Page 1

© 2016 Pentair Equipment Protection 89115889Rev. E P/N 89115890© 2016 Pentair Equipment Protection 89115889Rev. E P/N 89115890

Hazardous Location Heaters

Thermostat

INSTRUCTION MANUAL

Page 2

© 2016 Pentair Equipment Protection

- 2 -

89115889

NOTE: The respective operating instructions must be observed. For EC Type

Examination Certificate PTB 03 ATEX 1136X and IEC Scheme Certificate

IECEX PTB 07.0054X, see www.pentairprotect.com.

TABLE OF CONTENTS

Application .............................................................................................................. 3

Control Accuracy .............................................................................................................. 3

Technical Data ........................................................................................................ 3

Design Data ....................................................................................................................... 3

HLTSTAT Thermostat Nominal Setpoints ....................................................................... 3

Explosion Protection ........................................................................................................ 4

Installation Instructions ........................................................................................ 4

ROUTINE CHECK TESTS.................................................................................................. 5

Initial Operation ................................................................................................................ 5

Wiring Diagram ...................................................................................................... 7

Maintenance ........................................................................................................... 7

CE Declaration of Conformity ............................................................................... 8

WARRANTY........................................................................................................... 10

RETURN AND REPAIR POLICY ...................................................................................... 10

LIMITATION OF LIABILITY .............................................................................................. 11

Page 3

© 2016 Pentair Equipment Protection

89115889

- 3 -

APPLICATION

When connected to an electric heater, the thermostat can regulate the temperature in a

housing to the pre-set, nominal, setpoint; see HLTSTAT Thermostat Nominal Setpoints

table below.

The thermostat closes the circuit when the temperature is below the setpoint and opens

it when the temperature is above the setpoint.

CONTROL ACCURACY

The air temperature in a heated housing is not the same everywhere. Depending on the

difference between inside and outside temperature (delta T), insulation, configuration

of the heater and the installed equipment etc., the temperature (e.g. between top and

bottom) can fluctuate by 18 F [10 C] or more.

For exact temperature control of an instrument, a proportional controller with

temperature sensor should be used.

