Page 1

OWNER’S MANUAL

Shallow Well Jet Pumps/

Tank Systems

Series “HN” and “SN”

Installation/Operation/Parts

For further operating, installation or maintenance assistance:

Call 1-800-782-7482

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.BERKELEYPUMPS.COM

PH: 888-782-7482

© 2013 Pentair, Ltd. All Rights Reserved. BE424 (Rev. 02/25/13)

Page 2

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury:

warns about hazards that will cause seri-

ous personal injury, death or major property damage if

ignored.

ous personal injury, death or major property damage if

ignored.

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

California Proposition 65 Warning

tain chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

warns about hazards that can cause seri-

warns about hazards that will or can cause

This product and related accessories con-

ELECTRICAL SAFETY

Capacitor voltage may be hazardous.

To discharge motor capacitor, hold insulated handle

screwdriver BY THE HANDLE and short capacitor terminals together. Do not touch metal screwdriver blade

or capacitor terminals. If in doubt, consult a qualified

electrician.

GENERAL SAFETY

Do not touch an operating motor. Modern

motors can operate at high temperatures. To avoid burns

when servicing pump, allow it to cool for 20 minutes

after shut-down before handling.

Do not allow pump or any system component to freeze.

To do so will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on pumps.

Keep work area clean, uncluttered and properly lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

Pump body may explode if used as a

booster pump unless relief valve capable of passing full

pump flow at 75 psi is installed.

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect power

before working on pump,

motor or tank.

Wire motor for correct

voltage. See

“Electrical” section of

this manual and motor

nameplate.

Ground motor before

connecting to power

supply.

Meet National

Electrical Code,

Canadian Elec tri cal

Code, and local codes

for all wiring.

Follow wiring

instructions in this

manual when

connecting motor to

power lines.

WARNING

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.

Page 3

Table of Contents 3

Thank you for purchasing a top quality, factory tested pump.

Page

General Safety .....................................................................................................2

Warranty..............................................................................................................3

Installation ........................................................................................................4,5

Connecting Discharge Piping...............................................................................6

Electrical ...........................................................................................................7,8

Preparing To Start The Pump ...............................................................................9

Repair Parts .................................................................................................10-11

Troubleshooting ................................................................................................. 12

Limited Warranty

BERKELEY warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free

from defects in material and workmanship for the Warranty Period shown below.

Product Warranty Period

Water Systems:

Water Systems Products — jet pumps, small centrifugal pumps, submersible pumps and

related accessories

Pro-Source™ Composite Tanks 5 years from date of original installation

Pro-Source™ Steel Pressure Tanks 5 years from date of original installation

Pro-Source™ Epoxy-Lined Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products

Agricultural/Commercial:

Centrifugals – close-coupled motor drive, frame mount, SAE mount, engine drive, VMS, SSCX,

SSHM, solids handling, submersible solids handling

Submersible Turbines, 6” diameter and larger

Our limited warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication,

improper installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase

power through a phase converter will void the warranty. Note also that three phase motors must be protected by three-leg,

ambient compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and BERKELEY’s only duty, is that BERKELEY repair or replace defective products (at BERKELEY’s choice). You

must pay all labor and shipping charges associated with this warranty and must request warranty service through the installing

dealer as soon as a problem is discovered. No request for service will be accepted if received after the Warranty Period has

expired. This warranty is not transferable.

BERKELEY SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration of an

implied warranty, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You

may also have other rights which vary from state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

whichever occurs first:

12 months from date of original installation, or

18 months from date of manufacture

12 months from date of original installation, or

18 months from date of manufacture

12 months from date of original installation, or

24 months from date of manufacture

12 months from date of original installation, or

24 months from date of manufacture

In the U.S.: BERKELEY, 293 Wright St., Delavan, WI 53115

In Canada: 269 Trillium Dr., Kitchener, Ontario N2G 4W5

Page 4

Installation 4

To Household

Pump Priming

2347 0396

REPLACING AN OLD PUMP

Hazardous voltage. Disconnect power to

pump before working on pump or motor.

Step 1. Drain and remove the old pump. Check the old

pipe for scale, lime, rust, etc., and replace it if

necessary.

Step 2. Install the pump in the system. Make sure that all

pipe joints in the suction pipe are air-tight as well

as water tight. If the suction pipe can suck air, the

pump will not be able to pull water from the well.

Step 3. Adjust the pump mounting height so that the

plumbing connections do not put a strain on the

pump body. Support the pipe so that the pump

body does not take the weight of piping or fittings.

You have just completed the well plumbing for

your new shallow well jet pump. Please go to

Page 6 for discharge pipe and tank connections.

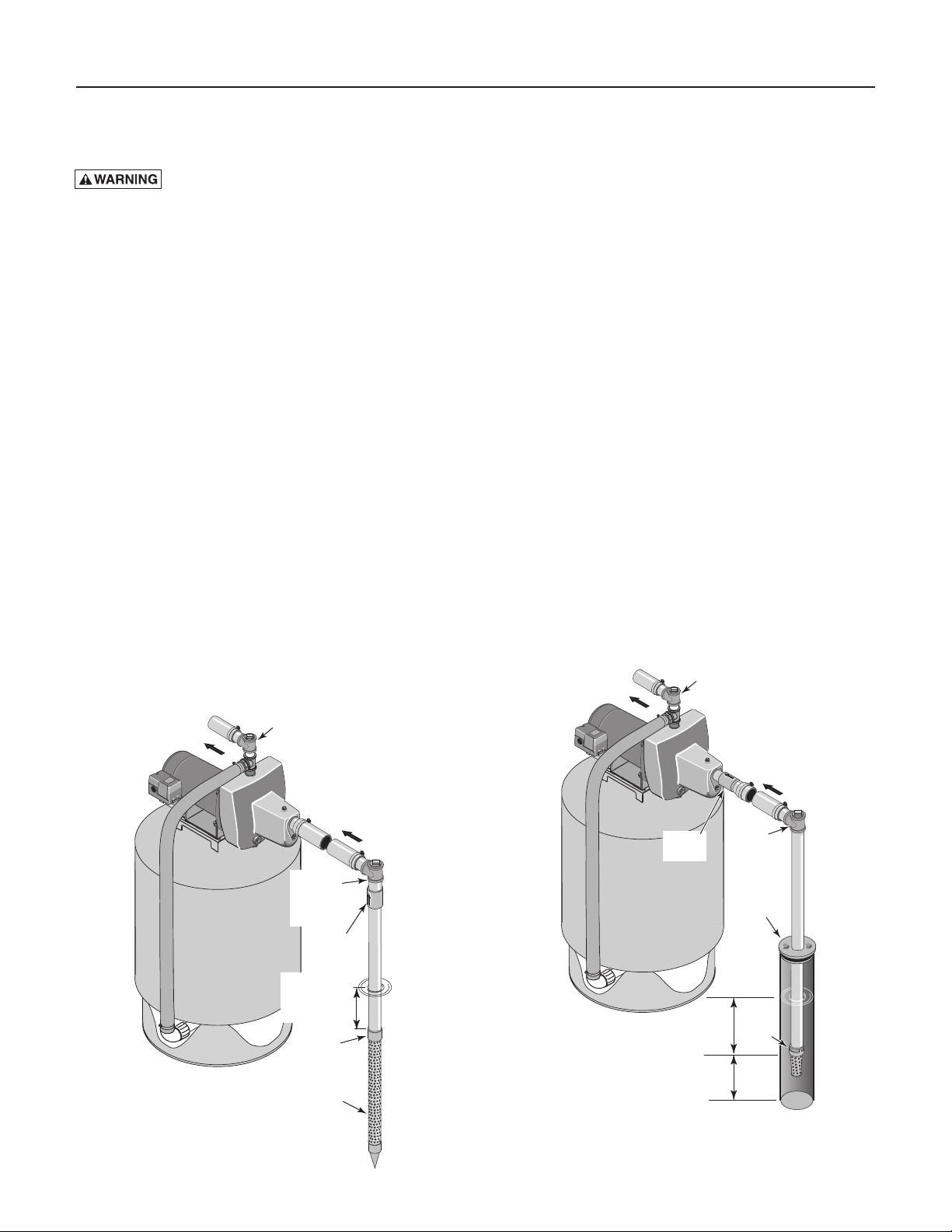

WELL POINT (DRIVEN POINT)

INSTALLATION (Figure 1)

Step 1. Drive the well, using “drive couplings” and a

“drive cap”. “Drive fittings” are threaded all the

way through and allow the pipe ends to butt

against each other so that the driving force of the

maul is carried by the pipe and not by the threads.

The ordinary fittings found in hardware stores are

not threaded all the way through the fitting and

can collapse under impact. “Drive fittings” are

also smoother than standard plumbing fittings,

making ground penetration easier.

To Household

Water System

Pump Priming

Tee and Plug

Suction Pipe

From Well

Priming

Tee and

Plug

Step 2. Mount the pump as close to the well as possible.

Step 3. Use the fewest possible fittings (especially

elbows) when connecting the pipe from the well

point to the pump suction port. The suction pipe

should be at least as large as the suction port on

the pump (include a check valve if your pump is

not equipped with one – see Figure 1). Support

the pipe so that there are no dips or sags in the

pipe, so it doesn’t strain the pump body, and

so that it slopes slightly upward from the well

to the pump (high spots can cause air pockets

which can air lock the pump). Seal the suction

pipe joints with PTFE pipe thread sealant tape.

Joints must be air- and water-tight. If the suction

pipe can suck air, the pump cannot pull water

from the well. If one well point does not supply

enough water, consider connecting two or three

well points to one suction pipe.

You have just completed the suction piping for

your new shallow well jet pump. Please go to

Page 6 for discharge pipe and tank connections.

CASED WELL INSTALLATION, 2” OR

LARGER CASING (Figure 2)

Step 1. Mount the pump as close to the well as possible.

Step 2. Assemble the foot valve, strainer, and well pipe

(see Figure 2). Make sure that the foot valve

works freely.

Water System

Check

Valve

Tee and Plug

Suction Pipe

From Well

Priming

Tee and

Plug

Sanitary

Well Seal

Drive point

below water

level

Not

to

Scale

Figure 1: Driven Point Installation

Check

Valve

Drive

Coupling

Drive

Point

Not

to

Scale

Figure 2: Cased Well Installation

5–10'

10'

Min.

Well

Casing

Foot

Valve

Page 5

Installation 5

To Household

Pump Priming

Step 3. Lower the pipe into the well until the strainer is

five feet above the bottom of the well. It should

also be at least 10 feet below the well’s water level

while the pump is running in order to prevent the

pump from sucking air. Install a sanitary well seal.

Step 4. Install a priming tee, priming plug, and suction pipe

to the pump (see Figure 2). Connect the pipe from

the well to the pump suction port, using the fewest

possible fittings – especially elbows – as fittings

increase friction in the pipe (however, include a

foot valve – see Figure 2). The suction pipe should

be at least as large as the suction port on the pump.

