RETROFIT SYSTEMS

INSTALLATION AND SERVICE MANUAL

Engineered for quick and easy replacement of existing

progressive cavity grinder systems.

• Fully assembled

• Uses existing ball valve and latch

• Uses existing underground wiring and alarm panel

This manual covers the following retrofit systems:

• HPD200 Float Control

• HPD200 Pressure Control

• HPGR200 Float Control

• HPGR200 Pressure Control

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-482 | Part # 5625-482-1 | © 2014 Pentair Ltd. | 03/28/14

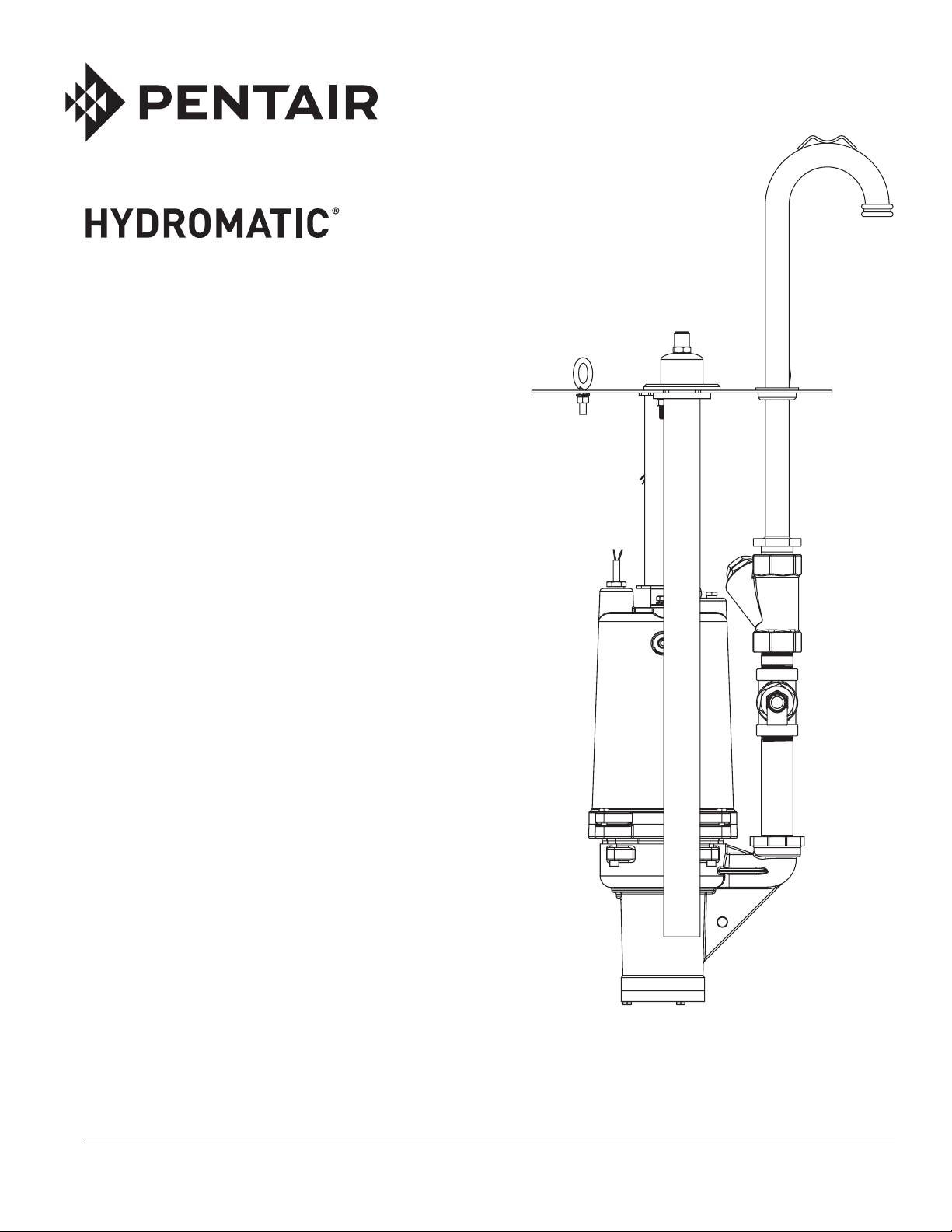

HPD200

Pressure Control

Shown

General

Information

ATTENTION: This manual

contains important information for

the safe use of this product. Read

this manual completely before

using this product and refer to it

often for continued safe product

use. DO NOT THROW AWAY

OR LOSE THIS MANUAL. Keep

it in a safe place so that you may

refer to it often.

Check local codes and

requirements before installation.

WARNING – Before handling

these pumps and controls, always

disconnect the power first. Do

not smoke or use sparkable

electrical devices or flames in a

septic (gaseous) or possible septic

sump.

CALIFORNIA PROPOSITION

65 WARNING:

This product and

related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductive

harm.

Grinder Installation

Instructions

1. Remove existing pump and

pipe system.

2. Make sure pump compartment

is clean of any debris.

3. Clean bolt hole (mating)

surface.

4. Make sure there is sufficient

amount of power/control/

alarm cord to be able to

splice into power/control/

alarm cords at the new

junction box.

5. Lift preassembled unit into

place using lift rope supplied.