TECHNICAL DATA

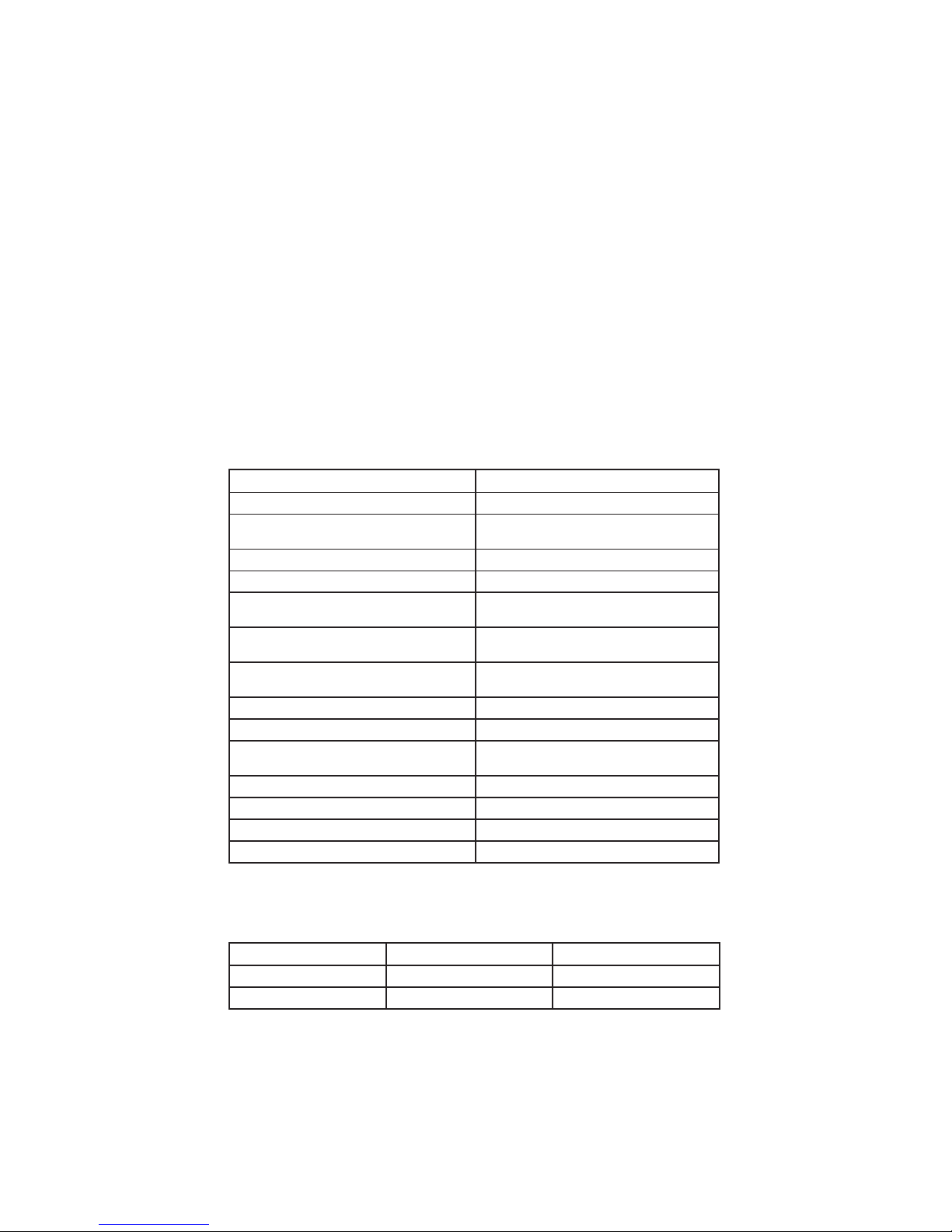

DESIGN DATA

HLTSTAT10C, HLTSTAT20C

Rated voltage (VAC or VDC) 0 - 400V

Maximum Rated Current (Amps)

(acc. to DIN VDE 0298)

10

Temperature Tolerance +/- 5 F [3 C]

Temperature class T6

Ambient temperature

-76 to +140 F

(-60 to +60 C)

Maximum permissible operating

temperature range at normal rating

-76 to +302 F

(-60 to +150 C)

Connection cable

39 (1m) long silicone cable, notch and oil

resistant, 3x AWG16; Ø 0.37 (9.4mm)

Conduit connection ½ NPT

Ingress Protection IP66 / IP68 (1bar/30min)

Material

seawater-proof aluminium, black

anodized

Length (in./mm) 3.5 (89)

Width (in./mm) 1.6 (41)

Depth (in./mm) 1.2 (30)

Weight (lb./g) 1.1 (28)

