Pentair Hydromatic S4PP, Hydromatic H4HP, Hydromatic H3HP, Hydromatic S4MP, Hydromatic S4HVP Installation And Service Manual

...

INSTALLATION AND SERVICE MANUAL

HYDROMAT IC

SUBMERSIBLE

SOLIDS HANDLING

PUMP

Models

C4S(X)P, H3H(X)P,

H4H(X)P, S4M(X)P,

S4P(X)P, S4HV(X)P

and S4MV(X)P

(Class I, Division 1, Groups C & D): FM

ENGLISH: PAGES 2-12

Installation and Service Manual

For use with product built with Premium

Efficient motor.

Make sure this manual is provided to the owner

of the equip ment or to the responsible party who

maintains the system.

NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible

party who maintains the system.

Item # E-03-557 | Part # 056255571 | © 2018 Pentair plc | 09/25/18

(Hazardous Location

Motor End)

General Information

Attention:

This manual contains important

information for the safe use of this

product. Read completely and do not

throw away.

Reasonable care and safe methods

should be practiced. Check local codes

and requirements before installation.

Unpacking Pump:

When unpacking unit, check for damage.

Claims for damage must be made at

the receiving end through the delivery

carrier. Damage cannot be processed

from the factory.

WARNING: Before handling these

pumps and controls, always

disconnect the power first. Do not

smoke or use sparkable electrical

devices or flames in a septic

(gaseous) or possible septic sump.

CALIFORNIA PROPOSITION 65 WARNING:

This product and

related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductiveharm.

Pumps in Storage or Not Operating:

Pumps with silicon/carbide seals

must have impellers manually rotated

(6 revolutions) after setting nonoperational for 3 months or longer and

prior to electrical start-up.

Pumps with tungsten carbide seals

must have impellers manually rotated

(6 revolutions) after setting nonoperational for 3 weeks or longer and

prior to electrical start-up.

Seal Failure Probes:

All hazardous location submersible

pumps have two factory installed

moisture detectors (seal failure

probes). They are in a normally open

series circuit in the seal chamber.

Under normal operating conditions,

the circuit remains open. If the lower

seal leaks and moisture enters this

chamber, the moisture would settle to

the bottom of the chamber and will

complete the circuit between the

moisture detectors.

This circuit must be connected to a

sensing unit and signaling device. This

is supplied in a Hydromatic® built control

panel.

NOTE: Failure to install such a device

negates all warranties by Hydromatic.

Heat Sensors:

All motors in this family have heat

sensors on or embedded in the motor

winding to detect excessive heat.

This prevents damage to the motor.

If sensor trips due to excessive

winding temperature, the starter in

the panel breaks power to the pump.

Once the sensor resets, the starter is

automatically reset for FM for continued

operation of the pump. This circuitry is

supplied in a Hydromatic control panel.

The sensors are set to trip at 130°C.

NOTE: Failure to install such circuitry

would negate FM approvals and all

warranties by Hydromatic.

Power Cords:

The power cord and heat sensor seal

failure cord are potted into the cord

cap. The cords must not be spliced.

NOTE: Each cable has a green lead.

This is the ground wire and must

be grounded properly per NEC and/

or local codes. Cords should be

inspected for abnormal wear and

replaced accordingly.

Overload Heaters:

If the Hydromatic electrical panel is not

used, starters with 3 leg overload relay

must be supplied on 3 phase pumps.

Each leg is to have an identical heater

sized in accordance with the nameplate

amps on the motor housing. The amp

draw on these submersible motors is

slightly higher than a corresponding

horsepower surface motor, so heaters

must be sized by the nameplate rating.

Capacitor start single phase pumps

have a run and start winding that draws

different currents. To adequately

protect these windings with the

appropriate heaters, consult the

factory.

NOTE: The red lead is always the

start winding of a pump using single

phase.

Pump Installation

Installing Sump Level Controls Float

Controls:

In either simplex, duplex or triplex

systems the lower or turn-off control

is to be set to maintain a minimum level

in the sump. This level shall be no more

than 3-1/4" from the top of the motor

housing down to the surface of the

sewage.

