slip Female Adapter 1

2 1-1/2” Schedule 40 PVC Pipe, to fit 1

3 1-1/2” NPT x 1-1/2” Slip Male Adapter 1

4 1-1/4” NPT Galvanized Nipple (to fit) 1

5 1-1/4” NPT Galvanized Union 1

6 1-1/4” NPT x 1-1/4” Male Adapter 2

7 1-1/4” Schedule 40 PVC Pipe, to fit 4

8 1-1/4” Socket to Socket 90° Elbow 1

9 1-1/4” Schedule 40 PVC Pipe to Drain As Needed

PVC Pipe Cement As Needed

PTFE pipe thread sealant tape As Needed

1-1/2” Plastic Solvent Union

(For Drop Pipe – Optional)

NOTE: Be careful to avoid cross-threading;

Use only a plastic-compatible pipe-threading

compound or PTFE pipe thread sealant tape

when connecting threaded fittings to plastic adapters.

Figure 1: Typical method of mounting the pump.

Installation 3

PUMP INSTALLATION

Mount the pump

NOTICE: DO NOT use plumber’s pipe threading

compound (“pipe dope”) on plastic pipe; it can damage

the plastic, causing leaks and piping failure and voiding

the warranty.

1. Place the sink in its final location.

2. Remove any existing drain fittings back to the tail

piece (Figure 1). Make sure the existing tail piece does

not leak.

NOTICE: If the sink-drain tail piece is not 1-1/2" NPT,

you will have to adapt it (bushings, reducers, etc.). In

this case, wrap all joints with PTFE pipe thread sealant

tape before making connections.

3. Glue the 1-1/2” PVC pipe into the female adapter

(purchase separately).

follow the cement manufacturer’s instructions when

using PVC cement. Do not use near fire or open

flame.

4. Wrap the threads of the tail piece with 1 to 1-1/2

turns of PTFE pipe thread sealant tape. Thread the

1-1/2" NPT female adapter onto the sink-drain tail

piece. Thread it hand tight plus 1/2 turn with a pipe

wrench or slip joint pliers. DO NOT overtighten.