HLTSTAT THERMOSTAT NOMINAL SETPOINTS

Type Switch on Switch off

HLTSTAT10C 50 F / 10 C 64 F / 18 C

HLTSTAT20C 68 F / 20 C 82 F / 28 C

Page 4

© 2016 Pentair Equipment Protection

- 4 -

89115889

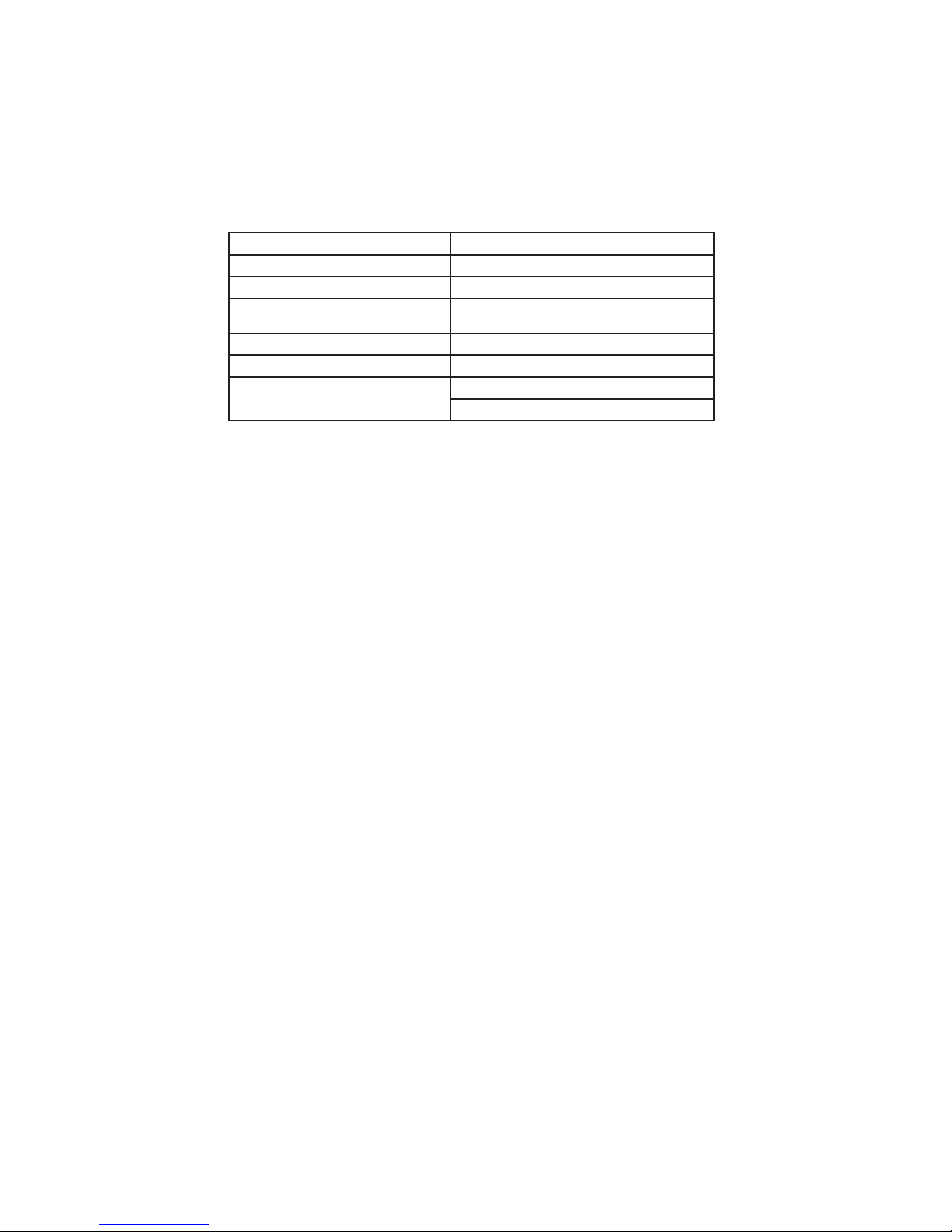

EXPLOSION PROTECTION

TAE

Manufacturer INTERTEC-Hess

CSA Certificate 1655545 (LR43674)

CSA Type of Protection

Cl. I, Grp. ABCD T6

Cl. II Grp. EFG

IEC Scheme Certificate IECEx PTB 07.0054X

EC Type Examination Certificate PTB 03 ATEX 1136 X

Marking

II 2 G Ex d IIC T6

II 2 D Ex tD A21 IP68 T80 C

INSTALLATION INSTRUCTIONS

The thermostat must be attached to the face of the heater as noted. Pentair DAHHL

finned heaters are equipped with slotted mounting rails in the fins. Slightly loosen the

mounting bolt included in the thermostat.

Insert the head of the bolt into one of the slotted mounting rails of the finned profile.

The PTFE spacer must remain outside, as this provides the right gap from the

thermostat to the surface of the heater fins. Carefully tighten the bolt by turning the

thermostat. DO NOT OVERTIGHTEN.

The thermostat is equipped with a ground terminal. Use a cable gland or a ½ NPT

conduit depending on the application.

Be careful not to bend or exert any load on the connection cable during unpacking and

transport.

Before entering the customer-supplied Ex junction box, the connection cable must be

firmly installed and mechanically protected observing the permissible bending radius of

5 times the outside cable diameter.

If the connection is made in a hazardous area, the connection cable must be connected

in a housing that meets the requirements of one of the types of ignition protection

mentioned in EN 50014 Section 1.2.

When determining the operating temperature, the maximum permissible ambient

temperature, self-heating and, possibly, heat transfer (medium) must be considered.