The second or turn-on control is set

above the lower turn-off control. The

exact distance between the two floats

must be a compromise between a

frequent pumping cycle (10 starts per

hour max.) to control septicity, solids

and a slower cycle for energy economy.

This distance should be determined by

the engineer or consulting engineer,

depending on the conditions of

the application.

Installing Pump in Sump:

Before installing the pump in the

sump, lay it on its side and rotate

impeller. Impeller may be slightly

stuck due to factory test water.

The impeller should turn freely.

Do not connect the power until

after this test.

Clean all debris from sump and connect

pump to piping. A check valve must

be installed on each pump. A gate or

plug valve in each pump discharge is

highly recommended. This valve should

be installed on the discharge side of the

check valve so if necessary to service

the check valve, the line pressure can

be cut off. Single pump systems are

sometimes installed without a check

valve where it is desirable to self-drain

the discharge line to prevent freezing.

This can be done only with short

discharge lines; otherwise water will

return to the sump and cause short

cycling of the pump.

Making Electrical Connections:

All electrical wiring must be in

accordance with local codes, and only

competent electricians should make

the installations. Complete wiring

diagrams are glued to the inside

cover of the panel. All wires should be

checked for grounds with an ohmmeter

or Megger® after the connections are

made.

2

THIS IS IMPOR TANT, AS ONE GROUNDED

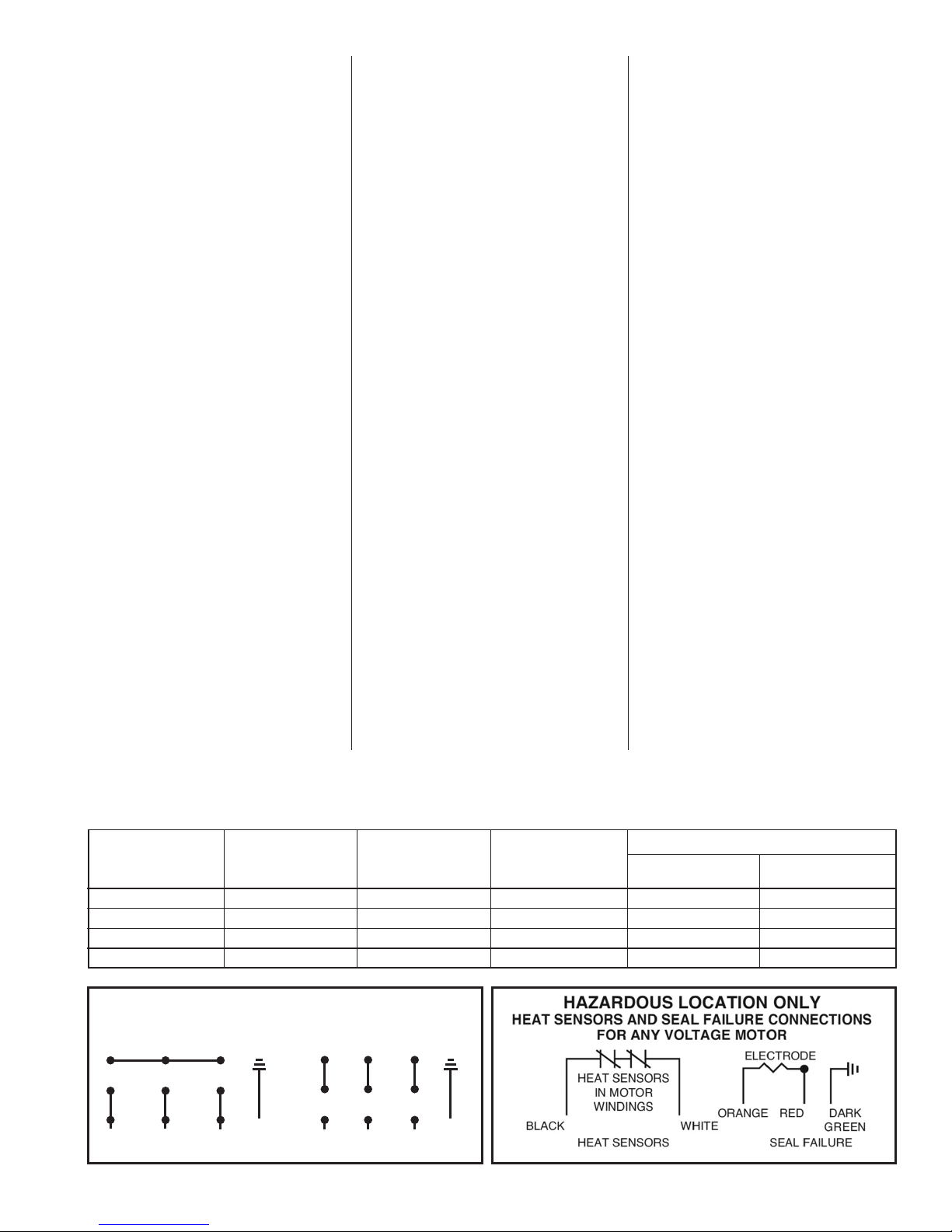

WIRE SIZE TABLE

FOR REMOTE LOCAT ION OF CONTROL PA NEL

LENGTHS ARE BASED ON A VOLTAGE DROP OF TWO PERCENT

Maximum length in feet from NEMA 4 Junction Box to control panel. All contro l wire s can be = 14–16 or 18 gauge wire. If power lines are greater than

300 volts, and the control wires are used in the same conduit, then the insulation of the control wires must be for 600 volts.

1 Phase 3 Phase

HP HP

Wire Size Volts 1

1

⁄2 2 3 5 Volts 11⁄2 2 3 5 71⁄2 10 15