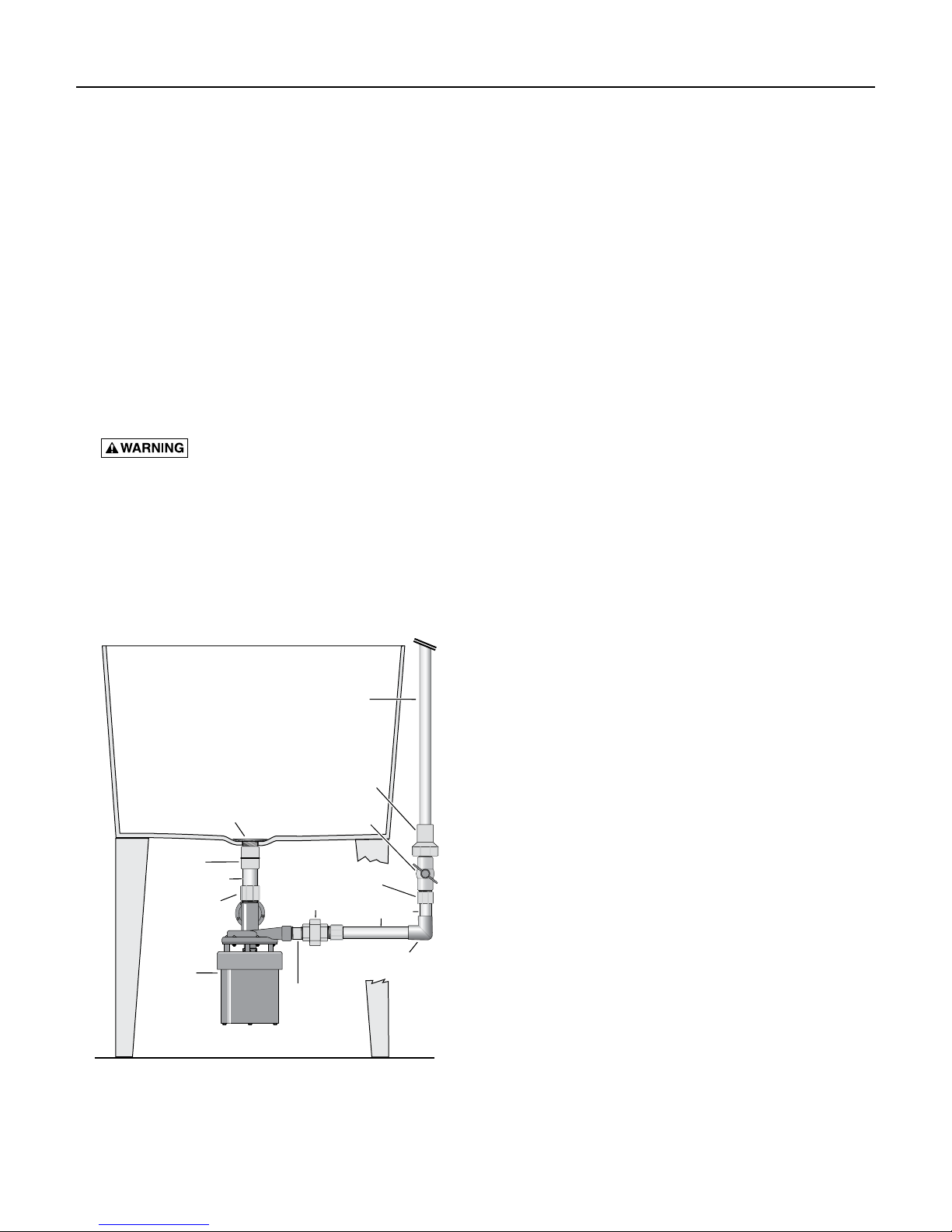

* Required and included

** Purchase separately

†

For easier removal for servicing or cleaning,

install a 1-1/2” solvent union in the drop pipe.

Figure 2: Pump Installed.

Fire and explosion hazard. Be sure to

Discharge Pipe**

Laundry

Sink

Check Valve*

Shut-Off/FlowBalancing Valve*

1-1/4” Male Adapter**

1-1/4” Union**

1-1/4” Socket to

Socket 90° Elbow**

1-1/4” Nipple**

1-1/2” Female

Adapter**

1-1/2” PVC**

1-1/2” Male

Adapter**

Pump*

Screen*

†

1-1/4” PVC

5799 0308

5. Wrap the threads of the 1-1/2” male adapter with

1 to 1-1/2 turns of PTFE pipe thread sealant tape

and install it in the pump inlet. Tighten it hand tight

plus 1/2 turn with a pipe wrench or slip joint pliers.

DO NOT overtighten!

6. Measure the 1-1/2” PVC pipe against the drain and

the pump and trim the pipe to fit.

7. Do a trial assembly (dry - no glue) of the pump onto

the drain pipe. Swing the pump until it accurately

faces the discharge piping, and then mark the pump

and the inlet pipe/adapter assembly so that you

can accurately install the pump in Step 8. Arrange

a temporary support under the pump to relieve the

strain on the sink drain piping while the glue is

setting. Leave it in place while you measure and cut

the discharge piping (Step 12).

8. Slide the pump up into position and glue the pipe into

the male adapter (on the pump).

• Don’t allow any glue to get on the pump or in

the motor;

• Make sure the pump is facing the correct direction

(match the marks from Step 7);

• Put the support in place under the motor.

9. Wrap the 1-1/4” galvanized nipple with 1-1/2 to 2

turns of PTFE pipe thread sealant tape on each end

and thread it into the pump discharge port.

NOTICE: Tighten this only enough to prevent leaking.

Over-tightening can crack the plastic.

10. Hold the nipple with a pipe wrench and thread one

half of the 1-1/4” union onto it, hand tight plus 1-1/2

turns with a pipe wrench or slip-joint pliers.

11. At this time, wrap the threads on both the 1-1/4”

male adapters with 1-1/2 to 2 turns of PTFE pipe

thread sealant tape. Thread one of the adapters into

the other half of the 1-1/4” union, hand tight plus

1/2 turn with a wrench or a pair of slip-joint pliers.

DO NOT overtighten!