In dust hazardous areas, the applicable requirements of the EN 60079-14 have to be

observed.

CAUTION! Remove the RED protection cap only for ½ NPT conduit installation. Never

remove the adapter. See Figure 3 on page 6

The components must only be connected and secured by certified technical personnel

in accordance with the label specifications rated voltage and rated current. Circuit

breakers suitable for up to 16 A can be used for short circuit and line protection.

A ground terminal is provided for the purpose of ensuring potential equalization; see

Figure 1 on page 5. The terminal is marked as such.

Page 5

© 2016 Pentair Equipment Protection

89115889

- 5 -

ROUTINE CHECK TESTS

The following check tests have to be carried out on the installed heating system:

ɒ Do a Visual inspection to determine if the conditions specified under

Installation Instructions are met.

ɒ Conduct an insulation test.

INITIAL OPERATION

When the routine tests are successfully completed, the device can be switched on.

Spacer

Mounting Surface

Figure 1

Page 6

© 2016 Pentair Equipment Protection

- 6 -

89115889

Figure 2

Figure 3

Page 7

© 2016 Pentair Equipment Protection

89115889

- 7 -

WIRING DIAGRAM

ϑ>

Heater

L

bu

ye/gn

N

PE

bn

bu =blue bn=brown ye/gn=yellow/green

PA.

PA.

bn

bu

Junction Box

(Customer

Supplied)

Thermostat

Figure 4

MAINTENANCE

The thermostat is completely encapsulated in silicone, and requires no maintenance.

Performance and safety tests can be conducted at intervals as determined by the

operator in compliance with current regulations.

Repairs must only be done by the manufacturer. In dust hazardous areas, applicable

requirements of EN 60079-17 and EN 60079-19 must be observed.

Page 8

© 2016 Pentair Equipment Protection

- 8 -

89115889

CE DECLARATION OF CONFORMITY

INTERTEC-Hess GmbH · Raffineriestraße 8 · D-93333 Neustadt/Donau · Tel: +49 (0) 9445/95 32-0 · Fax: +49 (0)9445/95 32 32

BINT040

Erklärung der EG-Konformität

Declaration of EC-Conformity

Ɂɚɹɜɥɟɧɢɟɨɫɨɨɬɜɟɬɫɬɜɢɢ

ɞɢɪɟɤɬɢɜɚɦȿɋ

INTERTEC Hess GmbH

Raffineriestraße 8

93 333 Neustadt / Donau

Wir We Ɇɵ

INTERTEC Hess GmbH,

erklären in alleiniger

Verantwortung, dass das Produkt

declare under our sole

responsibility that the product

ɡɚɹɜɥɹɟɦɩɨɞɫɜɨɸ

ɢɫɤɥɸɱɢɬɟɥɶɧɭɸ

ɨɬɜɟɬɫɬɜɟɧɧɨɫɬɶɱɬɨɩɪɨɞɭɤɰɢɹ

TA …

auf das sich diese Erklärung

bezieht den Bestimmungen der

folgenden Richtlinien entspricht

to which this declaration relates is

in accordance with the provision of

the following directives

ɧɚɤɨɬɨɪɭɸɪɚɫɩɪɨɫɬɪɚɧɹɟɬɫɹ

ɞɚɧɧɨɟɡɚɹɜɥɟɧɢɟɫɨɨɬɜɟɬɫɬɜɭɟɬ

ɫɥɟɞɭɸɳɢɦɞɢɪɟɤɬɢɜɚɦ

2014/34/EU (ATEX)

2006/95/EG (LVD)

2014/30/EU (EMC)

2011/65/EU (RoHS)

2012/19/EU (WEEE)

2014/34/EU (ATEX)

2006/95/EC (LVD)

2014/30/EU (EMC)

2011/65/EU (RoHS)

2012/19/EU (WEEE)

2014/34/EU (ATEX)

2006/95/EC (LVD)

2014/30/EU (EMC)

2011/65/EU (RoHS)