Use PTFE pipe thread sealant tape on threaded pipe

joints. Support the pipe so that there are no dips

or sags in the pipe, so it doesn’t strain the pump

body, and so that it slopes slightly upward from the

well to the pump (high spots can cause air pockets

which can air lock the pump). Seal the suction pipe

joints with PTFE pipe thread sealant tape. Joints

must be air- and water-tight. If the suction pipe

can suck air, the pump cannot pull water from the

well.

You have just completed the suction piping for

your new shallow well jet pump. Please go to

Page 6 for discharge pipe and tank connections.

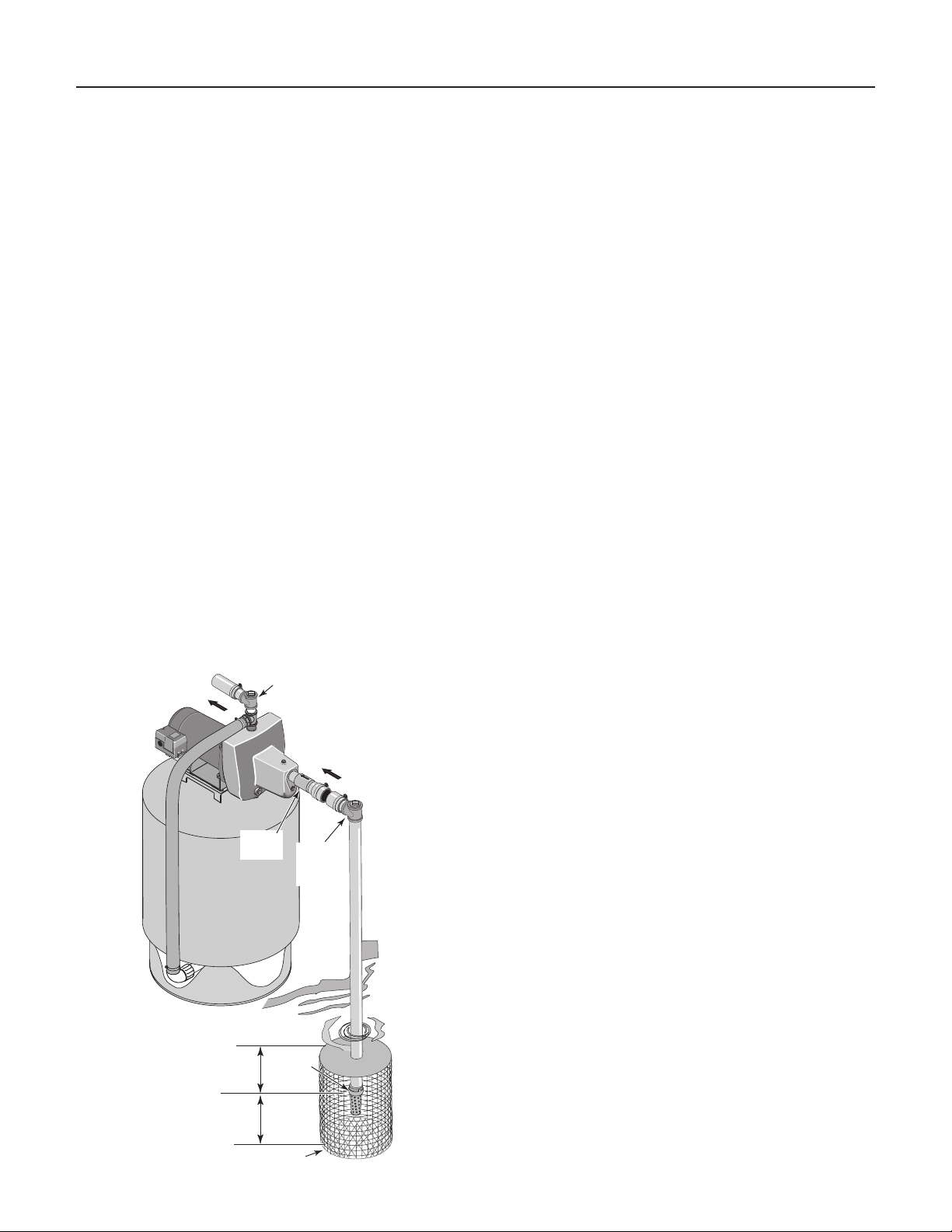

INSTALLATION FOR SURFACE WATER

(Figure 3)

Step 1. The pump should be installed as close to the

water as possible, with the fewest possible fittings

(especially elbows) in the suction pipe. The

suction pipe should be at least as large as the

suction port on the pump.

Step 2. Assemble a foot valve and suction pipe (see

Figure 3). Make sure that the foot valve works

freely. Use PTFE pipe thread sealant tape on

threaded pipe joints. Protect the foot valve

assembly from fish, trash, etc, by installing a

screen around it (see Figure 3).

Step 3. Lower the pipe into the water until the strainer

is five feet above the bottom. It should also be

at least 10 feet below the water level in order to

prevent the pump from sucking air.

Step 4. Install a priming tee, priming plug, and suction

pipe to the pump (see Figure 3). Support the pipe

so that there are no dips or sags in the pipe, so

it doesn’t strain the pump body, and so that it

slopes slightly upward from the well to the pump

(high spots can cause air pockets which can air

lock the pump). Seal the suction pipe joints with

PTFE pipe thread sealant tape. Joints must be airand water-tight. If the suction pipe can suck air,

the pump cannot pull water from the well.

You have just completed the plumbing for your

new shallow well jet pump. Please go to Page 6

for discharge pipe and tank connections.

Water System

Not

to

Scale

Check

Valve

10'

Min.

5–10'

Tee and Plug

Suction Pipe

From Well

Priming

Tee and

Plug

Foot

Valve

Screen

Figure 3: Surface Water Installation

Page 6

Discharge Pipe and Pressure Tank Connections 6

To Household

Pump Priming

2349 0396

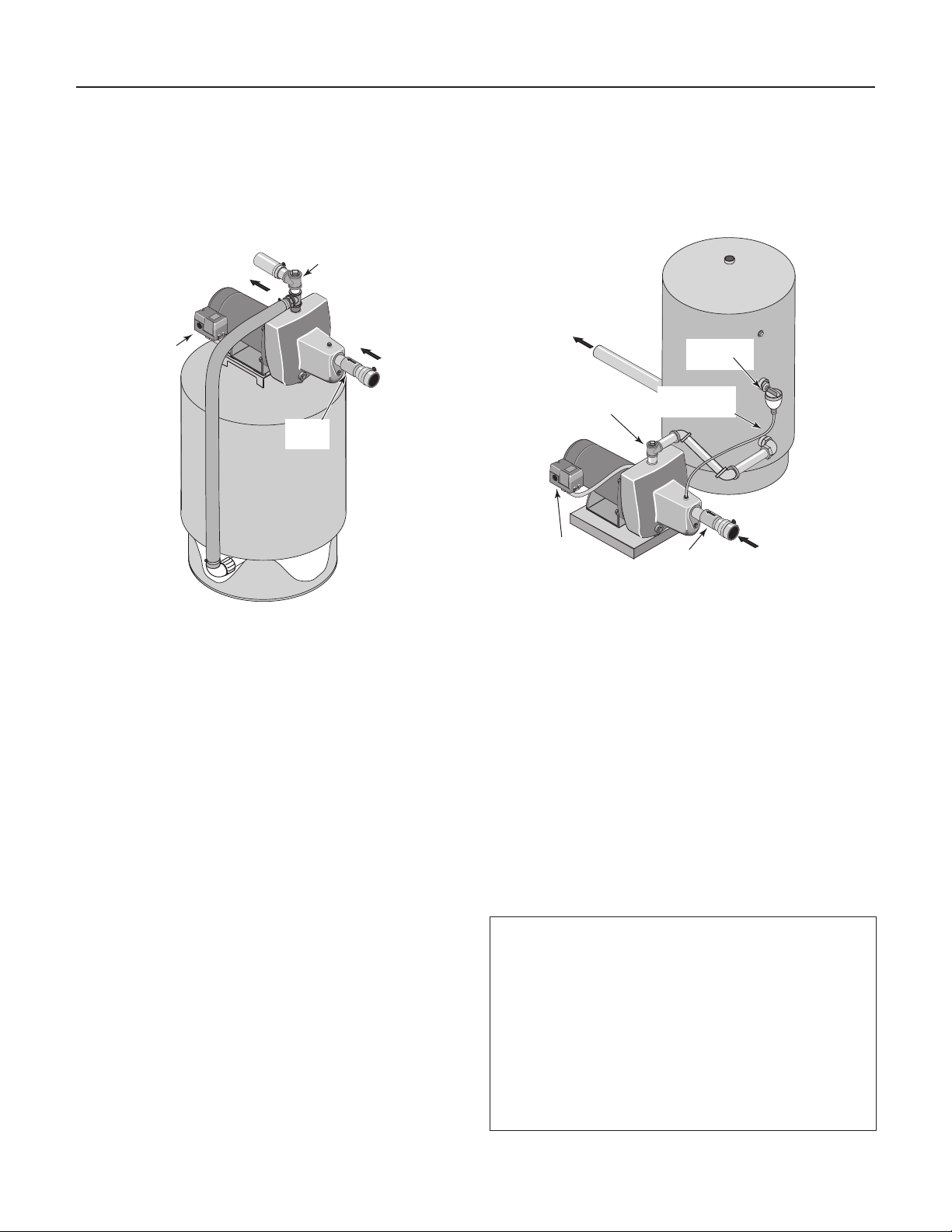

PRE-CHARGE TANK CONNECTION

(Figure 4)

Step 1. Install two tees in the pump discharge port (see

Figure 4). The pipe size must be at least as large

as the discharge port.

Water System

Pressure

Switch

Tee and Plug

From Well

Check

Valve

STANDARD TANK CONNECTION

(Figure 5)

Step 1. Install one tee in the pump discharge port (see

Figure 5).

To Household

Water System

Air Volume

Control

Pump

Priming Tee

and Plug

Pressure

Switch

Air Volume

Control Tube

From

Well

Check

Valve

Figure 4: Pre-charged Tank Connections

Step 2. Run a pipe or reinforced hose from one arm of

the first tee to the port on the pre-charged tank.

Step 3. Connect the other end of the discharge tee to

your plumbing system.

Step 4. Check the pre-charge of air in the tank with an

ordinary tire gauge. The pre-charge should be

2 PSI less than the cut-in setting of the pump’s

pressure switch. The pre-charge is measured

when there is no water pressure in the tank. Your

new pump has a 30/50 PSI switch, so adjust the

tank pre-charge pressure to 28 PSI.

Congratulations! You have just completed the

tank connection for your jet pump.

Please go to Pages 7 and 8 for electrical hookup.

Figure 5: Standard Tank Connections

Step 2. Run a pipe from the pump discharge port to the

inlet port of your tank. The pipe size must be at

least as large as the discharge port.