200V - - - - 200 217 190 101 - - - -

230 105 95 - - 230 291 250 134 - - - -

12 460 1165 1019 540 412 333 233 -

575 1820 1450 820 624 515 364 -

200 121 111 103 - 200 340 297 158 119 - - -

230 163 148 139 - 230 456 390 210 161 - - -

10

460 1822 1594 846 645 522 364 -

575 2847 2270 1360 976 806 569 -

200 190 175 162 - 200 533 466 249 187 155 - -

230 257 232 219 - 230 715 613 330 252 204 - -

8 460 2860 2500 1328 1013 819 572 390

575 4468 3570 2145 1532 1266 894 -

200 296 272 252 - 200 830 726 387 291 242 170 -

230 400 362 340 181 230 1114 955 514 393

318 223 -

6 460 4455 3898 2068 1577 1275 891 607

575 - - 3341 2386 1972 1392 -

200 452 416 384 - 200 1268 1110 592 444 370 260 -

230 610 553 520 276 230 1701 1458 785 601 486 340 232

4 460 - - 3160 2410 1449 1361 928

575 - - - 3646 2513 2127 -

200 689 633 586 - 200 1932 1690 902 676 563 395 -

230 930 842 792 421 230 2592 2222 1196 915 741 578 353

*2* 460 - - - 3672 2969 2074 1414

575 - - - - 4590 3240 -

*Special junction box required for wire sizes larger than #4.

WIRE CAN CAUSE CONSIDERABLE

TROUBLE.

IMPORTANT: If equipment is not

properly wired and protected as

recommended, the warranty is void.

Caution: The 230 volt 3 phase pump

has a dual marked nameplate. Voltage

may be rewired by the manufacturer

or a Class I Div 1 equipment qualified

electrician. Once the voltage is changed,

the factory cord tag indicating 230 volt

3 phase must be removed.

For record keeping purposes, we

suggest the pump be marked externally

with the new voltage and qualified

personnel that performed the change.

Pumps shipped from the factory as 460

volt 3 phase cannot be rewired to any

other voltage.

To Re-wire the pump from 230V to

460V 3 phase:

Only a 230V pump from the factory

is considered dual voltage, a cord

label clearly states the factory wound

voltage.

Remove all six cap screws then raise

the cord cap assembly enough to slip

a prying instrument on opposite sides

between the cord cap casting and

the motor housing. Take care to not

damage the o-ring or the machined

surfaces of the castings. Doing so

could void FM agency certifications.