2012/19/EU (WEEE)

und mit folgenden Normen oder

normativen Dokumenten

übereinstimmt

and is in conformity with the

following standards or other

normative documents

ɢɫɨɨɬɜɟɬɫɬɜɭɟɬɫɥɟɞɭɸɳɢɦ

ɫɬɚɧɞɚɪɬɚɦɢɥɢɞɪɭɝɢɦɧɨɪɦɚɬɢɜɧɵɦɞɨɤɭɦɟɧɬɚɦ

EN IEC 60079-0:2012 EN IEC 60079-1:2007 EN IEC 60079-31:2014

EN IEC 60529:1991+A1:2000+A2:2013 EN IEC 61000-6-4:2007+A1:2011

Kennzeichnung Marking Ɇɚɪɤɢɪɨɜɤɚ

) 0102

F II 2 G Ex db IIC T6

F II 2 D Ex tb IIIC T80°C

Degree of protection IP66/ IP68

1bar/ 30min

PTB 03 ATEX 1136 X

Neustadt, den 28.04.2016

Dipl.-Ing. Martin Hess

Geschäftsführer

)

Page 9

© 2016 Pentair Equipment Protection

89115889

- 9 -

NOTES

Page 10

© 2016 Pentair Equipment Protection

- 10 -

89115889

WARRANTY

Pentair Equipment Protection warrants that the Goods manufactured by Pentair Equipment

Protection will be free from defects in material and workmanship for a period of one (1)

year from the date of shipment by Pentair Equipment Protection, subject to the following

conditions and exclusions:

A. Conditions. All Goods must be installed and operated according to the following

specifications:

1. Maximum voltage variation no greater than plus or minus 10% of nameplate nominal

rating;

2. Maximum frequency variation no greater than plus or minus 3 Hz of nameplate nominal

rating;

3. Must not exceed minimum and maximum stated temperatures on the nameplate;

4. Must not exceed (BTU/Hr) rating, including any heat sink as indicated on the nameplate;

5. Refrigerant bearing Goods must not be restarted for a period of one (1) minute after

intentional or accidental shut-off;

6. The filters (if applicable) must be cleaned regularly;

7. The Goods and any parts thereof must not be modified, unless prior written

authorization is received from Pentair Equipment Protection; and

8. All Goods must be installed and grounded in accordance with all relevant electrical and

safety codes, as well as the National Electric Code and OSHA rules and regulations.

9. All Goods must be installed in a stationery application, free of vibration.

A violation of any one of these conditions shall render the warranty hereunder void and of no

effect.

B. Exclusions. This warranty shall be void if product is misapplied in any way or:

1. Buyer specified product is inappropriate for system or environment in which it is

operating.

2. Goods are not installed in accordance with Pentair Equipment Protection specifications.

3. Removal or modification of Pentair Equipment Protection label affixed to product without

written Pentair Equipment Protection approval.

Pentair Equipment Protection must be notified of a claim in writing not later than fourteen

(14) days from the date when Buyer has become aware of such occurrence, or where the

defect is such that it may cause damage, immediately, such notice containing a description of

how the defect manifests itself. Failure to provide such prompt notice to Pentair Equipment

Protection shall result in forfeiture of Buyer’s rights under this warranty.

In the event of a warranty claim, Buyer is to return defective goods to Pentair Equipment

Protection in accordance with Pentair Equipment Protection Return Policy. Warranty period

for repaired goods remains at 1 year from shipment of original goods. Pentair Equipment

Protection sole obligation to Buyer under this warranty will be, at Pentair Equipment

Protection option:

C. Repair or replace Pentair Equipment Protection products or parts found to be defective in

material or workmanship.

D. Issue credit for the purchase price paid by Buyer relating to such defective Goods or part.

THIS WARRANTY CONSTITUTES THE ENTIRE WARRANTY WITH RESPECT TO THE

GOODS AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY AND IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

RETURN AND REPAIR POLICY

Pentair Equipment Protection products that: (i) are made to order, (ii) have been modified by

Buyer, (ii) have special finishes, or (iv) are determined by Pentair Equipment Protection to

constitute “custom” products that cannot be returned to stock or resold to other Buyers, will

not be accepted for return by Pentair Equipment Protection.

All returns require a Return Material Authorization number (RMA #), regardless of reason for

return, whether it be for warranty or out of warranty repair. Returns without an RMA # will be

refused by our Receiving Department. An RMA # is valid for 30 days.