Step 3. Remove the 1/8” NPT pipe plug from the pump

Air Volume Control (AVC) port (see Figure 5).

Run tubing from the pump’s AVC port (see Figure

5) to the port on the AVC mounted on the tank.

See instructions provided with tank and AVC for

details. AVC port location will vary, depending on

your pump model (see exploded views, Page 10).

Congratulations! You have just completed the

tank connection for your jet pump.

Please go to Pages 7 and 8 for electrical hookup

Sealing Pipe Joints

Use only PTFE pipe thread sealant tape for making

all threaded connections to the pump itself. Do not

use pipe joint compounds on plastic pumps: they

can react with the plastic in pump components.

Make sure that all pipe joints in the suction pipe are

air tight as well as water tight. If the suction pipe

can suck air, the pump will not be able to pull water

from the well.

Page 7

Electrical 7

3187 0704H

Disconnect power before working on pump, motor, pressure switch, or wiring.

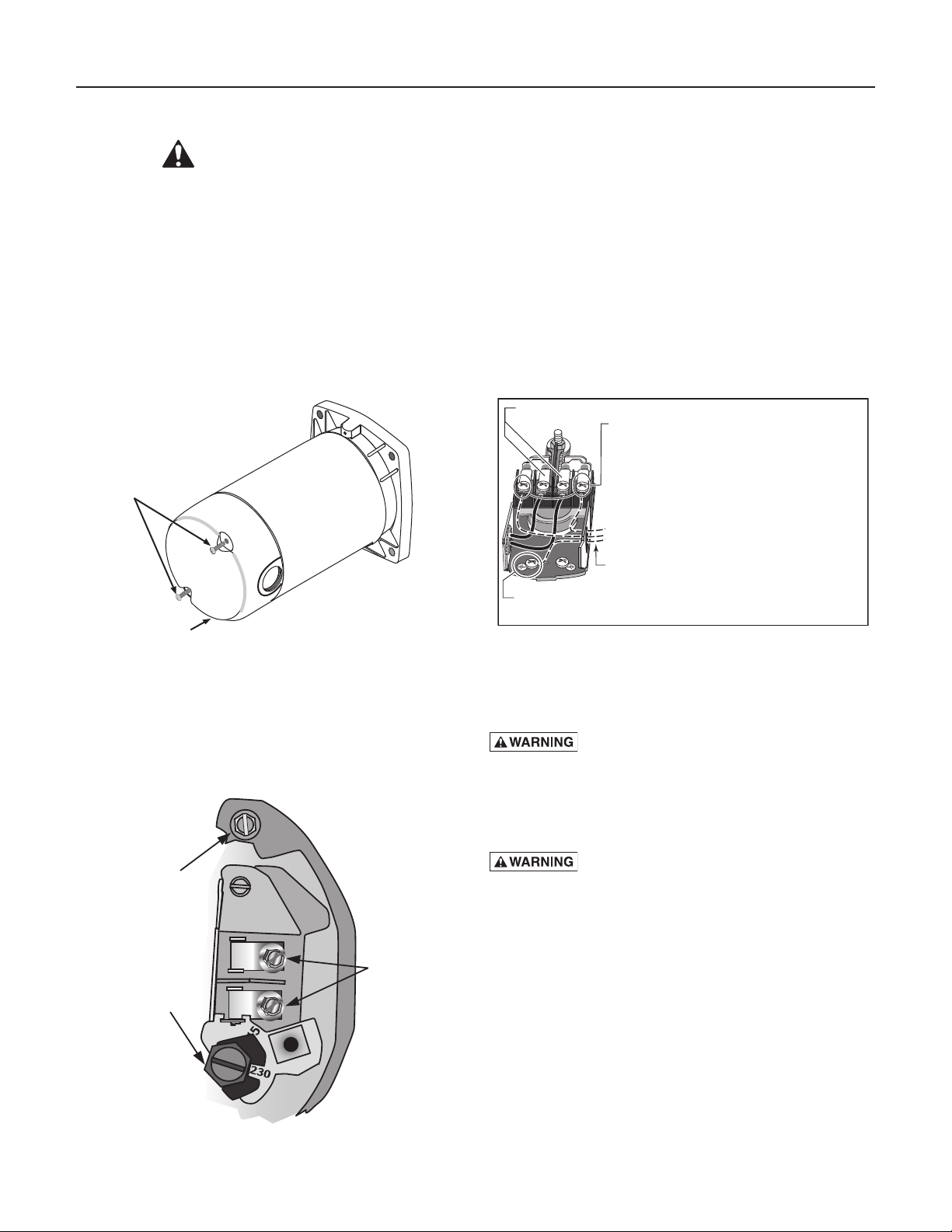

MOTOR SWITCH SETTINGS

Dual-voltage motors (motors that can operate at either

115 or 230 volts), are set at the factory to 230 volts. Do

not change motor voltage setting if line voltage is 230

volts, or if you have a single voltage motor.

NOTE: Never wire a 115 volt motor to a 230 volt line.

Remove Motor End Cover

If you have a dual-voltage motor, and will connect it to

115 volts, follow the procedure below.

End Cover Screws

Motor

End Cover

Figure 6: Removing Motor End Cover

To change to 115 volts:

Step 1. Make sure power is off.

Step 2. Turn the dial counter-clockwise until 115 shows

in the dial window.

Step 3. The wires from the pressure switch should

already be attached to to power lead terminals.

Step 4. Reinstall the Motor end cover.

Pressure Switch Wiring

Motor wires connect here.

Power supply wires connect here.

230 Volt: Connect 2 hot wires (black and red)

here and cap the white (neutral) wire. It does

not matter which wire goes to which screw.

115 Volt: Connect one hot wire (black or red)

to one of these screws (it doesn't matter

which one). Connect the white (neutral) wire

to the other screw. Cap any remaining

black or red wires.

Clamp the power cable to prevent strain

on the terminal screws.

Connect the green (or bare copper) ground wire

to the green ground screw.

Figure 8: Pressure Switch Wiring

You will need to remove the motor end cover to change

the voltage setting.

Your motor terminal board (located under the motor end

cover) should look like that shown below.

Ground

Screw

Power Lead

Voltage

Change Dial

Te rminals

Step 5. Go to Wiring Connections below.

Hazardous voltage. Can shock, burn, or

kill. Connect ground wire before connecting power

supply wires. Use the wire size (including the ground

wire) specified in the wiring chart. If possible, connect

the pump to a separate branch circuit with no other

appliances on it.

Explosion hazard. Do not ground to a gas

supply line.

Figure 7: Voltage set to 230 volts, Dial Type

Page 8

Electrical 8

WIRING CONNECTIONS

Fire hazard. Incorrect voltage can cause

a fire or seriously damage the motor and voids the

warranty. The supply voltage must be within ±10% of

the motor nameplate voltage.

NOTICE: Dual-voltage motors are factory wired for 230

volts. If necessary, reconnect the motor for 115 volts, as

shown. Do not alter the wiring in single voltage motors.

Install, ground, wire, and maintain your pump in

compliance with the United States National Electrical

Code (NEC) or the Canadian Electrical Code (CEC), as

applicable, and with all local codes and ordinances that

apply. Consult your local building inspector for code

information.

Connection Procedure:

Step 1. Connect the ground wire first as shown in Figure

6. The ground wire must be a solid copper wire

at least as large as the power supply wires.

Step 2. There must be a solid metal connection between

the pressure switch and the motor for motor

grounding protection. If the pressure switch is

not connected to the motor, connect the green

ground screw in the switch to the green ground

screw under the motor end cover. Use a solid

copper wire at least as large as the power supply

wires.

Step 3. Connect the ground wire to a grounded lead in

a service panel, to a metal underground water

pipe, to a metal well casing at least ten feet (3M)

long, or to a ground electrode provided by the

power company or the hydro authority.

Step 4. Connect the power supply wires to the pressure

switch as shown in Figure 6.

You have just completed the wiring for your

pump.

Please go to Page 9 for startup preparations.

Wiring Chart – Recommended Wire and Fuse Sizes

Series HP Volts Amp Amp AWG WIRE SIZE (mm

5HN 1/2 115/230 12.2/6.1 20/15 12/14(3/2) 10/14(5.5/2) 8/14(8.4/2) 6/12(14/3) 6/12(14/3)

7HN 3/4 115/230 14.8/7.4 20/15 12/14(3/2) 8/14(8.4/2) 6/14(14/2) 6/12(14/3) 4/10(21/5.5)

10HN 1 115/230 19.2/9.6 25/15 10/14(5.5/2) 8/14(8.4/2) 6/12(14/3) 4/10(21/5.5) 4/10(21/5.5)

5SN 1/2 115/230 8.8/4.4 15/15 14/14(2/2) 12/14(3/2) 10/14(5.5/2) 8/14(8.4/2) 8/12(8.4/3)

7SN 3/4 115/230 12.2/6.1 20/15 12/14(3/2) 10/14(5.5/2) 8/14(8.4/2) 6/12(14/3) 6/12(14/3)

10SN 1 115/230 14.8/7.4 20/15 12/14(3/2) 8/14(8.4/2) 6/14(14/2) 6/12(14/3) 4/10(21/5.5)

15SN 1-1/2 115/230 19.2/9.6 25/15 10/14(5.5/2) 8/14(8.4/2) 6/14(14/2) 4/10(21/5.5) 4/10(21/5.5)

Motor

Max.

Load

DISTANCE IN FEET(METERS) FROM MOTOR TO SUPPLY

Branch

0 - 100 101 - 200 201 - 300 301 - 400 401 - 500

Fuse

(0 - 30) (31 - 61) (62 - 91) (92 - 122) (123 - 152)

Rating

2

)

Page 9

Preparing to Start the Pump 9

PRIMING

Never run pump against closed discharge.

To do so can boil water inside pump, causing hazardous

pressure in unit, risk of explosion and possibly scalding

persons handling pump.

Never run pump dry. Running pump without

water may cause pump to overheat, damaging seal and

possibly causing burns to persons handling pump. Fill

pump with water before starting.

Fill pump

and piping

through

priming tee.

Step 1. Remove the priming plug from the pump and fill

the pump, fill all piping between the pump and

the well, and make sure that all piping in the

well is full. If you have also installed a priming

tee in the suction piping, remove the plug from

the tee and fill the suction piping.

Step 2. Replace all fill plugs.

Step 3. Power on! Start the pump. If you don’t have

water after 2 or 3 minutes, stop the pump and

remove the fill plugs. Refill the pump and piping.

You may have to repeat this several times in

order to get all the trapped air out of the piping.

A pump lifting water 25’ may take as long as 15

minutes to prime.

Step 4. After the pump has built up pressure in the

system and shut off, check the pressure switch

operation by opening a faucet or two and

running enough water out to bleed off pressure

until the pump starts. The pump should start

when pressure drops to 30 PSI and stop when

pressure reaches 50 PSI. Run the pump through

one or two complete cycles to verify correct

operation. This will also help clean the system of

dirt and scale dislodged during installation.