While prying evenly on both sides;

NUMBER OF CONDUCTORS REQUIRED BETWEEN CONTROL PANEL AND NEMA 4 JUNCTION BOX

POWER LINES AND CONTROL WIRES CAN BE CARRIED IN CONDUIT OR CAN BE UNDERGROUND BURIED CABLE

System Number of Number of Number of

Type Control Wires Power Lines Ground Wires #8 Number of Number of

Sensor Wires Ground Wires

Simplex 4 3 1 3 1

Simplex with Alarm 6 3 1 3 1

Duplex 6 6 2 6 2

Duplex with Alarm 8 6 2 6 2

230V 3ø 460V 3ø

3 PHASE MOTOR WIRING

DUAL VOLTAGE

separate the cord cap casting from the

motor housing, the assembly is airtight

and will have a vacuum effect when

disassembling. Once separated, the

cord cap can be inverted and rotated

to the outside of the pump assembly,

and a bolt can be re-used to secure

the upside down cord cap to the motor

housing for ease of rewiring.

Refer to the wiring diagram within

this manual for wiring details. Once

all electrical connections are finished

and secure (a crimped electrical

connector is best to prevent issues

due to vibration if required), the cord

cap should be re-attached reversing

the steps above. Ensure the o-ring is

in place and perform a hi-pot test for

safety once everything is complete.

Heat Sensors and Seal Failure Connections:

Be sure heat sensor wires are

connected in series with the starter

coil. Connections are provided on the

terminal strip.

Pump Operations

Starting System:

1. Double check all wire connections.

2. Turn pumps to Off position on

H-O-A switches.

3. Turn on breakers.

4. When using single phase pumps,

make sure red pump lead is

connected to capacitor circuit.

Connect amprobe to pump power

cord and turn pump on. The pump will

show high amp draw momentarily,

then as pump comes off start wirings,

amps will drop to normal nameplate

amps.

When using three phase pumps

(230/460/575), turn the H-O-A

switch to Hand position on one

pump and notice operation. If

pump is noisy and vibrates, rotation

is wrong. To change rotation,

interchange any two line leads to

pump. Do not interchange main

incoming lines. Check rotation of

all pumps in this same manner.

5. Now set both H-O-A switches to

Auto position and allow water to

rise in sump until one pump starts.

Allow pump to operate until the

level drops to turn-off point.

6. Allow sump level to rise to start

other pump(s). Notice run lights

in panel. Pumps should alternate

on each successive cycle of

operation.

7. Turn both H-O-A switches to Off

position and allow sump to ll to

the override control level(s).

8. Turn switches to Auto position, and

pumps should start and operate

together until level drops to turnoff point.

9. Repeat this operation and cycle

several times before leaving the

job.

HEAT SENSOR & SEAL FAILURE

45 6

78 9

12 3

BL

(L1)

W

(L2)

GREEN GREEN

R

(L3)

45 6

78 9

12 3

BL

(L1)

W

(L2)

R

(L3)

ELECTRODE RESISTANCE 330 kΩ

3

10. Check voltage when pumps are

operating and check the amp draw

of each pump. Check amps on each

wire as sometimes a high leg will

exist. For excessive voltage on one

leg, the electric utility company

should be consulted.

Pump Maintenance

As the motors are oil filled, no lubrication

or other maintenance is required.

If the heat sensor and seal failure are

hooked up properly, no attention is

necessary as long as the seal failure

indicator light does not come on. To

ensure continuity of the seal sensor

leads, a test light is provided on

intrinsically safe Hydromatic panels as

standard equipment.

Pump should be checked every quarter

for corrosion and wear.