12. Install the discharge piping as shown in Figures 1

and 2. The order is:

1-1/4” PVC Pipe cut to fit,

90° Socket to Socket elbow,

1-/14” PVC Pipe cut to fit,

Male adapter,

Flow Control/Ball Valve,

Check Valve,

(NOTICE: Install the check valve in the vertical

discharge pipe with the threads down. Be sure the flow

arrow points AWAY from the pump. That is, when the

check valve is correctly installed, the arrow showing

direction of flow should point UP.)

1-1/4” Outlet Pipe.

13. Connect the discharge piping to the building drain.

Plug in the Pump

AFTER the pump is completely installed, plug the switch

into a GFCI-protected, properly grounded outlet. Plug the

pump into the back of the switch’s plug.

Installation / Maintenance 4

Adjusting The Flow

The drain pump can pump up to 27 gallons per minute

(GPM). Normal sink drains allow only 5 to 6 GPM to

flow. Adjust the discharge shut-off/flow balancing valve as

follows so that the pump does not cycle on and off when

the faucets are on full.

1. Run water into the sink. The pump will start when it

detects water.

2. Check for leaks. If leaks are found, unplug the pump

power cord and fix the leaks before proceeding.

3. Put a stopper in the drain and allow the sink to fill up

a few inches.

4. Open the discharge shut-off valve, open the faucets,

and remove the stopper to drain the sink.

5. The pump will start. Adjust the discharge shut-off/flow

balancing valve until the pump runs continuously

while the faucets are running and the sink is draining.

If the water level rises with the pump on, slightly open

the discharge valve to balance the flow. If it drops,

slightly close the discharge valve.

Washing Machine Use

Washing machines usually discharge more water than

the faucets do, and it is normal for the water level to rise

in the sink while the pump is discharging. Do not adjust

the discharge valve to match the flow w hen the washing

machine discharges into it, unless the sink is ONLY used

for washing machine discharge.

NOTICE: Washing machine discharge water contains

fiber and lint. Unfiltered washing machine discharge

could plug the pump and require pump disassembly for

cleaning. To avoid this, install a lint trap or bag type filter

in the washing machine discharge line and clean it out

regularly.

MAINTENANCE

This pump requires very little maintenance and should

provide a long service life. Problems are rare; when the

pump flow drops off, the most likely cause is something

solid going down the drain and jamming the impeller.