Figure 9: Prime the Pump

2351 0396

Congratulations on a successful installation.

If you were unsuccessful, please refer to the

Troubleshooting section (Page 12) or call our customer

service technical staff, at 1-888-782-7483.

Page 10

Repair Parts 10

1

Exploded View

Models 5SN, 7SN, 10SN, 15SN

8

10

11

11A

11B

12

12

Nozzle

Cleanout

Port

AVC Port

12

18

17

19

14

15

20

16

13

2

3

4

5

6

7

9

12

REPAIR PARTS LIST

Model and Horsepower

Key Part No. 5SN 7SN 10SN 15SN

No. Description Used 1/2 HP 3/4 HP 1 HP 1-1/2 HP

1 Motor 1 J218-582APKG J218-590PKG J218-596PKG J218-601PKG

2 Hex Capscrew - 3/8” - 16 x 1-1/4” Lg. 4 U30-75ZP U30-75ZP U30-76ZP U30-76ZP

#§3 Water Slinger 1 17351-0009 17351-0009 17351-0009 17351-0009

4 Seal Plate 1 N3-1043P N3-1043P L3-10 L3-10

#§5 Seal Plate Gasket 1 N20-35 N20-35 C20-21 C20-21

#§6 Shaft Seal 1 U109-6A U109-6A U109-6A U109-6A

#7 Impeller 1 J105-40P J105-42P J105-8PAN J105-22PA

#8 Diffuser 1 L1-25P L1-25P L1-23P L1-23P

• DiffuserScrew 3 – – U30-489SS U30-489SS

#§9 Diffuser Ring 1 N20-34 N20-34 L21-1 L21-1

10 Quick Connect - 1/4” NPT 1 U11-217P U11-217P U11-217P U11-217P

11 Pump Body Assembly 1 N176-43G N176-43GB N176-44G N176-44GA

11A Venturi (1) N32P-66 N32P-75 N32P-64 N32P-65

11B Nozzle (1) N34P-17 N34P-21 J34P-44 J34P-44

12 Pipe Plug - 1/4” NPT Hex Hd. 4 U78-941ZPV U78-941ZPV U78-941ZPV U78-941ZPV

13 Base 1 J4-9 J4-9 J104-9C J104-9C

14 Rubber Pad 1 C35-5 C35-5 C35-5 C35-5

15 Tube 3/8” O.D. x 14-1/2” Lg. 1 U37-672P U37-672P U37-677P U37-677P

16 Quick Connect Elbow - 1/4” NPT 1 U11-218P U11-218P U11-218P U11-218P

17 Pressure Switch 1 U217-1225 U217-1225 U217-1225 U217-1225

18 Locknut - 1/2” 1 U36-112ZP U36-112ZP U36-112ZP U36-112ZP

19 Connector 1 L43-5C L43-5C L43-5C L43-5C

SERVICE KITS

§ Seal and Gasket Kit PP1550 PP1550 PP1551 PP1551

# Overhaul Kit PP1560 PP1561 PP1563 PP1554

NOTE: § Included in Seal and Gasket Kit.

# Included in Overhaul Kit.

Page 11

Repair Parts 11

1

Exploded View

2

22

21

20

15B

3

4

5

6

7

Models 5HN, 7HN and 10HN

8

9

10

19

18

17

16

15A

11

12

13

Nozzle

Cleanout

Port

14

13

13

13

REPAIR PARTS LIST

Model and Horsepower

Key Part No. 5HN 7HN 10HN

No. Description Used 1/2 HP 3/4 HP 1 HP

1 Motor - 60 Cycle - 115/230V 1 J218-590PKG J218-596PKG J218-601PKG

#§2 Water Slinger 1 17351-0009 17351-0009 17351-0009

3 Seal Plate 1 N3-1043P L3-10 L3-10

#§4 Gasket - Seal Plate 1 N20-35 C20-21 C20-21

#§5 Shaft Seal 1 U109-6A U109-6A U109-6A

#6 Impeller 1 J105-42P J105-8PAN J105-22PA

#7 Volute Diffuser Assembly 1 L1-25P L1-23P L1-23P

8 Screw 3 – U30-489SS U30-489SS

#§9 Diffuser Ring 1 N20-34 L21-1 L21-1

10 Venturi (1) N32P-75 N32P-64 N32P-65

11 Nozzle (1) N34P-21 J34P-44 J34P-444

12 Quick Connect - 1/4” NPT 1 U11-217P U11-217P U11-217P

13 Pipe Plug - 1/4” NPT Hex Hd. 4 U78-941ZP U78-941ZPV U78-941ZP

14 Pump Body Assembly 1 N176-43GB N176-44G N176-44GA

15A Capscrew - 3/8” - 16 x 1-1/2” Lg.* 2 U30-75ZP U30-76ZP U30-76ZP

15B Capscrew - 3/8” - 16 x 1-1/4” Lg. 2 U30-75ZP U30-75ZP U30-75ZP

16 Base 1 J4-9 J104-9C J104-9C

17 Rubber Pad 1 C35-5 C35-5 C35-5

18 Switch Tube 3/8” O.D. x 14-1/2” Lg. 1 U37-672P U37-672P U37-677P

19 Quick Connect Elbow - 1/4” NPT 1 U11-218P U11-218P U11-218P

20 Pressure Switch 1 U217-1216 U217-1216 U217-1216

21 Locknut - 1/2” NPT 1 U36-112ZP U36-112ZP U36-112ZP

22 Connector 1 L43-5C L43-5C L43-5C

AVC Port

* 1-1/4” long in Model 5HN.

SERVICE KITS

§ Seal and Gasket Kit PP1550 PP1551 PP1551

# Overhaul Kit PP1561 PP1564 PP1564

NOTE: § Included in Seal and Gasket Kit.

# Included in Overhaul Kit.

Page 12

Troubleshooting 12

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not run Disconnect switch is off Be sure switch is on.

Fuse is blown or circuit breaker tripped Replace fuse or reset circuit breaker.

Starting switch is defective DISCONNECT POWER; Replace starting switch.

Wires at motor are loose, Refer to instructions on wiring (Page 8). DISCONNECT POWER; check and

disconnected, or wired incorrectly tighten all wiring.

capacitor, hold insulated handle screwdriver BY THE HANDLE and

short capacitor terminals together. Do not touch metal screwdriver

blade or capacitor terminals. If in doubt, consult a qualified electrician.

Pressure switch contacts are dirty DISCONNECT POWER and file contacts with emery board or nail file.

Motor runs hot and Motor is wired incorrectly Refer to instructions on wiring.

overload kicks off

(See Electrical / Wiring Chart).

Pump cycles too frequently See section below on too frequent cycling.

Motor runs but no Pump in new installation did In new installation:

water is delivered* not pick up prime through:

1. Improper priming 1. Re-prime according to instructions.

2. Air leaks 2. Check all connections on suction line, AVC, and ejector with

soapy water or shaving cream.

* (Note: Stop pump;

3. Leaking foot valve or check valve 3. Replace foot valve or check valve.

then check prime

Pump has lost prime through: In installation already in use:

before looking

1. Air leaks 1. Check all connections on suction line and shaft seal.

for

other causes.

2. Water level below suction pipe inlet 2. Lower suction line into water and re-prime. If receding water level

Unscrew

in well exceeds 25’ (7.6M), a deep well pump is needed.

plug and see if water

Foot valve or strainer is plugged Clean foot valve or strainer.

is in priming hole).

Ejector or impeller is plugged Clean ejector or impeller.

Check valve or foot valve is stuck shut Replace check valve or foot valve.

Pipes are frozen Thaw pipes. Bury pipes below frost line. Heat pit or pump house.

Foot valve and/or strainer are Raise foot valve and/or strainer above bottom of water source.

buried in sand or mud Clean foot valve and strainer.

Water level is too low for shallow well A deep well jet package may be needed (over 25 ft. to water)

setup to deliver water to deliver water.

Voltage is too low Check with power company. Install heavier wiring if wire size is too small

priming

Capacitor voltage may be hazardous. To discharge

Pump does not Water level in well is lower than A deep well jet will be needed if your well is more than 25’ (7.6M)

deliver water to full estimated depth to water.

capacity

limed, causing excess friction

Piping is too small in size Use larger piping.

Packed well point Backflush well point or sink new point.

Pump delivers water but Pressure switch is out of adjustment or DISCONNECT POWER; adjust or replace pressure switch.

does not shut off or contacts are welded together

Standard pressure tank is waterlogged Drain tank to air volume control port. Check AVC for defects. Check

and has no air cushion all connections for air leaks.

Pipes leak Check connections.

Foot valves leak Replace foot valve.

Air charge too low in pre-charged tank DISCONNECT POWER and open faucets until all pressure is relieved.

Using tire pressure gauge, check air pressure in tank at valve stem

located on the tank. If less than pressure switch cut-in setting (30-50

PSI), pump air into tank from outside source until air pressure is 2 PSI

less than cut-in setting of switch. Check air valve for leaks (use soapy

solution) and replace core if necessary.

Air spurts from faucets Pump is picking up prime When pump has picked up prime, it should pump solid water with no air.

Leak in suction side of pump Suction pipe is sucking air. Check joints for leaks with soapy water.

Well is gaseous Consult factory about installing a sleeve in the well

Intermittent over-pumping of well. Lower foot valve if possible, otherwise restrict pump discharge

Steel piping (if used) is corroded or Replace with plastic pipe where possible, otherwise with new steel pipe.

pump cycles too

frequently

Faucets have been left open Close faucets.

Venturi, nozzle or impeller is clogged Clean venturi, nozzle or impeller.

(Water drawn down below foot valve.)

Page 13

NOTICE D’UTILISATION

Systems de pompes enfonte

montées sur réservoir pour

puisage en eau peu profonde

Série «HN» et «SN»

Installation/Fonctionnement/Pièces

Pour plus de reseignements concernant l’utilisation, l’installation ou l’entretien:

Composer le 1 (888) 782-7482

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.BERKELEYPUMPS.COM

PH: 888-782-7482

© 2013 Pentair, Ltd. All Rights Reserved. BE424 (Rév. 25/02/13)

Page 14

Sécurité 2

LIRE TOUTES CES INSTRUCTIONS

ET LES SUIVRE!

Ce symbole indique qu'il faut être prudent.

Lorsque ce symbole apparaît sur la pompe ou dans

cette Notice, rechercher une des mises en garde qui

suivent, car elles indiquent un potentiel possible de blessures corporelles :

avertit d'un danger qui causera des blessures

corporelles, la mort ou des dommages matériels importants

si on l'ignore.

des blessures corporelles, la mort ou des dommages matériels importants si on l'ignore.

risquera de causer des blessures corporelles, la mort ou des

dommages matériels importants si on l'ignore.

Le mot NOTA indique des instructions spéciales et

importantes n'ayant aucun rapport avec les dangers.

Lire attentivement toutes les consignes de sécurité

contenues dans cette Notice ou collées sur la pompe.

Garder les autocollants de sécurité en bon état; les

remplacer s'ils manquent ou s'ils ont été endommagés.