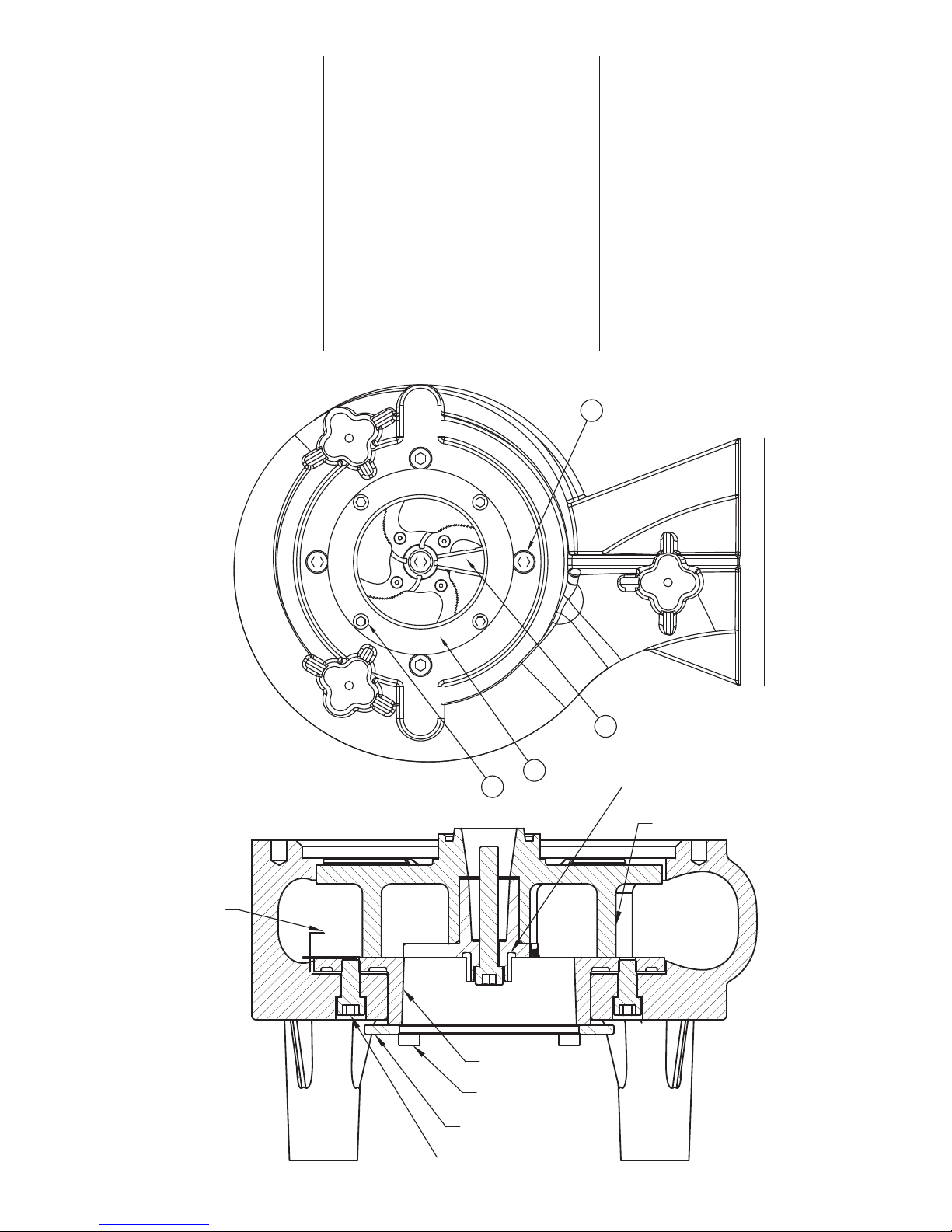

Field Service on Hydromatic Hazardous Location Pumps:

If a Hydromatic hazardous location

pump is used in a hazardous location,

the pump must be returned to the

factory for electrical and motor

service. This will ensure the integrity

of the hazardous location rating of the

pump and comply with our warranty

requirements.

A

The quick disconnect cords, upper

and lower seal, volute and impeller

components may be repaired or

replaced by an authorized Hydromatic

service facility without compromising

the hazardous location rating to the

pump.

Any time the seal is disturbed, it must

be replaced.

Check the pump for proper rotation

before returning to service.

RECOMMENDED

MAX CUTTER GAP

.015

.010

B

C

CHOPPER PLATE

3/8-16 BOLTS

PLATE RETAINING RING

1/2-20 BOLTS

D

CUTTER INSERT

IMPELLER

4

Loading...

Loading...