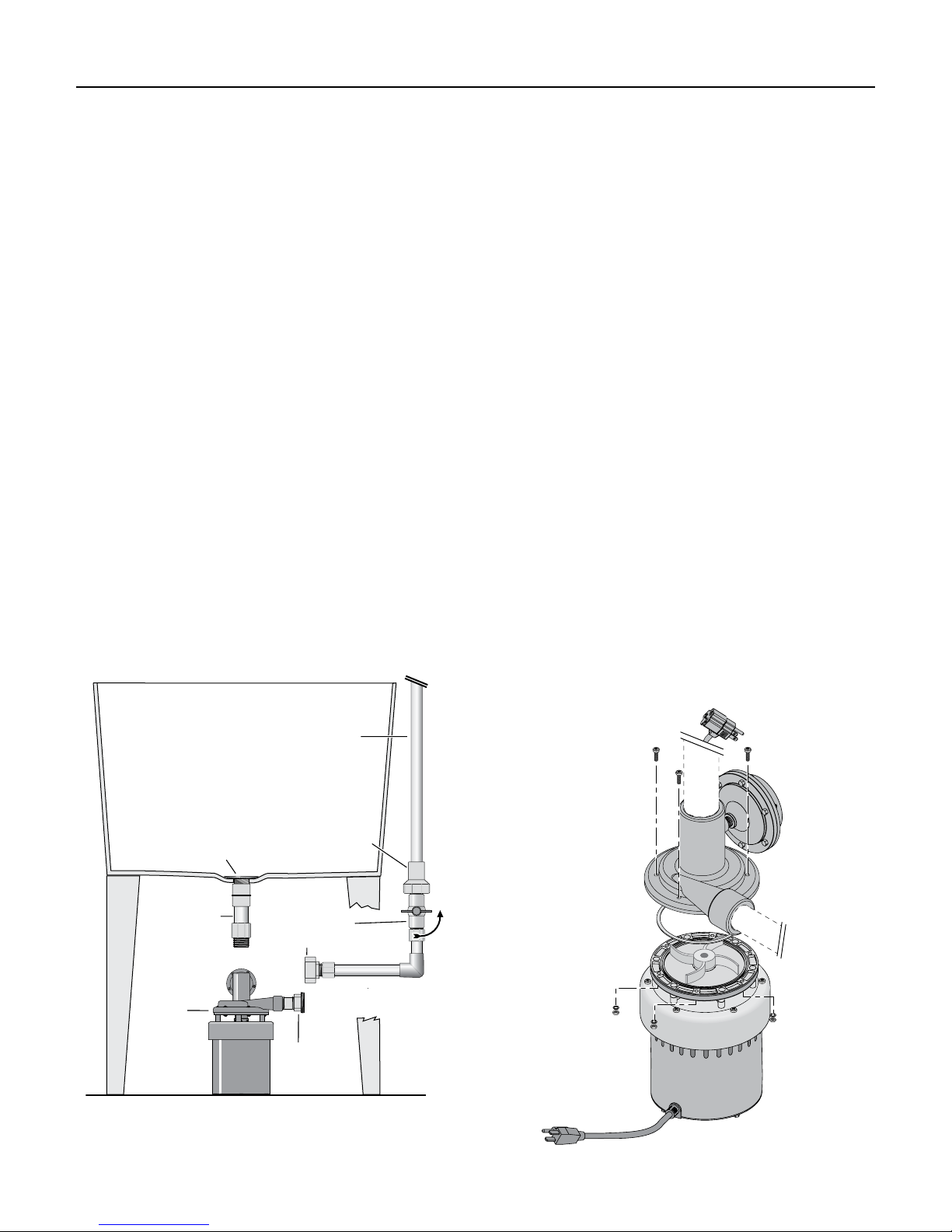

To clear a jammed impeller:

1. Unplug the Pump.

2. Close the discharge shutoff valve.

3. Bail out the sink as much as possible.

4. Disconnect the union, unscrew the pump from the

sink tail piece, lower the pump to the floor, and slide

it out from under the sink (see Figure 3).

5. Remove the six housing screws (see Figure 4).

6. Clean out the pump. Make sure that the pump

discharge is clear. If necessary, replace the impeller.

7. Install the new gasket (included with impeller).

Reassemble the pump.

8. Raise the pump back into position, thread it back onto

the sink tail piece, and reconnect the union.

9. Plug in the pump. Run water in the sink until the

pump has run at least one complete cycle to make

sure the pump is operating correctly and there are

no leaks.

Discharge Pipe

Discharge Pipe

Laundry

Laundry

Sink

Sink

Check Valve

Screen

Screen

†

1-1/2” PVC

1-1/2” PVC

Pump

Pump

†

†

For easier removal for servicing or cleaning,

For easier removal for servicing or cleaning,

install a 1-1/2” solvent union in the drop pipe.

install a 1-1/2” solvent union in the drop pipe.

†

Check Valve

Shut-Off/Flow-

Shut-Off/FlowBalancing Valve

Balancing Valve

1-1/4” Union Half

1-1/4” Union Half

1-1/4” Union

1-1/4” Union

Half

Half

Figure 3: Pump Removal.

5800 0308

5800 0308

5801 0308

Figure 4: Remove 6 housing screws to clean out pump.

Troubleshooting 5

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Pump does not run when water Pump unplugged. Plug in pump.

flows in from sink

Pump impeller jammed. Unplug pump; follow procedure under “Maintenance”

to clear pump.

Sink stopper in drain. Remove stopper.

Pump runs, but does not empty Drain clogged. Clear drain screen.

sink

Clogged discharge line. Unplug pump, open and clear discharge line.

Shut-off valve closed. Open shut-off valve slightly.

System discharge line too Unplug pump and reduce height or length of discharge line

high or too long. (11’ Max. Height).

Check valve installed Make sure flow arrow on check valve points away

backwards from pump.

Pump cycles on and off when Check valve not installed. Unplug pump and install check valve (see Figures 2

no water is in the sink and 3, Pages 3 and 4).

Check valve jammed. Unplug pump; open discharge line and clean check valve.

Pump cycles on and off when the Shut-off valve not adjusted. See “Adjusting the Flow”, Page 3.

sink is at maximum water

flow or is full

Outlet unpowered. Check fuse / breaker.