Avertissement lié à la Proposition 65 de la Californie

contiennent des produits chimiques reconnus dans l’État

de la Californie comme pouvant provoquer des cancers,

des anomalies congénitales ou d’autres dangers relatifs à la

reproduction.

avertit d'un danger qui risque de causer

avertit d'un danger qui causera ou qui

Ce produit et les accessoires connexes

SÉCURITÉ CONCERNANT L'ÉLECTRICITÉ

La tension du condensateur peut être

dangereuse. Pour décharger le condensateur du moteur,

tenir un tournevis à manche isolé PAR LE MANCHE et

mettre en court-circuit les bornes du condensateur. Ne pas

toucher la lame métallique du tournevis ni les bornes du

condensateur. En cas de doute, consulter un électricien

qualifié.

SÉCURITÉ GÉNÉRALE

Ne pas toucher un moteur qui fonctionne. Les

moteurs modernes peuvent fonctionner à des températures

élevées. Pour ne pas se brûler lorsque l'on interviendra sur la

pompe, la laisser refroidir pendant 20 minutes après l'avoir

arrêtée avant de la toucher.

Ne pas laisser geler la pompe ni aucun autre élément du

système, sinon la garantie sera annulée.

Ne pomper que de l'eau avec cette pompe.

Périodiquement, inspecter la pompe et tous les éléments du

système.

Toujours porter des lunettes de sécurité lorsque l'on

intervient sur une pompe.

Garder la zone de travail propre, non encombrée et bien

éclairée; tous les outils et tout l'équipement non utilisés

doivent être entreposés correctement.

Ne pas laisser les visiteurs s'approcher de la zone de travail.

pompe est utilisée en tant que pompe de surpression, à

moins qu'une soupape de sûreté pouvant laisser passer le

débit maximum de la pompe à 75 lb/po

Le corps de la pompe peut exploser si la

2

soit posée.

Câbler le moteur en

AVERTISSEMENT

fonction de la bonne

tension. Voir la

Section «Électricité»

de cette Notice et la

plaque signalétique du

moteur.

Mettre à la terre le

moteur avant de le

Tension dangereuse. Risque

de secousses électriques, de

brûlures, voire de mort.

Mettre à la terre la pompe

avant de la brancher sur le

courant électrique. Couper

l'arrivée de courant avant d'intervenir sur la pompe, sur le

moteur ou sur le réservoir.

brancher sur le courant électrique.

Conforme au Code

national de l'électricité, au Code canadien

de l'électricité et aux

codes municipaux

pour tous les câblages.

Respecter les instructions de câblage figurant

dans cette Notice lorsque l'on branche le moteur

sur une ligne haute tension.

AVERTISSEMENT

Pression dangereuse!

Poser une soupape de sûreté

sur le tuyau de refoulement.

Dissiper toute la pression

du système avant d'intervenir

sur un élément.

Page 15

Table des matières 3

Merci d'avoir acheté une pompe de qualité supérieure mise à l'essai à l'usine.

Page

Sécurité ........................................................................................................................... 2

Garantie ........................................................................................................................... 3

Installation .................................................................................................................... 4,5

Branchement de la tuyauterie de refoulement ................................................................. 6

Électricité ...................................................................................................................... 7/8

Préparations avant le démarrage de la pompe ................................................................. 9

Pièces de rechange ................................................................................................... 10-11

Diagnostic des pannes ................................................................................................... 12

Garantie limitée

BERKELEY garantit au consommateur initial (ci-après appelé l’« Acheteur ») que les produits énumérés dans les présentes sont exempts de

défaut de matériau et de fabrication pendant la durée des garanties à compter de la durée des garanties indiquées ci-dessous.

Produits Durée des garanties

Systèmes d’eau :

Produits de systèmes d’eau — Pompes à éjecteur, petites pompes centrifuges, pompes

submersibles et tous les accessoires connexes

Réservoirs composites Pro-Source™ 5 ans à compter de la date de la première installation

Réservoirs sous pression en acier Pro-Source™ 5 ans à compter de la date de la première installation

Réservoirs revêtus d’époxyde Pro-Source™ 3 ans à compter de la date de la première installation

Produits de puisard/d’égout/d’effluents

Agricole/commercial:

Centrifuges – entraînement par moteur monobloc, monté sur cadre, monté sur SAE,

entraînement par moteur à combustion, multiétagé vertical, SSCX, SSHM, pompes

pour les matières solides, pompes submersibles pour les matières solides

Turbines submersibles, diamètre de 6po et plus grand

Nos garanties limitée ne s’appliquent pas aux produits ayant fait l’objet de négligence, d’une mauvaise utilisation, d’une mauvaise

installation ou d’un manque d’entretien adéquat. Sans aucune limitation des présentes, la garantie des moteurs triphasés submersibles

sera nulle et non avenue si ces moteurs sont branchés et fonctionnent sur le courant monophasé par l’intermédiaire d’un déphaseur. Il faut

également noter que les moteurs triphasés doivent être protégés par un relais de surcharge tripolaire thermocompensé à déclenchement

extrêmement rapide du calibre recommandé, sinon la garantie sera nulle et non avenue.

Le seul recours de l’Acheteur et la seule responsabilité de BERKELEY consistent à réparer ou à remplacer (au choix de BERKELEY) les

produits qui se révéleraient défectueux. L’Acheteur s’engage à payer tous les frais de main d’œuvre et d’expédition du produit couvert par

sa garantie et de s’adresser au concessionnaire-installateur ayant procédé à l’installation dès qu’un problème est découvert pour obtenir

un service sous garantie. Aucune demande de service en vertu de sa garantie ne sera acceptée après expiration de la durée de sa garantie.

Ces garanties ne sont pas transférables.

BERKELEY DÉCLINE TOUTE RESPONSABILITÉ POUR TOUT DOMMAGE INDIRECT OU FORTUIT QUEL QU’IL SOIT.

LA GARANTIE LIMITÉE SUSMENTIONNÉE EST EXCLUSIVE ET REMPLACE TOUTES LES AUTRES GARANTIES EXPRESSES ET TACITES, Y

COMPRIS, MAIS SANS S’Y LIMITER, LES GARANTIES DE QUALITÉ MARCHANDE ET D’ADAPTATION À UN USAGE PARTICULIER. LA

GARANTIE LIMITÉE SUSMENTIONNÉE NE DOIT PAS ÊTRE PROLONGÉE AU-DELÀ DE LA DURÉE PRÉVUE AUX PRÉSENTES.

Certains états, territoires et certaines provinces ne permettent pas l’exclusion ou la limitation des dommages indirects ou fortuits, ni les

limitations relatives à la durée des garanties tacites. Par conséquent, il se peut que les limitations ou les exclusions stipulées dans les

présentes ne s’appliquent pas dans ce cas. Ces garanties accordent des droits juridiques précis, bien que l’on puisse bénéficier d’autres

droits, selon la province, le territoire ou l’état dans lequel on réside.

La présente garantie limitée est entrée en vigueur le 1er juin 2011 et remplace toute garantie non datée ou antérieure à cette date.

Selon le premier terme atteint :

12 mois à compter de la date de la première installation ou

18 mois à compter de la date de fabrication

12 mois à compter de la date de la première installation ou

18 mois à compter de la date de fabrication

12 mois à compter de la date de la première installation ou

24 mois à compter de la date de fabrication

12 mois à compter de la date de la première installation ou

24 mois à compter de la date de fabrication

Aux États-Unis : BERKELEY, 293 Wright St., Delavan, WI 53115

Au Canada : 269 Trillium Dr., Kitchener, Ontario N2G 4W5

Page 16

Installation 4

REMPLACEMENT D'UNE ANCIENNE

POMPE

Tension dangereuse. Couper l'arrivée de

courant à la pompe avant d'intervenir sur la pompe ou sur le

moteur.

1 ° Vider toute l'eau de l'ancienne pompe; déposer l'ancienne

pompe. Vérifier l'ancienne tuyauterie à la recherche de

dépôts de tartre, de chaux, de rouille, etc.; la remplacer

selon le besoin.

2 ° Brancher la pompe sur le système. S'assurer que tous les

raccords du tuyau d'aspiration sont bien étanches, aussi bien

à l'air qu'à l'eau. Si le tuyau d'aspiration aspire de l'air, la

pompe ne pompera pas l'eau du puits.

3 ° Régler la hauteur de montage de la pompe de façon que

les raccords de plomberie n'exercent aucune contrainte sur

le corps de la pompe. Supporter les tuyaux de façon que le

corps de la pompe ne supporte pas le poids de la tuyauterie

ni des raccords.

Le branchement de cette pompe à éjecteur neuve pour puits

profonds sur la tuyauterie du puits est maintenant terminé.

Passer à la page 6 pour le branchement de la tuyauterie de

refoulement et sur un réservoir.

INSTALLATION DE LA POINTE

FILTRANTE

1 ° Enfoncer la pointe dans le sol, en utilisant des «raccords

d'enfoncement» et des «chapeaux de battage». Les «raccords

d'enfoncement» sont filetés sur toute leur longueur, ce

qui permet aux extrémités des tuyaux de venir en butée

l'une contre l'autre de façon que la force d'enfoncement

du maillet soit absorbée par le tuyau et non pas par les

filets. Les raccords ordinaires que l'on trouve dans les

quincailleries ne sont pas filetés sur toute leur longueur et ils

risquent de s'écraser sous l'impact des coups. Les «raccords

Vers le système d'eau

To Household

de la maison

Water System

(Figure 1)

Bouchon et té

Pump Priming

d’amorçcage

Tee and Plug

de la pompe

d'enfoncement» sont également plus lisses que les raccords

de plomberie standard, ce qui leur permet de pénétrer plus

facilement dans le sol.

2 ° Monter la pompe aussi près que possible du puits.

3 ° Utiliser le moins possible de raccords (en particulier des

coudes) lorsque l'on branche la tuyauterie de la pointe

filtrante sur l'orifice d'aspiration de la pompe. Le diamètre

du tuyau d'aspiration doit être au moins aussi grand que le

diamètre de l'orifice d'aspiration de la pompe (y compris

le clapet anti-retour si la pompe n'en comporte pas un

- voir la Figure 1). Supporter le tuyau de façon qu'il ne

soit pas cintré afin qu'il n'exerce pas de contraintes sur le

corps de la pompe; de plus, il doit être légèrement incliné

vers le haut, du puits jusqu'à la pompe (les points hauts

risquent de causer des poches et des bouchons d'air dans

la pompe). Rendre étanches les joints du tuyau d’aspiration

avec du ruban d’étanchéité en PTFE pour filetage. Les

raccords doivent être étanches à l'air et à l'eau. Si le tuyau

d'aspiration aspire de l'air, la pompe ne pompera pas l'eau

du puits. Si une pointe filtrante ne fournit pas suffisamment

d'eau, considérer brancher deux ou trois pointes filtrantes sur

un même tuyau d'aspiration.