6. Be sure that gasket stays in

place beneath cover.

7. Grease O-ring.

8. Guide tabs will line up with

existing alignment brackets.

Retrofit system discharge

piping should mate with

existing female socket.

9. After gooseneck is lined

up directly above ball

valve socket, drop into

place. Make certain that

adapter is forced all the

way into socket to ensure

a pressure-tight seal.

11. Attach cover with screws,

sleeves and washers provided.

12. Power, control cords, pressure

tubing (for PCP units only)

and high water alarm to be

routed through junction box.

13. Properly calibrate operation

of the unit by ensuring that

the liquid level in the basin

is at its lowest level when

the control panel cycles off.

Make sure to cut off excess

pressure tubing to prevent

condensation from forming

inside tubing.

Electrical Note: Ensure that

existing wiring is adequate for

the pump service requirements.

Pump

HPD200 12 20 amp

HPGR200 15 20 amp

Full Load

Amps

Circuit

Breaker

Installation

Instructions

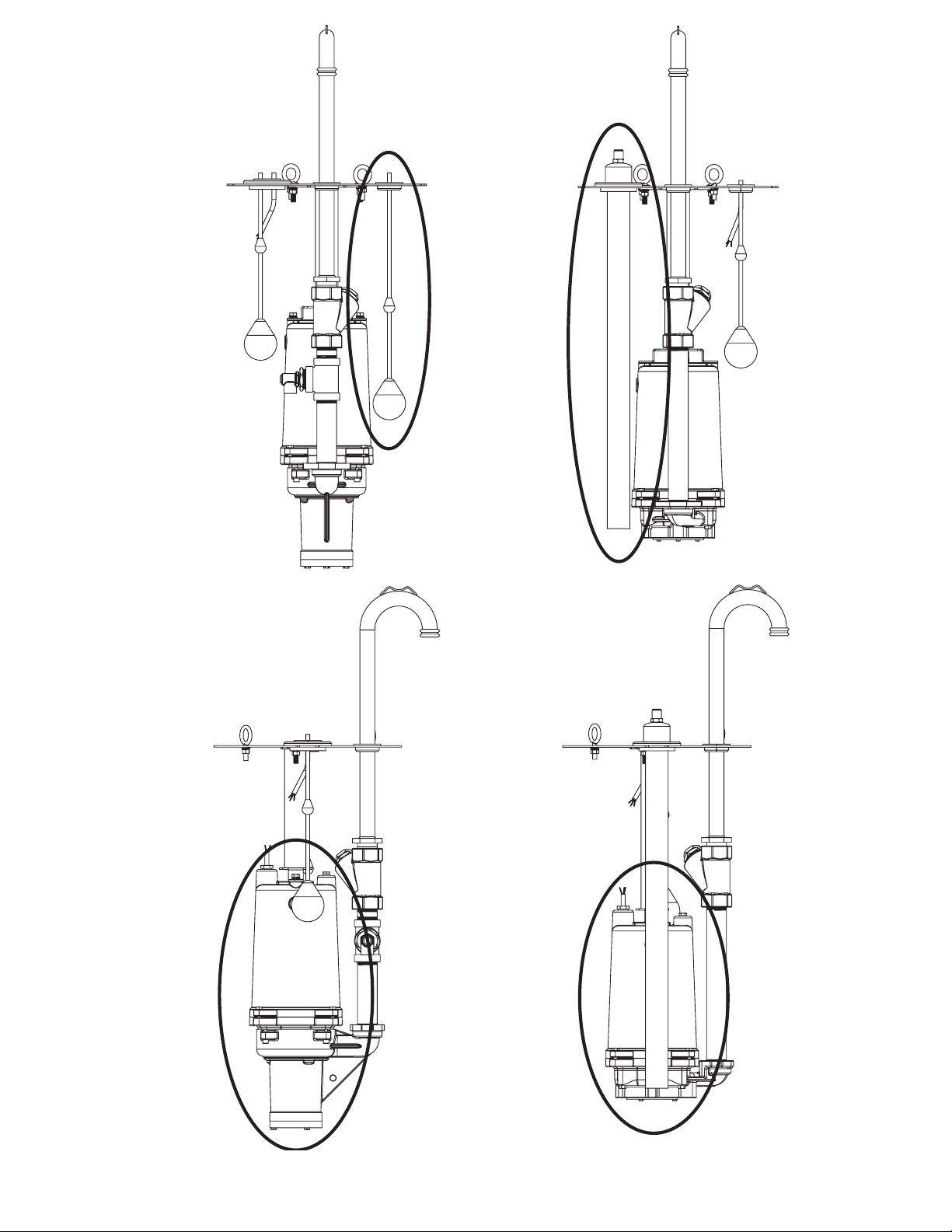

This manual covers retrofit

systems with either semipositive

displacement (HPD200) or

centrifugal (HPGR200) grinder

pumps using either pressure

controls or mechanical floats.

Please make sure you know which

system you are installing.

2

10. Rotate ball valve handle/latch

to secure piping and open

valve. If gooseneck is not

completely forced into the

female socket as described

above, ball valve handle/latch

will not close completely over

gooseneck piping.

Pressure ControlFloat Control

Semipositive Displacement Pump

(HPD200)

Centrifugal Pump

(HPGR200)

3

Loading...

Loading...