Shut-off valve not installed. Unplug pump and install shut-off valve (see Figures 2

and 3, Pages 3 and 4).

1

3

2

5802 0308

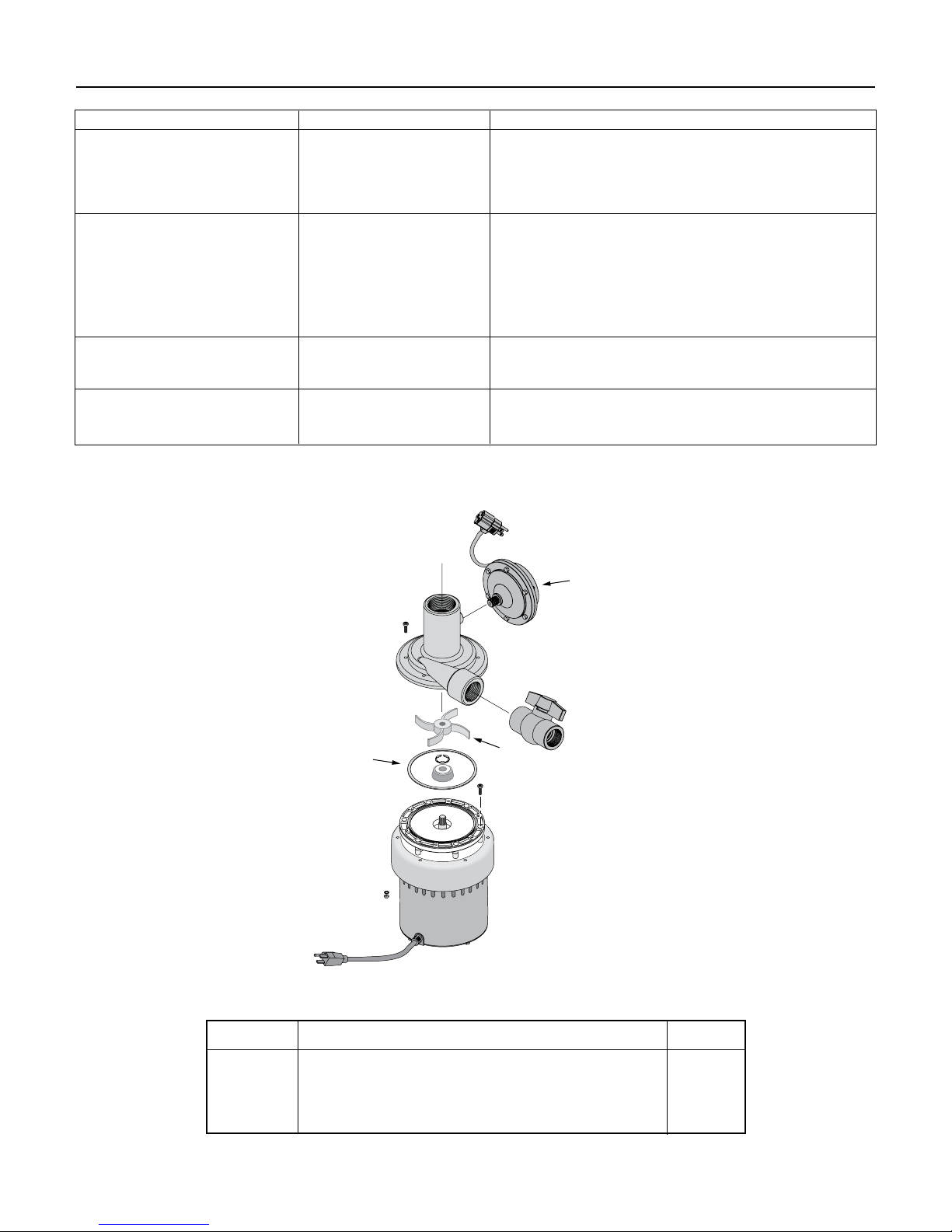

REPAIR KIT, Part No. PS20-137REP

Key No. Part Description Qty.

Kit Includes:

1 Diaphragm Switch 1

2 Impeller 1

3 Gasket 1

Loading...

Loading...