Le branchement de cette pompe à éjecteur neuve pour puits

profonds sur la tuyauterie du puits est maintenant terminé.

Passer à la page 6 branchement pour la tuyauterie de

refoulement et sur un réservoir.

INSTALLATION SUR UN PUITS À

TUBAGE DE 2 POUCES DE DIAMÈTRE OU

PLUS GRAND

1 ° Monter la pompe aussi près que possible du puits.

2 ° Brancher le clapet de pied, la crépine et le tuyau du

puits (voir la Figure 2). S'assurer que le clapet de pied

fonctionne librement.

Vers le système d'eau

To Household

de la maison

Water System

(voir la Figure 2)

Bouchon et té

Pump Priming

d’amorçcage

Tee and Plug

de la pompe

Tuyau d'aspiration

Suction Pipe

venant du puits

From Well

Té

Priming

d'amorçage

Tee and

et bouchon

Plug

Clapet

Check

anti-retour

Valve

Drive point

Pointe filtrante

sous le niveau

below water

de l’eau.

level

Not

Pas à

to

l'échelle

Raccord d'enfoncement

de la pointe filtrante

Drive

Coupling

Drive

Pointe

Point

filtrante

Scale

Figure 1: Installation avec une pointe filtrante

Tuyau d'aspiration

Suction Pipe

venant du puits

From Well

Not

Pas à

to

l'échelle

Scale

Clapet

Check

anti-retour

Valve

Au moins

10'

10 pi

Min.

5 à 10 pi

5–10'

Té

Priming

d'amorçage

Tee and

etbouchon

Plug

Sanitary

Joint sanitaire

du puits

Well Seal

Tubage

Well

de puits

Casing

Clapet

Foot

de pied

Valve

Figure 2 : Installation dans un puits à tubage

Page 17

Installation 5

Screen

3 ° Abaisser le tuyau dans le puits jusqu'à ce que la crépine

soit à cinq pieds du fond du puits. Pour que la pompe

n'aspire pas d'air, la crépine doit être au moins à 10 pieds

sous le niveau de l'eau du puits pendant que la pompe

fonctionne. Poser un joint sanitaire de puits.

4 ° Poser le té d'amorçage, le bouchon d'amorçage et

le tuyau d'aspiration sur la pompe (voir la Figure 2).

Brancher le tuyau provenant du puits sur l'orifice

d'aspiration de la pompe en utilisant le moins possible

de raccords - en particulier des coudes - étant donné que

les raccords augmentent le frottement de l'eau dans les

tuyaux (il faut toutefois ajouter un clapet de pied — voir

la Figure 2). Le diamètre du tuyau d'aspiration doit être au

moins aussi grand que le diamètre de l'orifice d'aspiration

de la pompe. Utiliser du ruban d’étanchéité en PTFE pour

filetage sur les raccords de tuyaux filetés. Supporter le

tuyau de façon qu'il ne soit pas cintré afin qu'il n'exerce

pas de contraintes sur le corps de la pompe; de plus, il

doit être légèrement incliné vers le haut, du puits jusqu'à

la pompe (les points hauts risquent de causer des poches

et des bouchons d'air dans la pompe). Rendre étanches

les joints du tuyau d’aspiration avec du ruban d’étanchéité

en PTFE pour filetage. Les raccords doivent être étanches

à l'air et à l'eau. Si le tuyau d'aspiration aspire de l'air, la

pompe ne pompera pas l'eau du puits.

Le branchement de cette pompe à éjecteur neuve pour puits

profonds sur la tuyauterie du puits est maintenant terminé.

Passer à la page 6 pour le branchement de la tuyauterie de

refoulement et sur un réservoir.

INSTALLATION DANS LE CAS D'EAUX EN

Vers le système

To Household

d'eau de la maison

Water System

Bouchon et té

Pump Priming

d’amorçcage

Tee and Plug

de la pompe

SURFACE

(Figure 3)

1 ° Monter la pompe aussi près que possible du puits en

utilisant le moins possible de raccords (en particulier des

coudes) sur le tuyau d'aspiration. Le diamètre du tuyau

d'aspiration doit être au moins aussi grand que le diamètre

de l'orifice d'aspiration de la pompe.

2 ° Assembler le clapet de pied et le tuyau d'aspiration (voir

la Figure 3). S'assurer que le clapet de pied fonctionne

librement. Utiliser du ruban d’étanchéité en PTFE pour

filetage sur les raccords de tuyaux filetés. Poser une

crépine autour du clapet de pied pour le protéger contre

les poissons, les déchets, etc. (voir la Figure 3).

3 ° Abaisser le tuyau dans le puits jusqu'à ce que la crépine

soit à cinq pieds du fond du puits. Pour que la pompe

n'aspire pas d'air, la crépine doit être au moins à 10 pieds

sous le niveau de l'eau du puits pendant que la pompe

fonctionne.

4 ° Poser le té d'amorçage, le bouchon d'amorçage et le tuyau

d'aspiration sur la pompe (voir la Figure 3). Supporter le

tuyau de façon qu'il ne soit pas cintré afin qu'il n'exerce

pas de contraintes sur le corps de la pompe; de plus, il

doit être légèrement incliné vers le haut, du puits jusqu'à

la pompe (les points hauts risquent de causer des poches

et des bouchons d'air dans la pompe). Rendre étanches

les joints du tuyau d’aspiration avec du ruban d’étanchéité

en PTFE pour filetage. Les raccords doivent être étanches

à l'air et à l'eau. Si le tuyau d'aspiration aspire de l'air, la

pompe ne pompera pas l'eau du puits.

Le branchement de cette pompe à éjecteur neuve pour puits

profonds sur la tuyauterie du puits est maintenant terminé.

Passer à la page 6 pour le branchement de la tuyauterie de

refoulement et sur un réservoir.

Tuyau d'aspiration

Suction Pipe

venant du puits

From Well

Clapet

Check

Pas à

Not

l'échelle

to

Scale

anti-retour

Au moins

10'

10 pied

Min.

5 à 10 pi

5–10'

Valve

Bouchon et té

d’amorçcage

de la pompe

Clapet de

Foot

pied

Valve

Crépine

Priming

Tee and

Plug

Figure 3 : Installation pour les eaux de surface

Page 18

Branchement de la tuyauterie de refoulement

To Household

Pump Priming

2349 0396

et sur un réservoir sous pression 6

BRANCHEMENT SUR UN RÉSERVOIR

PRÉCHARGÉ

1 ° Poser deux tés dans l'orifice de refoulement de la pompe

(voir la Figure 4). Le diamètre du tuyau doit être au moins

aussi grand que le diamètre de l'orifice de refoulement.

Manocontacteur

Pressure

Switch

(Figure 4)

Vers le système

d'eau de la maison

Water System

Clapet

Check

anti-retour

Valve

Bouchon et tée

d’amorçage

Tee and Plug

de la pompe

En provenance

du puits

From Well

BRANCHEMENT SUR UN RÉSERVOIR

STANDARD

(Figure 5)

1 ° Poser un té dans l'orifice de refoulement de la pompe (voir

la Figure 5).

To Household

Vers le système

d'eau de la maison

Water System

Air Volume

Contrôleur

d'air

Control

Pump

Priming Tee

Té d'amorçage

and Plug

et bouchon

Pressure

Manocontacteur

Switch

Tube du

Air Volume

contrôleur d'air

Control Tube

Clapet

Check

anti-retour

Valve

En provenance

From

du puits

Well

2350 0396

Figure 4 : Branchements sur un réservoir préchargé

2 ° Poser un tuyau rigide ou un tuyau souple renforcé entre

une des branches du premier té et l'orifice du réservoir

préchargé.

3 ° Brancher l'autre extrémité du té de refoulement sur le

système de la plomberie.

4 ° Vérifier la précharge d'air dans le réservoir avec un

manomètre pour pneu. La précharge doit être de 2 lb/

2

inférieure au réglage de la pression d'enclenchement

po

du manocontacteur de la pompe. La précharge se mesure

lorsqu'il n'y a pas de pression d'eau dans le réservoir.

Cette pompe neuve est équipée d'un manocontacteur

30/50 lb/po

donc être réglée à 28 lb/po

Félicitations! Le branchement de la pompe à éjecteur sur le

réservoir est maintenant terminé.

Passer aux pages 7 et 8 pour les branchements électriques.

2

; la pression de précharge du réservoir devra

2

.

Figure 5 : Branchements sur un réservoir standard

2 ° Poser un tuyau entre l'orifice de refoulement de la pompe

et l'orifice d'admission du réservoir. Le diamètre du tuyau

doit être au moins aussi grand que le diamètre de l'orifice

de refoulement de la pompe.

3 ° Déposer le bouchon fileté de 1/8 de pouce NPT de

l'orifice du contrôleur d'air de la pompe (voir la Figure

5). Poser un tube entre l'orifice du contrôleur d'air (voir

la Figure 5) de la pompe et l'orifice du contrôleur d'air

monté sur le réservoir. Pour plus de détails, se reporter aux

instructions fournies avec le réservoir et le contrôleur d'air.

L'emplacement de l'orifice du contrôleur d'air variera

en fonction du modèle de pompe (se reporter aux vues

éclatées, page 10).

Félicitations! Le branchement de la pompe à éjecteur sur le

réservoir est maintenant terminé.

Passer aux pages 7 et 8 pour les branchements électriques.

Étanchéité des raccords des tuyaux

Effectuer tous les raccordements filetés à la pompe

seulement avec du ruban d’étanchéité en PTFE

pour filetage. Ne pas utiliser de pâte pour raccords

filetés sur les pompes en plastique : cette pâte peut

réagir avec les éléments en plastiques de la pompe.

S'assurer que tous les raccords du tuyau d'aspiration

sont bien étanches, aussi bien à l'air qu'à l'eau. Si

le tuyau d'aspiration aspire de l'air, la pompe ne

pompera pas l'eau du puits.

Page 19

Électricité 7

Débrancher le courant électrique avant d'intervenir sur la pompe, le moteur, le manostat ou le câblage.

RÉGLAGES DU MOTEUR

Les moteurs bitension (c’est-à-dire ceux qui fonctionnent sur

le courant de 115 ou de 230 volts) sont réglés à l’usine pour

fonctionner sur le courant de 230 volts. Ne pas modifier le

réglage de la tension du moteur si la tension secteur est de 230

volts ou si le moteur est un moteur à une seule tension.

REMARQUE: Ne jamais câbler un moteur fonctionnant sur le

courant de 115 volts sur un circuit de 230 volts.

Pour déposer le couvercle du moteur

Dans le cas d’un moteur bitension devant être branché sur le

courant de 115 volts, procéder commeil est indiqué ci-dessous.

Vis du couvercle

End Cover Screws

Couvercle

Motor

du moteur

End Cover

Figure 6: Dépose du couvercle du moteur

Pour faire fonctionner le moteur sur le courant de 115 volts:

1 ° S’assurer que le courant est coupé.