Page 11

© 2016 Pentair Equipment Protection

89115889

- 11 -

E. An RMA # will be issued by our Product Return Department in Anoka, MN at 763-422-2211.

Buyer should have following information available at time of RMA request:

1. Complete Model Number, Serial Number and description of damaged unit being

returned.

2. Original Buyer Purchase Order number and date product was received by Buyer.

3. Quantity to be returned and a brief description of failure for each unit, if different.

4. Contact information of Buyer that must include: name of company, billing and shipping

address, phone, number, fax number, freight carrier and the name and phone number of

a Buyer contact who can elaborate on the claimed defect in detail.

5. Buyer must provide a Repair Purchase Order number for both warranty and out of

warranty repairs. The PO will not exceed 50% of a new unit. Buyer will be notified of

repair charges that exceed approved PO amount.

F. All returns to Pentair Equipment Protection must be securely packed, using original cartons if

possible. All returns must have the RMA number visible on the outside of the carton. Pentair

Equipment Protection is not responsible for material damaged in transit. Any refrigerantbearing Goods must be shipped upright for return.

G. Shipping cost for all non-warranty repairs is the responsibility of the sender and must be

shipped prepaid. Shipping costs for all warranty related repairs will be covered by Pentair

Equipment Protection provided the goods are returned using a Pentair Equipment Protection

approved carrier. If after diagnoses the product is determined by Pentair Equipment

Protection not be covered under warranty, Buyer will be responsible for all shipping charges

and will be billed accordingly.

H. Non-warranty repairs are subject to a $105 minimum analysis fee. If approval is not received

within 30 days, material will be scrapped and all shipping expenses and corresponding

analysis fees will be billed to Buyer.

I. At Buyer’s request, Failure Analysis can be provided by Pentair Equipment Protection for

warrantable goods at no charge. Failure analysis for non-warranty repairs are subject to a

$150 per hour Engineering charge plus any other incurred testing costs.

J. All returned merchandise must be sent to the following address: Pentair Equipment

Protection, 2100 Hoffman Way, Anoka, MN 55303-1745.

K. Credit for accepted returns shall be at the original selling price or the current selling price,

whichever is lower, less the restocking charge indicated as follows:

1. Within 60 days of invoice date - 20% of applicable selling price.

2. Within 61-120 days of invoice date - 30% of applicable selling price.

3. Within 121-180 days of invoice date - 40% of applicable selling price.

4. Beyond 180 days - subject to individual review by Pentair Equipment Protection.

If product being returned for credit requires repair or modification, the cost of any labor or

material necessary to bring product into saleable condition will be deducted from credit.

Buyer may not take credit against returns without prior written Pentair Equipment Protection

approval.

LIMITATION OF LIABILITY

PENTAIR EQUIPMENT PROTECTION WILL NOT BE LIABLE UNDER ANY

CIRCUMSTANCES FOR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES,

INCLUDING WITHOUT LIMITATION ANY LOST PROFITS OR LABOR COSTS, ARISING

FROM THE SALE, USE OR INSTALLATION OF THE GOODS, FROM THE GOODS BEING

INCORPORATED INTO OR BECOMING A COMPONENT OF ANOTHER PRODUCT, FROM

ANY BREACH OF THIS AGREEMENT OR FROM ANY OTHER CAUSE WHATSOEVER,

WHETHER BASED ON WARRANTY (EXPRESSED OR IMPLIED) OR OTHERWISE BASED

ON CONTRACT, OR ON TORT OR OTHER THEORY OF LIABILITY, AND REGARDLESS OF

ANY ADVICE OR REPRESENTATIONS THAT MAY HAVE BEEN RENDERED BY PENTAIR

EQUIPMENT PROTECTION CONCERNING THE SALE, USE OR INSTALLATION OF THE

GOODS.

Page 12

© 2016 Pentair Equipment Protection 89115889Rev. E P/N 89115890

Pentair Equipment Protection

2100 Homan Way

Minneapolis, MN 55303 USA

+1.763.422.2211

+1.763.576.3200

PentairProtect.com

Loading...

Loading...