2 ° Tourner le sélecteur vers la gauche jusqu’à ce que «115»

apparaisse dans la fenêtre du cadran.

3 ° Les fils du manostat doivent déjà être branchés sur les

bornes.

4 ° Reposer le couvercle du moteur.

Câblage du manostat

Les câbles du moteur se branchent ici.

Les câbles de l’alimentation électrique

se branchent ici.

230 volts: Brancher 2 câbles chargés

(noir et rouge) ici et assemble le câble blanc

(neutre). Il n’y a pas de différence entre quel

câble va avec quelle vis.

115 volts: Brancher un câble chargé (noir

ou rouge) à l’une de ces vis (n’importe

laquelle). Brancher le câble blanc (neutre) à

l’autre vis. Assembler tout câble noir

ou rouge restant.

Serrer le câble électrique afin de prévenir de

mettre une tension sur les vis de bornes.

Brancher le fil de la mise à terre vert (ou cuivre nu)

à la vis de la mise à terre verte.

Figure 8: Câblage du manostat

5 ° Voir connexions de câblage ci-dessous.

Le couvercle du moteur devra être déposé pour modifier le

réglage de la tension.

La paquette à bornes du moteur (qui se trouve sous le

couvercle du moteur) doit ressembler à celle montrée

ci-dessous.

Vis de

Ground

Screw

mise à

la terre

Bornes

Power Lead

Fiche de

Voltage

Change Dial

changement

des fils

Te rminals

d’alimentation

de tension

Figure 7 : Tension réglée sur le courant de 230 volts.

Sélecteur rotatif

Tension dangereuse. Risque de

secousses électriques, de brûlures, voire la mort. Brancher

le fil de terre avant de brancher les fils de tension. Utiliser

des fils de calibre spécifié (y compris le fil de terre) dans le

tableau de câblage. Dans la mesure du possible, brancher la

pompe sur un circuit séparé, sur lequel aucun autre appareil ne

sera branché.

Risque d'explosion. Ne pas mettre à

la terre sur une conduite de gaz.

Page 20

Électricité 8

CONNEXIONS DES FILS

Risque d'incendie. L'utilisation

d'une mauvaise tension risque de causer un incendie ou

d'endommager gravement le moteur et d'annuler la garantie.

La tension d'alimentation doit correspondre à ± 10 % de la

tension figurant sur la plaque signalétique du moteur.

NOTA : Les moteurs bi-tension sont câblés à l'usine pour

fonctionner sur le 230 volts. Au besoin, recâbler le moteur

pour qu'il fonctionne sur le 115 volts, comme il est illustré.

Ne pas modifier le câblage des moteurs fonctionnant sur une

tension.

Installer la pompe, la mettre à la terre, la câbler et l'entretenir

conformément au National Electrical Code (NEC) ou au

Code canadien de l'électricité, selon le cas, et conformément

à tous les codes et décrets en vigueur de la municipalité.

Consulter l'inspecteur des bâtiments de la localité pour plus de

renseignements sur les codes.

Méthodes de connexion :

1 ° Brancher tout d'abord le fil de mise à la terre, comme il

est illustré à la Figure6. Le fil de mise à la terre doit être

un fil de cuivre massif d'un diamètre au moins aussi gros

que le diamètre des fils de tension.

2 ° Il doit y avoir un raccordement en métal solide entre le

manostat et le moteur pour une protection à la terre du

moteur. Si le manostat n'est pas branché sur le moteur,

brancher la vis verte de mise à la terre du manostat sur la

vis verte de mise à la terre qui se trouve sous le couvercle

du moteur. Utiliser un fil de cuivre massif ayant un

diamètre au moins aussi gros que celui des fils de tension.

3 ° Brancher le fil de mise à la terre sur le fil de mise à la terre

du tableau de distribution, sur un tuyau métallique d'eau

enterré, sur le tubage d'un puits en métal ayant au moins

10 pieds (3 mètres) de long, ou sur une électrode de mise

à la terre que fournira la compagnie d'électricité.

4 ° Brancher les fils de tension sur le manostat, comme il est

illustré à la Figure6.

Le câblage de la pompe est maintenant terminé.

Se reporter à la page 9 pour les préparations avant le

démarrage.

Tableau de câblage - Câbles et diamètres des fusibles recommandés

DISTANCE EN PIEDS (EN MÈTRES) ENTRE LE MOTEUR

ET LE COURANT D’ALIMENTATION

Série en ch Tension ampères en ampères DIAMÈTRE DU FIL - CALIBRE AWG (mm

5HN 1/2 115/230 12.2/6.1 20/15 12/14(3/2) 10/14(5.5/2) 8/14(8.4/2) 6/12(14/3) 6/12(14/3)

7HN 3/4 115/230 14.8/7.4 20/15 12/14(3/2) 8/14(8.4/2) 6/14(14/2) 6/12(14/3) 4/10(21/5.5)

10HN 1 115/230 19.2/9.6 25/15 10/14(5.5/2) 8/14(8.4/2) 6/12(14/3) 4/10(21/5.5) 4/10(21/5.5)

5SN 1/2 115/230 8.8/4.4 15/15 14/14(2/2) 12/14(3/2) 10/14(5.5/2) 8/14(8.4/2) 8/12(8.4/3)

7SN 3/4 115/230 12.2/6.1 20/15 12/14(3/2) 10/14(5.5/2) 8/14(8.4/2) 6/12(14/3) 6/12(14/3)

10SN 1 115/230 14.8/7.4 20/15 12/14(3/2) 8/14(8.4/2) 6/14(14/2) 6/12(14/3) 4/10(21/5.5)

15SN 1-1/2 115/230 19.2/9.6 25/15 10/14(5.5/2) 8/14(8.4/2) 6/14(14/2) 4/10(21/5.5) 4/10(21/5.5)

Puissance

du motor

Charge

max. en Intensité

Fusible

0 - 100 101 - 200 201 - 300 301 - 400 401 - 500

(0 - 30) (31 - 61) (62 - 91) (92 - 122) (123 - 152)

2

)

Page 21

Préparations avant le démarrage de la pompe 9

AMORÇAGE

Ne jamais faire fonctionner la pompe

contre un refoulement fermé, sinon l'eau risque de bouillir à

l'intérieur de la pompe, des pressions dangereuses peuvent

s'accumuler à l'intérieur de la pompe, une explosion risque de

s'ensuivre et les personnes qui manipulent la pompe pourront

être ébouillantées.

sec. Faire fonctionner la pompe sans eau risque de causer

une surchauffe de la pompe, d'endommager les joints

et, possiblement, causer des brûlures aux personnes qui

manipuleront la pompe. Faire le plein d'eau de la pompe avant

de la démarrer.

Ne jamais faire fonctionner la pompe à

Remplir la pompe

Fill pump

et les tuyaux par le

and piping

té d’amorçage.

through

priming tee.

1 ° Déposer le bouchon d'amorçage de la pompe et faire le

plein de la pompe et de tous les tuyaux branchés entre la

pompe et le puits et s'assurer que tous les tuyaux du puits

sont pleins. Si un té d'amorçage a déjà été posé sur le

tuyau d'aspiration, le déposer du té et faire le plein de la

tuyauterie d'aspiration.

2 ° Reposer tous les bouchons de remplissage.

3 ° Établir le courant! Démarrer la pompe. S'il n'y a pas de

présence d'eau après 2 ou 3 minutes de fonctionnement,

arrêter la pompe et déposer les bouchons de remplissage.

Refaire le plein de la pompe et de la tuyauterie. Cette

opération devra peut-être être répétée plusieurs fois de

façon à chasser tout l'air emprisonné dans la tuyauterie. Il

faudra jusqu'à 15 minutes pour qu'une pompe aspirant de

l'eau à 25 pieds s'amorce.

4 ° Après que la pression se sera accumulée dans le système

et que la pompe se sera arrêtée, vérifier le fonctionnement

du manocontacteur en ouvrant un ou deux robinets du

système; laisser couler suffisamment d'eau pour dissiper

la pression jusqu'à ce que la pompe redémarre. La

pompe doit redémarrer lorsque la pression chute à 30 lb/

2

po

et s'arrêter lorsque la pression atteint 50 lb/po2. Faire

fonctionner la pompe pendant un ou deux cycles complets

pour confirmer son bon fonctionnement. Ceci permettra

également de nettoyer le système de toute la saleté et de

tout le tartre qui se seront détachés pendant l'installation.

Félicitations pour une installation réussie.

Si l'installation n'est pas réussie, se reporter à la Section

Diagnostic des pannes (à la page 12) ou appeler notre

personnel technique du service à la clientèle, 1-888-782-7483.

Figure 8 : Amorçage de la pompe

2351 0396

Page 22

Pièces de rechange 10

1

Éclaté

Modéles 5SN, 7SN, 10SN

10

11

12

Orifice de

nettoyage

de la buse

12

Nozzle

Cleanout

Port

Orifice du

contrôleur

d’air

12

18

17

19

14

15

20

16

13

2

3

4

5

6

7

8

9

11A

11B

12

LISTE DES PIÈCES DE RECHANGE

Modèle et puissance

Réf. Nbre 5SN 7SN 10SN 15SN

no. Désignation des pièces utilisé 1/2 ch 3/4 ch 1 ch 1-1/2 ch

1 Moteur 1 J218-582APKG J218-590PKG J218-596PKG J218-601PKG

2 Vis à chapeau à tête hexagonale de 3/8

de po - 16 x 1-1/4 po de long 4 U30-75ZP U30-75ZP U30-76ZP U30-76ZP

#§3 Déflecteur d’eau 1 17351-0009 17351-0009 17351-0009 17351-0009

4 Plaque d’étanchéité 1 N3-1043P N3-1043P L3-10 L3-10

#§5 Joint de la plaque d’étanchéité 1 N20-35 N20-35 C20-21 C20-21

#§6 Joint d’arbre 1 U109-6A U109-6A U109-6A U109-6A

#7 Impulseur 1 J105-40P J105-42P J105-8PAN J105-22PA

#8 Diffuseur 1 L1-25P L1-25P L1-23P L1-23P

• Visdu diffuseur 3 – – U30-489SS U30-489SS

#§9 Bague du diffuseur 1 N20-34 N20-34 L21-1 L21-1

10 Branchement rapide - 1/4 de po 1 U11-217P U11-217P U11-217P U11-217P

11 Corps de la pompe 1 N176-43G N176-43GB N176-44G N176-44GA

11A Venturi (1) N32P-66 N32P-75 N32P-64 N32P-65

11B Buse (1) N34P-17 N34P-21 J34P-44 J34P-44

12 Bouchon fileté - 1/4 de po, à tête hexagonale 4 U78-941ZPV U78-941ZPV U78-941ZPV U78-941ZPV

13 Socle 1 J4-9 J4-9 J104-9C J104-9C

14 Support en caoutchouc 1 C35-5 C35-5 C35-5 C35-5

15 Tube de 3/8 de po de diamètre extérieur

x 14-1/2 po de long 1 U37-672P U37-672P U37-677P U37-677P

16 Coude à branchement rapide - 1/4 de po 1 U11-218P U11-218P U11-218P U11-218P

17 Manocontacteur 1 U217-1225 U217-1225 U217-1225 U217-1225

18 Écrou de 1/2 po 1 U36-112ZP U36-112ZP U36-112ZP U36-112ZP

19 Connector 1 L43-5C L43-5C L43-5C L43-5C

NÉCESSAIRES DE RÉPARATION

§ Nécessaire de joints et de bagues d’étanchéité PP1550 PP1550 PP1551 PP1551

# Nécessaire de révision PP1560 PP1561 PP1563 PP1554

NOTA : § Font partie du nécessaire de joints et de bagues d’étanchéité.

# Font partie du nécessaire de révision.

Page 23

Pièces de rechange 11

1

Éclaté

2

22

21

20

15B

3

4

5

6

7

Modéles 5HN, 7HN, et 10 HN

8

9

10

19

18

17

16

15A

11

12

13

Orifice de

Nozzle

nettoyage

Cleanout

Port

de la buse

14

13

Orifice du

contrôleur

d’air

13

13

LISTE DES PIÈCES DE RECHANGE

Modèle et puissance

Réf. Nbre 5HN 7HN 10HN

no. Désignation des pièces utilisé 1/2 ch 3/4 ch 1 ch

1 Moteur 1 J218-590PKG J218-596PKG J218-601PKG

#§2 Déflecteur d’eau 1 17351-0009 17351-0009 17351-0009

3 Plaque d’étanchéité 1 N3-1043P L3-10 L3-10

#§4 Joint de la plaque d’étanchéité 1 N20-35 C20-21 C20-21

#§5 Joint d’arbre 1 U109-6A U109-6A U109-6A

#6 Impulseur 1 J105-42P J105-8PAN J105-22PA

#7 Volute Diffuser Assembly 1 L1-25P L1-23P L1-23P

8 Vis 3 – U30-489SS U30-489SS

#§9 Bague du diffuseur 1 N20-34 L21-1 L21-1

10 Venturi (1) N32P-75 N32P-64 N32P-65

11 Buse (1) N34P-21 J34P-44 J34P-44

12 Branchement rapide - 1/4 de po 1 U11-217P U11-217P U11-217P

13 Bouchon fileté - 1/4 de po, à tête hexagonale 4 U78-941ZP U78-941ZPV U78-941ZP

14 Corps de la pompe 1 N176-43GB N176-44G N176-44GA

15A Vis à chapeau à tête de 3/8 de po - 16 x 1-1/2 po de long* 2 U30-75ZP U30-76ZP U30-76ZP

15B Vis à chapeau à tête de 3/8 de po - 16 x 1-1/4 po de long 2 U30-75ZP U30-75ZP U30-75ZP

16 Socle 1 J4-9 J104-9C J104-9C

17 Support en caoutchouc 1 C35-5 C35-5 C35-5

18 Tube de 3/8 de po de diamètre extérieur x 14-1/2 po de long 1 U37-672P U37-672P U37-677P

19 Coude à branchement rapide - 1/4 de po 1 U11-218P U11-218P U11-218P

20 Manocontacteur 1 U217-1216 U217-1216 U217-1216

21 Écrou de 1/2 po 1 U36-112ZP U36-112ZP U36-112ZP

22 Connector 1 L43-5C L43-5C L43-5C

* 1 1/4 pouce de long dans le cas du modèle 5HN.

NÉCESSAIRES DE RÉPARATION

§ Nécessaire de joints et de bagues d’étanchéité PP1550 PP1551 PP1551

# Nécessaire de révision PP1561 PP1564 PP1564

NOTA : § Font partie du nécessaire de joints et de bagues d’étanchéité.

# Font partie du nécessaire de révision.

Page 24

Diagnostic des pannes 12

SYMPTÔMES CAUSES PROBABLES REMÈDES

Le moteur ne tourne

pas

Le moteur chauffe et le

dispositif de protection

contre les surcharges

se déclenche.

Le moteur fonctionne

mais l'eau n'est pas

pompée*

* (Nota : Arrêter la

pompe; puis vérifier

l'amorçage avant de

rechercher toute autre

cause. Dévisser le

bouchon d'amorçage et

voir si le trou d'amorçage

contient de l'eau.)

La pompe ne pompe

pas l'eau à pleine

capacité.

La pompe pompe l'eau

mais ne s'arrête pas ou

bien elle fonctionne

trop fréquemment.

L'air jaillit des robinets.

Le sectionneur est ouvert.

Le fusible est sauté ou le disjoncteur est

déclenché.

L'interrupteur de démarrage est défectueux.

Les fils côté moteur sont desserrés, débranchés ou

mal branchés.

Les contacts du manocontacteur sont sales.

Le moteur est mal branché.

La tension est trop faible.

La pompe se met en marche trop fréquemment.

Dans une installation nouvelle, la pompe ne s'est

pas amorcée à cause :

1. d'un mauvais amorçage;

2. de prises d'air;

3. de fuites du clapet anti-retour ou du clapet

de pied.

La pompe s'est désamorcée :

1. à cause de prises d'air;

2. parce que le niveau d'eau est plus bas que

la prise d'eau du tuyau d'aspiration.

Le clapet de pied ou la crépine sont bouchés.

L'éjecteur ou l'impulseur sont bouchés.

S'assurer que le clapet anti-retour ou que le

clapet de pied ne sont pas grippés en position

fermée.

Les tuyauteries sont gelées.

Le clapet de pied et/ou la trémie sont enfouis

dans le sable ou la boue.

Le niveau de l'eau est trop bas pour que le puits

peu profond débite de l'eau.

Le niveau de l'eau du puits est plus bas que

celui estimé.

La tuyauterie en acier (le cas échéant) est cor

rodée ou bouchée par la chaux, ce qui cause

un frottement excessif.

Le diamètre de la tuyauterie est trop petit.

Pointe filtrante bouchée.

Le manocontacteur est déréglé ou bien ses con

tacts sont soudés ensemble.

Les robinets sont restés ouverts.

Le venturi, la buse ou l'impulseur sont bouchés.

Le niveau d'eau du puits profond est inférieur au

niveau estimé.

Le réservoir sous pression standard est saturé

d'eau et n'a plus de coussin d'air.

Fuite des tuyaux.

Fuite du clapet de pied.

La charge d'air du réservoir préchargé est trop

basse.

La pompe s'amorce.

Fuite du côté aspiration de la pompe.

Le puits est gazeux.

Surpompage intermittent du puits. (L'eau est

pompée plus bas que le clapet de pied.)

S'assurer que le sectionneur est enclenché.

Remplacer le fusible ou réenclencher le disjoncteur.

COUPER L'ARRIVÉE DE COURANT; remplacer l'interrupteur de démarrage.

Se reporter aux instructions sur le câblage (page 20). COUPER L'ARRIVÉE DE COURANT;

vérifier tout le câblage et le resserrer.

La tension du condensateur peut être dangereuse. Pour décharger le

condensateur du moteur, tenir un tournevis à manche isolé PAR LE MANCHE et mettre en

court-circuit les bornes du condensateur. Ne pas toucher la lame métallique du tournevis

ni les bornes du condensateur. En cas de doutes, consulter un électricien qualifié.

COUPER L'ARRIVÉE DE COURANT et nettoyer les contacts avec un morceau de feuille

émeri ou une lame à ongles.

Se reporter aux instructions concernant le câblage.

S'adresser à la compagnie d'électricité. Poser un câblage plus gros si le diamètre des fils

est trop petit (voir Électricité/Tableau de câblage).

Voir la section ci-dessous en cas de démarrages trop fréquents.

Dans le cas d'une installation neuve :

1. Réamorcer la pompe conformément aux instructions.

2. Vérifier tous les raccords de la conduite d'aspiration, le contrôleur d'air et l'éjecteur.

3. Remplacer le clapet de pied ou le clapet anti-retour.

Dans le cas d'une installation déjà en utilisation :

1. Vérifier tous les raccords de la conduite d'aspiration et le joint de l'arbre.

2. Abaisser la conduite d'aspiration dans l'eau et réamorcer la pompe. Si, dans le puits,

l'abaissement du niveau d'eau dépasse la hauteur géométrique d'aspiration, il faudra

utiliser une pompe pour puits profond.

Nettoyer le clapet de pied ou la crépine.

Nettoyer l'éjecteur ou l'impulseur.

Remplacer le clapet anti-retour ou le clapet de pied.

Dégeler les tuyauteries. Enterrer les tuyauteries sous la limite de gel. Chauffer la fosse ou

le bâtiment où se trouve la pompe.

Relever le clapet de pied et/ou la trémie plus haut que la source d'eau. Nettoyer le clapet

de pied et la trémie.

Un éjecteur pour puits peu profond est peut-être requis (plus de 25 mètres jusqu'à l'eau)

pour obtenir un débit d'eau.

Un éjecteur pour puits peu profond est peut-être requis (plus de 7,6 mètres (25 pieds)

jusqu’a l’eau) pour obtenir un débit d’eau.

-

Dans la mesure du possible, remplacer le tuyau par un tuyau en plastique, sinon poser un

tuyau en acier neuf.

Utiliser une tuyauterie de plus grand diamètre.

Laver à contre-courant la pointe filtrante ou la remplacer par une neuve.

COUPER L'ARRIVÉE DE COURANT; régler le manocontacteur ou le remplacer.

-

Les fermer.

Nettoyer le venturi, la buse ou l'impulseur.

Remplacer la buse et le venturi par la bonne combinaison en fonction du puits.

Vider le réservoir jusqu'à l'orifice du contrôleur d'air. S'assurer que le contrôleur d'air ne

montre pas de défectuosités. S'assurer qu'il n'y a pas de prises d'air à aucun raccord.

Vérifier les raccords.

Remplacer le clapet de pied.

COUPER L'ARRIVÉE DE COURANT et ouvrir les robinets jusqu'à ce que toute la pression

soit dissipée. À l'aide d'un manomètre de pneu, vérifier la pression d'air dans le réservoir

par la tige de la valve qui se trouve sur le réservoir. Si la pression est inférieure au réglage

de déclenchement du manocontacteur (30 à 50 lb/po

à partir d'une source extérieure jusqu'à ce que la pression d'air soit de 2 lb/po

au réglage de déclenchement du manocontacteur. S'assurer que la valve ne fuit pas (uti

liser une solution savonneuse pour cela) et, au besoin, remplacer l'obus de la valve.

Lorsque la pompe s'amorcera, tout l'air sera éjecté.

Le tuyau d'aspiration aspire de l'air. Vérifier tous les raccords

de l'eau savonneuse.

S'adresser à l'usine concernant l'installation d'un manchon dans le puits.

Dans la mesure du possible, abaisser le clapet de pied, sinon limiter le refoulement de la

pompe.

2

), pomper de l'air dans le réservoir

à la recherche de fuite avec

2

inférieure

-

Loading...

Loading...